Multi-Objective Immune Optimization of Path Planning for Ship Welding Robot

Abstract

1. Introduction

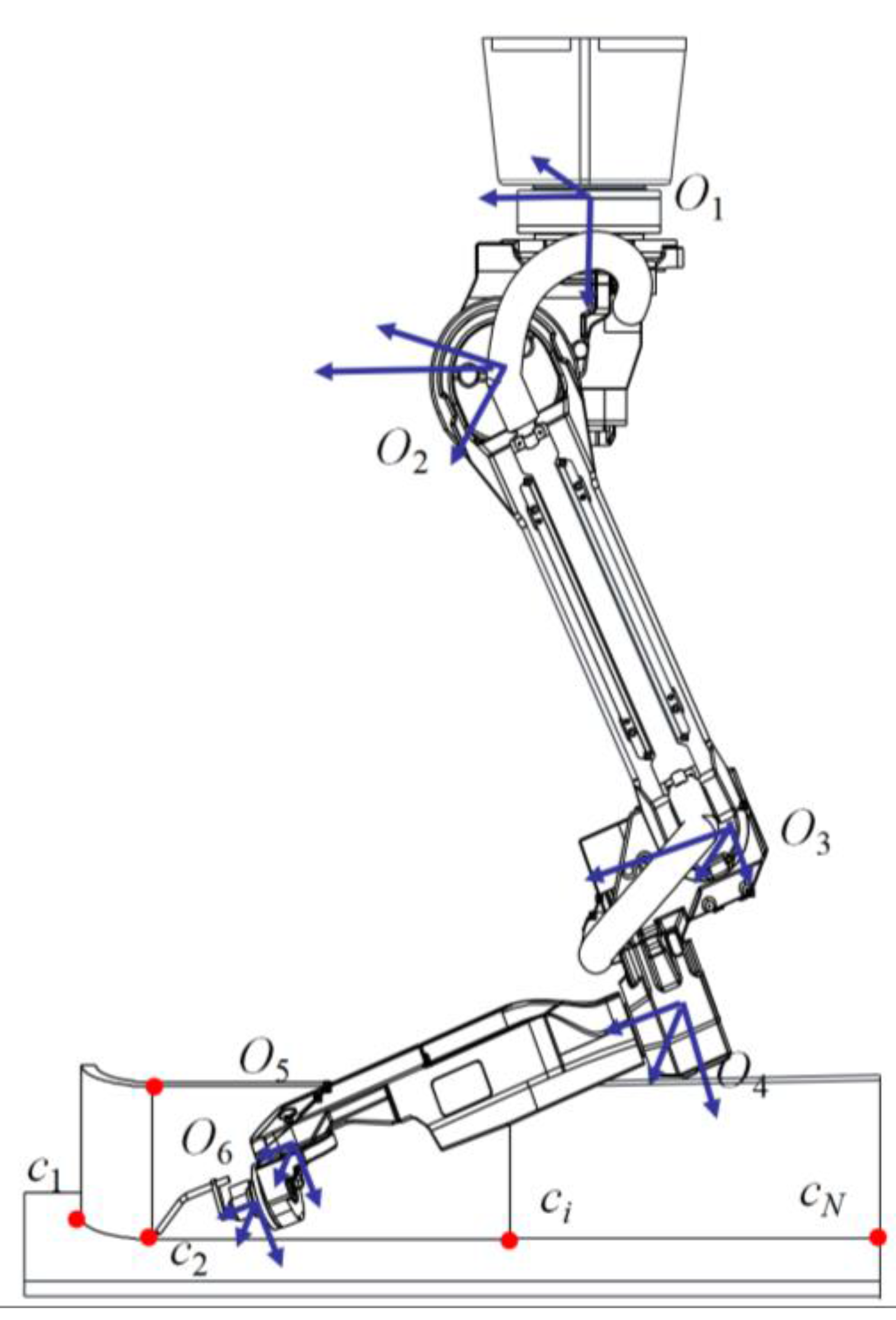

2. Definition and Modeling of Welding Robot Path Planning

2.1. Path Planning Definition

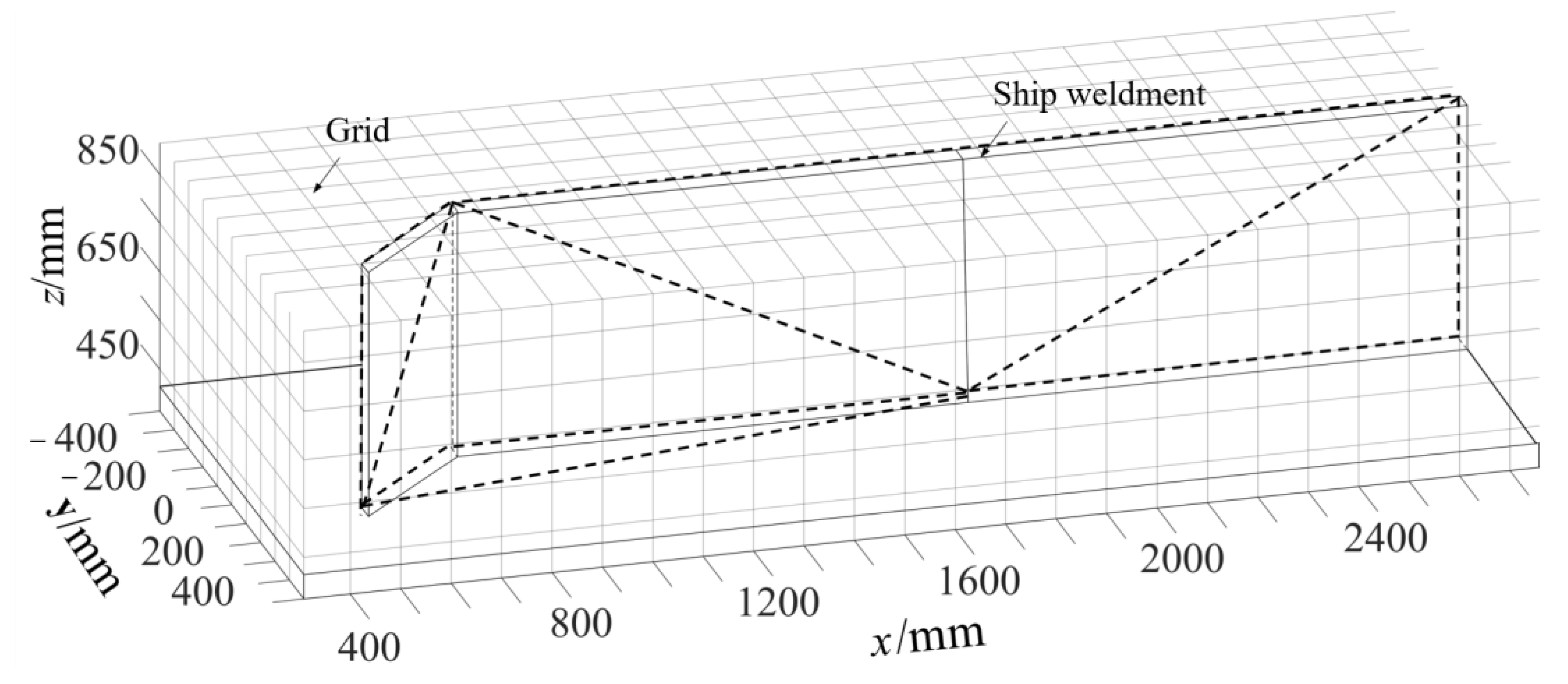

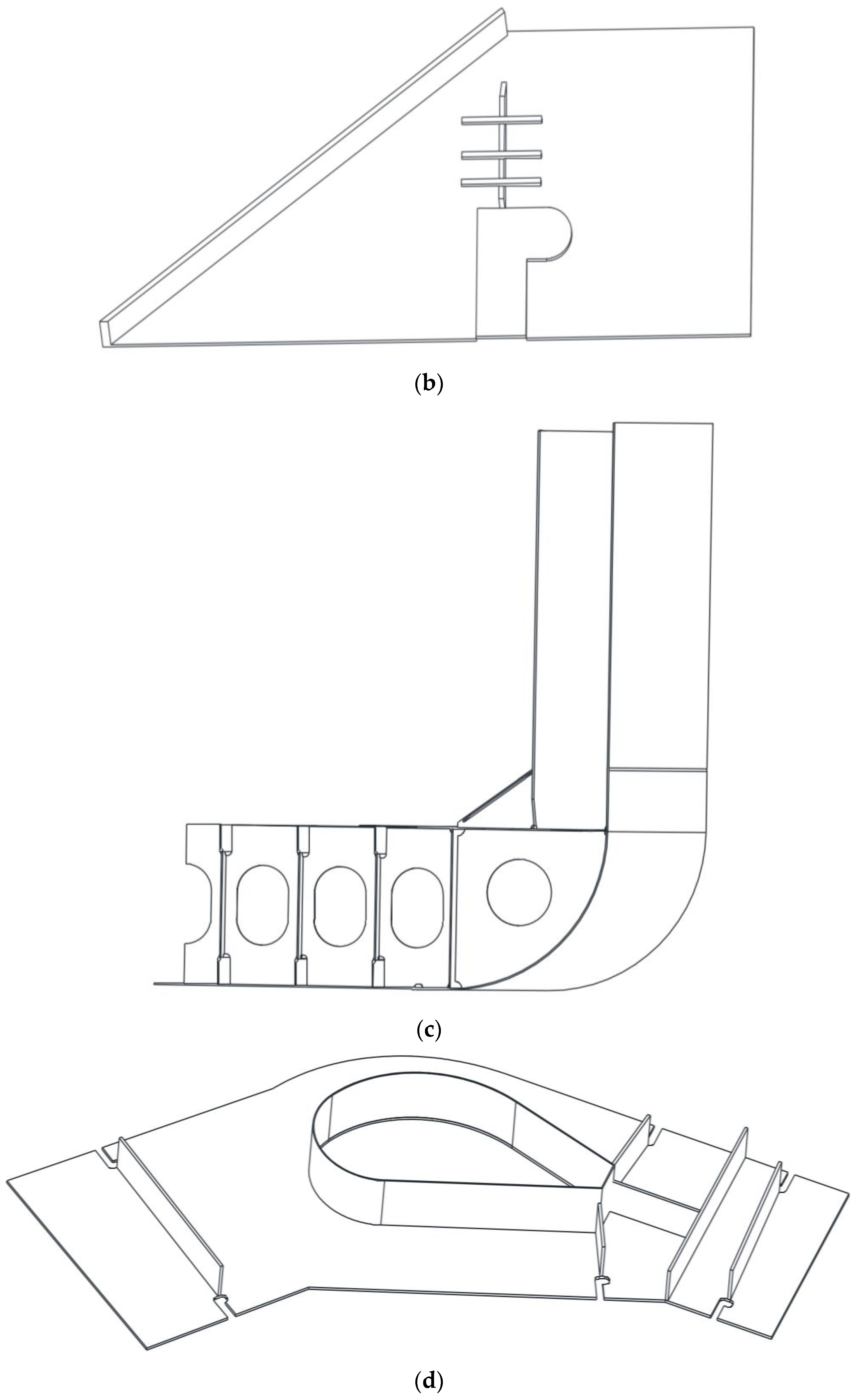

2.2. Environmental Modeling

3. Construction of Objective Function for Path Planning of Welding Robot

3.1. Objective Function Based on Path Length

3.1.1. Path Length Based on Welded Seam

3.1.2. The Moving Length of the Welding Torch without Welding

3.1.3. Total Welding Path Length f(C) of Welding Robot

3.2. Objective Function Based on Energy Loss

- Step 1

- Calculate the kinetic energy and potential energy of the system according to the robot pose at the two welding spots.

- Step 2

- Solve the torque of all joints of the welding robot using inverse dynamics.

- Step 3

- Calculate the energy consumption of the robot moving between the following two welding spots:where T is the total time that the robot moves between two welding spots.

- Step 4

- Calculate the total welding energy consumption by adding the energy consumption between all welding spots according to the planning path of the welding robot.where e△(ci, ci+1) is the energy loss between the welding spot ci and ci+1, and N is the total number of welding spots.

3.3. Multi-Objective Optimization Function

4. Multi-Objective Immune Optimization of Welding Path Planning

