1. Introduction

Since the 1970s, Human Reliability Analysis (HRA) techniques [

1,

2,

3,

4] have been widely implemented in Nuclear Power Plants (NPPs) to quantify the human error contribution to the occurrence of accidents [

5]. Only in recent years, HRA methods have been also extended to other fields [

6,

7,

8,

9], owing to the central role played by human behavior to the risk exposure in whatever workplace.

Among HRA methodologies, the second-generation ones aim both to identify the root causes of human errors, which lead to accidents, and to evaluate the Human Error Probability (HEP) when performing a generic task. In particular, these techniques are based on the use of Performance Shaping Factors (PSFs) to consider the dependence of worker performance on personal, contextual, and cognitive factors strictly related to the work environment. Although HRA methods generally disregard the existence of mutual interactions among PSFs, the empirical evidence shows otherwise. As a result, HEP may be over- or underestimated. Therefore, it is important to account for whether some PSFs affect each other, or whether PSFs have different phenomena affected by the same cause [

6,

10].

To evaluate the degree of interrelationship between PSFs, only a few contributions to the literature propose qualitative guidelines [

1,

3,

4] and/or analytical methodologies [

6,

10,

11,

12,

13,

14,

15,

16], mainly implementing statistical-based analyses. While qualitative methods do not provide a well-structured approach, the quantitative ones are very challenging to implement, owing to both the computational effort and the sample size (i.e., input data) required to assure the significance of results [

10,

11,

12,

13,

17,

18]. With this recognition, Multi Criteria Decision Making (MCDM) methods may represent a robust, structured, and easier way to assess the mutual influence among PSFs, also owing to the absence of limitations and/or assumptions on the number of involved decision makers (i.e., sample size) [

19]. In this regard, authors have recently proposed a DEcision MAking Trial and Evaluation Laboratory (DEMATEL)-based approach [

20] to deal with the SPARH PSFs interrelationship issue in the agri-food sector. Developed by Gabus and Fontela [

21], DEMATEL allows both the cause-and-effect scheme among factors of a complex decision problem and their relative importance (i.e., weights) to be obtained [

22,

23,

24,

25]. In addition, the method may be easily implemented and supplies a clear representation of results [

