Integrating Virtual Reality into Welding Training: An Industry 5.0 Approach

Abstract

1. Introduction

- Training Safety Risks: Industrial environments present potential hazards, particularly for novice operators. The operation of heavy machinery, tools, or chemicals involves intrinsic risks. VR allows for practice within a controlled virtual environment, thus mitigating the likelihood of accidents during training [3].

- Elevated costs associated with prototyping and testing: The creation of physical prototypes for the evaluation of new designs or assembly processes, as well as the temporary cessation of machine operations for training purposes, can incur substantial financial expenditures. Alternatively, a virtual reality environment facilitates the development of virtual prototypes and the simulation of their behavior, thereby markedly reducing both the costs and the duration of development [3].

- Increased difficulty adapting to complexity: The advent of new technologies and the mass customization of products in Industry 5.0 require that operators rapidly acclimate to increasingly complex processes. VR aids in the comprehension of these complexities by allowing operators to engage with intricate virtual models [11,12].

- Ergonomics and Operator Well-being: The performance of repetitive tasks or tasks that require awkward postures has the potential to cause injuries and affect the health of operators, which can ultimately result in disability. VR can facilitate the simulation of workstations and the evaluation of design ergonomics, thus helping to prevent injuries and optimize operator well-being [13].

- Constraints on Human–Robot Collaboration: Industry 5.0 aims to advance the integration of human–robot collaboration. However, a significant factor to consider is the lack of familiarity with robotics, which can engender apprehension and impede effective interaction. Virtual reality facilitates the acquaintance of operators with robotic systems within a virtual and secure environment [7].

