A Novel Water Level Control System for Sustainable Aquarium Use

Abstract

1. Introduction

2. Research

3. System Design

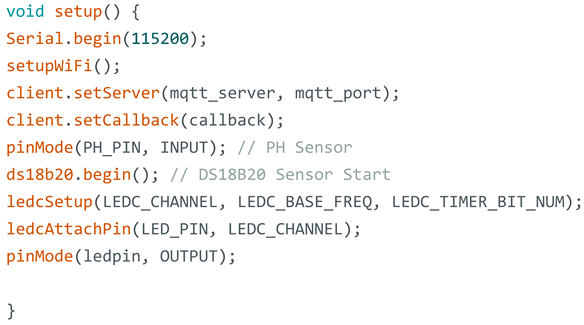

3.1. System Block Diagram

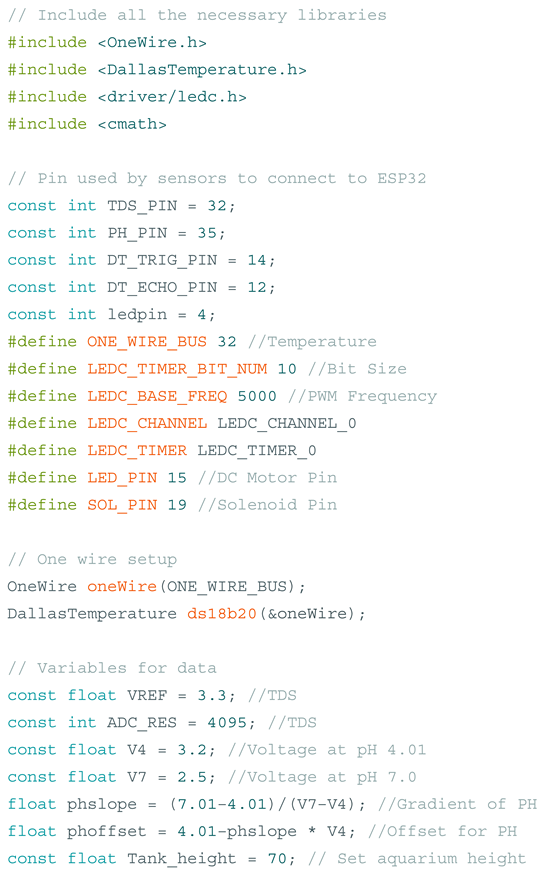

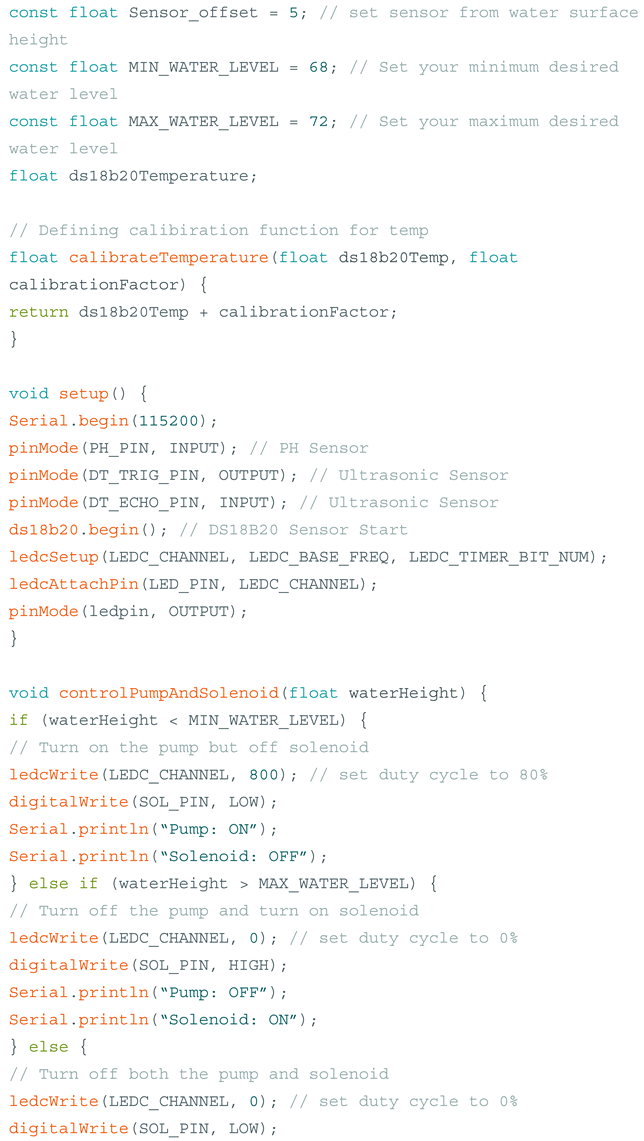

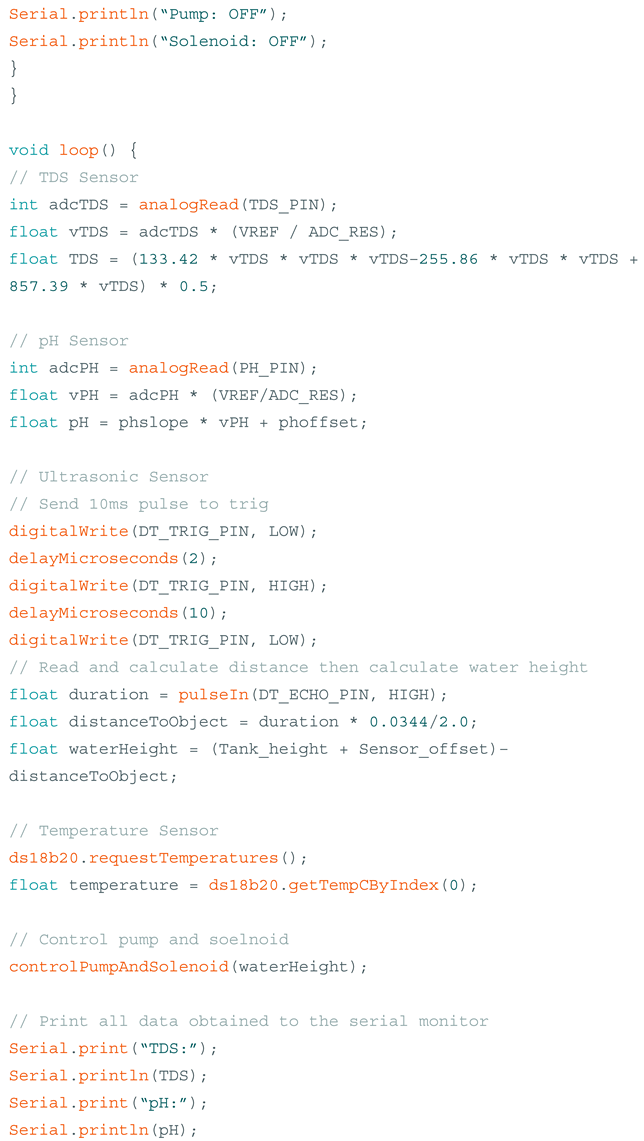

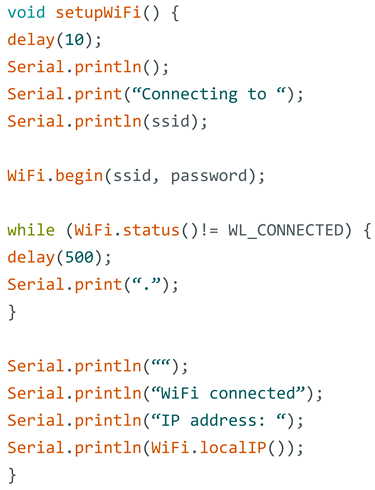

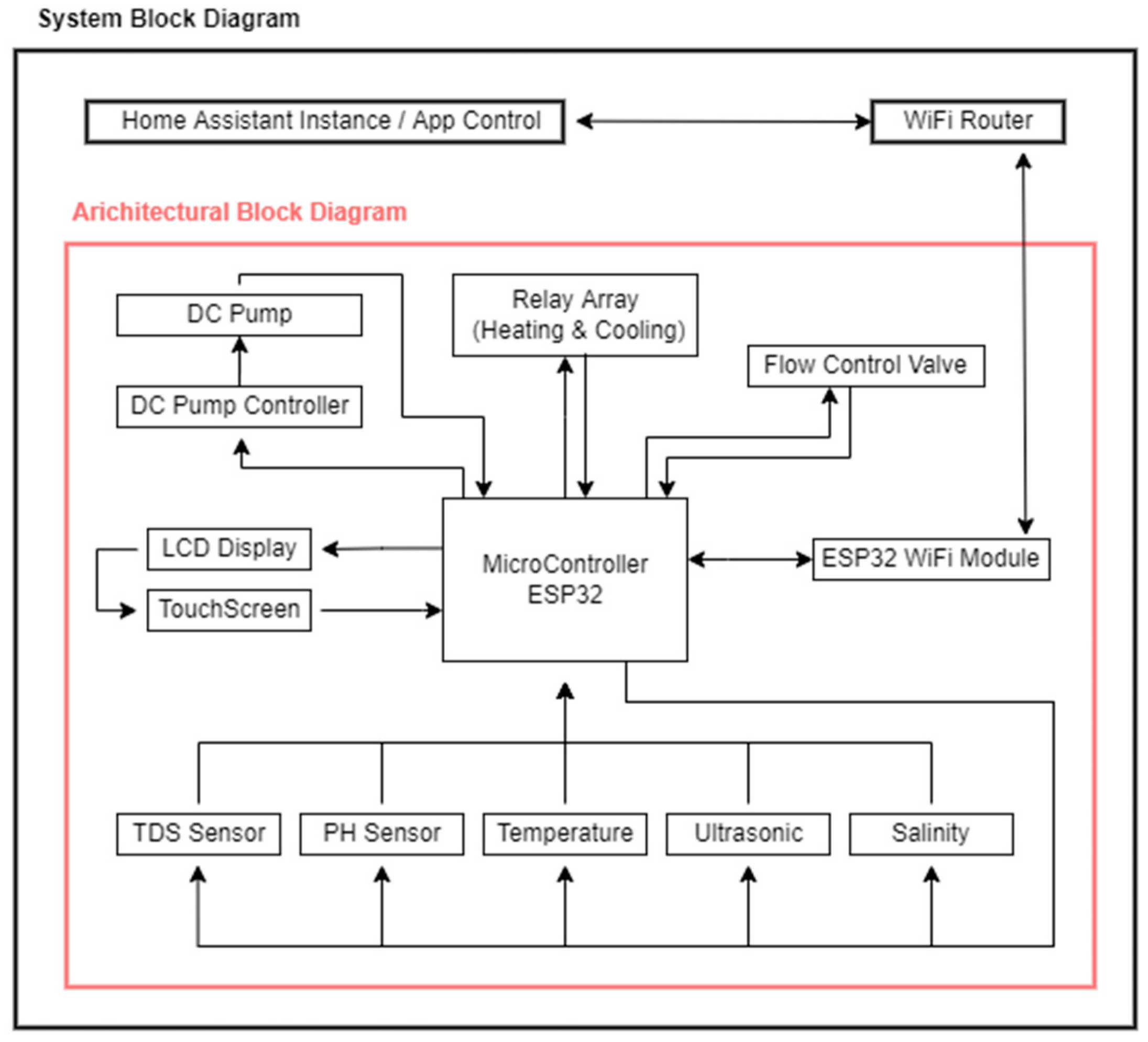

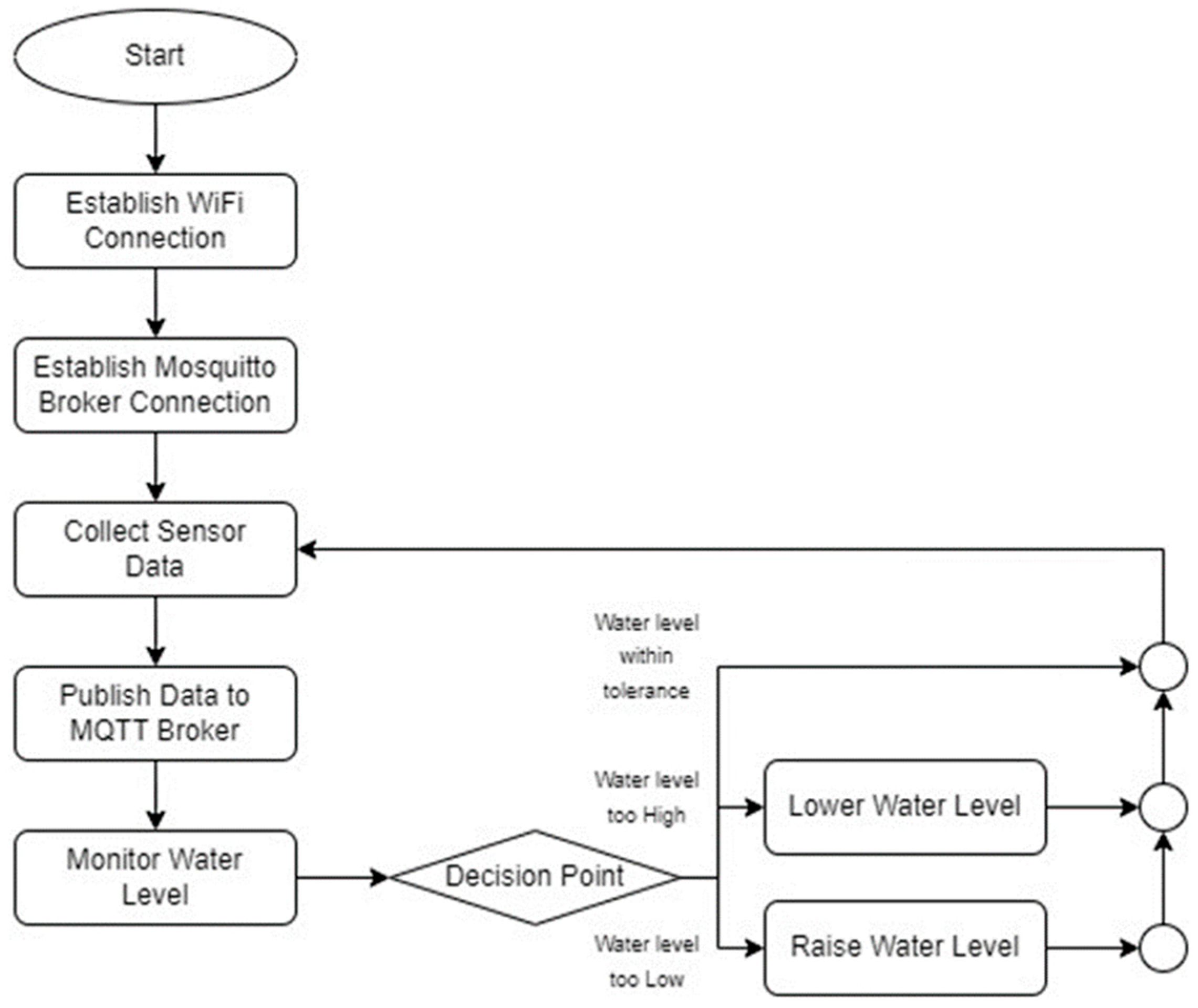

3.2. Firmware and Algorithm Design

- Start: system turns on and boots up.

- Establish Wi-Fi Connection: repeated attempts until connected to the local network.

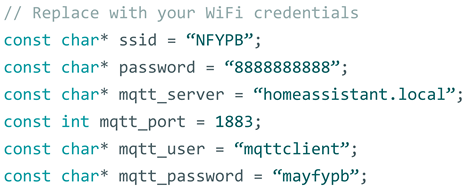

- Connect to MQTT Broker: after Wi-Fi, connects to MQTT broker on the Home Assistant (HA), after a successful link.

- Sensor Data Collection: gathers data such as water level, temperature and other pertinent parameters once all connections are in place.

- Data Transmission: publishes sensor data to Home Assistant

- Monitor Water Level: constantly checks tank level against the setpoint.

- Decision Point:

- High Level: proceeds to Step 8.

- Low Level: proceeds to Step 9.

- Within Range: returns to Step 4.

- Lower Water Level: activates components (e.g., drain valve) to remove surplus water until desired water level, then returns to Step 4.

- Raise Water Level: activates components (e.g., water pump) to add water until desired water level, then returns to Step 4.

