1. Introduction

Remote mountainous areas and villages are scattered, and far from the primary grid, with long transmission distances. They are prone to geological disasters such as landslides, leading to faults in the main grid transmission lines. In recent years, with the development and widespread application of renewable energy, microgrids have rapidly developed due to their flexible regulation capabilities, which can be independent of the main grid and form an island mode to achieve self-sufficiency [

1,

2,

3].

Microgrid systems connected to the main grid for a long time do not need to be equipped with sufficient reserve capacity for the internal load, which can reduce system configuration costs. Once an extreme situation occurs, an independent islanded microgrid can be formed. However, insufficient configuration may lead to power shortages in the system, resulting in a decrease in frequency, and in severe cases, it may cause system crashes [

4,

5]. In August 2019, the super typhoon, “Lekima”, made landfall on the southeastern coast of China, causing over 4000 power line failures and leaving 6.7695 million users without electricity in provinces such as Zhejiang. To ensure the stability of system frequency and the operation of some important loads, it is particularly important to optimize the scheduling of islanded microgrids formed under extreme working conditions [

6,

7,

8].

For systems that only contain new energy generation and energy storage equipment, there are two methods for optimizing scheduling: direct load control and energy storage charging and discharging plans. Direct load control is the process of directly cutting off user loads during power imbalance to maintain power balance and system stability. The traditional load reduction mode only reduces the load in stages, with low precision and errors between the actual system and scheduling strategies. The importance of the load has not been classified, resulting in low economic efficiency. Fixed unit load-cutting cost coefficients are commonly used for load reduction, or loss compensation is set for unit load-cutting cost coefficients in gradient intervals of load-cutting volume. Without considering the reduction period, reducing a large load during peak electricity consumption is easy, which is inconvenient for users [

9,

10,

11,

12,

13] and affects their electricity comfort [

14,

15]. In this regard, this article proposes to combine time-of-use electricity prices with unit load shedding cost coefficients, which can minimize peak load shedding and improve load stability compared to traditional fixed coefficients.

Model predictive control utilizes current measurement data to optimize the predictive model in the rolling time domain, obtaining the optimal control sequence in the future control time domain and then implementing closed-loop optimal control through feedback correction to improve control accuracy [

16]. Using the model predictive control (MPC) method for microgrid optimization scheduling and designing energy storage charging and discharging plans can improve the system’s anti-interference ability and enhance the system’s power supply stability [

17,

18].

In power systems, model predictive control technology has shown robustness in dealing with uncertain power sources such as wind power and photovoltaics (PVs) and has received increasing attention. Reference [

19] provides a comprehensive overview of model predictive control (MPC) applications in building energy management, offering a unified framework for its implementation across various engineering disciplines. It critically discusses the outcomes of different MPC algorithms in thermal regulation, HVAC (Heating, Ventilation, and Air Conditioning) system optimization, and the management of energy storage and renewable sources, highlighting MPC’s potential to improve energy efficiency in buildings by considering constraints and multiple conflicting objectives such as thermal comfort and energy demand. Reference [

20] introduces a model predictive control (MPC) strategy for energy management in a series hybrid electric tracked bulldozer (HETB), demonstrating a 6% improvement in fuel economy over rule-based methods and achieving 98% of the fuel optimality of dynamic programming, with proven robustness under large disturbances. Reference [

21] proposes a risk-aware dynamic optimization method for independent microgrids, incorporating future operational risks and uncertainties in a CVaR-based day-ahead energy scheduling model. The method enhances long-period operational reliability by optimizing power scheduling strategies and reserve requirements for diesel generators, photovoltaic systems, energy storage, and flexible loads, reducing expected load losses and PV curtailment. Reference [

22] introduces a novel dynamic power system scheduling approach to reduce generation costs in microgrids, utilizing a multi-vector energy model that integrates electricity, heating, and water generation sources. It evaluates the use of photovoltaic systems for partial load supply, incorporates a price-based demand response program to mitigate renewable energy source (RES) uncertainty, and minimizes system costs over a 24 h period. The above studies are all focused on scheduling in the grid-connected mode, with a greater emphasis on improving the economic efficiency of the system. In extreme operating conditions, an islanded microgrid focuses more on protecting essential loads.

