Abstract

This paper presents the application of shallow neural networks (SNNs): multi-layer perceptron (MLP) and self-organizing Kohonen maps (SOMs) to the early detection and classification of the stator and rotor faults in permanent magnet synchronous motors (PMSMs). The neural networks were trained based on the vector coming from measurements on a real object. The elements of the input vector of SNNs constituted the selected amplitudes of the diagnostic signal spectrum. The stator current and axial flux were used as diagnostic signals. The test object was a 2.5 kW PMSM motor supplied by a frequency converter operating in a closed-loop control structure. The experimental verification of the proposed diagnostic system was carried out for variable load conditions and values of the supply voltage frequency. The obtained results were compared with an approach based on a deep neural network (DNN). The research presented in the article confirm the possibility of detection and assessing the individual damage of stator winding and permanent magnets as well as the simultaneous faults of the PMSM stator and rotor using SNNs with simple signal preprocessing.

1. Introduction

For many years, shallow neural structures have dominated automatic measurements and diagnostic systems using artificial intelligence methods [1]. However, recently deep neural networks (DNNs) have also been used more intensively in the diagnosis of induction motor (IM) faults, as well as permanent magnet synchronous motors (PMSMs) [2,3]. They provide very good (nearly 100%) efficiency in detecting and classifying machine winding faults, but they require very complex structures and a long learning time, and their practical implementation on available processors is difficult. Moreover, the DNNs require a large set of training data, and, most importantly, are characterized by a lack of formal rules for the selection of structures and parameters of the training process. These limitations often result in a resignation from the practical use of DNN in machine diagnostics, especially for objects that are not a priority in the context of the entire production line. In this case, a better approach is to use neural structures characterized by a simple mathematical description (multilayer perceptron—MLP, self-organizing map—SOM) and, at the same time, high generalization abilities. It should be noted that shallow networks are a very efficient diagnostic tool if the number of training data is relatively small and the dynamics of the drive system is well known. However, they require the preprocessing of diagnostic signals to extract fault symptoms and supply them to the network input. Therefore, the overwhelming number of applications of NN in diagnostics includes the use of MLP [3,4,5] and SOM [6,7,8,9]. This is due to the basic tasks set for diagnostic systems, namely the detection and assessment of the degree of damage to the machine.

In most cases, the practical implementation involves the use of NN structures in diagnostic tasks for induction motors [6,7] (and many more, listed in the references of these articles). The literature analysis allows us to observe that there are currently a small number of articles involving the use of shallow NNs in PMSM fault diagnostic applications [4,5,8,9]. However, none of these works showed a comparison of the methods used and, in particular, the effectiveness of damage-detection and classification was not presented. Furthermore, the ability to distinguish between mixed failures using a shallow NN was not shown in the literature. It should be noted that the operation of an NN in diagnostic applications is related to the inherent cooperation of the neural network with analytical techniques for the extraction of symptoms.

In most cases, the initial processing of diagnostic signals is connected with the use of spectral analysis. The fast Fourier transform provides good quality information about the technical condition of the machine based on information about the amplitudes of the measured signal spectrum. Normalized amplitudes of the characteristic spectrum of the considered failures are used as an element of the input vector of the neural network. However, the FFT has some limitations, primarily related to the need to ensure static operating conditions of the machine at the time of measuring the diagnostic value. In the case of fault detection in transient states, FFT analysis cannot be used. The solution is to use time-frequency analyzes that provide diagnostic information in transients as well. However, higher-order methods such as wavelet analysis in continuous [10,11] or discrete form [12,13], as well as the Hilbert–Huang transformation [14,15], the estimation of signal parameters via rotational invariant techniques (ESPRIT) [16,17], or the short-time Fourier transform [18,19], most closely related to FFT, require a very large computational effort. As a result, these methods result in an extension of the response time of the detection system. It should be noted that the transient states of machines usually cover short periods. Therefore, the use of higher-order methods with high computational requirements does not give the desired effect, because the time to calculate and extract symptoms may be longer than the transient state of the machine itself. Therefore, this article focusses on the use of FFT analysis, which, despite some limitations, can be successfully used in low-cost systems. It should be emphasized that the practical implementation of diagnostic systems based on FFT and supported by classic neural structures is relatively simple.

In connection with the above, in this paper the application of two different shallow neural network (SNN) structures based on the stator current and axial flux signals is presented. These SNNs are MLP, which constitutes the most popular data approximator, and SOM, which is characterized by a high accuracy of data classification even for a small number of training samples. Due to the difficulties in the process of designing SOM-based classifiers, the article presents an original approach that enables the automatic separation of areas characteristic of individual classes. Diagnostic systems based on SOM described in the literature so far show an analysis of the network response for empirically determined areas characteristic of individual faults. In our studies, these areas are defined analytically, using Euclidean distance calculation, due to which the entire process can be fully automated, and also in terms of developing the classifier for subsequent damage (online learning of the neural network).