4. Component Design

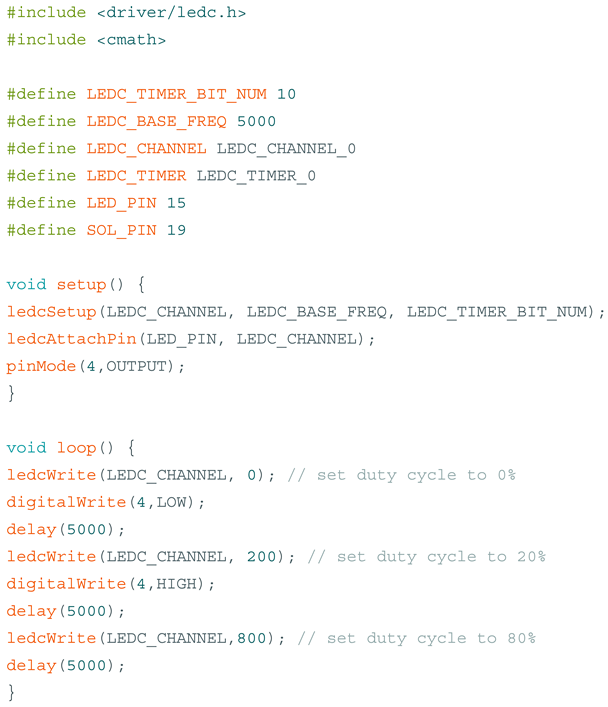

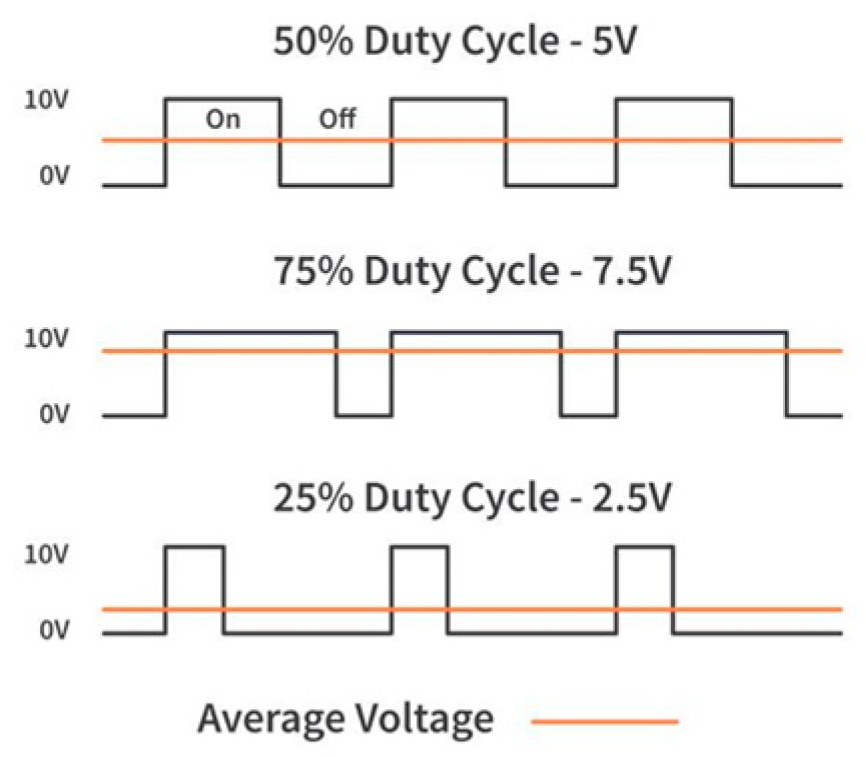

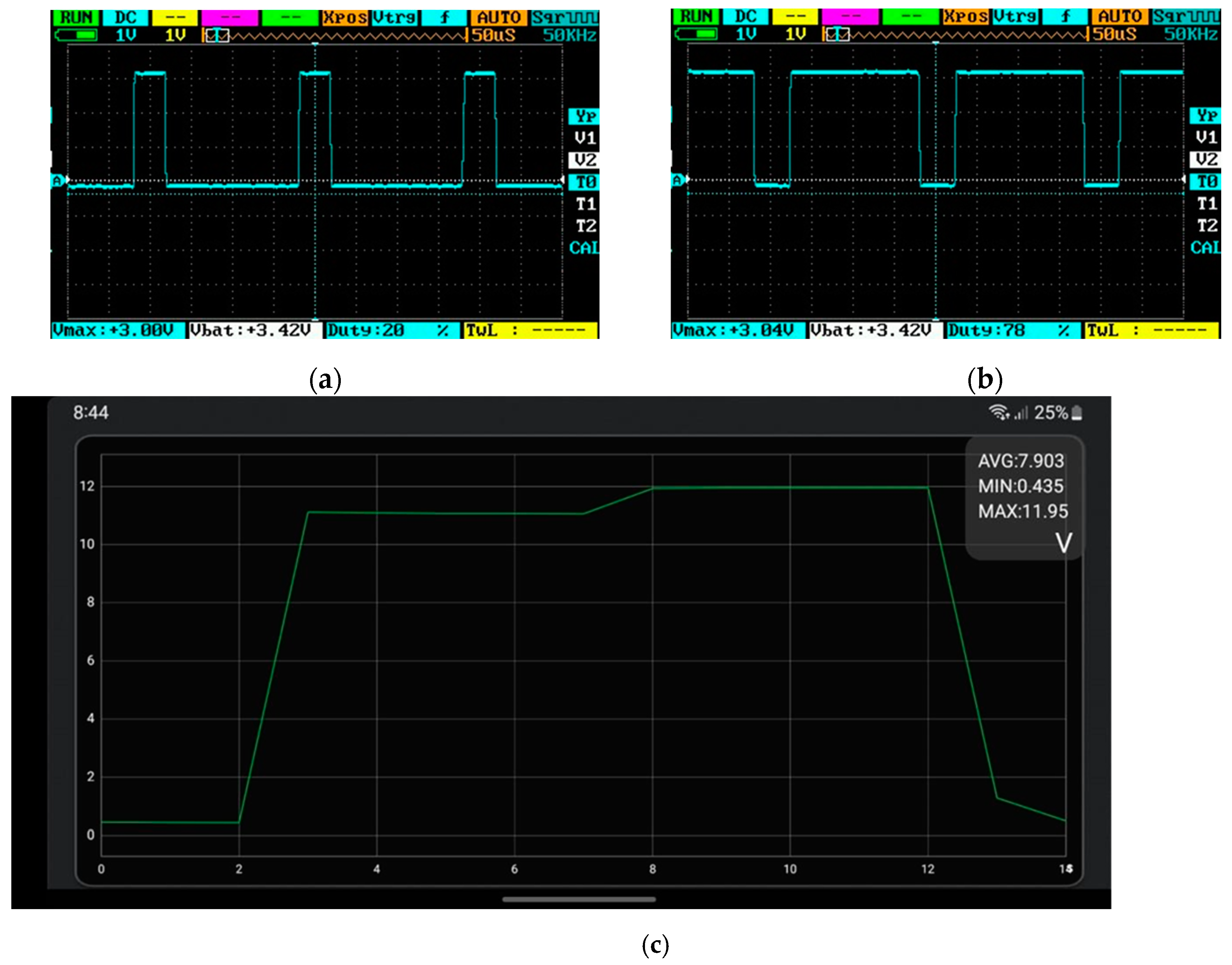

4.1. PWM Controller for Motor

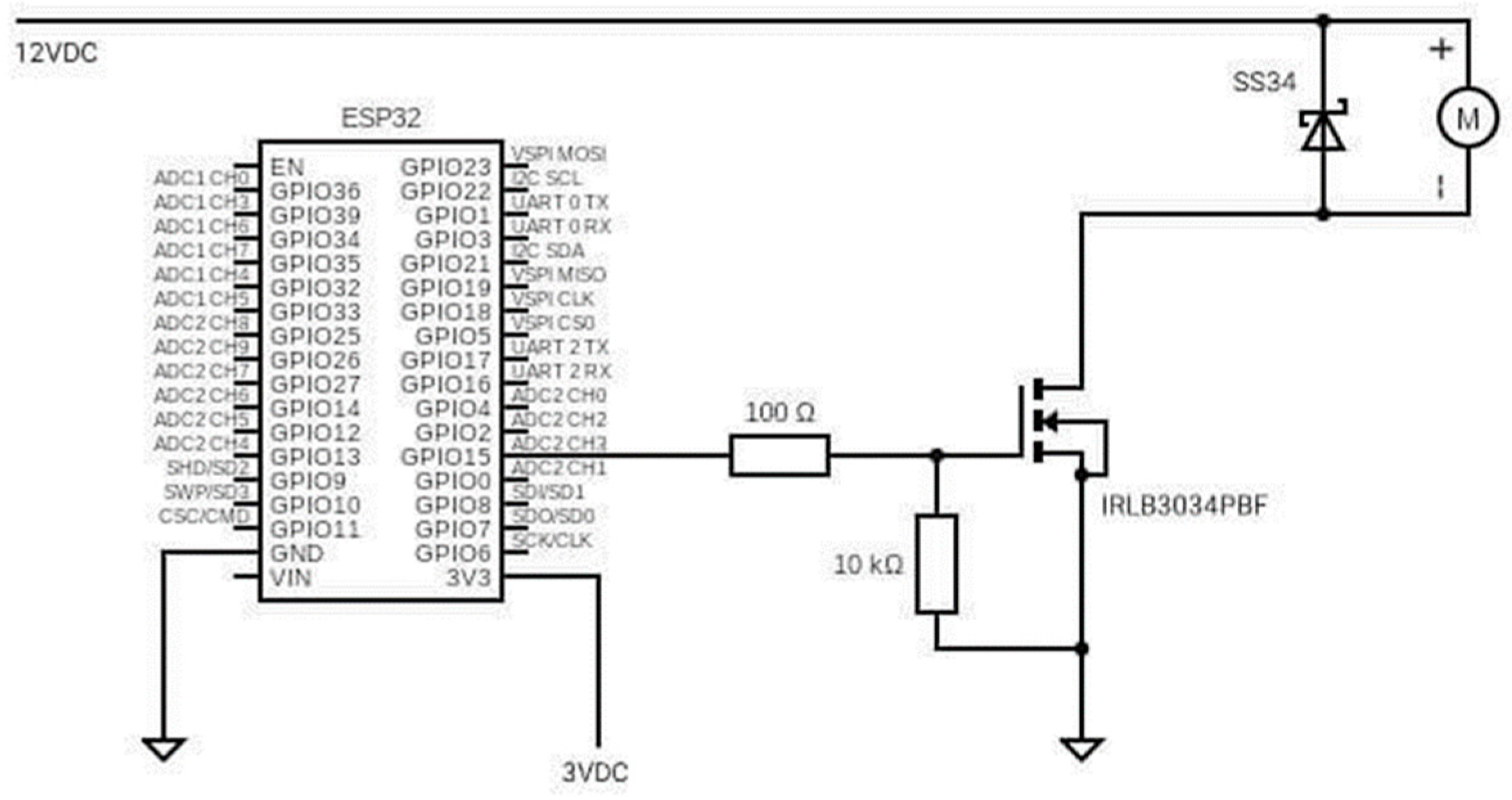

4.2. PWM MOSFET Calculations

4.3. PWM Gate Resistor Calculations

4.4. PWM Pull-Down Resistor Calculations

4.5. PWM Diode Calculations

4.6. PWM Circuit Design

4.7. Solenoid Valve Switch

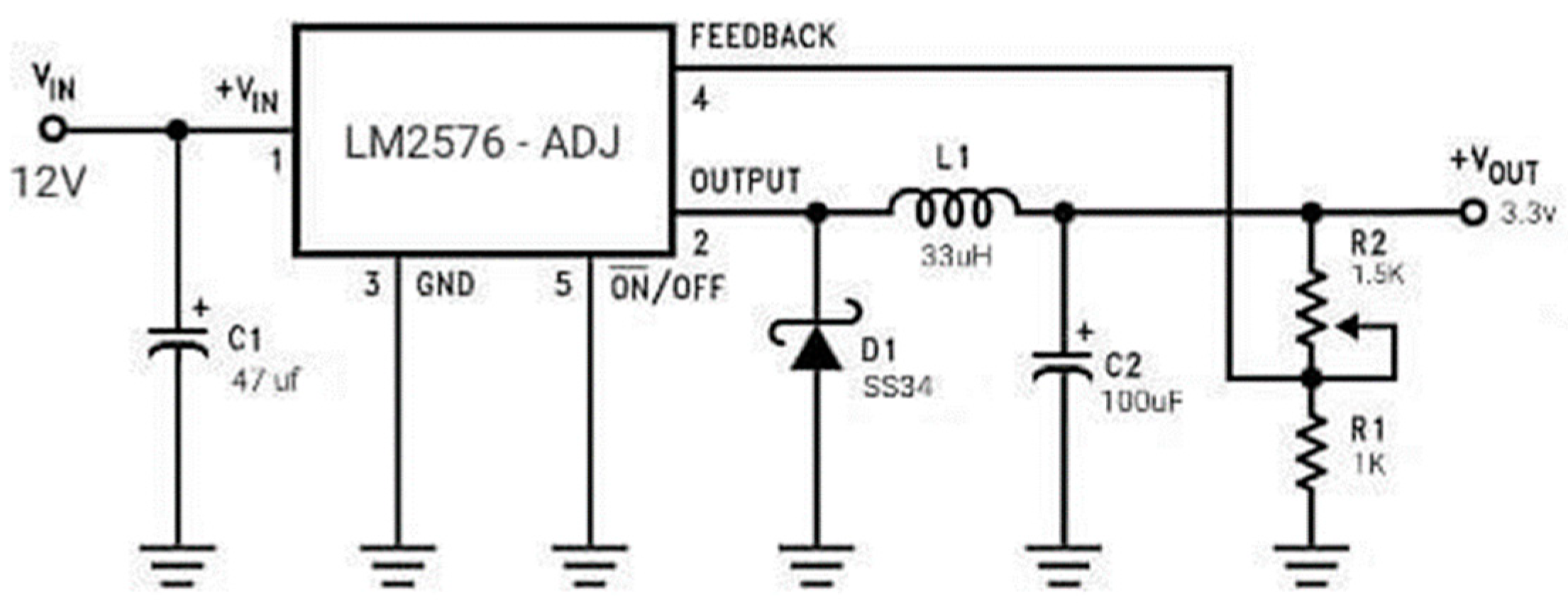

4.8. 12 V to 3.3 V Voltage Converter

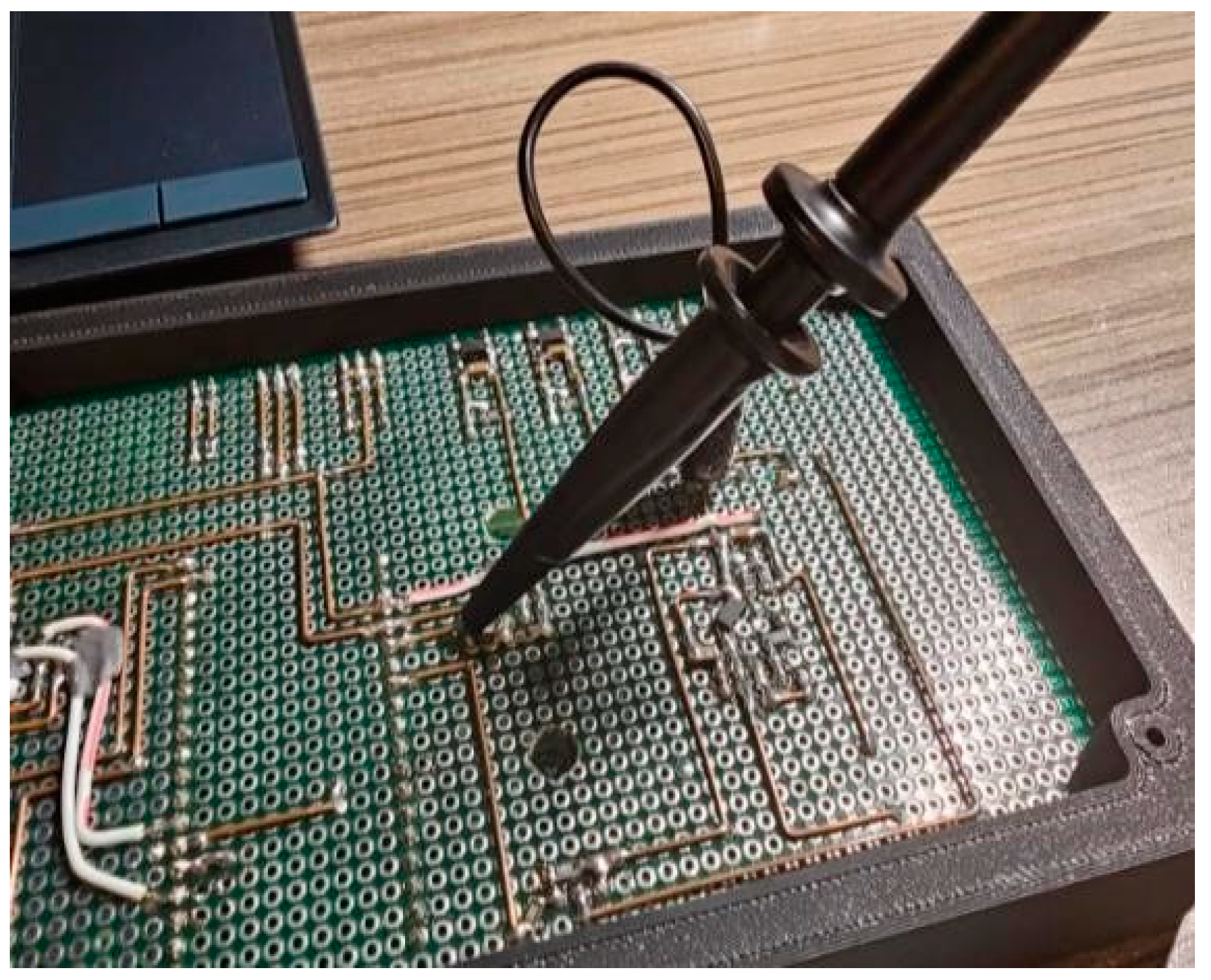

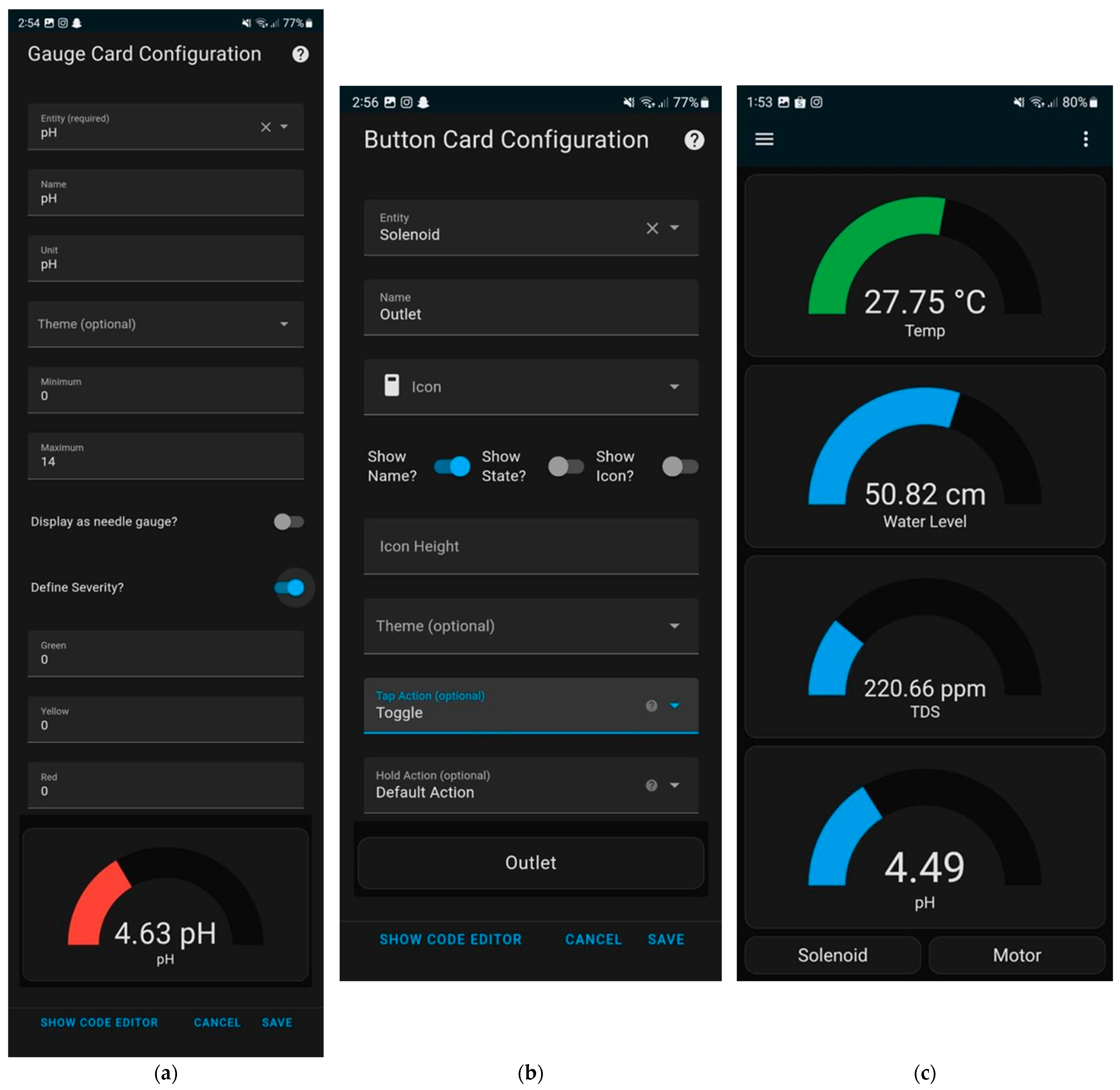

5. Project Integration

6. Results of Component Testing and Calibration

6.1. ESP32 Microcontroller

6.2. PH-5402C pH Sensor

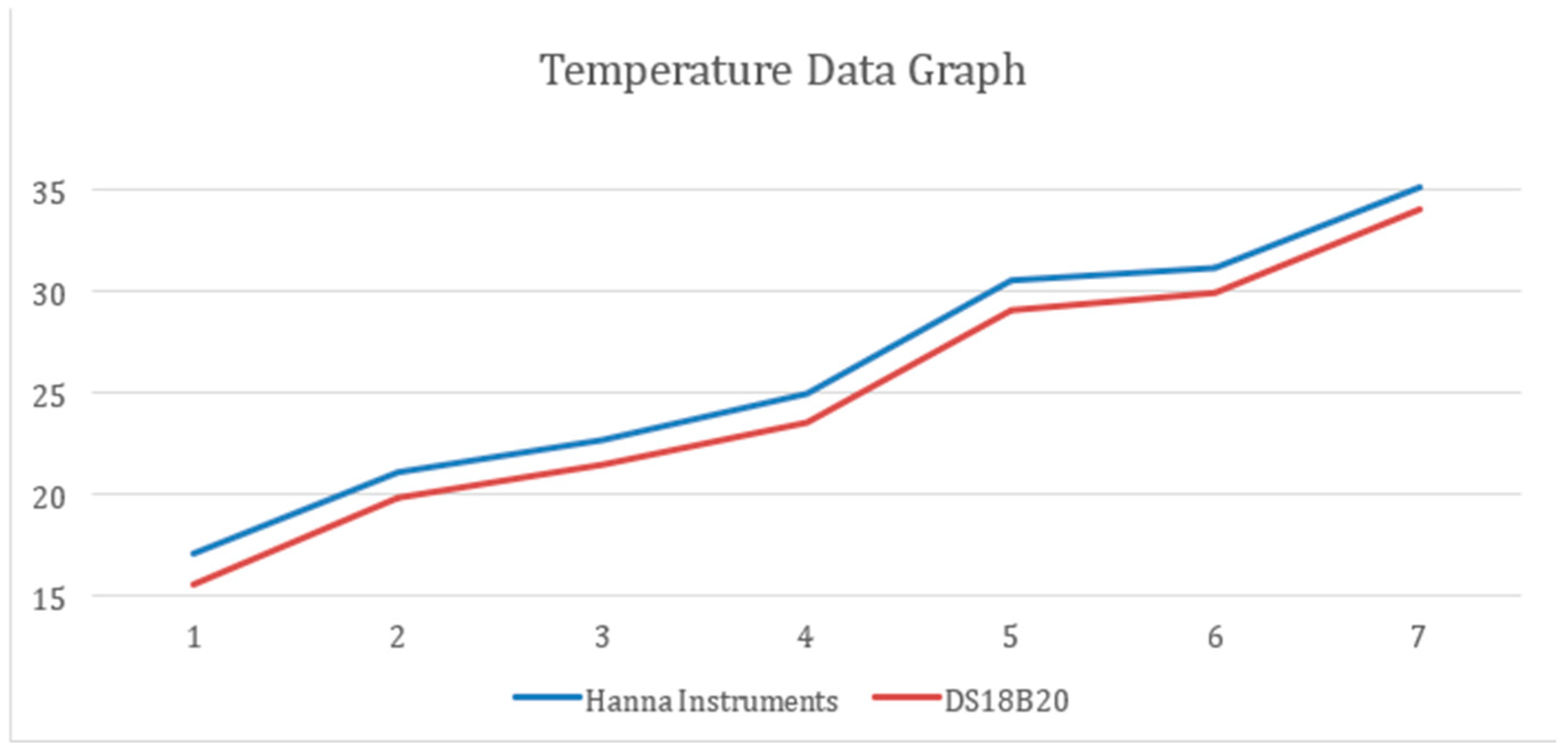

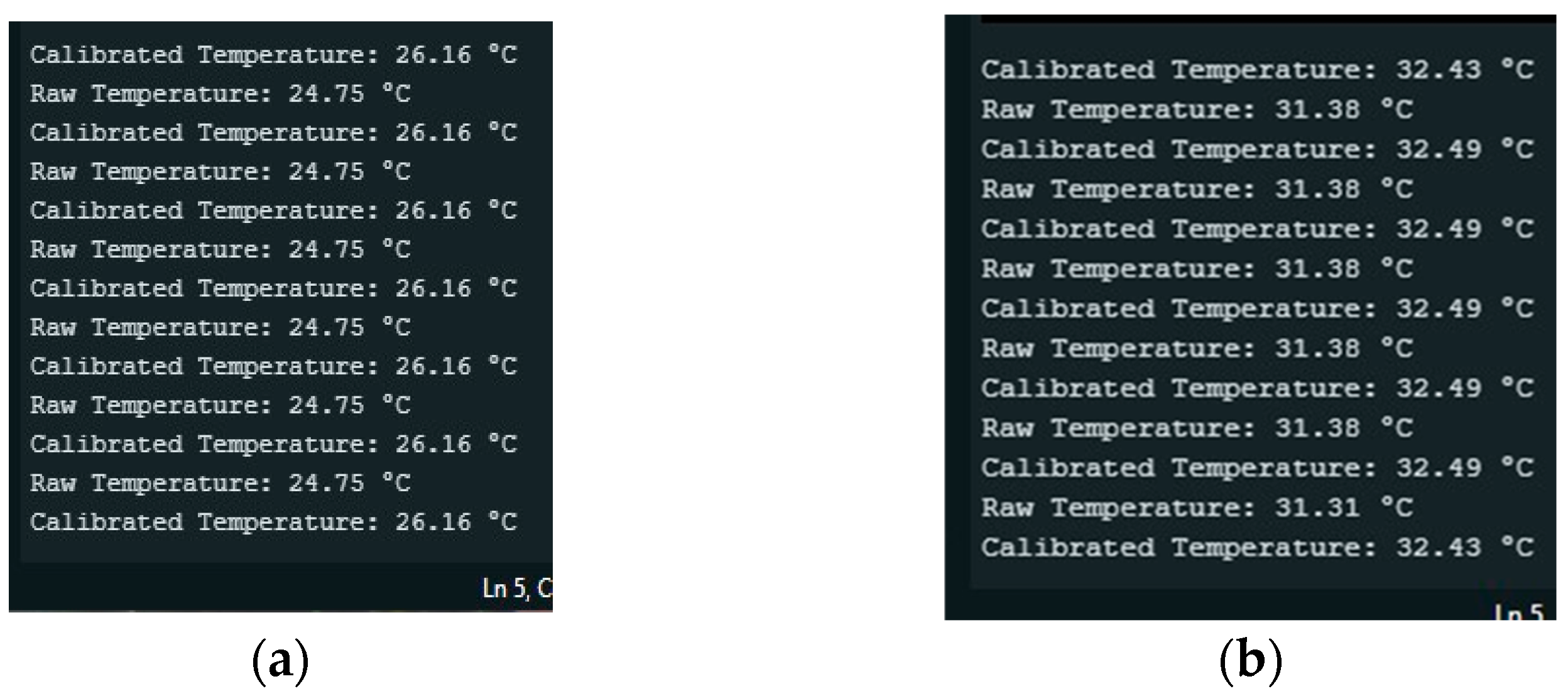

6.3. DS18B20 Temperature Probe

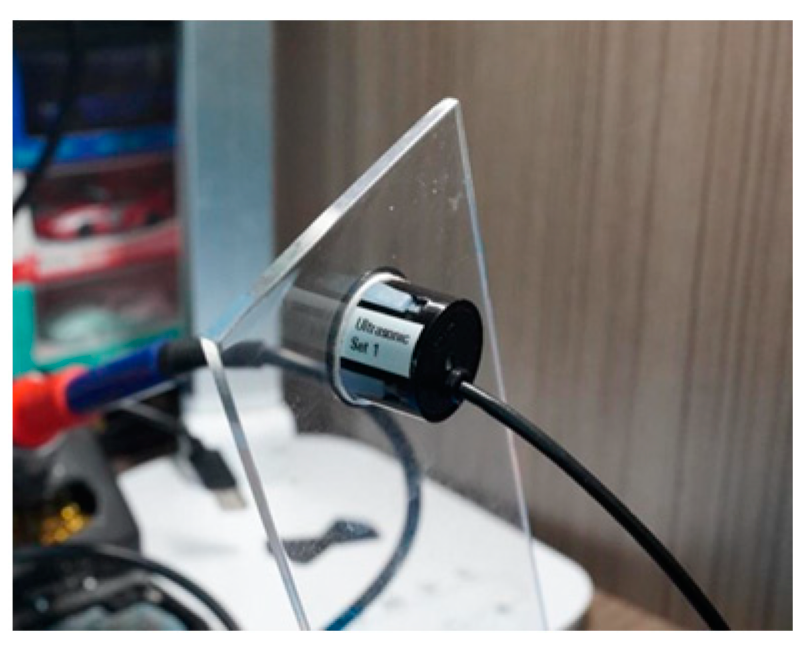

6.4. JST SR04T Ultrasonic Sensor

6.5. TDS Meter V1.0 Sensor

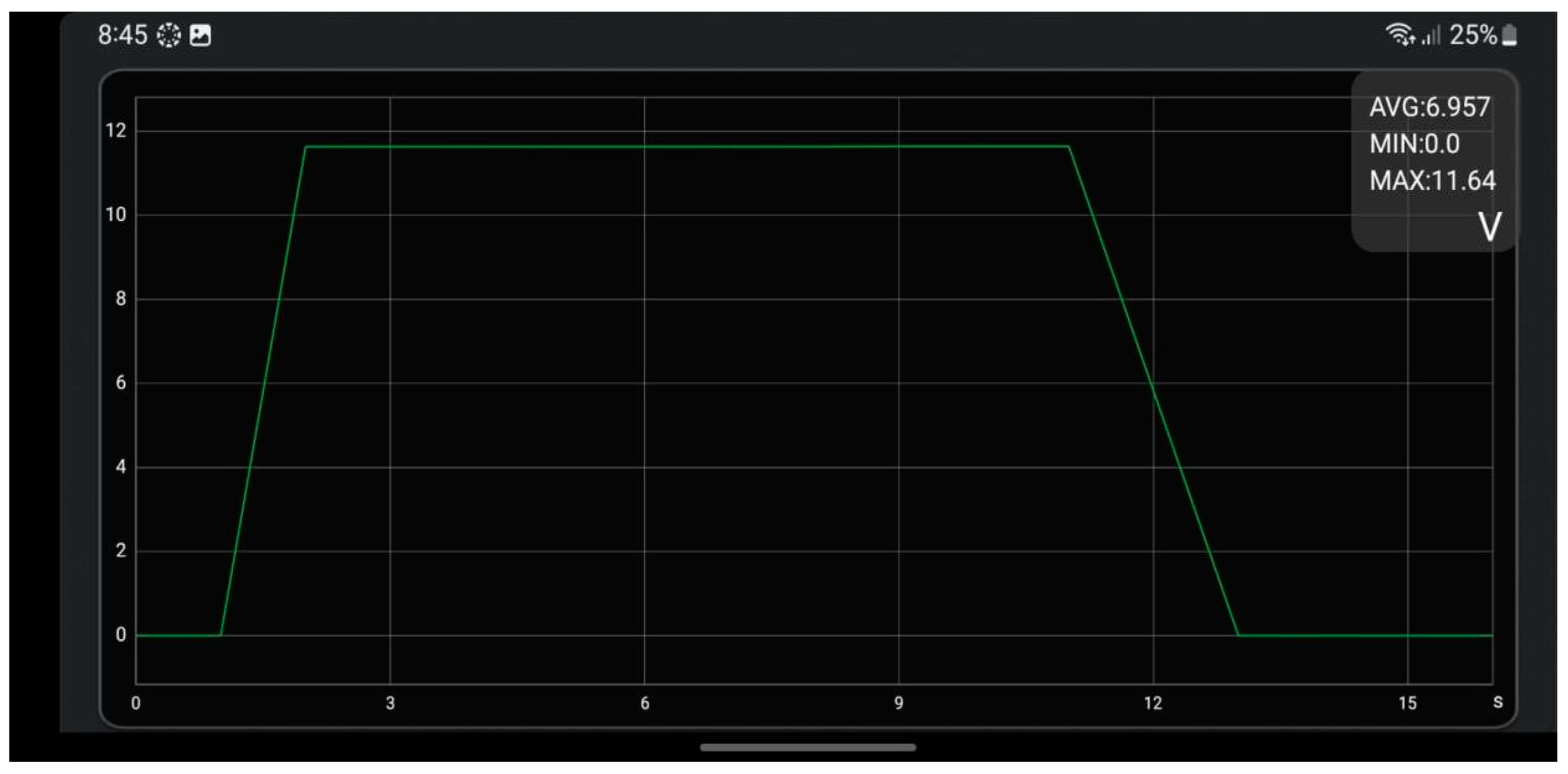

6.6. IRLB3034PBF PWM Motor Controller

6.7. IRLB3034PBF Solenoid Controller

