Double-Regulated Active Cruise Control for a Car Model with Nonlinear Powertrain Design

Abstract

1. Introduction

- -

- The usage of a mathematical dynamic model of vehicle for the initial investigation of control parameters (enabling the control of such systems in a more efficient way),

- -

- The application of the system of the double PID controller for drive and braking systems,

- -

- Numerical simulations are used for the theoretical validation of the proposed solution.

2. Simulation Models as a Way of Active Cruise Control Development

3. Modeling Methodology

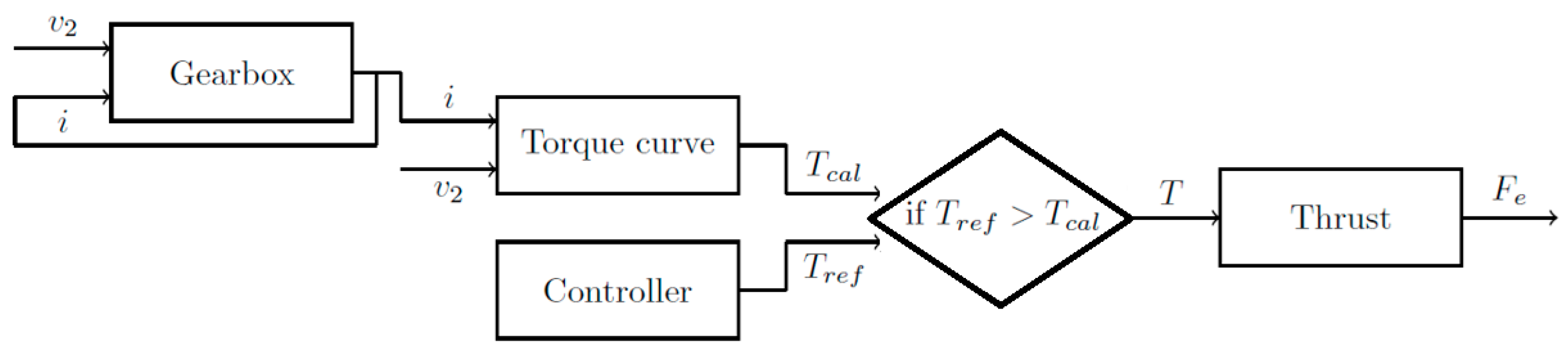

- The gearbox block, with which the gear and transmission are chosen. The gear choice is intent on simple logic functions. The main goal of this block is to increase the range of a torque curve;

- The torque curve block, which represents the implemented functions responsible for calculating the maximum available torque for the current rotational speed. Calculations are carried out with an use of approximated polynomial function that represents the real maximum torque curve of a simulated car;

- The controller, with which the reference value is obtained;

- The function block, which represents the functions liable for adjusting a proper throttle open angle. It is obtained with the use of a prepared logic layout;

- The thrust block, which represents a torque converter. This block consists of a function that calculates an engine force based on the current gear and the system’s dynamic variables.

