Progress on the Microcavity Lasers Based on Microstructured Optical Fiber

Abstract

1. Introduction

2. Resonant Cavity in Fiber Microcavity Lasers

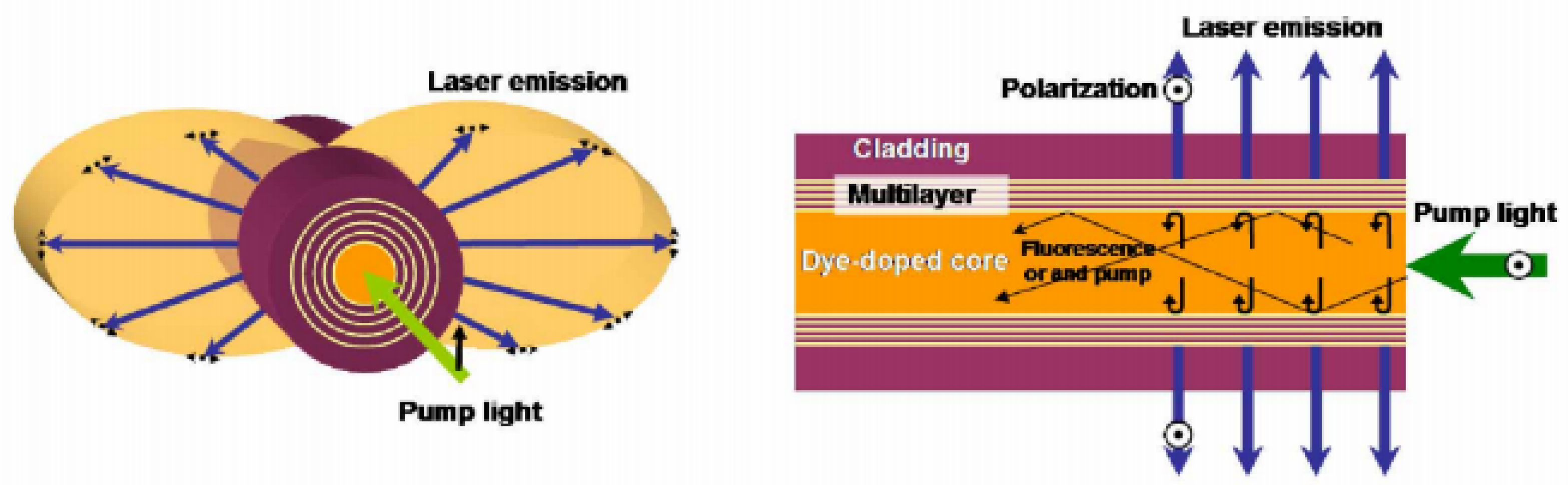

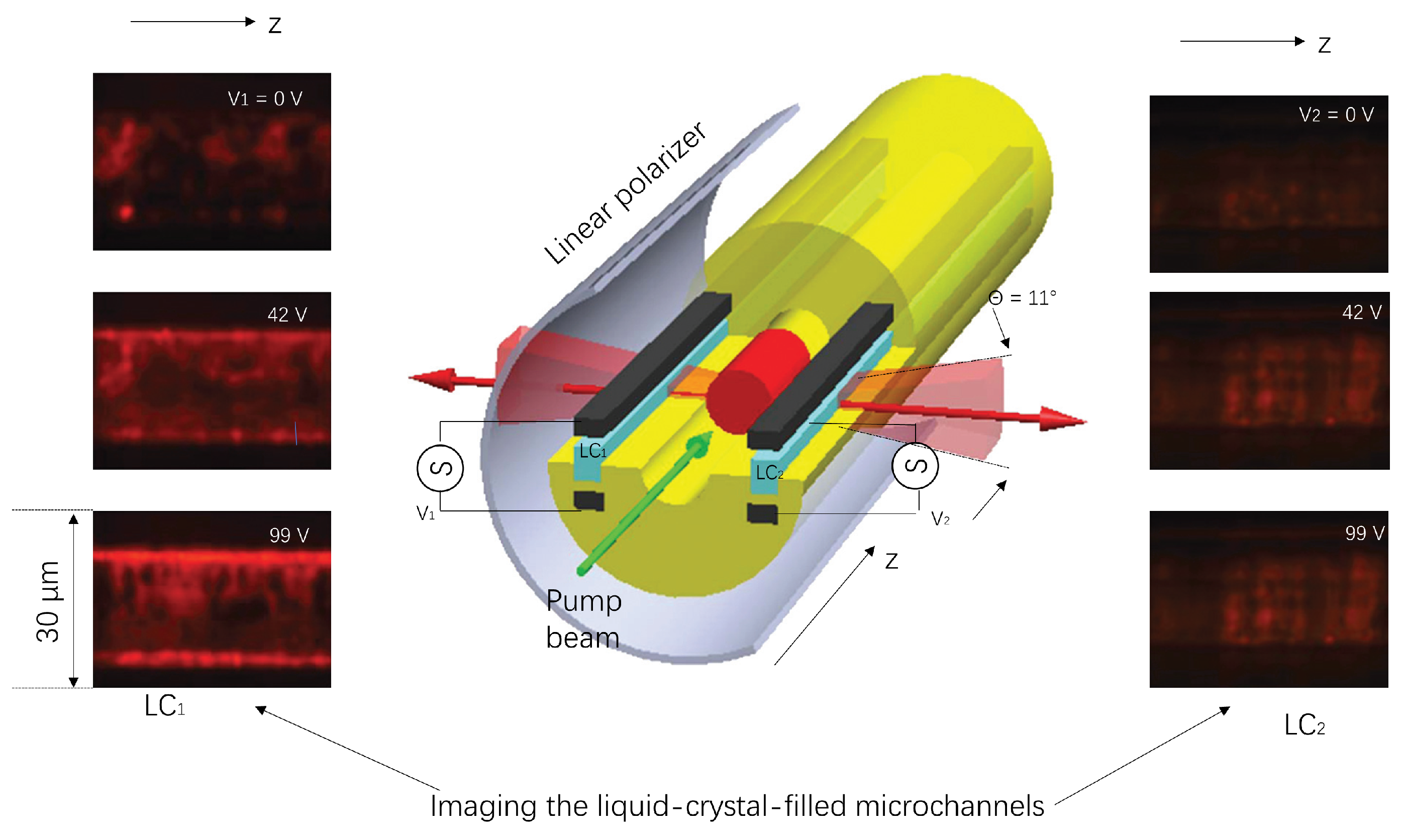

2.1. Fiber Microcavity Laser Based on Hollow Core Bragg Fiber

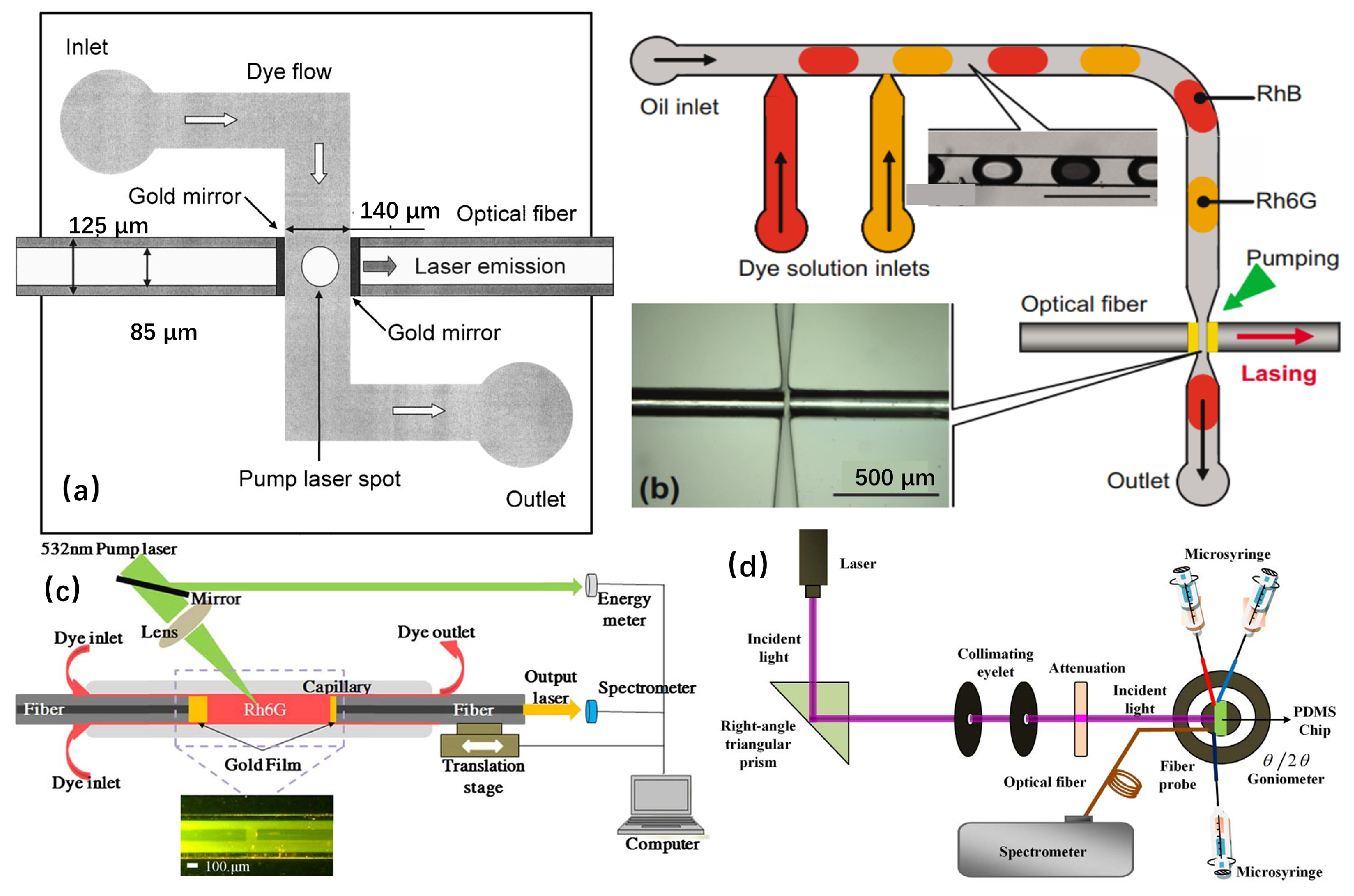

2.2. Fiber Microcavity Laser Based on Fabry–Perot Cavity

