A Virtual Reality Environment Based on Infrared Thermography for the Detection of Multiple Faults in Kinematic Chains

Abstract

1. Introduction

2. Background Materials and Methods

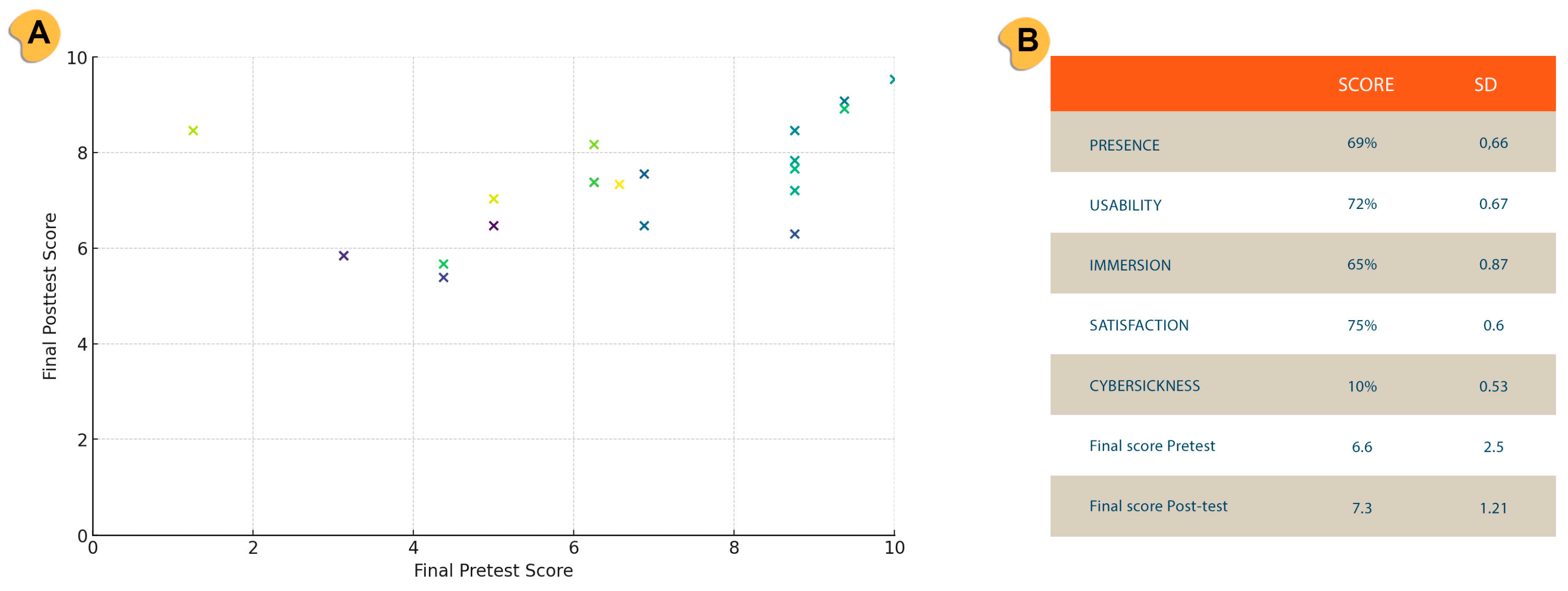

2.1. Faults in the Kinematic Chain

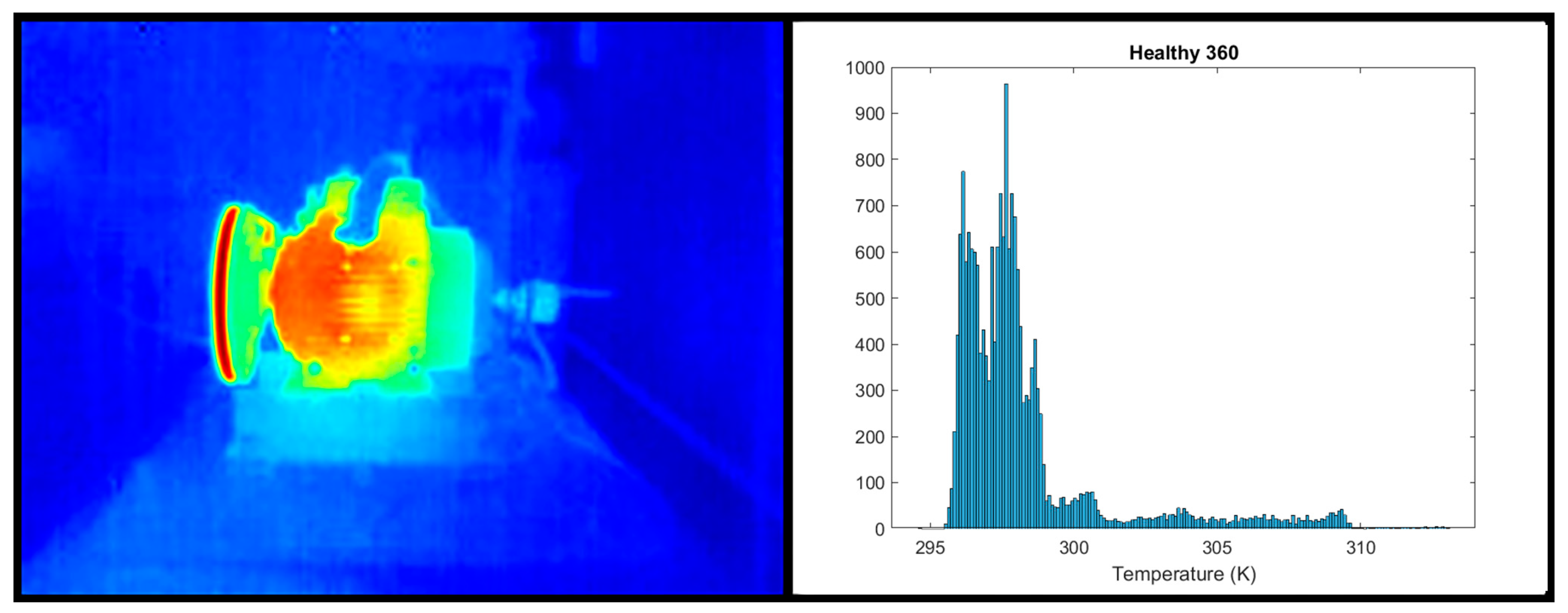

2.2. Thermographic Image Processing

2.3. Statistical Features

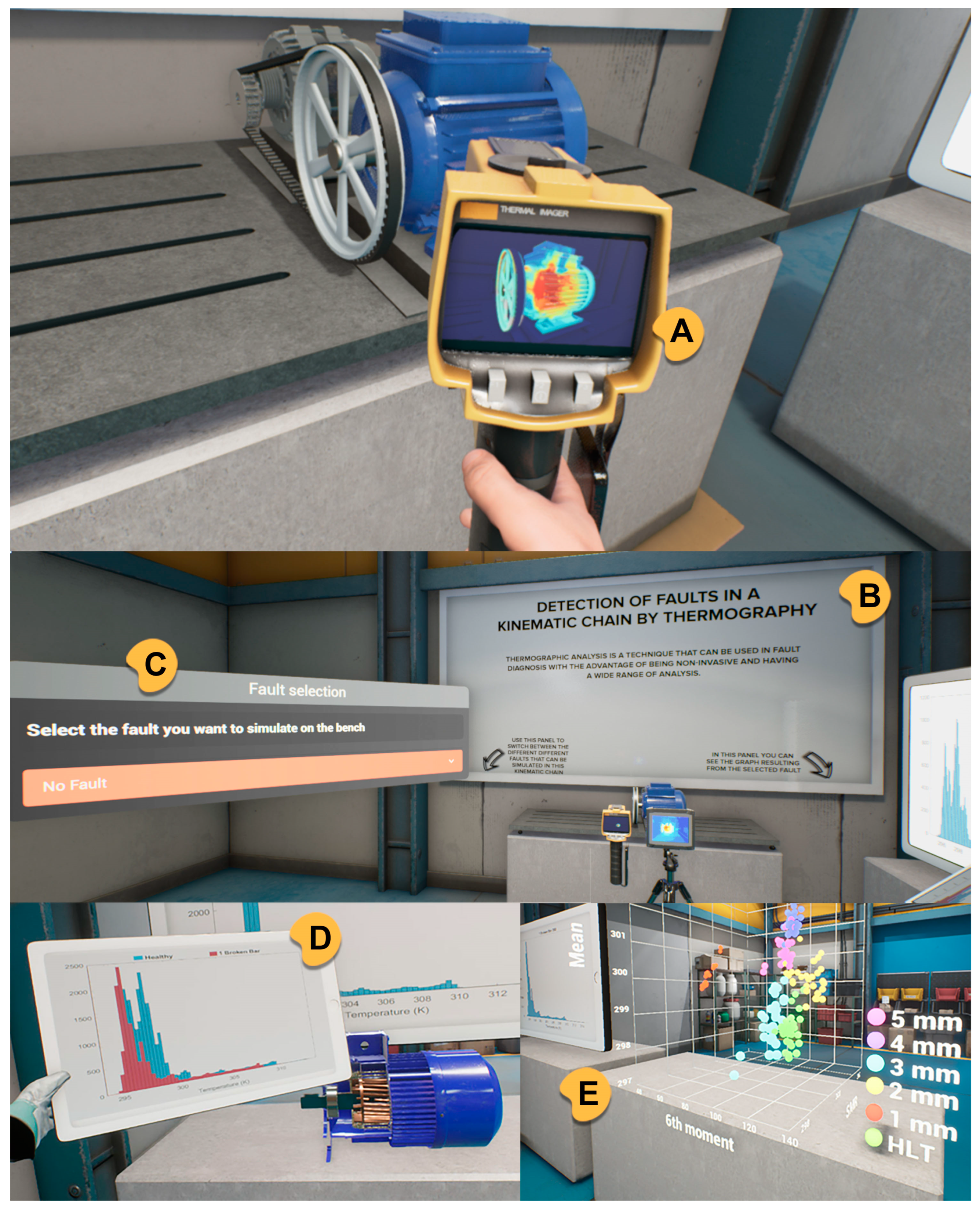

2.4. Virtual Reality

3. Materials and Methods

3.1. Acquisition and Processing of Thermal Images

3.1.1. Thermal Image Acquisition

- Three-phase induction motor, an output power of 0.74 kW (1 HP).

- Output pulley.

- Transmission belt.

- Alternator as a mechanical load.

3.1.2. Thermal Image Processing

3.2. Development of Virtual Reality Application

3.2.1. D Modeling

3.2.2. Environments and Interaction Design

4. Evaluation

5. Discussion

