Apple-Picking Robot Picking Path Planning Algorithm Based on Improved PSO

Abstract

1. Introduction

2. Method of Apple-Picking Path Planning

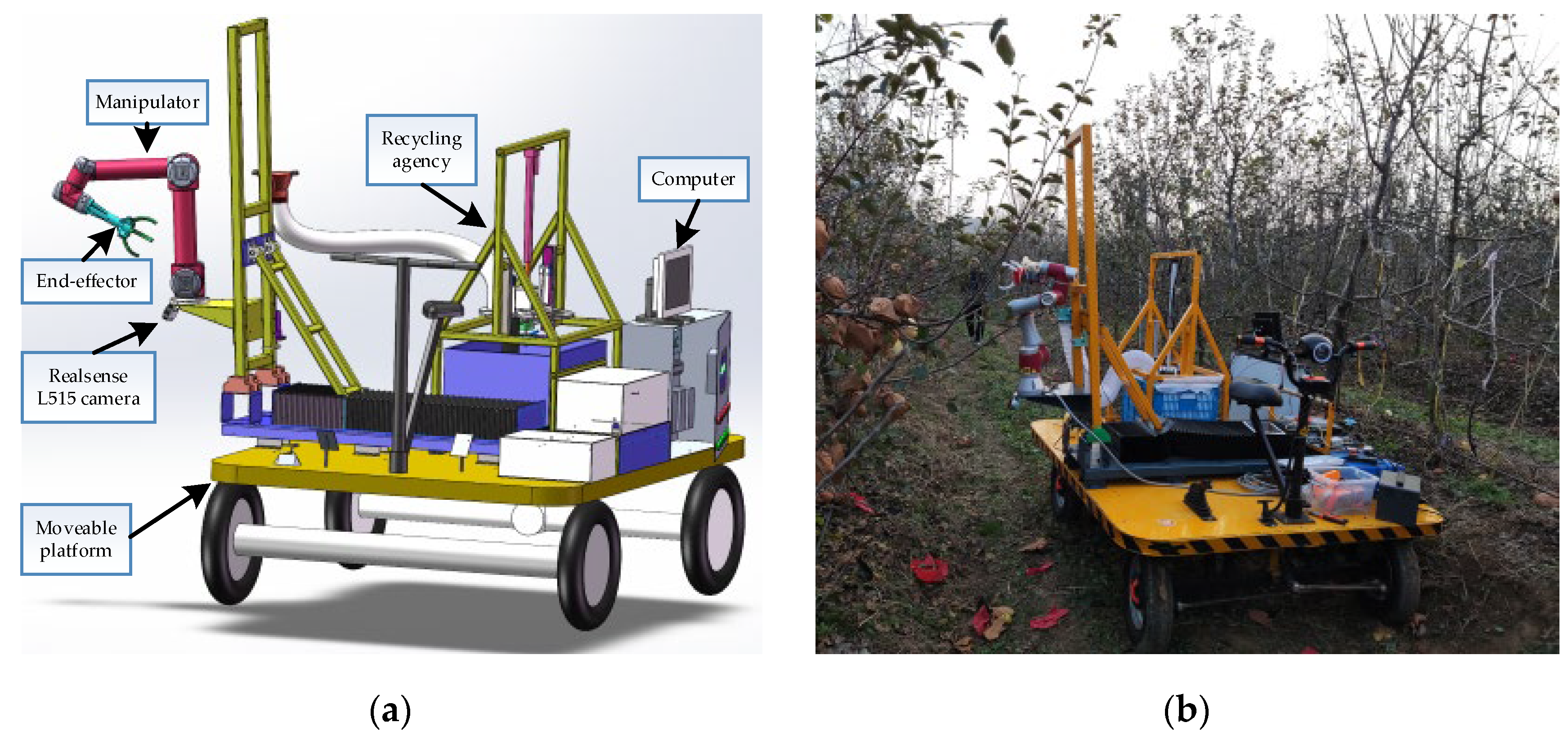

2.1. Components of the Apple-Picking Robot System