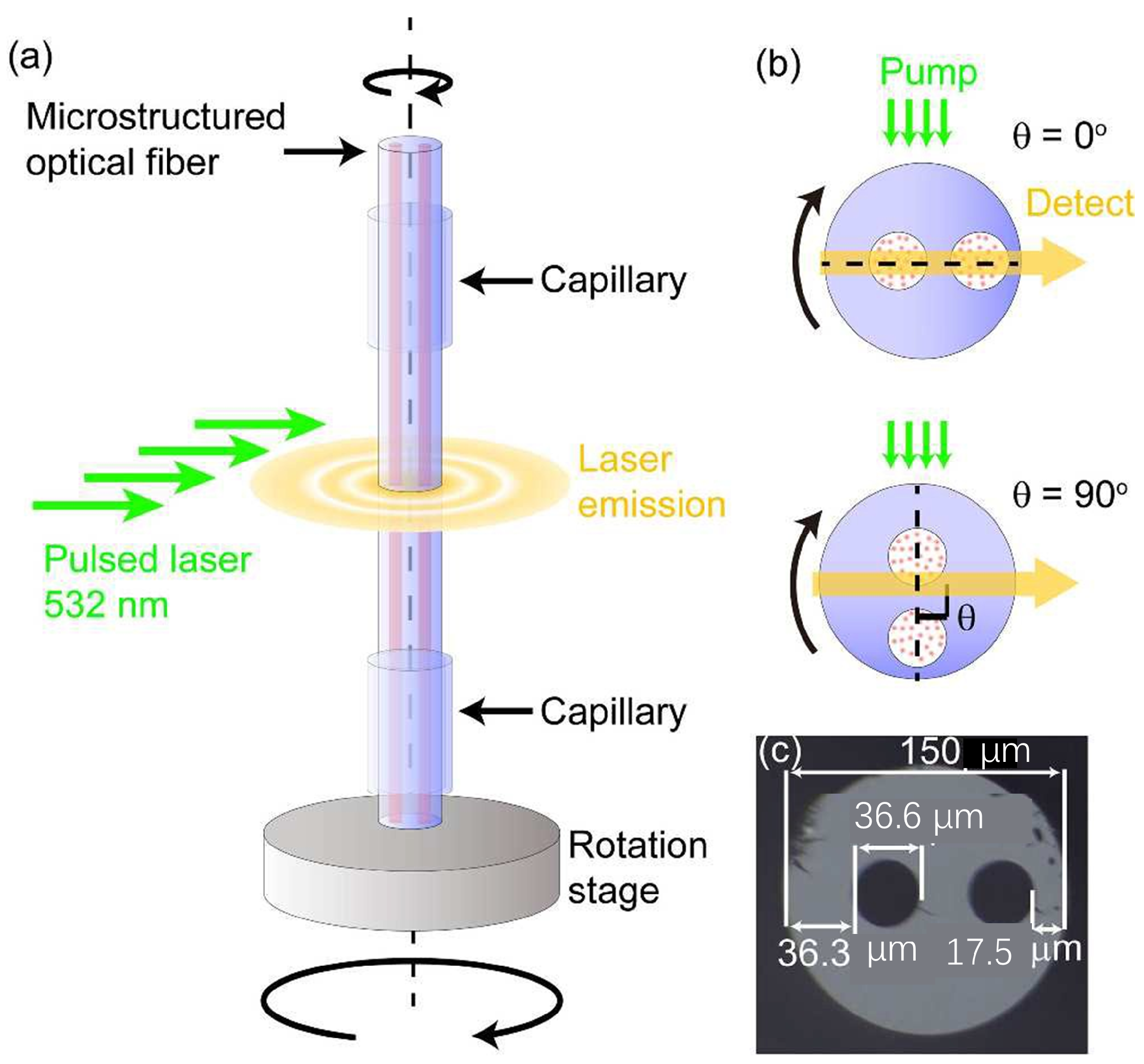

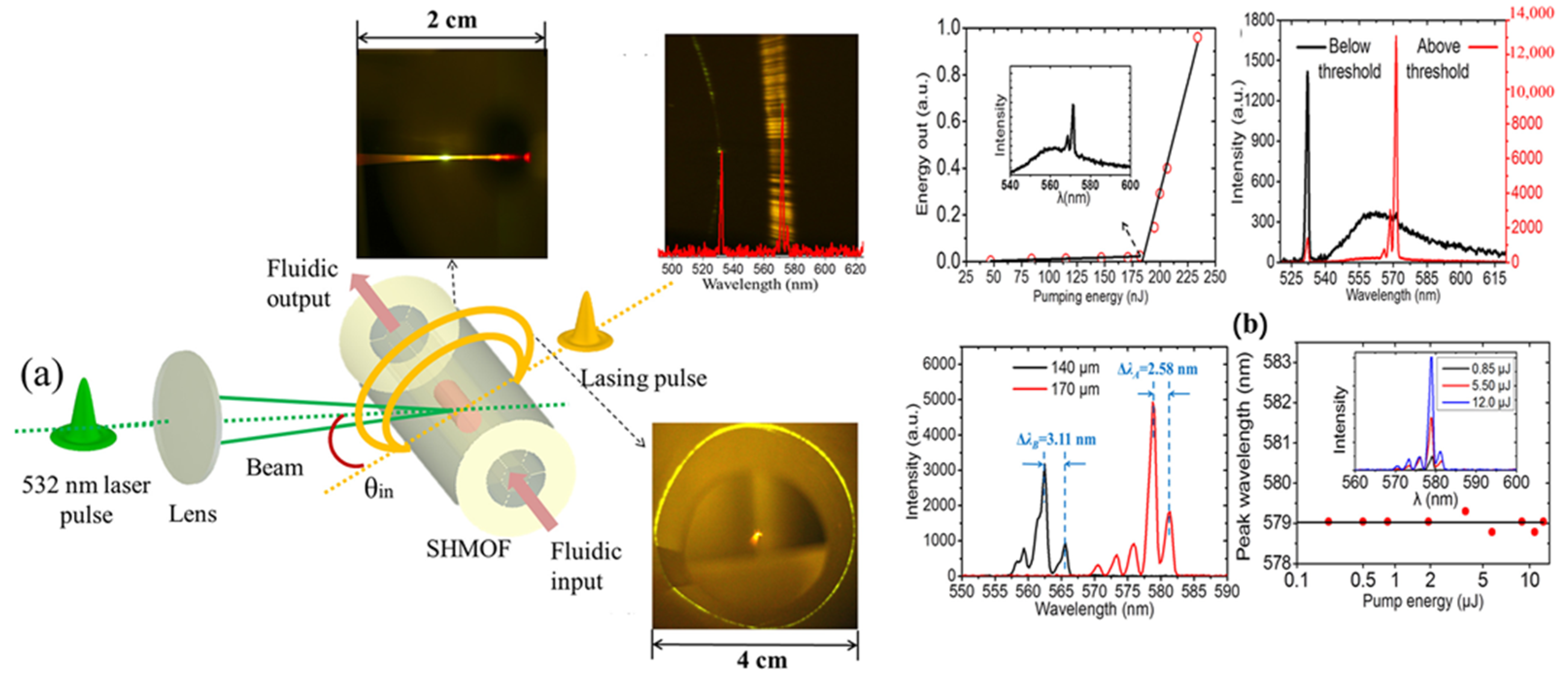

2.3. Fiber Microcavity Laser Based on Fiber Micro-Ring Resonator

3. Gain Medium in Fiber Microcavity Lasers

3.1. Organic Dyes

3.2. Biological Gain Materials

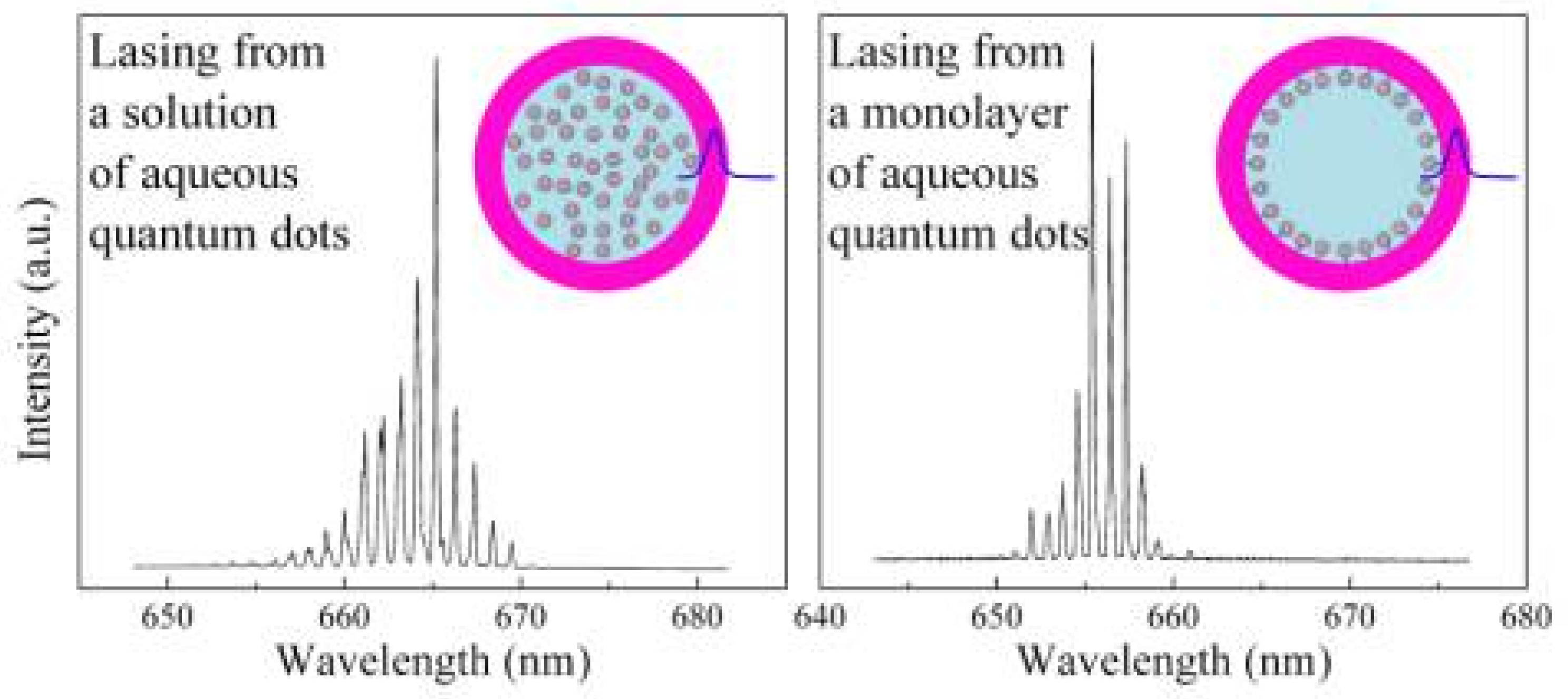

3.3. Quantum Dot

4. Discussion

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Vahala, K. Optical microcavities. Nature 2003, 424, 839. [Google Scholar] [CrossRef] [PubMed]

- Xiao, Y.; Liu, Y.; Li, B.; Chen, Y.; Li, Y.; Gong, Q. Strongly enhanced light-matter interaction in a hybrid photonic-plasmonic resonator. Phys. Rev. A 2012, 85, 031805. [Google Scholar] [CrossRef]

- Coles, D.; Somaschi, N.; Michetti, P.; Clark, C.; Lagoudakis, P.; Savvidis, P.; Lidzey, D. Polariton-mediated energy transfer between organic dyes in a strongly coupled optical microcavity. Nat. Mater. 2014, 13, 712–719. [Google Scholar] [CrossRef]

- Jiang, X.; Xiao, Y.; Zou, C.; He, L.; Dong, C.; Li, B.; Li, Y.; Sun, F.; Yang, L.; Gong, Q. Highly unidirectional emission and ultralow-threshold lasing from on-chip ultrahigh-Q microcavities. Adv. Mater. 2012, 24, OP260. [Google Scholar] [CrossRef]

