Abstract

Under the auspice of further developing 5G mobile communication technology and integrating it with the latest advancements in the field of Industrial Internet-of-Things, this study conducts in-depth research and detailed analysis on the combination of 5G with industrial systems based on composite structures, communication network architectures, wireless application scenarios, and communication protocols. The status quo, development trend, and necessity of 5G mobile communication technology are explored and its potential in industrial applications is analyzed. Based on the current practical development level of 5G technology, by considering different requirements for bandwidth, real-time performance, and reliability in communication networks of industrial systems, this study proposes three feasible paths for the integration between 5G and industrial systems, including the method to use 5G in place of field buses. Finally, by introducing real-world cases, this study has successfully demonstrated the integration of 5G and industrial systems by extending 5G terminals as field bus gateways. This study provides valuable references for research and practice in related fields.

1. Introduction

1.1. Current Situation and Development Trend of 5G and Industrial IoT

Industrial manufacturing is regarded as one of the primary areas for future competition among countries. Intelligent manufacturing is the vision and major driver for changes in industrial manufacturing. As early as 2011, Industry 4.0 (henceforth I4.0) first appeared at HANNOVER MESSE in Germany. I4.0 is not only the fourth generation of industry technology but also highlights that the development model and the competition mode between industrial enterprises that need to be modified. I4.0 is necessary to reduce the work intensity of the factory workers and realize production intelligence while ensuring production speed and efficiency. In the context of I4.0, domestic and foreign governments have successively issued white papers on the guidance of I4.0. Germany officially proposed the Reference Architecture Model of Industry 4.0 (RAMI4.0) in March 2015. The United States launched Industrial Internet Reference Architecture (IIRA) in June 2015. Japan launched the Industrial Value Chain Reference Architecture (IVRA) in December 2016. China launched the Industrial Internet Architecture in 2017. Nowadays, such topics have already become the hottest in the fields of industry and information globally. The idea of I4.0 has taken root in various intelligent manufacturing enterprises [1,2,3,4].

The applications of 5G networks have shown a diversified trend, especially in the field of I4.0, where their role is increasingly prominent. Notably, 5G is one of the key driving forces for promoting industrial intelligence transformation. As a representative of the new generation of the industrial revolution, I4.0 integrates various cutting-edge technologies such as the Internet of Things, big data, cloud computing, next-generation communication technology, advanced robotics technology, and artificial intelligence to provide enterprises with more flexible, cheaper, environmentally friendly, and sustainable intelligent production methods, promoting the transformation of manufacturing towards intelligence. In the field of communication, compared with other technologies, 5G has KPIs such as ultra-high bandwidth (theoretical peak speed can reach 20G bps), lower latency (in milliseconds), massive connections, and higher reliability. These characteristics enable 5G to play a crucial role in the intelligent transformation of industrial systems, providing stable and efficient network support for applications such as the Internet of Things (henceforth IoT), machine learning, and artificial intelligence [5,6,7,8,9,10,11]. The difference between industrial IoT (henceforth IIoT) and non-industrial IoT mainly lies in bandwidth, latency, and reliability. Industrial IoT typically requires higher bandwidth, lower latency, and higher reliability to meet real-time, stability, and security requirements, whereas non-industrial IoT is relatively more flexible and relaxed. In summary, industrial IoT emphasizes real-time, stability, and security, rather than being more flexible and relaxed.

With the deepening of I4.0 and the rapid development of 5G technology, some research has been made to deeply integrate it with industrial systems, in order to achieve low latency and high reliability. Ref. [12] proposes a conversion scheme for the protocol adaptation between Modbus RTU/Modbus TCP and 5G, while developing a wireless Programmable Logic Controller (PLC) prototype system based on 5G. Reference [13] proposes a solution for low-latency transmission and resource management based on configured grant scheduling, so as to provide Time-Sensitive Network (TSN) services for a 5G IIoT prototype system. Ref. [14] designs a technique to translate the traffic in TSN and 5G communications and tested it in a simulated factory environment. Ref. [15] puts forward a similar technique, which it evaluated in an automotive industrial use case. References [12,13,14,15] combine 5G and industrial systems to meet more accurate time and data transmission requirements in industrial automation environments. However, the practical application of 5G has only just begun and there is still a long way to go before 5G is widely deployed in real-world factories.

With the development of 5G technology, during the last few years, many authors started exploring the application of 5G and above networks in Industrial Systems. Ref. [2] paper first analyzes the development status of smart factories and understands that there are problems, such as slow communication speed of equipment, insufficient level of production information acquisition, and inability to guarantee equipment information security, and gives the application Strategy of IoT in the Smart Factory under the Background of Industry 4.0 and 5G Communication Technology. There is no mention of the paths for the integration between 5G and industrial systems in this paper. Mahmood et al. [16] present the state-of-the-art 5G architecture, transformative technologies, and recent design trends. They also identify several research challenges in these promising design trends that beyond-5G systems must overcome to support the rapidly unfolding transition in creating value-centric industrial wireless networks. On a more advanced level, Meira et al. [11] present a practical implementation of IIoT over 5G composed of different infrastructure and application components. From the infrastructure perspective, the implementation includes a 5G Internet of Things (IoT) end device that collects sensing data from shop floor assets and the surrounding environment and makes these data available over an industrial 5G Network. Application-wise, the implementation includes an intelligent assistant that consumes such data to generate valuable insights that allow for the sustainable operation of assets. Despite these efforts, most solutions mentioned above are replacing enterprise communication networks and control networks with 5G. The focus of this article is to study the 5G replacing control-layer communication network, which requires low latency and high reliability in real-time networks.

To summarize, the little existing literature has systematically explored the integration schemes, key technologies, and feasibility assessments of 5G with industrial systems. This study is dedicated to closing this gap by proposing certain paths and key technologies for the integration between 5G and industrial systems. Consequently, the outcomes garnered from this research will significantly drive the implementation of 5G technology across vertical industries.

1.2. The Necessity of 5G Integration with Industry

In industry, most executives and experts believe that 5G networks can provide solutions to industrial applications in terms of Ultra-Reliable Low Latency Communication (URLLC) and massive Machine Type Connection (mMTC) [17,18]. The advancement of the 5G standard, particularly 3GPP Release 18, has significantly contributed to the enhancement of cross-sector applications [19]. Indeed, 5G networks can provide more comprehensive bandwidth connectivity for I4.0 environments, which entail extremely fast and tremendous data transmission [20].

In the feature, 5G can meet the requirements of the industrial Internet in terms of connectivity diversity, performance differentiation, communication diversity, high-speed data acquisition, remote control, stable and reliable data transmission, business continuity, and other conditions in industrial scenarios, thus helping deliver digitalized, networked, and intelligent industrial Internet. In a word, the profound combination of 5G mobile communication technology and industrial Internet can promote the rapid development of the latter.