2. Related Work

2.1. AI and Digital Twins for Personalized VR Training

2.2. Virtual Reality and I5.0

2.3. Instructional Design Principles and Theoretical Foundations

3. Virtual Welding

3.1. Development

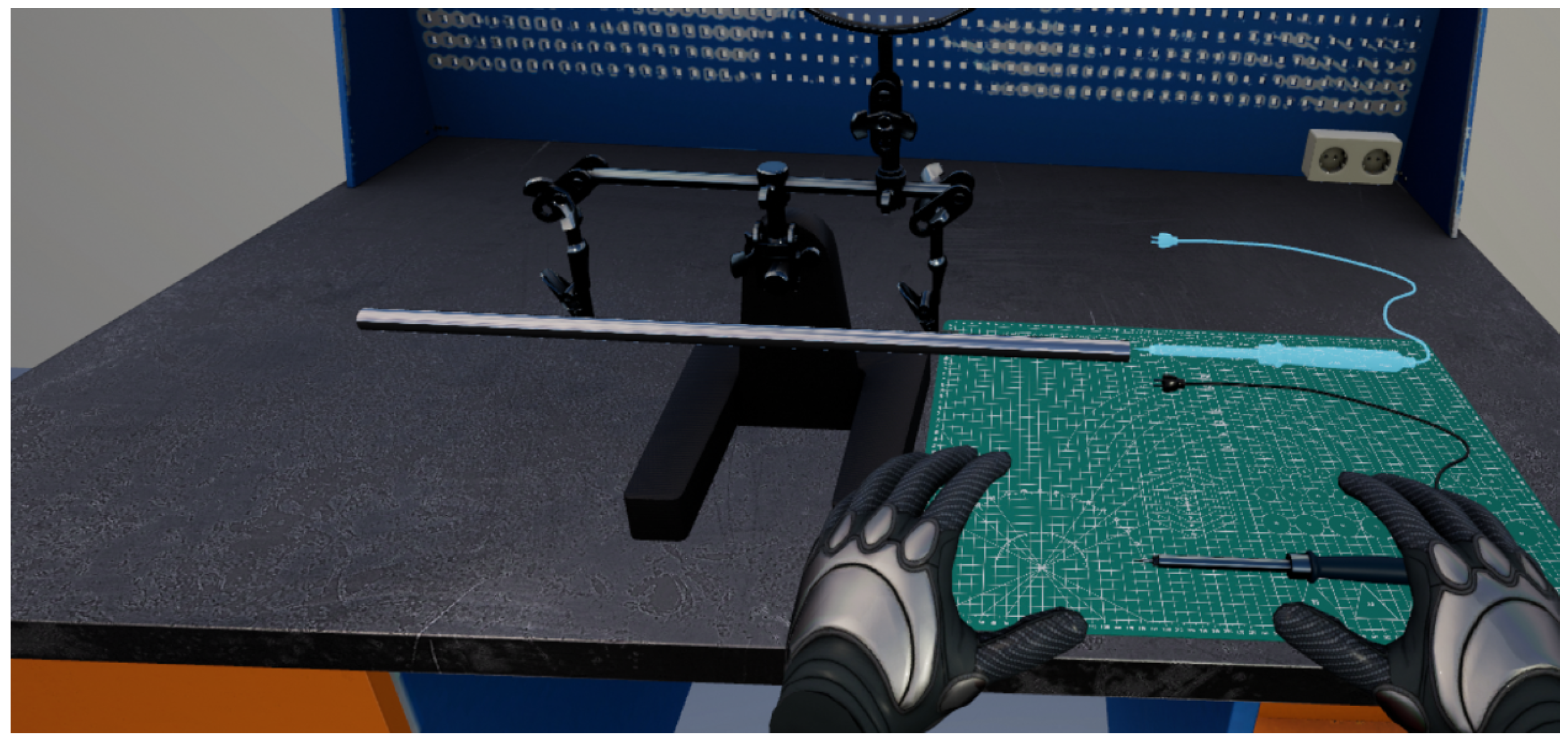

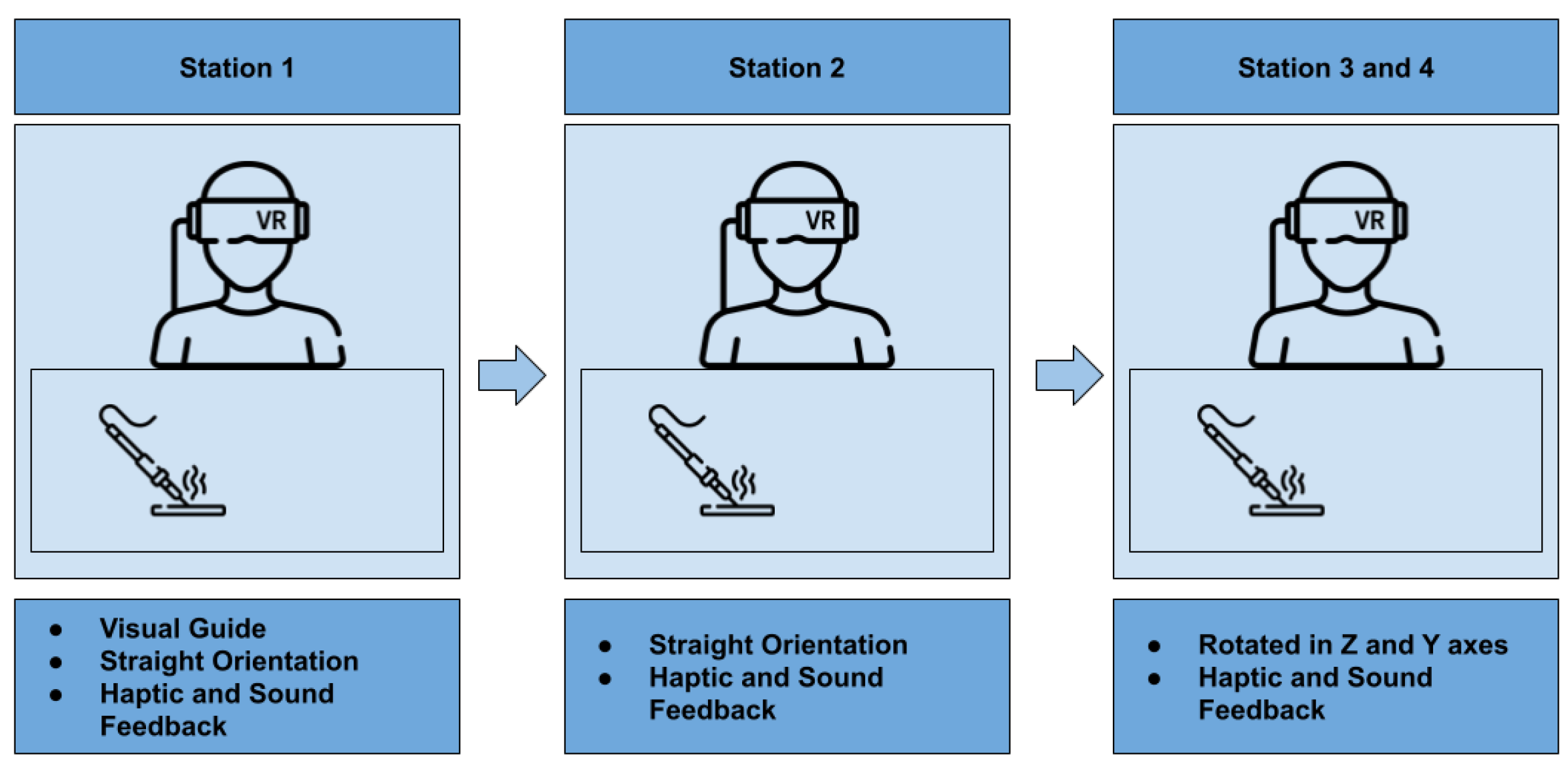

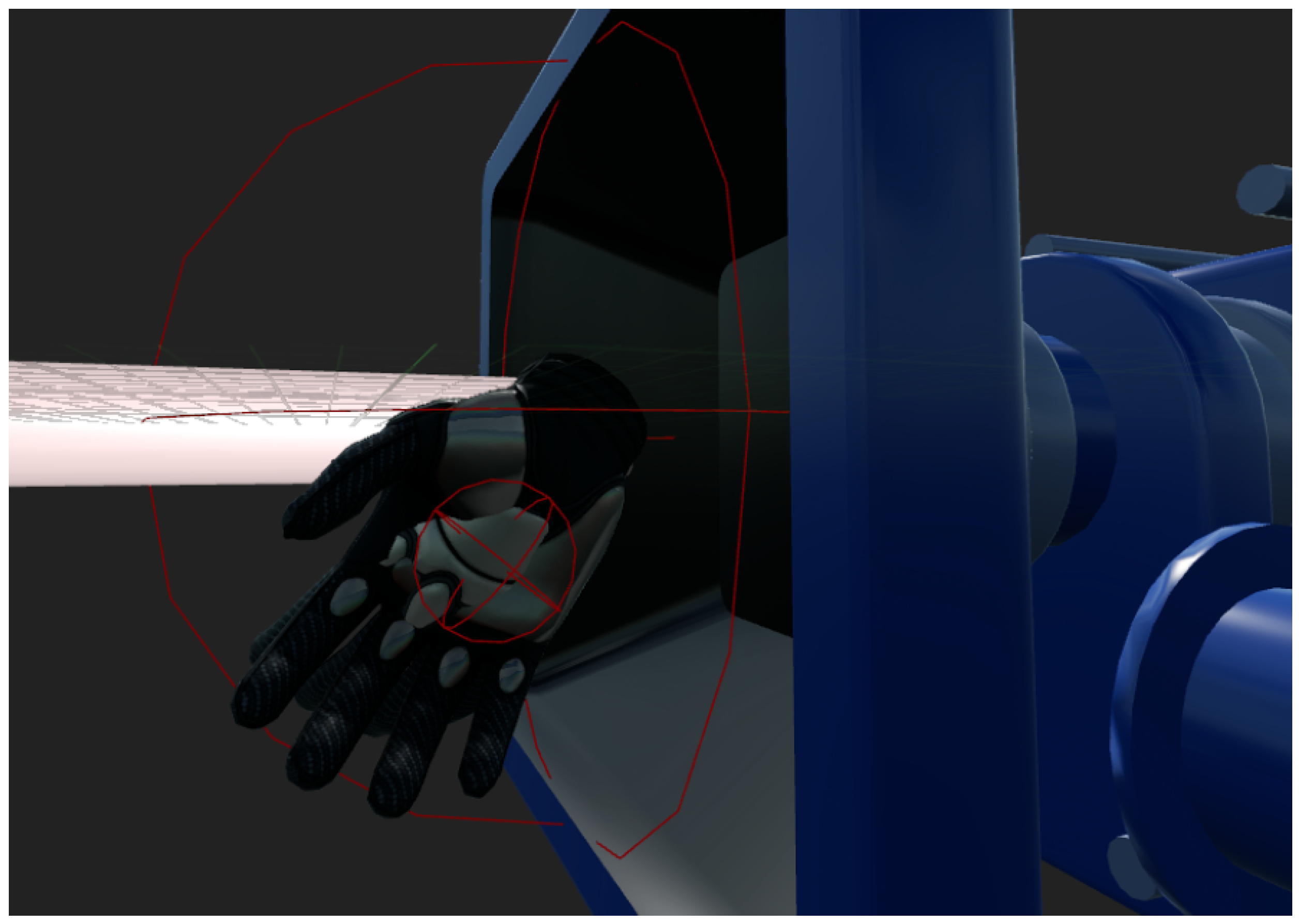

- Station 1: Figure 2 illustrates that this initial station is designed to instruct the user how to properly grip the soldering iron and its optimal alignment relative to the metal tube in a fixed linear orientation. It comprises a visual guide, which is a semi-transparent depiction of the soldering iron in the optimal position, indicating the appropriate orientation, position, and duration required for soldering. The instruction is further enhanced by providing the user with haptic and audible feedback.

- Station 2: At the second station, the visual guide is eliminated to enhance the user’s mastery of the technique using an independent application. The metal tube maintains the same straight and fixed orientation as observed in the previous station, thereby necessitating the user to rely on muscle memory and the knowledge acquired, devoid of direct visual assistance. Haptic and auditory feedback continues to be provided.