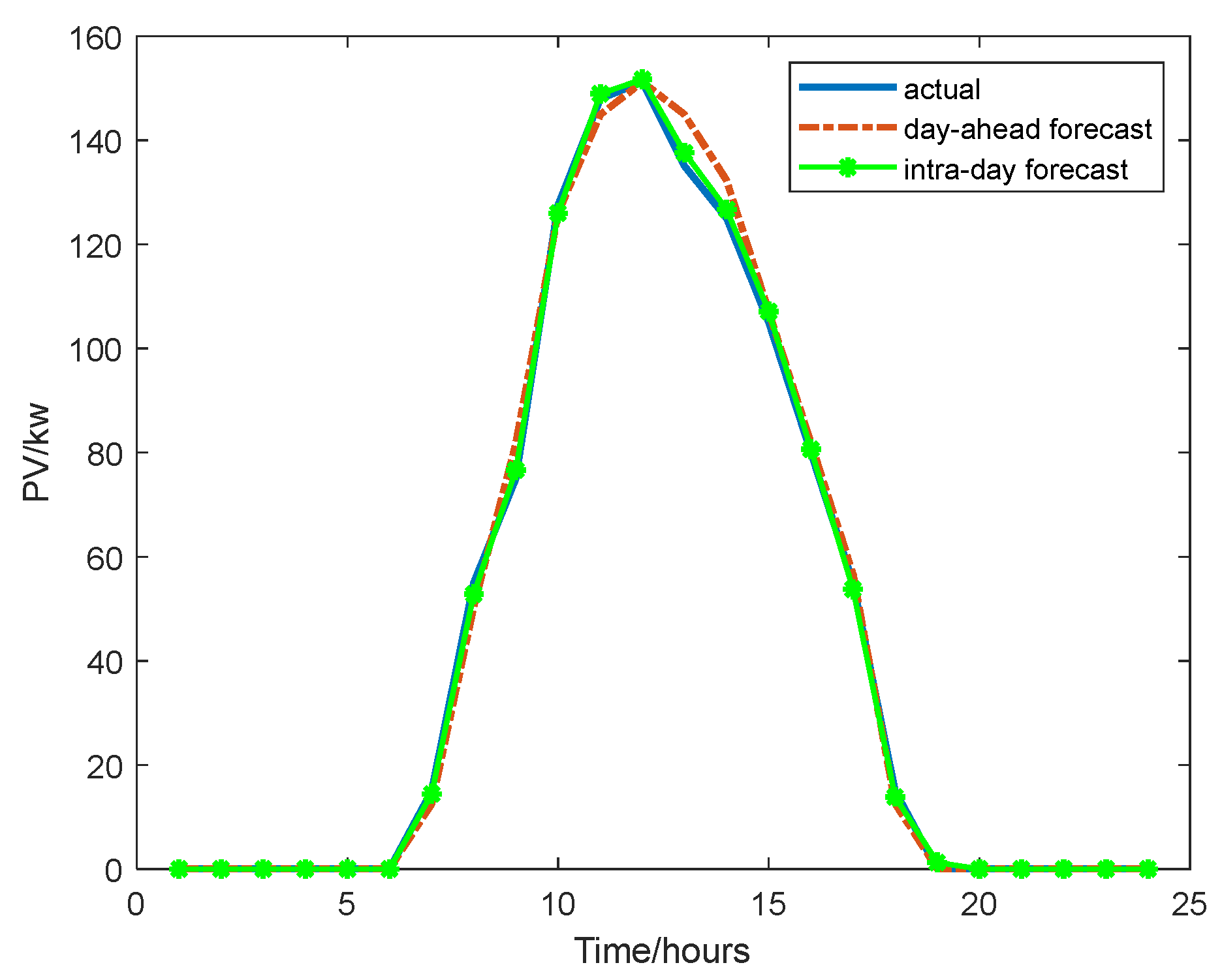

In order to improve the economic, environmental, and necessary load supply operation of the islanded microgrid system, this paper proposes a rolling optimization economic dispatch strategy for an islanded microgrid under extreme working conditions: A load classification and dispatch framework model for each node of the high-proportion new energy-islanded microgrid is established. On the load side, the load is divided into three categories according to the importance level. The load is predicted through price-based demand response, and the load shedding cost coefficient is set based on the time of use, electricity price, and load importance. The charging and discharging strategy for grid-connected energy storage is obtained through recent optimization scheduling. The remaining power of grid-connected energy storage is considered on the power supply side through intra-day rolling optimization to obtain a load reduction plan. The optimization scheduling for charging and discharging of grid-connected energy storage is obtained through feedback correction. The model is solved using analytical methods and intelligent optimization algorithms. The contribution of this article is as follows:

- (1)

This paper proposes a new load shedding optimization scheduling method, specifically designed for the operational characteristics of islanded microgrids. The method enhances the utilization of photovoltaic energy and energy storage systems through precise load shedding strategies, while ensuring the stability of power supply to critical loads. Specifically, the study designs a dynamic load shedding scheme based on load priorities and power system constraints, which can intelligently schedule power resources in response to sudden load fluctuations or energy shortages. This approach maximizes the absorption of renewable energy and ensures the continuous and stable operation of the system in the island mode.

- (2)

This paper further explores the demand response (DR) mechanism and its operating modes at different time scales, and proposes a multi-level demand response optimization scheduling scheme to address the demand fluctuations and power supply–demand imbalances in islanded microgrids. In particular, this research not only considers conventional load management measures but also integrates time-of-use pricing mechanisms and load importance evaluation strategies. Targeted incentive and subsidy policies are designed to optimize consumer behavior. Through multi-stage optimization, this paper enables flexible adjustment of the demand response intensity at different time periods, effectively reducing grid load pressure and improving the economic and operational efficiency of the system.