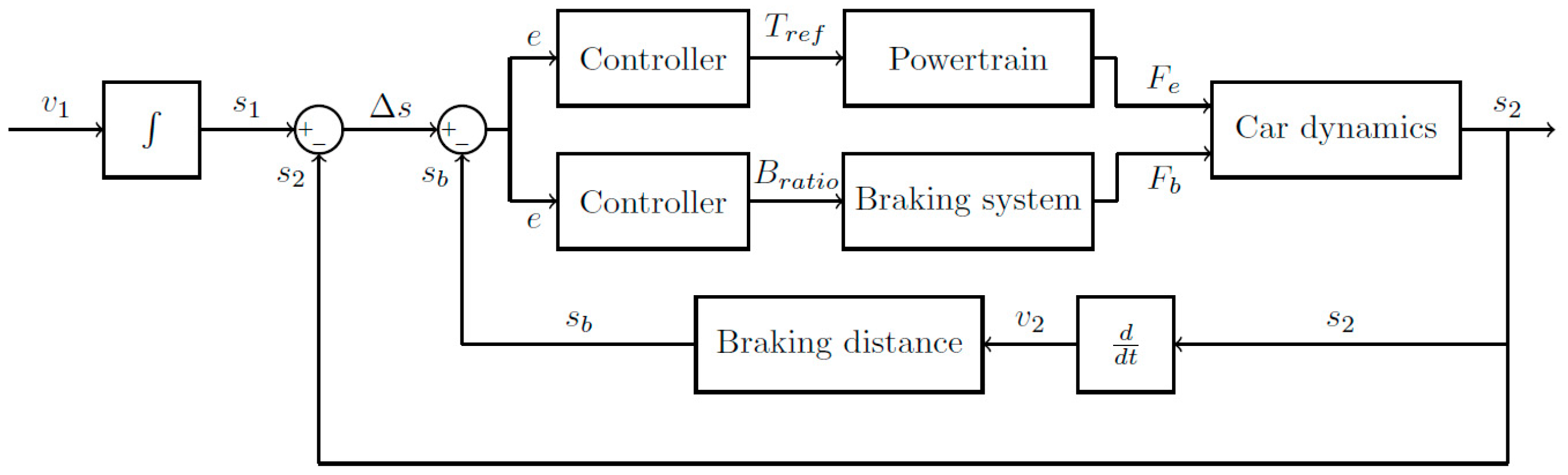

4. Control System Development

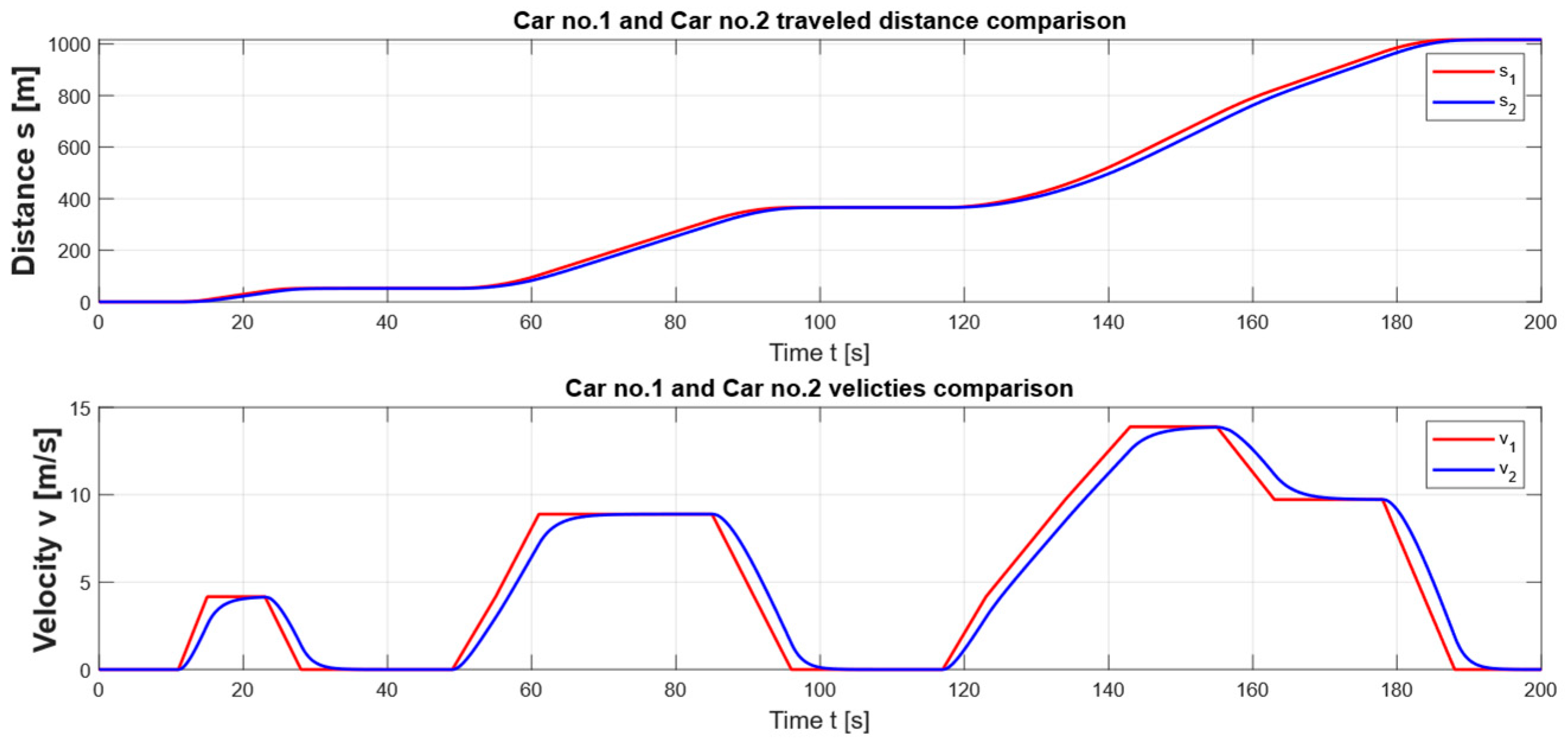

5. Simulation Analysis

6. Summary

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, L.; Zhou, C.; Huang, J.; Liu, Z.; Xie, J.; Tan, Z. Car-following safety modeling risk assessment of autonomous vehicle in icy and snowy weather. Accid. Anal. Prev. 2025, 214, 107982. [Google Scholar] [CrossRef] [PubMed]

- Channamallu, S.S.; Almaskati, D.; Kermanshachi, S.; Pamidimukkala, A. Autonmous vehicle safety: An advanced bagging classifier technique for crash injury prediction. Multimodal Transporation 2025, 4, 100189. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhu, Y.; Zhao, L.; Huang, J.; Zhi, Q. Behavioral decision-making and safety verification approaches for autonomous driving system in extreme scenarios. J. Syst. Softw. 2025, 226, 112385. [Google Scholar] [CrossRef]

- Wang, X.; Qian, B.; Zhou, J.; Liu, W. An Autonomous Vehicle Behavior Decision Method Based on Deep Reinforcement Learning with Hybrid State Space and Driving Risk. Sensors 2025, 25, 774. [Google Scholar] [CrossRef]

- Fagnant, D.J.; Kockelman, K. Preparing a nation for autonomous vehicles: Opportunities, barriers and policy recommendations. Transp. Res. Part A Policy Pract. 2015, 77, 167–181. [Google Scholar] [CrossRef]

