Examination of a Method for Estimating Solid Fraction at Flow Cessation from Flow Velocity of Mushy Formation Molten Alloys

Abstract

1. Introduction

2. Calculation Method

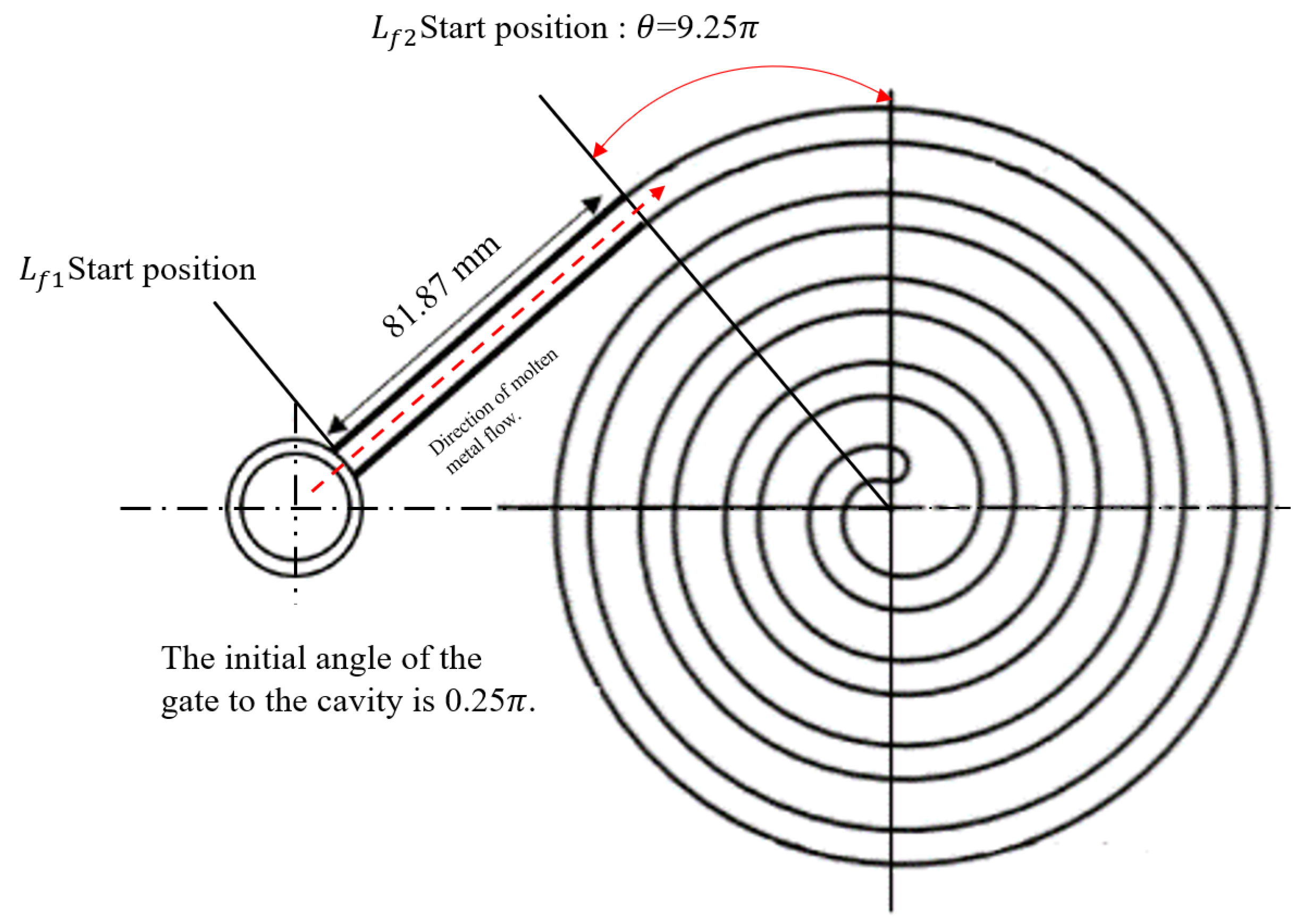

2.1. Calculation Method of Flow Length in Spiral Cavity

2.2. Proposed Method for Estimating the Solid Fraction at the Flow Cessation

3. Experimental Method