5. Conclusions

When long-term grid-connected microgrids experience connection failures due to natural disasters and operate in the extreme islanding mode, the reliability of their optimized scheduling is relatively poor due to the impact of insufficient self-configured capacity. This article establishes a rolling time-domain optimization scheduling model based on MPC for the operation mode of an islanded microgrid in extreme situations. The results show that

- (1)

The DR-MPC-based method, compared to methods that do not consider time-of-use pricing and load importance, reduces the overall operating costs by 0.6% and 30%, respectively, while also improving the renewable energy absorption rate of the microgrid system.

- (2)

This paper proposes a load classification scheduling framework for islanded microgrids with a high penetration of renewable energy, and based on this, designs a precise load shedding optimization scheduling strategy. By dynamically adjusting the output of the energy storage system, the method maximizes the utilization of renewable energy and ensures the stability of power supply to critical loads. Additionally, this study combines time-of-use pricing and load importance assessment to propose an innovative demand response incentive subsidy policy, effectively optimizing the scheduling of critical loads during peak load periods, ensuring the stability of power supply, and alleviating the power supply–demand imbalance.

This strategy can be applied to the emergency load shedding strategy optimization scheduling and energy storage capacity configuration calculation of an isolated microgrid. In the future, the proposed models and algorithms can be applied to optimize the scheduling of microgrid cluster systems. The method adopted in this study effectively improves system stability but still has certain limitations. First, rolling optimization increases the computational burden of the system and imposes higher requirements on hardware devices. While the MPC method reduces the inaccuracy of supply–demand balance, its ability to mitigate renewable energy curtailment is limited, requiring increased storage capacity to alleviate this issue. Moreover, the pre-shedding approach faces multiple challenges in practical applications, such as the complexity of load prioritization, low user acceptance, insufficient load forecasting accuracy, and inadequate support from energy storage systems. To overcome these limitations, future work should integrate advanced prediction and optimization techniques, enhance the reliability of energy storage and communication systems, and improve relevant policies and standards.