1. Introduction

With increasing power consumption, electrical fire accidents caused by electrical equipment failure and electrical line aging are also increasing year by year. In 2023, there were 1941 electrical fires in the country, accounting for 29.1%, which was the primary cause of fires [

1]. The number of lines and equipment in low-voltage distribution networks is large, network topology and operating environments are complex, and there is a lack of regular operation and maintenance. Therefore, the hidden danger of the safe operation of low-voltage distribution networks, especially the hidden danger of electrical fires, is very prominent. Among them, series arc faults, as a common fault type, have created great challenges for the safe operation of low-voltage distribution networks due to the difficulties of detection and accurate positioning. Therefore, it is necessary to carry out research on the effective detection method of arc faults in low-voltage distribution networks to meet the needs of the effective prevention and control of fires caused by arc faults.

According to the arc-fault detection method, the existing technology can be divided into mechanical and electrical types [

2]. The main defect of the mechanical arc-fault detection method is that the sensor must be set near the arc position to perform reliable detection. Therefore, the mechanical detection method is only suitable for fixed-point detection scenarios, such as switch cabinets, and the practicability is poor. The electrical arc-fault detection method usually detects an arc fault by the abnormal changes in the electrical characteristics corresponding to the current and voltage. The arc-fault detection method based on the changes in the voltage and current characteristics in the line has attracted more and more attention. Kim et al. [

3] studied the symmetrical energy distribution of arc-fault voltage, and proposed an arc-fault identification method based on this. However, due to the unpredictable location of the arc, the arc voltage waveform is usually difficult to obtain in the actual line. In contrast, the arc current signal is easier to collect and process, which is the focus of current research. H. Zhao et al. [

4] combined the current zero-break time ratio and the normalized mean square error coefficient of the waveform to obtain the comprehensive feature recognition coefficient of the series arc fault, and compared it with the empirical threshold to determine whether there is a series arc fault. However, the paper does not consider the fact that the nonlinear load work will cause the algorithm to misidentify the issue at hand. The method based on the low-frequency characteristics of arc currents has certain limitations. In recent years, many scholars have begun to study the arc-fault identification method based on frequency domain analysis. Xiong Qing et al. [

5] used the relationship between the Fourier integral amplitude and frequency of arc currents to identify and locate arc faults. Due to the increase in nonlinear loads in the distribution network environment, high-order harmonics and distortions will also occur in the normal current of the load. Similar to the arc-fault current, the traditional arc-fault identification method easily causes misjudgments. Moreover, the time–frequency domain characteristics of an arc current are easily affected by the type of load, and the artificially set threshold is no longer universal. The recognition algorithm is prone to misoperation and rejection, and the reliability is poor.

In recent years, artificial intelligence technology has developed rapidly [

6]. W. Yu et al. proposed a data-driven fault detection and diagnosis method [

7,

8,

9]. The generalized convolutional neural network with incremental learning ability is used to diagnose industrial faults. Robust monitoring and fault isolation for nonlinear industrial processes are achieved using denoising autoencoders and resilient networks. MoniNet with the concurrent analysis of temporal and spatial information is used to detect industrial faults. The development of artificial intelligence has opened up new ideas for the research of arc-fault diagnosis technology. The advantage of using artificial intelligence for arc-fault identification is that artificial intelligence can automatically extract the deep features of the input signal, eliminate the interference of human factors, and automatically establish a series arc-fault identification model. Compared with the traditional machine learning algorithm, the deep learning algorithm can obtain more original signal features, reduce the data preprocessing process, and obtain the arc-fault recognition results more directly. Y. Wang et al. [

10] proposed a hybrid arc-fault detection method based on improved Mel frequency cepstrum coefficient (MFCC) preprocessing and the arc recognition neural network model based on ARC_MFCC. The detection accuracy can reach 99.34%. G. Zhou et al. [

11] proposed a series arc-fault detection method based on double-filter feature selection and improved hierarchical clustering, which significantly improved the training and detection speed. Y. Wang et al. [

12] proposed an AC arc-fault recognition model based on a convolutional neural network, which can realize the real-time processing and state recognition of current signals in hardware. L. Zhao et al. [

13] introduced a method for selecting the phase of a fault arc in three phases using a global time convolution network, and the global attention mechanism was used to extract the fault depth representation. C. D. Prasad et al. [

14] used the energy coefficient of the optimal transient extraction transform as an indicator to detect high-resistance arc faults, and used the particle swarm optimization algorithm to obtain the fault data set in OTET. F. Zhang et al. [

15] used sparse coding to obtain signal features, and used the neural network for feature learning and classification, which can avoid the misoperation of the switching characteristic load start-up process. The experimental results show that the SRFCNN method is effective and versatile for arc-fault detection of various load types. At the same time, the design architecture and analysis method of the SRFCNN method reveal the potential of this method in other signal feature extractions, fault diagnoses, and classifications.