Thus, the purpose of this article is to show the possibility of using the selected SNN structure as part of the diagnostic procedure to assess and, most of all, distinguish electrical and magnetic damage to the PMSM stator and rotor. An additional purpose of the article was to show the advantages and disadvantages of SNN in relation to the DNN network, which has recently been very popular in the diagnosis of electrical motor damage. The main contributions of this research are as follows:

- (1)

- The evaluation of the applicability of FFT analysis of the stator current and stray flux to extract electrical and magnetic damage symptoms in a PMSM drive;

- (2)

- The development of an MLP-based fault detector and fault level classifier for ITSC and PM faults based on a relatively small dataset;

- (3)

- The development of an SOM-based fault detector and fault level classifier for ITSC and PM faults based on a relatively small dataset, and proposing a method for the analytical determination of areas in a Kohonen map characteristic of individual faults, which enables the automatization of the fault-type classification;

- (4)

- The comparison of the effectiveness of the fault detectors and classifiers developed based on MLP and SOM with simple preprocessing of the input signals;

- (5)

- The comparison of the pros and cons of using SNN and CNN in the diagnostic task of incipient electrical and magnetic faults in a PMSM drive with vector control.

The article consists of five sections. In the next section, the symptoms of PMSM drive stator and rotor failure are briefly described. Next, the idea of detecting stator winding and permanent magnet faults of the PMSM drive is presented. The experimental setup that was used for diagnostic signal assessment and fault detector testing is briefly described. The method adopted for the physical modelling of the analyzed faults to the stator winding—interturn short-circuits (ITSCs) and permanent magnet (PM)—is presented. In the fourth section, the training and testing processes of the SNN-based fault detectors and classifiers are demonstrated, and their detection accuracy is evaluated. In this section, the advantages and disadvantages of using analyzed SSNs versus the DNNs that are being increasingly often applied are discussed. The article ends with a short conclusion.

2. Symptoms of Stator and Rotor Faults in PMSM Drive

The detection of ITSC in the stator winding of a PMSM is most often carried out on the basis of a spectral analysis of phase currents. Amplitudes with characteristic frequencies are sought in the current spectrum and stray flux, respectively, as follows [20,21]:

where: fs—basic frequency of the supplying voltage, fs—rotational frequency, pp—pole pairs, k = 1, 2, 3, …, m = 1, 3, 5, …2 pp -1.

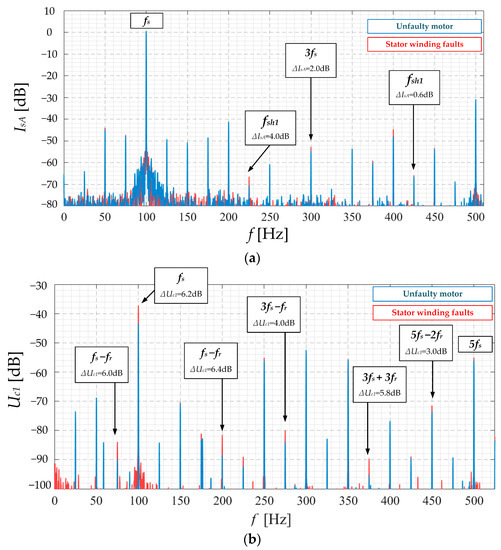

As can be observed in Figure 1, turn-to-turn faults also result in an increase in spectrum amplitudes with odd harmonics of the fundamental frequency. Diagnostics of stator winding damage can also be performed based on the information contained in the stray flux signal. In the case of new undamaged motors, the stray flux signal is of low value. This is due to the design inaccuracies of the machine and the heterogeneity of the materials used in the motor construction process. Winding damage disturbs machine symmetry, resulting in an increase in the value of this flux [22,23].

Figure 1.

Analysis of the phase current (a) and axial flux (b) spectrum during inter-turn short-circuits.

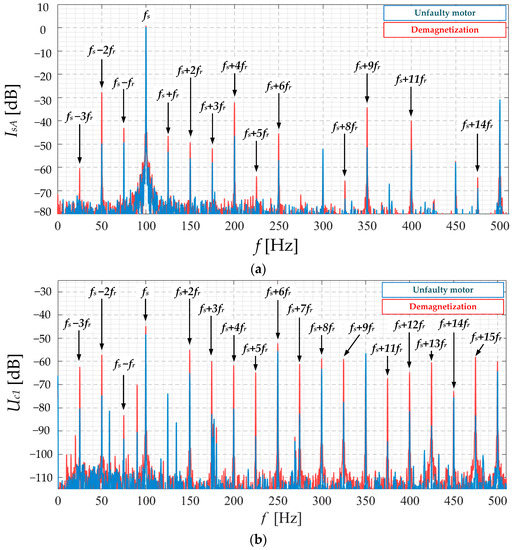

It is particularly difficult to distinguish between electrical damage to the stator winding and damage to the magnetic circuit. The limitations of the implementation of analytical methods of PMSM fault detection compared to IM result directly from the principle of operation of these motors, namely the lack of slip. As a result of the synchronism of the stator and rotor fields, the spectra of currents, voltages, and fluxes contain overlapping components from the power source and interharmonics related to the rotational frequency. Therefore, distinguishing the symptoms of PMSM rotor and stator damage is extremely difficult, much more difficult than in the case of IM stator and rotor damage. In the case of damage to the IM rotor above the load at the level of 20% of the rated torque, the components characteristic of ITSC faults are already clearly separated from those attributed to damage to the rotor cage bars [7]. On the other hand, the advantage of PMSM is the lack of influence of the load on the rotational speed, which means that it does not force the diagnostic system to the minimum value of the load torque, and the developed detectors can work in the entire range of load changes with similar precision. PMSM rotor damage caused by the demagnetization of the permanent magnets results in oscillations of the stator phase currents. The impact of this damage is visible in the spectrum of phase currents and axial flux in the form of an increase in amplitudes (Figure 2) with frequencies described as follows [1,24]:

Figure 2.