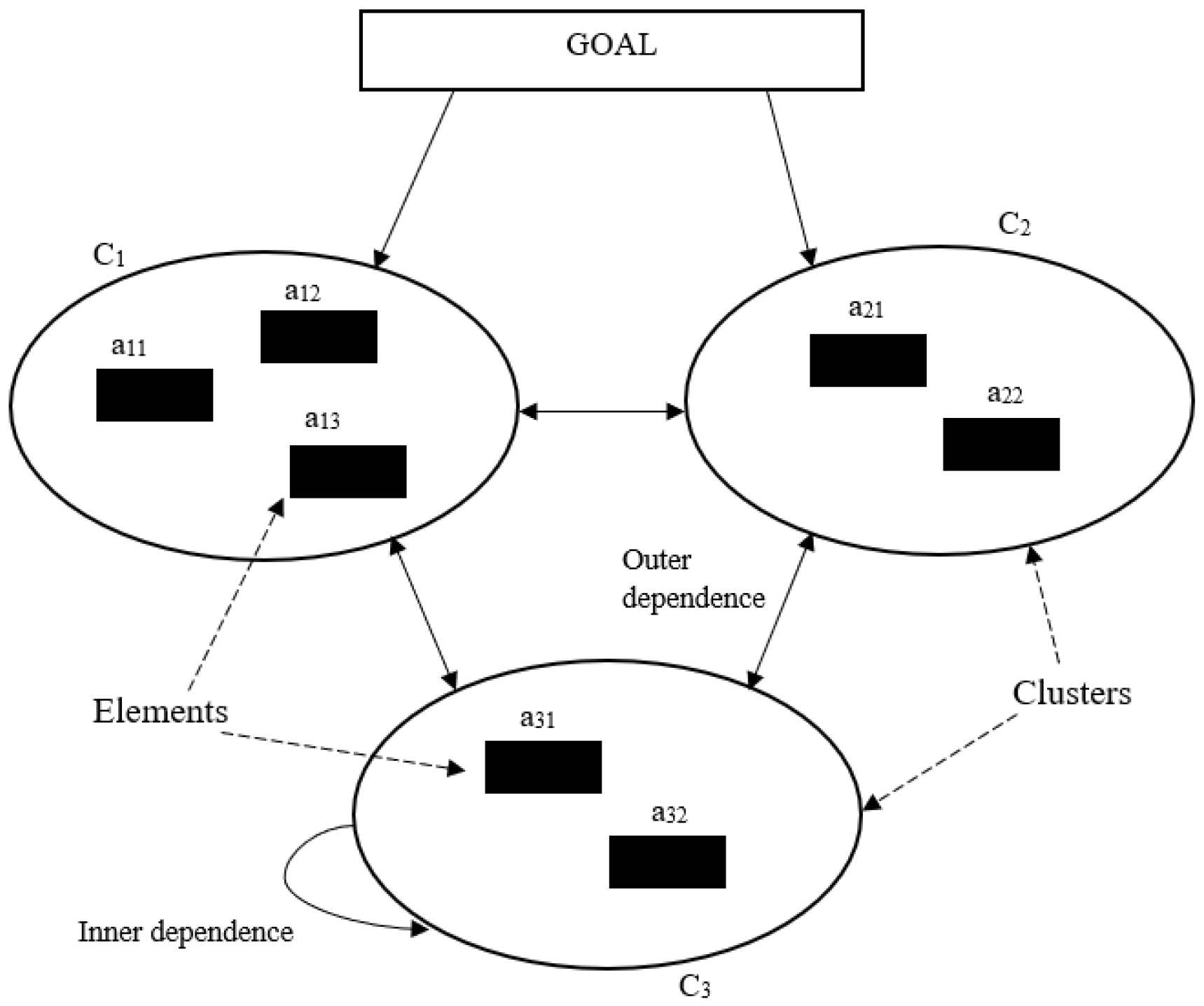

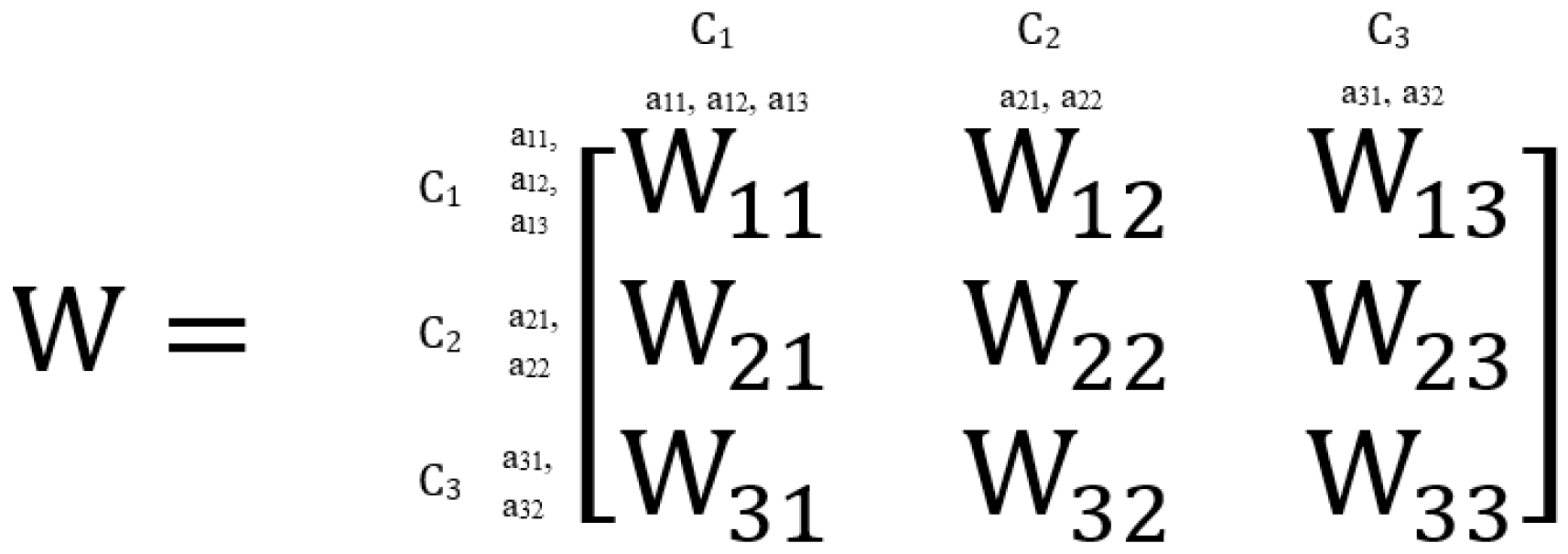

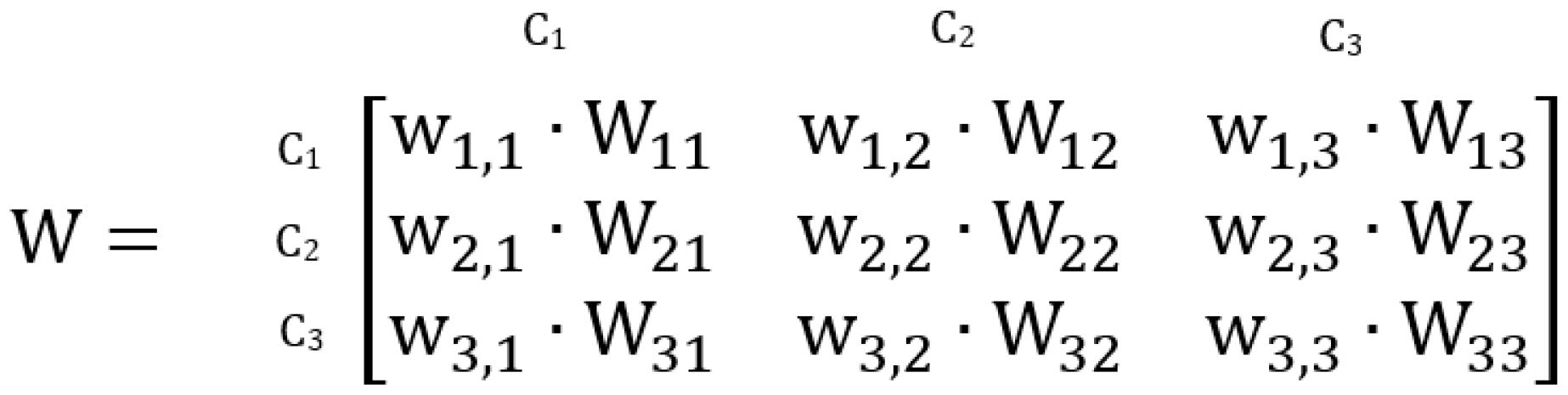

23]. Among MCDM methodologies, the Analytic Network Process (ANP) [

26] is an alternative approach which also allows the interdependence among decision factors to be considered. Therefore, a comparison analysis between DEMATEL and ANP is performed in the present paper in the attempt to highlight the main advantages and disadvantages of applying both methods within HRA. To this purpose, the analysis is performed in relation to the agri-food company involved in the prior work of the authors [

20], where the generic tasks carried out by workers during the pistachio’s production process are considered to evaluate the dependence among PSFs of the SPARH method. As a result, the most central PSFs on which corrective measures are needed with priority to improve the overall human reliability are found.

The remainder of the paper is organized as follows. The literature review is presented in

Section 2, while a short overview of the two MCDM methods is given in

Section 3. The case study is presented and discussed in

Section 4 and

Section 5, respectively, whilst conclusions are given in

Section 6.

2. Literature Review

HRA methods propose similar PSF taxonomies—even if differently named—to consider the contribution of personal, cognitive, and environmental factors to worker reliability when performing tasks. In this regard, the Technique for Human Error Rate Prediction (THERP) [

1] takes into account a group of sixty-seven PSFs organized in external, internal, and stress factors. Their evaluation is aimed to compute an error factor, which allows to adjust the nominal HEP already provided by THERP for a listed set of human errors. The Human Error Assessment and Reduction Technique (HEART) [

27] proposes a set of thirty-eight Error Producing Conditions (EPCs) (e.g., distraction, tiredness, and cramped conditions), whose qualitative evaluation is used to compute their effect on HEP. The Cognitive Reliability and Error Analysis Method (CREAM) [