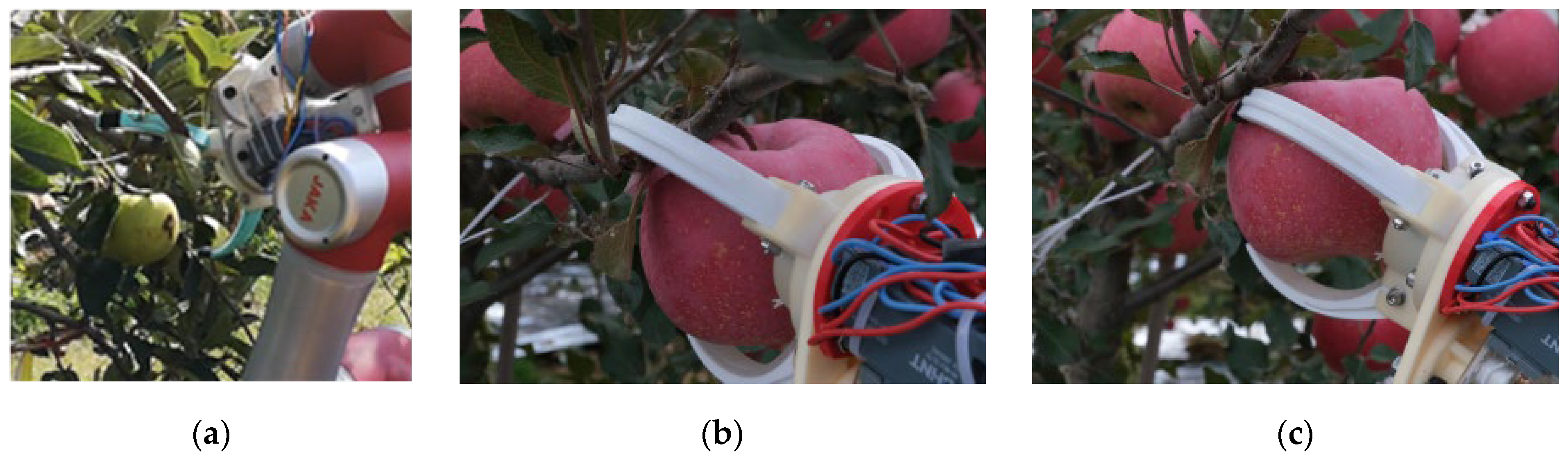

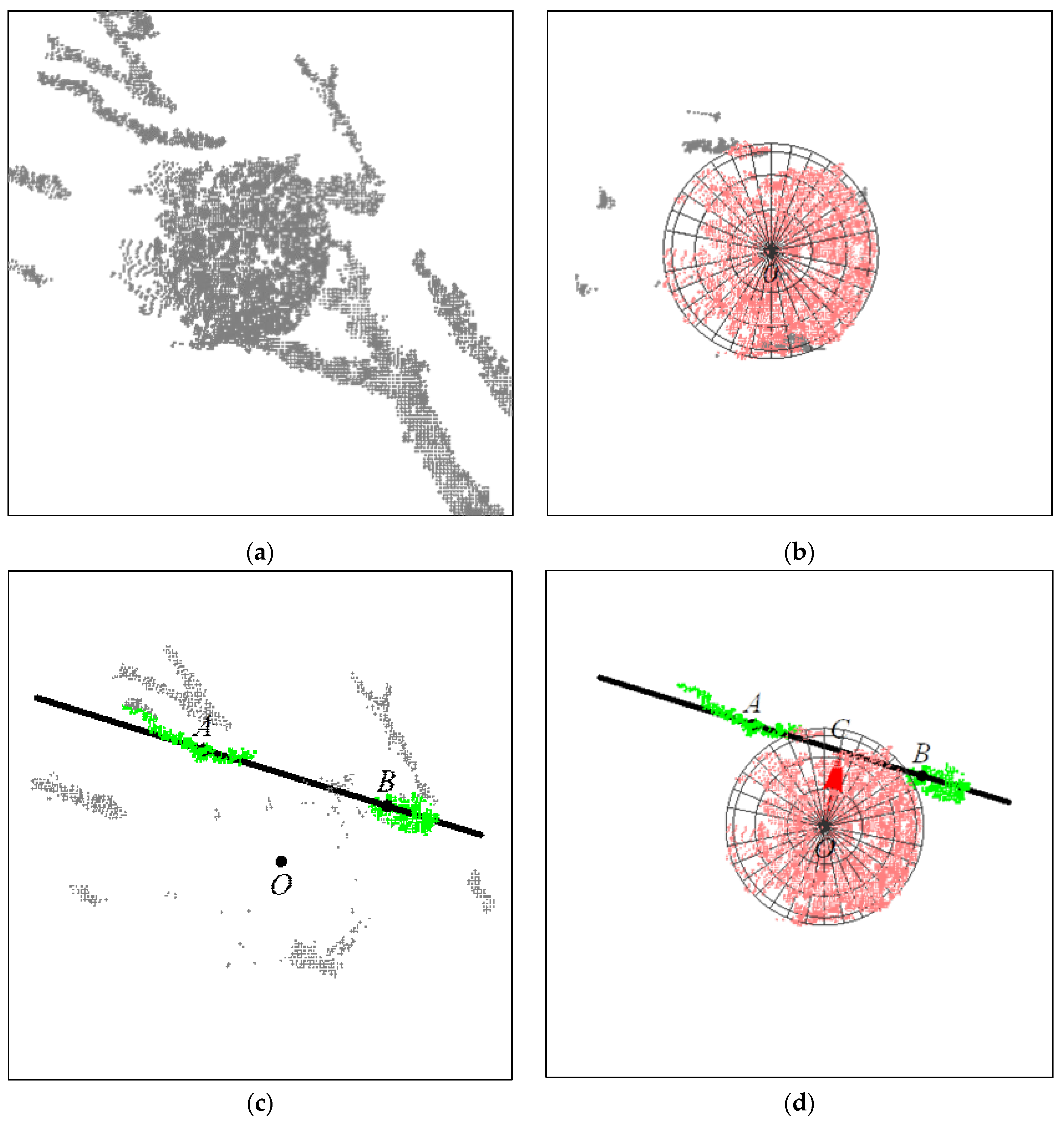

2.2. Calculation of Apple-Picking Direction

- Firstly, the apple’s region of interest (ROI) is delineated in the RGB image using a target recognition algorithm.