Despite its broad application prospects in industries, 5G still faces numerous challenges in its industrial application. Technically, 5G has not yet fully met the stringent requirements of industrial field communication; in terms of cost, there is still a significant gap to traditional industrial communication methods and in terms of system integration, the introduction of 5G imposes new requirements and challenges for the existing stable industrial models [21,22,23]. By exploring key technologies for the integration between 5G and industrial systems, this study aims to solve the current problems and promote further application of 5G in the industrial field.

This paper is organized as follows: Section 2 analyzes industrial system communication networks; Section 3 discusses the industrial applications that require wired or wireless communication; Section 4 uses a typical field bus communication protocol, i.e., Modbus, to illustrate how 5G could match the real-time support by field buses; Section 5 details the key findings of this study with regard to how 5G would be applied in industrial settings; and finally, Section 6 concludes this study.

2. Composition and Communication Networks of Industrial Systems

2.1. System Structure and Main Equipment

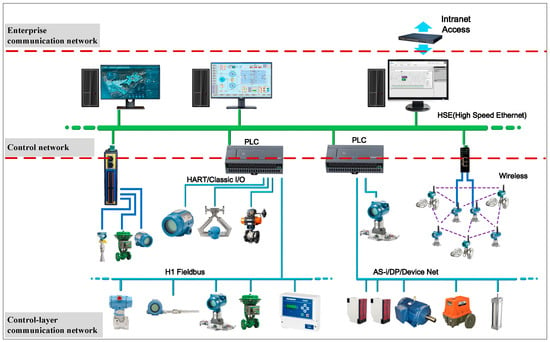

There are two categories of industrial system architectures: process-oriented and discrete-oriented. Process-oriented industrial systems mainly rely on the DCS (Distributed Control System) to achieve precise control, while discrete-oriented industrial systems mainly rely on a PLC (Programmable Logic Controller) to complete control tasks. DCS is typically employed in large-scale continuous process control, offering greater flexibility and programmability to support complex control strategies and algorithms, as well as handling intricate control logic and vast amounts of real-time data. Conversely, PLC is geared towards discrete event and sequence control, featuring lower costs and better suitability for medium- to small-scale control tasks. There is not much difference in automation control between the discrete industry and the process industry. But the production processes are more dispersed and the production equipment is more diverse in the latter than in the former. Here, we choose the DCS system as a representative for in-depth analysis and its structure is shown in Figure 1 [24]. The DCS system is based on computer control, display, and communication technology to achieve decentralized control of on-site processes. It adopts a multi-layer hierarchical and cooperative autonomous structural form, thereby achieving centralized management, control, and operation of the production process.

Figure 1.

A production case in the process-oriented industry.

2.2. Hierarchy and Characteristics of Communication Networks

According to the business and communication requirements supported, communication networks in industrial systems can be divided into four network levels (from top to bottom) [25,26,27].

- Outside-enterprise communication network: When connected to the Internet, the communication network outside enterprises’ industrial firewalls would act as a bridge between the public Internet and the communication network inside enterprises. It can easily and efficiently realize business applications, e.g., to provide services for customers and enterprise cooperation through the Web. The amount of data transmitted at this level is not limited, so a large bandwidth for communication is required, but with no real-time requirements. As a result, consumer communication technologies, such as Ethernet and Internet, can be adopted. Application of wireless technologies (including 5G) at this level is natural, so this study would not focus on this level;

- Enterprise communication network: All communication networks within enterprise industrial firewalls, except the control network and control-layer communication network. Internal communication networks within enterprises are office networks used by enterprises for efficient information resource sharing, communication, and management, generally adopting the client/server structure. Enterprise communication networks require large bandwidth and basically have no control and real-time requirements, so they also use consumer-level communication technologies, such as Ethernet and general-purpose computers. The application of wireless technologies, such as 5G, at this level is also natural so it is not the focus of this study;

- Control network: The control network is used for automated control management and users can interact with controllers used for field control through control networks on computers. The interaction is mainly for field data, device status information, and user control information. The bandwidth requirement of control networks’ data transmission is relatively low but with certain real-time requirements. Ethernet can be used as their communication protocol but needs to be improved to enhance security by such methods as using switches instead of hubs, limiting communication network usage, etc. This study will discuss how to apply 5G successfully at this level;

- Control-layer communication network: The control-layer communication network connects industrial control system equipment for controlling automated field production. It shall obtain the real-time device working status information, support network status monitoring, and facilitate analysis and statistics by network management personnel or intelligent network management software. It can also manage device configuration through wired network interfaces for functions such as basic device information management, diagnosing scope and alarm threshold management, device firmware upgrades, etc. The control-layer communication network transmits the least amount of data but requires low latency and high reliability, so industrial-grade field buses are often used, such as the foundation field bus, Profibus, Modbus, industrial Ethernet, etc. Applying 5G at this level shall be the focus of this study.

3. Typical Applications in Industrial Systems

Industrial applications can be divided into three categories: enterprise level, shop level, and field level. This classification corresponds to the hierarchy of industrial system communication networks: enterprise-level scenarios use intra-enterprise communication networks; shop-level ones use control networks; and field-level ones use control-layer communication networks. The existing 5G technology can replace the Ethernet communication protocol used in enterprise communication networks and control networks but cannot replace the field bus used in control-layer communication networks. Therefore, 5G can support industrial applications at the enterprise and shop levels but not at the field level. In order to promote better integration of 5G with industry, it is necessary to solve the problems and gaps with the application of 5G in field scenarios [28,29,30,31]. Some examples of field-level PLC and shop-level Autonomous Guided Vehicles (AGV) applications are described below.

3.1. PLC Automated Production

With the transition of industrial manufacturing to I4.0, automated production has become an inevitable trend and an important component of industrial manufacturing. As the most widely used and important control equipment in the field of automation [32], PLC can be used for many applications, whether they are simple or complicated control systems [33]. Given the importance and typicality of PLC, PLC is chosen to analyze the application of 5G in field-level scenarios.

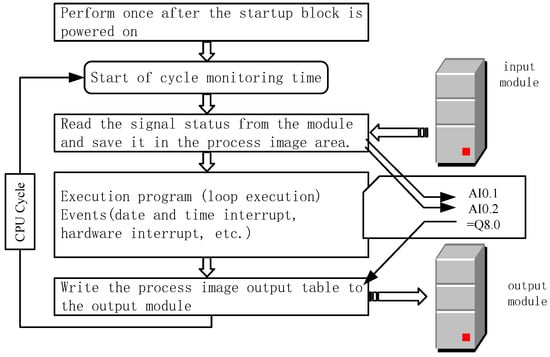

3.1.1. PLC’s Working Principle

PLC refers to a microcomputer system specifically used for industrial control, so its working principle is nowadays basically the same as computer systems. The CPU of PLC adopts the principle of time-sharing operation—executing one operation at a time and executing operations in chronological order. Programs in PLC are divided into two types: operating system programs and user programs. The CPU in PLC executes user programs and performs control functions in a cyclic scanning manner. Figure 2 shows the flowchart of the cyclic scanning working mode of PLC [34,35].