3] provides a list of nine Common Performance Conditions (CPCs), whose qualitative evaluation of their effect on human reliability (i.e., “improved”, “reduced”, or “not significant”) leads to a control mode (i.e., “Scrambled”, “Opportunistic”, “Tactical”, and “Strategic”) which corresponds to a specific HEP range. On the other hand, the Standardized Plant Analysis Risk-Human reliability analysis (SPARH) [

4] is based on eight PSFs which are semi-quantitatively assessed to adjust the nominal HEP of a generic task.

Nevertheless, the traditional HRA methods disregard the interdependence among PSFs when computing the human reliability, although the empirical evidence demonstrates that overlapping and mutual influences may exist in some circumstances [

10,

15]. As a consequence, HEP may be over- or underestimated [

12]. In the literature, little attention has been paid to the PSF interdependence issue so far, and only few qualitative guidelines or analytical methodologies have been provided to assess its effect on HEP. In this regard, CREAM simply mentions that CPCs may affect one another, but no guidelines about the way to quantify these interactions are provided. SPARH suggests a procedure to prevent analysts from the double counting of PSFs, based on the use of linguistic variables (i.e., zero, low, medium, high, and complete) to assign a qualitative correlation degree between PSFs. Groth [

11] proposes a hybrid statistical method which combines correlation and factor analyses to determine PSF interrelationships. After analyzing the reports of eighty-two nuclear incidents, Boring [

12] performs a correlation analysis to quantify the mutual relation degree among PSFs of SPARH. With relation to the Air Traffic Control (ATC) room operation field, De Ambroggi and Trucco [

6] propose an ANP-based method, while Groth and Swiler [

13] deal with the PSF interdependence issue by Bayesian Networks (BNs). After interviewing fifty-two workers of the railway staff, Kyriakidis et al. [

