1. Introduction

Industries dedicated to the mass production of consumer goods work at a continuous pace. This is due to the high competitiveness of their productive sector [

1]. This implies that the processes cannot be paralyzed for interventions in case that required using redesigns of its components or changes in the ways of working. This has generated in recent technological advances, proposals for automation and control of industrial processes through the implementation of information and communication technologies. These allow replicating processes virtually and submitting them to changes, redesigns, and adaptations that can be applied to the real plant [

2].

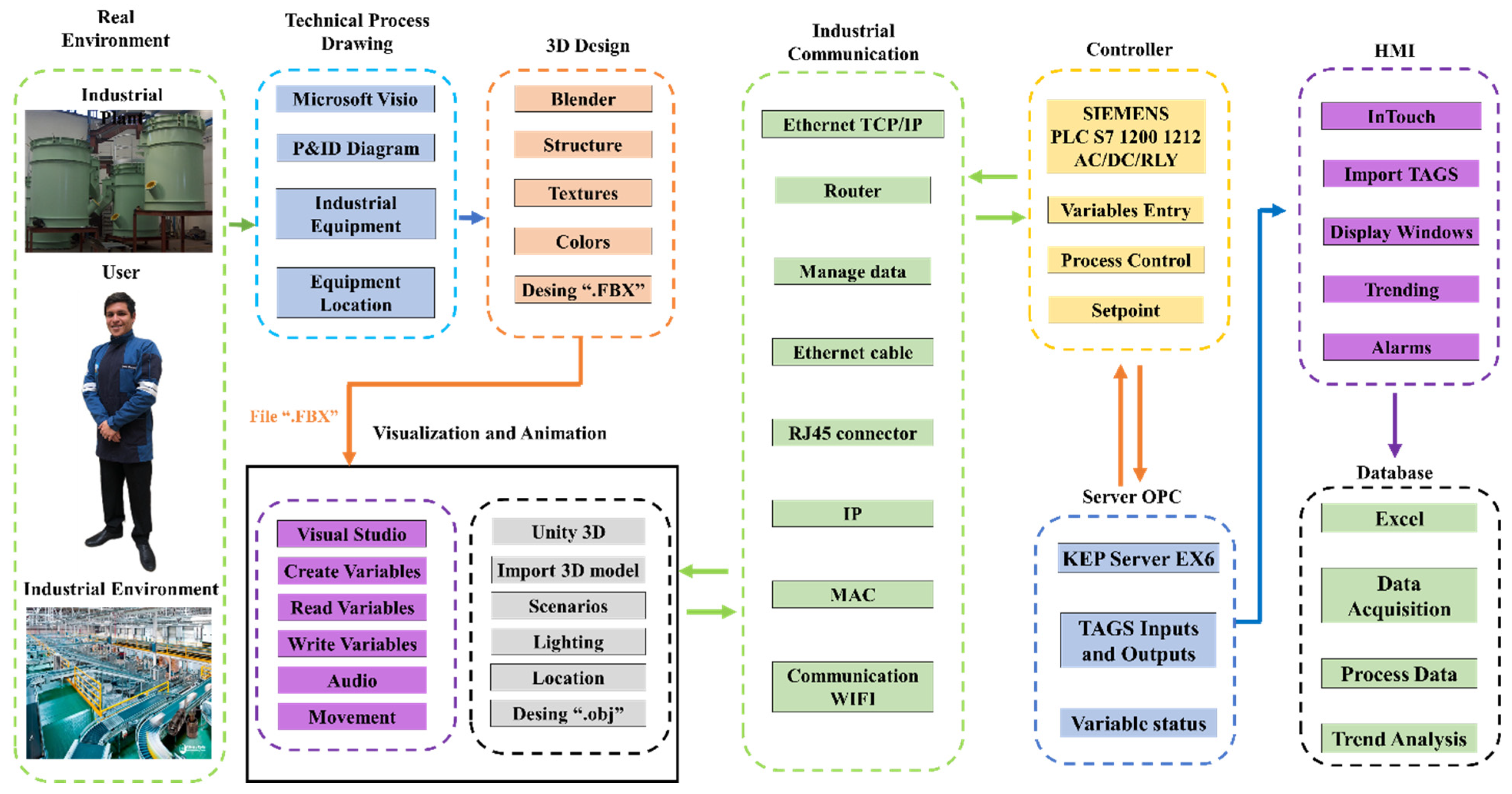

The design of the virtual environment of the industrial process will be carried out in Unity 3D software, which in its beginnings was oriented to the creation of video games, and over the years has been used for the virtualization of industrial plants, which makes it possible to simulate the dynamics and its physical variables by creating an immersive virtual environment [

3]. A plant recreated in Unity 3D as in real life needs processes controlled by a programmable automaton to perform control tasks, so that the industrial process has a realistic operation considering the characteristics of the process; in addition, the operation should be similar to that found in the real process [

4].

The transmission of information is useful for the plant operator because it indicates the status of the plant, but to achieve this utility, it is necessary to have an information management tool, such as the SCADA (Supervisory Control and Data Acquisition) system, which is responsible for collecting data from the plant. Data collection occurs through the use of an OPC (Open Platform Communication) server [

5]. The OPC server has the ability to acquire data from field devices and offers a communication technology with a client and server architecture, where one application acts as a server providing data and another as a client reading or manipulating it [

6]. This allows the exchange of information between various devices without manufacturer restrictions. Although the hardware and software come from various commercial brands, compliance with the OPC standard enables continuous real-time communication in advanced industrial environments. Consequently, the selected OPC server is OPC KepServer EX6, which is considered as an OPC UA because it offers interoperability between manufacturers and, thus, does not require an additional hardware driver to convert proprietary protocols to the client protocol, reduces the load on the data source devices, and allows real-time monitoring and management of data [

7,

8]. With the SCADA system, the plant is monitored and controlled from a remote control panel, thus sending the information obtained to the central station, alerting the station that a change has occurred in the process, analyzing whether the information is critical, and presenting it in a logical and organized manner [

9]. As indicated in [

10], by integrating the third level of the Automation pyramid with the design and implementation of the SCADA system, a fundamental step is taken towards learning and understanding optimization in control processes, which makes use of management tools, such as monitoring, logs, trends, alarms, and historical data, which aim to provide process information to users. This shows the importance of an adequate design that correctly covers the different needs presented in each case.