- Faisal, A.; Yigitcanlar, T.; Kamruzzaman, M.d.; Currie, G. Understanding autonomous vehicles: A systematic literature review on capability, impact, planning and policy. J. Transp. Land Use 2019, 12, 45–72. [Google Scholar] [CrossRef]

- Johnson, M.A.; Moradi, M.H.; Crowe, J. PID Control: New Identification and Design Methods; Springer: New York, NY, USA, 2005. [Google Scholar]

- Martínez-Díaz, M.; Soriguera, F. Autonomous vehicles: Theoretical and practical challenges. Transp. Res. Procedia 2018, 33, 275–282. [Google Scholar] [CrossRef]

- Rojas-Rueda, D.; Nieuwenhuijsen, M.J.; Khreis, H.; Frumkin, H. Autonomous Vehicles and Public Health. Annu. Rev. Public Health 2020, 41, 329–345. [Google Scholar] [CrossRef]

- Boruta, G.; Piętak, A. Mechatronika Samochodu: Układy Bezpieczeństwa Czynnego i Biernego; Wydawnictwo Uniwersytetu Warmińsko-Mazurskiego: Olsztyn, Poland, 2012. [Google Scholar]

- Fischer-Wolfarth, J.; Meyer, G. Advanced Microsystems for Automotive Applications; Springer International Publishing: Cham, Switzerland, 2014. [Google Scholar]

- Olejnik, K. Permissible distance—Safety system of vehicles in use. Open Eng. 2021, 11, 303–309. [Google Scholar] [CrossRef]