Figure 2.

The cyclic scanning working mode of PLC.

3.1.2. PLC’s Communication Protocols

PLC is crucial for industrial automation and its communication mechanism is the key to achieving its control functions. At present, the mainstream PLC equipment generally adopts Modbus and Profibus protocols, both of which have advantages in terms of market shares, technical characteristics, and application scenarios. Used for unit-level and field-level SIMITAC networks, Profibus is suitable for medium- and small-scale data transmission. Modbus is the world’s first truly industrial field bus protocol and it is also a universal language of electronic controllers. Aimed at the application of PLC, Modbus is the most commonly used protocol in PLC control systems [36]. Through this protocol, controllers can communicate with each other, as well as with other devices via a network (such as Ethernet). Therefore, Modbus has become a universal industrial standard to connect the control equipment produced by different manufacturers to an industrial network for centralized monitoring. Given the important position of Modbus protocol in PLC control, it is regarded as the typical model in the future.

3.2. AGV for Automatic Loading

With ongoing changes in manufacturing and, in particular, the growing importance of internal logistics based on AGV, the use of wireless communication across industries is no longer an option but a necessity [37]. The entire workflow of the AGV system hardly requires manual intervention, so AGV has the characteristics of high automation, good flexibility, no noise, and no pollution. Therefore, AGV has a wide range of implementations in many industries. Generally, AGV consists of the following elements: a vehicle body, driving and steering components, guidance devices, load transfer devices, safety devices, power supply devices, onboard control systems, and communication devices. AGV mainly communicates with its upper control system during its operation and the communication content between them mainly includes task commands, vehicle status information, operation instructions, traffic management information, and information for interaction with peripheral devices.

Compared to wired networks, wireless communication has the following advantages: low installation costs, little mechanical wear and tear, and the ability to provide crucial information even with moving AGVs. At present, most AGV scenarios adopt Wi-Fi technology to deliver communications between AGV cars and their upper control systems. However, due to the use of unauthorized frequency bands in Wi-Fi, it is very susceptible to interference, especially when there are a large number of metal shelves in factories, which can cause serious attenuation of Wi-Fi signals, resulting in on-site wireless networks’ poor reliability, long latency, and high packet loss rate, or even AGV’s disconnection [38,39]. Similarly, due to excessive transmission delay, 4G is difficult to support real-time transmission of AGV data. Compared to Wi-Fi and 4G, the technology of 5G has such performance advantages as large bandwidth, high reliability, and low latency, which can better support AGV scenarios and promote their large-scale applications.

However, as a wireless communication technology not designed for industrial settings, 5G still faces certain problems when applied in AGV systems. Firstly, the transmission power of 5G base stations is limited and the star-shaped topology can generate 5G communication blind spots that make it difficult to cover the edge areas or lead to communication barriers with base stations, resulting in poor signal quality for AGV vehicles that are far away from base stations [40,41]. Meanwhile, as a wireless communication method, 5G is inevitably affected by interferences from its surrounding environments, which may lead to the loss of individual data packets and incomplete status information uploading by AGV vehicles, thereby endangering the generation of control instructions by the upper control system for the next steps. Similarly, partial control instructions may be received by AGV, thereby affecting its normal operation. Secondly, 5G is a consumer-level communication technology, which is not as dedicated to ensuring communication certainty as industrial-level communication protocols. It competes with base stations and can cause certain losses in system efficiency. The best-effort communication protocol is currently a hindrance to 5G. These problems may be solved in the future by improving the performance specifications of 5G [42]. Therefore, the problems that exist in the application of AGV are also a focus of this study.

4. Modbus Protocol

As discussed above, it can be concluded that the common deployment pattern in the field of industrial control is PLC plus Modbus. This pattern has great research significance for the widespread application of 5G in industry. How to implement the Modbus protocol in PLC will be deeply discussed below.

4.1. Introduction to Modbus

4.1.1. Modbus Communication Method

Modbus defines the application-layer message transmission protocol on the seventh layer of the OSI model. Other OSI layers are different based on different communication media but the message format is the same at the application layer. It provides client/server communication between devices connected to different types of buses or networks. Modbus defines three different communication media:

- Ethernet: The corresponding communication mode is Modbus TCP/IP, applied to Ethernet links. Modbus/TCP is widely used in industrial automation and control systems because of its ease of implementation and its open and license-free features. Modbus/TCP clients, such as SCADAs, PLCs, and human–machine interfaces (HMIs), initiate communication with PLCs (Modbus/TCP servers), which then respond to an appropriate request (e.g., read or write process data) based on the function code value [43];

- Asynchronous serial transmission: The corresponding communication mode is Modbus RTU or Modbus ASCII, applied to serial port links, such as RS232, RS485, RS422, etc. It is especially suitable for short-distance communication between field devices [44];

- High-speed token passing network: The corresponding communication mode is Modbus PLUS, which is suitable for scenarios that require high-speed and reliable communication. Especially, in large-scale industrial automation systems with a large number of devices, the stability and real-time performance of communication can be guaranteed [45].

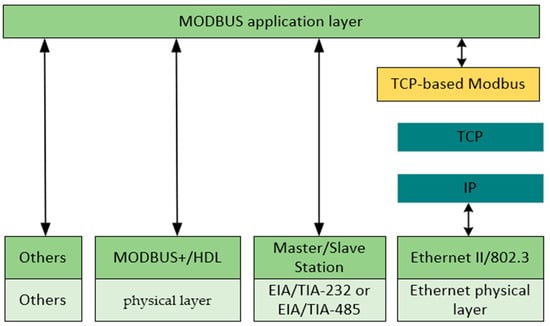

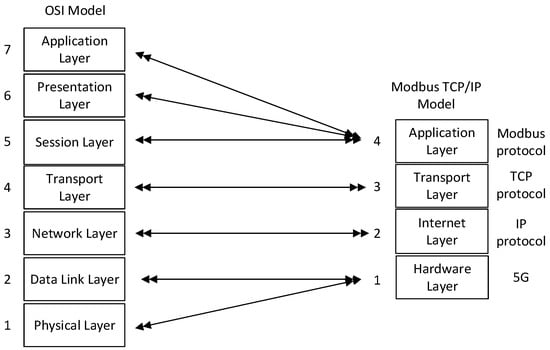

4.1.2. Modbus Communication Stack

The Modbus communication stack is shown in Figure 3 [46], where the bottom two layers are physical layers, the hardware of which is specified by IEEE. The first column on the right side defines the protocol on the Modbus Ethernet link, where IP belongs to the network layer and TCP corresponds to the transport layer. TCP-based Modbus is mainly used to process information from Modbus TCP/IP packet headers and then transmit it upwards to the Modbus application layer [47]. The second column from the right side of the figure defines the protocol on the Modbus serial link. The physical layer of serial transmission is RS-485 or RS-232, which defines the specifications of signal transmission. The Modbus serial link protocol directly defines different packet types and standards on RS-485 or RS-232 for communication on the serial link. Modbus+/HDL and others represent Modbus protocols on different physical layers. The Modbus protocol only specifies the format of data packets, so there is no restriction on what must be carried on RS485 or Ethernet. Any device that can communicate can be used to apply the Modbus protocol.