Analysis of the phase current (a) and axial flux (b) spectrum during partial demagnetization of PMSM rotor.

Based on (1) and (2), it is clearly visible that the magnitudes of the frequency components characteristic of the stator and rotor faults of PMSM can overlap, making the diagnostic process based on their analysis difficult. Therefore, in this paper the chosen NN structures were used to support fault detection and differentiation. The efficiency of these simple NNs in the diagnostic process was evaluated.

3. Application of Shallow Neural Networks in the Detection of PMSM Damage

3.1. The Idea of PMSM Fault Neural Detectors Based on MLP and SOM

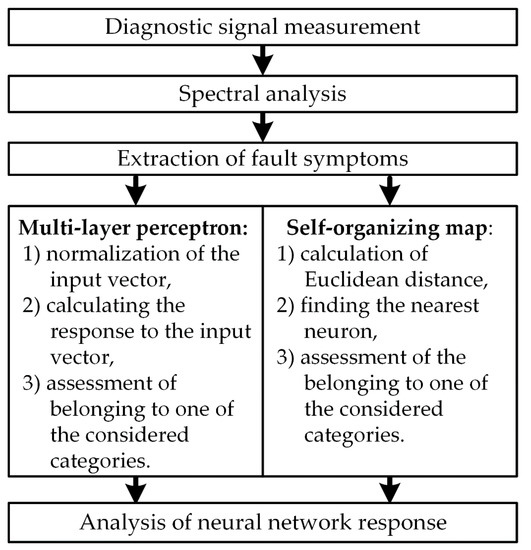

In electrical machine diagnostic systems using a classical (shallow) NN, the path of signal flow is connected with the necessity to identify the symptoms of failures, enabling the assessment of the technical condition (Figure 3). The NN is usually the last element of the diagnostic system, and its role results from the type of neural structure. In diagnostic applications, shallow NNs can play the role of fault detectors, classifiers of diagnostic data, and enable the analysis of the future behavior of the tested object. Most of the implemented structures act as data approximators, in which the multilayer perceptron is mostly used. However, in recent years, data classifiers based on self-organizing Kohonen networks have gained importance. Their task is to automatically recognize the features of a heterogeneous set of input data and assign samples with similar features to appropriate classes. It should be noted that high precision from NN-based fault detectors is possible only in the case of a close relationship between the damage and its symptoms. Therefore, it is necessary to properly select the elements of the NN input vector, which is the result of the selected preprocessing method of the measured signals.

Figure 3.

The illustration of the PMSM damage-detection process using shallow neural network.

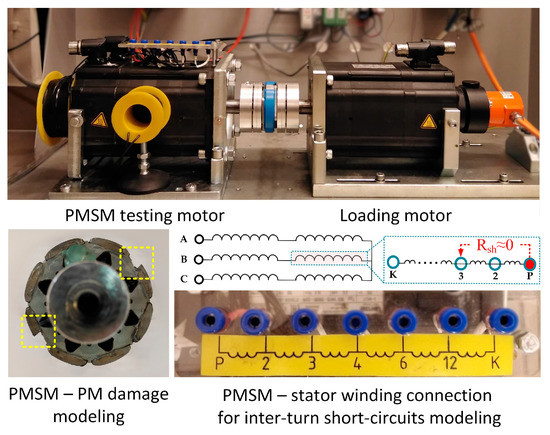

3.2. Description of the Experimental Setup and Conducted Tests

The following sections discuss the operation of the systems for detecting damage to the stator windings and damage to the permanent magnet of the PMSM drive. The test object was a 2.5 kW PMSM powered by a frequency converter operating in a closed-loop control structure (Figure 4). The experimental verification of the NN-based diagnostic systems developed on the basis of training and testing data measured in the drive system was carried out for various operating conditions of the PMSM drive. The range of changes in load torque was TL = 0−TLN with a step of 0.2 TLN. Furthermore, the value of the supply voltage frequency was changed in the range fs = 50−100 Hz. During the studies, three types of fault were analyzed: incipient ITSCs (1−3 shorted turns of the B phase of the stator winding), PM fault (5% demagnetization), and mixed faults (simultaneous faults of the stator winding and the rotor magnets).

Figure 4.

Experimental setup.

During the research, the cooperation of two programming environments was used. Measurement of diagnostic signals was possible thanks to the LabVIEW environment. These signals were subjected to spectral analysis to extract the input vectors of the neural networks. The development of the neural structure, the training process, and the verification of the system operation were carried out using the Matlab environment. The use of the Matlab environment in neural calculations allowed us to significantly accelerate the learning process and quickly determine the responses of the neural network.

The classic method of physical modeling of damage to permanent magnets (PMs) resulting directly from their parameters is the heat treatment of individual rotor magnets. However, thermal modeling of PM defects by exceeding the Curie temperature makes it impossible to determine the degree of the analyzed damage. The modeling of the mechanical damage of the PM does not have the aforementioned disadvantages, and this approach also ensures the weakening of the resultant flux from the damaged magnet. Therefore, as part of the research presented in this article, it was decided to remove a piece of the pole of one magnet to obtain the assumed fault level (Figure 4). The rated parameters of the motor tested are given in the following (Table 1).

Table 1.

Rated parameters of the tested PMSM.