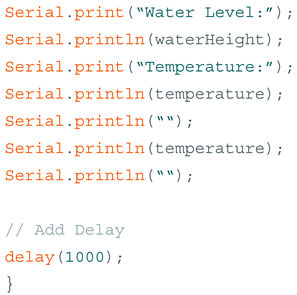

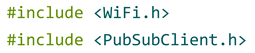

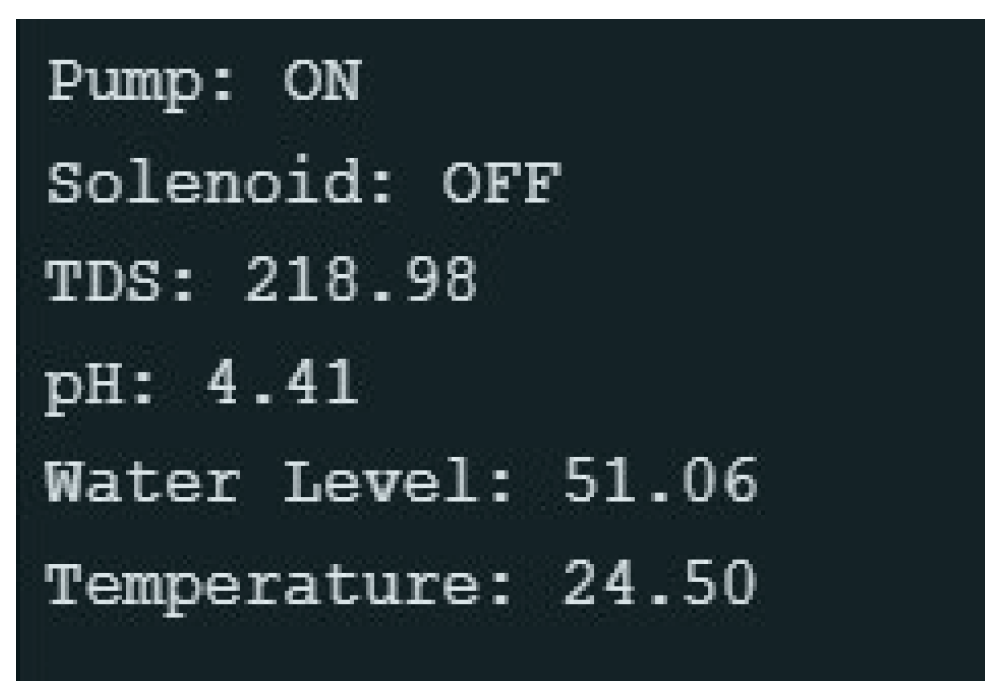

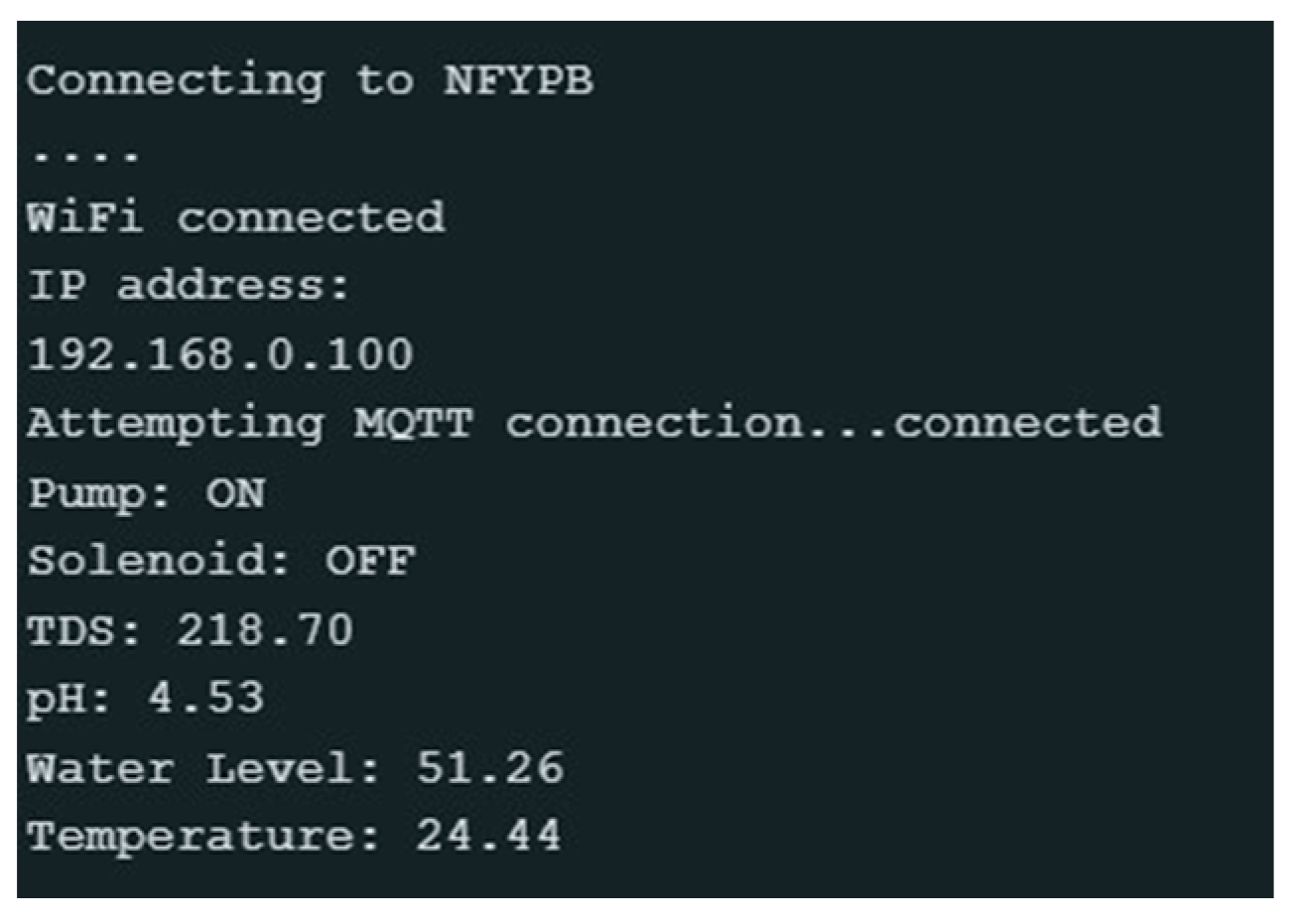

6.8. Sensor Test Final Code

7. Discussion

8. Conclusions

9. Future Work

10. User Experience Feedback from Aquarium Hobbyists

- Positive Feedback:

- Enhancements Suggested:

- Constructive Criticism:

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ramaiah, N.; DeepaT, P.; Sridhar, S.; Chatterjee, N.; RahulS, N.; Khadka, B. Fish Tank Monitoring System Using IoT. Int. J. Sci. Res. Sci. Technol. 2020, 298–304. Available online: https://consensus.app/papers/tank-monitoring-system-using-ramaiah/967c4098749d50489c422baadead0f49 (accessed on 16 June 2023).

- Theagarajan, P.; Padmanaban, B.; Palanisamy, K.; Raja, P.; Poomagan, P. Development of An Automated IoT-based Fish Tank Maintenance Assistive System. In Proceedings of the 2023 7th International Conference on Intelligent Computing and Control Systems (ICICCS), Madurai, India, 17–19 May 2023; Available online: https://consensus.app/papers/development-automated-iotbased-fish-tank-maintenance-theagarajan/1efca537f85c50eea4a46be8d200aa4a (accessed on 16 June 2023).