Figure 3.

Modbus communication stack.

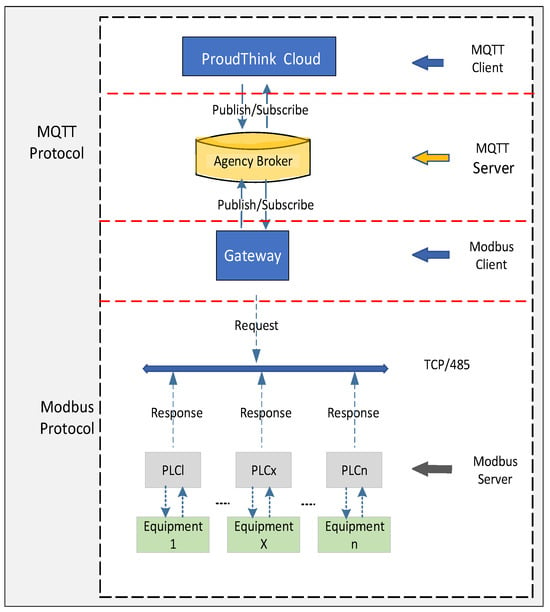

4.2. Modbus Application Case

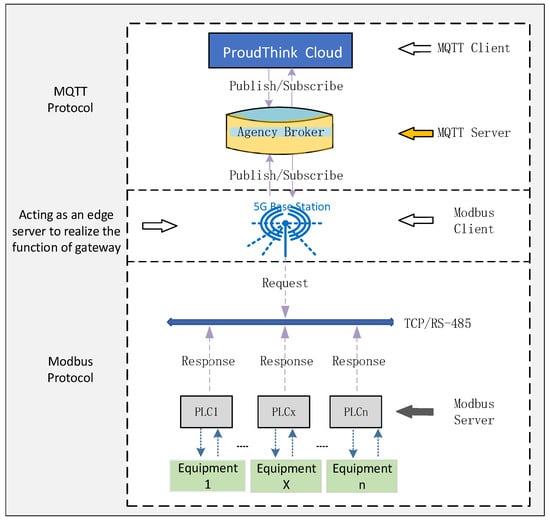

Figure 4 illustrates a typical application case of Modbus in factory management optimizations. The case system consists of four parts, namely the self-developed ProudThink cloud platform, the communication gateway, PLC, and the field equipment. The cloud collects the required data from devices through PLC and communicates with the gateway in the TCP or RS-485 protocol. The gateway is mainly used to parse and encapsulate the data collected by PLC and then upload the encapsulated data to a cloud platform. Finally, the cloud platform conducts statistical analysis on these data and presents the results in an interface format, so as to facilitate customer companies to monitor and manage production-line equipment. This case system can monitor equipment status in real time, adjust production plans dynamically, identify downtime reasons, and establish a rapid response mechanism. Thus, it can significantly improve the production efficiency and capacity of factories, effectively reduce unnecessary downtime and production costs, and help achieve efficient and refined management.

Figure 4.

Case architecture diagram.

5. Integration of 5G with Industrial Systems

5.1. Three Integration Paths

5.1.1. End-to-End 5G Solution

Very low latency and high reliability are two of the main requirements of new applications exploiting 5G networks. In order to replace field buses with 5G, relevant technologies must be implemented, mainly including real-time IoT and 5G-related technologies. Some other 5G-based wireless real-time communication protocols shall also be defined, such as the 5G Real-Time protocol. Sensors and actuators need to directly support such protocols, so as to achieve seamless 5G integration in industrial scenarios. Therefore, significant improvements to 5G technology need to be made to meet the following three core conditions [48,49,50,51]:

- (1)

- Given that a field bus is an industrial-grade real-time communication protocol, if 5G is to replace a field bus, 5G must be upgraded to a real-time protocol to ensure real-time and reliable data transmission;

- (2)

- It is necessary to enhance the functionality of 5G base stations so that they can play the role of servers, similar to the master in field bus in a LAN composed of base stations and their connected multiple terminals, in order to deliver real-time communication within the LAN;

- (3)

- The topology of 5G networks can implement a new architecture of “terminal extension as gateway”, in which the real-time data forwarding needs to be made between the network within a base station and the network within a gateway.

The ongoing work in 5G Real-time Media Transport Protocol Configurations (3GPp TS 26.522 version 18.0.0 Release 18) is the latest such effort. It deals with immersive media such as online concerts. It would be a good fit to include it in the support for industrial control communication.

5.1.2. The 5G Adapter Module

An adapter module shall be designed to support both 5G and traditional field bus protocols. By connecting field bus devices through physical means, this module is responsible for converting the physical signals of devices into 5G signals and sending them to base stations. In addition, it can convert the 5G signals received from base stations back to physical signals for the devices.

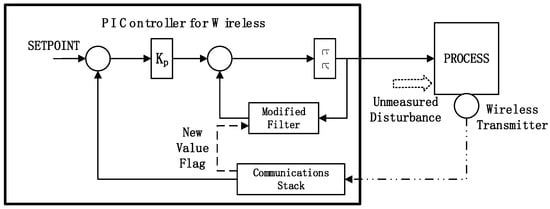

5.1.3. Modification to the 5G Protocol

For optimizing the 5G protocol to achieve compatibility with field bus protocols, inspiration can be drawn from the design concept of the WirelessHART protocol. Considering that the 5G protocol emphasizes the physical layer and data link layer in the wireless network architecture, necessary adjustments need to be made to achieve integration with the field bus protocol, so as to ensure the implementation of the required functions. Taking Modbus TCP/IP protocol as an example, the core components of the TCP/IP protocol are its network layer and transport layer. In the TCP/IP model, the network interface layer (corresponding to the physical layer and data link layer in the OSI model) is usually considered to be a black box. Most protocols at the network interface layer are not mandatory in the TCP/IP protocol group; therefore, these protocols are replaceable. For example, the wired communication protocols and devices (such as fiber optic, copper, Ethernet, High-level Data Link Control, Frame Relay, etc.) at the network interface layer can be replaced with wireless protocols (such as 4G, 5G, WiFi, etc.). Thus, theoretically, 5G technology can be used to replace the Hardware Layer in the Modbus TCP/IP protocol. Based on this idea, the upper layer protocol of the Modbus TCP/IP protocol can be implemented, thus forming a new communication protocol with real-time support. The modified model is shown in Figure 5.