- Bravo-Abad, J.; Rodriguez, A.; Bermel, P.; Johnson, S.; Joannopoulos, J.; Soljačić, M. Enhanced nonlinear optics in photonic-crystal microcavities. Opt. Express 2007, 15, 16161–16176. [Google Scholar] [CrossRef] [PubMed]

- Spillane, S.; Kippenberg, T.; Vahala, K. Ultralow-threshold Raman laser using a spherical dielectric microcavity. Nature 2002, 415, 621–623. [Google Scholar] [CrossRef]

- Tang, L.; Yoshie, T. High-Q hybrid 3D-2D slab-3D photonic crystal microcavity. Opt. Lett. 2010, 35, 3144–3146. [Google Scholar] [CrossRef] [PubMed]

- Zhou, H.; Yuan, S.; Wang, X.; Xu, T.; Wang, X.; Li, H.; Zheng, W.; Fan, P.; Li, Y.; Sun, L.; et al. Vapor growth and tunable lasing of band gap engineered cesium lead halide perovskite micro/nanorods with triangular cross section. ACS Nano 2017, 11, 1189–1195. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Yu, H.; Li, P.; Zhang, Y.; Wen, Y.; Qiu, Y.; Liu, Z.; Li, Y.; Liu, L. Femtosecond laser-based processing methods and their applications in optical device manufacturing: A review. Opt. Laser Technol. 2021, 135, 106687. [Google Scholar] [CrossRef]

- Bakhshkandi, R.; Ghoranneviss, M. The Effect of Heat Treatment on Growth of TiO2 Nanorods. J. Nov. Appl. Sci. 2015, 4, 852–856. [Google Scholar]

- Knight, J. Photonic crystal fibres. Nature 2003, 424, 847–851. [Google Scholar] [CrossRef] [PubMed]

- Berneschi, S.; Barucci, A.; Brenci, M.; Cosi, F.; Farnesi, D.; Conti, G.; Pelli, S.; Soria, S.; Righini, G. Optical Microbubble Resonator: A Novel Structure for Sensing Applications. In Sensors, Proceedings of the First National Conference on Sensors, Rome, Italy, 15–17 February 2012; Springer: New York, NY, USA, 2014; pp. 359–362. [Google Scholar]

- Chang, H.; Zhang, J. From cavity optomechanics to cavity-less exciton optomechanics: A review. Nanoscale 2022, 14, 16710–16730. [Google Scholar] [CrossRef] [PubMed]

- Painter, O.; Lee, R.; Scherer, A.; Yariv, A.; O’brien, J.; Dapkus, P.; Kim, I. Two-Dimensional Photonic Band-Gap Defect Mode Laser. Science 1999, 284, 1819–1821. [Google Scholar] [CrossRef] [PubMed]

- Vučković, J.; Lončar, M.; Mabuchi, H.; Scherer, A. Design of photonic crystal microcavities for cavity QED. Phys. Rev. E 2001, 65, 016608. [Google Scholar] [CrossRef] [PubMed]

- Zhen, B.; Chua, S.; Lee, J.; Rodriguez, A.; Liang, X.; Johnson, S.; Shapira, O. Enabling enhanced emission and low-threshold lasing of organic molecules using special Fano resonances of macroscopic photonic crystals. Proc. Natl. Acad. Sci. USA 2013, 110, 13711–13716. [Google Scholar] [CrossRef] [PubMed]

- Hood, C.; Kimble, H.; Ye, J. Characterization of high-finesse mirrors: Loss, phase shifts, and mode structure in an optical cavity. Phys. Rev. A 2001, 64, 033804. [Google Scholar] [CrossRef]

- Buck, J.; Kimble, H. Optimal sizes of dielectric microspheres for cavity QED with strong coupling. Phys. Rev. A 2003, 67, 033806. [Google Scholar] [CrossRef]

- Hood, C.; Lynn, T.; Doherty, A.; Parkins, A.; Kimble, H. The atom-cavity microscope: Single atoms bound in orbit by single photons. Science 2000, 287, 1447–1453. [Google Scholar] [CrossRef]

- Pinkse, P.; Fischer, T.; Maunz, P.; Rempe, G. Trapping an atom with single photons. Nature 2000, 404, 365–368. [Google Scholar] [CrossRef]

- Rempe, G.; Thompson, R.; Kimble, H.; Lalezari, R. Measurement of ultralow losses in an optical interferometer. Opt. Lett. 1992, 17, 363–365. [Google Scholar] [CrossRef]

- Psaltis, D.; Quake, S.; Yang, C. Developing optofluidic technology through the fusion of microfluidics and optics. Nature 2006, 442, 381–386. [Google Scholar] [CrossRef]

- Gorodetsky, M.; Ilchenko, V. Optical microsphere resonators: Optimal coupling to high-Q whispering-gallery modes. JOSA B 1999, 16, 147–154. [Google Scholar] [CrossRef]

- Hart, S.; Maskaly, G.; Temelkuran, B.; Prideaux, P.; Joannopoulos, J.; Fink, Y. External reflection from omnidirectional dielectric mirror fibers. Science 2002, 296, 510–513. [Google Scholar] [CrossRef] [PubMed]

- Gorodetsky, M.; Fomin, A. Geometrical theory of whispering-gallery modes. IEEE J. Sel. Top. Quantum Electron. 2006, 12, 33–39. [Google Scholar] [CrossRef]

- Du, W.; Zhang, S.; Shi, J.; Chen, J.; Wu, Z.; Mi, Y.; Liu, Z.; Li, Y.; Sui, X.; Wang, R.; et al. Strong exciton–photon coupling and lasing behavior in all-inorganic CsPbBr3 micro/nanowire Fabry-Pérot cavity. ACS Photonics 2018, 5, 2051–2059. [Google Scholar] [CrossRef]