28] combine ANP and Success Likelihood Index Methodology (SLIM) techniques on a customized PSF taxonomy. Based on a review performed on 224 events from 2002 to 2017 in Korean NPPs, Park et al. [

10] suggest a statistical methodology combining correlation and factor analyses to quantify the mutual dependence between PSFs in NPPs control room operations. According to the opinion of 432 civil flight pilots, Wang et al. [

18] implement statistical moderating and mediating effect analyses to determine the mutual dependence degree among PSFs which affect crew operations. Liu et al. [

15] assess the interdependence between PSFs of SPARH through a system-dynamics-based approach, while La Fata et al. [

16] combine HEART and SPARH methods to compute the HEP, taking into account PSFs correlations based on Boring’s results [

12]. Finally, Adelfio et al. [

20] implement DEMATEL in the agro-food sector to evaluate the mutual relation of PSFs of the SPARH method.

4. Case Study: Input Data and Results

Referring to an agri-food company operating in Southern Italy, DEMATEL and ANP are used in the present paper to assess the interdependence degree among PSFs influencing the workers’ reliability. In the MCDM perspective, PSFs are hence considered as dependent criteria whose mutual influences have to be properly identified and computed. In this regard, the SPARH list of PSFs [

4,

7,

8,

16] is here taken into account (

Table 4).

The company involved in the study deals with the pistachio production chain, including cultivation, harvesting, and product processing. The assessment of the PSFs interdependence is carried out on activities performed at the production plant, owing to their criticality as stated by the company’s owner. The production process is completely automated, and activities performed by workers mainly concern quality checks and the setting of process parameters. In detail, the production process tasks are described in the following.

- (a)

Waste separation: pistachios are loaded onto a hopper (

Figure 5) and sent to a gravity separator machine and to a rotary drum sorter through a cochlea, in order to remove harvesting wastes (e.g., leaves and stones). In this phase, two operators supervise the pistachio flow, avoiding blockage and modifying the process parameters if required (i.e., rotation speed of the cochlea and flow rate of the air jet of the gravity separator machine).

- (b)

Husking process: pistachios are cleaned and separated from the husk through a hulling machine (

Figure 6). In this phase, the operators have to set the rotation speed of the hulling machine and the flow rate of the cleaning water, which allows them to take away the husk from the pistachios.

- (c)

Drying process: pistachios are finally sent to a dryer (

Figure 7) powered by a diesel burner, where the moisture content of the products is reduced up to 4–6 wt% through streams of heated air. The main parameters to be set are the drying time, the temperature of the hot air, and the product temperature, which must not exceed 45 °C.

With relation to the PSFs dependence, input data required by the two MCDM methods were elicited from the company’s owner (i.e., decision maker), owing to his/her expertise in the field under investigation. Regarding DEMATEL, the decision maker was asked to answer the question “How much does the

PSFi affect the

PSFj?”. Based on the five-point linguistic scale of

Table 1, the pairwise comparison matrix (i.e., direct-relation matrix

Z) of

Table 5 is obtained.

Once the normalized-relation matrix is computed according to Equation (1), the total-relation matrix

T (

Table 6) is obtained by Equation (2), where every element

tij represents both the direct and indirect influence of the

PSFi on the

PSFj.