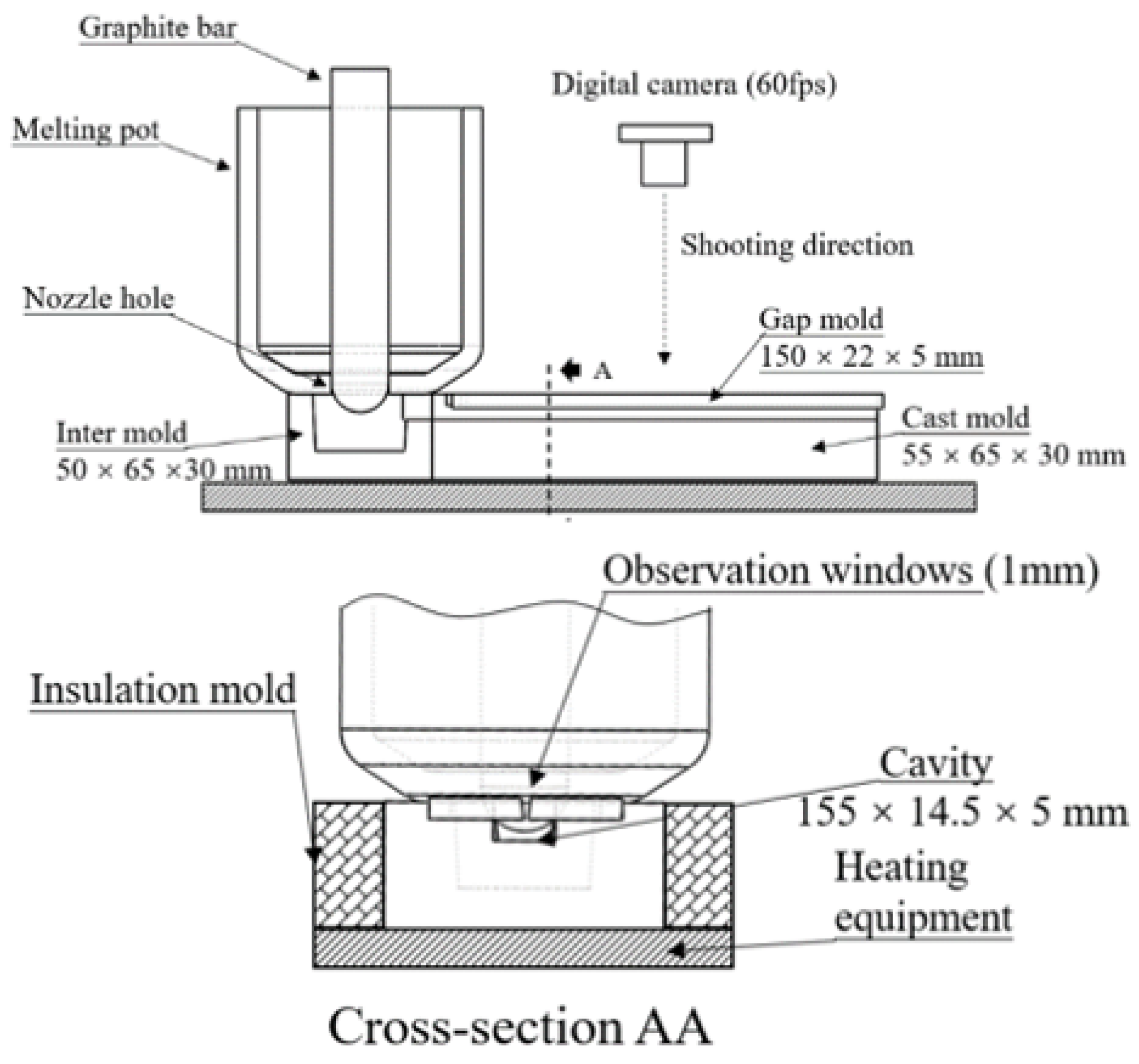

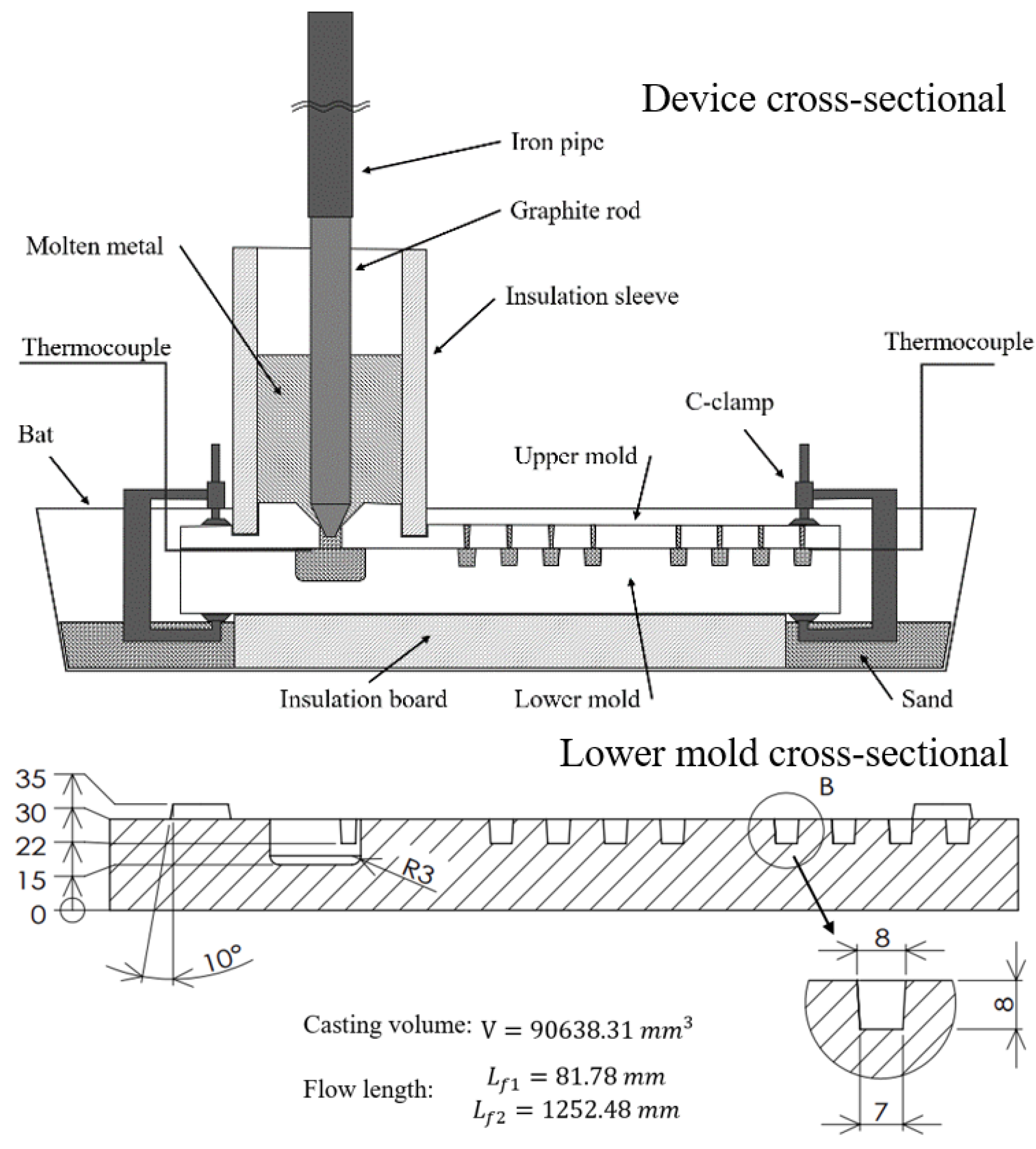

3.1. Linear Cavity Aluminum Alloy Experiment

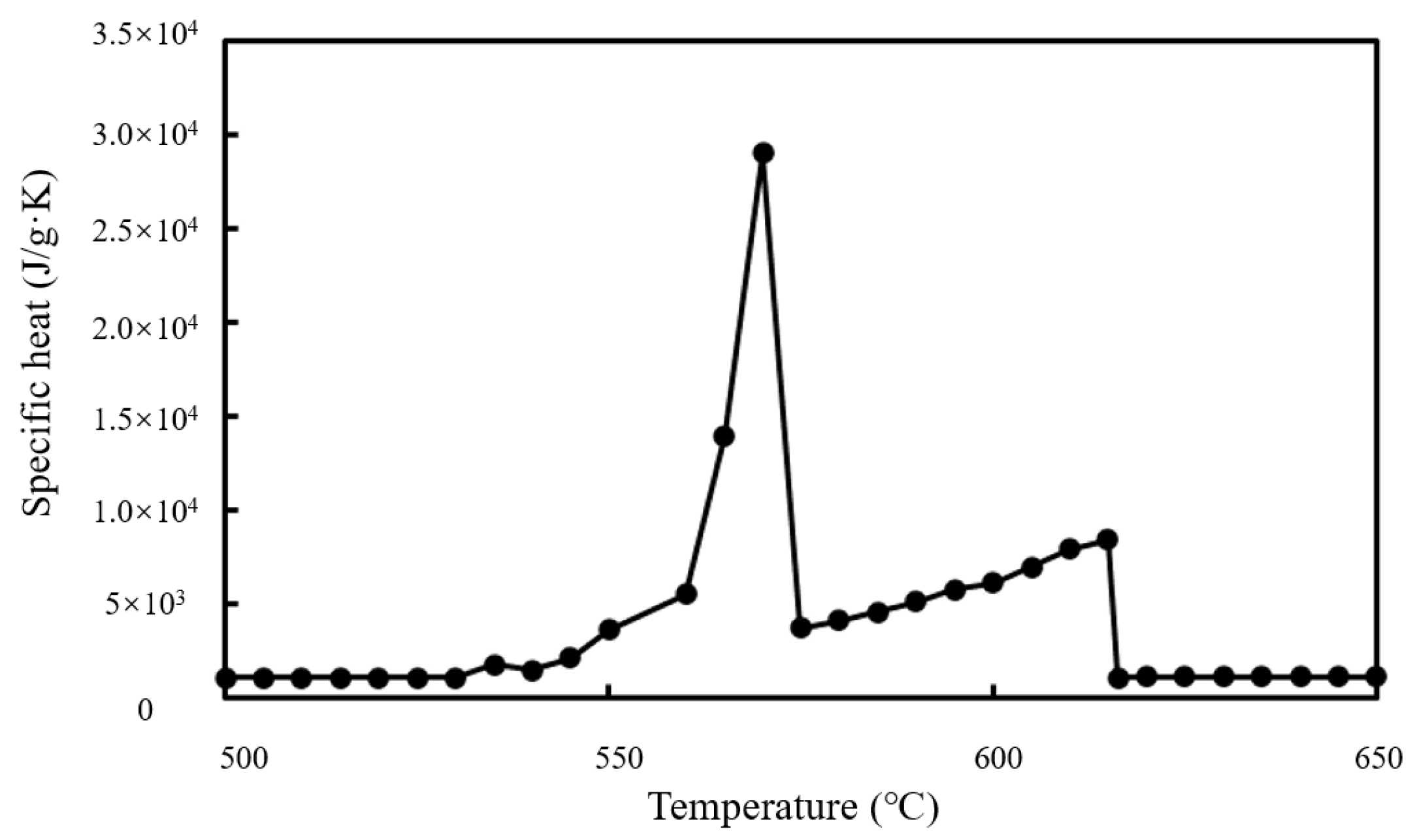

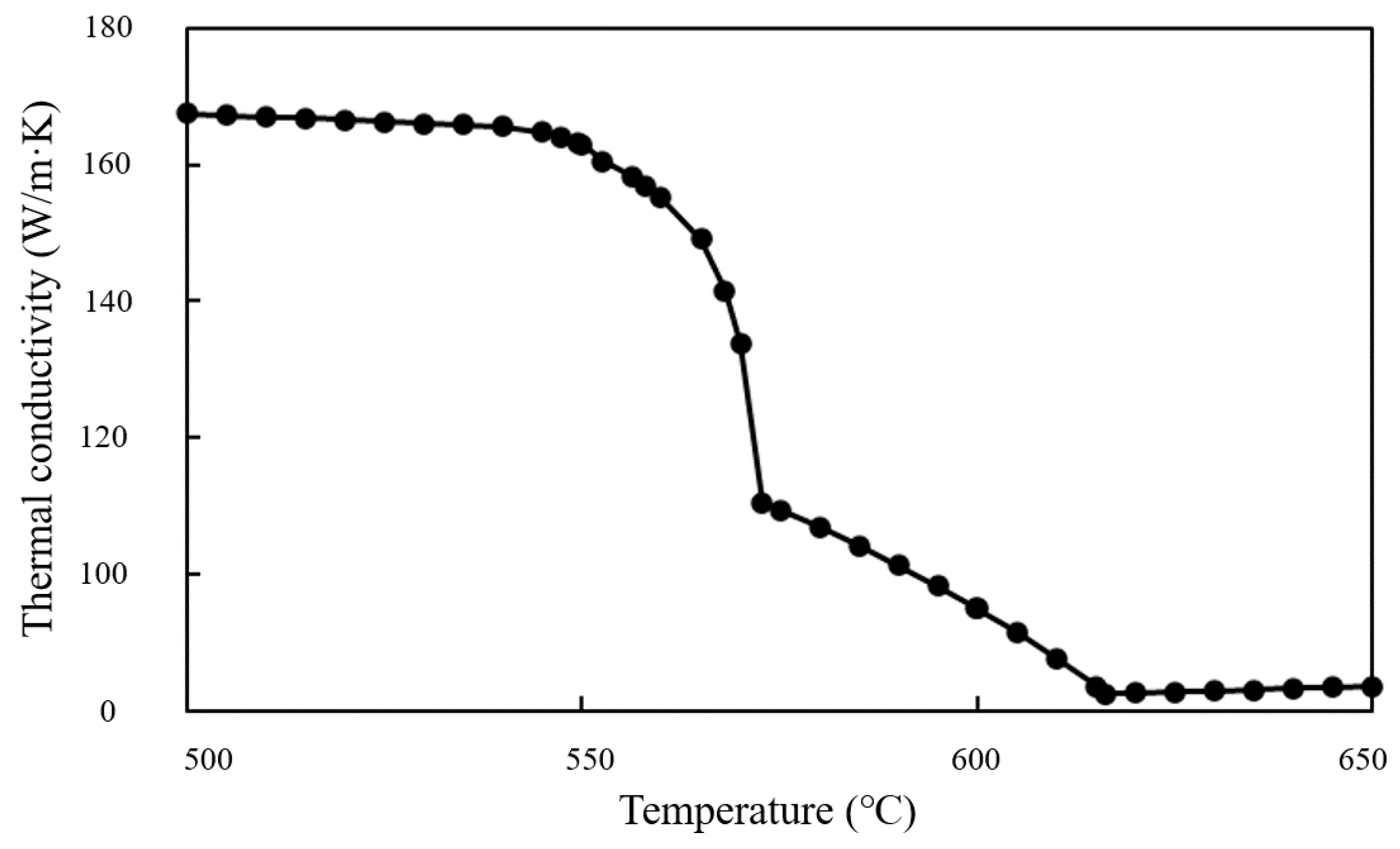

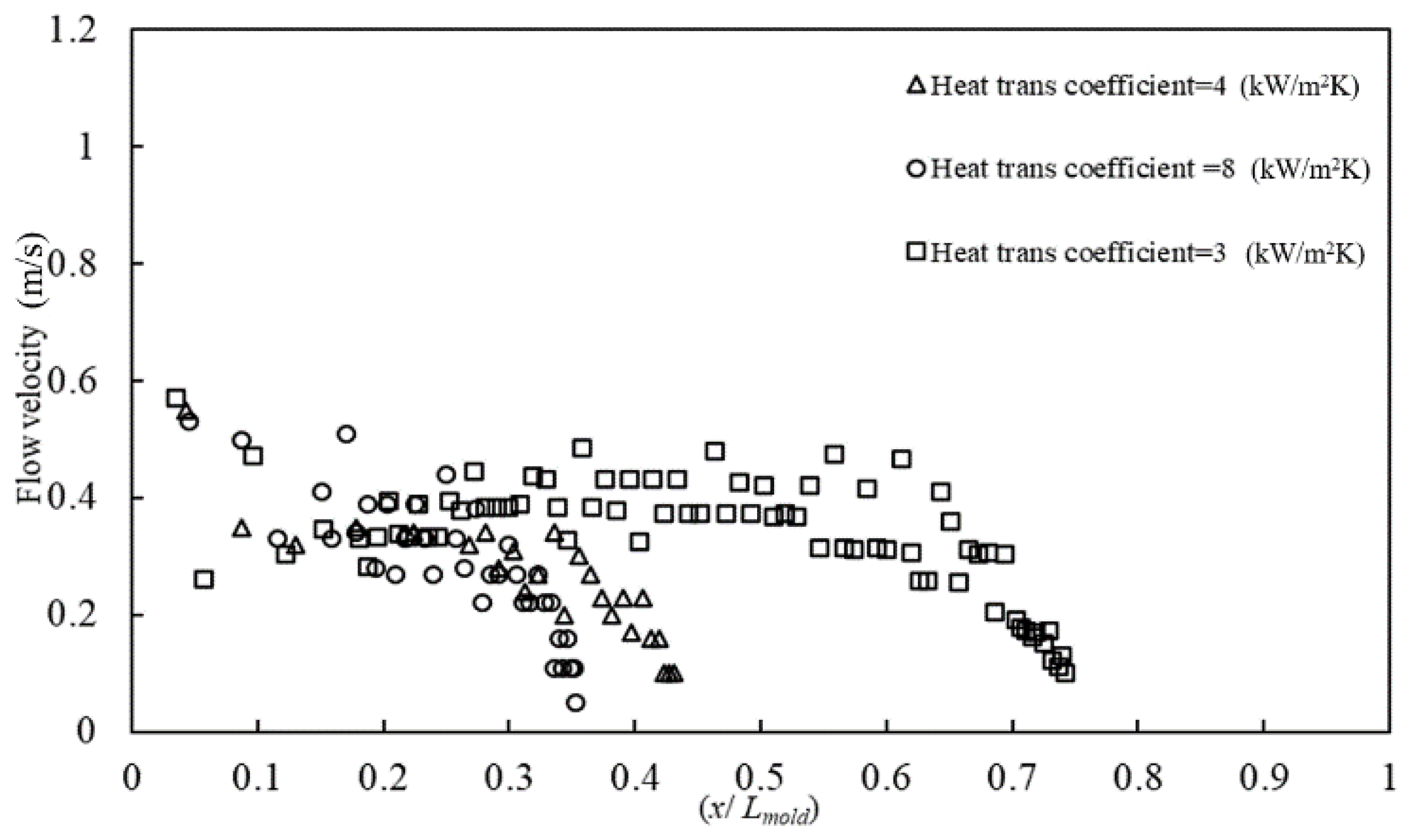

3.2. Computer Simulation of the Linear Cavity

3.3. Spiral Cavity Copper Alloy Experiment

3.4. Computer Simulation of the Spiral Cavity