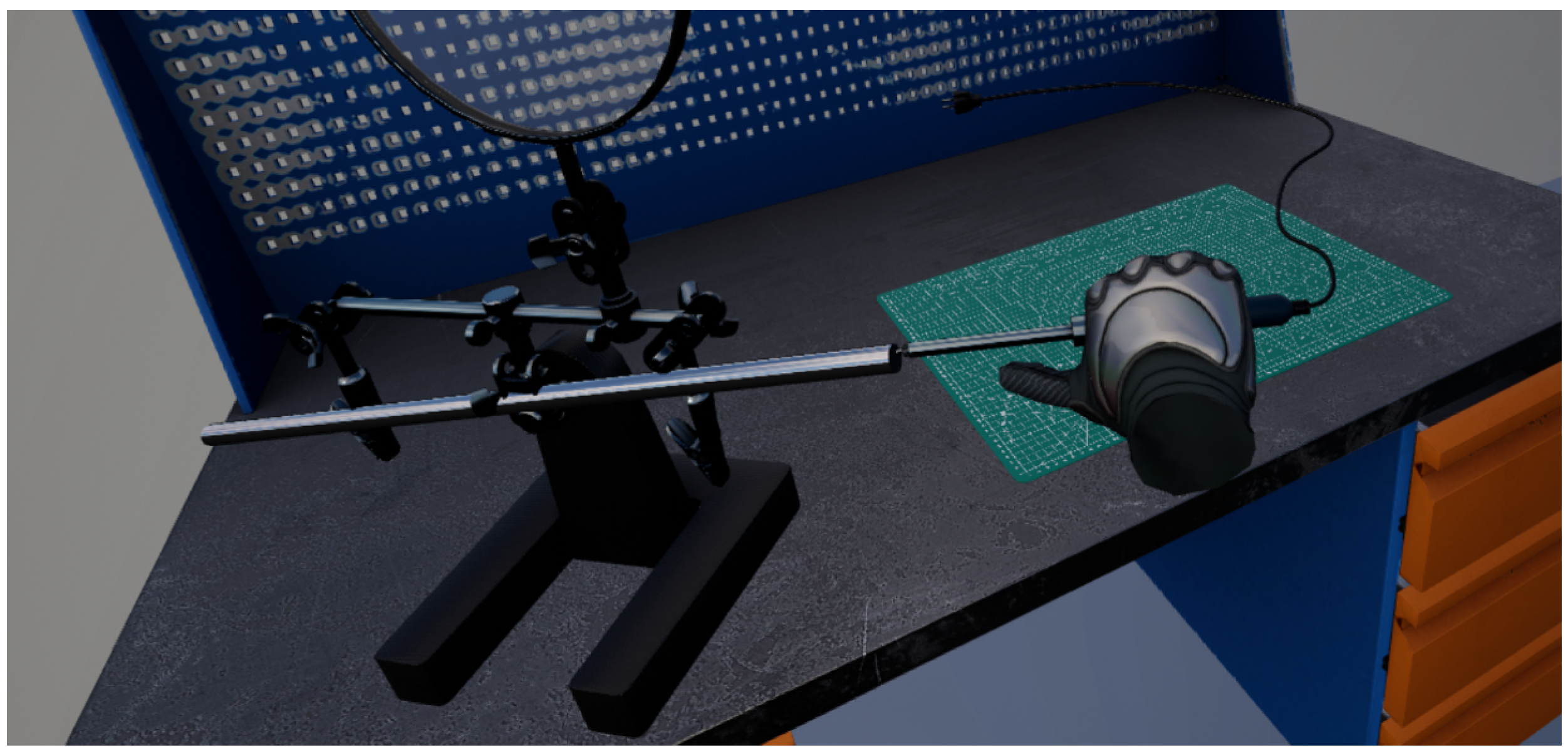

- Station 3 and 4: These stations slightly mitigate the challenge of improving proficiency in soldering iron handling. However, visual guidance remains unavailable, and the metal tube is subject to rotation along the Z and Y axes, as illustrated in Figure 3 for Station 4. This variability requires the user to actively adjust the grip and positioning of the soldering iron to maintain the correct technique across different spatial orientations, thus assessing their ability to generalize the acquired skill. Haptic and auditory feedback continues to be provided.

