A Fault Diagnosis Method for Power Battery Based on Multiple Model Fusion

Abstract

:1. Introduction

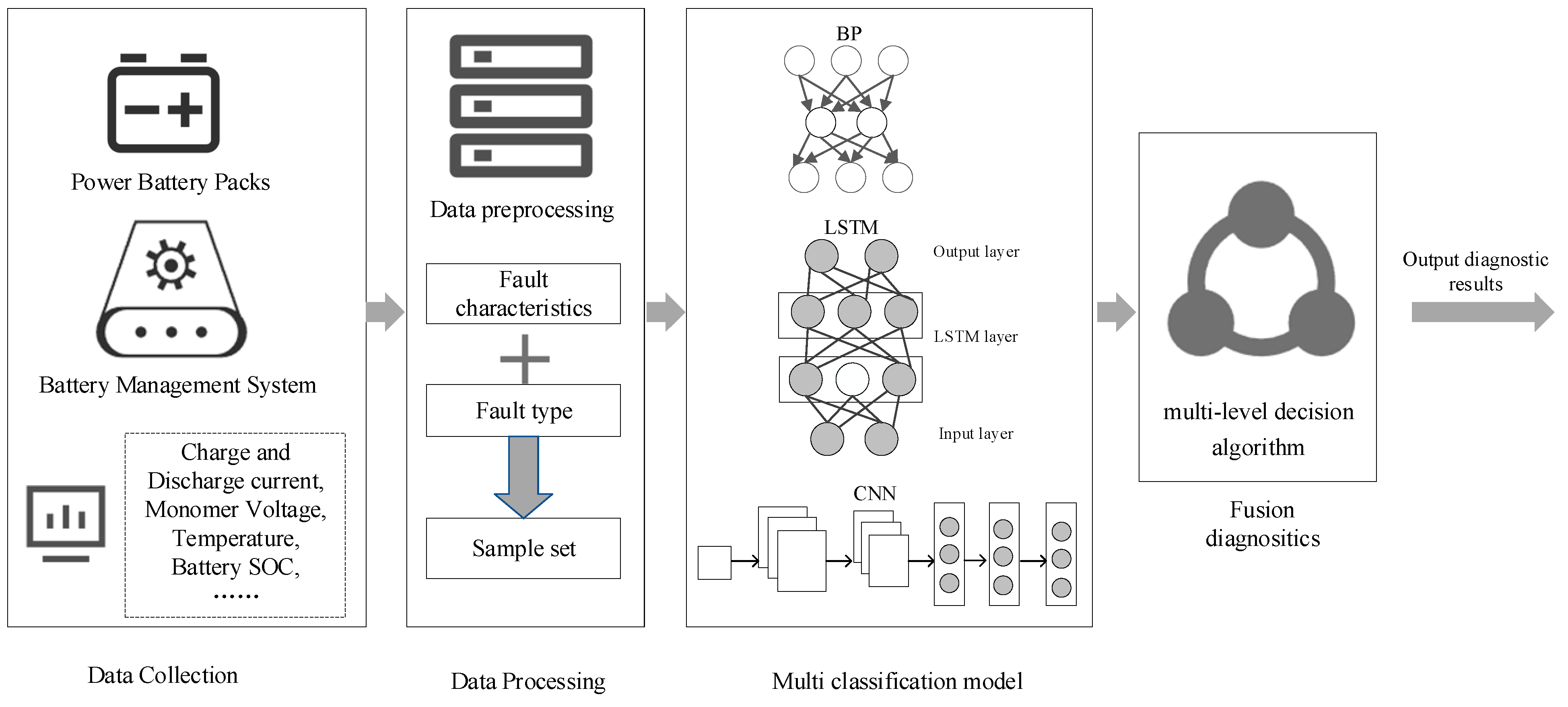

2. Multiple Model Fusion Diagnostic Method

2.1. Multiple Model Fusion Architecture

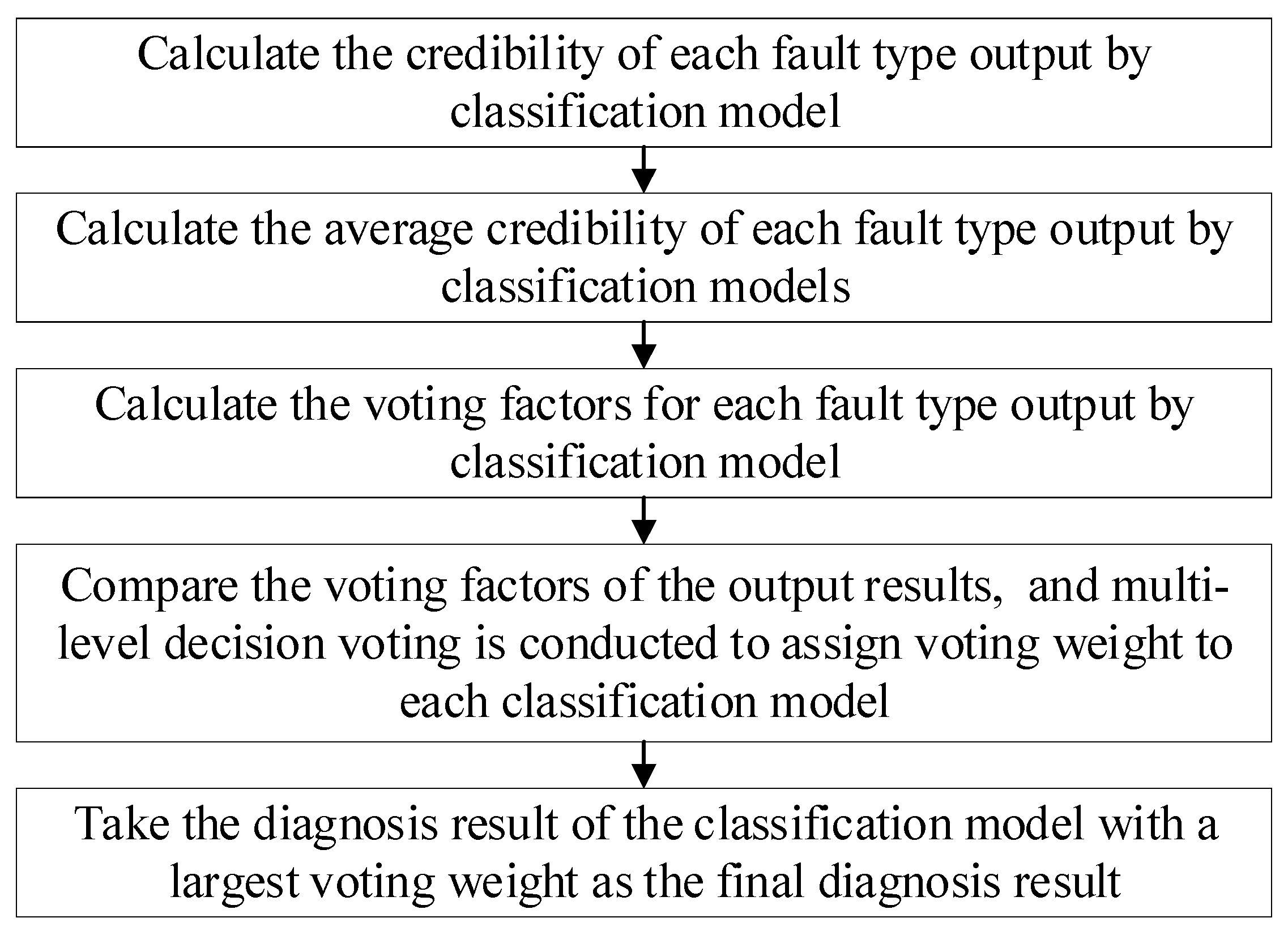

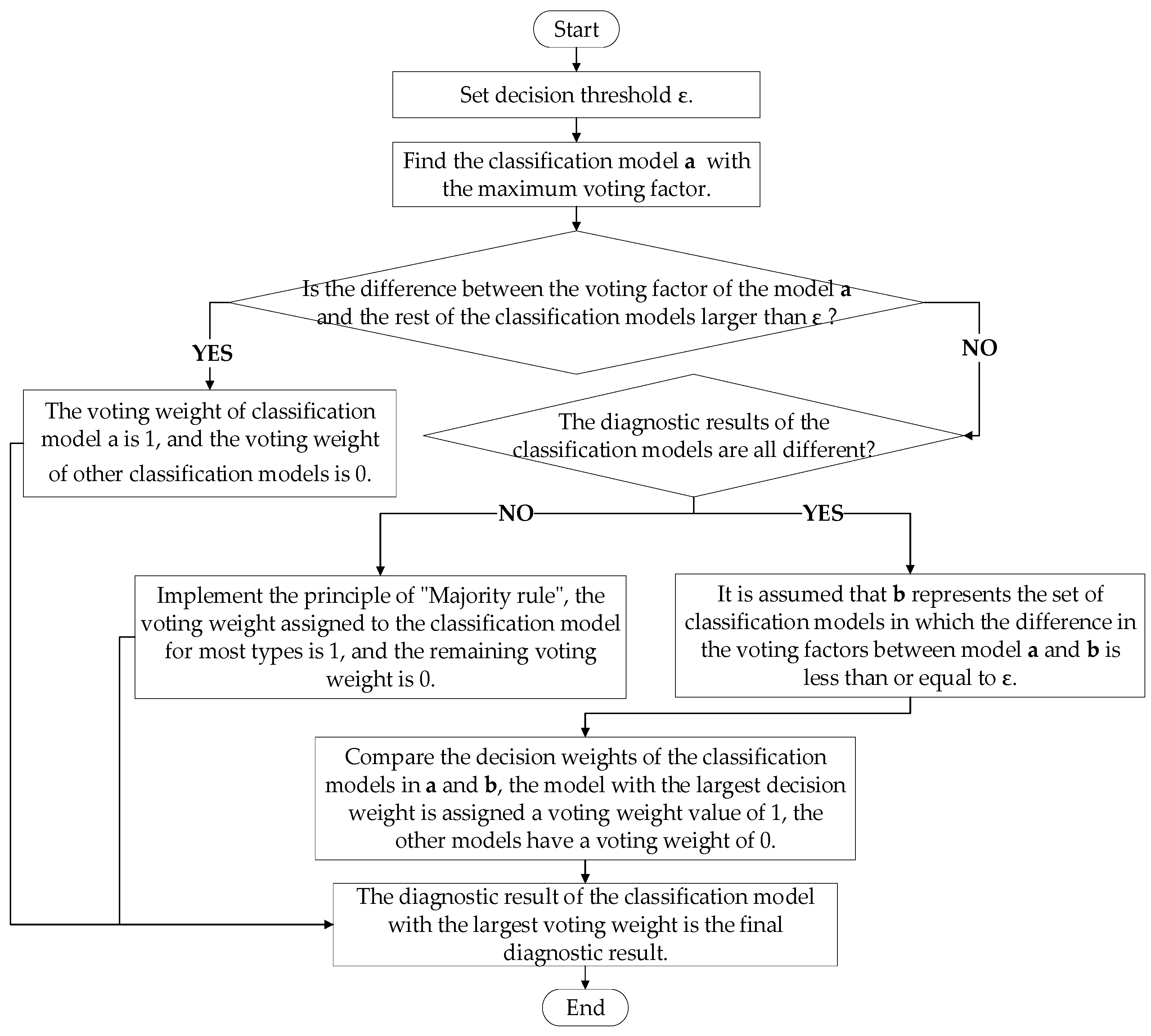

2.2. Multi-Level Decision Algorithm

- (1)

- Set a decision threshold , when there is no significant difference in the voting factors between the two classification models, it is necessary to make the next level judgment on the results of the classification model to determine the final diagnostic result.

- (2)

- Classification model with the maximum voting factor is identified. When the difference between the voting factors of the model and other classification models is larger than , assign a voting weight of 1 to the classification model , and 0 to the other classification models. Otherwise, skip to the next level of decision—step 3.

- (3)

- When the same diagnostic results exist in the classification models, the principle of majority rule is implemented to identify the majority in the output results.

- (4)

- Assuming represents the set of base class models whose difference in voting factors of classification model is less than or equal to , compare the decision weight of model and the models in set as is shown in Equation (9).

- (5)

- Based on the above multi-level decision algorithm, the diagnostic results of the classification models with the maximum voting weight are selected.

3. Experimental Design and Result Analysis

3.1. Preparation and Processing of Experimental Data

3.1.1. Data Introduction

- (1)

- Excessive temperature difference: It refers to the uneven temperature inside the battery system, which affects the performance and lifespan of the battery. When the temperature difference inside the battery system is too large, it will lead to battery capacity reduction, slow charging speed, and may lead to battery fire and other safety issues. Long-term use of the battery in high- or low-temperature environments, and uneven heat dissipation of the system, may lead to excessive battery temperature difference.