4. Results and Discussion

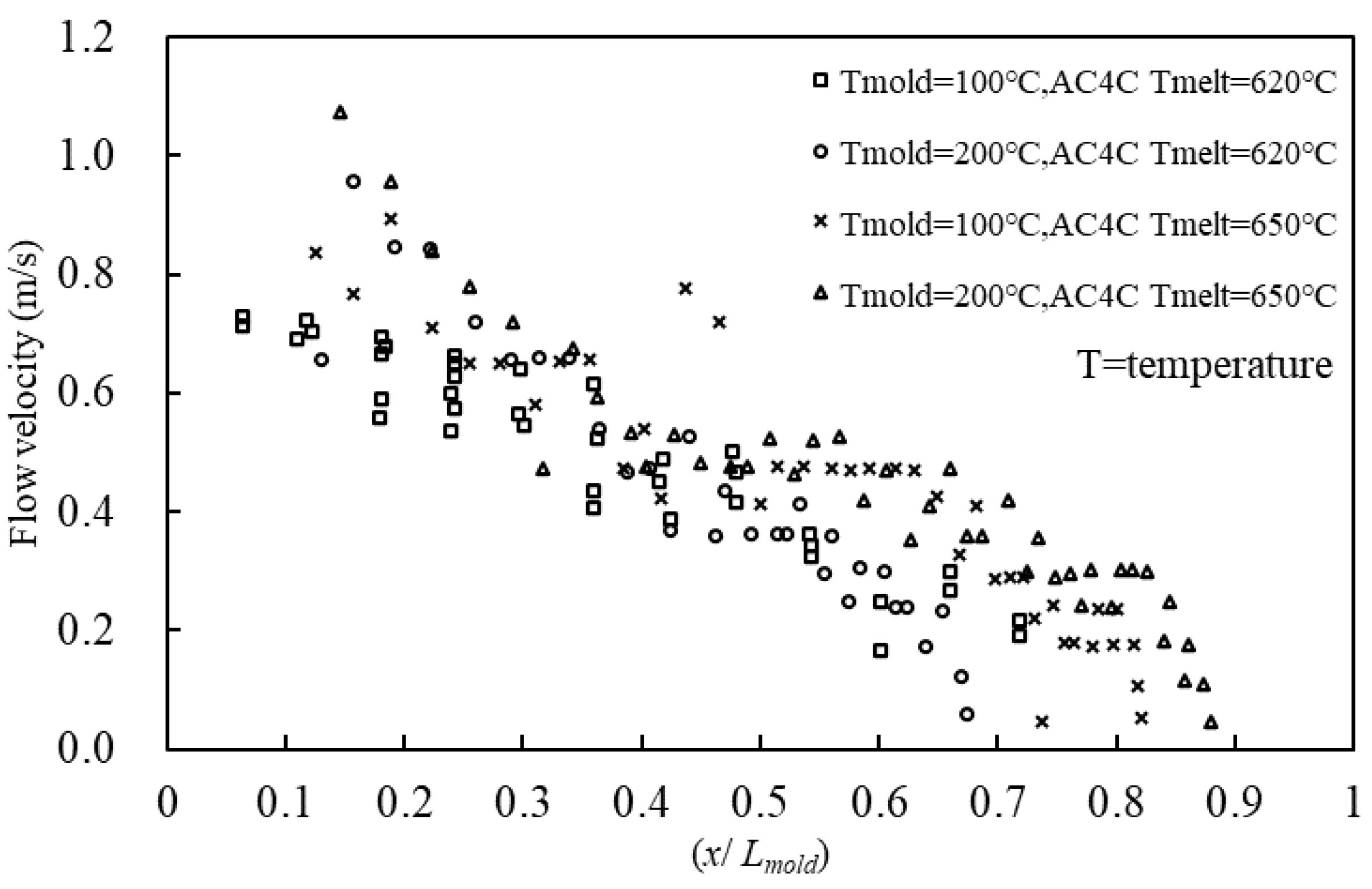

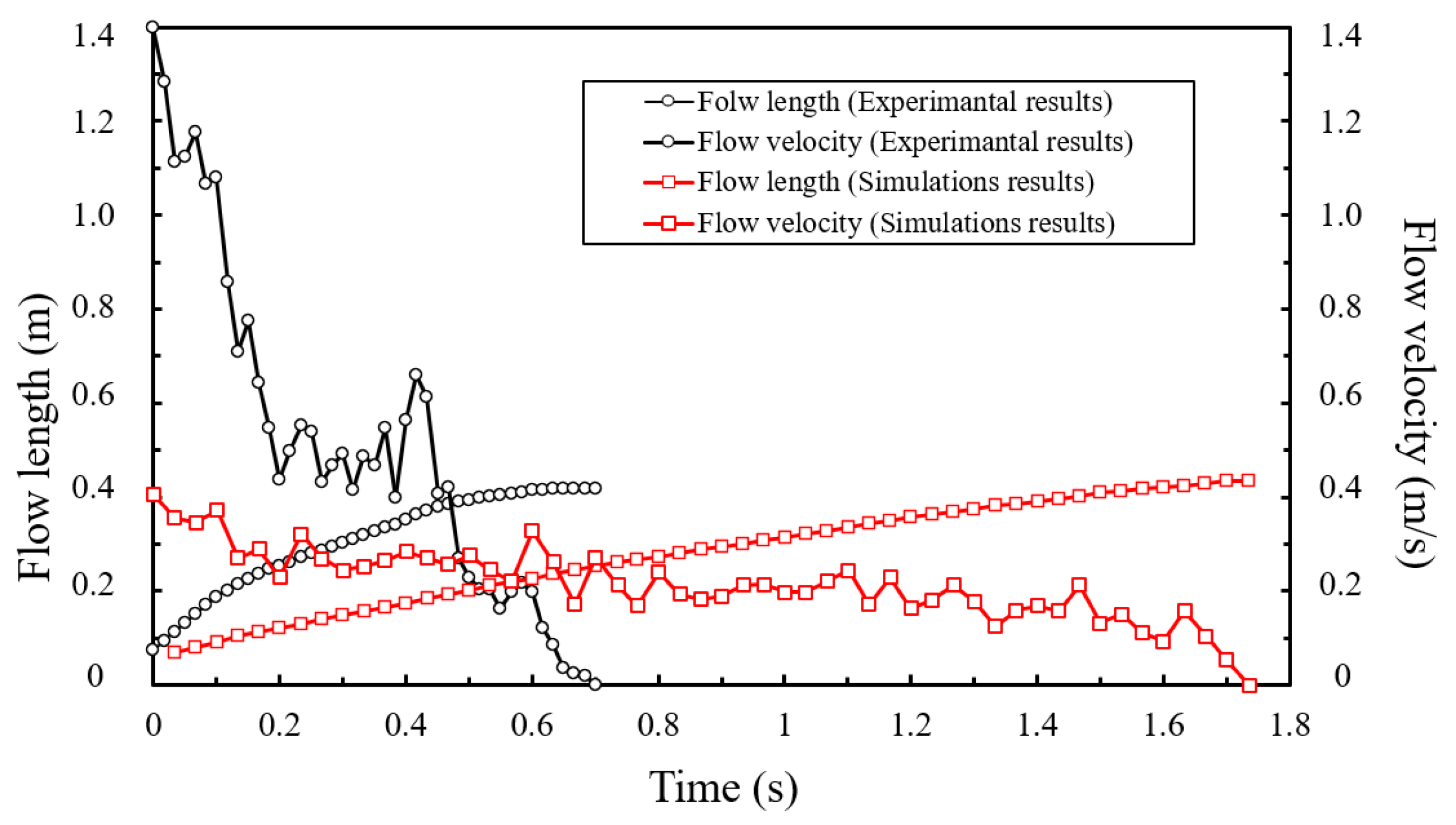

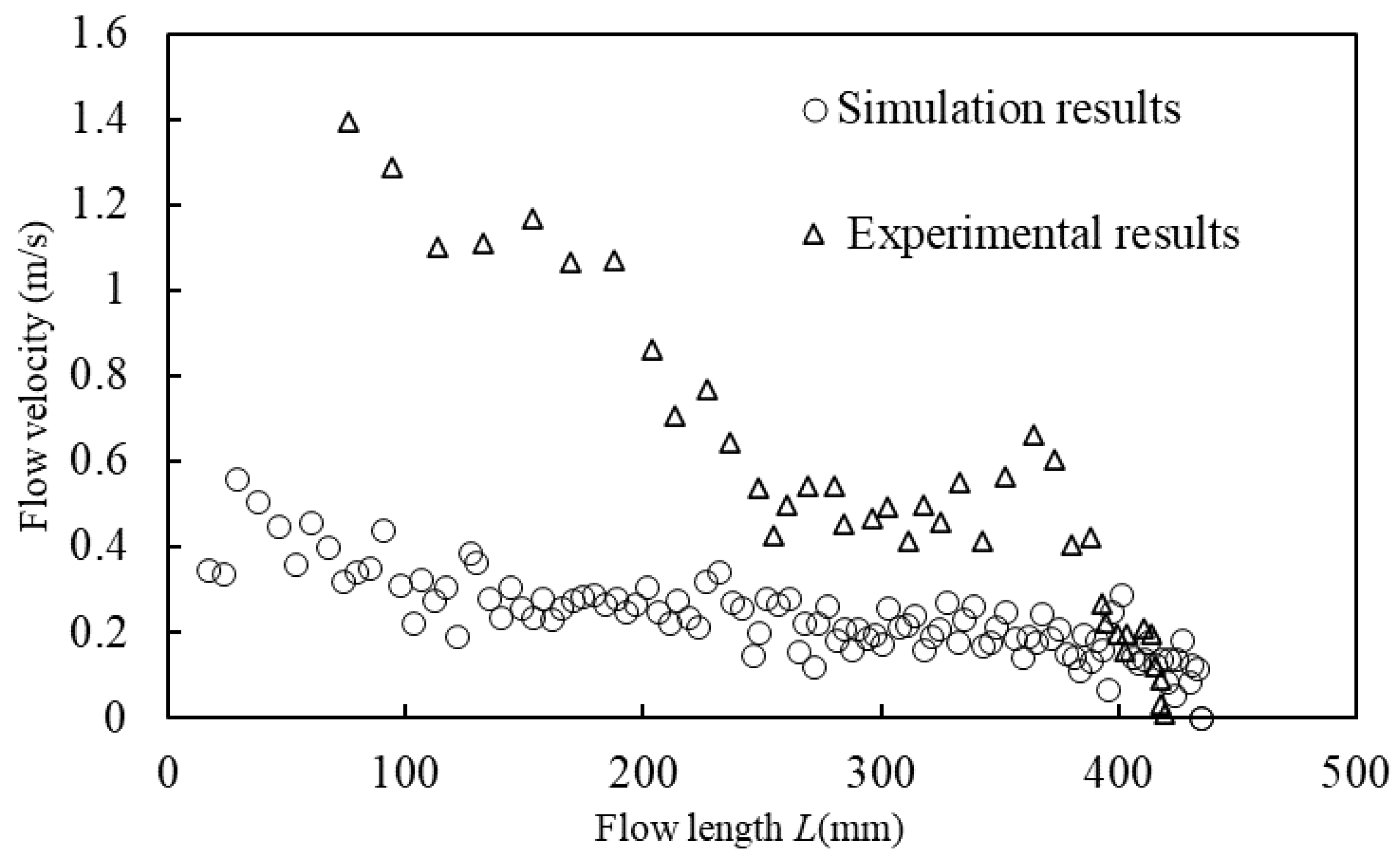

4.1. Linear Cavity Aluminum Alloy Experiment Results

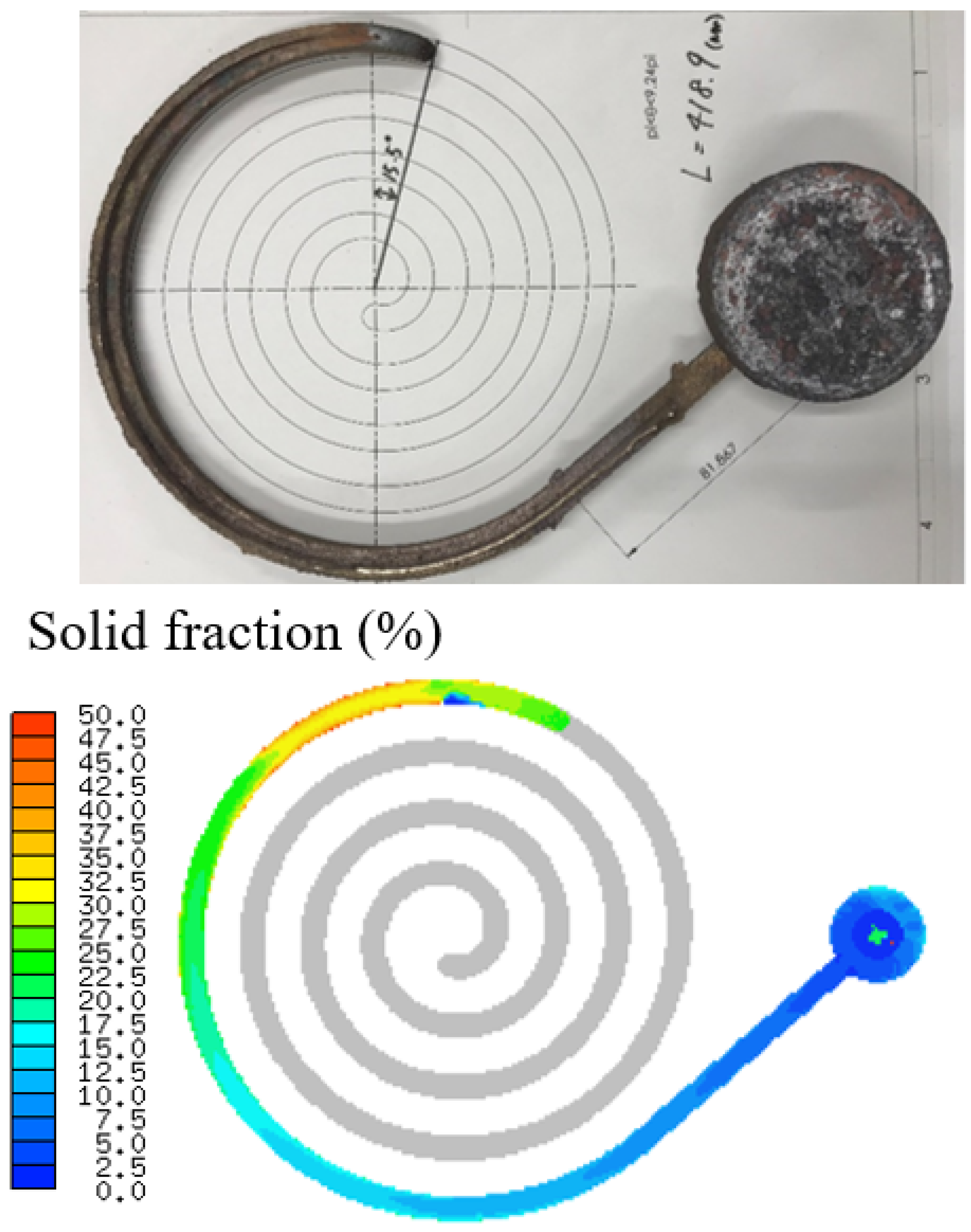

4.2. Spiral Cavity Copper Alloy Experiment Results

5. Conclusions

- A method was proposed to estimate the solid fraction at flow