4. Experimental Verification of the Tested Fault Detectors

4.1. The MLP-Based Detector of PMSM Stator and Rotor Faults

The popularity of the MLP structure in the diagnostics of electrical machines results primarily from the simplicity of its implementation and its ability to map any function. The application of MLP in PMSM damage-detection systems requires the proper selection of training vector elements, network structure, and training process parameters that ensure the assumed effectiveness. In the following studies, information from the phase current spectrum was used to assess the degree of damage to the stator and rotor of the PMSM motor. The input vector of the network was the current spectrum amplitudes at frequencies (3fsIsA, 3fsIsB, 5fsIsB) and (fsIsA + 2frIsA, fsIsB + 2frIsB, fsIsC + 2frIsC). The best results were obtained for NN: {6-12-8-2}, with 6 inputs, 12 and 8 neurons (with sigmoidal activation functions) in the hidden layers, respectively. The network training process was carried out following the Levenberg–Marquardt algorithm for 3000 learning epochs. The training vector was developed based on information from 144 measurements for various types and degrees of damage with changes in the load torque within the range TL = {0, 0.4, 0.8}TLN and the supply voltage frequency fs = {50, 60, 70, 80, 90, 100} Hz. The testing vector also included data from 144 measurements, with different values of the load moment TL = {0.2, 0.6, 1.0} TLN.

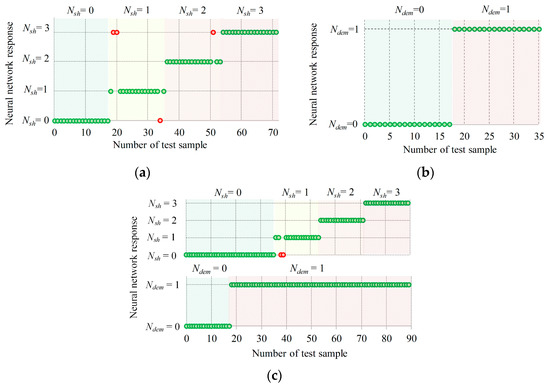

The responses of the designed MLP network to the test data presented in Figure 5 confirm the high efficiency of the network, both in the case of a single rotor failure (Figure 5b) or stator failures (Figure 5a) and mixed failures (Figure 5c). The responses of the neural network marked in Figure 5 with red dots indicate an incorrect classification of the technical condition of the machine, while the green ones indicate a response consistent with the actual technical condition of the machine. The estimated efficiency of the evaluation of stator winding damage for the test vector that included 144 samples was greater than 94%, with simultaneous short-circuit detection precision at a level close to 99%. Moreover, during the experimental verification, it was found that the NN provides only correct information about the technical condition of the rotor magnets, both in the case of single defects (Figure 5b) and mixed failures (Figure 5c). The reaction of the MLP-based diagnostic system to the vector containing information about the spectrum components during the occurrence of mixed faults confirms the lack of influence of demagnetization on the effectiveness of ITSC detection. The effectiveness of the evaluation of the degree of defect presented in Figure 5c was greater than 98%.

Figure 5.

Experimental verification of the MLP-based fault detector of the PMSM motor: (a) inter-turn short-circuits; (b) permanent magnet fault; (c) mixed damage: Nsh—number of shorted turns, Ndem—permanent magnet technical condition (0—unfaulty, 1—partial demagnetization).

The results of the experimental verification (response to test samples) of the MLP-based damage detector are presented in Table 2. In Table 2, the two types of accuracy can be distinguished: detection accuracy, understood as the ability to recognize the difference between a state of no damage and a defect; and classification effectiveness, defining the ability to recognize the type and degree of damage, e.g., the number of shorted turns (Equation (3)).

where: ηc—classification effectiveness, xP—number of correct neural network responses in the category considered, xN—number samples in the category considered.

Table 2.

The experimental validation of MLP-based PMSM fault detector.

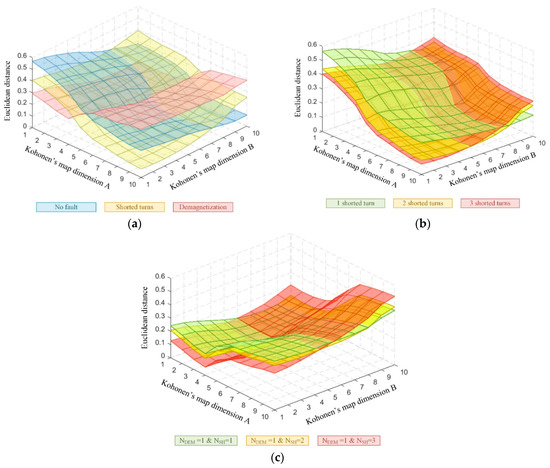

4.2. The PMSM Stator and Rotor Fault Detector Based on Self-Organizing Kohonen Maps

Neural data classifiers based on self-organizing Kohonen maps can both act as a detector and provide a preliminary assessment of the degree of damage. During the research, information from the voltage spectrum induced in the measuring coils was used [2,24]. For this purpose, two measuring coils were used, placed on the outer part of the motor, the first coaxial with the shaft (uC1) and the second radially placed (uC2). The input vector of the SOM network with 100 neurons (map dimension 10 × 10) consisted of the spectrum amplitudes at frequencies: fsuc1, fsuc2. The network training process was carried out according to the “Winner Takes Most” method using the Gaussian neighborhood function for 500 learning epochs. During network training, a vector of learning data from 144 measurements performed on a real object was used. The application of the Kohonen network in the PMSM motor diagnostic system discussed in the following included the detection and assessment of the degree of stator damage, as well as the detection of the rotor defect (Figure 6a,b). An additional aim of the research was to check the influence of demagnetization on the possibility of detection of inter-turn short-circuits (Figure 6c).