- Secondly, segment the point cloud data inside this region, use the random sampling consistent algorithm (RANSAC) [23,24] to eliminate the abnormal data in the point cloud, and fit the point cloud of the fruit surface to a sphere, with the center of the sphere as the center of the apple, to improve the accuracy and anti-interference ability of the fruit localization algorithm.

- Then, extract the point cloud of the sphere space with the target apple as the center and three times the radius of the fruit as the radius and use the RANSAC algorithm in this point cloud to extract the branch with the most surface point cloud that has the most influence on picking and fit it to a straight line.

- Finally, the analytical geometry calculates the straight line over the center of the sphere and perpendicular to the known spatial line.

2.3. Obstacle Modeling

2.3.1. Fitting the Fruit to a Sphere

2.3.2. Fitting Tree Branches to Parallel Hexahedra

- Form the covariance matrix A with all the points in the electric cloud:where:

- Solving the unit eigenvectors of the covariance matrix, which are the three principal directions , , and of the requested minimum external parallel hexahedron.

- Rotate the three main directions obtained to be parallel to the axes of the world coordinate system, and the rotation matrix is , and the point cloud after rotation is :

- After rotating the point cloud in the main direction, the length, width, and height are calculated from the polar values of the three coordinates:where , , , , , and are the maximum and minimum values of the rotated point cloud in the direction of the x, y, and z three-coordinate axes.

- Find the geometric center of the cube

- Since this center is obtained by rotating the point cloud, it is necessary to counter-rotate this center back to the original coordinate system:

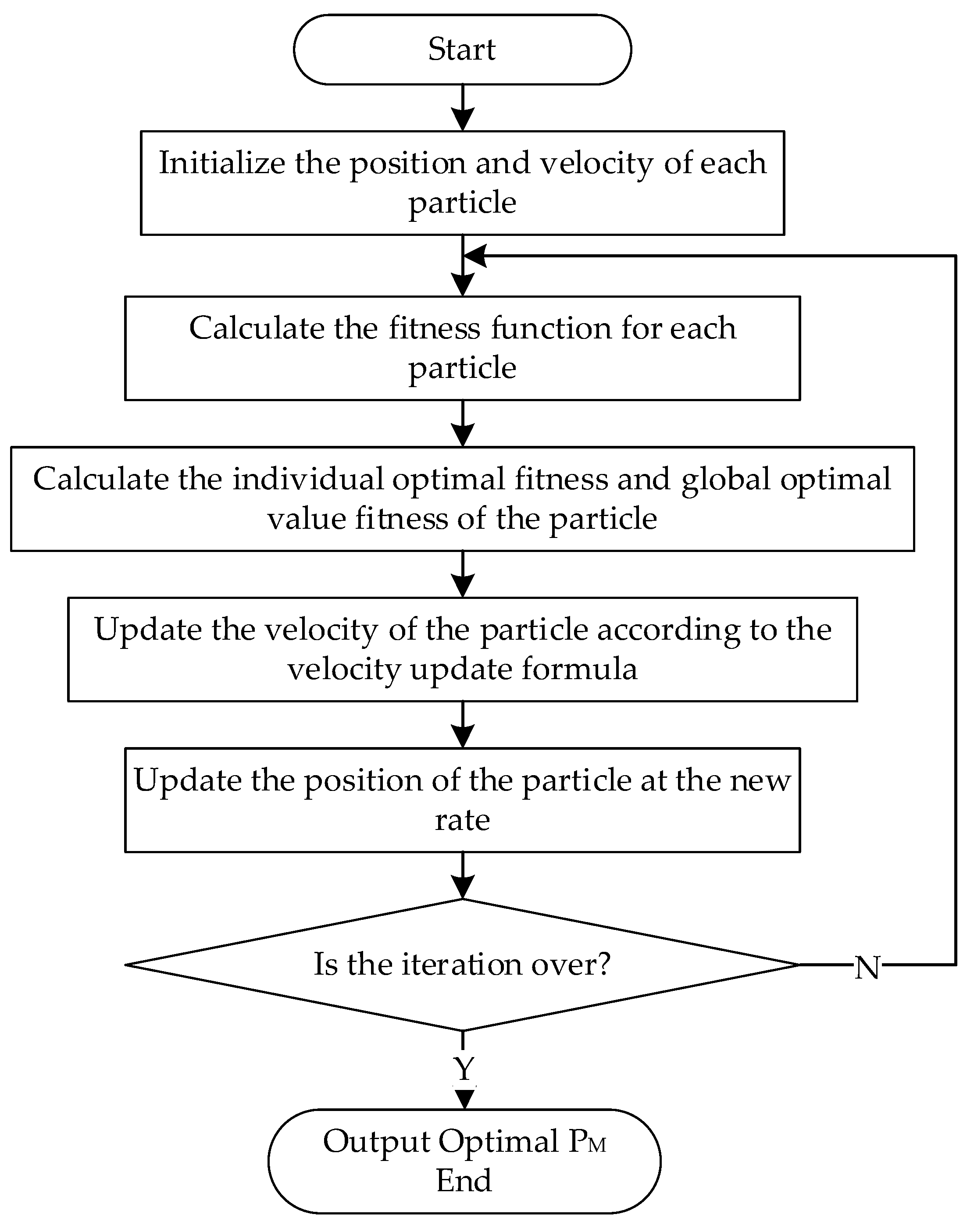

2.4. Picking Path Planning Based on Improved PSO Algorithm

2.4.1. Mathematical Representation of Apple-Picking Paths

2.4.2. Obstacle Avoidance Point Selection Based on Adaptive Parameter PSO Algorithm

- Initialization: In the robot workspace, n particles are randomly generated, and for each particle, an initial position and an initial moving velocity are randomly selected, and each particle can determine a picking path , with i denoting the particle number and j denoting the number of iterations.