At present, the research on low-voltage AC arc-fault detection still faces many challenges. Traditional arc-fault detection methods lack accuracy. Using artificial intelligence methods to detect arc faults can improve the accuracy, but artificial intelligence methods often lack interpretability. In the face of multiple loads, different loads will have overlapping frequency bands, and it is difficult to distinguish arc-free signals. Therefore, it is necessary to use artificial intelligence to perform detections. Most of the existing artificial intelligence methods lack interpretability, which limits the parameter adjustment, accuracy improvement, and light weight of the model. The output of the model cannot be reasonably explained, and correct sample analysis is also difficult. The interpretability of the model is helpful to the improvement of the model. In the process of model improvement, interpretability helps to judge the flow process of the data. In the field of arc-fault detection, due to the particularity of the power system, the detection of the arc fault has accurate and rapid requirements. Therefore, a detection model needs to be continuously improved with the changes in application scenarios and requirements. Therefore, the interpretability of the detection model is important in the context of arc-fault detection.

Before using the artificial intelligence method to identify an arc fault, it is necessary to manually extract the arc characteristics as the input parameters of the machine learning algorithm. The selection of arc characteristics directly determines the final accuracy of the machine learning algorithm [

16]. At present, the feature selection of machine learning methods is mainly based on field experience, and it cannot guarantee that the selected arc features match the artificial intelligence algorithm used, resulting in the arc detection algorithm easily malfunctioning. The attention mechanism plays an important role in the field of deep learning. It imitates the way the human brain processes information and helps the neural network selectively focus on specific inputs [

17]. In order to solve the problem of arc feature selection, this paper proposes an arc-fault detection method based on the attention weight automatic extraction of arc features. The key arc features are selected by extracting the attention weight embedded in the algorithm, and the insensitive redundant features are eliminated for arc-fault identification. An anti-interference test is carried out, and the results show the effectiveness of the method.

This paper proposes an interpretable lightweight model for low-voltage AC arc-fault detection. The specific effects of the method are as follows.