Figure 6.

Experimental verification of the SOM-based fault detector of the PMSM motor: (a) fault classification—SOM response for training data; (b) assessment of stator damage degree—SOM response for training data; (c) simultaneous fault of the PMSM stator and rotor—SOM response for training dataset: Nsh—number of shorted turns, Ndem—permanent magnet technical condition (0—unfaulty, 1—partial demagnetization).

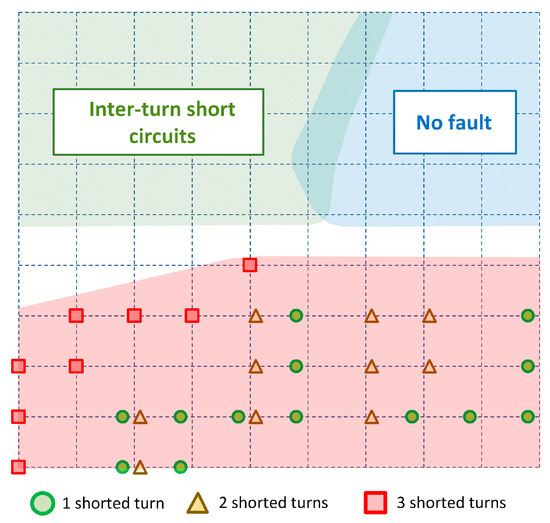

Based on the network responses to the training data, approximate zones characteristic of the damage categories were obtained. To show the classification ability of the SOM, in these investigations, the analysis of individual network responses was first replaced with the mean value of the Euclidean distance measures for all training samples (Figure 6). Due to this, it was possible to verify the correctness of the network for training data, as well as to accurately separate zones characteristic of individual forms of PMSM damage. Characteristic zones can be considered as areas of the minimum distance between input vectors and neurons of the Kohonen map.

As can be observed in Figure 6a, the area of the map characteristic of no damage (blue color) is separated from those assigned to the failure states. Moreover, the areas characteristic of the stator (yellow color) and permanent magnet (red color) faults are located in the extreme parts of Kohonen’s map.

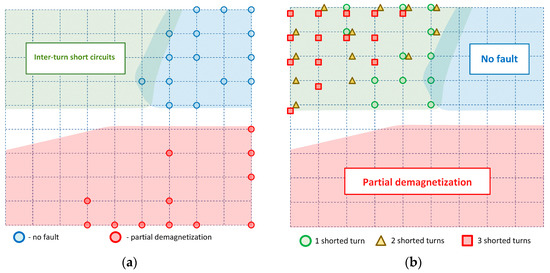

In most of the known applications of SOM in fault diagnostic applications, Kohonen’s map analysis consists of observing an active neuron and assigning it to one of the observed zones (concentration of active neurons with the same characteristic features) [6,7]. Therefore, the next part of the verification focused on the analysis of neuronal activity in areas of the Kohonen map specific to individual fault categories (Figure 7). The characteristic areas presented in Figure 7 are the result of the analysis of the response of the network in the form of Euclidean distance measures to the given input vectors presented in Figure 6. The SOM zones marked correspond to the shortest distance to the input vector assigned to one of the fault categories. On the basis of developed Kohonen maps, it was possible to determine the affiliation of an active neuron to one of the considered types of PMSM damage.

Figure 7.

Experimental verification of the SOM-based fault detector of the PMSM motor: (a) partial demagnetization of the PMSM– SOM response for testing dataset; (b) assessment of stator damage degree—SOM response for testing dataset: Nsh—number of shorted turns.

The analysis of the Kohonen maps presented in Figure 7 shows that damage to the stator and rotor of the PMSM motor resulted in the activation of neurons in different areas of the map. The zones characteristic of the undamaged motor and the defect of the permanent magnet are separated (Figure 7a). Additionally, as can be seen in Figure 7b, due to the short-circuit of a small number of turns, neurons located near the zone assigned to the undamaged motor (Figure 7b) are activated. This fact results in the partial overlap of the areas for the short-circuit condition and no damage to the PMSM motor. With an increase in the number of short-circuited turns, active neurons gradually move away from the area characteristic of the undamaged motor. The next stage of the research concerned the assessment of the possibility of detecting turn-to-turn shorts during the simultaneous occurrence of permanent magnet damage (Figure 8).

Figure 8.

Experimental verification of the SOM-based fault detector of the PMSM motor: simultaneous fault of the PMSM stator and rotor—SOM response for testing dataset.

The analysis of the responses of the Kohonen network shown in Figure 8 shows that it is possible to assess the degree of stator damage in the case of mixed damage. With the increase in the number of short-circuited turns, neurons are activated toward the zone assigned to short-circuited turns. However, the activity of neurons in the area characteristic of permanent magnet damage shows that this defect has a predominant influence on diagnostic signals.