- Moon, H.; Chough, Y.; Kim, J.; An, K.; Yi, J.; Lee, J. Cavity-Q-driven spectral shift in a cylindrical whispering-gallery-mode microcavity laser. Appl. Phys. Lett. 2000, 76, 3679–3681. [Google Scholar] [CrossRef]

- Fu, L.; Lu, Q.; Liu, X.; Chen, X.; Wu, X.; Xie, S. Combining whispering gallery mode optofluidic microbubble resonator sensor with GR-5 DNAzyme for ultra-sensitive lead ion detection. Talanta 2020, 213, 120815. [Google Scholar] [CrossRef]

- Kiraz, A.; Chen, Q.; Fan, X. Optofluidic lasers with aqueous quantum dots. ACS Photonics 2015, 2, 707–713. [Google Scholar] [CrossRef]

- Gerard, J.; Barrier, D.; Marzin, J.; Kuszelewicz, R.; Manin, L.; Costard, E.; Rivera, T. Quantum boxes as active probes for photonic microstructures: The pillar microcavity case. Appl. Phys. Lett. 1996, 69, 449–451. [Google Scholar] [CrossRef]

- Levy, U.; Campbell, K.; Groisman, A.; Mookherjea, S.; Fainman, Y. On-chip microfluidic tuning of an optical microring resonator. Applied Physics Letters 2006, 88, 111107. [Google Scholar] [CrossRef]

- Armani, D.; Kippenberg, T.; Spillane, S.; Vahala, K.J. Ultra-high-Q toroid microcavity on a chip. Nature 2003, 421, 925–928. [Google Scholar] [CrossRef]

- Li, L.; Hong, M.; Schmidt, M.; Zhong, M.; Malshe, A.; Huis, B.; Kovalenko, V. Laser nano-manufacturing–state of the art and challenges. CIRP Ann. 2011, 60, 735–755. [Google Scholar] [CrossRef]

- Yang, L.; Armani, D.; Vahala, K. Fiber-coupled erbium microlasers on a chip. Appl. Phys. Lett. 2003, 83, 825–826. [Google Scholar] [CrossRef]

- Wang, Y.; Leck, K.; Ta, D.; Chen, R.; Nalla, V.; Gao, Y.; Sun, H. Blue liquid lasers from solution of CdZnS/ZnS ternary alloy quantum dots with quasi-continuous pumping. Adv. Mater. 2015, 27, 169–175. [Google Scholar] [CrossRef] [PubMed]

- Li, B.; Zhao, Y.; Zhang, Y.; Zhang, A.; Li, X.; Gu, J.; Zhou, G. Functionalized Micro Structured Optical Fibers and Devices for Sensing Applications: A Review. J. Light. Technol. 2021, 39, 3812–3823. [Google Scholar] [CrossRef]

- Li, Z.; Psaltis, D. Optofluidic dye lasers. Microfluid. Nanofluid. 2008, 4, 145–158. [Google Scholar] [CrossRef]

- Smart, R.; Hanna, D.; Tropper, A.; Davey, S.; Carter, S.F.; Szebesta, D. CW room temperature upconversion lasing at blue, green and red wavelengths in infrared-pumped Pr3+-doped fluoride fibre. SPIE Milest. Ser. 2000, 161, 379–381. [Google Scholar] [CrossRef]

- Gather, M.; Yun, S. Single-cell biological lasers. Nature Photonics 2011, 5, 406–410. [Google Scholar] [CrossRef]

- Martino, N.; Kwok, S.; Liapis, A.; Forward, S.; Jang, H.; Kim, H.; Yun, S. Wavelength-encoded laser particles for massively multiplexed cell tagging. Nat. Photonics 2019, 13, 720–727. [Google Scholar] [CrossRef]

- Klimov, V.; Mikhailovsky, A.; Xu, S.; Malko, A.; Hollingsworth, J.; Leatherdale, A.; Bawendi, M. Optical gain and stimulated emission in nanocrystal quantum dots. Science 2000, 290, 314–317. [Google Scholar] [CrossRef]

- Shapira, O.; Kuriki, K.; Orf, N.; Abouraddy, A.; Benoit, G.; Viens, J.; Brewster, M. Surface-emitting fiber lasers. Opt. Express 2006, 14, 3929–3935. [Google Scholar] [CrossRef] [PubMed]

- Stolyarov, A.; Wei, L.; Shapira, O.; Sorin, F.; Chua, S.; Joannopoulos, J.; Fink, Y. Microfluidic directional emission control of an azimuthally polarized radial fibre laser. Nat. Photonics 2012, 6, 229–233. [Google Scholar] [CrossRef]

- Zhang, M.; Liu, J.; Cheng, W.; Cheng, J.; Zheng, Z. A tunable optical Bragg grating filter based on the droplet sagging effect on a superhydrophobic nanopillar array. Sensors 2019, 19, 3324. [Google Scholar] [CrossRef]

- Hu, J.; Fu, D.; Xia, C.; Zhang, C.; Yao, L.; Lu, C.; Liu, Y. A three-layer egg-configurated Bragg microcavity of polyglycerol coated cholesteric-liquid-crystal encapsulated by hollow-glass-microsphere. Liq. Cryst. 2020, 47, 508–515. [Google Scholar] [CrossRef]

- Helbo, B.; Kristensen, A. Menon. A micro-cavity fluidic dye laser. J. Micromechanics Microengineering 2003, 13, 307. [Google Scholar] [CrossRef]

- Kou, Q.; Yesilyurt, I.; Chen, Y. Collinear dual-color laser emission from a microfluidic dye laser. Appl. Phys. Lett. 2006, 88, 091101. [Google Scholar] [CrossRef]