- Rajamani, R. Vehicle Dynamics and Control; Springer: New York, NY, USA, 2006. [Google Scholar]

- Shakouri, P.; Ordys, A. Nonlinear Model Predictive Control approach in design of Adaptive Cruise Control with automated switching to cruise control. Control Eng. Pract. 2014, 26, 160–177. [Google Scholar] [CrossRef]

- Sun, X. Design of ACC Adaptive Cruise System Based on Ultrasonic Ranging and Internet of Vehicles. J. Phys. Conf. Ser. 2020, 1650, 022029. [Google Scholar] [CrossRef]

- Baum, D.; Hamann, C.D.; Schubert, E. High Performance ACC System Based on Sensor Fusion with Distance Sensor, Image Processing Unit, and Navigation System. Veh. Syst. Dyn. 1997, 28, 327–338. [Google Scholar] [CrossRef]

- Bian, N.; Liu, J.; Du, J.; Guo, S.; Yang, Y.; Chen, J.; Shi, T.; Yue, Z. The Development and Application of ACC System. In Proceedings of the 2014 Sixth International Conference on Measuring Technology and Mechatronics Automation, Zhangjiajie, China, 10–11 January 2014; pp. 692–695. [Google Scholar]

- Pananurak, W.; Thanok, S.; Parnikchun, M. Adaptive cruise control for an intelligent vehicle. In Proceedings of the 2008 IEEE International Conference on Robotics and Biomimetics, Bangkok, Thailand, 22–25 February 2009; pp. 1794–1799. [Google Scholar]

- Qing, X.; Hedrick, K.; Sengupta, R.; VanderWerf, J. Effects of vehicle-vehicle/roadside-vehicle communication on adaptive cruise controlled highway systems. In Proceedings of the IEEE 56th Vehicular Technology Conference, Vancouver, BC, Canada, 24–28 September 2002; pp. 1249–1253. [Google Scholar]

- Park, C.; Lee, H. A Study of Adaptive Cruise Control System to Improve Fuel Efficiency. Int. J. Environ. Pollut. Remediat. 2017, 5, 15–19. [Google Scholar] [CrossRef]

- Shakouri, P.; Ordys, A.; Laila, D.S.; Askari, M. Adaptive Cruise Control System: Comparing Gain-Scheduling PI and LQ Controllers. IFAC Proc. Vol. 2011, 44, 12964–12969. [Google Scholar] [CrossRef]

- Sivaji, V.V.; Sailaja, D.M. Adaptive Cruise control systems for vehicle modeling using stop and go manoeuvres. Int. J. Eng. Res. Appl. 2013, 3, 2453–2456. [Google Scholar]

- Guo, L.; Ge, P.; Sun, D.; Qiao, Y. Adaptive Cruise Control Based on Model Predictive Control with Constraints Softening. Appl. Sci. 2020, 10, 1635. [Google Scholar] [CrossRef]

- Mao, J.; Yang, L.; Hu, Y.; Liu, K.; Du, J. Research on Vehicle Adaptive Cruise Control Method Based on Fuzzy Model Predictive Control. Machines 2021, 9, 160. [Google Scholar] [CrossRef]

- Nie, Z.; Farzaneh, H. Adaptive Cruise Control for Eco-Driving Based on Model Predictive Control Algorithm. Appl. Sci. 2020, 10, 5271. [Google Scholar] [CrossRef]

- Ruina, D.; He, C.; Qiang, Z.; Keqiang, L.; Yusheng, L. ACC of electric vehicles with coordination control of fuel economy and tracking safety. In Proceedings of the 2012 IEEE Intelligent Vehicles Symposium, Madrid, Spain, 3–7 June 2012; pp. 240–245. [Google Scholar]

- Wang, M.; Yu, H.; Dong, G.; Huang, M. Dual-Mode Adaptive Cruise Control Strategy Based on Model Predictive Control and Neural Network for Pure Electric Vehicles. In Proceedings of the 2019 5th International Conference on Transportation Information and Safety, Liverpool, UK, 14–17 July 2019; pp. 1220–1225. [Google Scholar]