4.3. Comparison of Diagnostic System Based on Neural Networks

The use of shallow neural structures in electrical machine diagnostics is currently the basic approach to the design of automatic fault detection systems. However, currently developed systems based on the direct processing of signals by deep neural networks shed new light on the approach to assessing the technical condition of machines. The possibility of omitting the stage of symptom extraction using signal-processing methods while maintaining very high precision speaks to the use of deep learning in diagnostic tasks. On the other hand, the implementation of such systems is much more difficult, especially in the case of microprocessor systems with limited computing capacity and without the memory necessary to store a large number of network parameters (neural connections) [2,25,26,27]. In connection with the above, the process of designing diagnostic systems should assume a compromise between the required system tasks (detection/classification/prediction), drive-system operating characteristics (load and speed changes, dynamic properties), and hardware capabilities (hardware implementation).

In the case of drive systems with known dynamics, where the only requirement is to detect a fault state to switch to a redundant system, a good approach is to use classic neural structures based on known signal-processing methods. They enable easy implementation of the NN-based fault detector in programmable systems. In addition, they do not require a very large set of training data. The detection and assessment of the degree of damage possible in dynamic states force the use of deep structures or the extension of the classical approach with the extraction of symptoms using higher-order methods of signal analysis. However, the use of deep structures extends the design time of the systems due to the difficulties in selecting the parameters of the structure and the training process, and the long training time associated with a very large dataset [2,26,27]. On the other hand, the use of higher-order methods for signal preprocessing, due to a large number of calculations, significantly extends the process of extracting symptoms, which, assuming dynamic states of drives, does not bring the expected results.

Based on the research of the authors on the use of artificial neural networks in the diagnostics of electrical machines, four basic structures are compared in Table 3: SOM, which is the basic data classifier, is used especially in the tasks of distinguishing the type of fault (categorization); MLP used to detect and assess the exact technical condition of the machine (damage level classification); CNN, which is the basic representative of deep learning in the field of diagnostics [2,25]; and CNN-TL (CNN with transfer learning), which is the latest approach to fault diagnosis [28].

Table 3.

Comparison of the neural network-based methods of PMSM fault diagnostic.

The comparison of the characteristics of individual neural structures used in electrical machine diagnostics, presented in Table 3, determines the general nature of systems based on shallow and deep neural structures. On the basis of the comparison, it can be unequivocally stated that in terms of the simplicity of designing detection systems, the classic structures of the multilayer perceptron and Kohonen networks stand out. The disadvantage of these methods is the low precision of the assessment of the degree of damage, especially in the case of turn-to-turn faults. This fact is related to small quantitative changes in the input vectors, which can be a serious limitation during the operation of the diagnostic system for various operating conditions of the machine (changes in load torque and rotational speed). Additionally, the use of preprocessing for NN input signals extends the response time of the system to any fault that occurs. Resignation from signal preprocessing is primarily associated with DNN [2,25,26]. This approach ensures a short reaction to damage and eliminates the need to empirically determine the symptoms of damage (developing the input vector of the network). The entire process of the extraction and inference of symptoms takes place inside the DNN structure. This is possible only due to a very extensive network architecture and, most of the time, many hours of training processes involving a large dataset [25,26]. Moreover, DNN networks require excellent knowledge regarding fine-tuning network hyperparameters. Due to the lack of formal rules for their selection, the training process and thus designing a diagnostic system are difficult. A partial solution to the problem of developing diagnostic applications based on DNN is the use of the idea of transfer learning.

The DNN-structure training process, according to the idea of transfer learning in its basic version, allows the use of a neural structure previously trained to develop a diagnostic system for a new task [28]. Thanks to this, the development of seemingly new structures does not require changing the parameters of the training process and selection of architecture, but only updating neural connections in a small range of all network connections. Extending the scope of the analyzed damage can be carried out based on the ability to extract automatic features acquired by the primary neural structure in the training process. Such an approach to the learning process, discussed by the authors in [28], allows for a nearly 50-fold reduction in network training time compared to the standard approach. In addition, the use of transfer learning is supported by the fact that there is no need to re-select the values of the hyperparameters of the neural structure, which is presented in Table 3. However, an analysis of the results of the research presented in [2,25,26,28] allows us to observe that the precision of the detection system based on classical deep network convolutional learning and CNN using transfer learning does not differ significantly, and the amount of agreement is more than 99%. Additionally, the response time of the systems to an emerging fault was less than 0.06 seconds in both cases. In connection with the above, the advantage of transfer learning over the classic approach to deep learning of CNN is mainly due to the ease of designing new systems characterized for neural-network-based transfer learning, resistance to interference assigned to instance-based transfer learning, and the ability to freely expand the functions of diagnostic applications.

To summarize the presented comparison, it should be noted that the approach based on shallow neural structures proposed in the article may be an optimal solution for a small number of training data (e.g., 144 training samples for the analyzed case) compared to the CNN (more than 7000 samples) and CNN-TL (5400 samples) used [2,28]. In addition, the presented approach to the automatic extraction of areas characteristic of individual failures based on information on Euclidean distance measures provides a much higher level of automation in the process of designing diagnostic systems. It should be clearly emphasized that the selection of the neural structure that constitutes the main decision-making element of the diagnostic system should take into account both the computational capabilities of the master system, the amount of available diagnostic information (learning vectors), and the characteristics of the drive operation. Only then is it possible to select the neural structure for the task performed without overloading the computing systems and maintaining high precision in detection and classification.