4.1. Immune Algorithm Based on Cluster Analysis and Self-Circulation

4.1.1. Clustering Operator

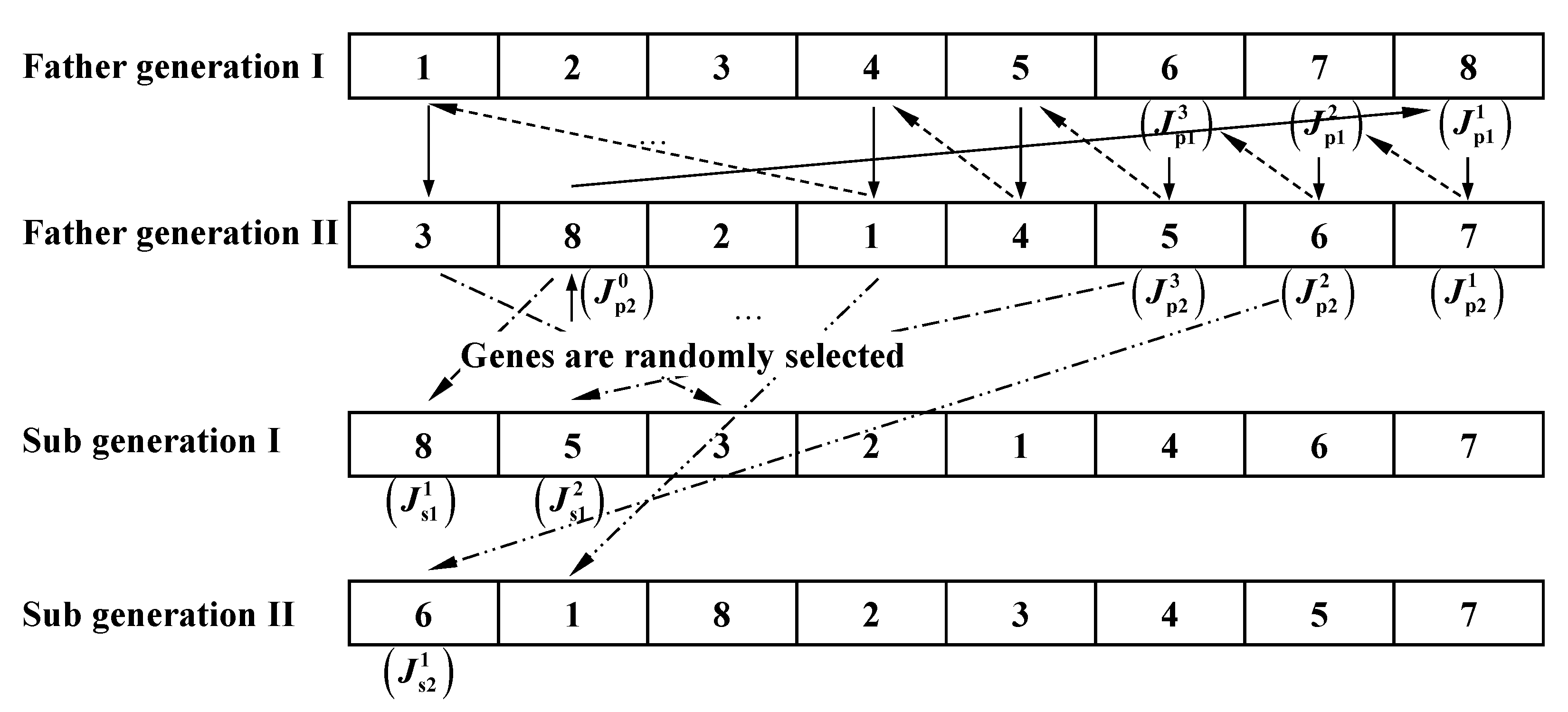

4.1.2. Self-Circulation Crossover Operator

4.1.3. Adaptive Mutation Operator

4.2. Multi-Objective Immune Optimization Process for Path Planning

- Step 1

- Parameter initialization: population size N, iteration generation k, maximum evolutionary generation kmax, k←0, etc.

- Step 2

- Initialize the cluster center Ć according to the coordinate data of the welding spots, and then perform welding spot clustering H←T(Ć) and obtain each new sub-clustering center H(h1, h2, …).

- Step 3

- Search for the optimal planning path for each subclass in H using IOACS.

- ①

- ∀ i = 1, 2,…, initialize the population A(0) for the subclass containing the cluster center hi.

- ②

- Perform self-circulation crossover operator.

- ③

- Perform adaptive mutation operator.

- ④

- Perform immune selection on A’’(k), and obtain a new population A(k + 1).

- ⑤

- Judge whether all classes in H have completed the shortest path planning? If they have, then go to Step 4 (otherwise, go to ①).

- Step 4

- Plan the clustering center using IOACS for each cluster center h1, h2,…, hk in H.

- Step 5

- Perform the connection of each sub-category clustered by adjacent welding spots according to the path of the cluster center planned in Step 4.

- Step 6

- Output the optimal path of the welding robot and terminate the planning.