Figure 5.

Comparison and correlation between the OSI protocol and TCP/IP protocol.

5.2. Practical Cases

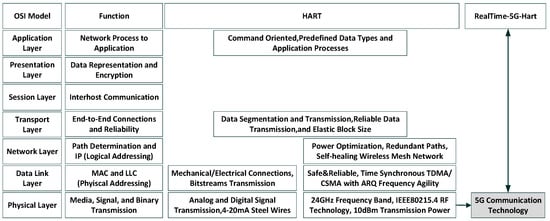

5.2.1. The 5G-RealTime-HART Module

Figure 6 shows the process of building a 5G-RealTime-HART module based on the HART network. In the implementation principle of the HART protocol, the wireless part will be replaced with a 5G module and necessary adjustments to the 5G communication protocol shall be made according to the actual needs. This means that the application layer of HART remains unchanged, while the underlying layer will be adjusted accordingly. By introducing a 5G HART module, effective integration between 5G and HART can be achieved.

Figure 6.

The RealTime-5G-HART structure.

The HART standard [52] has been in existence since the late 80’s. In its initial release, the HART Field Communications Protocol was superimposed on a 4–20 mA signal providing two-way communications with smart field instruments without compromising the integrity of the measured data. During its years of existence, the HART protocol has evolved from a simple 4–20 mA-based protocol to the current wired and wireless-based technology with extensive features supporting security, unsolicited data transfers, event notifications, block mode transfers, and advanced diagnostics. The complete HART network layers are shown in Figure 6.

5.2.2. Extension of the 5G Terminal as a Gateway

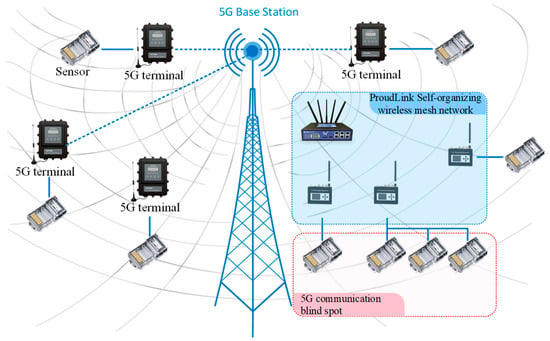

By adopting a star-topology structure, a 5G network allows 5G base stations to communicate directly with terminals. However, when the communication path between a base station and a terminal is blocked by obstacles, blind spots in 5G communication will be generated, causing failed communication between the two. To address this problem, the concept of 5G terminals can be evolved from a “point” to an “area”. Specifically, the original 5G terminal can be expanded into a wireless communication LAN of field bus quality, known as the ProudLink self-organizing wireless mesh network, as shown in Figure 7. In this network, link communication nodes are directly wired to sensors, field devices, and PLC systems, thereby achieving smooth data conversion between the wireless LAN and the field. In addition, 5G gateways, as a special type of 5G terminal equipment, are used to play the data communication functions between the LAN and 5G base stations. We have demonstrated this approach in a real-world case. The OpenRAN split architecture can be considered with a front-haul connected to radio units, a mid-haul connected to a 5G gateway, and a backhaul to a 5G base station.

Figure 7.

The topology for the terminal extension to the gateway.

5.2.3. Cloud Platform Solution

The architecture of this platform is shown in Figure 8. As seen, the 5G base station is used as an edge server. In particular, small 5G base stations deployed in factories are integrated with servers that provide edge computing capabilities. The functions of the website can be deployed in the edge server. Specifically, the edge server reads data points from the PLC through the Modbus protocol; and then, these data are packaged and transmitted to the Internet and finally to the cloud platform. In this case, although the gateway is located inside the edge server, it is actually a fully functional gateway. This means that it supports communication protocols for both uplink and downlink. The downlink communication uses the standard Modbus protocol to connect with the PLC, while the uplink communication uses the Ethernet TCP/IP protocol on the Internet to connect with the cloud platform. In this architecture, the design of the cloud platform remains consistent with the previous architecture and the way it interfaces with the PLC remains unchanged. This architecture also retains gateway components, with the only difference being that the functionality of the gateway is now implemented in edge servers located next to 5G base stations.

Figure 8.

The Architecture of Puao ProudThink cloud platform.

As shown in Figure 9, functions such as equipment management, production management, efficiency management, and downtime management can be achieved on the ProudThink cloud platform. By displaying the equipment status indicators, production line diagrams, virtual screens in factories, real-time status, efficiency, alarms, and other key business data items of the equipment, the statuses can be monitored. By utilizing the traffic management function, real-time production statistics can be performed to generate historical production reports, further facilitating in-depth analysis of production. The efficiency management function can clearly showcase the efficiency status of equipment. During the shutdown management process, PLC can collect three data items, namely “automatic mode”, “equipment failure”, and “equipment warning”, so as to calculate and obtain their corresponding values and then carry out corresponding alarm management.

Figure 9.

The case of the ProudThink cloud platform.

5.3. Key Technologies for Replacing Field Buses with 5G

At present, diverse communication protocols are adopted at various layers of real-time IoT networks in the field of intelligent manufacturing, undoubtedly increasing the complexity of maintenance and operation. To achieve a “one network to the bottom” communication architecture, 5G end-to-end solutions are used, where all the four layers’ network protocols are replaced with 5G technology. To replace the field bus with 5G, it is necessary to implement relevant technologies, including real-time IoT technology as well as technologies closely related to 5G.

5.3.1. Slicing Techniques

For different real-time requirements of different hierarchical networks, 5G slicing technology can be used to adapt to diverse and complex application scenarios. Network slicing technology divides physical networks into multiple different types of virtual networks according to different levels of service requirements (in terms of latency, bandwidth, reliability, etc.), so as to cope with complex and ever-changing application scenarios. For example, real-time 5G slicing can be used at the field bus layer to meet real-time requirements and the remaining 5G bandwidth and resources can be placed at other levels [53].

Ensuring collaborative work between different shard networks is one of the core challenges in implementing the “one network to the bottom” architecture in 5G. A good slicing scheme can make each shard act like an independent network, and their collaboration is similar to that of any independent network. If dynamic sharing technology is adopted, network resources can be borrowed between different shards, thus creating a different pattern from the situation of independent networks. In addition, as network slicing shares physical resources, it is also necessary to consider the negative impact on each other [54].

