Correlation of Crystal Defects with Device Performance of AlGaN/GaN High-Electron-Mobility Transistors Fabricated on Silicon and Sapphire Substrates

Abstract

1. Introduction

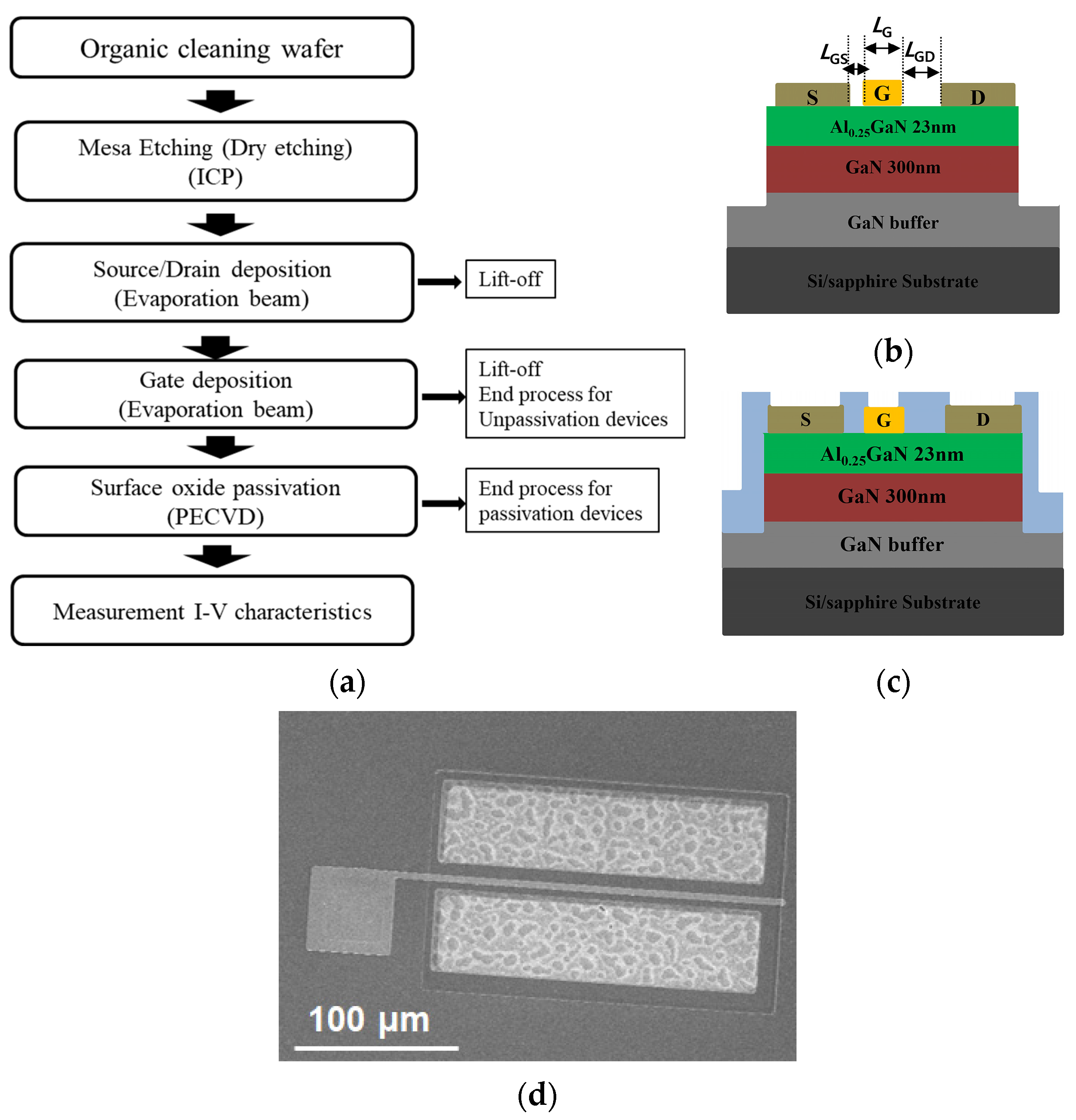

2. Materials and Methods

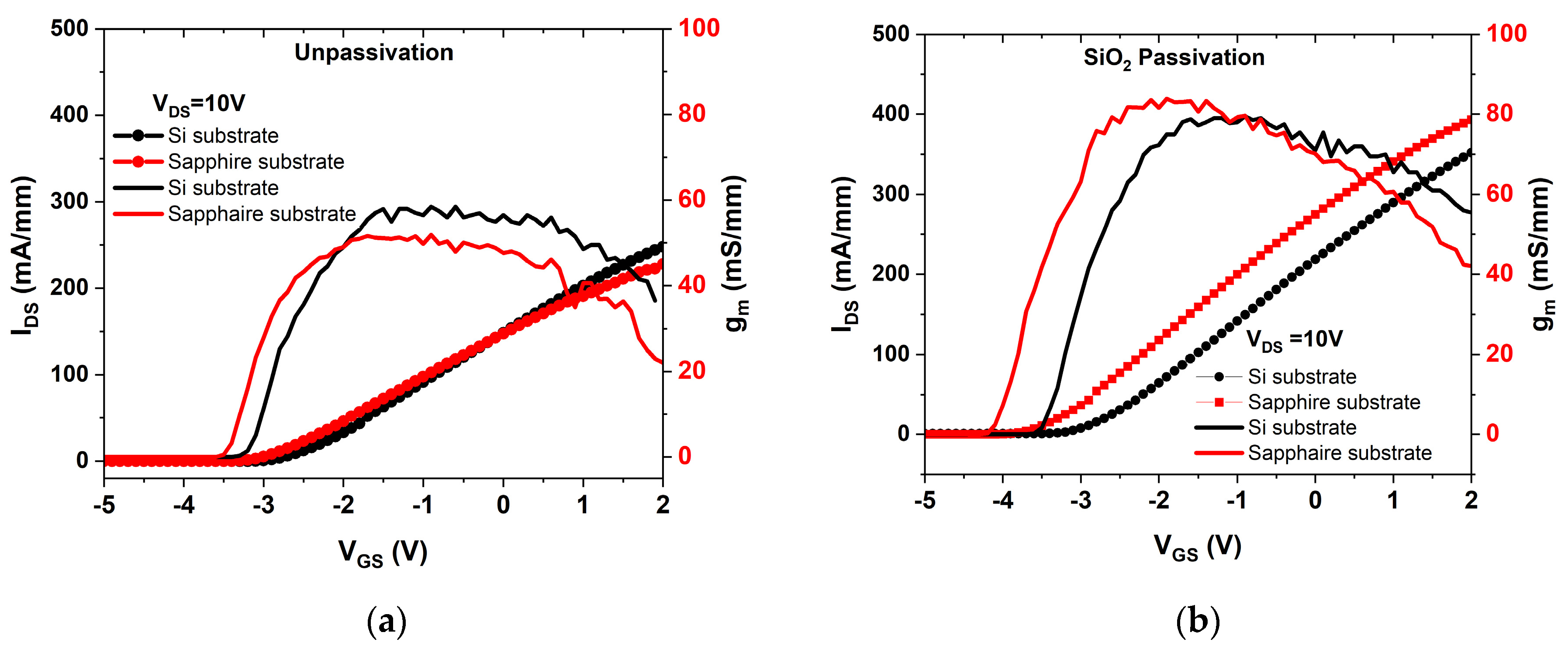

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kushvaha, S.S.; Pal, P.; Shukla, A.K.; Joshi, A.G.; Gupta, G.; Kumar, M.; Singh, S.; Gupta, B.K.; Haranath, D. Effect of growth temperature on defects in epitaxial GaN film grown by plasma assisted molecular beam epitaxy. AIP Adv. 2014, 4, 027114. [Google Scholar] [CrossRef]

- Qi, M.; Nomoto, K.; Zhu, M.; Hu, Z.; Zhao, Y.; Protasenko, V.; Song, B.; Yan, X.; Li, G.; Verma, J.; et al. High breakdown single-crystal GaN pn diodes by molecular beam epitaxy. Appl. Phys. Lett. 2015, 1072, 32101. [Google Scholar] [CrossRef]