3.2. Results

3.2.1. Qualitative Evaluation

3.2.2. Quantitative Evaluation

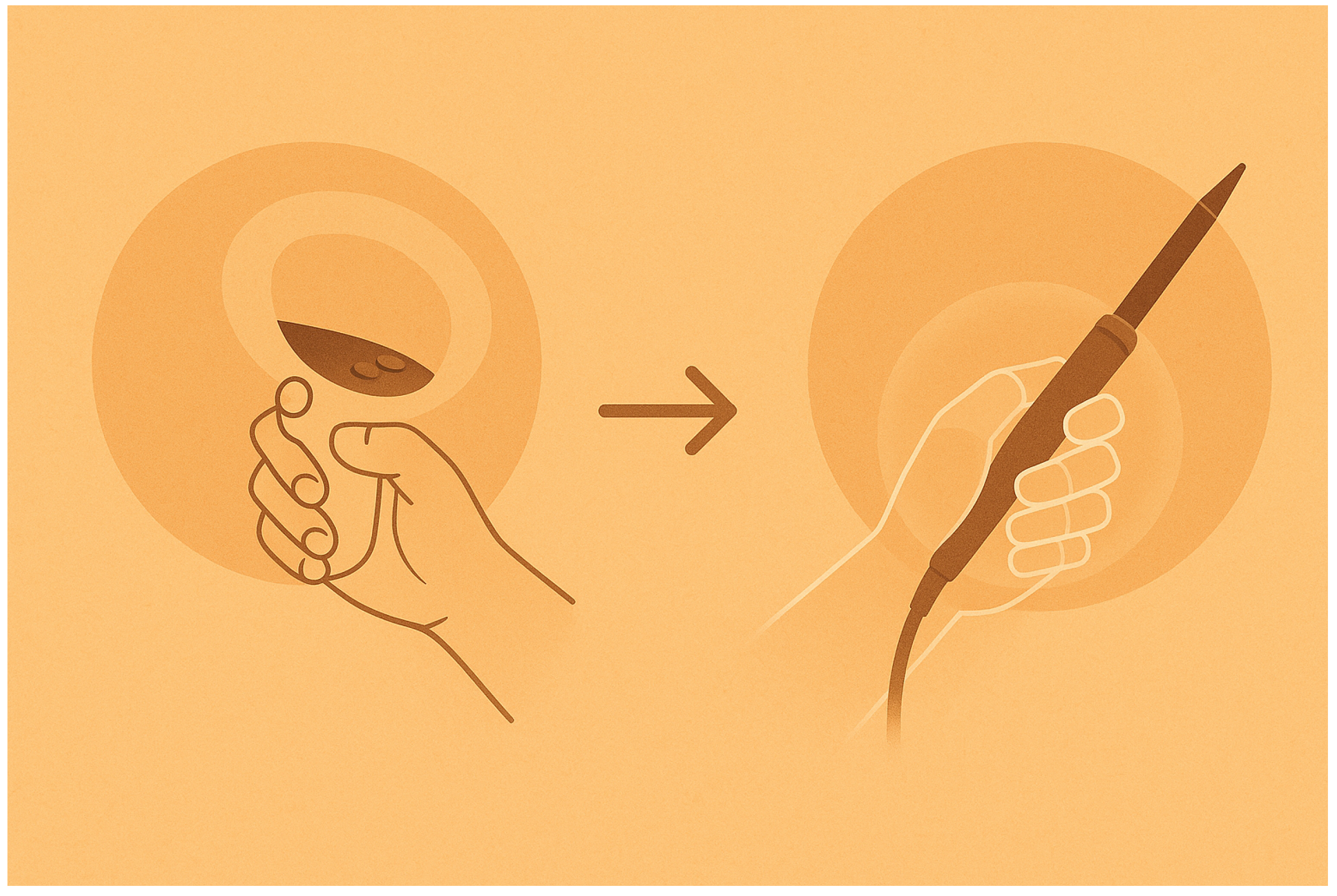

3.3. Practical Skill Assessment After VR Training

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, B.; Zhou, H.; Li, X.; Yang, G.; Zheng, P.; Song, C.; Yuan, Y.; Wuest, T.; Yang, H.; Wang, L. Human Digital Twin in the context of Industry 5.0. Robot. Comput. Integr. Manuf. 2024, 85, 102626. [Google Scholar] [CrossRef]

- Nicoletti, L.; Solina, V.; Amin, K.; Lessi, C.; McHard, P.; Qiu, R.; Tedeschi, S. Exploiting Extended Reality under the Manufacturing as a Service paradigm. Procedia Comput. Sci. 2024, 232, 2213–2219. [Google Scholar] [CrossRef]

- Soori, M.; Arezoo, B.; Dastres, R. Virtual manufacturing in Industry 4.0: A review. Data Sci. Manag. 2024, 7, 47–63. [Google Scholar] [CrossRef]

- Verdu, R.C.; Macia, N.S.; Strand, M.; Holm, M.; Schmidt, B.; Olsson, J. Enhancing Manual Assembly Training using Mixed Reality and Virtual Sensors. Procedia CIRP 2024, 126, 769–774. [Google Scholar] [CrossRef]

- Manghisi, V.; Evangelista, A.; Uva, A. A Virtual Reality Approach for Assisting Sustainable Human-Centered Ergonomic Design: The ErgoVR tool. Procedia Comput. Sci. 2022, 200, 1338–1346. [Google Scholar] [CrossRef]