- Calculate the fitness: Calculate the fitness of each particle at this time. In this project, use the length of the picking path as the fitness of this particle at this time, that is , then the smaller the value of the fitness means that this particle is better. If this path collides with an obstacle, then this particle does not participate in the fitness evaluation this time and adjusts its moving direction so that the path avoids the obstacle.

- Find the individual history best adaptation value , that is, the best adaptation value in the first j iterations of the ith particle, whose corresponding particle position is .

- Find the population’s best adaptation value , that is, the best adaptation value among all particles, and this particle position is .

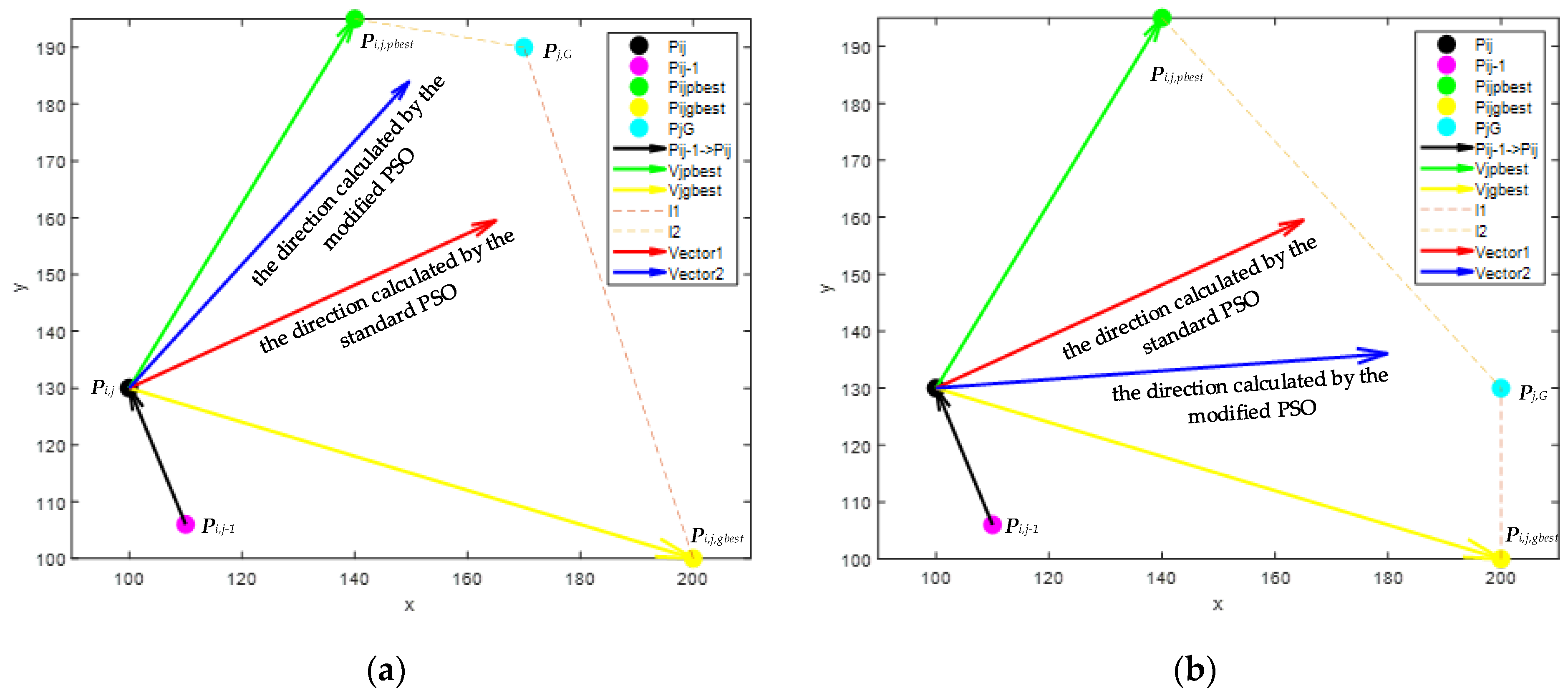

- Update the velocity and position of the particles: The difference of the PSO algorithm with adaptive weights proposed in this paper is the way to update the velocity. Equation (13) is the particle velocity update formula.where and are random numbers between 0 and 1 to increase the randomness of particle search, is the inertia weight, is the own learning factor, and is the population learning factor. To prevent the occurrence of a blind search of particles and skipping the optimal solution due to excessive velocity, the maximum value of velocity needs to be limited.