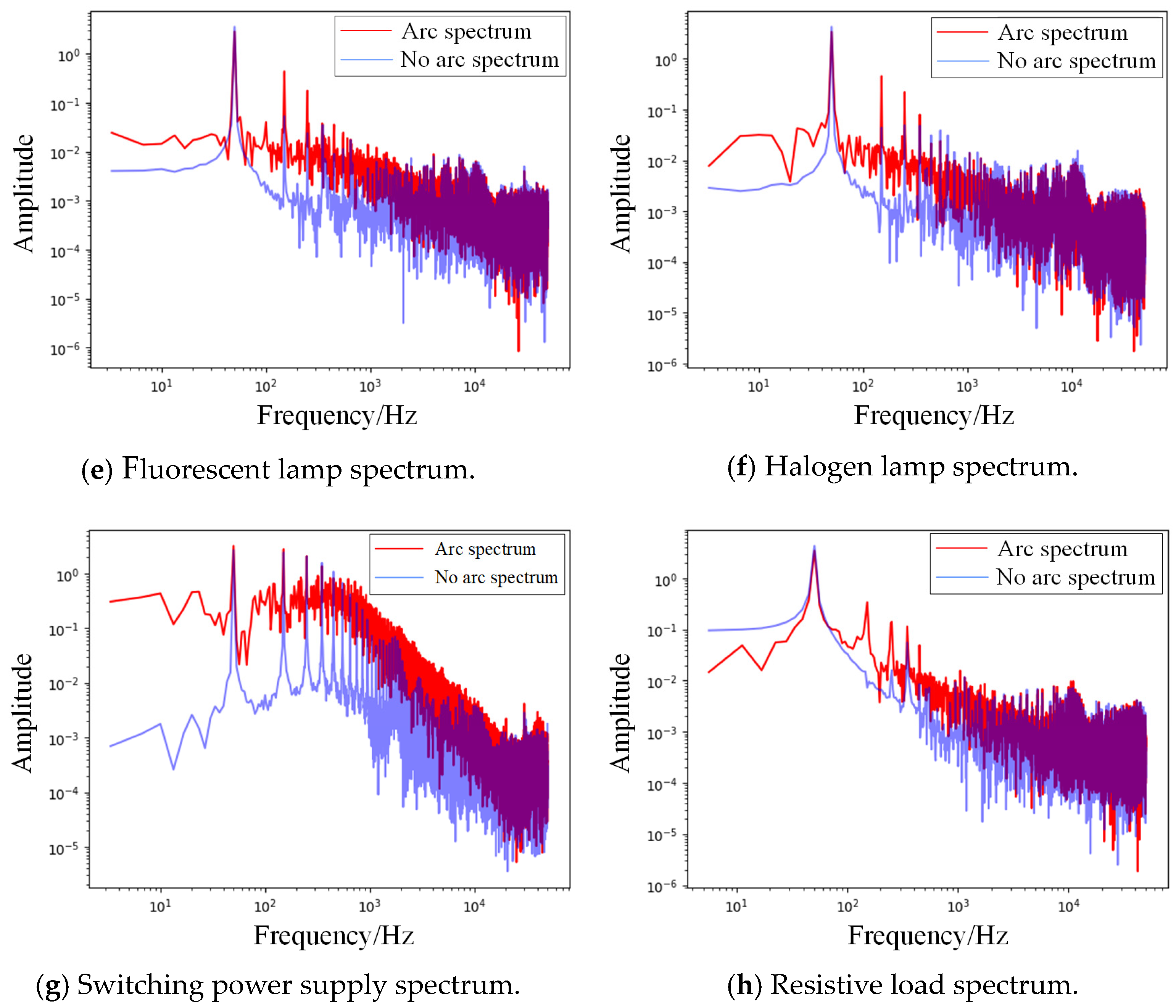

First, through frequency domain analysis, it is found that the spectrum information of arc-fault currents can reflect certain characteristics of AC arc-faults under multi-type loads. The use of frequency domain information combined with the attention mechanism model in this paper can better combine the prior experience in the field of arc faults, which is helpful to obtain the characteristic frequency band of arc faults from the perspective of the model output, and provide the basis for model accuracy improvement and light weight.

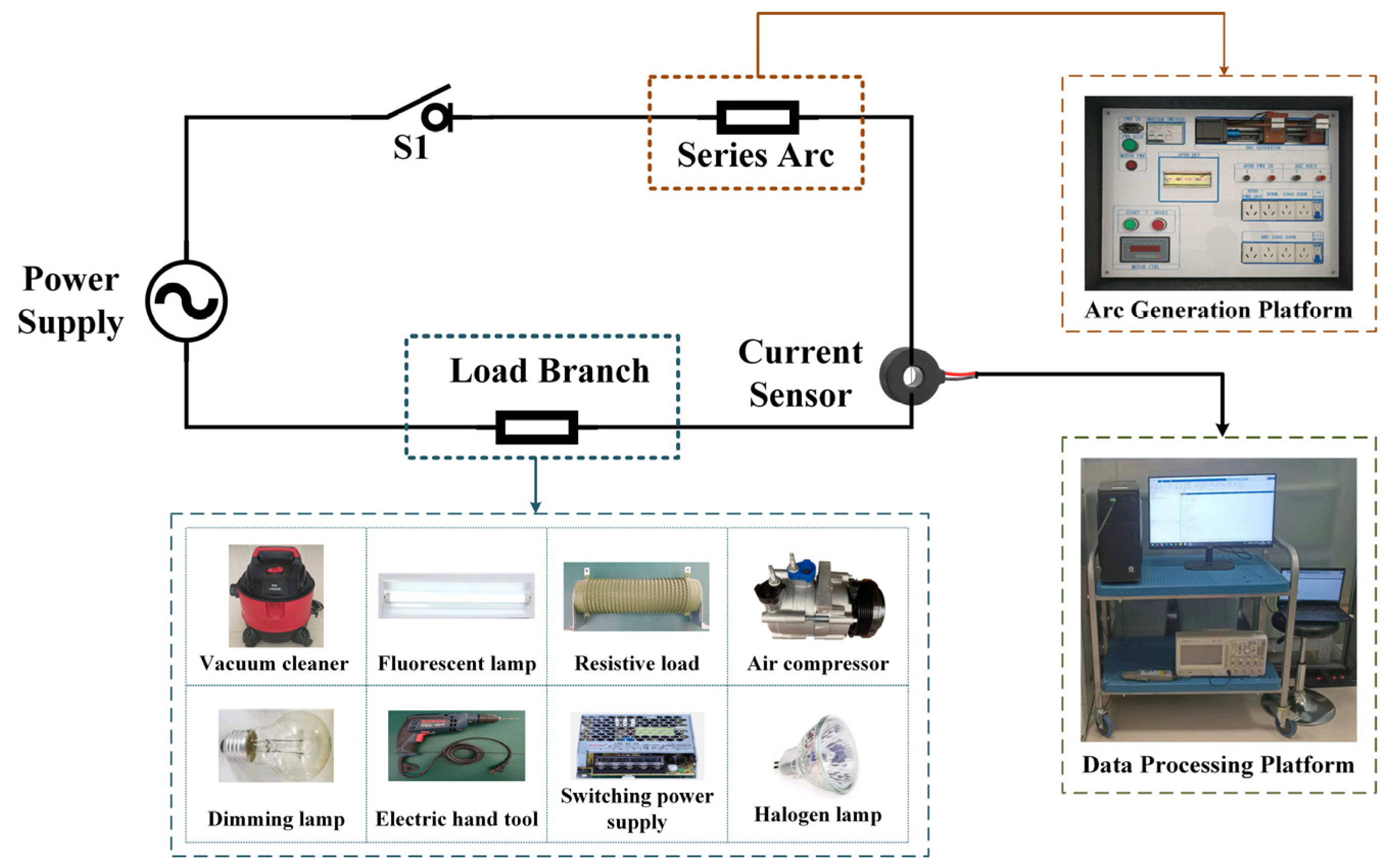

Second, a true arc-fault test platform was built. Arc-fault data under various typical AC loads were collected by high-precision transformers and a data set was made. An arc-fault detection model based on the attention mechanism is built, and an arc-fault detection algorithm with the best performance in detection accuracy is formed.