- Alam, M.D.; Gaevski, M.; Jewel, M.U.; Mollah, S.; Mamun, A.; Hussain, K.; Floyd, R.; Simin, G.; Chandrashekhar, M.V.S.; Khan, A. Excimer laser liftoff of AlGaN/GaN HEMTs on thick AlN heat spreaders. Appl. Phys. Lett. 2021, 119, 132106. [Google Scholar] [CrossRef]

- Chen, H.; Tang, N.; Zuo, Z. Improvement and Reduction of Self-Heating Effect in AlGaN/GaN HEMT Devices. J. Sens. 2022, 10, 1–10. [Google Scholar] [CrossRef]

- Benzarti, Z.; Sekrafi, T.; Bougrioua, Z.; Khalfallah, A.; El Jani, B. Effect of SiN Treatment on Optical Properties of Inx Ga1− xN/GaN MQW Blue LEDs. J. Electron. Mater. 2017, 46, 4312–4320. [Google Scholar] [CrossRef]

- Wośko, M.; Paszkiewicz, B.; Szymański, T.; Paszkiewicz, R. Comparison of electrical, optical and structural properties of epitaxially grown HEMT’s type AlGaN/AlN/GaN heterostructures on Al2O3, Si and SiC substrates. Superlattices Microstruct. 2016, 100, 619–626. [Google Scholar] [CrossRef]

- Pharkphoumy, S.; Janardhanam, V.; Jang, T.H.; Park, J.; Shim, K.H.; Choi, C.J. Optimized Device Geometry of Normally-On Field-Plate AlGaN/GaN High Electron Mobility Transistors for High Breakdown Performance Using TCAD Simulation. Electronics 2021, 10, 2642. [Google Scholar] [CrossRef]

- He, X.G.; Zhao, D.G.; Jiang, D.S. Formation of two-dimensional electron gas at AlGaN/GaN heterostructure and the derivation of its sheet density expression. Chin. Phys. B 2015, 24, 067301. [Google Scholar] [CrossRef]

- Rathore, S.U.; Dimitrijev, S.; Amini Moghadam, H.; Mohd-Yasin, F. Equations for the electron density of the two-dimensional electron gas in realistic AlGaN/GaN heterostructures. Nanomanufacturing 2021, 1, 12. [Google Scholar] [CrossRef]

- Chang, S.J.; Cho, K.J.; Lee, S.Y.; Jeong, H.H.; Lee, J.H.; Jung, H.W.; Bae, S.B.; Choi, I.G.; Kim, H.C.; Ahn, H.K.; et al. Substrate Effects on the Electrical Properties in GaN-Based High Electron Mobility Transistors. Crystals 2021, 11, 1414. [Google Scholar] [CrossRef]

- Yusuf, Y.; Samsudin, M.E.A.; Taib, M.I.M.; Ahmad, M.A.; Mohamed, M.F.P.; Kawarada, H.; Falina, S.; Zainal, N.; Syamsul, M. Two-Step GaN Layer Growth for High-Voltage Lateral AlGaN/GaN HEMT. Crystals 2023, 13, 90. [Google Scholar] [CrossRef]

- Borga, M.; Meneghini, M.; Rossetto, I.; Stoffels, S.; Posthuma, N.; Van Hove, M.; Marcon, D.; Decoutere, S.; Meneghesso, G.; Zanoni, E. Evidence of time-dependent vertical breakdown in GaN-on-Si HEMTs. IEEE Trans. Electron Devices 2017, 64, 3616–3621. [Google Scholar] [CrossRef]

- Borga, M.; Meneghini, M.; Stoffels, S.; Van Hove, M.; Zhao, M.; Li, X.; Decoutere, S.; Zanoni, E.; Meneghesso, G. Impact of the substrate and buffer design on the performance of GaN on Si power HEMTs. Microelectron. Reliab. 2018, 88-90, 584–588. [Google Scholar] [CrossRef]