cessation in Al–7%Si–0.3%Mg alloys with a mushy formation morphology from the flow velocity at the tip of the molten metal.

- The resulting solid fraction was similar to the values reported in other studies, and it was verified in the fluidity experiment of the Cu–8%Sn alloy with the same solidification mode, demonstrating the effectiveness of this method.

- This method was examined only for mushy-type solidified metals. Its effectiveness has not been proved with other solidification-type metals. Additional research is planned.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Nikawa, M.; Iba, Y.; Yamashita, M. Solid Fraction Examination at Flow Cessation and Flow Cessation Mechanism of Al-Si-Mg Alloy. Int. J. Autom. Technol. 2020, 14, 835–842. [Google Scholar] [CrossRef]

- Iwata, Y.; Dong, S.; Sugiyama, Y.; Iwahori, H. Effects of Solidification Behavior during Filling on Surface Defects of Aluminum Alloy Die Casting. Mater. Trans. 2013, 54, 1944–1950. [Google Scholar] [CrossRef]

- Sugiyama, A.; Ohnaka, I.; Iwane, J.; Yasuda, H. Direct Observation and Numerical Simulation of Mold Filling. J. Jpn. Foundry Eng. Soc. 2006, 78, 691–697. [Google Scholar]

- Nakae, H.; Oota, K.; Sato, K. Influence of Wettability between Molten Metal and Mold Materials on Fluidity Using Water Model. J. Jpn. Foundry Eng. Soc. 2007, 79, 285–290. [Google Scholar]

- Kashiwa, S.; Zhu, J.D.; Ohnaka, I. Numerical Prediction of Mold Filling and Misrun of AC4C Plate Castings. J. Jpn. Foundry Eng. Soc. 2001, 73, 592–597. [Google Scholar]