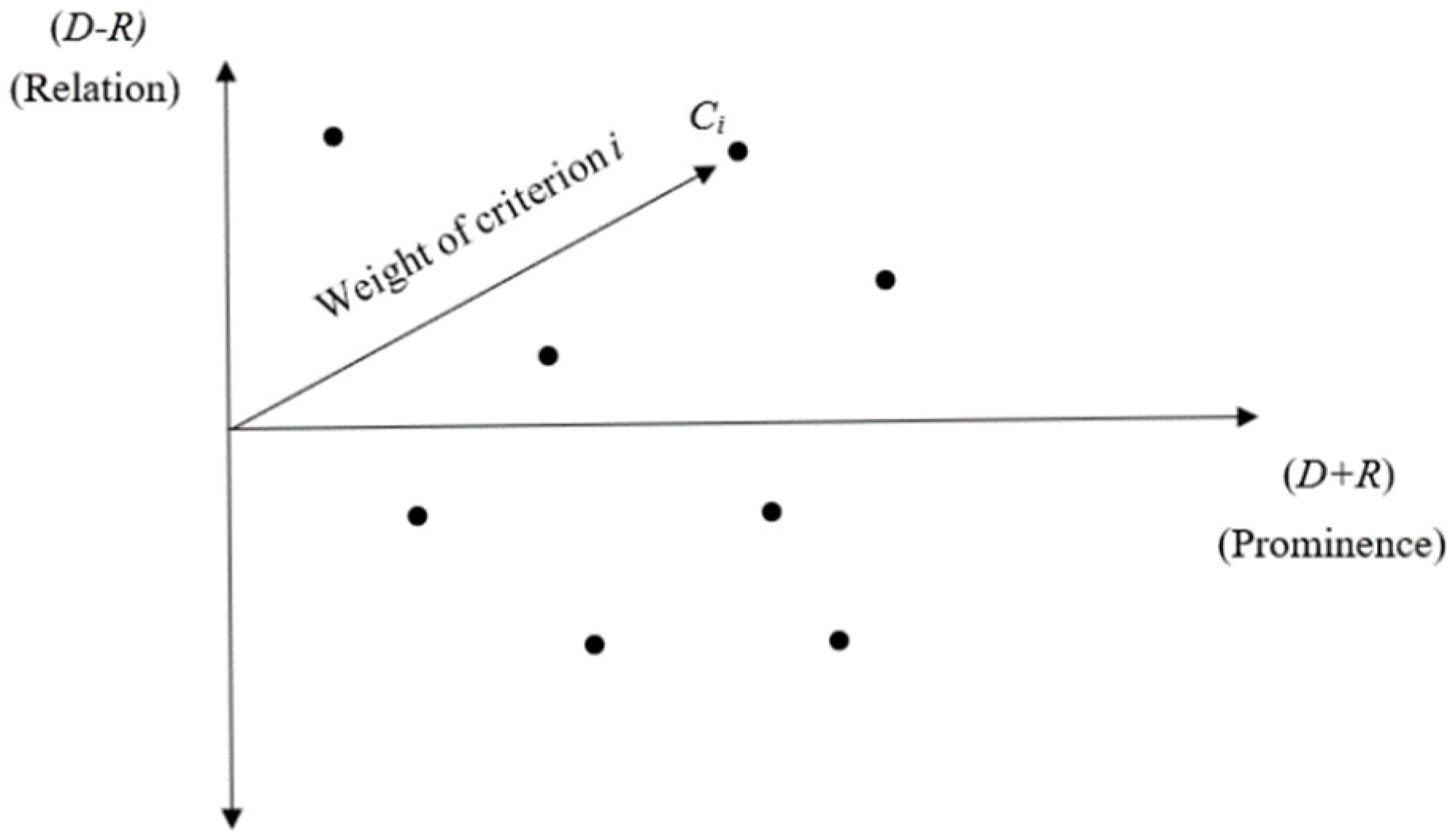

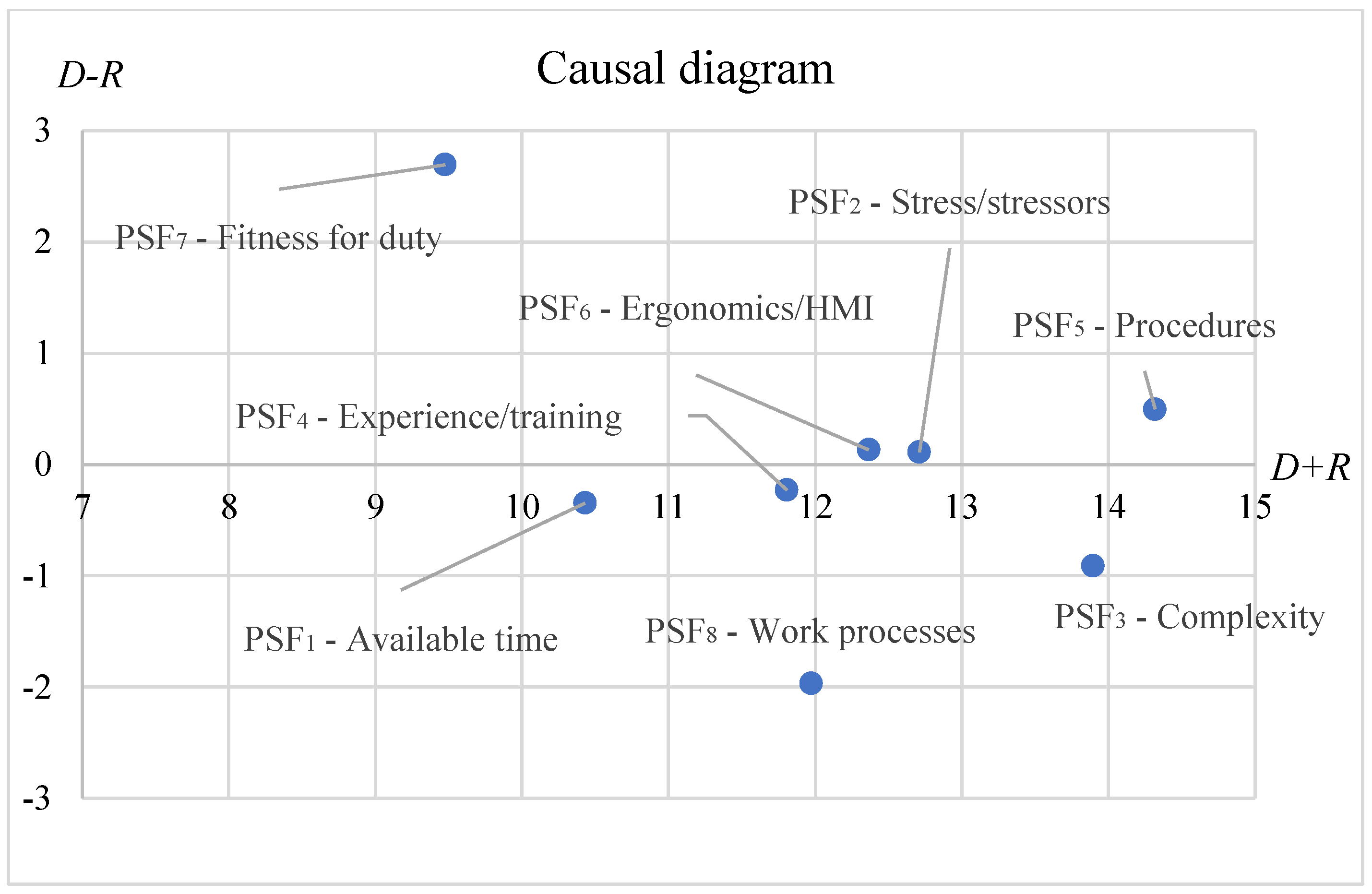

The resulting values of prominence (

D +

R), relation (

D −

R), weights, and normalized weights are computed by Equations (3)–(6) and summarized in

Table 7, while the causal diagram is reported in

Figure 8.