- Aubry, G.; Kou, Q.; Soto-Velasco, J.; Wang, C.; Meance, S.; He, J.; Haghiri-Gosnet, A. A multicolor microfluidic droplet dye laser with single mode emission. Appl. Phys. Lett. 2011, 98, 111111. [Google Scholar] [CrossRef]

- Zhou, H.; Feng, G.; Yao, K.; Yang, C.; Yi, J.; Zhou, S. Fiber-based tunable microcavity fluidic dye laser. Opt. Lett. 2013, 38, 3604–3607. [Google Scholar] [CrossRef] [PubMed]

- Gerosa, R.; Sudirman, A.; Menezes, L.; Margulis, W.; de Matos, C. All-fiber high repetition rate microfluidic dye laser. Optica 2015, 2, 186–193. [Google Scholar] [CrossRef]

- Kong, Y.; Dai, H.; He, X.; Zheng, Y.; Chen, X. Reconfigurable RGB dye lasers based on the laminar flow control in an optofluidic chip. Opt. Lett. 2018, 43, 4461–4464. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.; Zhao, Y.; Wei, H.; Zhu, C.; Krishnaswamy, S. 3D printed castle style Fabry-Perot microcavity on optical fiber tip as a highly sensitive humidity sensor. Sens. Actuators B Chem. 2021, 328, 128981. [Google Scholar] [CrossRef]

- Gourley, P.; Drummond, T. Visible, room-temperature, surface-emitting laser using an epitaxial Fabry–Perot resonator with AlGaAs/AlAs quarter-wave high reflectors and AlGaAs/GaAs multiple quantum wells. Appl. Phys. Lett. 1987, 50, 1225–1227. [Google Scholar] [CrossRef]

- Zhu, J.; Ozdemir, S.; Xiao, Y.; Li, L.; He, L.; Chen, D.R.; Yang, L. On-chip single nanoparticle detection and sizing by mode splitting in an ultrahigh-Q microresonator. Nature photonics 2010, 4, 46–49. [Google Scholar] [CrossRef]

- Lee, W.; Sun, Y.; Li, H.; Reddy, K.; Sumetsky, M.; Fan, X. A quasi-droplet optofluidic ring resonator laser using a micro-bubble. Appl. Phys. Lett. 2011, 99, 091102. [Google Scholar] [CrossRef]

- Sun, Y.; Suter, D.; Fan, X. Robust integrated optofluidic-ring-resonator dye lasers. Opt. Lett. 2009, 34, 1042–1044. [Google Scholar] [CrossRef]

- Li, Z.; Zhou, W.; Liu, Y.; Ye, Q.; Ma, Y.; Wei, H.; Tian, J. Highly efficient fluorescence detection using a simplified hollow core microstructured optical fiber. Appl. Phys. Lett. 2013, 102, 011136. [Google Scholar] [CrossRef]

- Li, Z.L.; Zhou, W.Y.; Luo, M.M.; Liu, Y.G.; Tian, J.G. Tunable optofluidic microring laser based on a tapered hollow core microstructured optical fiber. Opt. Express 2015, 23, 10413–10420. [Google Scholar] [CrossRef]

- Gong, C.; Gong, Y.; Chen, Q.; Rao, Y.; Peng, G.; Fan, X. Reproducible fiber optofluidic laser for disposable and array applications. Lab Chip 2017, 17, 3431–3436. [Google Scholar] [CrossRef]

- Gao, R.; Lu, D.; Zhang, M.; Qi, Z. Optofluidic immunosensor based on resonant wavelength shift of a hollow core fiber for ultratrace detection of carcinogenic benzo [a] pyrene. ACS Photonics 2018, 5, 1273–1280. [Google Scholar] [CrossRef]

- Yu, J.; Liu, Y.; Wang, Y.; Zheng, Z.; Wang, Z.; Zhang, X.; Liu, X.; Wang, P. Optofluidic laser based on a hollow-core negative-curvature fiber. Nanophotonics 2018, 7, 1307–1315. [Google Scholar] [CrossRef]

- Zhang, M.; Cheng, W.; Zheng, Z.; Cheng, J.; Liu, J. Meridian whispering gallery modes sensing in a sessile microdroplet on micro/nanostructured superhydrophobic chip surfaces. Microfluid. Nanofluid. 2019, 23, 1–13. [Google Scholar] [CrossRef]

- Xu, Y.; Gong, C.; Chen, Q.; Luo, Y.; Wu, Y.; Wang, Y.; Gong, Y. Highly reproducible, isotropic optofluidic laser based on hollow optical fiber. IEEE J. Sel. Top. Quantum Electron. 2018, 25, 1–6. [Google Scholar] [CrossRef]

- Lin, J.; Chiu, C.; Mo, T.; Lee, C. All-Optical Directional Control of Emission in a Photonic Liquid Crystal Fiber Laser. J. Light. Technol. 2020, 38, 5149–5156. [Google Scholar] [CrossRef]

- Moon, H.; Chough, Y.; An, K. Cylindrical microcavity laser based on the evanescent-wave-coupled gain. Phys. Rev. Lett. 2000, 85, 3161. [Google Scholar] [CrossRef]

- Li, Z.L.; Liu, Y.G.; Yan, M.; Zhou, W.Y.; Ying, C.F.; Ye, Q.; Tian, J.G. A simplified hollow-core microstructured optical fibre laser with microring resonators and strong radial emission. Appl. Phys. Lett. 2014, 105, 071902. [Google Scholar] [CrossRef]