- Weyher, J.L.; Ashraf, H.; Hageman, P.R. Reduction of dislocation density in epitaxial GaN layers by overgrowth of defect-related etch pits. Appl. Phys. Lett. 2009, 95, 031913. [Google Scholar] [CrossRef]

- Halidou, I.; Benzarti, Z.; Bougrioua, Z.; Boufaden, T.; El Jani, B. Correlation between morphological, electrical and optical properties of GaN at all stages of MOVPE Si/N treatment growth. Superlattices Microstruct. 2006, 40, 490–495. [Google Scholar] [CrossRef]

- Boughrara, N.; Benzarti, Z.; Khalfallah, A.; Evaristo, M.; Cavaleiro, A. Comparative study on the nanomechanical behavior and physical properties influenced by the epitaxial growth mechanisms of GaN thin films. Appl. Surf. Sci. 2022, 579, 152188. [Google Scholar] [CrossRef]

- Wang, X.; Huang, S.; Zheng, Y.; Wei, K.; Chen, X.; Zhang, H.; Liu, X. Effect of GaN channel layer thickness on DC and RF performance of GaN HEMTs with composite AlGaN/GaN buffer. IEEE Trans. Electron Devices 2014, 61, 1341–1346. [Google Scholar] [CrossRef]

- Guan, H.; Shen, G.; Liu, S.; Jiang, C.; Wu, J. A Simulation Optimization Factor of Si (111)-Based AlGaN/GaN Epitaxy for High Frequency and Low-Voltage-Control High Electron Mobility Transistor Application. Micromachines 2023, 14, 168. [Google Scholar] [CrossRef]

- Singhal, J.; Chaudhuri, R.; Hickman, A.; Protasenko, V.; Xing, H.G.; Jena, D. Toward AlGaN channel HEMTs on AlN: Polarization-induced 2DEGs in AlN/AlGaN/AlN heterostructures. APL Mater. 2022, 10, 111120. [Google Scholar] [CrossRef]

- Green, B.M.; Chu, K.K.; Chumbes, E.M.; Smart, J.A.; Shealy, J.R.; Eastman, L.F. The effect of surface passivation on the microwave characteristics of undoped AlGaN/GaN HEMTs. IEEE Electron Device Lett. 2000, 21, 268–270. [Google Scholar] [CrossRef]

- Vetury, R.; Zhang, N.Q.; Keller, S.; Mishra, U.K. The impact of surface states on the DC and RF characteristics of AlGaN/GaN HFETs. IEEE Trans. Electron Devices 2001, 48, 560–566. [Google Scholar] [CrossRef]

- Adivarahan, V.; Simin, G.; Yang, J.W.; Lunev, A.; Khan, M.A.; Pala, N.; Shur, M.; Gaska, R. SiO2-passivated lateral-geometry GaN transparent Schottky-barrier detectors. Appl. Phys. Lett. 2000, 77, 863–865. [Google Scholar] [CrossRef]

- Xing, H.; Dora, Y.; Chini, A.; Heikman, S.; Keller, S.; Mishra, U.K. High breakdown voltage AlGaN-GaN HEMTs achieved by multiple field plates. IEEE Electron Device Lett. 2004, 25, 161–163. [Google Scholar] [CrossRef]

- Wang, W.K.; Lin, C.H.; Lin, P.C.; Lin, C.K.; Huang, F.H.; Chan, Y.J.; Chen, G.T.; Chyi, J.I. Low-/spl kappa/BCB passivation on AlGaN-GaN HEMT fabrication. IEEE Electron Device Lett. 2004, 25, 763–765. [Google Scholar] [CrossRef]

- Kang, M.J.; Kim, H.S.; Cha, H.Y.; Seo, K.S. Development of Catalytic-CVD SiNx Passivation Process for AlGaN/GaN-on-Si HEMTs. Crystals 2020, 10, 842. [Google Scholar] [CrossRef]

- Huang, C.Y.; Mazumder, S.; Lin, P.C.; Lee, K.W.; Wang, Y.H. Improved Electrical Characteristics of AlGaN/GaN High-Electron-Mobility Transistor with Al2O3/ZrO2 Stacked Gate Dielectrics. Materials 2022, 15, 6895. [Google Scholar] [CrossRef] [PubMed]