3. Results

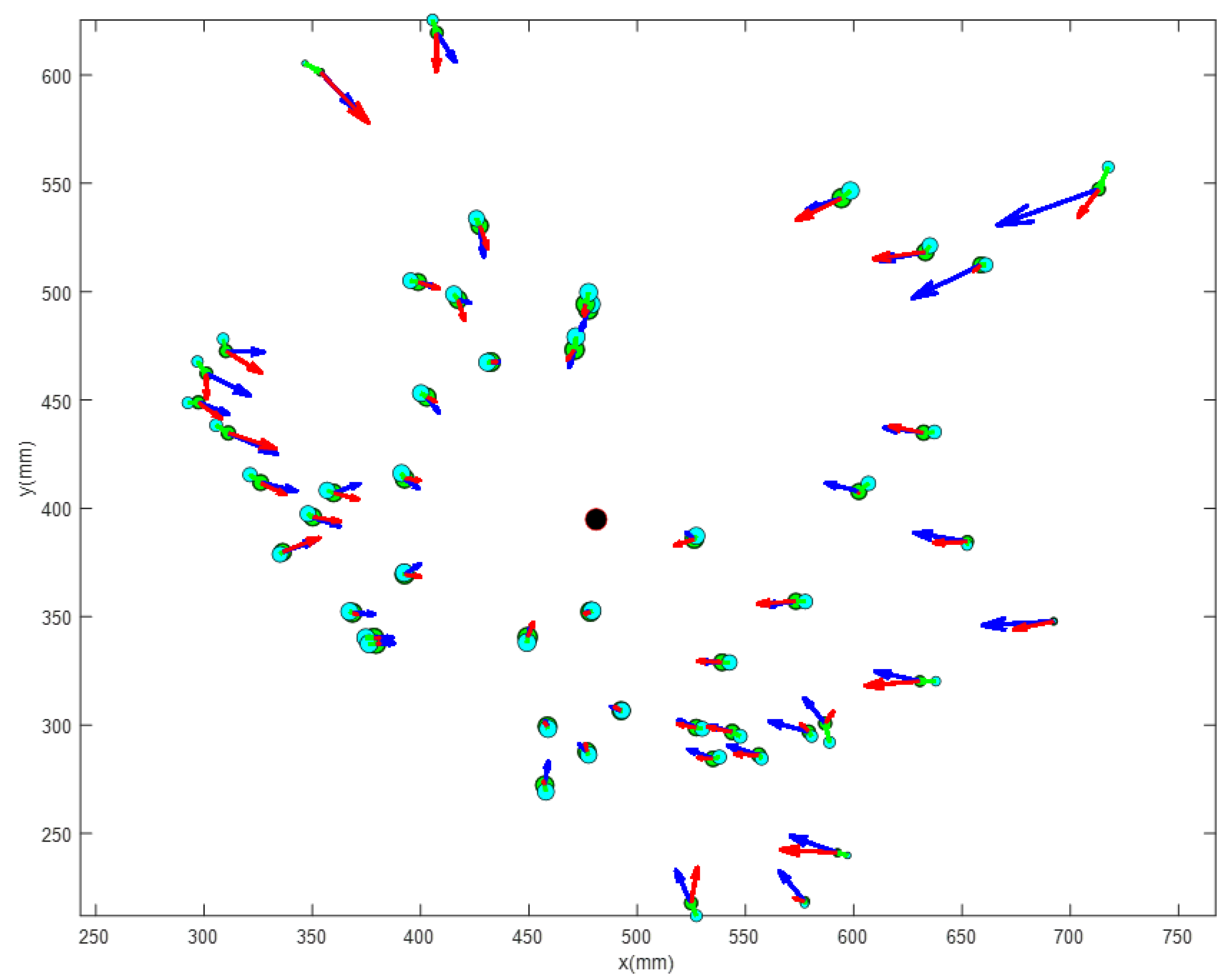

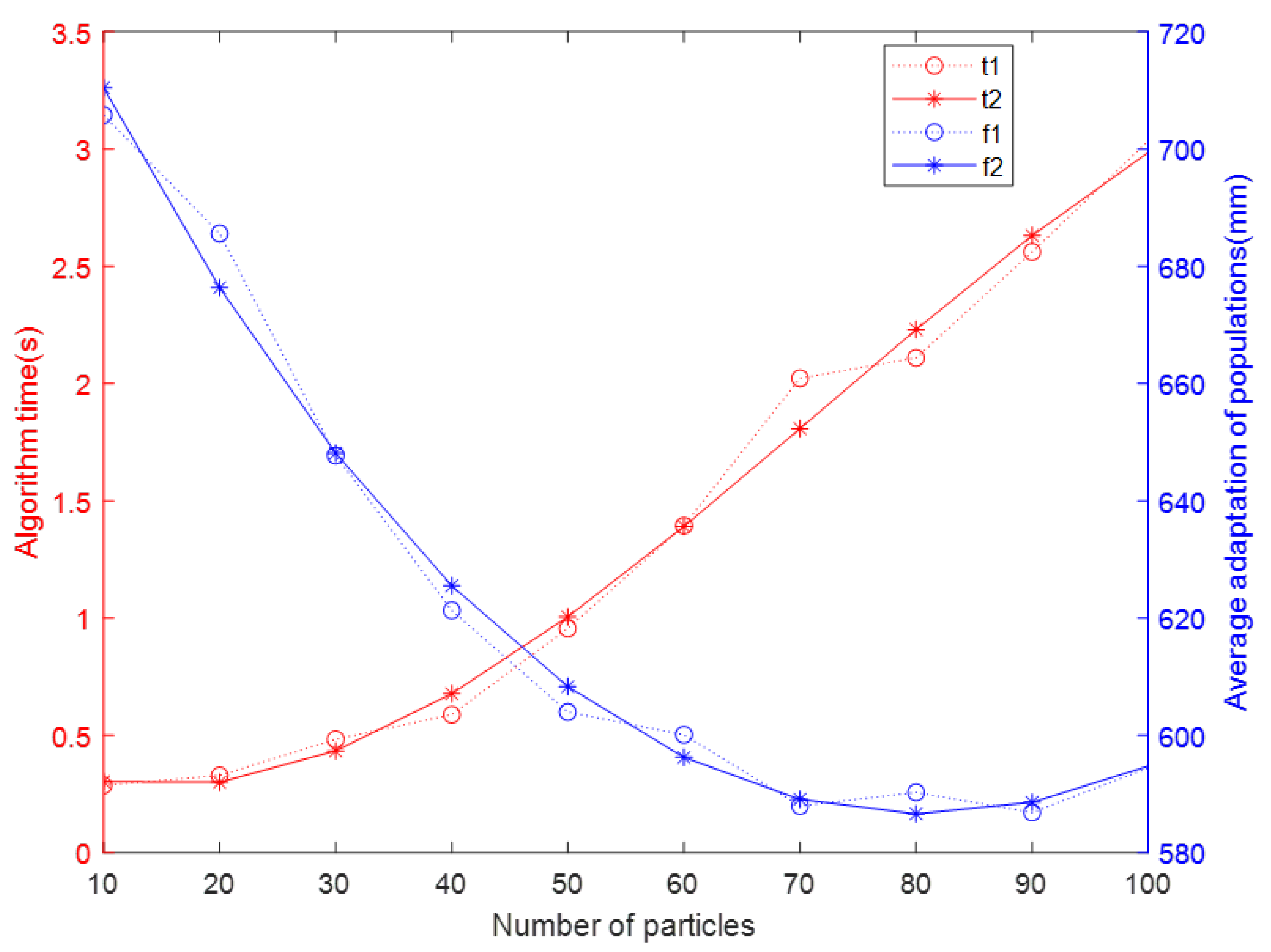

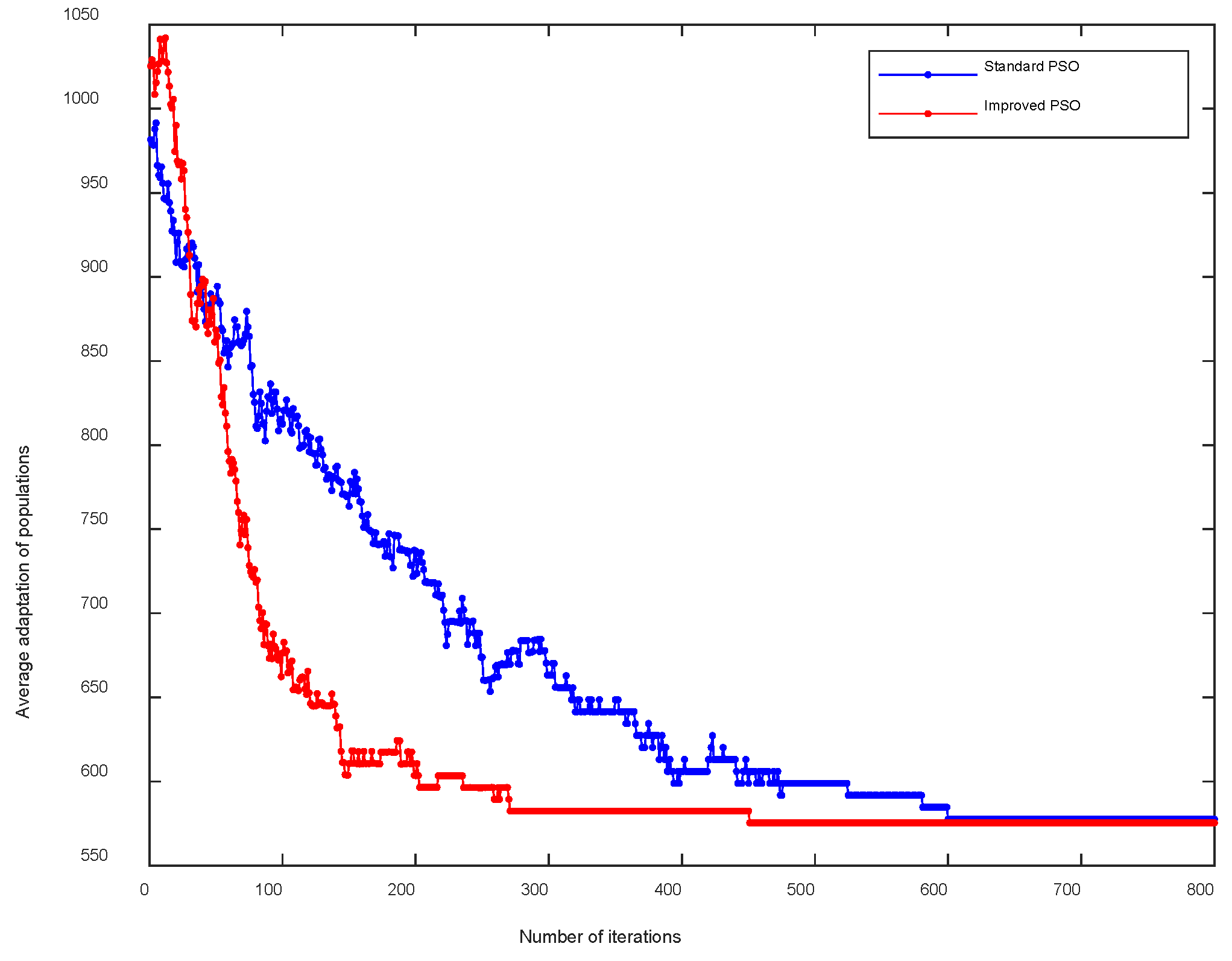

3.1. Experiment with Path Planning Based on Improved PSO Algorithm

3.2. Experiments in an Orchard Environment

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rose, D.C.; Wheeler, R.; Winter, M.; Lobley, M.; Chivers, C.A. Agriculture 4.0: Making it work for people, production, and the planet. Land Use Policy 2021, 100, 104933. [Google Scholar] [CrossRef]

- Duckett, T.; Pearson, S.; Blackmore, S.; Grieve, B.; Chen, W.H.; Cielniak, G.; Cleaversmith, J.; Dai, J.; Davis, S.; Fox, C.; et al. Agricultural robotics: The future of robotic agriculture. arXiv 2018, arXiv:1806.06762. [Google Scholar]

- Bechar, A.; Vigneault, C. Agricultural robots for field operations: Concepts and components. Biosyst. Eng. 2016, 149, 94–111. [Google Scholar] [CrossRef]

- Zhang, Z.; Heinemann, P.H.; Liu, J.; Baugher, T.A.; Schupp, J.R. The development of mechanical apple harvesting technology: A review. Trans. ASABE 2016, 59, 1165–1180. [Google Scholar] [CrossRef]