The way in which the PLC (Programmable Logic Controller) controls the actuators and receives information from the sensors depends on the communication protocol that has been selected. Ethernet is an open interfaced communication protocol, which allows the integration of devices, regardless of their manufacturer, and handles client–server communication by queries for information transmission [

11]. The use of the Ethernet protocol involves advantages, such as high-speed transmission, due to the support of bandwidth between 10 Mbps up to 100 Gbps, as established in the IEEE 802.2 and 802.3 standard, as well as the reduction of commissioning time by configuring devices directly from the system and allowing plug-and-play operations. In the same way, there are several engineering works for the development of virtual processes, such as [

12,

13], where the modeling of a Sorting Module (Sorting Station) is performed in CAD design software to be virtualized in Unity 3D; in addition, there is an Arduino microcontroller that will be responsible for the encoding and decoding of TCP/IP (Transmission Control Protocol/Internet Protocol) packets so that they can communicate a PLC S7-1200 with Unity, thus achieving a bidirectional communication. In the industry, there are different projects of design and construction of industrial machinery as presented, in which there is an automated system for closing round cans similar to that present in the canning industries [

14].

Taking into account these factors at the research and educational level, different projects have been proposed for the virtualization and monitoring of industrial processes, such as in [

15], where the use of Unity 3D is described; the document focuses on the main features of programming environments and objects, under a conventional programming language, thus facilitating the experience with the user and other applications. It also highlights that being a program compatible with several platforms allows generating applications for each of them. Meanwhile, in [

16], it mentions that stamping processes, especially the cyclic repetitive pattern of force, tension, acoustic emission, or energy consumption signals, have been the basis of detailed monitoring systems. However, most of the work performed focuses on monitoring and comparing signals from different physical conditions in a controlled environment developed in Virtual Plant software, in which the mechanism is replicated with an eye-catching, realistic 3D design that allows interaction with the process through a controllable avatar. In addition, in [

17], the common problems of study in the stamping machine are analyze, which are reduce noise and vibration, improve the machining accuracy, etc. The mechanical system is implemented in a simulator dedicated to autonomous manipulators and robotics called Virtual Universe Pro [

18]. It generates a virtual environment created to grant maximum immersion with the use of virtual reality glasses and to evidence that the inertia forces will increase as the stroke speed increases. Regular stamping machines generally adopt sliding crank, and hence, the inertia forces in the regular crank-slider mechanism will be extremely high, and therefore, to alleviate such problems, low inertia forces are proposed by using a balancing structure in a stamping machine. As described, information and communication technologies generate several benefits to industrial processes, in which stand out the ability to virtualize plants with realistic functionality considering the physical behavior of the variables involved, as well as the flexibility of Unity 3D software to connect with other software for programming with physical devices, such as PLC’s and control panels, and support computer-aided drawing files [

19].

The distribution of this article considers six sections:

Section 1, Introduction which describes the bibliographic review of the use of the HIL (Hardware in The Loop) technique in automated industrial processes;

Section 2, Work Proposal which details the software, hardware, and communication of the process to be virtualized;

Section 3, Software Development, which details each of the stages of the process, as well as the virtualization and design of the HMI (Human–Machine Interface);

Section 4, Communication, which details the type of communication, as well as the industrial protocol to be used for sending and receiving data between the software and the hardware;

Section 5, Results which presents the functional tests of the implementation of the virtualized plant, as well as the process usability test; and finally,

Section 6, Discussion and Conclusions which details the approach of the work at the teaching and engineering level, possible future work, comments, and conclusions.

2. Work Proposal

This section describes the proposal for a bottle sealing process using the HIL technique, for which a division of the work will be made, the same that is focused on the simulation part and the hardware part.