- Khan, M.A.; Hu, X.; Sumin, G.; Lunev, A.; Yang, J.; Gaska, R.; Shur, M.S. AlGaN/GaN metal oxide semiconductor heterostructure field effect transistor. IEEE Electron Device Lett. 2000, 21, 63–65. [Google Scholar] [CrossRef]

- Ha, M.W.; Lee, S.C.; Park, J.H.; Her, J.C.; Seo, K.S.; Han, M.K. Silicon dioxide passivation of AlGaN/GaN HEMTs for high breakdown voltage. In Proceedings of the 2006 IEEE International Symposium on Power Semiconductor Devices and IC’s, Naples, Italy, 4–8 June 2006; IEEE: Piscataway, NJ, USA, 2006; pp. 1–4. [Google Scholar] [CrossRef]

- Geng, K.; Chen, D.; Zhou, Q.; Wang, H. AlGaN/GaN MIS-HEMT with PECVD SiNx, SiON, SiO2 as gate dielectric and passivation layer. Electronics 2018, 7, 416. [Google Scholar] [CrossRef]

- Arulkumaran, S.; Egawa, T.; Ishikawa, H.; Jimbo, T.; Sano, Y. Surface passivation effects on AlGaN/GaN high-electron-mobility transistors with SiO2, Si3N4, and silicon oxynitride. Appl. Phys. Lett. 2004, 84, 613–615. [Google Scholar] [CrossRef]

- Boughrara, N.; Benzarti, Z.; Khalfallah, A.; Oliveira, J.C.; Evaristo, M.; Cavaleiro, A. Thickness-dependent physical and nanomechanical properties of AlxGa1−xN thin films. Mater. Sci. Semicond. Process. 2022, 151, 107023. [Google Scholar] [CrossRef]

- Gupta, A.; Chatterjee, N.; Kumar, P.; Pandey, S. Effect of surface passivation on the electrical characteristics of nanoscale AlGaN/GaN HEMT. IOP Conf. Ser. Mater. Sci. Eng. 2017, 225, 012095. [Google Scholar] [CrossRef]

- Mukhopadhyay, P.; Bag, A.; Gomes, U.; Banerjee, U.; Ghosh, S.; Kabi, S.; Chang, E.Y.; Dabiran, A.; Chow, P.; Biswas, D. Comparative DC characteristic analysis of AlGaN/GaN HEMTs grown on Si (111) and sapphire substrates by MBE. J. Electron. Mater. 2014, 43, 1263–1270. [Google Scholar] [CrossRef]

- Ji, H.; Das, J.; Germain, M.; Kuball, M. Laser lift-off transfer of AlGaN/GaN HEMTs from sapphire onto Si: A thermal perspective. Solid-State Electron. 2009, 53, 526–529. [Google Scholar] [CrossRef]

- Nigam, A.; Bhat, T.N.; Rajamani, S.; Dolmanan, S.B.; Tripathy, S.; Kumar, M. Effect of self-heating on electrical characteristics of AlGaN/GaN HEMT on Si (111) substrate. AIP Adv. 2017, 7, 085015. [Google Scholar] [CrossRef]

- Asubar, J.T.; Yatabe, Z.; Hashizume, T. Reduced thermal resistance in AlGaN/GaN multi-mesa-channel high electron mobility transistors. Appl. Phys. Lett. 2014, 105, 053510. [Google Scholar] [CrossRef]

- Song, L.; Fu, K.; Zhang, Z.; Sun, S.; Li, W.; Yu, G.; Hao, R.; Fan, Y.; Shi, W.; Cai, Y.; et al. Interface Si donor control to improve dynamic performance of AlGaN/GaN MIS-HEMTs. AIP Adv. 2017, 7, 125023. [Google Scholar] [CrossRef]

- Ha, M.W.; Choi, Y.H.; Park, J.H.; Seo, K.S.; Han, M.K. Hot Carrier Stress Effects of SiO2 Passivated AlGaN/GaN High Electron Mobility Transistors. ECS Trans. 2006, 3, 213–220. [Google Scholar] [CrossRef]