- Ipsita, A.; Erickson, L.; Dong, Y.; Huang, J.; Bushinski, A.; Saradhi, S.; Villanueva, A.; Peppler, K.; Redick, T.; Ramani, K. Towards Modeling of Virtual Reality Welding Simulators to Promote Accessible and Scalable Training. In Proceedings of the Conference on Human Factors In Computing Systems-Proceedings, New Orleans, LA, USA, 29 April–5 May 2022. [Google Scholar]

- Wan, K.; Li, C.; Lo, F.; Zheng, P. Manufacturing Letters A virtual reality-based immersive teleoperation system for remote human-robot collaborative manufacturing. Manuf. Lett. 2024, 41, 43–50. [Google Scholar]

- Wolfartsberger, J.; Zimmermann, R.; Obermeier, G.; Niedermayr, D. Analyzing the potential of virtual reality-supported training for industrial assembly tasks. Comput. Ind. 2023, 147, 103838. [Google Scholar] [CrossRef]

- Damtew, L.; Ganser, P.; Venek, T.; Bergs, T. Intuitive toolpath planning in computer-aided manufacturing systems using artificial intelligence in a virtual reality environment. Procedia CIRP 2024, 126, 354–359. [Google Scholar] [CrossRef]

- Moller, D.; Vakilzadian, H.; Haas, R. From Industry 4.0 towards Industry 5.0. In Proceedings of the 2022 IEEE International Conference on Electro Information Technology (eIT), Mankato, MN, USA, 19–21 May 2022; pp. 61–68. [Google Scholar]

- Mahmood, K.; Otto, T.; Chakraborty, A. Layout planning and analysis of a Flexible Manufacturing System based on 3D Simulation and Virtual Reality. Procedia CIRP 2023, 120, 201–206. [Google Scholar] [CrossRef]

- Rueckert, P.; Goetsche, A.; Tracht, K. Assembly workshops in virtual reality as an integral part of the assembly planning process. Procedia CIRP 2024, 126, 793–798. [Google Scholar] [CrossRef]

- Arkouli, Z.; Tompoulidis, I.; Kontos, M.; Michalos, G.; Makris, S. Collaborative human-centered design of manufacturing tasks: A multi-user immersive VR experience. Procedia CIRP 2024, 128, 597–602. [Google Scholar] [CrossRef]

- Piccarozzi, M.; Silvestri, L.; Silvestri, C.; Ruggieri, A. Roadmap to Industry 5.0: Enabling technologies, challenges, and opportunities towards a holistic definition in management studies. Technol. Forecast. Soc. Change 2024, 205, 123467. [Google Scholar] [CrossRef]

- Dhanda, M.; Rogers, B.; Hall, S.; Dekoninck, E.; Dhokia, V. Reviewing human-robot collaboration in manufacturing: Opportunities and challenges in the context of industry 5.0. Robot. Comput. Integr. Manuf. 2025, 93, 102937. [Google Scholar] [CrossRef]

- Huynh-The, T.; Pham, Q.; Pham, X.; Nguyen, T.; Han, Z.; Kim, D. Artificial Intelligence for the Metaverse: A Survey. Eng. Appl. Artif. Intell. 2022, 117, 105581. [Google Scholar] [CrossRef]

- Martínez-Gutiérrez, A.; Díez-González, J.; Perez, H.; Araújo, M. Towards industry 5.0 through metaverse. Robot. Comput. Integr. Manuf. 2024, 89, 102764. [Google Scholar] [CrossRef]

- Denisart, L.; Zapata-Dominguez, D.; David, X.; Leclere, A.; Lelong, R.; Liu, C.; Xu, J.; Loup-Escande, E.; Franco, A. Combining Virtual Reality with Mixed Reality for Efficient Training in Battery Manufacturing. Batter. Supercaps 2024, 7, e202300268. [Google Scholar] [CrossRef]

- Zheng, P.; Yang, J.; Lou, J.; Wang, B. Design and application of virtual simulation teaching platform for intelligent manufacturing. Sci. Rep. 2024, 14, 12895. [Google Scholar] [CrossRef]

- Obermair, F.; Althaler, J.; Wolfartsberger, J.; Niedermayr, D.; Feichtenschlager, H. Assembly Training for Electric Motor Wiring with Virtual Reality Compared to Paper Instructions: Experiment and Analysis. IFAC-PapersOnLine 2024, 58, 398–406. [Google Scholar] [CrossRef]

- Aivaliotis, S.; Lotsaris, K.; Gkournelos, C.; Fourtakas, N.; Koukas, S.; Kousi, N.; Makris, S. An augmented reality software suite enabling seamless human robot interaction. Int. J. Comput. Integr. Manuf. 2023, 36, 3–29. [Google Scholar] [CrossRef]