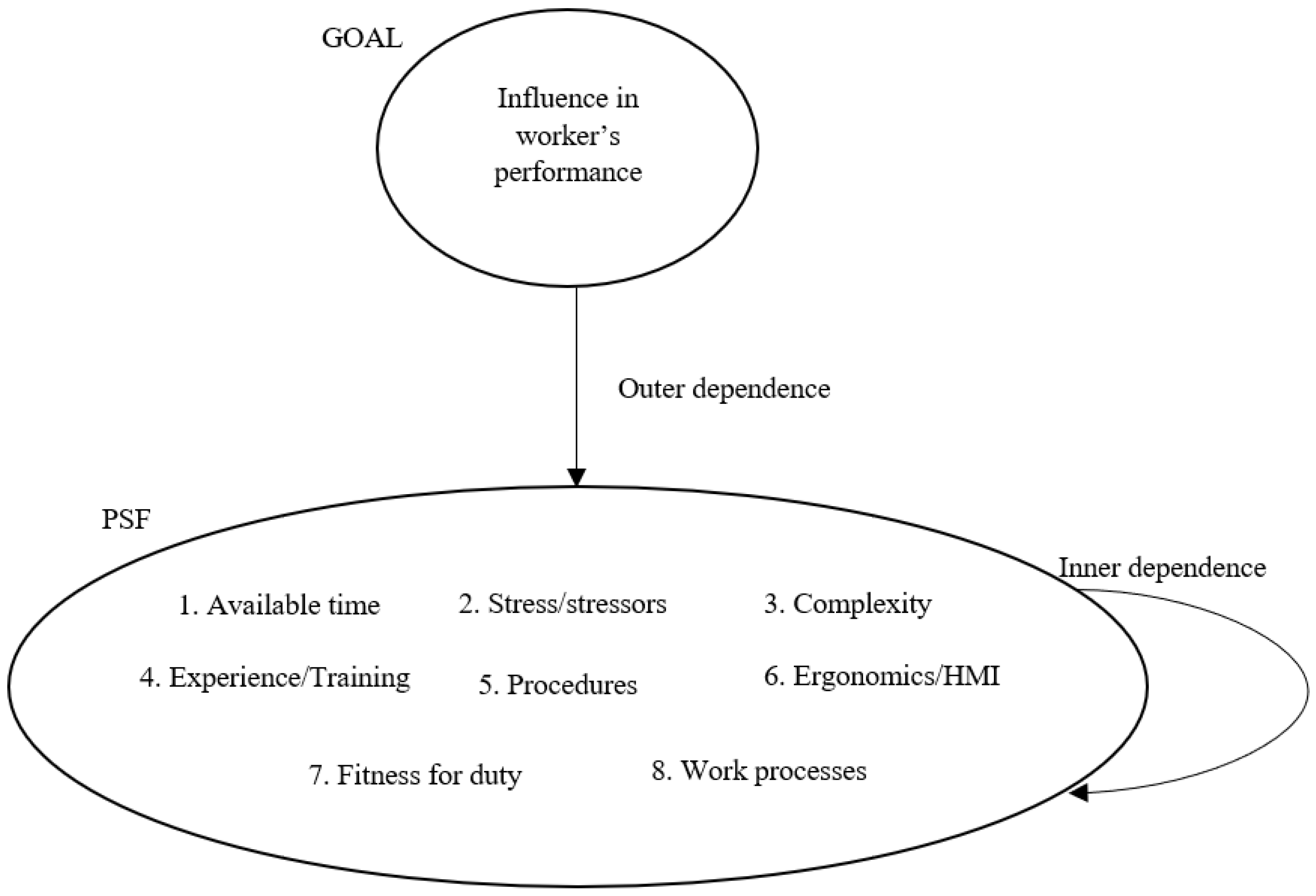

Regarding the implementation of ANP, the decision problem network was firstly developed (

Figure 9), and all PSFs were grouped into a single cluster. Afterwards, the SuperDecisions software (

https://www.superdecisions.com/, accessed on 25 October 2022) was used to evaluate the relative importance of PSFs. To this aim, the decision maker was asked to provide pairwise comparison judgements, answering the question “How much is the

PSFi more dominant than the

PSFj in influencing the

PSFk?”.

Table 8 shows one of the pairwise comparison matrices as example.

Once pairwise comparisons were uploaded in the SuperDecisions software, the inconsistency degree of pairwise comparison matrices were computed. Since some pairwise comparison matrices obtained a degree of inconsistency higher than 0.1, the decision maker was asked to reformulate some of his/her judgements in order to obtain all matrices with an inconsistency degree lower than 0.1. Afterwards, the software returned the super limit matrix, providing the relative priority values (i.e., weights) of PSFs (

Table 9).

Table 10 synthetizes PSF weights obtained by ANP and DEMATEL, whereas rankings are shown in

Table 11.

5. Discussion

Based on the causal diagram of

Figure 8 related to the implementation of DEMATEL, “Fitness for duty” (i.e., PSF

7) and “Procedures” (i.e., PSF

5) belong to the “net causer in the system” group, with a clear positive relation value. Instead, “Complexity” (i.e., PSF

3) and “Work processes” (i.e., PSF

8) belong to the “net receiver in the system” group, as they have a negative relation value. The other factors are close to the

x-axis, namely they tend to cause and receive influence equally. As stated in

Section 3.1, particular attention should be paid to net causer factors, because taking corrective actions on them indirectly improves the PFSs on which they exert their influence. Among the net causers, “Procedures” represents the most influencing one, with the highest prominence value (i.e., 14.317) and a positive relation value equal to 0.499. As a result, the company’s owner should primarily implement corrective actions on “Procedures” to increase worker reliability, simultaneously improving the other factors. Despite having the highest relation value (i.e., 2.696), “Fitness for duty” has the lowest prominence (i.e., 9.473), so it may be neglected by the company’s owner when deciding corrective measures to be implemented with priority. In addition, the total-relation matrix (

Table 6) shows that “Stress/stressors” (PSF

2) and “Ergonomics/HMI” (PSF

6) have a high influence on “Complexity” (PSF

3), “Procedures” (PSF

5), and “Work processes” (PSF

8). Hence, the company’s owner should limit workplace stress/stressors and assure a more comfortable interaction with equipment to improve PSF

3, PSF

5, and PSF

8. Among the net receiver factors, “Complexity” (PSF

3) has a high prominence value (i.e., 13.894) and a relation value equal to (-0.908). Based on

Table 6, “Complexity” is strongly influenced by “Procedures” (PSF

5), “Stress/stressors” (PSF

2), “Fitness for duty” (PSF

7), and “Ergonomics/HMI” (PSF

6). As concerns “Work processes” (PSF

8), it receives a very high influence from all the other factors except for PSF

1. Regarding PSF

1 and PSF

4, they are characterized by low prominence values and receive a very strong influence from “Procedures” (i.e., PSF

5) (

Table 6).

The ANP results show that “Procedures” (i.e., PSF5) takes the first position, followed by “Complexity” (i.e., PSF3) and “Stress/Stressor” (i.e., PSF2). The weight obtained by “Procedures” is justified by the high automation level of the production line. On the other hand, “Fitness for duty” (i.e., PSF7) and “Available time” (i.e., PSF1) take the last two positions, owing to the absence of tight time constraints when performing tasks, as well as quality checks and parameter setting not requiring any physical workers’ fitness.