5.3.2. Control in the Field

In industrial systems, control modules (i.e., functional blocks) can run on field devices, so the calculations of control algorithms (including sensing, control, output, and execution steps) are also executed in the field. Similarly, if a 5G base station is designed as an edge server, it also needs to be able to run control modules. At this point, the local network composed of a 5G base station server and its connected terminals can be regarded as a wireless field bus network, where both the 5G base station server and the 5G terminals are important components of the entire network. Specifically, the 5G base station server plays the role of the master in the field bus system, while the 5G terminals are equivalent to other field devices. Given that the control modules can run on both the base station server and terminals, all control algorithms and communications can be implemented at the 5G base station and below, without the need for access to 5G backbone networks. In addition, communications between the base station and the outside world can be regarded as occurring at another layer of the network, so the base station server also needs to integrate gateway functions, so as to support the ability of 5G terminals to communicate with the outside.

5.3.3. Improvement in Control Algorithms

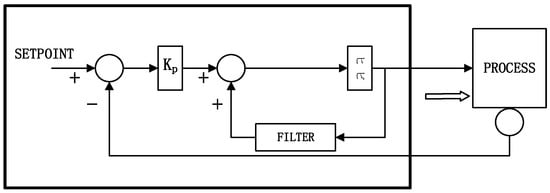

In traditional automatic control processes, control algorithms usually need to be executed in a strict periodical manner. When the execution time deviates from the preset cycle, it will inevitably affect the control quality. This situation is called “jitter”. In the process of industrial automation, PID, as a classic control algorithm, is designed based on the strict periodicity of field bus communication, assuming zero jitters. The schematic diagram of the PID algorithm is shown in Figure 10.

Figure 10.

PID control algorithm.

However, in wireless communication environments, jitters are inevitable due to various factors. Therefore, the application effect of the PID algorithm is no longer ideal, so corresponding adjustments and improvements need to be made to the PID algorithm according to the characteristics of wireless communication environments. Born in this context when formulating the WirelessHART standard, the PID+ algorithm is an improved version of the PID algorithm, designed to address the jitter issues. This algorithm is described in detail in a US patent titled “Non periodic control communications in wireless and other process control systems” (Blevins T L, D Chen, and Nixon M J et al.) [55]. It has been shown that the control effect of the PID+ algorithm is not inferior to PID control based on traditional wired field bus. The schematic diagram of PID+ algorithm is shown in Figure 11. In summary, when considering using 5G technology to replace field bus, it is also necessary to address jitter-related issues, so as to ensure the stability and effectiveness of control algorithms [56,57].

Figure 11.

“PID+” control algorithm.

As shown in Figure 11, the positive feedback network may be modified to accommodate non-periodic measurement updates. Specifically, the filter used in this network can be modified to have the following behavior:

- (1)

- Maintain the last calculated filter output until a new measurement is communicated;

- (2)

- When a new measurement is received, calculate the new filter output based on the last controller output and the elapsed time since a new measurement value was last communicated.

To account for the process response, the filter output is calculated using formula (1) whenever a new measurement is received.

where

FN = New filter output

FN–1 = Filter output last execution = Filter output after last new measurement

ON–1 = Controller output last execution

ΔT = Elapsed time since a new value was communicated

6. Conclusions

This study explores the profound significance of integrating and advancing 5G mobile communication technology within the context of the industrial Internet. With a systematic investigation into the current state and developmental trajectory of these technologies, the study provides insights into their implications. By analyzing the architecture, communication network, wireless application scenarios, and communication protocols of industrial systems, this study addresses the potential and challenges of 5G technology in industrial Internet applications. In response to the different requirements for bandwidth, real-time performance, and reliability of four-layer industrial system communication networks, this study proposes three forward paths and elaborates on the key technologies required for 5G to replace field buses, in combination with the current development status of 5G technology. By introducing real application cases, this study demonstrates the role of 5G bus adapter modules in promoting the integration between 5G and industrial systems, providing insights and guidance for future research and practice in related fields. The research results of this study are poised not only to advance the application of 5G technology in the field of the industrial Internet but also to reveal the future development direction of wireless industrial communication technology.

Author Contributions

Data curation, J.S.; Investigation, J.S., C.L., Y.X. and W.Z.; Methodology, D.C.; Resources, J.S., D.C., Q.W., Z.L., Y.X., W.Z. and J.L.; Software, C.L.; Supervision, D.C. and Q.W.; Writing—original draft, J.S. and M.W.; Writing—review and editing, J.S. and D.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Noor-A-Rahim, M.; John, J.; Firyaguna, F.; Sherazi, H.H.R.; Kushch, S.; Vijayan, A.; O’Connell, E.; Pesch, D.; O’Flynn, B.; O’Brien, W.; et al. Wireless Communications for Smart Manufacturing and Industrial IoT: Existing Technologies, 5G and Beyond. Sensors 2023, 23, 73. [Google Scholar] [CrossRef] [PubMed]

- Diao, Z.; Sun, F. Application of Internet of Things in Smart Factories under the Background of Industry 4.0 and 5G Communication Technology. Math. Probl. Eng. 2022, 2022, 4417620. [Google Scholar] [CrossRef]

- Sanchez, M.; Exposito, E.; Aguilar, J. Industry 4.0: Survey from a system integration perspective. Int. J. Comput. Integr. Manuf. 2020, 33, 1017–1041. [Google Scholar] [CrossRef]

- O’Connell, E.; Moore, D.; Newe, T. Challenges Associated with Implementing 5G in Manufacturing. Telecommunications 2020, 1, 48–67. [Google Scholar] [CrossRef]

- Bildirici, M.; Kayıkçı, F.; Ersin, Ö.Ö. Industry 4.0 and Renewable Energy Production Nexus: An Empirical Investigation of G20 Countries with Panel Quantile Method. Sustainability 2023, 15, 14020. [Google Scholar] [CrossRef]

- Allnutt, C. The Ultimate Guide to Industry 4.0–Inside the Fourth Industrial Revolution. 2022. Available online: www.microsourcing.com/learn/blog/what-is-industry-4-0-the-ultimate-guide/ (accessed on 2 August 2023).

- Alcácer, V.; Cruz-Machado, V. Scanning the industry 4.0: A literature review on technologies for manufacturing systems. Eng. Sci. Technol. Int. J. 2019, 22, 899–919. [Google Scholar] [CrossRef]

- Morgan, J.; Halton, M.; Qiao, Y.; Breslin, J. Industry 4.0 smart reconfigurable manufacturing machines. J. Manuf. Syst. 2021, 59, 481–506. [Google Scholar] [CrossRef]

- McKinsey & Company. What are Industry 4.0, the Fourth Industrial Revolution, and 4IR? 17 August 2022. Available online: https://www.mckinsey.com/featured-insights/mckinsey-explainers/what-are-industry-4-0-the-fourth-industrial-revolutionand-4ir (accessed on 2 February 2023).