5. Conclusions

These tests have demonstrated the effectiveness of the use of shallow neural network structures in the detection process of the electric and magnetic faults of a PMSM motor. Among the two NN structures presented in the paper, including distinguishing between the damaged/undamaged state of the motor (fault detection) and the assessment of fault levels of the PMSM stator winding (fault classification), the most effective is the multilayer perceptron. The self-organizing Kohonen network used in the PMSM diagnostic system is characterized by high precision in the detection and assessment of the degree of stator damage. It should be noted that the experimental results presented in this article also confirm the possibility of assessing the mixed damage of the stator winding and demagnetization faults based on a simple spectral analysis of the stator phase current, which has not been mentioned in the literature so far. However, it should be noted that the assessment of the degree of the incipient inter-turn short-circuits is difficult due to the small changes of the value of input vector elements (fault symptoms) due to the short-circuits on an early stage. However, taking into account the results of the experimental tests, as well as the advantages of the presented neural structures, such as ease of implementation, a simple mathematical description of the training process and, very importantly, the small size of the training vector, ensuring high efficiency of data classification, the proposed shallow neural networks could constitute very good tools supporting PMSM diagnostic systems.

Author Contributions

All the authors contributed equally to the conception of the paper, M.S., T.O.-K. and C.T.K., proposed the methodology and paper organization, M.S. carried out the measurements and analyzed the experimental data, M.S. and T.O.-K. prepared the original draft, M.S. validated the obtained results, C.T.K. supervised the project, T.O.-K. revised and edited the final paper. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the National Science Centre Poland under grants number 2017/27/B/ST7/00816 and 2021/41/N/ST7/01673.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ruiz, J.-R.R.; Espinoza, A.G.; Romeral, L.; Cusido, J. Demagnetization diagnosis in permanent magnet synchronous motors under nonstationary speed conditions. Electr. Power Syst. Res. 2010, 80, 1277–1285. [Google Scholar] [CrossRef]

- Skowron, M.; Orlowska-Kowalska, T.; Kowalski, C.T. Application of simplified Convolutional Neural Networks for initial stator winding fault detection of PMSM drive using different raw signal data. IET Electr. Power Appl. 2021, 15, 932–946. [Google Scholar] [CrossRef]

- Pietrzak, P.; Wolkiewicz, M.; Orlowska-Kowalska, T. PMSM Stator Winding Fault Detection and Classification Based on Bispectrum Analysis and Convolutional Neural Network. IEEE Trans. Ind. Electron. 2023, 7, 5192–5202. [Google Scholar] [CrossRef]

- Shen, T.; Kilic, A.; Thulfaut, C.; Reuss, H. An Intelligent Diagnostic Method for Permanent Magnet Synchronous Motors (PMSM) in the Electric Drive of Autonomous Vehicles. In Proceedings of the 21st European Conference on Power Electronics and Applications (EPE’19 ECCE), Genova, Italy, 2–6 September 2019. [Google Scholar]

- Sá, B.A.; Barros, C.M.V.; Siebra, C.A.; Barros, L.S. A Multilayer Perceptron-Based Approach for Stator Fault Detection in Permanent Magnet Wind Generators. In Proceedings of the 2019 IEEE PES Innovative Smart Grid Technologies Conference—Latin America (ISGT Latin America), Gramado, Brazil, 15–18 September 2019. [Google Scholar]

- Skowron, M.; Wolkiewcz, M.; Orlowska-Kowalska, T.; Kowalski, C.T. Application of Self-Organizing Neural Networks to Electrical Fault Classification in Induction Motors. Appl. Sci. 2018, 9, 616. [Google Scholar] [CrossRef]

- Skowron, M.; Wolkiewicz, M.; Orlowska-Kowalska, T.; Kowalski, C.T. Effectiveness of Selected Neural Network Structures Based on Axial Flux Analysis in Stator and Rotor Winding Incipient Fault Detection of Inverter-fed Induction Motors. Energies 2019, 12, 2392. [Google Scholar] [CrossRef]

- Quiroga, J.; Cartes, D.A.; Edrington, C.S.; Liu, L. Neural network based fault detection of PMSM stator winding short under load fluctuation. In Proceedings of the 13th International Power Electronics and Motion Control Conference (EPE-PEMC), Poznan, Poland, 1–3 September 2008. [Google Scholar]

- Chuang, C.; Wei, Z.; Zhifu, W.; Zhi, L. The Diagnosis Method of Stator Winding Faults in PMSMs Based on SOM Neural Networks. Energy Procedia 2016, 105, 2295–2301. [Google Scholar] [CrossRef]

- Park, C.H.; Lee, J.; Ahn, G.; Youn, M.; Youn, B.D. Fault Detection of PMSM under Non-Stationary Conditions Based on Wavelet Transformation Combined with Distance Approach. In Proceedings of the 2019 IEEE 12th International Symposium on Diagnostics for Electrical Machines, Power Electronics and Drives (SDEMPED), Toulouse, France, 27–29 August 2019. [Google Scholar]

- Ruiz, J.R.; Rosero, J.A.; Espinosa, A.G.; Romeral, L. Detection of Demagnetization Faults in Permanent-Magnet Synchronous Motors Under Nonstationary Conditions. IEEE Trans. Magn. 2009, 45, 2961–2969. [Google Scholar] [CrossRef]