- Pratticò, F.; Lamberti, F. Towards the adoption of virtual reality training systems for the self-tuition of industrial robot operators: A case study at KUKA. Comput. Ind. 2021, 129, 103446. [Google Scholar] [CrossRef]

- Ipiales, J.; Araque, E.; Andaluz, V.; Naranjo, C. Virtual Training System for the Teaching-Learning Process in the Area of Industrial Robotics. Electronics 2023, 12, 974. [Google Scholar] [CrossRef]

- Dianatfar, M.; Latokartano, J.; Lanz, M. Concept for virtual safety training system for human-robot collaboration. Procedia Manuf. 2020, 51, 54–60. [Google Scholar] [CrossRef]

- Hoang, K.; Chan, W.; Lay, S.; Cosgun, A.; Croft, E. Virtual Barriers in Augmented Reality for Safe and Effective Human-Robot Cooperation in Manufacturing. In Proceedings of the 2022 31st IEEE International Conference on Robot and Human Interactive Communication (RO-MAN), Napoli, Italy, 29 August–2 September 2022. [Google Scholar]

- González-Böhme, L.; Valenzuela-Astudillo, E. Mixed Reality for Safe and Reliable Human-Robot Collaboration in Timber Frame Construction. Buildings 2023, 13, 1965. [Google Scholar] [CrossRef]

- Mourtzis, D.; Angelopoulos, J. Development of an Extended Reality-Based Collaborative Platform for Engineering Education: Operator 5.0. Electronics 2023, 12, 3663. [Google Scholar] [CrossRef]

- Tu, X.; Autiosalo, J.; Ala-Laurinaho, R.; Yang, C.; Salminen, P.; Tammi, K. TwinXR: Method for using digital twin descriptions in industrial eXtended reality applications. Front. Virtual Real. 2023, 4, 1019080. [Google Scholar] [CrossRef]

- Panter, L.; Leder, R.; Keiser, D.; Freitag, M. Requirements for Human-Machine-Interaction Applications in Production and Logistics within Industry 5.0—A Case Study Approach. Procedia Comput. Sci. 2024, 232, 1164–1171. [Google Scholar] [CrossRef]

- Vaughan, N.; Gabrys, B.; Dubey, V. An overview of self-adaptive technologies within virtual reality training. Comput. Sci. Rev. 2016, 22, 65–87. [Google Scholar] [CrossRef]

- Contini, G.; Grandi, F.; Peruzzini, M. Human-Centric Green Design for automatic production lines: Using virtual and augmented reality to integrate industrial data and promote sustainability. J. Ind. Inf. Integr. 2025, 44, 100801. [Google Scholar] [CrossRef]

- Schrader, C.; Diekmann, C.; Schulz, P.; Mack, N.; Bohrmann-Linde, C.; Zeller, D. Hands-on training: Effects on virtual presence, learning-centered emotions, cognitive load and learning outcome when learning with virtual reality. Comput. Hum. Behav. Rep. 2024, 16, 100487. [Google Scholar] [CrossRef]

- Rey-Becerra, E.; Barrero, L.; Ellegast, R.; Kluge, A. Improvement of short-term outcomes with VR-based safety training for work at heights. Appl. Ergon. 2023, 112, 104077. [Google Scholar] [CrossRef]

- Lehikko, A.; Nykänen, M.; Lukander, K.; Uusitalo, J.; Ruokamo, H. Exploring interactivity effects on learners’ sense of agency, cognitive load, and learning outcomes in immersive virtual reality: A mixed methods study. Comput. Educ. X Real. 2024, 4, 100066. [Google Scholar] [CrossRef]

| ID | Question |

|---|---|

| User Experience | |

| Q1 | How intuitive did you find the VR welding simulator? |

| Q2 | How realistic did the welding simulation feel to you? |

| Q3 | Did you feel that the simulator interface was easy to understand and use? |

| Q4 | How would you rate the comfort of the simulator during the training session? |

| Q5 | Did you find that the simulation responded fluidly to your movements and actions? |

| Knowledge Transfer and Skill Retention | |

| Q6 | How confident did you feel about welding before and after training in VR? |

| Q7 | Do you feel that VR training adequately prepared you for real-world welding? |

| Q8 | How easy was it to recall the correct soldering iron posture in real welding after VR training? |

| Q9 | How many times do you think you would need to practice in VR before attempting real welding? |

| Training Preferences and Improvements | |

| Q10 | If you were to train in VR again, what aspects would you improve or change? |

| Q11 | Which training method do you prefer for learning welding? |

| Q12 | Do you believe VR training reduces the fear or anxiety of making mistakes in real welding? |

| Q13 | Did you feel more or less anxious practicing in VR compared to a real instructor? |