- Xu, L.D.; Xu, E.L.; Li, L. Industry 4.0: State of the art and future trends. Int. J. Prod. Res. 2018, 56, 2941–2962. [Google Scholar] [CrossRef]

- Meira, J.; Matos, G.; Perdigão, A.; Cação, J.; Resende, C.; Moreira, W.; Antunes, M.; Quevedo, J.; Moutinho, R.; Oliveira, J.; et al. Industrial Internet of Things over 5G: A Practical Implementation. Sensors 2023, 23, 5199. [Google Scholar] [CrossRef] [PubMed]

- Xu, C.; Du, X.; Li, X.; Tu, Y.; Li, L.; Jin, X.; Xia, C. 5G-Based Industrial Wireless Controller: Protocol Adaptation, Prototype Development, and Experimental Evaluation. Actuators 2023, 12, 49. [Google Scholar] [CrossRef]

- Yang, M.; Lim, S.; Oh, S.M.; Shin, J. An Uplink Transmission Scheme for TSN Service in 5G Industrial IoT. In Proceedings of the 2020 International Conference on Information and Communication Technology Convergence (ICTC), Jeju-do, Republic of Korea, 21–23 October 2020; pp. 902–904. [Google Scholar]

- Jiang, X.; Pang, Z.; Zhan, M.; Dzung, D.; Luvisotto, M.; Fischione, C. Packet Detection by a Single OFDM Symbol in URLLC for Critical Industrial Control: A Realistic Study. IEEE J. Sel. Areas Commun. 2019, 37, 933–946. [Google Scholar] [CrossRef]

- Satka, Z.; Pantzar, D.; Magnusson, A.; Ashjaei, M.; Fotouhi, H.; Sjödin, M.; Daneshtalab, M.; Mubeen, S. Developing a Translation Technique for Converged TSN-5G Communication. In Proceedings of the 2022 IEEE 18th International Conference on Factory Communication Systems (WFCS), Pavia, Italy, 27–29 April 2022; pp. 1–8. [Google Scholar]

- Mahmood, A.; Beltramelli, L.; Abedin, S.F.; Zeb, S.; Mowla, N.I.; Hassan, S.A.; Sisinni, E.; Gidlund, M. Industrial IoT in 5G-and-beyond networks: Vision, architecture, and design trends. IEEE Trans. Ind. Inform. 2021, 18, 4122–4137. [Google Scholar] [CrossRef]

- Ramirez, R.; Huang, C.-Y.; Liang, S.-H. 5G Digital Twin: A Study of Enabling Technologies. Appl. Sci. 2022, 12, 7794. [Google Scholar] [CrossRef]

- Krummacker, D.; Veith, B.; Fischer, C.; Schotten, H.D. Analysis of 5G Channel Access for Collaboration with TSN Concluding at a 5G Scheduling Mechanism. Network 2022, 2, 440–455. [Google Scholar] [CrossRef]

- Moldovan, C.; Ulrich, S.; Köster, V.; Tiemann, J.; Lewandowski, A. Advancing Digital Twin-Based Collision Avoidance: A Comprehensive Analysis of 5G Networks for Safety-Critical Applications in Industry 4.0. Sensors 2024, 24, 1405. [Google Scholar] [CrossRef] [PubMed]

- Rekoputra, N.M.; Tseng, C.-W.; Wang, J.-T.; Liang, S.-H.; Cheng, R.-G.; Li, Y.-F.; Yang, W.-H. Implementation and Evaluation of 5G MEC-Enabled Smart Factory. Electronics 2023, 12, 1310. [Google Scholar] [CrossRef]

- Christina, C. Lessi; Andreas Gavrielides; Vittorio Solina; Renxi Qiu; Letizia Nicoletti; Daiyou Li.5G and Beyond 5G Technologies Enabling Industry 5.0: Network Applications for Robotics. Procedia Comput. Sci. 2024, 232, 675–687. [Google Scholar]

- Mourtzis, D.; Angelopoulos, J.; Panopoulos, N. Smart Manufacturing and Tactile Internet Based on 5G in Industry 4.0: Challenges, Applications and New Trends. Electronics 2021, 10, 3175. [Google Scholar] [CrossRef]

- Mourtzis, D.; Siatras, V.; Angelopoulos, J. Real-time remote maintenance support based on Augmented Reality (AR). Appl. Sci. 2020, 105, 1855. [Google Scholar] [CrossRef]

- Sun, J.; Chen, D.; Li, R.; Xiao, Y. DEPS: A Demand-Oriented Framework for Edge Intelligent Production System. In Proceedings of the 2023 IEEE/ACIS 23rd International Conference on Computer and Information Science (ICIS), Wuxi, China, 23–25 June 2023; pp. 65–72. [Google Scholar]

- Homay, A.; Chrysoulas, C.; El Boudani, B.; de Sousa, M.; Wollschlaeger, M. A security and authentication layer for SCADA/DCS applications. Microprocess. Microsyst. 2021, 87, 103479. [Google Scholar] [CrossRef]

- Chen, B.; Wan, J.; Shu, L.; Li, P.; Mukherjee, M.; Yin, B. Smart Factory of Industry 4.0: Key Technologies, Application Case, and Challenges. IEEE Access 2018, 6, 6505–6519. [Google Scholar] [CrossRef]

- Lippi, M.; Martinelli, M.; Picone, M.; Zambonelli, F. Enabling causality learning in smart factories with hierarchical digital twins. Comput. Ind. 2023, 148, 103892. [Google Scholar] [CrossRef]

- Hosseini, S.; Abbasi, A.; Magalhaes, L.G.; Fonseca, J.C.; da Costa Nuno, M.C.; Moreira, A.H.J.; Borges, J. Immersive Interaction in Digital Factory: Metaverse in Manufacturing. Procedia Comput. Sci. 2024, 232, 2310–2320. [Google Scholar] [CrossRef]

- Bellavista, P.; Bicocchi, N.; Fogli, M.; Giannelli, C.; Mamei, M.; Picone, M. Requirements and design patterns for adaptive, autonomous, and context-aware digital twins in industry 4.0 digital factories. Comput. Ind. 2023, 149, 103918. [Google Scholar] [CrossRef]

- Culot, G.; Orzes, G.; Sartor, M.; Nassimbeni, G. The future of manufacturing: A Delphi-based scenario analysis on Industry 4.0. Technol. Forecast. Soc. Change 2020, 157, 120092. [Google Scholar] [CrossRef] [PubMed]

- Liang, W.; Zheng, M.; Zhang, J.; Shi, H.; Yu, H.; Yang, Y.; Liu, S.; Yang, W.; Zhao, X. WIA-FA and Its Applications to Digital Factory: A Wireless Network Solution for Factory Automation. Proc. IEEE 2019, 107, 1053–1073. [Google Scholar] [CrossRef]