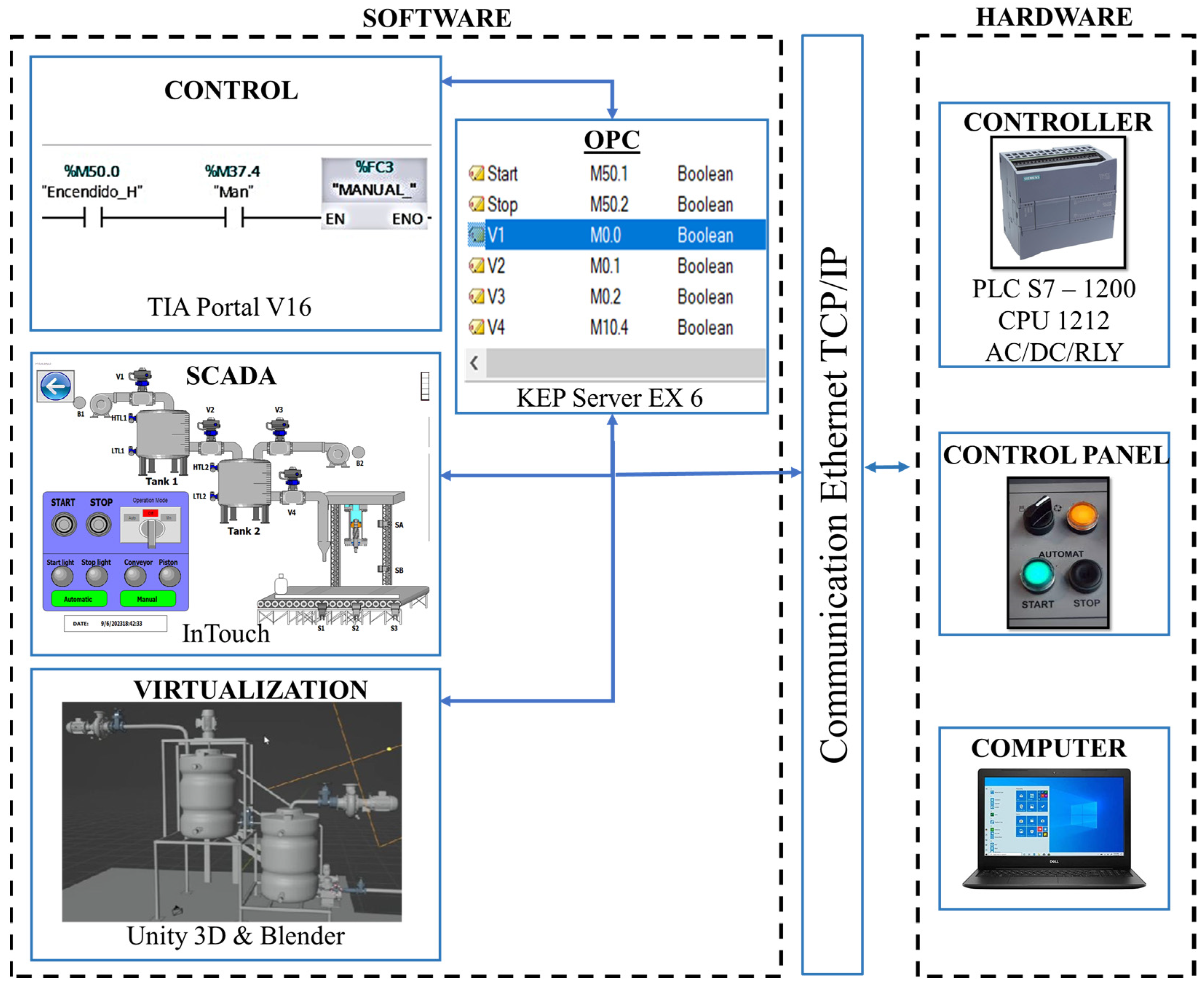

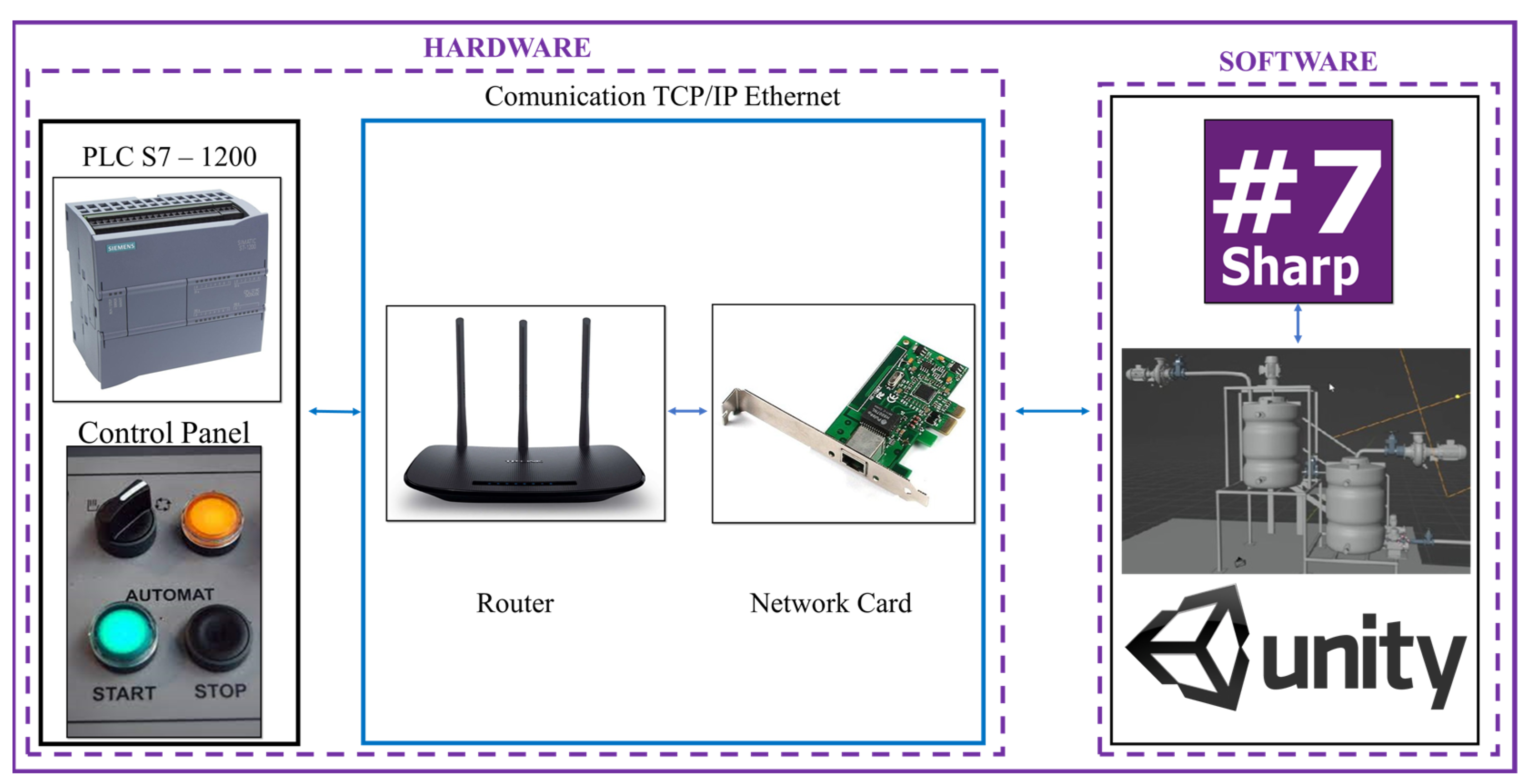

As shown in

Figure 1, the HIL technique consists of the software part, which is made up of (i) Control: performs the sequential control of the filling and sealing of bottles, which is performed in the TIA Portal (Totally Integrated Automation Portal) software; (ii) SCADA: interface in charge of the supervision, control, and data acquisition of the process in real time, which is designed in InTouch; (iii) Virtualization: allows the creation of a virtual plant environment with a realistic approach, in which the user will visualize the process in real time and will be able to interact by manipulating an avatar in Unity 3D software; (iv) OPC KEPserver EX6: allows communication in the control field and supervision of the sealing process.

The hardware part will consist of the inputs and outputs for the manipulation and visualization of the process variables. It consists of (a) S7-1200 controller: CPU 1212C AC/DC/RLY, in charge of the process control; (b) Control panel: the physical console that allows the input of digital signals and the visualization of alarms; (c) Computer: it contains the software for the visualization of the virtual process and the communication with the process control system.

Therefore, the communication between the two detailed parts will be accomplished through the standard Ethernet protocol because the data transmission can be implemented at speeds ranging from 10 Mbps to 100 Mbps, with great flexibility to make changes in the process and to be structured in various communication topologies, where the most common is the star type; plus, it is an open protocol, thus achieving easily management of data at the industry and office level, giving way to having applications for data analysis, production, maintenance, and use of commercial techniques [

20,

21].

3. Software Development

This section describes the development of the control, manipulation, data acquisition, and visualization of the bottle sealing plant using the HIL technique.

3.1. Process Automation

The automated process has the piping and instrumentation diagram (P&ID), in such a way that the implementation of symbols established in the International Society of Automation (ISA S5.1) standards allows the identification of the installed equipment and instruments and their distribution in the plant, as shown in

Figure 2 [

22].