| Q14 | Do you think using VR helps reduce learning time compared to a human instructor? |

| Feedback and Interaction | |

| Q15 | Did the VR simulation provide enough visual and auditory feedback for you to understand if you were welding correctly? |

| Question ID | Mean Score (1–5) | % Rated |

|---|---|---|

| Q1 | 4.11 | 88.9% |

| Q2 | 4.61 | 100.0% |

| Q3 | 4.11 | 77.8% |

| Q4 | 4.39 | 94.4% |

| Q5 | 4.22 | 88.9% |

| Q6 | 4.00 | 72.2% |

| Q7 | 3.61 | 38.9% |

| Q8 | 4.56 | 94.4% |

| Q12 | 4.39 | 100.0% |

| Q15 | 3.89 | 61.1% |

| Error Type | First Attempt | Second Attempt |

|---|---|---|

| Iron positioning inaccuracies | 6 errors | 0 errors |

| Grip errors | 13 errors | 0 errors |

| Statistic | Value |

|---|---|

| Number of participants (n) | 23 |

| Mean of Attempt 1 (min) | 2.92 |

| Standard deviation of Attempt 1 | 0.45 |

| Mean of Attempt 2 (min) | 2.36 |

| Standard deviation of Attempt 2 | 0.34 |

| Mean difference () | 0.56 |

| Standard deviation of the differences | 0.31 |

| Standard error of the mean () | 0.055 |

| Calculated t statistic | 10.25 |

| Degrees of freedom () | 22 |

| p-value (two-tailed) |

| Aspect | Optimal | Acceptable | Deficient |

|---|---|---|---|

| Joint quality | All joints solid and well-formed | Some with excess or poor shape | Incomplete joints |

| Iron positioning | Correct and stable placement throughout the process | Slight misalignment, but adjusted | Frequent mispositioning affecting joint quality |

| Solder application | Appropriate amount of solder evenly applied at each joint | Slight excess or insufficient solder, but joints remain functional | Excessive, insufficient, or poorly distributed solder compromising joint quality |

| Execution fluency | Maintains a continuous workflow with confident, autonomous actions | Minor delays or hesitation, but completes task independently | Frequent interruptions, visible uncertainty, or required assistance to complete the task |

| User | Joint Quality | Iron Positioning | Solder Application | Execution Fluency | Total |

|---|---|---|---|---|---|

| User 1 | 2 | 2 | 2 | 2 | 8 |

| User 2 | 3 | 3 | 2 | 2 | 10 |

| User 3 | 2 | 3 | 2 | 2 | 9 |

| User 4 | 2 | 3 | 2 | 2 | 9 |

| User 5 | 2 | 2 | 2 | 2 | 8 |

| User 6 | 2 | 2 | 2 | 2 | 8 |

| User 7 | 3 | 2 | 2 | 2 | 9 |

| User 8 | 3 | 3 | 3 | 2 | 11 |

| User 9 | 3 | 3 | 3 | 2 | 11 |

| User 10 | 3 | 3 | 3 | 2 | 11 |

| User 11 | 3 | 2 | 3 | 2 | 10 |

| User 12 | 3 | 2 | 3 | 2 | 10 |

| User 13 | 3 | 2 | 3 | 2 | 10 |

| User 14 | 3 | 2 | 3 | 2 | 10 |

| User 15 | 3 | 2 | 3 | 2 | 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alfaro-Viquez, D.; Zamora-Hernandez, M.; Fernandez-Vega, M.; Garcia-Rodriguez, J.; Azorin-Lopez, J. Integrating Virtual Reality into Welding Training: An Industry 5.0 Approach. Electronics 2025, 14, 1964. https://doi.org/10.3390/electronics14101964

Alfaro-Viquez D, Zamora-Hernandez M, Fernandez-Vega M, Garcia-Rodriguez J, Azorin-Lopez J. Integrating Virtual Reality into Welding Training: An Industry 5.0 Approach. Electronics. 2025; 14(10):1964. https://doi.org/10.3390/electronics14101964

Chicago/Turabian StyleAlfaro-Viquez, David, Mauricio Zamora-Hernandez, Michael Fernandez-Vega, Jose Garcia-Rodriguez, and Jorge Azorin-Lopez. 2025. "Integrating Virtual Reality into Welding Training: An Industry 5.0 Approach" Electronics 14, no. 10: 1964. https://doi.org/10.3390/electronics14101964

APA StyleAlfaro-Viquez, D., Zamora-Hernandez, M., Fernandez-Vega, M., Garcia-Rodriguez, J., & Azorin-Lopez, J. (2025). Integrating Virtual Reality into Welding Training: An Industry 5.0 Approach. Electronics, 14(10), 1964. https://doi.org/10.3390/electronics14101964