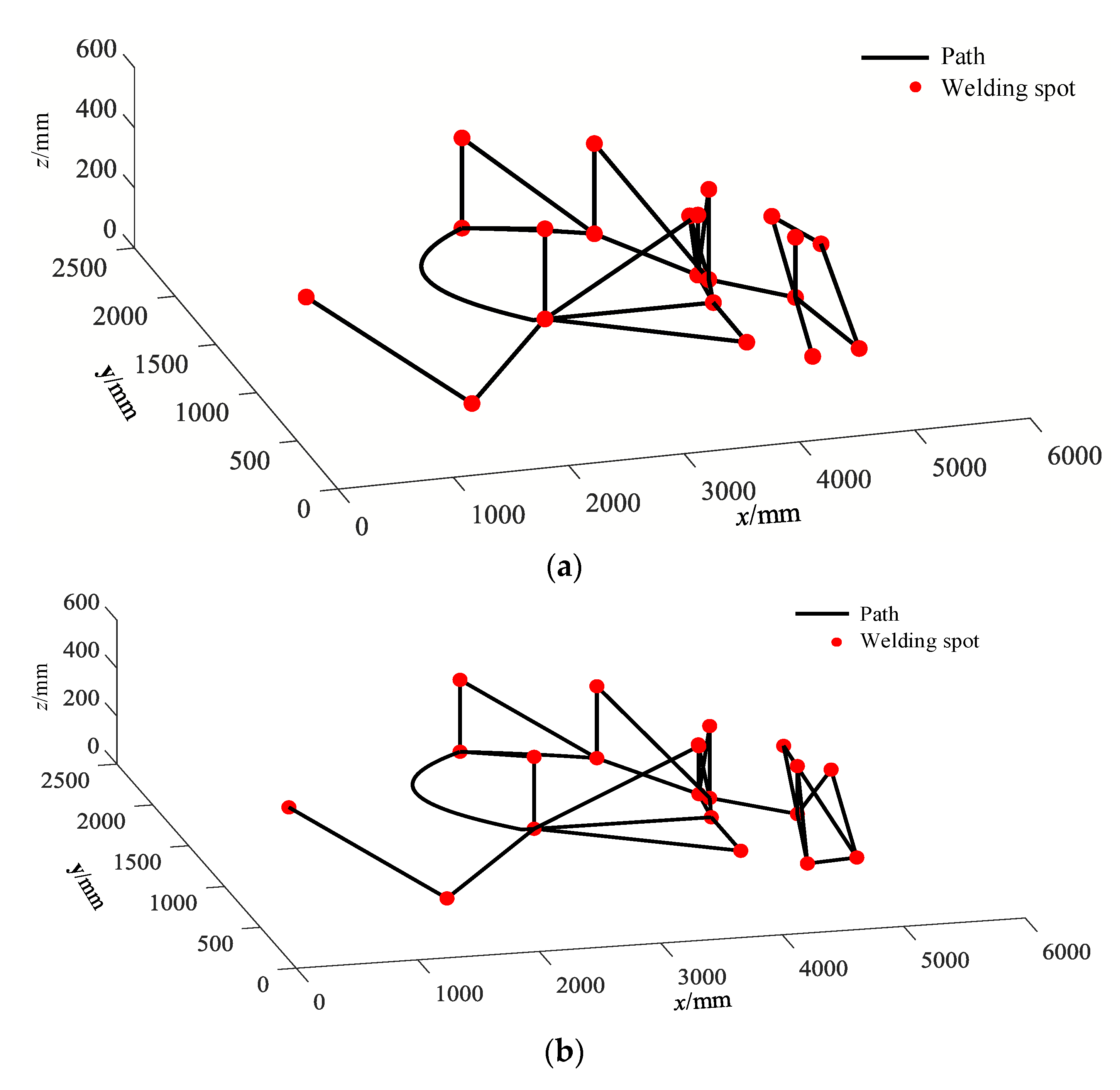

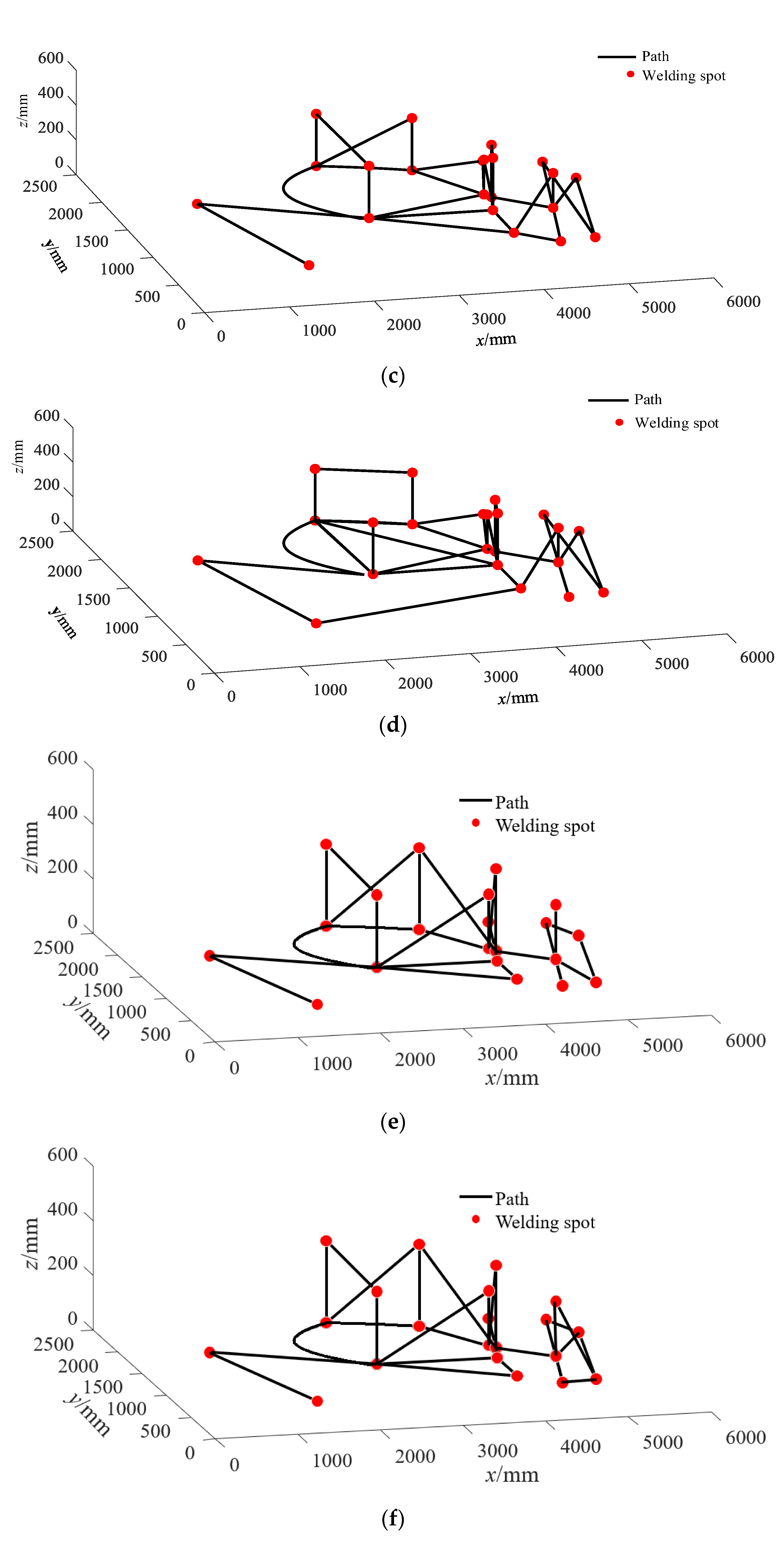

5. Test and Analysis of Multi-Objective Path Planning

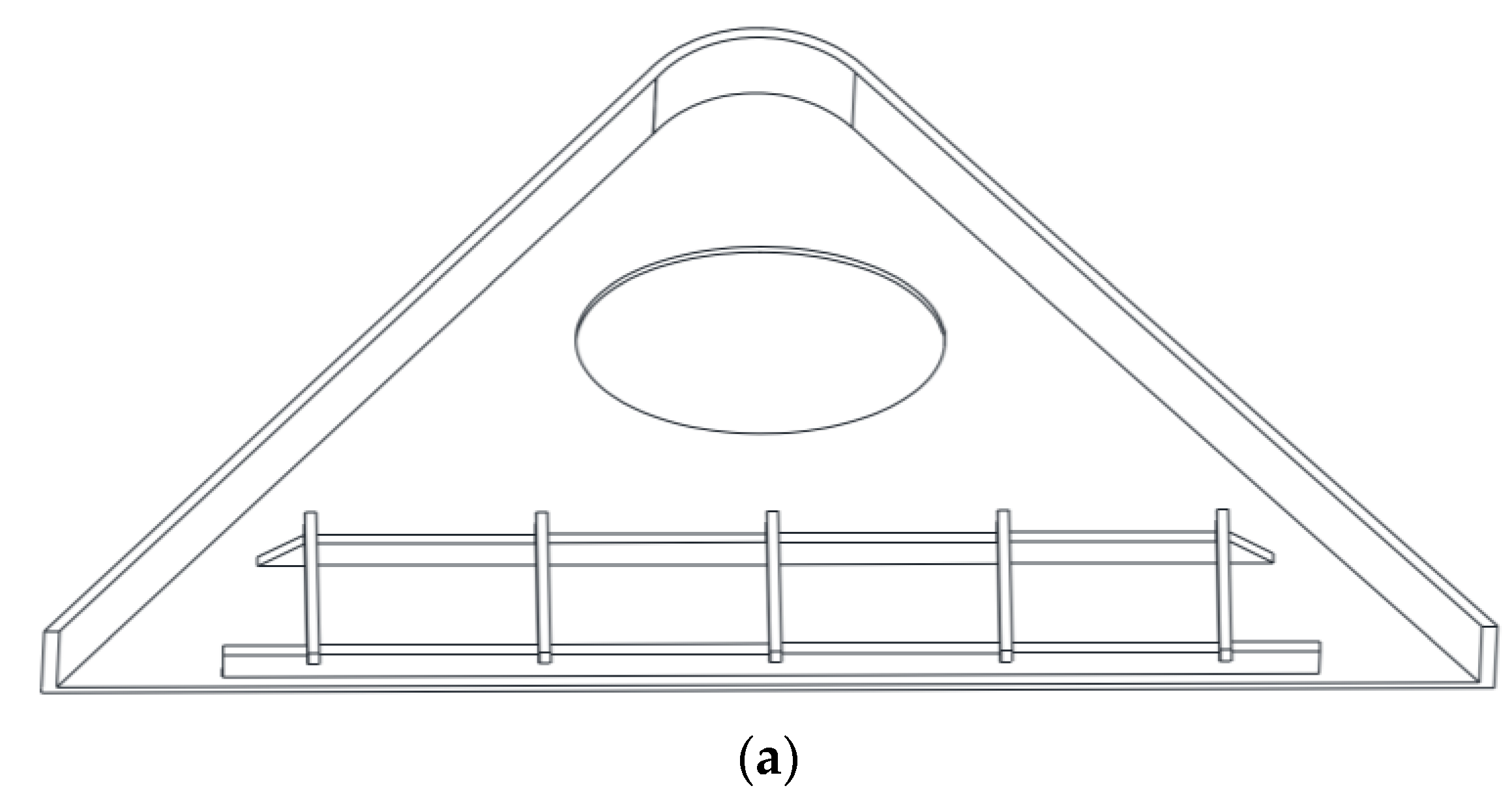

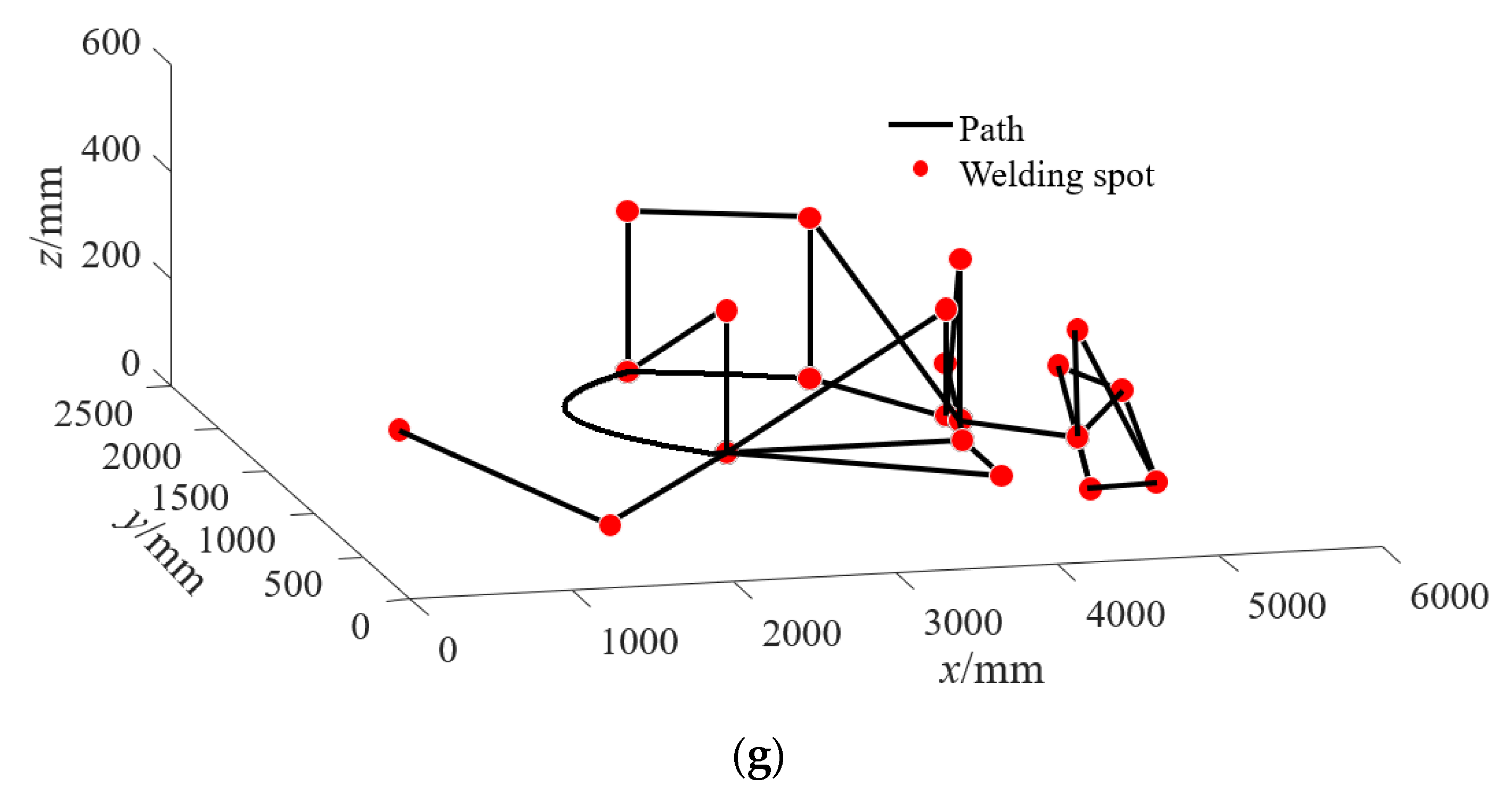

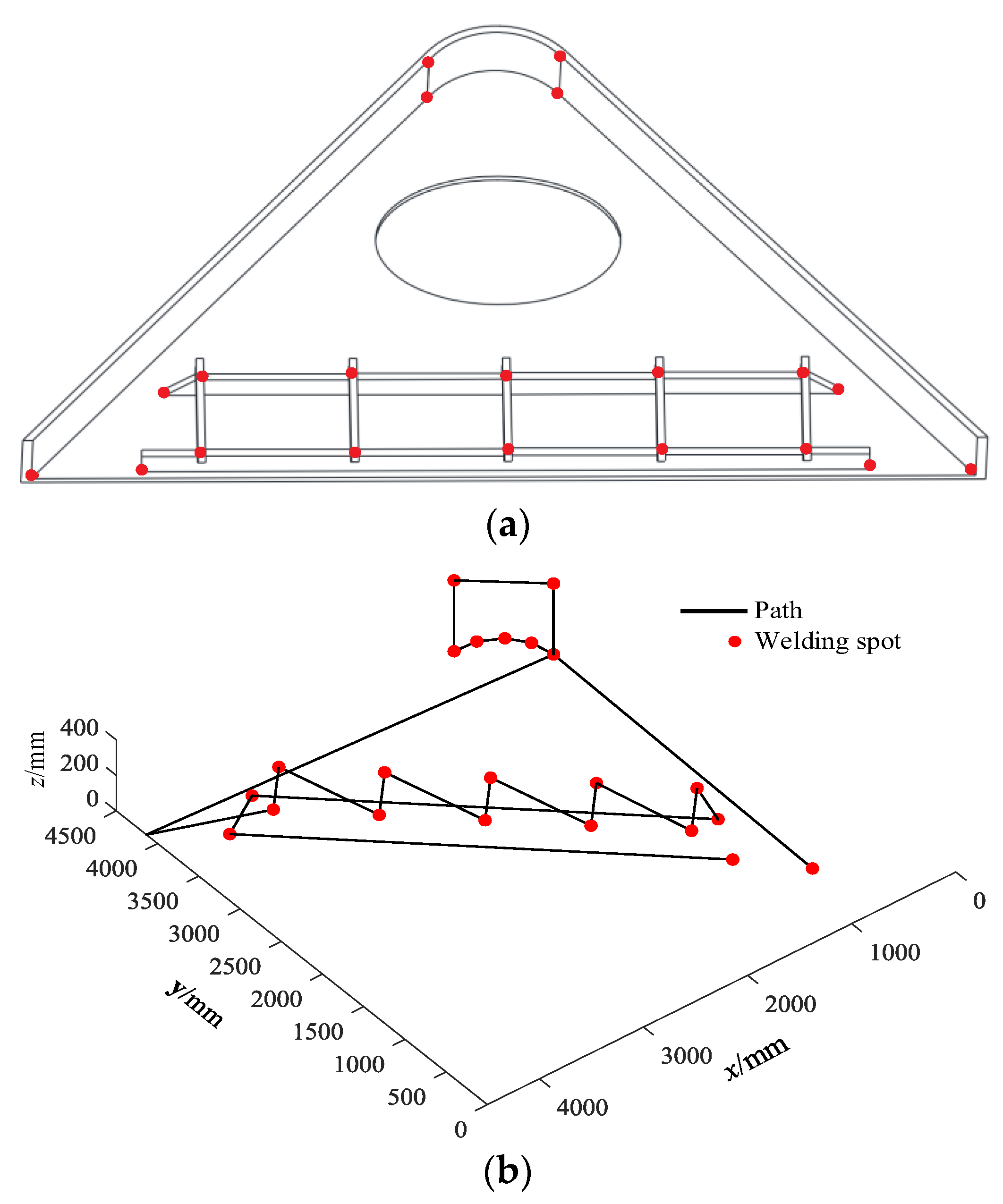

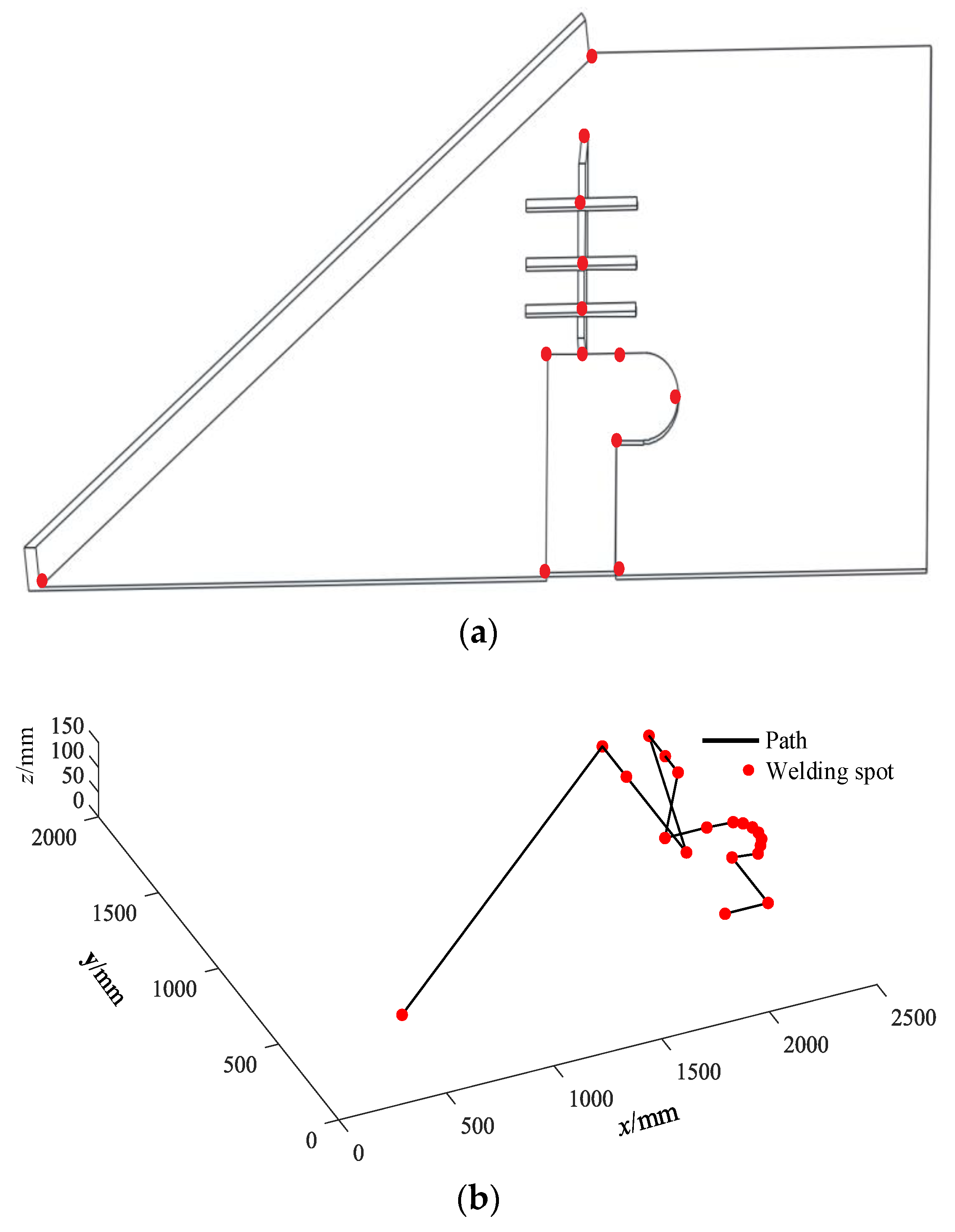

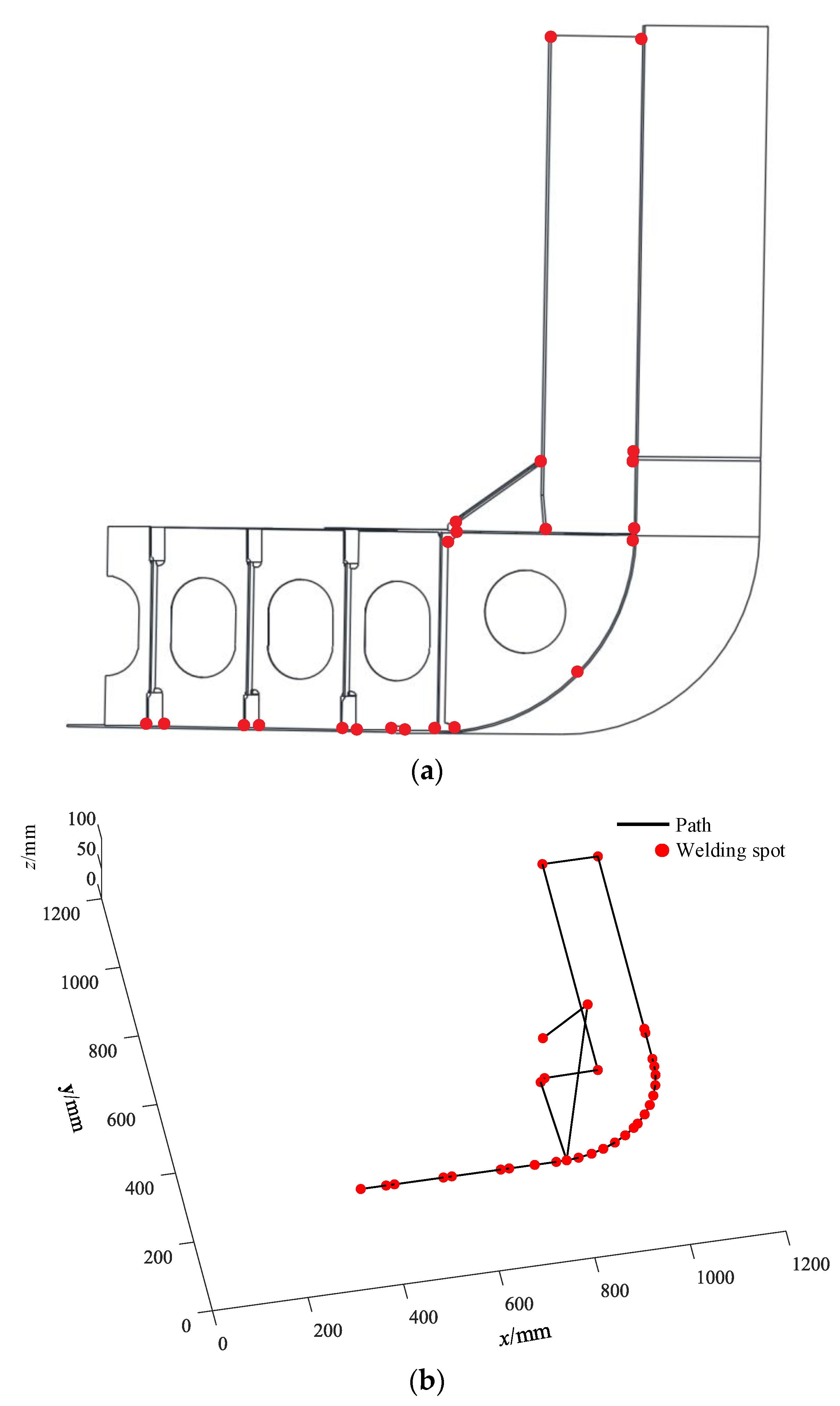