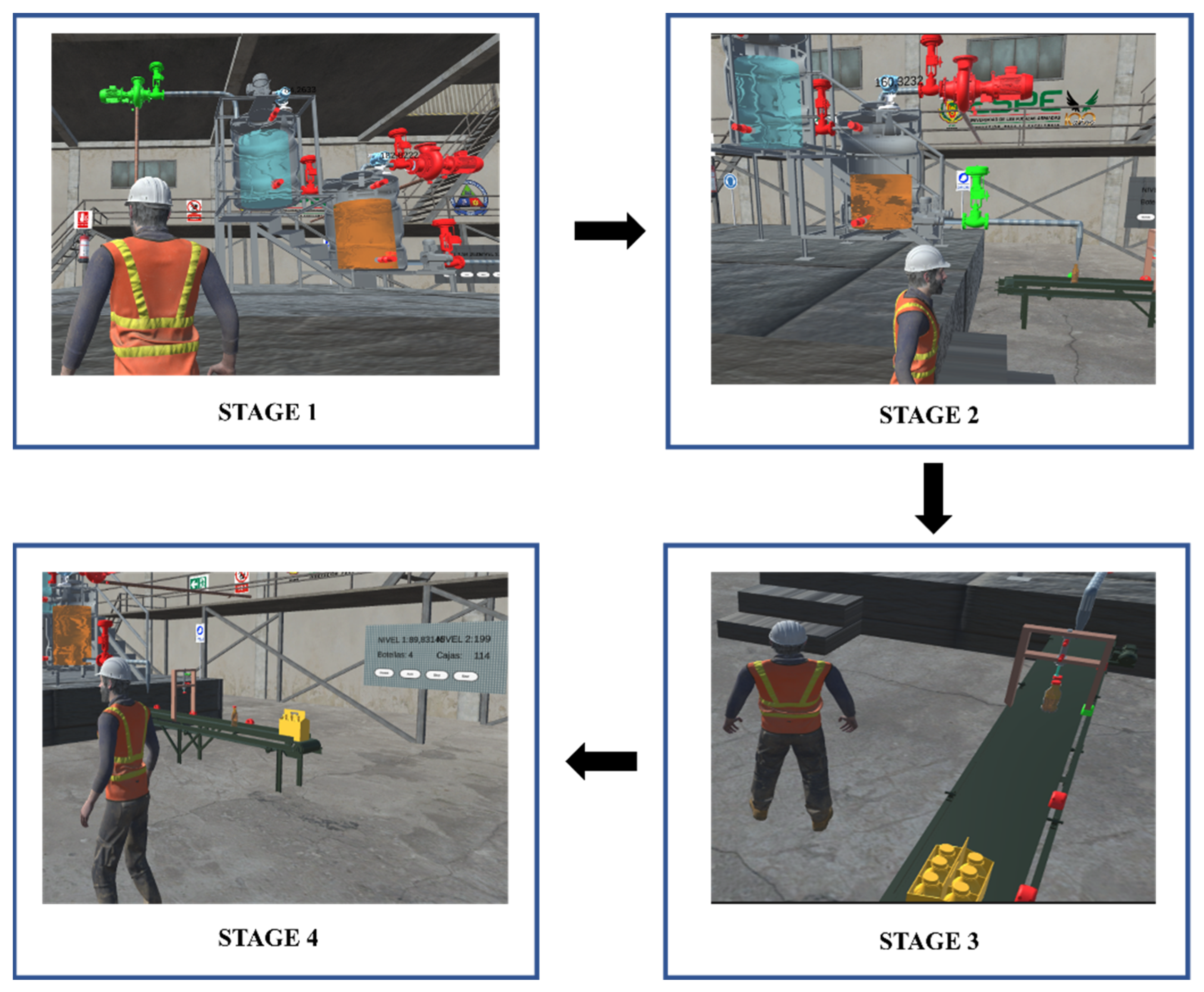

The P&ID diagram allows knowing the dynamics of the process and the elements that constitute a bottle sealing plant, thus achieving automation, for which a sequential control is used, which considers timers for the activation of the final control elements, such as valves, pumps, pneumatic piston, and belt. In addition, there are counters that register the quantity of sealed bottles and the packaging of the batches. Using TIA Portal with the configuration of a PLC S7-1200 CPU 1212C AC/DC/RL, therefore, the stages shown in