- Likitha, R.; Madhuri, M.G.; Sanjana, N.M.; Manisha, D.; Kavya, A.P. Smart Aquarium Monitoring System Using IoT. Int. J. Res. Appl. Sci. Eng. Technol. 2023, 11, 1526–1529. Available online: https://consensus.app/papers/smart-aquarium-monitoring-system-using-r/00bf1097945157e3a359b675c6ed08ba (accessed on 16 June 2023).

- Palconit, M.G.B.; Concepcion, R.S.; Tobias, R.R.; Alejandrino, J.D.; Almero, V.J.D.; Bandala, A.; Vicerra, R.R.; Sybingco, E.; Dadios, E. Development of IoT-based Fish Tank Monitoring System. In Proceedings of the 2021 IEEE 13th International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment, and Management (HNICEM), Manila, Philippines, 28–30 November 2021; Available online: https://consensus.app/papers/development-iotbased-fish-tank-monitoring-system-palconit/f6a2da301df755868434b455e6220edf (accessed on 16 June 2023).

- Nuanmeesri, S.; Poomhiran, L. Smart Aquarium Water Quality Monitoring and Changing for Ornamental Fish Store Using IoT through Data. 2020. Available online: https://consensus.app/papers/quality-smart-aquarium-water-quality-monitoring-changing-nuanmeesri/aa3f2d01598756518898db5e758cc6dc (accessed on 16 June 2023).

- Smitha, J.A.; Shreya Agarwal, K.L.; Hitha, L. Smart Aquarium for Fresh Water Fishes. Int. J. Innov. Res. Adv. Eng. 2023. Available online: https://consensus.app/papers/smart-aquarium-fresh-water-fishes-a/e1a0c50d1f985c86a6f9d51e733fc637 (accessed on 16 June 2023).

- Daud, A.K.P.M.; Sulaiman, N.; Yusof, Y.W.M.; Kassim, M. An IoT-Based Smart Aquarium Monitoring System. In Proceedings of the 2020 IEEE 10th Symposium on Computer Applications & Industrial Electronics (ISCAIE), Penang, Malaysia, 18–19 April 2020; Available online: https://consensus.app/papers/iotbased-smart-aquarium-monitoring-system-daud/1bff6b07a0e25fe48884e043bb29692c/?utm_source=chatgpt (accessed on 16 June 2023).