- Mu, H.; Li, L.; Mei, M.; Zhao, Y. A hierarchical Control Scheme for Adaptive Cruise Control System Based on Model Predictive Control. Actuators 2023, 12, 249. [Google Scholar] [CrossRef]

- Yang, Z.; Wang, Z.; Yan, M. An Optimization Design of Adaptive Cruise Control System Based on MPC and ADRC. Actuators 2021, 10, 110. [Google Scholar] [CrossRef]

- Mohd, T.A.T.; Hassan, M.K.; Aziz, W.A. Mathematical modeling and simulation of an electric vehicle. J. Mech. Eng. Sci. 2015, 30, 1312–1321. [Google Scholar] [CrossRef]

- Szost, K. Simulation model of a vehicle with an internal combustion engine and automatic gearbox. Przemysł Chem. 2024, 103, 1548–1552. [Google Scholar]

- Khayyam, H.; Nahavandi, S.; Davis, S. Adaptive cruise control look-ahead system for energy management of vehicles. Expert Syst. Appl. 2012, 39, 3874–3885. [Google Scholar] [CrossRef]

- Luu, D.L.; Lupu, C.; Van Nguyen, T. Design and Simulation Implementation for Adaptive Cruise Control Systems of Vehicles. In Proceedings of the 2019 22nd International Conference on Control Systems and Computer Science, Bucharest, Romania, 28–30 May 2019; pp. 1–6. [Google Scholar]

- Tan, D.; Lu, C.; Zhang, X. Dual-loop PID control with PSO algorithm for the active suspension of the electric vehicle driven by in-wheel motor. J. Vibroengineering 2016, 18, 3915–3929. [Google Scholar] [CrossRef]

- Narwade, P.; Deshmukh, R.; Nagarkar, M.; Bankar, M. Modeling and Simulation of a Semi-active Vehicle Suspension system using PID Controller. IOP Conf. Ser. Mater. Sci. Eng. 2020, 1004, 12003. [Google Scholar] [CrossRef]

- Ang, K.H.; Chong, G.C.Y.; Li, Y. PID control system analysis, design, and technology. IEEE Trans. Control Syst. Technol. 2005, 13, 559–576. [Google Scholar]

- Sierociński, D.; Chiliński, B.; Gawiński, F.; Radomski, A.; Przybyłowicz, P. DynPy—Python Library for Mechanical and Electrical Engineering: An Assessment with Coupled Electro-Mechanical Direct Current Motor Model. Energies 2025, 18, 332. [Google Scholar] [CrossRef]

- Bogumilchilinski/Dynpy. Available online: https://github.com/bogumilchilinski/dynpy (accessed on 25 March 2025).

- Reński, A. Active Safety of the Car: Suspensions, Braking and Steering System; Oficyna Wydawnicza Politechniki Warszawskiej: Warszawa, Poland, 2011. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kozłowski, S.; Szost, K.; Chiliński, B.; Połaniecki, A. Double-Regulated Active Cruise Control for a Car Model with Nonlinear Powertrain Design. Electronics 2025, 14, 2257. https://doi.org/10.3390/electronics14112257

Kozłowski S, Szost K, Chiliński B, Połaniecki A. Double-Regulated Active Cruise Control for a Car Model with Nonlinear Powertrain Design. Electronics. 2025; 14(11):2257. https://doi.org/10.3390/electronics14112257

Chicago/Turabian StyleKozłowski, Szymon, Kinga Szost, Bogumił Chiliński, and Adrian Połaniecki. 2025. "Double-Regulated Active Cruise Control for a Car Model with Nonlinear Powertrain Design" Electronics 14, no. 11: 2257. https://doi.org/10.3390/electronics14112257

APA StyleKozłowski, S., Szost, K., Chiliński, B., & Połaniecki, A. (2025). Double-Regulated Active Cruise Control for a Car Model with Nonlinear Powertrain Design. Electronics, 14(11), 2257. https://doi.org/10.3390/electronics14112257