- Riera-Guasp, M.; Antonino-Daviu, J.A.; Pineda-Sanchez, M.; Puche-Panadero, R.; Perez-Cruz, J. A General Approach for the Transient Detection of Slip-Dependent Fault Components Based on the Discrete Wavelet Transform. IEEE Trans. Ind. Electron. 2008, 55, 4167–4180. [Google Scholar] [CrossRef]

- Rosero, J.; Espinosa, A.G.; Cusido, J.; Ortega, J.A.; Romeral, L. Simulation and Fault Detection of Short Circuit Winding in a Permanent Magnet Synchronous Machine (PMSM) by means of Fourier and Wavelet Transform. In Proceedings of the 2008 IEEE Instrumentation and Measurement Technology Conference, Victoria, BC, Canada, 12–15 May 2008. [Google Scholar]

- Alvarez-Gonzalez, F.; Griffo, A.; Wang, B. Permanent magnet synchronous machine stator windings fault detection by Hilbert–Huang transform. J. Eng. 2019, 17, 3505–3509. [Google Scholar] [CrossRef]

- Urresty, J.; Riba, J.; Romeral, L.; Rosero, J.; Serna, J. Stator short circuits detection in PMSM by means of Hilbert-Huang transform and energy calculation. In Proceedings of the 2009 IEEE International Symposium on Diagnostics for Electric Machines, Power Electronics and Drives, Cargèse, France, 31 August–3 September 2009. [Google Scholar]

- Bracale, A.; Carpinelli, G.; Piegari, L.; Tricoli, P. A High Resolution Method for On Line Diagnosis of Induction Motors Faults. In Proceedings of the 2007 IEEE Lausanne Power Tech, Lausanne, Switzerland, 1–5 July 2007. [Google Scholar]

- Xu, B.; Sun, L.; Xu, L.; Xu, G. Improvement of the Hilbert Method via ESPRIT for Detecting Rotor Fault in Induction Motors at Low Slip. IEEE Trans. Energy Convers. 2013, 28, 225–233. [Google Scholar] [CrossRef]

- Arabaci, H.; Bilgin, O. The Detection of Rotor Faults By Using Short Time Fourier Transform. In Proceedings of the IEEE 15th Signal Processing and Communications Applications, Eskisehir, Turkey, 11–13 June 2007. [Google Scholar]

- Strangas, E.G.; Aviyente, S.; Zaidi, S.S.H. Time–Frequency Analysis for Efficient Fault Diagnosis and Failure Prognosis for Interior Permanent-Magnet AC Motors. IEEE Trans. Ind. Electron. 2008, 55, 4191–4199. [Google Scholar] [CrossRef]

- Halder, S.; Bhat, S.; Bhaumik, C.; Rakshit, R. Stator Inter-Turn Diagnosis in Permanent Magnet Synchronous Motor. In Proceedings of the 2020 IEEE First International Conference on Smart Technologies for Power, Energy and Control (STPEC), Nagpur, India, 25–26 September 2020. [Google Scholar]

- Faiz, J.; Exiri, S.A.H. Short-circuit fault diagnosis in permanent magnet synchronous motors—An overview. In Proceedings of the 2015 Intl Aegean Conference on Electrical Machines & Power Electronics (ACEMP), 2015 Intl Conference on Optimization of Electrical & Electronic Equipment (OPTIM) & 2015 Intl Symposium on Advanced Electromechanical Motion Systems (ELECTROMOTION), Side, Turkey, 2–4 September 2015. [Google Scholar]

- Assaf, T.; Henao, H.; Capolino, G.A. Simplified axial flux spectrum method to detect incipient stator inter-turn short-circuits in induction machine. In Proceedings of the IEEE International Symposium on Industrial Electronics, Ajaccio, France, 4–7 May 2004. [Google Scholar]

- Irhoumah, M.; Pusca, R.; Lefèvre, E.; Mercier, D.; Romary, R. Stray Flux Multi-Sensor for Stator Fault Detection in Synchronous Machines. Electronics 2021, 10, 2313. [Google Scholar] [CrossRef]

- Wang, C.; Delgado, P.M.; Romeral, L.; Chen, Z.; Blaabjerg, F.; Liu, X. Detection of partial demagnetization fault in PMSMs operating under nonstationary conditions. IEEE Trans. Magn. 2016, 52, 8105804. [Google Scholar] [CrossRef]

- Kao, I.-H.; Wang, W.-J.; Lai, Y.-H.; Perng, J.-W. Analysis of Permanent Magnet Synchronous Motor Fault Diagnosis Based on Learning. IEEE Trans. Instrum. Meas. 2019, 68, 310–324. [Google Scholar] [CrossRef]

- Maraaba, L.S.; Milhem, A.S.; Nemer, I.A.; Al-Duwaish, H.; Abido, M.A. Convolutional Neural Network-Based Inter-Turn Fault Diagnosis in LSPMSMs. IEEE Access 2020, 8, 81960–81970. [Google Scholar] [CrossRef]

- Wang, C.-S.; Kao, I.-H.; Perng, J.-W. Fault Diagnosis and Fault Frequency Determination of Permanent Magnet Synchronous Motor Based on Deep Learning. Sensors 2021, 21, 3608. [Google Scholar] [CrossRef] [PubMed]

- Skowron, M.; Kowalski, C.T. Permanent Magnet Synchronous Motor Fault Detection System Based on Transfer Learning Method. In Proceedings of the IECON 2022—48th Annual Conference of the IEEE Industrial Electronics Society, Brussels, Belgium, 17–20 October 2022. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).