6. Experimental Research on Path Planning of Welding Robot

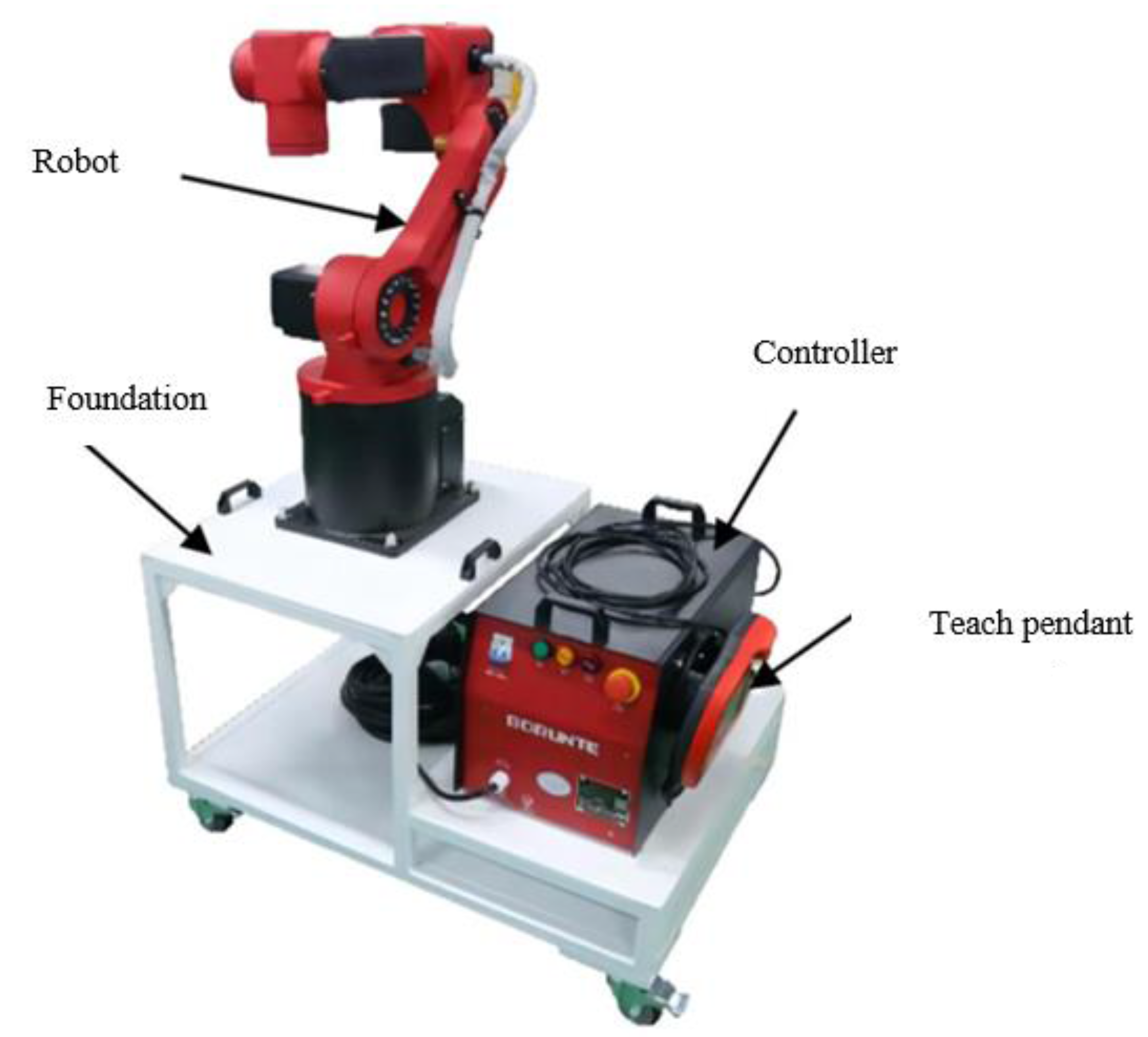

6.1. Construction of Welding Experiment Platform

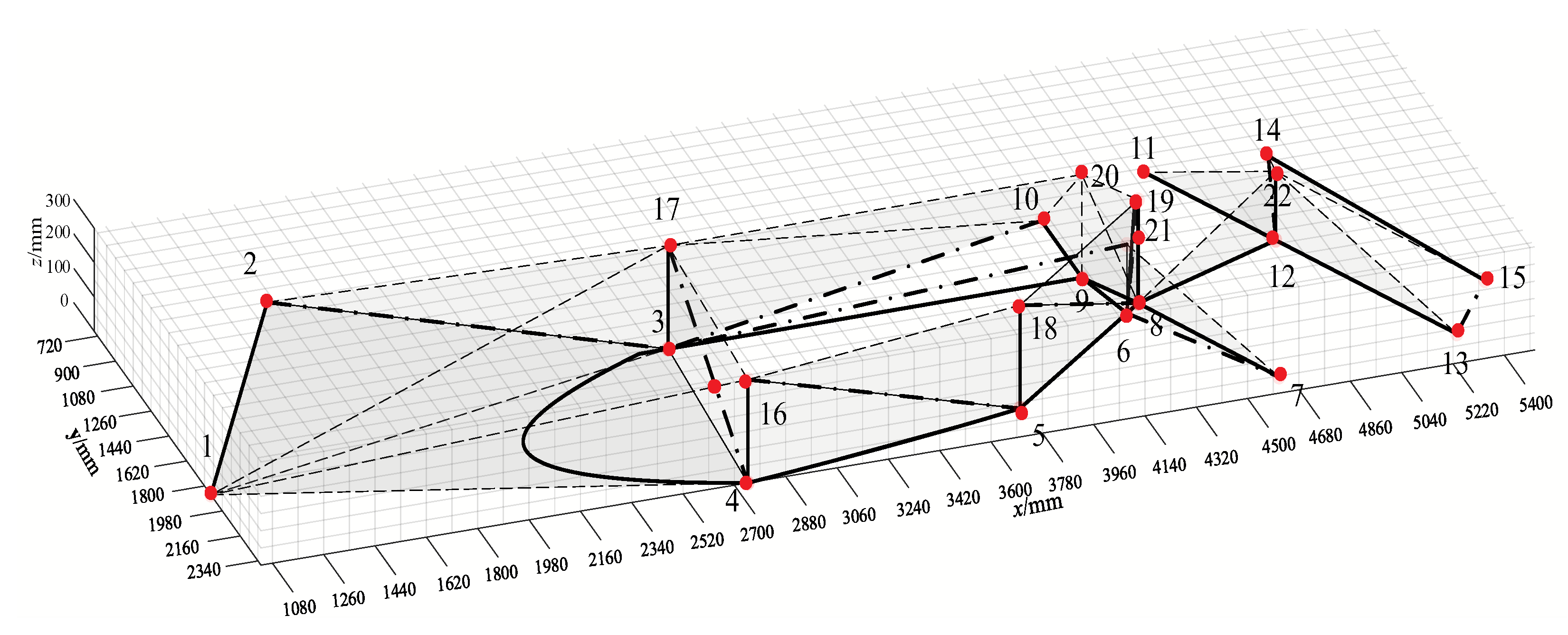

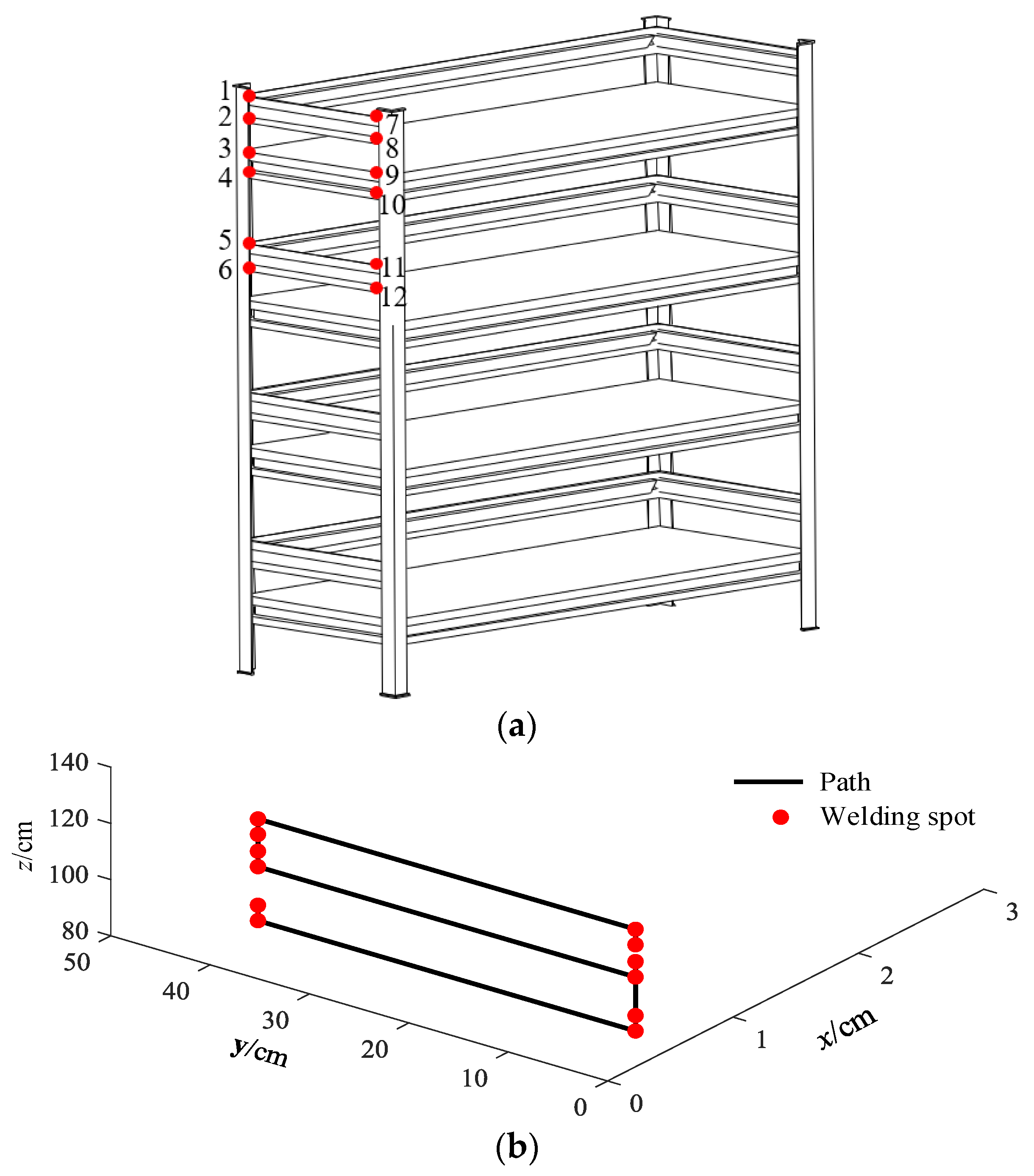

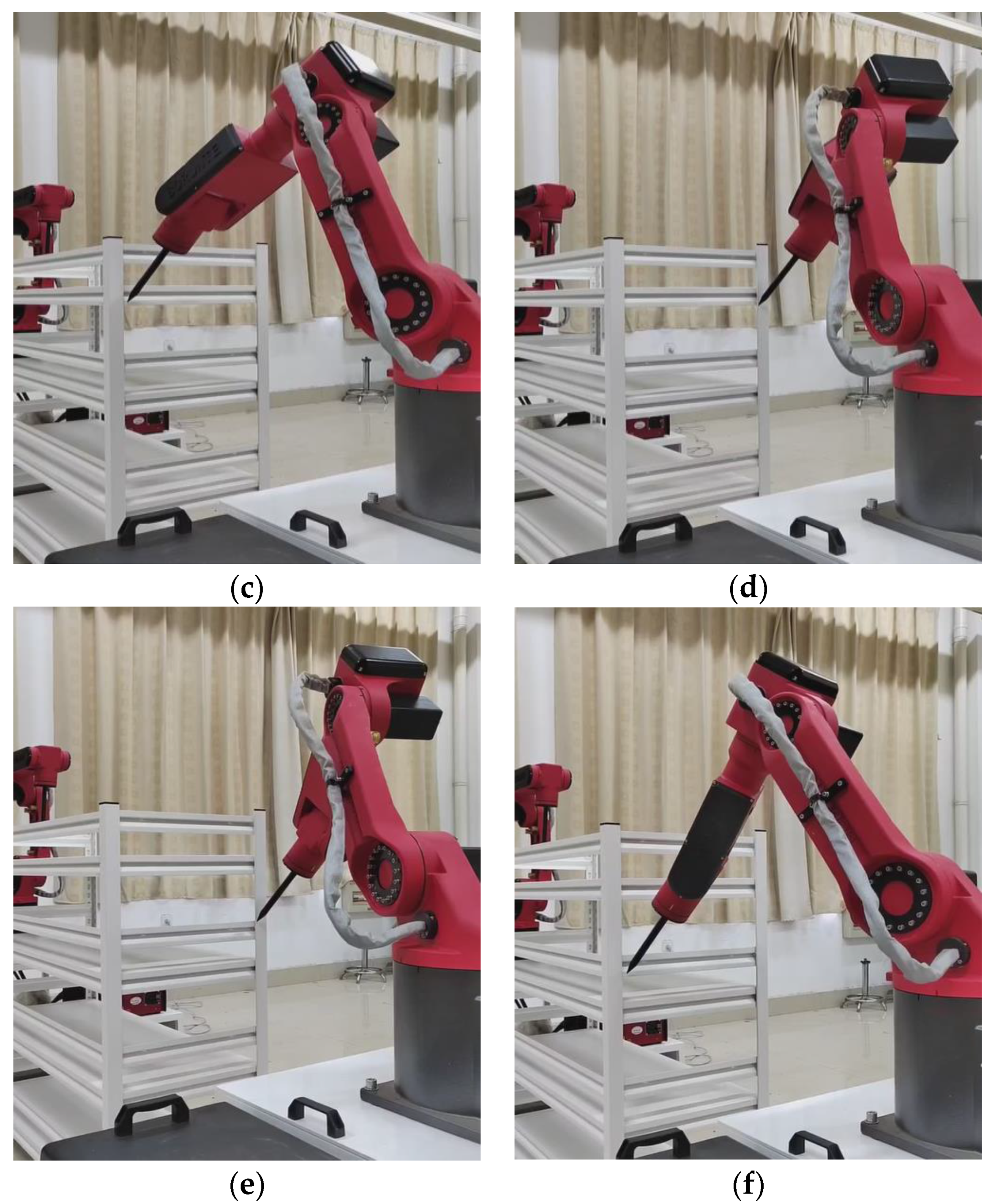

6.2. Experiment and Analysis of Path Planning

7. Discussion

8. Conclusions and Future Work

- According to the working characteristics of the ship welding robot, the length objective function including the welded seam path and the moving path of the welding torch without welding is constructed, which avoids the optimal path search based on a single seam and realizes the path length optimization in the whole working process of the welding robot;

- Based on the dynamic analysis of the welding robot, the energy loss objective function for the path planning of the welding robot is constructed based on the Lagrange equation, which helps to improve the energy utilization rate of the welding robot, reduce joint wear and improve the welding accuracy;