- Balasubramani, S.; AakashRam, S.; AkshayBharadwaj, S.; BennetNiffin, N. Smart Aquarium Management System. Adv. Parallel Comput. 2020, 37, 523–527. Available online: https://consensus.app/papers/smart-aquarium-management-system-balasubramani/fcc5cbe02b2d5179934d4fb08e3c82e9/ (accessed on 16 June 2023).

- Nuanmeesri, S.; Poomhiran, L. Improvement of Smart Farm by using IoT for Ornamental Fishes and Aquatic Animals Store. Int. J. Innov. Technol. Explor. Eng. 2020, 9, 2201–2206. Available online: https://consensus.app/papers/improvement-smart-farm-using-ornamental-fishes-aquatic/8823ea04632155a897c30cb26420b70c (accessed on 16 June 2023). [CrossRef]

- Antonio, D.T.S.; Rivera, J.R.A.; Balid, A.C.N.; Belaos, R.R.P.; Brizuela, A.I.; Caballero, J.A. IoT-Based Water Quality Monitoring and Automated Fish Feeder: Enhancing Aquaculture Productivity. In Proceedings of the 2023 IEEE Region 10 Symposium (TENSYMP), Canberra, Australia, 6–8 September 2023; Available online: https://consensus.app/papers/water-quality-monitoring-automated-fish-feeder-enhancing-antonio/babb9aa01f5f5e72b96b6e6a22e09772 (accessed on 16 June 2023).