- Dong, G.; Zhu, Z.H. Position-based visual servo control of autonomous robotic manipulators. Acta Astronaut. 2015, 115, 291–302. [Google Scholar] [CrossRef]

- Arad, B.; Balendonck, J.; Barth, R.; Ben-Shahar, O.; Edan, Y.; Hellström, T.; Hemming, J.; Kurtser, P.; Ringdahl, O.; Tielen, T.; et al. Development of a sweet pepper harvesting robot. J. Field Robot. 2020, 37, 1027–1039. [Google Scholar] [CrossRef]

- Barth, R.; Hemming, J.; Van Henten, E.J. Angle estimation between plant parts for grasp optimisation in harvest robots. Biosyst. Eng. 2019, 183, 26–46. [Google Scholar] [CrossRef]

- Wang, X.; Kang, H.; Zhou, H.; Au, W.; Chen, C. Geometry-aware fruit grasping estimation for robotic harvesting in apple orchards. Comput. Electron. Agric. 2022, 193, 106716. [Google Scholar] [CrossRef]

- Kang, H.; Zhou, H.; Wang, X.; Chen, C. Real-time fruit recognition and grasping estimation for robotic apple harvesting. Sensors 2020, 20, 5670. [Google Scholar] [CrossRef]

- Kang, H.; Zhou, H.; Chen, C. Visual perception and modeling for autonomous apple harvesting. IEEE Access 2020, 8, 62151–62163. [Google Scholar] [CrossRef]

- Chen, W.; Xu, T.; Liu, J.; Wang, M.; Zhao, D. Picking robot visual servo control based on modified fuzzy Neural network sliding mode algorithms. Electronics 2019, 8, 605. [Google Scholar] [CrossRef]

- Ling, X.; Zhao, Y.; Gong, L.; Liu, C.; Wang, T. Dual-arm cooperation and implementing for robotic harvesting tomato using binocular vision. Robot. Auton. Syst. 2019, 114, 134–143. [Google Scholar] [CrossRef]

- Lin, G.; Tang, Y.; Zou, X.; Xiong, J.; Li, J. Guava detection and pose estimation using a low-cost RGB-D sensor in the field. Sensors 2019, 19, 428. [Google Scholar] [CrossRef]

- Vrochidou, E.; Tziridis, K.; Nikolaou, A.; Kalampokas, T.; Papakostas, G.; Pachidis, T.; Mamalis, S.; Koundouras, S.; Kaburlasos, V. An Autonomous Grape-Harvester Robot: Integrated System Architecture. Electronics 2021, 10, 1056. [Google Scholar] [CrossRef]