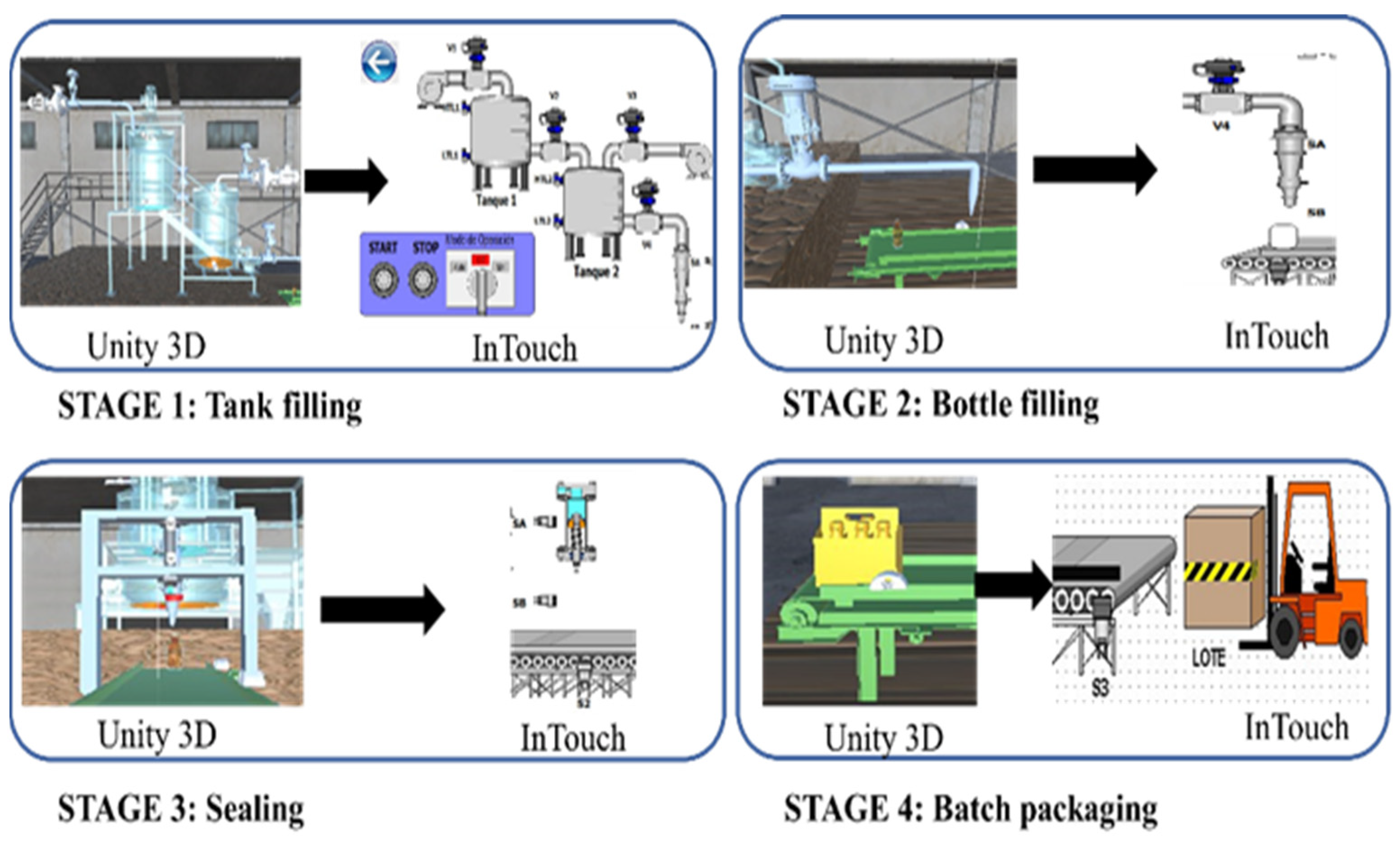

Figure 3 have been considered.

Thus, the process has been subdivided into four stages: (i) Tank filling: when the start button is pressed, solenoid valves V1 and V3, which are normally closed, are activated by a positive edge. After two seconds, pumps B1 and B2 are turned on, until the maximum level entered from InTouch is reached, then valve V2 is turned on to empty tank 1, taking into account that the valves must first be activated to avoid overloading the pump. (ii) Tank filling: the tank is placed on sensor S1 with the activation of the band; after two seconds valve 4 is activated, the tank filling starts, and the band is activated. The precise location of the sensors ensures that the bottle is filled, and no waste is generated. (iii) Sealing: this stage starts when the sensors Sa and S2 are activated. The piston is in retraction, and the bottle is located under it, and then the band is stopped, and the piston is actuated until the end of the stroke Sb, thus sealing the bottle. The stage ends with the activation of the belt. And finally, (iv) Batch packing: when the bottle passes through the sensor S3, it activates a counter with a maximum range of six bottles; when the maximum number of bottles is reached, these are packed in a box, a batch counter is activated, ending the stage and the process.

3.2. SCADA System

Based on the programming in TIA portal for the bottle sealing plant process using the HIL technique, all the input and output variables to be used in the SCADA system are defined.

Table 1 defines the inputs and outputs used to generate the Tags in the OPC server; note that the inputs save their information in internal PLC memories, while the outputs are sent directly to the PLC outputs.

Each of the variables are entered into the OPC KEPserver EX6 server and then imported into the InTouch HMI software. In the OPC KEPserver EX6 server, a new channel is created, where the type of communication to be used is defined, in this case Siemens TCP/IP Ethernet, then a new device is defined, in which the model of the implemented PLC (S7-1200) is specified with its respective IP address 192.168.0.30.