- (2)

- Battery overheating: It refers to the internal temperature of the battery being too high, exceeding the rated temperature of the battery system. The charging and discharging process of the power battery is accompanied by the violent motion of the electrons, which brings about the thermal effect, Overheating may cause the battery to rapidly lose capacity, slow down charging speed, or in more severe cases, cause the battery to catch fire and explode, resulting in serious safety issues. Frequent charging and discharging may lead to battery overheating, especially in high-temperature environments, external short-circuit, internal short-circuit, and insufficient cooling system cooling capacity.

- (3)

- Battery overvoltage: It refers to the working voltage of the battery exceeding the rated voltage value of the battery system. Overvoltage in batteries usually leads to a sharp decrease in energy density, slower charging speed, and reduced capacity. In more severe cases, the battery may catch fire or even explode due to internal heating, causing harm to personnel and property. Long-term overcharging, high charging voltage, especially when using non-standard battery chargers or unreliable power sources, and failure to follow the charging time, charging voltage, and charging current limits provided in the battery instructions during battery charging, may lead to battery overvoltage.

- (4)

- Battery undervoltage: It refers to the working voltage of the battery is lower than the rated voltage value of the battery system, especially during continuous use. Undervoltage of the battery can lead to a decrease in battery performance, reduced capacity, and slower charging speeds, which may affect the battery’s lifespan. Using the battery when the battery level is low, frequent excessive discharge, and failure to follow the charging time, voltage, and current limits in the battery instructions may lead to battery undervoltage.