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Roy, S.S.; Chatterjee, S.; Roy, S.; Bamane, P.; Paramane, A.; Rao, U.M.; Tariq Nazir, M. Accurate Detection of Bearing Faults Using Difference Visibility Graph and Bi-Directional Long Short-Term Memory Network Classifier. IEEE Trans. Ind. Appl. 2022, 58, 4542–4551. [Google Scholar] [CrossRef]

- Kumar, V.; Mukherjee, S.; Verma, A.K.; Sarangi, S. An AI-Based Nonparametric Filter Approach for Gearbox Fault Diagnosis. IEEE Trans. Instrum. Meas. 2022, 71, 1–11. [Google Scholar] [CrossRef]

- Zhang, T.; Chen, J.; Li, F.; Zhang, K.; Lv, H.; He, S.; Xu, E. Intelligent Fault Diagnosis of Machines with Small & Imbalanced Data: A State-of-the-Art Review and Possible Extensions. ISA Trans. 2022, 119, 152–171. [Google Scholar] [CrossRef] [PubMed]

- Hassan, O.E.; Amer, M.; Abdelsalam, A.K.; Williams, B.W. Induction Motor Broken Rotor Bar Fault Detection Techniques Based on Fault Signature Analysis–A Review. IET Electr. Power Appl. 2018, 12, 895–907. [Google Scholar] [CrossRef]

- Zhang, X.; Long, Z.; Peng, J.; Wu, G.; Hu, H.; Lyu, M.C.; Qin, G.; Song, D. Fault Prediction for Electromechanical Equipment Based on Spatial-Temporal Graph Information. IEEE Trans. Ind. Inform. 2023, 19, 1413–1424. [Google Scholar] [CrossRef]

- Choudhary, A.; Goyal, D.; Shimi, S.L.; Akula, A. Condition Monitoring and Fault Diagnosis of Induction Motors: A Review. Arch. Comput. Methods Eng. 2019, 26, 1221–1238. [Google Scholar] [CrossRef]

- Agah, G.R.; Rahideh, A.; Khodadadzadeh, H.; Khoshnazar, S.M.; Hedayatikia, S. Broken Rotor Bar and Rotor Eccentricity Fault Detection in Induction Motors Using a Combination of Discrete Wavelet Transform and Teager-Kaiser Energy Operator. IEEE Trans. Energy Convers. 2022, 37, 2199–2206. [Google Scholar] [CrossRef]