Third, according to the weight calculation of the input data by the model attention mechanism module, the input spectrum data are divided. Through experiments, the performance of different part data combinations on the accuracy of the model is tested, and the effect of each part data on the accuracy of the model is determined. Then, the input data combination with the best accuracy performance is obtained, and the input data optimization method in line with the existing knowledge in the field of arc-fault detection is formed, which fundamentally reduces the calculation pressure of the model. The lightweight model is more suitable for deployment on industrial-grade embedded platforms, and a complete arc-fault detection scheme is finally formed.

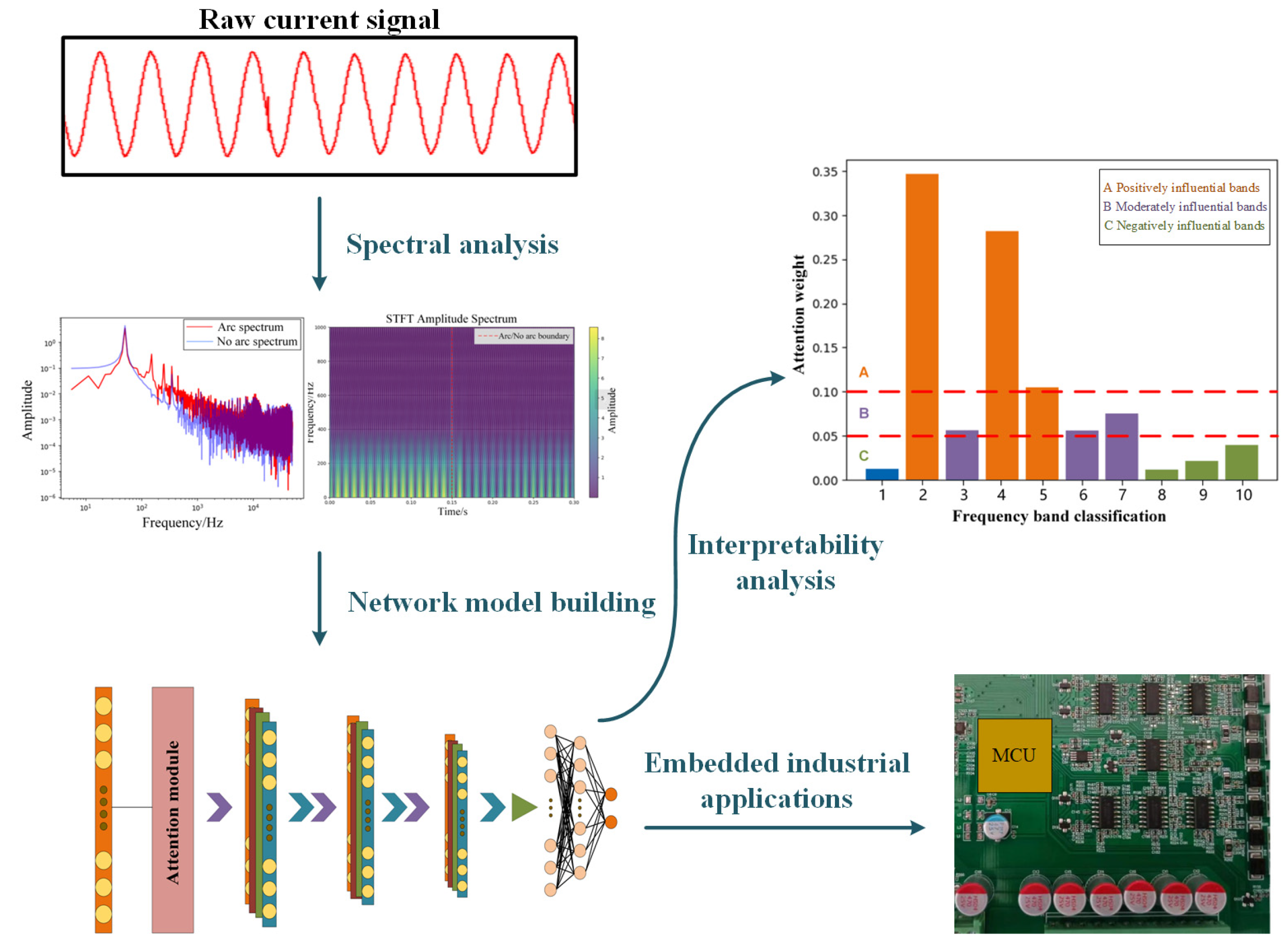

The flow chart of the proposed method is shown in

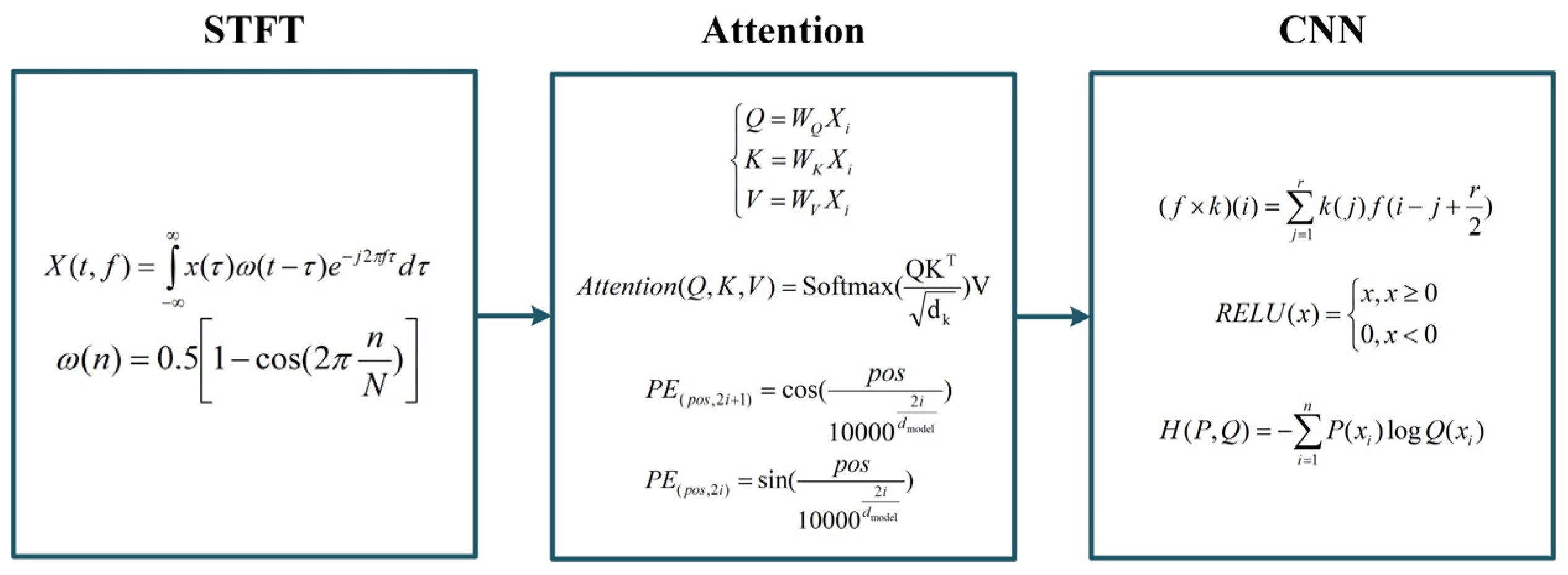

Figure 1. The algorithm flow chart of this paper is shown in

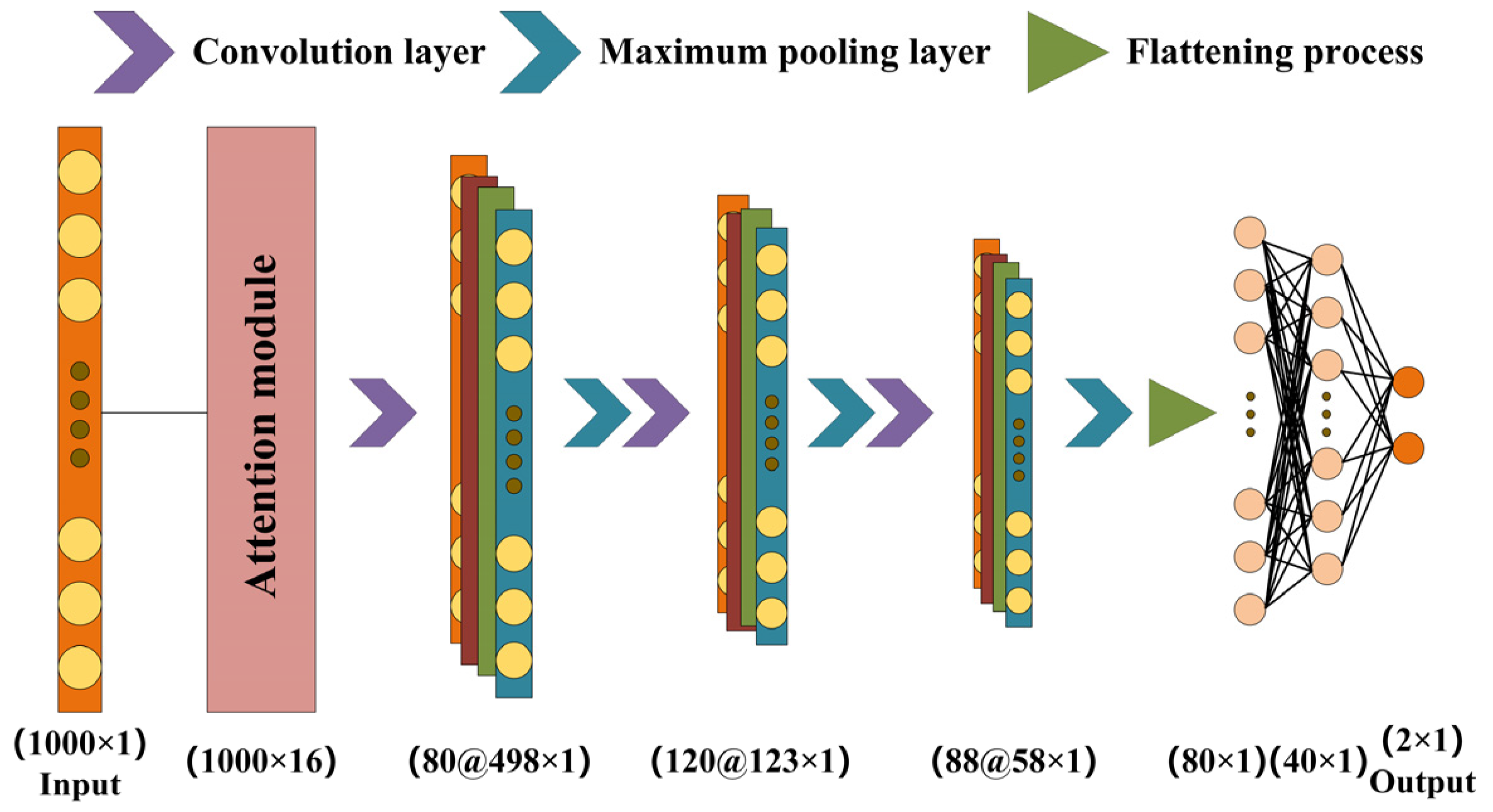

Figure 2. The attention mechanism is a technology widely used in the fields of machine learning and artificial intelligence. It simulates the human attention mechanism, so that the model can selectively focus on some parts of the input data, thereby improving the performance and efficiency of the model. In deep learning, the attention mechanism is usually used to process sequence data. It can help the model to pay different types of attention to the input data at each time step or vocabulary in order to better capture important information. The