3.1.2. Data Processing

3.2. Battery Fault Diagnosis Based on Three Classification Models

3.2.1. Settings for Classification Model

3.2.2. Fault Diagnostic Results of Classification Models

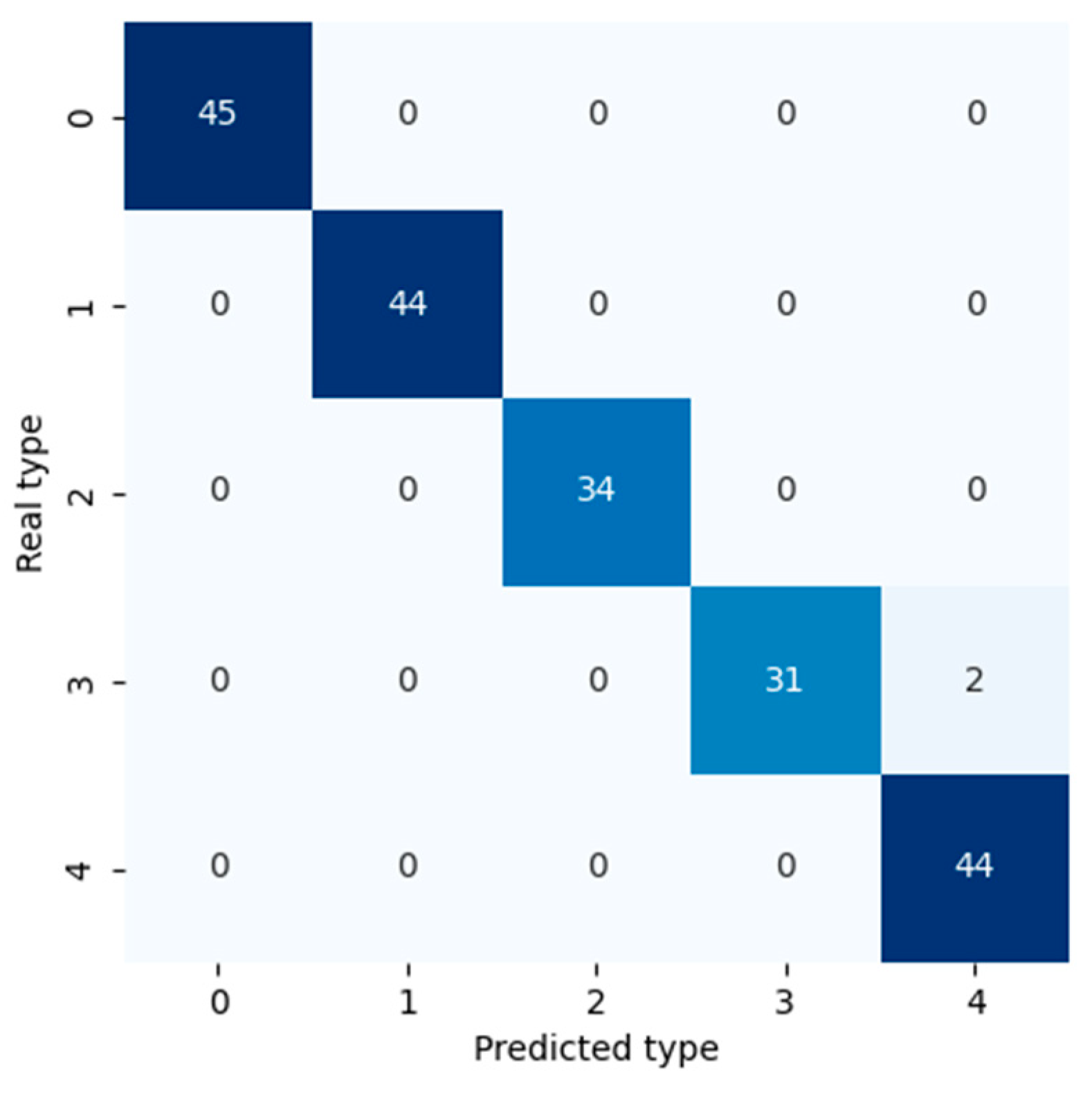

3.3. Multiple Model Fusion Diagnosis

3.3.1. Parameters of Multiple Model Fusion Algorithm

3.3.2. Results and Analysis of Multiple Model Fusion Diagnostic

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Abada, S.; Marlair, G.; Lecocq, A.; Petit, M.; Sauvant-Moynot, V.; Huet, F. Safety focused modeling of lithium-ion batteries: A review. J. Power Sources 2016, 306, 178–192. [Google Scholar] [CrossRef]

- Duan, J.; Tang, X.; Dai, H.; Yang, Y.; Wu, W.; Wei, X.; Huang, Y. Building safe lithium-ion batteries for electric vehicles: A review. Electrochem. Energy Rev. 2020, 3, 1–42. [Google Scholar] [CrossRef] [Green Version]

- Zou, C.; Klintberg, A.; Wei, Z.; Fridholm, B.; Wik, T.; Egardt, B. Power capability prediction for lithium-ion batteries using economic nonlinear model predictive control. J. Power Sources 2018, 396, 580–589. [Google Scholar] [CrossRef]

- Tang, X.; Zou, C.; Wik, T.; Yao, K.; Xia, Y.; Wang, Y.; Yang, D.; Gao, F. Run-to-run control for active balancing of lithium iron phosphate battery packs. IEEE Trans. Power Electron. 2020, 35, 1499–1512. [Google Scholar] [CrossRef] [Green Version]

- Deng, J.; Bae, C.; Marcicki, J.; Masias, A.; Miller, T. Safety modelling and testing of lithium-ion batteries in electrified vehicles. Nat. Energy 2018, 3, 261–266. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, P.; Wang, Z.; Zhang, L.; Hong, J. Fault and defect diagnosis of battery for electric vehicles based on big data analysis methods. Appl. Energy 2017, 207, 354–362. [Google Scholar] [CrossRef]

- Xia, K.; Guo, H.; He, S.; Yu, W.; Xu, J.; Dong, H. Binary classification model based on machine learning algorithm for the DC serial arc detection in electric vehicle battery system. IET Power Electron. 2019, 12, 112–119. [Google Scholar] [CrossRef]

- Xia, B.; Mi, C. A fault-tolerant voltage measurement method for series connected battery packs. J. Power Sources 2016, 308, 83–96. [Google Scholar] [CrossRef]

- Li, Y.; Wang, L.; Liao, C.; Wang, L.; Xu, D. Recursive modeling and online identification of lithium-ion batteries for electric vehicle applications. Sci. China Technol. Sci. 2014, 57, 403–413. [Google Scholar] [CrossRef]

- Panchal, S.; Mathew, M.; Dincer, I.; Agelin-Chaab, M.; Fraser, R.; Fowler, M. Thermal and electrical performance assessments of lithium-ion battery modules for an electric vehicle under actual drive cycles. Electr. Power Syst. Res. 2018, 163, 18–27. [Google Scholar] [CrossRef]