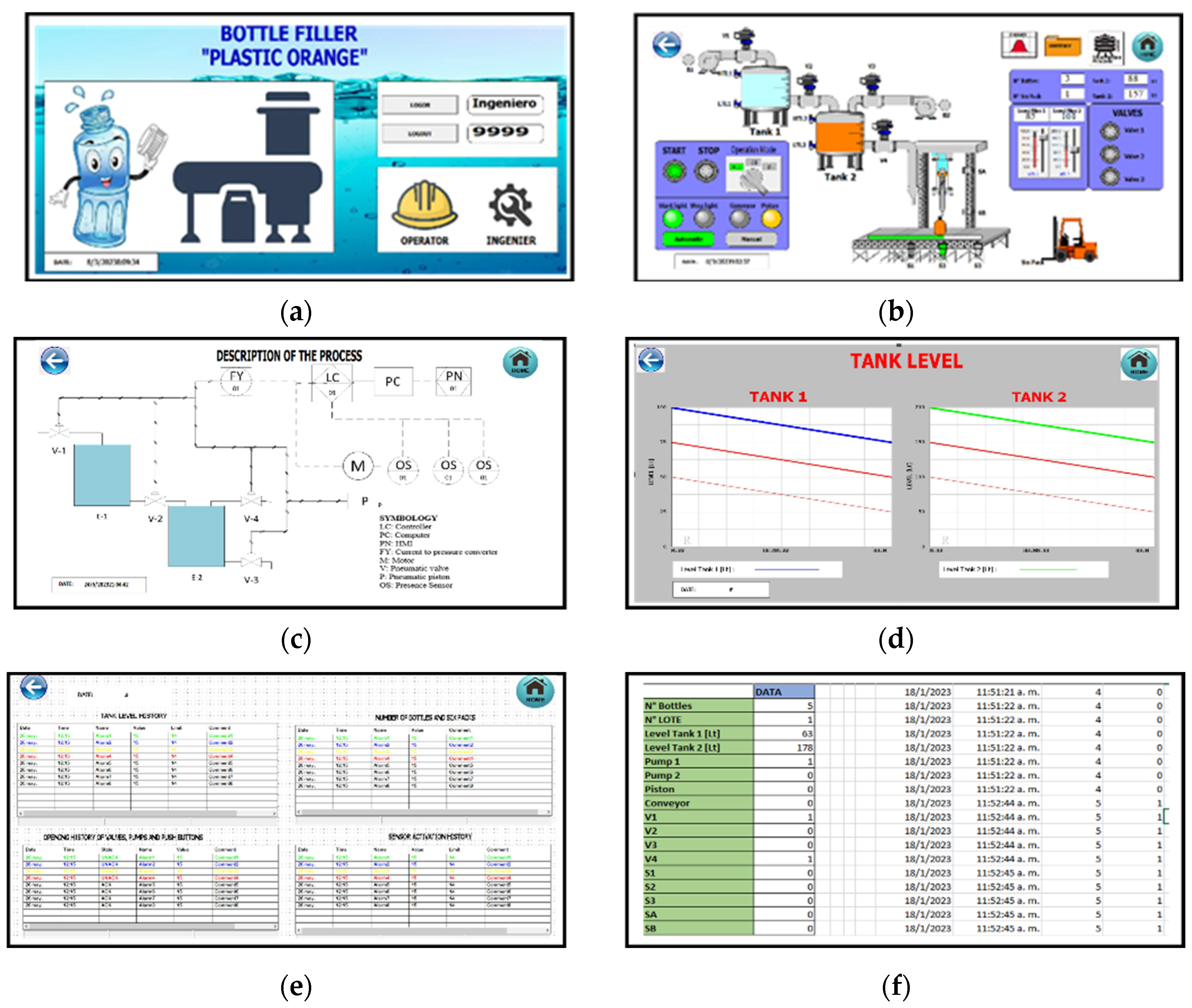

The IP address has been previously assigned in TIA Portal; an alias is also added to access the tags, called CONNECT_S7-1200, in order to import variables from the OPC (Open Platform Communication) server to InTouch software. In the InTouch visualization software, a new Access Name is configured with the same name of the previously created alias and with an application name server runtime, allowing extracting the variables from the PLC and creating a visualization, monitoring, and control interface, which models the dynamics of our bottle sealing plant, and finally upload it to a database. The database is accomplished in the Excel calculation software, first performing the programming of an Application Script, thus extracting the data from the variables in the Excel programmer, Microsoft Visual Basic, which collects the data and presents them in a spreadsheet. In this way, the SCADA system is designed as shown in

Figure 4. The SCADA system as shown in

Figure 5 contains the following navigation windows:

(a) Startup window: welcome window where the user profiles are presented with the hierarchy: manager, engineer, and operator. (b) Process: the process of filling and sealing bottles is presented; depending on the hierarchy, the manager will only have access to the process visualization and to a history window. (c) Process description: presents a description of each element that composes the process and details its operation. (d) Graphs: shows the liquid level reached in each tank. In the first tank, the set point is marked in red, while the level in blue; the same for tank 2, where the tank level is differentiated by the color green. (e) History: shows alarms and history of the operation of the process variables. (f) Database: it is presented in an Excel spreadsheet, which is communicated with via InTouch and TIA portal.

3.3. Virtualization

For the development of the virtualization environment, the P&ID diagram, detailed in

Section 3.1, is used to perform the 3D modeling in the graphic design software Blender, which generates a .FBX file, to be later integrated and rendered in a new project created in the Unity 3D graphic engine, where each of the objects needed to model the plant are added. For this, “prefaps” are created containing the animation objects of type .obj, which is a type of object configuration file in a virtual environment, which must be programmed in C++ language through scripts in Microsoft Visual Studio software, which generate the movements, communication settings, and sounds of the process—all this with the creation of records, a data buffer that store bytes, integration of textures, and tag assignment, as shown in

Figure 6. Within the Inspector, the collision functions are assigned, so that the avatar interacts with the virtualized industrial environment, limiting the work area.

5. Experimental Results

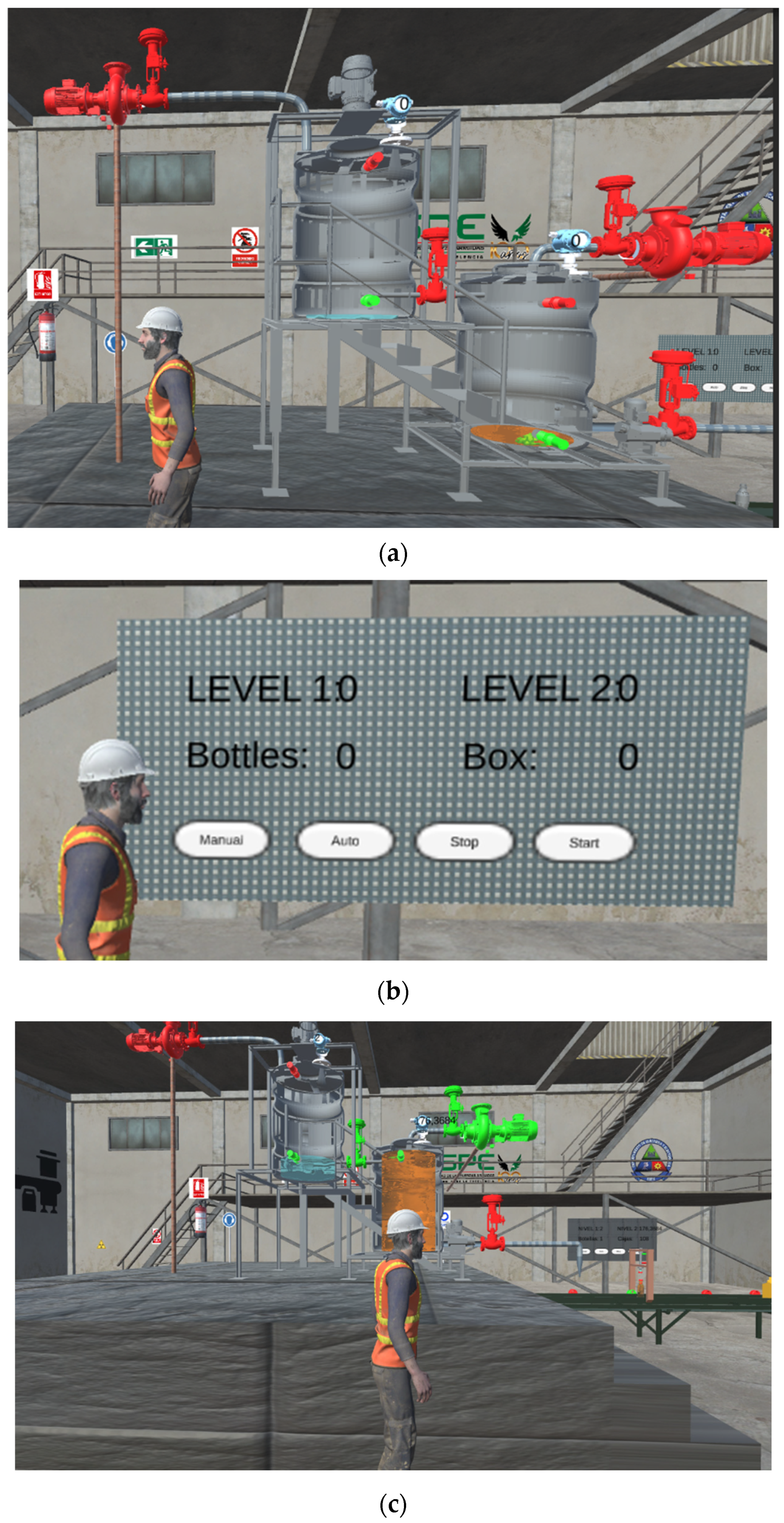

This section describes the results obtained with the implementation of the HIL technique for a bottle sealing process, taking into account the operation of the virtualized environment, which consists of actuators, such as the valves in charge of the passage of the liquid to the tanks.