- Rey, W.P. FishTank: An IOT-based Smart Aquarium Management System for Freshwater Fish Enthusiasts. In Proceedings of the 2023 9th International Conference on Industrial and Business Engineering, Beijing, China, 22–24 September 2023; Available online: https://consensus.app/papers/fishtank-iotbased-smart-aquarium-management-system-rey/aa3a7ff79f2154049befc9a5b18ecf2c (accessed on 16 June 2023).

- Arif, M.A.; Reza, M.R.; Mandal, A.B.; Akib, M.A.M.; Shuma, F.M.; Fehir, S.S.M. Towards Developing an IoT-Based Aquaculture Monitoring System. In Proceedings of the 2023 International Conference on Information and Communication Technology for Sustainable Development (ICICT4SD), Dhaka, Bangladesh, 21–23 September 2023; Available online: https://consensus.app/papers/towards-developing-aquaculture-monitoring-system-arif/4bed950d0b5e52ec84f9c261c226ead4 (accessed on 16 June 2023).

- Pasika, S.; Gandla, S.T. Smart water quality monitoring system with cost-effective using IoT. Heliyon 2020, 6, e04096. Available online: https://consensus.app/papers/water-quality-monitoring-system-using-pasika/2bf887a523b9521a99a994abfbf6b49d (accessed on 16 June 2023). [CrossRef]

- Shaikh, F.A.Z.; Bhaskarwar, U. Smart Aquarium using IoT. Int. J. Res. Appl. Sci. Eng. Technol. 2022, 10, 151–156. Available online: https://consensus.app/papers/smart-aquarium-using-shaikh/406ba1b5d0dd5c18a1a14c9efb0d08e7/ (accessed on 16 June 2023). [CrossRef]

- Yasruddin, M.L.; Ismail, M.A.H.; Husin, Z.; Tan, W. Development of Automated Real-Time Water Quality Monitoring and Controlling System in Aquarium. In Proceedings of the 2022 IEEE 12th Symposium on Computer Applications & Industrial Electronics (ISCAIE), Penang, Malaysia, 21–22 May 2022; Available online: https://consensus.app/papers/development-automated-realtime-water-quality-monitoring-yasruddin/b00ddcfc923050069c508ba8ebba1dc0/ (accessed on 16 June 2023).

- Makaran, J. Gate Charge Control for MOSFET Turn-Off in PWM Motor Drives Through Empirical Means. IEEE Trans. Power Electron. 2010, 25, 1339–1350. Available online: https://consensus.app/papers/gate-charge-control-mosfet-turnoff-motor-drives-through-makaran/6ac0bc0cf07e5d7ba63b0b61a66f8cc2/ (accessed on 16 June 2023). [CrossRef]

- Sengupta, S.J.; Goswami, B.; Das, P.; Sarkar, S. A Noise Immune Double Suspended Gate MOSFET for Ultra Low-Power Applications. Silicon 2021, 14, 5091–5101. Available online: https://consensus.app/papers/noise-immune-double-suspended-gate-mosfet-ultra-lowpower-sengupta/cf2ac0d113495df19368db06cca6a29a/ (accessed on 16 June 2023). [CrossRef]

- Covic, G.; Boys, J. Noise quieting with random PWM AC drives. IEE Proc. Electr. Power Appl. 1998, 145, 1–10. Available online: https://consensus.app/papers/noise-quieting-random-drives-covic/74d2b30d2c155f7680d325593a0a8ecd (accessed on 16 June 2023). [CrossRef]

- Das, M.; Capell, C.; Grider, D.; Leslie, S.; Ostop, J.; Raju, R.; Schutten, M.; Nasadoski, J.; Hefner, A. 10 kV, 120 A SiC half H-bridge power MOSFET modules suitable for high frequency, medium voltage applications. In Proceedings of the 2011 IEEE Energy Conversion Congress and Exposition, Phoenix, AZ, USA, 17–22 September 2011; Available online: https://consensus.app/papers/half-hbridge-power-mosfet-modules-frequency-medium-das/14d679ac2f1a584796df829b1fbc91bf/ (accessed on 16 June 2023).

- Ma, R.; Dai, L.; Qin, G. High-performance nano-Schottky diodes and nano-MESFETs made on single CdS nanobelts. Nano Lett. 2007, 7, 868–873. Available online: https://consensus.app/papers/highperformance-nanoschottky-diodes-nanomesfets-made-ma/3085568c1d34596e9fe1ff4820c6eeac/ (accessed on 16 June 2023). [CrossRef] [PubMed]

- Andang, A.; Hiron, N.; Chobir, A.; Busaeri, N. Investigation of ultrasonic sensor type JSN-SRT04 performance as flood elevation detection. IOP Conf. Ser. Mater. Sci. Eng. 2019, 550, 012018. Available online: https://consensus.app/papers/investigation-sensor-type-jsnsrt04-performance-flood-andang/15d4b97ce74f5b7c89b14b1f6dd126f6/ (accessed on 16 June 2023). [CrossRef]

- Dswilan, S.; Harmadi; Marzuki. Flood monitoring system using ultrasonic sensor SN-SR04T and SIM 900A. J. Phys. Conf. Ser. 2021, 1876, 012003. Available online: https://consensus.app/papers/flood-monitoring-system-using-sensor-snsr04t-900a-dswilan/9633256366e85784b22409fea07d165c (accessed on 16 June 2023). [CrossRef]

- Kumar, A.; Sarangi, A.; Singh, D.K.; Dash, S.; Mani, I. Evaluation of Ultrasonic Sensor for Flow Measurement in Open Channel. J. Sci. Ind. Res. 2023, 82, 1091–1099. Available online: https://consensus.app/papers/evaluation-ultrasonic-sensor-flow-measurement-open-kumar/43ef661478d95ed3b6cfb4db8b9ec8b5/ (accessed on 16 June 2023).

| MOSFET Model | RLB3034PBF | IRF3205 | IRLZ44N |

|---|---|---|---|

| VDSS | 39 V | 55 V | 55 V |

| Drain Current | 200 A | 110 A | 47 A |

| Resistance at 10 V | 1.6 mΩ | 8 mΩ | 17.5 mΩ |

| VGS | <2.5 V | 1.9 V–3.9 V | 1 V to 2 V |

| Capacitor Value | 47.0 µF |

| External Capacitor | 100.0 µF |

| Inductor | 33.0 µH |

| Diode | Voltage drop < 0.8 V |

| Sensor | ESP32 Pin |

|---|---|

| TDS Sensor | 34 |

| PH Sensor | 33 |

| Ultrasonic Trigger | 14 |

| Ultrasonic Echo | 12 |

| Solenoid | 4 |

| Relay | 15 |

| Sachet pH Value | Voltage Reading of Sensor |

|---|---|

| 4.01 | 3.2 V |

| 7.01 | 2.5 V |

| Hanna Instruments pHEP+ (°C) | DS18B20 (°C) |

|---|---|

| 17.0 | 15.5 |

| 21.0 | 19.81 |

| 22.6 | 21.44 |

| 24.9 | 23.5 |

| 30.5 | 29.06 |

| 31.1 | 29.94 |

| 35.1 | 34.06 |

| Ultrasonic Daughter Board | ESP32 |

| VCC | 3V3 |

| GND | GND |

| TRIG | GPIO14 |

| ECHO | GPIO12 |

| Hanna Instruments pHEP+ (°C) | DS18B20 (°C) |

|---|---|

| 17.0 | 15.5 |

| 21.0 | 19.81 |

| 22.6 | 21.44 |

| 24.9 | 23.5 |

| 30.5 | 29.06 |

| 31.1 | 29.94 |

| 35.1 | 34.06 |

| TDS Daughter Board | ESP32 |

| GND | GND |

| VCC | 3V3 |

| Analog | GPIO34 |

| TDS Solution | Voltage |

|---|---|

| 0 | 2.62 |

| 342 | 1.91 |

| 700 | 1.43 |

| 1000 | 1.06 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kok, C.L.; Ho, C.K.; Tanjodi, N.; Koh, Y.Y. A Novel Water Level Control System for Sustainable Aquarium Use. Electronics 2024, 13, 2033. https://doi.org/10.3390/electronics13112033

Kok CL, Ho CK, Tanjodi N, Koh YY. A Novel Water Level Control System for Sustainable Aquarium Use. Electronics. 2024; 13(11):2033. https://doi.org/10.3390/electronics13112033

Chicago/Turabian StyleKok, Chiang Liang, Chee Kit Ho, Nicholas Tanjodi, and Yit Yan Koh. 2024. "A Novel Water Level Control System for Sustainable Aquarium Use" Electronics 13, no. 11: 2033. https://doi.org/10.3390/electronics13112033

APA StyleKok, C. L., Ho, C. K., Tanjodi, N., & Koh, Y. Y. (2024). A Novel Water Level Control System for Sustainable Aquarium Use. Electronics, 13(11), 2033. https://doi.org/10.3390/electronics13112033