- The multi-objective path planning function of the welding robot is constructed by fusing the path length and energy loss, taking into account the efficiency and cost of the robot operation. At the same time, the global optimization of the welding path is realized through the immune algorithm based on clustering analysis and self-circulation, which improves the optimization accuracy, efficiency, and stability of the path planning algorithm and shows the effectiveness and superiority of the path planning algorithm in this paper.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Khajehzadeh, M.; Taha, M.R.; Elshafie, A.; Eslami, M. Search for critical failure surface in slope stability analysis by gravitational search algorithm. Int. J. Phys. Sci. 2011, 6, 5012–5021. [Google Scholar]

- Eslami, M.; Shareef, H.; Mohamed, A.; Khajehzadeh, M. Damping controller design for power system oscillations using hybrid GA-SQP. Int. Rev. Elec. Eng. 2011, 6, 888–896. [Google Scholar] [CrossRef]

- Eslami, M.; Shareef, H.; Mohamed, A.; Khajehzadeh, M. PSS and TCSC damping controller coordinated design using GSA. Energy Procedia 2012, 14, 763–769. [Google Scholar] [CrossRef]

- Eslami, M.; Shareef, H.; Mohamed, A. Optimization and coordination of damping controls for optimal oscillations damping in multi-machine power system. Int. Rev. Electr. Eng. 2011, 6, 1984–1993. [Google Scholar] [CrossRef]

- Wang, T.; Xue, Z.L.; Dong, X.Q.; Xie, S. Autonomous intelligent planning method for welding path of complex ship components. Robotica 2020, 39, 428–437. [Google Scholar] [CrossRef]

- Nie, F.; Zhao, Z.H. Path planning of welding robot based on changing step fruit fly optimization algorithm. Manuf. Technol. Mach. Tool 2021, 11, 21–25. [Google Scholar] [CrossRef]

- Xue, L.K.; Wang, X.W.; Gu, X.S. Welding robot path planning based on DTC-MOPSO algorithm. Inf. Control 2016, 45, 713–721. [Google Scholar] [CrossRef]

- Wang, X.W.; Shi, Y.P.; Yan, Y.X.; Gu, X.S. Intelligent welding robot path optimization based on discrete elite PSO. Soft Comput. 2016, 21, 5869–5881. [Google Scholar] [CrossRef]

- Yao, J.Y.; Wu, F.Y. Research on path planning method for welding robot based on improved bee colony algorithm. Mach. Tool Hydraul. 2019, 47, 49–52. [Google Scholar] [CrossRef]

- Gao, Y.; Zhang, Y.W. Path optimization of welding robot based on ant colony and genetic algorithm. J. Appl. Math. 2022, 12, 3608899. [Google Scholar] [CrossRef]

- Wang, Q.Y.; Sun, Y.K.; Tang, Q.C.; Ma, L.; Zhao, D.; Yang, J.P.; Xu, J. A dual-robot cooperative welding path planning algorithm based on improved ant colony optimization. In Proceedings of the 6th IFAC Symposium on Telematics Applications TA 2022, Nancy, France, 15–17 June 2022; pp. 7–12. [Google Scholar] [CrossRef]

- Zhang, B.C.; Wu, C.; Pang, Z.X.; Li, Y.; Wang, R.K. Hybrid global optimum beetle antennae search—Genetic algorithm based welding robot path planning. In Proceedings of the 9th Annual International Conference on CYBER Technology in Automation, Control, and Intelligent Systems, Suzhou, China, 29 July–2 August 2019; pp. 1520–1524. [Google Scholar] [CrossRef]

- Xu, Z.F.; Liu, L.L.; Zou, W.; Xu, T.; Yuan, S.B. Multi robot welding path planning based on improved ant colony algorithm. In Proceedings of the 11th International Workshop of Advanced Manufacturing and Automaiton, Zhengzhou, China, 11–12 October 2021; pp. 198–206. [Google Scholar] [CrossRef]

- Machmudah, A.; Parman, S.; Abbasi, A.; Solihin, M.I.; Manan, T.S.A.; Beddu, S.; Ahmad, A.; Rasdi, N.W. Cyclic path planning of hyper-redundant manipulator using whale optimization algorithm. Int. J. Adv. Comput. Appl. 2021, 12, 677–686. [Google Scholar] [CrossRef]

- Fang, Z.; Liang, X. Intelligent obstacle avoidance path planning method for picking manipulator combined with artificial potential field method. Ind. Robot 2022, 49, 835–850. [Google Scholar] [CrossRef]

- Li, X.J.; Liu, H.S.; Dong, M.H. A general framework of motion planning for redundant robot manipulator based on deep reinforcement learning. IEEE Trans. Ind. Inform. 2022, 18, 5253–5263. [Google Scholar] [CrossRef]

- Miao, C.W.; Chen, G.Z.; Yan, C.L.; Wu, C.L. Path planning optimization of indoor mobile robot based on adaptive ant colony algorithm. Comput. Ind. Eng. 2021, 56, 107230. [Google Scholar] [CrossRef]

- Tan, Z.; Liang, H.G.; Zhang, D.; Wang, Q.G. Path planning of surgical needle: A new adaptive intelligent particle swarm optimization method. Trans. Inst. Meas. Control. 2022, 44, 766–774. [Google Scholar] [CrossRef]

- Hu, X.B.; Deng, X. A gantry robot system for cutting single y-shaped welding grooves on plane workpieces. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2021, 235, 45–59. [Google Scholar] [CrossRef]

- Wang, X.W.; Tang, B.; Gu, X.S. Research on obstacle avoidance strategy for welding robot. J. Mech. Eng. 2019, 55, 77–84. [Google Scholar] [CrossRef]

- Wang, W.; Wei, D.D.; Li, L.M. Research on collaborative modeling and obstacle avoidance control for humanoid dual manipulator. Comput. Simul. 2018, 35, 299–305. [Google Scholar] [CrossRef]

- Qiu, B.; Shan, L.; Chang, L.; Wang, Z.Q.; Qu, Y. Collision avoidance path planning of dual manipulators based on bidirectional planning of improved artificial potential field method. J. Jiangsu Univ. Sci. Technol. 2021, 35, 72–79. [Google Scholar]

- Rout, A.; Bbvl, D.; Biswal, B.B. Optimal trajectory generation of an industrial welding robot with kinematic and dynamic constraints. Ind. Robot 2020, 47, 68–75. [Google Scholar] [CrossRef]

- Teng, Y.J.; Chen, W.J.; Yang, T.Y.; Jing, Z.L.; Liu, W.Y. Dynamics analysis of flexible manipulator driven by SMA spring. J. Shanghai Jiaotong Univ. 2021, 55, 1018–1026. [Google Scholar] [CrossRef]

- Zhang, Z.W.; Wu, L.H.; Zhang, W.Q.; Tao, P.; Jun, Z. Energy-efficient path planning for a single-load automated guided vehicle in a manufacturing workshop. Comput. Ind. Eng. 2021, 158, 107397. [Google Scholar] [CrossRef]

- Shen, Y.; Liu, S.D.; Yuan, M.X.; Dai, X.L.; Lan, J.C. Immune optimization of double-sided welding sequence for medium-small assemblies in ships based on inherent strain method. Metals 2022, 12, 1091. [Google Scholar] [CrossRef]

- Yuan, M.X.; Jiang, Y.F.; Hua, X.B.; Wang, B.B.; Shen, Y. A real-time immune planning algorithm incorporating a specific immune mechanism for multi-robots in complex environments. Proc. Inst. Mech. Eng. Part I J. Syst. Control Eng. 2017, 23, 29–42. [Google Scholar] [CrossRef]

- Stogiannos, M.; Alexandridis, A.; Sarimveis, H. An enhanced decentralized artificial immune-based strategy formulation algorithm for swarms of autonomous vehicles. Appl. Soft Comput. 2020, 89, 106135. [Google Scholar] [CrossRef]

- Gao, Y.Q.; Shen, Y.; Yang, Z.; Chen, D.P.; Yuan, M.X. Immune optimization algorithm for traveling salesman problem based on clustering analysis and self-circulation. In Proceedings of the 3rd International Conference on Advanced Information Science and System, Sanya, China, 26–28 November 2021; pp. 48–54. [Google Scholar] [CrossRef]

- Chen, T.G.; Shi, J.W.; Yang, J.J. Enhancing network cluster synchronization capability based on artificial immune algorithm. Hum.-Cent. Comput. Inf. Sci. 2019, 9, 11–19. [Google Scholar] [CrossRef]

- Sun, B.; Jiang, P.; Zhou, G.R.; Dong, D.Y. AGV optimal path planning based on improved genetic algorithm. Comput. Eng. Des. 2020, 41, 550–556. [Google Scholar]

- Lou, G.X.; Cai, Z.Y. Improved hybrid immune clonal selection genetic algorithm and its application in hybrid shop scheduling. Cluster Comput. 2019, 22, 3419–3429. [Google Scholar] [CrossRef]

- Wang, Y.; Han, Z.P. Ant colony optimization for traveling salesman problem based on parameters optimization. Appl. Soft Comput. 2021, 107, 107439. [Google Scholar] [CrossRef]

- Yang, Y.; Luo, K. An artificial bee colony algorithm based on improved search strategy. In Proceedings of the 2nd International Conference on Artificial Intelligence and Information Systems, Chongqing, China, 28 May 2021; pp. 1–4. [Google Scholar] [CrossRef]

- Ahmed, N.; Pawase, C.J.; Chang, K.H. Distributed 3-D path planning for multi-UAVs with full area surveillance based on particle swarm optimization. Appl. Sci. 2021, 11, 3417. [Google Scholar] [CrossRef]

- Shen, Y.; Yuan, M.X.; Wang, Q. Viros evolutionary immune clonal algorithm for optimization of manipulator. Comput. Eng. Appl. 2011, 47, 224–226. [Google Scholar] [CrossRef]