core idea of the attention mechanism is to dynamically allocate weights based on the input data, so that the model can focus on the most meaningful part of the current task. The convolutional neural network is a deep learning model, which is mainly used to deal with visual-related tasks, such as image classification, target detection, and image segmentation. The design inspiration of the CNN comes from the working principle of the biological vision system. The features in the image are extracted by the convolution operation and pooling operation and classified or regressed by the fully connected layer. In this paper, the data are processed by short-time Fourier transform, and the arc-fault detection model is built by combining an attention mechanism and convolutional neural network.

The arc-fault current feature set is obtained by the spectral analysis of the original current data. A convolutional neural network model based on an attention mechanism is built to process the frequency domain data of the arc fault. The model proposed in this paper is interpretable. By comparing the training effects of different feature frequency bands in the model, the readability of the model is enhanced. Finally, the proposed method is deployed on hardware. After verification, it is found that the detection accuracy and judgment time of the proposed method for arc faults meet the requirements.

4. Model Results and Analysis

4.1. Model Calculation Results

This paper utilized 120 epochs for training, with a batch size of 100 and an initial learning rate of 0.00001. The results show that the recognition accuracy of the proposed model for arc faults under different loads reaches 99.69%. The characteristic frequency band of the arc critical energy spectrum based on interpretability extraction can accurately characterize the arc characteristics, and reduce the network parameters and calculation amount while maintaining the accuracy of network identification, which proves the feasibility of using interpretability method to extract arc characteristics.

The selection of characteristic frequency band is very important for arc-fault identification. The characteristics of low-voltage AC series arc faults are mainly distributed in the frequency range of 1 kHz to 100 kHz. However, in frequencies higher than 20 kHz, the energy spectra of the arc state and the normal operation state overlap in some frequency bands. The energy spectrum of overlapping frequency bands will not be conducive to the identification of arc faults, and even reduce the accuracy of the model. Therefore, it is necessary to extract the key arc features that are conducive to arc-fault identification from the arc features from 1 kHz to 100 kHz.

The eight different loads specified in IEC62606 in AC series arc-fault detection are trained in combination with the interpretable arc-fault identification network based on the attention mechanism proposed in this paper. The training outcomes are presented in

Table 5, while the associated confusion matrix is displayed in

Figure 8.