- Miura, K.T.; Usuki, S.; Sekine, T. An Extension of algebraic spiral including Archimedes, Fermat, lituus and Hyperbolic Spirals and Its Properties. Proc. JSPE Semest. Meet. 2019, 679–680. [Google Scholar]

- Flemings, M.C.; Niiyama, E.; Taylor, H.F. Fluidity of Aluminum Alloys. Am. Foundrymen’s Soc. Trans. 1961, 69, 625–635. [Google Scholar]

- Kitaoka, S. Molten Metal and Solidification Properties of Aluminum Alloys. J. Jpn. Foundry Eng. Soc. 2013, 85, 697–707. [Google Scholar]

- Adachi, M.; Tachibana, H.; Koiwai, S.; Murase, K.; Yamagata, H. Study on Effects of B and Sr on Hot Tearing of JIS AC4C Alloy T-Shape Casting. J. Jpn. Foundry Eng. Soc. 2021, 87, 545–551. [Google Scholar]

- Toshiyuki, M.; Norio, S.; Yoshiki, M.; Shigek, K. Study on Casting for Quality Improvement and Quality Control Technique—Analysis for Coagulated Condition on Copper Alloy Casting. Available online: https://www.gitec.rd.pref.gifu.lg.jp/files/reports/2020/gitec_2020_06.pdf (accessed on 30 October 2022).

- Mu, K.; Nikawa, M.; Yamashita, M. Effect of Powder Mold Release Agent on Aluminum Alloy Melt under Gravity Casting Conditions. Int. J. Autom. Technol. 2022, 16, 888–896. [Google Scholar] [CrossRef]

- Loue, W.R.; Landkroon, S.; Kool, W.H. Rheology of Partially Solidified AlSi7Mg0.3 and the Influence of SiC Additions. Mater. Sci. Eng. A 1992, 151, 255–262. [Google Scholar] [CrossRef]

- Oya, S.; Sayashi, M.; Kambe, H.; Hosaka, K. Fluidity of Cu-Sn Alloys Related with Crystallizatio. J. Jpn. Foundrymen’s Soc. 1980, 52, 107–112. [Google Scholar]

- Yamamoto, M.; Hirai, Y. Effect of Nickel on Characteristics of Bismuth Bronze Castings. J. Jpn. Foundry Eng. Soc. 2009, 81, 170–176. [Google Scholar]

| Si | Mn | Mg | Fe | Ti | Cu | Zn | Cr |

|---|---|---|---|---|---|---|---|

| 7.0 | 0.40 | 0.35 | 0.25 | 0.16 | 0.10 | 0.07 | 0.01 |

| Simulation Parameters | Input Parameters |

|---|---|

| Mesh size (mm) | 0.5 |

| Initial temperatures molten metal (°C) | 620 |

| Initial temperatures cast mold (°C) | 100 |

| Ambient temperature (°C) | 22 |

| Liquidus temperature (°C) | 615 |

| Solidus temperature (°C) | 540 |

| Initial flow velocity distribution of gate (m/s) | 0.53 |

| 3.0 | |

| Heat transfer coefficient (kW/m2·K) | 4.0 |

| 8.0 |

| Physical Property | Input Data |

|---|---|

| Latent heat of solidification (J/kg) | |

| Denticity (kg/m3 | |

| Specific heat (J/kg·K) | |

| Flow length (m) | Experimental value |

| Flow velocity (m/s) | Experimental value |

| Peripheral length of the flow channel (m) | Measured value |

| Surface area of the flow channel (m2) | Measured value |

| Heat transfer coefficient (kW/m2·K) | Simulation value |

| Sn | Pb | Zn |

|---|---|---|

| 8.0 | 6.0 | 4.0 |

| Physical Property | Input Data |

|---|---|

| Latent heat of solidification (J/kg) | |

| Denticity (kg/m3) | |

| Specific heat (J/kg·K) | |

| Flow length (m) | Experimental value |

| Flow velocity (m/s) | Experimental value |

| Peripheral length of the flow channel (m) | Measured value |

| Surface area of the flow channel (m2) | Measured value |

| Heat transfer coefficient (kW/m2·K) | Simulation value |

| Simulation Parameters | Input Parameters |

|---|---|

| Mesh size (mm) | 0.5 |

| Initial temperatures molten metal (°C) | 1080 |

| Initial temperatures sand mold (°C) | 23 |

| Liquidus temperature (°C) | 1010 |

| Solidus temperature (°C) | 855 |

| Heat Transfer Coefficient | |

|---|---|

| 3 kW/m2K | 1.04 |

| 4 kW/m2K | 0.61 |

| 8 kW/m2K | 0.50 |

| Initial Cast Mold Temp (°C) | Initial Molten Metal Temp | Calculation Result |

|---|---|---|

| 620 | 0.35 | |

| 100 | 650 | 0.30 |

| 620 | 0.40 | |

| 200 | 650 | 0.36 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mu, K.; Nikawa, M.; Yamashita, M. Examination of a Method for Estimating Solid Fraction at Flow Cessation from Flow Velocity of Mushy Formation Molten Alloys. Electronics 2023, 12, 365. https://doi.org/10.3390/electronics12020365

Mu K, Nikawa M, Yamashita M. Examination of a Method for Estimating Solid Fraction at Flow Cessation from Flow Velocity of Mushy Formation Molten Alloys. Electronics. 2023; 12(2):365. https://doi.org/10.3390/electronics12020365

Chicago/Turabian StyleMu, Kuiyuan, Makoto Nikawa, and Minoru Yamashita. 2023. "Examination of a Method for Estimating Solid Fraction at Flow Cessation from Flow Velocity of Mushy Formation Molten Alloys" Electronics 12, no. 2: 365. https://doi.org/10.3390/electronics12020365

APA StyleMu, K., Nikawa, M., & Yamashita, M. (2023). Examination of a Method for Estimating Solid Fraction at Flow Cessation from Flow Velocity of Mushy Formation Molten Alloys. Electronics, 12(2), 365. https://doi.org/10.3390/electronics12020365