Figure 8 presents the implemented process, in which the user has full access to the SCADA system, so that the operator can control the process, that is, modify the Set Points of the different tanks, as well as manage the data and histories presented, acquired during the time of operation of the system. The user can manipulate the environment in two ways: (i) External devices of the computer, such as mouse and keyboard, to manipulate the elements and the screen to visualize the operation; and (ii) Haptic devices, such as HTC vive, for the manipulation of virtualized equipment, and Oculus Quest 2, which allows the user to visualize the operation of the virtual environment; this allows generating user immersion in the work environment.

5.1. Virtualization of the Process

This section describes four production stages based on the P&ID diagram presented in

Section 3.1: tank filling, bottle filling, sealing, and batch packing, as shown in

Figure 9.

The stages are operated in two modes of automatic/manual operation, which can be selected from the virtual panel in Unity 3D, the physical control panel, and the HMI in InTouch. In automatic operation mode, the plant starts performing the process described in

Section 3.1 indefinitely, as shown in

Figure 8, until the stop button is pressed, which stops the whole process. In manual operation mode, the valves (V1, V2, and V3) and the pumps (B1 and B2) are controlled and activated at the same time to fill the tanks. As shown in step 1, the activation is accomplished from the physical control panel, as shown in

Figure 10, and the HMI in InTouch by means of push buttons.

Each sensor and actuator in the virtual plant has a color change that determines its activation, where green indicates the activated state and red the deactivated state, as shown in

Figure 11, an animation of stage 2 of the filling of the tanks is shown, where the water and orange juice are poured. In stage 3, the bottle is filled by the V4 valve, showing the liquid inside. The conveyor belt moves the bottle, which passes through each of the optical sensors. The piston is activated in forward and reverse mode by placing a red cap. At the end of the conveyor belt, there is a box for packaging the bottles, as shown in stage 4. The whole process is located in a virtual industrial environment.

The virtual environment shown in

Figure 12 consists of a hangar with the bottle sealing plant inside. The infrastructure has safety signage and emergency exits; there is also a display panel that shows the level of the tanks, number of bottles and batches, as well as control buttons. In addition, there is a camera in third-person configuration, which is oriented with the mouse and can be moved with the directional arrows.

The stages detailed above can be interacted with through an avatar. The avatar allows the user to be immersed in the plant, thus having a more direct interaction with the virtualized process; it can move around the plant and inspect each stage, and it is equipped with safety boots, a reflective vest, and a safety helmet. The avatar has the following functionalities for its interaction with the plant: Pressing the plant start and stop buttons; switching the operation mode between automatic and manual; and visualization of the process.

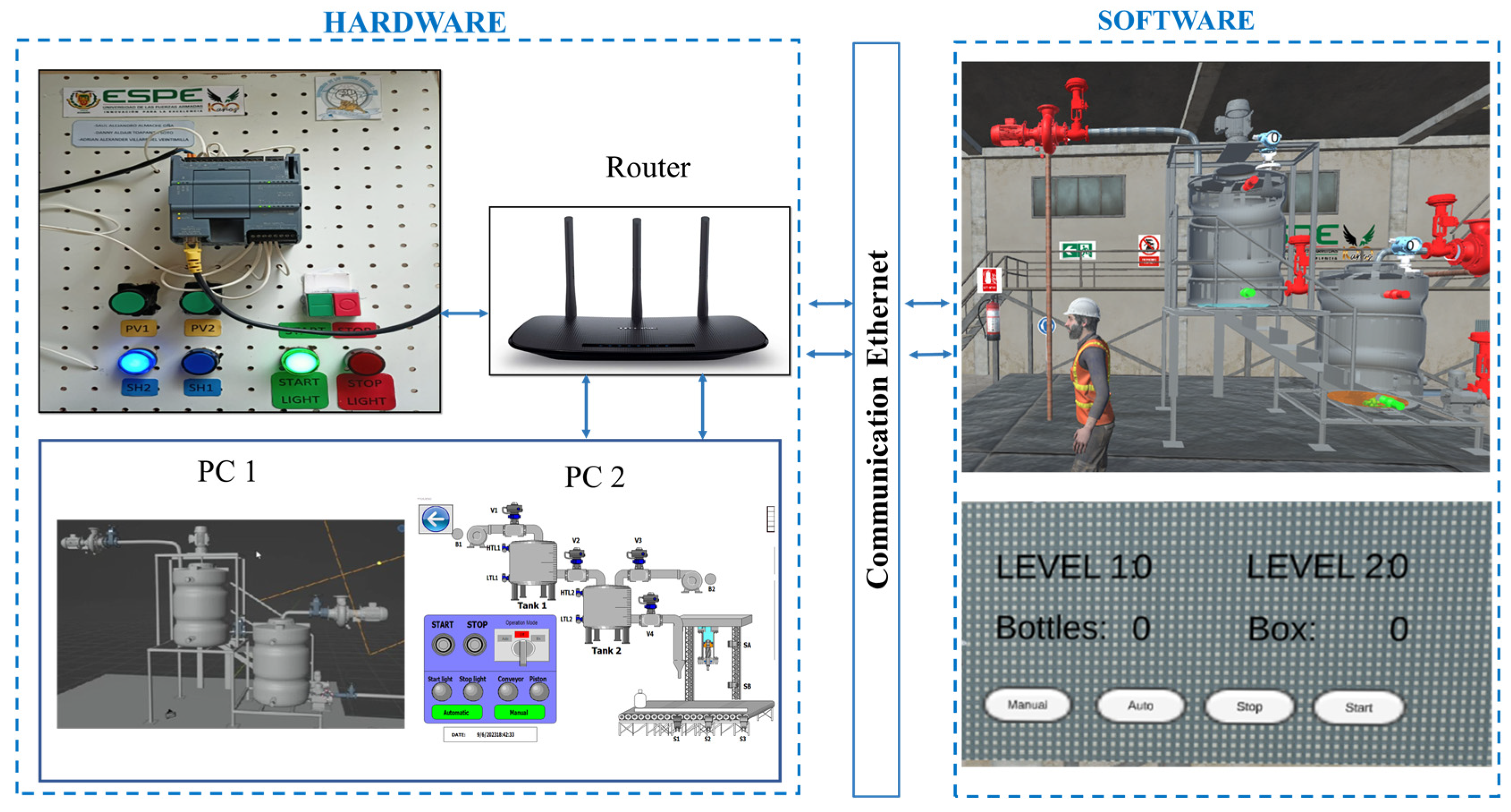

Finally, the communication between the PLC and Unity 3D, using the Ethernet IP protocol that makes use of a client–server architecture and a star topology, in which a router is connected as an Ethernet server, a PLC as a client and two computers with the software: InTouch and Unity 3D, as shown in

Figure 13, where the PLC becomes the client and the virtual environment as a server. This communication is performed at a speed of 10 Mbps.