Both rankings (

Table 11) are discussed with the company’s owner, who agrees with the first four positions, equal for both methods. In particular, “Procedures” and “Complexity” (i.e., PSF

5 and PSF

3, respectively) are placed in the first two positions in both cases, representing the most influencing factors on the worker performance. As confirmed by the company’s owner, the first and fourth positions, of “Procedures” and “Ergonomics/HMI”, respectively, are justified by the high automation level of the production line, which requires clear operating procedures and a comfortable interaction with equipment. As concerns “Complexity”, its importance depends on the high experience and training required to perform the quality check of products and to set the technological parameters of the process. Finally, the position of “Stress/stressors” (PSF

2) is strictly related to the uncomfortable environmental conditions of the workplace, characterized by a high level of noise. As concerns the remaining four PSFs, the decision maker is not able to choose between the two rankings, owing to the meaninglessness of PSFs which take these positions. In particular, “Fitness for duty” (PSF

7) and “Available time” (PSF

1) are almost negligible factors because the activities performed by workers (i.e., quality check and parameters setting) do not require any particular physical workers’ fitness or tight time constraints.

Comparing the two MCDM methods, the different qualitative scales used to express the pairwise comparisons provide a different width of the weights range of PSFs, even if two similar rankings are obtained, owing to the reliability of the decision maker judgments. As concerns the input data, DEMATEL requires only one pairwise comparison matrix, while ANP needs a higher number of pairwise comparison matrices. Therefore, DEMATEL allows for saving time and labor in data collection. As regards the computational complexity, DEMATEL is certainly simpler to understand—also by nonpractitioners—and easier to implement than ANP. In fact, the ANP procedure becomes prohibitive as the number of the network elements increases. This is the reason why ANP needs the support of a proper software to avoid even more decision-maker efforts to understand the method [

36]. On the other hand, ANP allows the inconsistency degree of pairwise comparison matrices to be evaluated [

37], while DEMATEL neglects this aspect. In this regard, the ANP method involves a more rigorous methodological approach, improving the management understanding and the transparency of the procedure [

37]. With relation to the implementation of DEMATEL and ANP in the case study presented here, both methods lead to the quantification of PSF weights, also taking into account the effect of mutual dependencies among them. However, only DEMATEL provides information about the direction and intensity of these influences, also facilitating their visualization by means of the causal diagram. As a result, the decision maker may easily identify those PSFs on which to prioritize attention to improve the overall worker reliability. Afterwards, the influence degree of these PSFs on the others may be observed by the total-relation matrix, and the effects of corrective actions directed at to their improvement may be also predicted.

6. Conclusions

Over the last decades, HRA methodologies have been widely used to compute the HEP in different fields, owing to the fundamental role played by the human factor in the occurrence of industrial accidents. Although the existence of the interrelationship among PSFs has been widely recognized in the literature, the majority of HRA methods assume their independence when computing HEP. In this regard, only few contributions suggest qualitative guidelines or quantitative approaches. While qualitative approaches do not have any theoretical basis, the majority of quantitative ones are statistically based, so they require a high computational effort and proper sample size (i.e., input data) to assure the significance of the results. Therefore, the present paper deals with the PSFs interdependence issue by two different MCDM methods (i.e., DEMATEL and ANP), aiming to overcome the main drawbacks of the literature in the field. The two methods were compared in an attempt to highlight the main advantages and disadvantages of applying both of them within HRA. To this aim, a case study was presented, related to an agri-food company which produces pistachios in Southern Italy. The input data required by the two methods were obtained from the company’s owner, who was asked to pairwise compare PSFs based on specific evaluation scales. The obtained results show that both methods are able to deal with the PSFs dependence within HRA and return the same PSFs ranking with regards to the first four positions. The company’s owner agrees with the PSFs hierarchies, arguing that “Procedures”, “Complexity”, “Stress/stressors”, and “Ergonomics/HMI” are playing a prominent role in influencing worker performance in the investigated workplace. However, only DEMATEL provides detailed information about the direction and intensity of influences, offering a clear representation of results by the causal diagram. As a result, the company’s owner may qualitatively predict the effect of a corrective measure through the mutual influence degree expressed by the total-relation matrix. On the other hand, the implementation of ANP is very challenging due to the high number of pairwise comparison judgements required, despite using the SuperDecisions software. However, ANP allows us to evaluate the inconsistency degree of the judgements and to decompose the decision problem into its elements, contrarily to DEMATEL.

Compared with the aforementioned qualitative guidelines or statistically based methodologies, DEMATEL and ANP require lesser computational effort and allow for making use of the available information, without any constraint on the sample size. They actually represent a structured, effortless, and replicable decision-aiding support tool for the risk analyst, both to assess the PSF interrelationships and to identify the most central factors on which corrective measures have to be primarily taken. Owing to the limited availability of (e.g., financial) resources, the latter perfectly meets the need of a company’s management to firstly focus on a few central factors to improve worker reliability, while initially disregarding the less-important PSFs. However, PSFs might depend on the specific work environment under investigation, so they should be properly selected and/or customized. Therefore, a possible future line of research could deal with this issue, also in a multi-group and uncertain decision context.