- Gong, C.; Gong, Y.; Zhao, X.; Luo, Y.; Chen, Q.; Tan, X.; Wu, Y.; Fan, X.; Peng, G.D.; Rao, Y.J. Distributed fibre optofluidic laser for chip-scale arrayed biochemical sensing. Lab Chip 2018, 18, 2741–2748. [Google Scholar] [CrossRef]

- Yan, D.; Liu, B.; Zhang, H.; Zhou, W.; Ying, C.; Ye, Q.; Tian, J. Observation of lasing emission based on a hexagonal cavity embedded in a Kagome PCF. IEEE Photonics Technol. Lett. 2018, 30, 1202–1205. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, Y.; Liao, C.; Peng, G.D.; Gong, Y.; Wang, Y. Polymer-coated hollow fiber optofluidic laser for refractive index sensing. J. Light. Technol. 2020, 38, 1550–1556. [Google Scholar] [CrossRef]

- Yoshida, Y.; Nishihara, Y.; Fujii, A.; Ozaki, M.; Yoshino, K.; Kim, H.; Choi, S. Optical properties and microring laser of conducting polymers with Sn atoms in main chains. J. Appl. Phys. 2004, 95, 4193–4196. [Google Scholar] [CrossRef]

- Yoshida, Y.; Nishimura, T.; Fujii, A.; Ozaki, M.; Yoshino, K. Dual ring laser emission of conducting polymers in microcapillary structures. Appl. Phys. Lett. 2005, 86, 141903. [Google Scholar] [CrossRef]

- Sun, Y.; Fan, X. Distinguishing DNA by Analog-to-Digital-like Conversion by Using Optofluidic Lasers. Angew. Chem. Int. Ed. 2012, 51, 1236–1239. [Google Scholar] [CrossRef] [PubMed]

- Chen, Q.; Ritt, M.; Sivaramakrishnan, S.; Sun, Y.; Fan, X. Optofluidic lasers with a single molecular layer of gain. Lab Chip 2014, 14, 4590–4595. [Google Scholar] [CrossRef] [PubMed]

- Lee, W.; Chen, Q.; Fan, X.; Yoon, D. Digital DNA detection based on a compact optofluidic laser with ultra-low sample consumption. Lab Chip 2016, 16, 4770–4776. [Google Scholar] [CrossRef] [PubMed]

- Protesescu, L.; Yakunin, S.; Bodnarchuk, M.; Krieg, F.; Caputo, R.; Hendon, C.H.; Kovalenko, M. Nanocrystals of cesium lead halide perovskites (CsPbX3, X= Cl, Br, and I): Novel optoelectronic materials showing bright emission with wide color gamut. Nano Lett. 2015, 15, 3692–3696. [Google Scholar] [CrossRef]

- Li, X.; Wu, Y.; Zhang, S.; Cai, B.; Gu, Y.; Song, J.; Zeng, H. CsPbX3 quantum dots for lighting and displays: Room-temperature synthesis, photoluminescence superiorities, underlying origins and white light-emitting diodes. Adv. Funct. Mater. 2016, 26, 2435–2445. [Google Scholar] [CrossRef]

- Rogacha, A. Water resistant CsPbX3 nanocrysals coated by polyhedral oligomeric silsesquioxane and their use as solid state luminophores in all-perovskite white light emitting devices. Chem. Sci. 2016, 7, 5699–5703. [Google Scholar]

- Zhang, N.; Liu, H.; Stolyarov, A.; Zhang, T.; Li, K.; Shum, P.P.; Wei, L. Azimuthally polarized radial emission from a quantum dot fiber laser. ACS Photonics 2016, 3, 2275–2279. [Google Scholar] [CrossRef]

- Luo, M.; Liu, Y.; Wang, Z.; Li, Z.; Zhou, W.Y.; Guo, J.; Liu, X. Manipulative dual-microsphere lasing based on nanosilica waveguide integrated in a simplified hollow-core microstructured optical fiber. J. Light. Technol. 2017, 35, 2183–2189. [Google Scholar] [CrossRef]

- Shi, H.; He, J.; Guo, H.; Liu, X.; Wang, Z.; Liu, Y. Single-resonator, stable dual-longitudinal-mode optofluidic microcavity laser based on a hollow-core microstructured optical fiber. Opt. Express 2021, 29, 10077–10088. [Google Scholar] [CrossRef]

- Yu, J.; Liu, Y.; Luo, M.; Wang, Z.; Yang, G.; Zhang, H.; Zhang, X. Single longitudinal mode optofluidic microring laser based on a hollow-core microstructured optical fiber. IEEE Photonics J. 2017, 9, 1–10. [Google Scholar] [CrossRef]

- Shi, H.; Yu, J.; Guo, H.; Wang, Z.; Liu, X.; Liu, Y. Fluid-controlled stable single longitudinal mode microcavity laser based on an antiresonant hollow-core fiber. Laser Phys. Lett. 2020, 17, 025101. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, Y.; Liu, J.; Luo, M.; Shi, H. Progress on the Microcavity Lasers Based on Microstructured Optical Fiber. Electronics 2023, 12, 1761. https://doi.org/10.3390/electronics12081761

He Y, Liu J, Luo M, Shi H. Progress on the Microcavity Lasers Based on Microstructured Optical Fiber. Electronics. 2023; 12(8):1761. https://doi.org/10.3390/electronics12081761

Chicago/Turabian StyleHe, Yansong, Jianfei Liu, Mingming Luo, and Huimin Shi. 2023. "Progress on the Microcavity Lasers Based on Microstructured Optical Fiber" Electronics 12, no. 8: 1761. https://doi.org/10.3390/electronics12081761

APA StyleHe, Y., Liu, J., Luo, M., & Shi, H. (2023). Progress on the Microcavity Lasers Based on Microstructured Optical Fiber. Electronics, 12(8), 1761. https://doi.org/10.3390/electronics12081761