According to the analyses of confusion matrix-, accuracy-, recall-, and precision-related parameters, the model proposed in this paper is tested under eight different loads specified in IEC62606, and the performance of the model proposed in this paper is verified in the test data set. The horizontal axis of the matrix is the model prediction category, and the vertical axis is the actual category. Diagonal data are the number of correctly identified samples. The inaccuracy of the confusion matrix has a minimal impact on the accuracy of arc detection, and it does not result in any incorrect or overlooked judgments. The detection error primarily occurs in the resistive, motor, and power electronic loads. The arc current waveform of both the resistive load and the motor load closely resembles the average current waveform of the power electronic load, resulting in a minimal detection error.

4.2. Model Attention Weight Analysis

Choosing specific frequency bands is crucial for identifying arc faults. The primary distribution of features for low-voltage AC series arc faults occurs between 1 kHz and 100 kHz. However, beyond a specific frequency range over 20 kHz, the energy spectrum without arcs overlaps, which hinders the detection of arc defects and even diminishes the precision of the model. Thus, the essential characteristics of the arc that help identify arc faults are removed. To validate the functionality of the attention mechanism employed in this paper, the attention spectrum weight map is depicted for various loads.

The horizontal axis in

Figure 9 depicts the categorization of frequency bands, whereas the vertical axis represents the magnitude of the attention weight for each frequency band. The collected data are organized into groups with a frequency interval of 5 kHz. The test data are further separated into ten groups to highlight the significance of weights in various frequency ranges.

It can be seen in

Figure 9 that the attention weights of groups 2, 4, and 5 are the largest, representing data in the ranges of 5–10 kHz and 15–25 kHz; the weights of groups 3, 6, 7 are the second highest, representing 10–15 kHz and 25–35 kHz; and the weights of groups 8, 9, and 10 are the smallest, representing a data range of 35–50 kHz. Due to the timeliness of arc detection, in order to meet the needs of arc-fault detection accuracy and detection efficiency, the influence of group 1 on test accuracy is not considered. In order to meet the timeliness of arc detection, the above frequency bands are divided into three levels, A, B, and C, according to the degree of attention influence, as shown in

Table 6.

It can be seen in

Table 7 that A, B, and C have a certain influence on the accuracy of the model proposed in this paper. In the case of pairwise combinations, AB has the highest accuracy, AC is the second highest, and BC is the lowest. Because A has a great influence on the frequency band of the test data and the attention weight accounts for a high proportion, when the data tested in the model include the data of the middle frequency band of A, it will have a positive impact on the accuracy of the results of the whole model’s operation. Similarly, because the influence weight of the C middle-frequency band on the whole test data band is very small, and the proportion of the attention weight is very low, when the data tested in the model include C middle-frequency band data, it will not be conducive to the accuracy of the whole model for arc-fault judgment. Because the corresponding data in the frequency band of B have a smaller influence weight on the attention of the whole model than A, it is larger than C, and the influence weight of the corresponding frequency band is moderate compared with the data in A and C. Therefore, the accuracy of the combination of A and C is higher than that of the combination of B and C; the accuracy of the combination of A and B is higher than that of the combination of A and C.

Since the three different classifications of A, B, and C represent the corresponding frequency band data under different attention weight distributions, when the frequency band data under each weight distribution are input, the model proposed in this paper can maximize the influence of the data. The processing volume of the model network is reasonably allocated to improve the operating efficiency of the model. At the same time, because the data input for the model takes into account different influence weights, the output of the proposed model has the highest accuracy. Because AB has the highest accuracy, it shows that the attention mechanism proposed in this paper has a significant effect. The experimental results show that the characteristic frequency band of the arc critical energy spectrum based on interpretability extraction can accurately characterize arc characteristics and reduce the network parameters and calculation amount while maintaining the accuracy of network identification. When the data with the highest weight ratio of the frequency band are used, that is, the data with frequency bands of 5–10 khz and 15–20 khz, the amount of data input to the model is reduced by 80%. After inputting these data into the model with only one convolution layer and one maximum pooling layer, the accuracy rate is only reduced by 0.32%. This proves that the light weight of the model proposed in this paper is effective.