- Alfredo Osornio-Rios, R.; Yosimar Jaen-Cuellar, A.; Ivan Alvarado-Hernandez, A.; Zamudio-Ramirez, I.; Armando Cruz-Albarran, I.; Alfonso Antonino-Daviu, J. Fault Detection and Classification in Kinematic Chains by Means of PCA Extraction-Reduction of Features from Thermographic Images. Measurement 2022, 197, 111340. [Google Scholar] [CrossRef]

- Mikropoulos, T.A.; Natsis, A. Educational Virtual Environments: A Ten-Year Review of Empirical Research (1999–2009). Comput. Educ. 2011, 56, 769–780. [Google Scholar] [CrossRef]

- Alvarado-Hernandez, A.I.; Checa, D.; Osornio-Rios, R.A.; Bustillo, A.; Antonino-Daviu, J.A. Design and Development of Virtual Reality Application Based on Infrared Thermography for the Detection of Multiple Faults in Kinematic Chains. In Proceedings of the 2022 International Conference on Electrical Machines, Valencia, Spain, 5–8 September 2022; ICEM: Valencia, Spain, 2022. [Google Scholar]

- Singh, G.; Mantri, A.; Sharma, O.; Kaur, R. Virtual Reality Learning Environment for Enhancing Electronics Engineering Laboratory Experience. Comput. Appl. Eng. Educ. 2021, 29, 229–243. [Google Scholar] [CrossRef]

- Valdez, M.T.; Ferreira, C.M.; Martins, M.J.M.; Barbosa, F.P.M. 3D Virtual Reality Experiments to Promote Electrical Engineering Education. In Proceedings of the 2015 International Conference on Information Technology Based Higher Education and Training (ITHET), Lisbon, Portugal, 11–13 June 2015; pp. 1–4. [Google Scholar]

- González Campos, J.S.; Sánchez-Navarro, J.; Arnedo-Moreno, J. An Empirical Study of the Effect That a Computer Graphics Course Has on Visual-Spatial Abilities. Int. J. Educ. Technol. High. Educ. 2019, 16, 41. [Google Scholar] [CrossRef]

- Kamińska, D.; Zwoliński, G.; Wiak, S.; Petkovska, L.; Cvetkovski, G.; Di Barba, P.; Mognaschi, M.E.; Haamer, R.E.; Anbarjafari, G. Virtual Reality-Based Training: Case Study in Mechatronics. Technol. Knowl. Learn. 2020, 26, 1043–1059. [Google Scholar] [CrossRef]

- Travassos Valdez, M.; Machado Ferreira, C.; Martins, M.J.M.; Maciel Barbosa, F.P. Virtual Labs in Electrical Engineering Education-The VEMA Environment. In Proceedings of the ITHET 2014–13th International Conference on Information Technology Based Higher Education and Training, York, UK, 11–13 September 2014. [Google Scholar]

- Vollmer, M.; Möllmann, K.P. Infrared Thermal Imaging: Fundamentals, Research and Applications; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Kaur, M.; Singh, M. Contrast Enhancement and Pseudo Coloring Techniques for Infrared Thermal Images. In Proceedings of the 2018 2nd IEEE International Conference on Power Electronics, Intelligent Control and Energy Systems, Delhi, India, 22–24 October 2018; ICPEICES: Delhi, India, 2018. [Google Scholar]

- Gonzalez, R.C.; Woods, R.E. Digital Image Processing, 4th ed.; Pearson Education: New York, NY, USA, 2018. [Google Scholar]

- Tan, L.; Jiang, J. Image Processing Basics. In Digital Signal Processing; Pearson Education: New York, NY, USA, 2019. [Google Scholar]

- Vergara, D.; Rubio, M.P.; Lorenzo, M.; Rodríguez, S. On the Importance of the Design of Virtual Reality Learning Environments. In Proceedings of the Advances in Intelligent Systems and Computing; Springer: Berlin/Heidelberg, Germany, 2020; Volume 1007. [Google Scholar]

- Vergara Rodriguez, D.; Rodriguez Martin, M.; Rubio Cavero, M.P.; Ferrer Marin, J.; Nuñez garcia, F.J.; Moralejo Cobo, L. Technical Staff Training in Ultrasonic Non-Destructive Testing Using Virtual Reality. Dyna 2018, 93, 150–154. [Google Scholar] [CrossRef] [PubMed]