- Liu, P.; Wu, Z.; Zhang, Z.; Sun, Z. Fault Diagnosis for Battery Systems Based on Voltage Frequency-domain Indicator and Abnormal Coefficient. China J. Highw. Transp. 2022, 35, 89–104. [Google Scholar] [CrossRef]

- Wang, Z.; Hong, J.; Liu, P.; Zhang, L. Voltage fault diagnosis and prognosis of battery system based on entropy and Z-score for electronic vehicles. Appl. Energy 2017, 196, 289–302. [Google Scholar] [CrossRef]

- Zhao, S.B.; Shen, C.Y.; Guo, Z.J. Research on Fault Diagnosis of Power Battery Based on Fuzzy Neural Network. Automob. Appl. Technol. 2020, 45, 7–8, 11. [Google Scholar] [CrossRef]

- Gu, A.; Zhang, X.W. Fault diagnosis system for power battery based on RBF neural network. Chin. J. Power Sources 2016, 40, 1943–1945. [Google Scholar] [CrossRef]

- Hong, J.C.; Wang, Z.P. Fault prognosis of battery system based on accurate voltage abnormity prognosis using long short-term memory neural networks. Appl. Energy 2019, 251, 113381. [Google Scholar] [CrossRef]

- Deng, F.X.; Bian, Y.D.; Zheng, H.R. Fault diagnosis for electric vehicle lithium batteries using a multi-classification support vector machine. Electr. Eng. 2021, 104, 1831–1837. [Google Scholar] [CrossRef]

- Qiu, Y.; Sun, J.; Shang, Y.L. A Fault Diagnosis and Prognosis Method for Lithium-Ion Batteries Based on a Nonlinear Autoregressive Exogenous Neural Network and Boxplot. Symmetry 2021, 13, 1714. [Google Scholar] [CrossRef]

- Taylor, S.J.; Letham, B. Forecasting at scale. Am. Stat. 2018, 72, 37–45. [Google Scholar] [CrossRef]

- Thiyagarajan, K.; Kodagoda, S.; Van Nguyen, L.; Ranasinghe, R. Sensor Failure Detection and Faulty Data Accommodation Approach for Instrumented Wastewater Infrastructures. IEEE Access 2018, 6, 56562–56574. [Google Scholar] [CrossRef]

- Thiyagarajan, K.; Kodagoda, S.; Van Nguyen, L. Predictive analytics for detecting sensor failure using autoregressive integrated moving average model. In Proceedings of the 2017 12th IEEE Conference on Industrial Electronics and Applications (ICIEA), Siem Reap, Cambodia, 18–20 June 2017; pp. 1926–1931. [Google Scholar]

- Xia, F.; Ma, X.; Luo, Z.; Zhang, H.; Sun, P. Application of improved D-S evidence theory in fault diagnosis of lithium batteries in electric vehicles. CAAI Trans. Intell. Syst. 2017, 12, 526–537. [Google Scholar] [CrossRef]

- Xu, Y.; Lu, Y.W. Adaptive weighted fusion: A novel fusion approach for image classification. Neurocomputing 2016, 168, 566–574. [Google Scholar] [CrossRef]

- Mazher, A.; Li, P.; Moughal, T.A.; Xu, H. A decision fusion method using an algorithm for fusion of correlated probabilities. Int. J. Remote Sens. 2016, 37, 14–25. [Google Scholar] [CrossRef]

- Gao, X.; Diao, X.P.; Liu, J.; Zhang, M.; Yang, H. A Multi-classification Method of Smart Meter Fault Type Based on Model Adaptive Selection Fusion. Power Syst. Technol. 2019, 43, 1955–1961. [Google Scholar] [CrossRef]

- Wang, Z.M.; Wang, K.; He, Y. Multiple classifier fusion model for activity recognition based on high reliability weighted. J. Comput. Appl. 2016, 36, 3353–3357. [Google Scholar] [CrossRef]