- Wu, Q.; Xu, Y.; Zhou, J.; Kong, Y.; Chen, T.; Wang, Y.; Lin, F.; Fu, Y.; Jia, Y.; Zhao, X.; et al. Performance comparison of GaN HEMTs on diamond and SiC substrates based on surface potential model. ECS J. Solid State Sci. Technol. 2017, 6, Q171–Q178. [Google Scholar] [CrossRef]

- Jin, D.; del Alamo, J.A. Mechanisms responsible for dynamic ON-resistance in GaN high-voltage HEMTs. In Proceedings of the 2012 24th International Symposium on Power Semiconductor Devices and ICs, Bruges, Belgium, 3–7 June 2012; pp. 333–336. [Google Scholar] [CrossRef]

- Ng, T.K.; Holguin-Lerma, J.A.; Kang, C.H.; Ashry, I.; Zhang, H.; Bucci, G.; Ooi, B.S. Group-III-nitride and halide-perovskite semiconductor gain media for amplified spontaneous emission and lasing applications. J. Phys. D Appl. Phys. 2021, 54, 143001. [Google Scholar] [CrossRef]

- Guillén-Cervantes, A.; Rivera-Álvarez, Z.; López-López, M.; Ponce-Pedraza, A.; Guarneros, C.; Sánchez-Reséndiz, V.M. Structural and optical properties of GaN thin films grown on Al2O3 substrates by MOCVD at different reactor pressures. Appl. Surf. Sci. 2011, 258, 1267–1271. [Google Scholar] [CrossRef]

- Liu, A.C.; Tu, P.T.; Langpoklakpam, C.; Huang, Y.W.; Chang, Y.T.; Tzou, A.J.; Hsu, L.H.; Lin, C.H.; Kuo, H.C.; Chang, E.Y. The evolution of manufacturing technology for GaN electronic devices. Micromachines 2021, 12, 737. [Google Scholar] [CrossRef] [PubMed]

| Substrates | Ra (nm) | HR-XRD 002 FWHM (Degree) | HR-XRD 004 FWHM (Degree) | XRC 002 FWHM (Arcsec) | XRC 102 FWHM (Arcsec) |

|---|---|---|---|---|---|

| AlGaN/GaN-on-Silicon | 2.96 | 0.20 | 0.23 | 720 | 1312 |

| AlGaN/GaN-on-sapphire | 0.88 | 0.13 | 0.12 | 368 | 647 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pharkphoumy, S.; Janardhanam, V.; Jang, T.-H.; Shim, K.-H.; Choi, C.-J. Correlation of Crystal Defects with Device Performance of AlGaN/GaN High-Electron-Mobility Transistors Fabricated on Silicon and Sapphire Substrates. Electronics 2023, 12, 1049. https://doi.org/10.3390/electronics12041049

Pharkphoumy S, Janardhanam V, Jang T-H, Shim K-H, Choi C-J. Correlation of Crystal Defects with Device Performance of AlGaN/GaN High-Electron-Mobility Transistors Fabricated on Silicon and Sapphire Substrates. Electronics. 2023; 12(4):1049. https://doi.org/10.3390/electronics12041049

Chicago/Turabian StylePharkphoumy, Sakhone, Vallivedu Janardhanam, Tae-Hoon Jang, Kyu-Hwan Shim, and Chel-Jong Choi. 2023. "Correlation of Crystal Defects with Device Performance of AlGaN/GaN High-Electron-Mobility Transistors Fabricated on Silicon and Sapphire Substrates" Electronics 12, no. 4: 1049. https://doi.org/10.3390/electronics12041049

APA StylePharkphoumy, S., Janardhanam, V., Jang, T.-H., Shim, K.-H., & Choi, C.-J. (2023). Correlation of Crystal Defects with Device Performance of AlGaN/GaN High-Electron-Mobility Transistors Fabricated on Silicon and Sapphire Substrates. Electronics, 12(4), 1049. https://doi.org/10.3390/electronics12041049