- Patel, R.V.; Shadpey, F.; Ranjbaran, F.; Angeles, J. A collision-avoidance scheme for redundant manipulators: Theory and experiments. J. Robot. Syst. 2005, 22, 737–757. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, Y.; Liu, X.; Xu, X. Analysis of obstacle avoidance strategy for dual-arm robot based on speed field with improved artificial potential field algorithm. Electronics 2021, 10, 1850. [Google Scholar] [CrossRef]

- Gul, F.; Mir, I.; Abualigah, L.; Sumari, P.; Forestiero, A. A consolidated review of path planning and optimization techniques: Technical perspectives and future directions. Electronics 2021, 10, 2250. [Google Scholar] [CrossRef]

- Zhou, C.; Huang, B.; Fränti, P. A survey of motion planning algorithms for intelligent robotics. arXiv 2021, arXiv:2102.02376. [Google Scholar]

- Contreras-Cruz, M.A.; Ayala-Ramirez, V.; Hernandez-Belmonte, U.H. Mobile robot path planning using artificial bee colony and evolutionary programming. Appl. Soft Comput. 2015, 30, 319–328. [Google Scholar] [CrossRef]

- Zhao, L.; Li, S. Object detection algorithm based on improved YOLOv3. Electronics 2020, 9, 537. [Google Scholar] [CrossRef]

- Kuznetsova, A.; Maleva, T.; Soloviev, V. Using YOLOv3 algorithm with pre- and post-processing for apple detection in fruit-harvesting Robot. Agronomy 2020, 10, 1016. [Google Scholar] [CrossRef]

- Gao, R.; Zhou, Q.; Cao, S.; Jiang, Q. An Algorithm for Calculating Apple Picking Direction Based on 3D Vision. Agriculture 2022, 12, 1170. [Google Scholar] [CrossRef]

- Nistér, D. Preemptive RANSAC for live structure and motion estimation. Mach. Vis. Appl. 2005, 16, 321–329. [Google Scholar] [CrossRef]

- Raguram, R.; Chum, O.; Pollefeys, M.; Matas, J.; Frahm, J.M. USAC: A universal framework for random sample consensus. IEEE Trans. Pattern Anal. Mach. Intell. 2012, 35, 2022–2038. [Google Scholar] [CrossRef]

- Yang, X.S. Nature-Inspired Metaheuristic Algorithms; Luniver Press: Beckington, UK, 2010. [Google Scholar]

- Wang, P.; Gao, S.; Li, L.; Sun, B.; Cheng, S. Obstacle avoidance path planning design for autonomous driving vehicles based on an improved artificial potential field algorithm. Energies 2019, 12, 2342. [Google Scholar] [CrossRef]

- Zhang, H.-Y.; Lin, W.-M.; Chen, A.-X. Path planning for the mobile robot: A review. Symmetry 2018, 10, 450. [Google Scholar] [CrossRef]

- Sengupta, S.; Basak, S.; Peters, R.A. Particle Swarm Optimization: A survey of historical and recent developments with hybridi-zation perspectives. Mach. Learn. Knowl. Extr. 2018, 1, 157–191. [Google Scholar] [CrossRef]

- Gasca, M.; Sauer, T. Polynomial interpolation in several variables. Adv. Comput. Math. 2000, 12, 377–410. [Google Scholar] [CrossRef]

| Type of Robot | Environmental Complexity Level | Cost | Obstacle Avoidance Capability | Harvesting Cycle |

|---|---|---|---|---|

| Automatic pepper-picking robot developed by Barth et al. | Single | High | High | 15 s |

| Apple-picking robot with adjustable picking posture developed by Kang et al. | Complex | High | Moderate | 6.5 s |

| Apple-picking robot developed by Chen et al. | Complex | Moderate | Low | 13.8 s |

| A two-arm collaborative tomato-picking robot developed by Zhao et al. | Moderate | High | Moderate | <30.0 s |

| Guava-picking robot developed by Lin et al. | Moderate | Moderate | High | 18.0 s |

| Grape-picking robot developed by Eleni et al. | Moderate | High | Low | Unknown |

| Experiment Number | Picking Times | Number of Successes | Success Rate | Harvesting Cycle |

|---|---|---|---|---|

| 1 | 87 | 51 | 58.62% | 20 s |

| 2 | 135 | 116 | 85.93% | 12 s |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, R.; Zhou, Q.; Cao, S.; Jiang, Q. Apple-Picking Robot Picking Path Planning Algorithm Based on Improved PSO. Electronics 2023, 12, 1832. https://doi.org/10.3390/electronics12081832

Gao R, Zhou Q, Cao S, Jiang Q. Apple-Picking Robot Picking Path Planning Algorithm Based on Improved PSO. Electronics. 2023; 12(8):1832. https://doi.org/10.3390/electronics12081832

Chicago/Turabian StyleGao, Ruilong, Qiaojun Zhou, Songxiao Cao, and Qing Jiang. 2023. "Apple-Picking Robot Picking Path Planning Algorithm Based on Improved PSO" Electronics 12, no. 8: 1832. https://doi.org/10.3390/electronics12081832

APA StyleGao, R., Zhou, Q., Cao, S., & Jiang, Q. (2023). Apple-Picking Robot Picking Path Planning Algorithm Based on Improved PSO. Electronics, 12(8), 1832. https://doi.org/10.3390/electronics12081832