5. Prototype Design and Experimental Verification

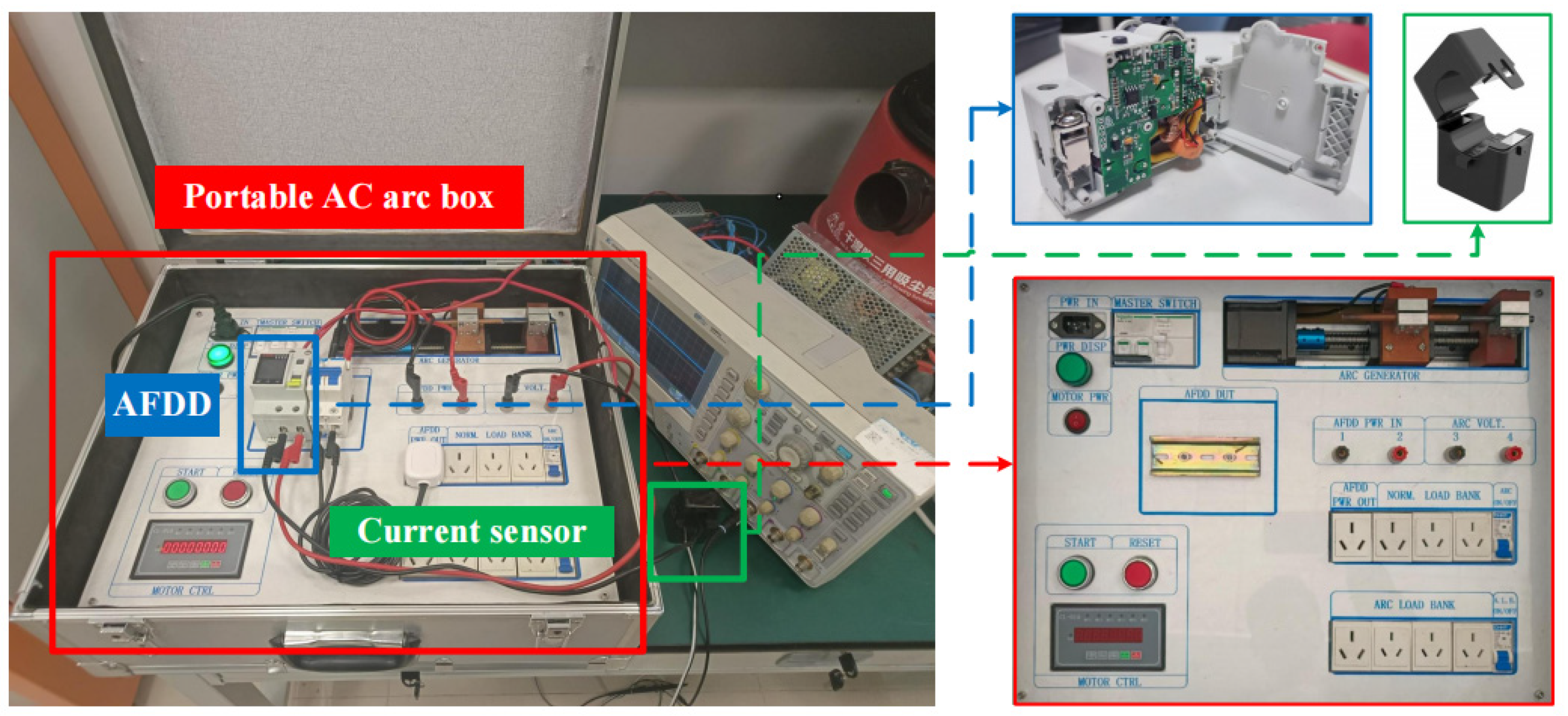

In order to evaluate the performance of the model proposed in this paper, intelligent circuit breakers and low-voltage AC arcing devices are selected to verify the effectiveness of the proposed model, as shown in

Figure 10. Firstly, the AC power supply, low-voltage AC arcing device, and intelligent circuit breaker are connected to the multi-load topology. The reliability and effectiveness of the proposed model are verified by testing the breaking of the intelligent circuit breaker under multi-load conditions. Among them, the electrical signal processing module of the intelligent circuit breaker is added to the relevant algorithm of the arc-fault judgment model proposed in this paper. The test samples obtained by different arcing methods are preprocessed by the algorithm and input into the model proposed in this paper for testing. The tripping time of the intelligent circuit breaker meets the IEC62606 standard.

The sampling results of the oscilloscope are displayed in

Figure 11.

After testing, the intelligent circuit breaker can meet the requirements of detection accuracy in actual production when using the relevant algorithm of the model proposed in this paper to detect the low-voltage AC series arc fault. The tripping situation of the intelligent short circuit breaker is shown in

Table 8.

In order to better illustrate the effectiveness of the proposed algorithm, it is compared with other low-voltage AC series arc-fault detection algorithms. This comparison covers a variety of factors, including the use of arc-fault feature data extraction methods, arc-fault identification methods, load types during detection, and the accuracy of different methods used. The test information related to the algorithm verification platform in

Table 8 is from the original text.

The suggested technique is compared to previous algorithms that identify arc faults in low-voltage AC series circuits. The pertinent data are derived from the primary source, as indicated in

Table 9. By comparing them, it is evident that this method has the best level of recognition accuracy. The method described in this paper has significant advantages, since it may fulfill the load type prescribed by IEC62606.

Table 9 shows the superiority of the proposed algorithm in detection accuracy. At the same time, this paper identifies the faults of several loads under the IEC62606 standard and has ideal accuracy. At the same time, the method used in this paper can meet the needs of circuit breakers for the timely tripping of arc faults, and the tripping time meets the IEC62606 standard. Therefore, the method proposed in this paper is superior to other methods.