- Kim, E.; Shin, G. User Discomfort While Using a Virtual Reality Headset as a Personal Viewing System for Text-Intensive Office Tasks. Ergonomics 2021, 64, 891–899. [Google Scholar] [CrossRef] [PubMed]

- Trimananda, R.; Le, H.; Cui, H.; Ho, J.T.; Shuba, A.; Markopoulou, A. OVRSEEN: Auditing Network Traffic and Privacy Policies in Oculus VR. In Proceedings of the 31st USENIX Security Symposium, Security, Boston, MA, USA, 10–12 August 2022. [Google Scholar]

- Roussos, M.; Johnson, A.; Moher, T.; Leigh, J.; Vasilakis, C.; Barnes, C. Learning and Building Together in an Immersive Virtual World. Presence: Teleoperators Virtual Environ. 1999, 8, 247–263. [Google Scholar] [CrossRef]

- Alsawaier, R.S. The Effect of Gamification on Motivation and Engagement. Int. J. Inf. Learn. Technol. 2018, 35, 56–79. [Google Scholar] [CrossRef]

- Checa, D.; Gatto, C.; Cisternino, D.; De Paolis, L.T.; Bustillo, A. A Framework for Educational and Training Immersive Virtual Reality Experiences. In Proceedings of the Augmented Reality, Virtual Reality, and Computer Graphics; De Paolis, L.T., Bourdot, P., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 220–228. [Google Scholar]

- Mayer, R. Computer Games for Learning: An Evidence-Based Approach; MIT Press: Cambridge, MA, USA, 2014; ISBN 9780262027571. [Google Scholar]

- Osti, F.; de Amicis, R.; Sanchez, C.A.; Tilt, A.B.; Prather, E.; Liverani, A. A VR Training System for Learning and Skills Development for Construction Workers. Virtual Real. 2021, 25, 523–538. [Google Scholar] [CrossRef]

- Miguel-Alonso, I.; Checa, D.; Guillen-Sanz, H.; Bustillo, A. Evaluation of the Novelty Effect in Immersive Virtual Reality Learning Experiences. Virtual Real. 2024, 28, 27. [Google Scholar] [CrossRef]

- Lee, I.J. Applying Virtual Reality for Learning Woodworking in the Vocational Training of Batch Wood Furniture Production. Interact. Learn. Environ. 2023, 31, 1448–1466. [Google Scholar] [CrossRef]

| FLIR LEPTON 3.5 | FLIR E5-XT | FLUKE PTi120 | |

|---|---|---|---|

| Resolution (px.) | 160 × 120 | 160 × 120 | 120 × 90 |

| Temp. range | −10 °C a 400 °C | −20 °C a 400 °C | −20 °C a 400 °C |

| Sampling frequency | 9 Hz | 9 Hz | 9 Hz |

| Dimensions | 11.8 × 12.7 × 7.2 mm | 244 × 95 × 140 mm | 89 × 127 × 25 mm |

| Price (USD) | 164 | 1629 | 1075 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alvarado-Hernandez, A.I.; Checa, D.; Osornio-Rios, R.A.; Bustillo, A.; Antonino Daviu, J.A. A Virtual Reality Environment Based on Infrared Thermography for the Detection of Multiple Faults in Kinematic Chains. Electronics 2024, 13, 2447. https://doi.org/10.3390/electronics13132447

Alvarado-Hernandez AI, Checa D, Osornio-Rios RA, Bustillo A, Antonino Daviu JA. A Virtual Reality Environment Based on Infrared Thermography for the Detection of Multiple Faults in Kinematic Chains. Electronics. 2024; 13(13):2447. https://doi.org/10.3390/electronics13132447

Chicago/Turabian StyleAlvarado-Hernandez, Alvaro Ivan, David Checa, Roque A. Osornio-Rios, Andres Bustillo, and Jose A. Antonino Daviu. 2024. "A Virtual Reality Environment Based on Infrared Thermography for the Detection of Multiple Faults in Kinematic Chains" Electronics 13, no. 13: 2447. https://doi.org/10.3390/electronics13132447

APA StyleAlvarado-Hernandez, A. I., Checa, D., Osornio-Rios, R. A., Bustillo, A., & Antonino Daviu, J. A. (2024). A Virtual Reality Environment Based on Infrared Thermography for the Detection of Multiple Faults in Kinematic Chains. Electronics, 13(13), 2447. https://doi.org/10.3390/electronics13132447