- Vadi, S.; Bayindir, R.; Toplar, Y.; Colak, I. Induction motor control system with a Programmable Logic Controller(PLC) and Profibus communication for industrial plants—An experimental setup. ISA Trans. 2022, 122, 459–471. [Google Scholar] [CrossRef] [PubMed]

- Alphonsus, E.R.; Abdullah, M.O. A review on the applications of programmable logic controllers (PLCs). Renew. Sustain. Energy Rev. 2016, 60, 1185–1205. [Google Scholar] [CrossRef]

- Hudedmani, M.G.; Umayal, R.M.; Kabberalli, S.K.; Hittalamani, R. Programmable logic controller (PLC) in automation. Adv. J. Grad. Res. 2017, 2, 37–45. [Google Scholar] [CrossRef]

- Ahmed, C.M.; Ochoa, M.; Zhou, J.; Mathur, A. Scanning the Cycle: Timing-based Authentication on PLCs. In Proceedings of the 2021 ACM Asia Conference on Computer and Communications Security (ASIA CCS ′21). Association for Computing Machinery, New York, NY, USA, 7–11 June 2021; pp. 886–900. [Google Scholar]

- Herath, K.; Samarasinghe, H.; Priyankara, H. Development of a Data Acquisition and Monitoring System Based on MODBUS RTU Communication Protocol. Int. J. Innov. Sci. Res. Technol. 2020, 5, 432–440. [Google Scholar]

- Kampen, A.-L.; Fojcik, M.; Cupek, R.; Stoj, J. The requirements for using wireless networks with AGV communication in an industry environment. In Proceedings of the 2021 17th International Conference on Wireless and Mobile Computing, Networking and Communications (WiMob), Bologna, Italy, 11–13 October 2021; pp. 212–218. [Google Scholar]

- 5G Smart Logistics Innovation Demonstration White Paper. Available online: https://wenku.baidu.com/view/207c04c5e309581b6bd97f19227916888486b93a.html?_wkts_=1715606774983 (accessed on 13 May 2024).

- HUAWEI. Available online: https://www.huawei.com/en/huaweitech/industry-insights/outlook/mobile-broadband/xlabs/insights-whitepapers/5g-smart-port-whitepaper (accessed on 13 May 2024).

- Wang, Q.; Jiang, J. Comparative examination on architecture and protocol of industrial wireless sensor network standards. IEEE Commun. Surv. Tutor. 2016, 18, 2197–2219. [Google Scholar] [CrossRef]

- Park, P.; Ergen, S.C.; Fischione, C.; Lu, C.; Johansson, K.H. Wireless network design for control systems: A survey. IEEE Commun. Surv. Tutor. 2018, 20, 978–1013. [Google Scholar] [CrossRef]

- Qiao, Y.; Fu, Y.; Yuan, M. Communication–Control Co-Design in Wireless Networks: A Cloud Control AGV Example. IEEE Internet Things J. 2023, 10, 2346–2359. [Google Scholar] [CrossRef]

- Katulić, F.; Sumina, D.; Groš, S.; Erceg, I. Protecting Modbus/TCP-Based Industrial Automation and Control Systems Using Message Authentication Codes. IEEE Access 2023, 11, 7007–47023. [Google Scholar] [CrossRef]

- Kekre, A.M.; Kothari, A. MODBUS-TR: Advanced MODBUS-RTU Protocol for IoT with Auto-discovery and Triggers. Wirel. Pers. Commun. 2022, 125, 2769–2780. [Google Scholar] [CrossRef]

- Yang, Y.-S.; Lee, S.-H.; Chen, W.-C.; Yang, C.-S.; Huang, Y.-M.; Hou, T.-W. TTAS: Trusted Token Authentication Service of Securing SCADA Network in Energy Management System for Industrial Internet of Things. Sensors 2021, 21, 2685. [Google Scholar] [CrossRef] [PubMed]

- Modbus. Available online: https://image.modbus.cn/wp-content/uploads/2022/03/2022031709192696.pdf (accessed on 13 May 2024).

- Modbus Organization. Modbus Messaging on TCP/IP Implementation Guide V1.0B; Modbus Organization: New York, NY, USA, 2006. [Google Scholar]

- Rico, D.; Merino, P. A Survey of End-to-End Solutions for Reliable Low-Latency Communications in 5G Networks. IEEE Access 2020, 8, 192808–192834. [Google Scholar] [CrossRef]

- Li, X.; Garcia-Saavedra, A.; Costa-Perez, X.; Bernardos, C.J.; Guimarães, C.; Antevski, K.; Mangues-Bafalluy, J. 5Growth: An End-to-End Service Platform for Automated Deployment and Management of Vertical Services over 5G Networks. IEEE Commun. Mag. 2021, 59, 84–90. [Google Scholar] [CrossRef]

- Quintana-Ramirez, I.; Tsiopoulos, A.; Lema, M.A.; Sardis, F.; Sequeira, L.; Arias, J.; Raman, A. The making of 5G: Building an end-to-end 5G-enabled system. IEEE Commun. Stand. Mag. 2018, 2, 88–96. [Google Scholar]

- Haile, H.; Grinnemo, K.-J.; Ferlin, S.; Hurtig, P.; Brunstrom, A. End-to-end congestion control approaches for high throughput and low delay in 4G/5G cellular networks. Comput. Netw. 2021, 186, 107692. [Google Scholar]

- HART. Available online: https://www.fieldcommgroup.org/technologies/hart (accessed on 21 May 2024).

- Galis, A.; Makhijani, K. Network Slicing Landscape: A holistic architectural approach, orchestration and management with applicability in mobile and fixed networks and clouds. In Proceedings of the IEEE Network Softwarization (NetSoft) 2018, Montreal, QC, Canada, 25–29 June 2018. [Google Scholar]

- Larrabeiti, D.; Contreras, L.M.; Otero, G.; Hernández, J.A.; Fernandez-Palacios, J.P. Toward end-to-end latency management of 5G network slicing and fronthaul traffic (Invited paper). Opt. Fiber Technol. 2023, 76, 103220. [Google Scholar] [CrossRef]

- Blevins, T.L.; Chen, D.; Nixon, M.J.; McMillan, G.K. Non-Periodic Control Communications in Wireless and Other Process Control System. U.S. Patent US 7945339 B2, 11 May 2011. [Google Scholar]

- Chen, J.-M.; Chu, C.-H.; Wu, E.H.-K.; Tsai, M.-F.; Wang, J.-R. Improving SCTP Performance by Jitter-Based Congestion Control over Wired-Wireless Networks. J. Wirel. Commun. Netw. 2011, 2011, 103027. [Google Scholar] [CrossRef]

- Kunst, R.; Avila, L.; Binotto, A.; Pignaton, E.; Bampi, S.; Rochol, J. Improving devices communication in Industry 4.0 wireless networks. Eng. Appl. Artif. Intell. 2019, 83, 1–12. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).