- Dai, X.L.; Shen, Y.; Cao, R.X.; Sun, H.W.; Yuan, M.X. Feature recognition of ship welding seam based on triangulation and contour analysis. Sci. Technol. Eng. 2022, 22, 12491–12498. [Google Scholar]

- Yuan, M.X.; Dai, X.L.; Liu, C.; Sun, H.W.; Wang, L. Feature parameters extraction of ship welds based on spatial position and contour distance. Trans. China Weld. Inst. 2023, 22, 84–92. [Google Scholar] [CrossRef]

| Ship Weldments | Performance Index | SGA | IGA | ACO | IOACS | |

|---|---|---|---|---|---|---|

| Side plate weldment | Length/mm | Minimum | 5107.16 | 4936.11 | 4801.07 | 4698.33 |

| Average | 5832.97 | 5371.61 | 5071.13 | 4869.34 | ||

| Standard deviation | 112.13 | 80.89 | 78.82 | 29.83 | ||

| Inner bottom plate weldment | Length/mm | Minimum | 2091.35 | 1879.31 | 1806.18 | 1791.12 |

| Average | 2310.17 | 1977.32 | 1910.11 | 1832.29 | ||

| Standard deviation | 65.93 | 47.29 | 59.61 | 24.98 | ||

| Bilge plate weldment | Length/mm | Minimum | 3521.19 | 3237.84 | 3018.19 | 2869.22 |

| Average | 3697.17 | 3431.91 | 3077.33 | 2981.39 | ||

| Standard deviation | 64.23 | 43.22 | 51.62 | 25.22 | ||

| Base plate weldment | Length/mm | Minimum | 5239.17 | 4896.25 | 4783.66 | 4633.15 |

| Average | 5362.71 | 5217.53 | 5007.32 | 4818.22 | ||

| Standard deviation | 109.31 | 71.11 | 72.7 | 27.31 | ||

| Ship Weldments | Performance Index | ABC | PSO | ICO | ||

| Side plate weldment | Length/mm | Minimum | 4931.40 | 4975.21 | 4731.05 | |

| Average | 5402.64 | 5569.33 | 4932.61 | |||

| Standard deviation | 81.42 | 91.93 | 35.42 | |||

| Inner bottom plate weldment | Length/mm | Minimum | 1869.44 | 1971.42 | 1801.21 | |

| Average | 2013.21 | 2108.26 | 1899.15 | |||

| Standard deviation | 49.34 | 53.12 | 34.23 | |||

| Bilge plate weldment | Length/mm | Minimum | 3269.40 | 3348.41 | 2938.26 | |

| Average | 3376.37 | 3578.16 | 3057.43 | |||

| Standard deviation | 44.57 | 52.34 | 36.28 | |||

| Base plate weldment | Length/mm | Minimum | 5041.27 | 4806.17 | 4702.41 | |

| Average | 5302.18 | 5116.43 | 4936.24 | |||

| Standard deviation | 88.74 | 68.94 | 51.48 | |||

| Ship Weldments | Performance Index | SGA | IGA | ACO | IOACS | |

|---|---|---|---|---|---|---|

| Side plate weldment | Energy consumption/KJ | Minimum | 8.07 | 7.38 | 7.17 | 7.03 |

| Average | 8.65 | 7.71 | 7.42 | 7.19 | ||

| Standard deviation | 0.69 | 0.43 | 0.36 | 0.29 | ||

| Inner bottom plate weldment | Energy consumption/KJ | Minimum | 4.92 | 4.53 | 4.67 | 4.47 |

| Average | 5.62 | 5.21 | 4.99 | 4.76 | ||

| Standard deviation | 0.63 | 0.58 | 0.45 | 0.42 | ||

| Bilge plate weldment | Energy consumption/KJ | Minimum | 6.43 | 5.82 | 5.48 | 5.26 |

| Average | 7.41 | 6.97 | 6.53 | 6.39 | ||

| Standard deviation | 1.62 | 1.41 | 1.29 | 1.46 | ||

| Base plate weldment | Energy consumption/KJ | Minimum | 8.61 | 7.66 | 7.21 | 6.99 |

| Average | 8.41 | 7.78 | 7.27 | 7.13 | ||

| Standard deviation | 0.39 | 0.27 | 0.29 | 0.23 | ||

| Ship Weldments | Performance Index | ABC | PSO | ICO | ||

| Side plate weldment | Energy consumption/KJ | Minimum | 7.29 | 7.94 | 7.12 | |

| Average | 7.65 | 8.41 | 7.34 | |||

| Standard deviation | 0.41 | 0.54 | 0.37 | |||

| Inner bottom plate weldment | Energy consumption/KJ | Minimum | 4.43 | 4.94 | 4.60 | |

| Average | 5.35 | 5.53 | 4.82 | |||

| Standard deviation | 0.54 | 0.62 | 0.46 | |||

| Bilge plate weldment | Energy consumption/KJ | Minimum | 5.88 | 6.13 | 5.30 | |

| Average | 7.09 | 7.04 | 6.42 | |||

| Standard deviation | 1.55 | 1.52 | 1.49 | |||

| Base plate weldment | Energy consumption/KJ | Minimum | 7.24 | 8.03 | 7.14 | |

| Average | 7.75 | 8.28 | 7.30 | |||

| Standard deviation | 0.28 | 0.31 | 0.22 | |||

| Ship Weldments | Performance Index | SGA | IGA | ACO | IOACS | |

|---|---|---|---|---|---|---|

| Side plate weldment | Convergence generation | Minimum | 766 | 637 | 601 | 267 |

| Average | 872.71 | 731.52 | 694.41 | 510.48 | ||

| Standard deviation | 109.32 | 77.43 | 82.33 | 30.12 | ||

| Inner bottom plate weldment | Convergence generation | Minimum | 498 | 421 | 376 | 159 |

| Average | 529.43 | 487.32 | 402.23 | 344.27 | ||

| Standard deviation | 67.15 | 47.32 | 52.51 | 27.11 | ||

| Bilge plate weldment | Convergence generation | Minimum | 511 | 487 | 456 | 177 |

| Average | 577.80 | 529.12 | 497.15 | 402.92 | ||

| Standard deviation | 71.12 | 46.73 | 53.66 | 26.11 | ||

| Base plate weldment | Convergence generation | Minimum | 723 | 605 | 540 | 180 |

| Average | 832.81 | 701.74 | 664.22 | 441.91 | ||

| Standard deviation | 97.17 | 74.18 | 77.44 | 30.53 | ||

| Ship Weldments | Performance Index | ABC | PSO | ICO | ||

| Side plate weldment | Convergence generation | Minimum | 615 | 715 | 421 | |

| Average | 714.63 | 792.40 | 533.41 | |||

| Standard deviation | 79.43 | 89.43 | 44.23 | |||

| Inner bottom plate weldment | Convergence generation | Minimum | 416 | 463 | 226 | |

| Average | 492.30 | 503.64 | 401.35 | |||

| Standard deviation | 45.28 | 48.32 | 35.69 | |||

| Bilge plate weldment | Convergence generation | Minimum | 481 | 504 | 237 | |

| Average | 543.25 | 562.53 | 396.46 | |||

| Standard deviation | 56.38 | 66.37 | 34.69 | |||

| Base plate weldment | Convergence generation | Minimum | 613 | 684.35 | 413 | |

| Average | 743.69 | 710.65 | 592.34 | |||

| Standard deviation | 69.84 | 84.36 | 44.94 | |||

| Number | x/mm | y/mm | z/mm | Number | x/mm | y/mm | z/mm |

|---|---|---|---|---|---|---|---|

| 1 | 1039.9 | 1864.1 | 0 | 12 | 4940.9 | 1382.2 | 0 |

| 2 | 1646.1 | 686.5 | 0 | 13 | 5298.9 | 2180.6 | 0 |

| 3 | 2797.1 | 1421.3 | 0 | 14 | 5105.5 | 832.6 | 0 |

| 4 | 2747.3 | 2369.9 | 0 | 15 | 5505.7 | 1868.8 | 0 |

| 5 | 3765.3 | 2186.6 | 0 | 16 | 2747.3 | 2369.9 | 300 |

| 6 | 4370.1 | 1690.6 | 0 | 17 | 2797.1 | 1421.3 | 300 |

| 7 | 4646.5 | 2265.3 | 0 | 18 | 3765.3 | 2186.6 | 300 |

| 8 | 4370.1 | 1637.9 | 0 | 19 | 4370.1 | 1637.9 | 300 |

| 9 | 4250.8 | 1413.3 | 0 | 20 | 4250.8 | 1413.3 | 300 |

| 10 | 4250.8 | 1002.7 | 0 | 21 | 4370.1 | 1690.6 | 200 |

| 11 | 4681.4 | 802.7 | 0 | 22 | 4940.9 | 1382.2 | 200 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, Y.; Gao, Y.; Yuan, M.; Sun, H.; Guo, Z. Multi-Objective Immune Optimization of Path Planning for Ship Welding Robot. Electronics 2023, 12, 2040. https://doi.org/10.3390/electronics12092040

Shen Y, Gao Y, Yuan M, Sun H, Guo Z. Multi-Objective Immune Optimization of Path Planning for Ship Welding Robot. Electronics. 2023; 12(9):2040. https://doi.org/10.3390/electronics12092040

Chicago/Turabian StyleShen, Yi, Yunqiang Gao, Mingxin Yuan, Hongwei Sun, and Zhenjie Guo. 2023. "Multi-Objective Immune Optimization of Path Planning for Ship Welding Robot" Electronics 12, no. 9: 2040. https://doi.org/10.3390/electronics12092040

APA StyleShen, Y., Gao, Y., Yuan, M., Sun, H., & Guo, Z. (2023). Multi-Objective Immune Optimization of Path Planning for Ship Welding Robot. Electronics, 12(9), 2040. https://doi.org/10.3390/electronics12092040