5.2. Usability of the Virtual Process

Education processes have undergone a constant evaluation thanks to the contribution of Information and Communication Technologies (ICTs), currently using various teaching techniques such as gamification, feedback, use of interactive classrooms, self-learning, among others. All with the purpose of exercising an active participation on the part of the student developing a significant learning [

25]. The same that aims to allow the student to acquire new knowledge from the classes taught by the teacher. Therefore, the use of interactive software, experimentation of case studies and work in virtualized environments are relevant in the teaching–learning process [

26]. The use of interaction techniques allows students to acquire a better understanding of the lectures given by teachers, and to use this knowledge to generate new knowledge. Several works describe the use of virtualized environments as a teaching tool since it allows the student to manipulate environments in a controlled environment, i.e., the student is not exposed to possible accidents and equipment that is considered expensive is not damaged. Therefore, this work develops a virtual process focused on the industrial area, which allows the student to manipulate and observe its operation in real time.

Therefore, an evaluation of two groups of Electronic Engineering students of the Industrial Automation course of two academic periods was carried out. The first group consists of 23 students of the first period analyzed, they use the traditional method, that is to say, they control and manipulate the variables of the industrial process, designing viable solutions for its correct operation. For which they make use of the TIA Portal software to program the process control and test its operation in a PLC S7 1200, visualizing the behavior in the physical control panel through light indicators. While the second group, with a number of 23 students in the second academic period are using virtualized work environments. The group of students must control and manipulate the industrial process in the same way, but they can observe the virtualized behavior of the process in real time. Determining that the second group has greater facility to design industrial process control solutions. It generates a meaningful learning that allows students to acquire and develop new knowledge in the field of Industrial.

In this context, a usability test of the virtualized work environment was carried out. For this purpose, a workstation with the virtual plant and the physical control panel was installed. Prior to the experimentation, an explanation of the use of the virtual environment was made so that the participants could understand the data and trends presented. For the explanation, the participants were considered to have a higher level of knowledge of the functionality of the equipment. At the end of the experiment, the experimental group completed a usability test of the execution of the virtual process. To determine the degree of usability, the System Usability Scale (SUS) [

27], was applied. The total average score achieved was 83%, which is an acceptable degree of usability for the simulation of a virtual bottle sealing process focused on the field of education and automation engineering. The usability test consists of 10 questions evaluated in a range of 1 to 5, focused on the working system, where the highest scores are presented in questions related to the ease of interaction with the environment and the ease of manipulating the variables of the industrial process. While in a score of 3, which is the lowest score obtained, it is mentioned that more interactive components can be added to generate greater realism.

6. Discussion and Conclusions

The work presented in this article has its educational utility, as it is a demonstration of the creation of virtual environments from scratch, starting from the construction of each element of the plant to the connection of each one to form the virtualized industrial environment and providing realism through animations, sounds, and movements. Likewise, it can be used to teach the steps for the use of an OPC server, a SCADA system, and HMI’s for the monitoring and control of an automated plant; students will be able to identify the hardware and software requirements to execute such connections. In summary, the work is demonstrative in nature, but can be disassembled for piecemeal analysis and changes for future work in the engineering field.

The study of electronics and automation engineering is focused on industrial processes, where there is the use of various sensors, programmable logic controllers, and actuators. The use and procurement of this equipment for a student is very expensive. Further, several institutions of higher education can provide this equipment; however, several pieces of equipment are not in excellent conditions of use or are outdated. Therefore, the present work attempts to enable the student to visualize the operation of an industrial process using an HMI interface and manual control from a physical control panel. The user can interact with the process remotely with the interface in such a way that it simulates a remote workstation in an industry. In addition, several types of industrial protocols can be used in an industry for RS 232 (Recommended Standard), RS 422, Profibus, Modbus, etc. communication. One of the open and most common protocols in homes and institutions is the Ethernet TCP/IP protocol, and several PLC manufacturers already include this protocol in their equipment because of its reliability and dependability. The communication at work focuses on the standardization of the relevant data or values of the process for analysis, so a SCADA system is implemented on a desktop computer or laptop.

The use of a home computer at the educational level is very beneficial for a student; however, it should be noted that several of the programs used in the work consume a lot of RAM memory, CPU consumption, and disk space storage, so depending on the equipment, may have delays in the simulation and control actions in the process.

Due to the focus of the work presented, it can be implemented in Industry 4.0, which contains several technologies, such as Big Data, IoT (Internet of Things), virtual reality, and augmented reality, in addition to its use in robotics and allowing a simulation of the processes before being implemented in real life. Several industries use the virtualization of processes for the training of engineers and operators in order to know each stage of the process and through animations to visualize the risks involved in the mishandling of industrial equipment.

The SCADA system has a real-time database and a graphic interface of the most important variables of the bottle sealing plant developed in Unity 3D. Data acquisition is achieved with an OPC server, which every 2000 ms acquires the information; in 3000 ms, the communication is checked to send data. The data are saved every 200 ms to be processed and analyzed in an Excel spreadsheet; with this, you can perform the respective analysis at the management level of the company. The graphical interface of the plant is designed so that the operator can control and visualize the process remotely via Ethernet communication; therefore, it is necessary that the control devices (PLC) and the virtual environment are connected to the same communication network.

The HIL communication between physical equipment and the virtualized process constitute a hybrid system, which involves the operation of a PLC S7 1200 with CPU 1212 AC/DC/RLY, which makes use of the Ethernet IP protocol for the connection with a router as data traffic manager and two computers, which run two software in real time, on one side InTouch, where the SCADA system is developed for the control, supervision, and monitoring of the process variables, while the other computer runs TIA Portal, whose function is to configure and program the PLC in charge of automating the process presented in Unity 3D. The development will be used as a basis for implementing a distributed control in industrial processes, intercommunicated with advanced communication protocols, such as the AS-interface, which will be accomplished through PLC communication as a control unit and virtualized environments as the operational part of the plant.