- Rokach, L.; Maimon, O. Arbel. Selective voting-getting more for less in sensor fusion. Int. J. Pattern Recognit. Artif. Intell. 2006, 20, 329–350. [Google Scholar] [CrossRef]

| Type | BP | CNN | LSTM | |||

|---|---|---|---|---|---|---|

| P | R | P | R | P | R | |

| 0 | 0.9184 | 1.0000 | 0.9737 | 0.9024 | 0.9667 | 0.7073 |

| 1 | 1.0000 | 1.0000 | 1.0000 | 1.0000 | 1.0000 | 1.0000 |

| 2 | 1.0000 | 0.9444 | 0.9184 | 0.9783 | 0.6618 | 0.9783 |

| 3 | 1.0000 | 0.8205 | 1.0000 | 0.9744 | 1.0000 | 0.7179 |

| 4 | 0.9123 | 1.0000 | 0.9706 | 1.0000 | 1.0000 | 1.0000 |

| Type | Credibility | Average Credibility | ||

|---|---|---|---|---|

| BP | CNN | LSTM | ||

| 0 | 1.0000 | 0.9024 | 0.7073 | 0.8699 |

| 1 | 1.0000 | 1.0000 | 1.0000 | 1.0000 |

| 2 | 0.9444 | 0.9783 | 0.9783 | 0.9670 |

| 3 | 0.8205 | 0.9744 | 0.7179 | 0.8376 |

| 4 | 1.0000 | 1.0000 | 1.0000 | 1.0000 |

| Type | BP | CNN | LSTM |

|---|---|---|---|

| 0 | 0.7989 | 0.7644 | 0.5948 |

| 1 | 1.0000 | 1.0000 | 1.0000 |

| 2 | 0.9132 | 0.8688 | 0.6261 |

| 3 | 0.6873 | 0.8162 | 0.6013 |

| 4 | 0.9123 | 0.9706 | 1.0000 |

| Data Number | Real Type | Predicted Type | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| BP | CNN | LSTM | Fusion Model | ||||||||

| Type | Type | Type | Type | ||||||||

| 1 | 0 | 0 | 0.7989 | 1 | 2 | 0.8688 | 0 | 0 | 0.5948 | 1 | 0 |

| 2 | 3 | 3 | 0.6873 | 0 | 3 | 0.8162 | 1 | 2 | 0.6261 | 0 | 3 |

| 3 | 0 | 0 | 0.7989 | 1 | 0 | 0.7644 | 1 | 2 | 0.6261 | 0 | 0 |

| 4 | 1 | 1 | 1.0000 | 1 | 1 | 1.0000 | 1 | 1 | 1.0000 | 1 | 1 |

| 5 | 2 | 0 | 0.7989 | 0 | 2 | 0.8688 | 1 | 3 | 0.6013 | 0 | 2 |

| Data Number | Real Type | Predicted Type | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| BP | CNN | LSTM | Multi-Level Decision | Voting | Maximum | |||||

| Type | E | Type | E | Type | E | Type | Type | Type | ||

| 1 | 0 | 0 | 0.7989 | 2 | 0.8688 | 0 | 0.5948 | 0 | 0 | 2 |

| 2 | 3 | 3 | 0.6873 | 3 | 0.8162 | 2 | 0.6261 | 3 | 3 | 3 |

| 3 | 0 | 0 | 0.7989 | 0 | 0.7644 | 2 | 0.6261 | 0 | 0 | 0 |

| 4 | 1 | 1 | 1.0000 | 1 | 1.0000 | 1 | 1.0000 | 1 | 1 | 1 |

| 5 | 2 | 0 | 0.7989 | 2 | 0.8688 | 3 | 0.6013 | 2 | / | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, J.; Wu, Z.; Zhang, S.; Wang, P. A Fault Diagnosis Method for Power Battery Based on Multiple Model Fusion. Electronics 2023, 12, 2724. https://doi.org/10.3390/electronics12122724

Zhou J, Wu Z, Zhang S, Wang P. A Fault Diagnosis Method for Power Battery Based on Multiple Model Fusion. Electronics. 2023; 12(12):2724. https://doi.org/10.3390/electronics12122724

Chicago/Turabian StyleZhou, Juan, Zonghuan Wu, Shun Zhang, and Peng Wang. 2023. "A Fault Diagnosis Method for Power Battery Based on Multiple Model Fusion" Electronics 12, no. 12: 2724. https://doi.org/10.3390/electronics12122724

APA StyleZhou, J., Wu, Z., Zhang, S., & Wang, P. (2023). A Fault Diagnosis Method for Power Battery Based on Multiple Model Fusion. Electronics, 12(12), 2724. https://doi.org/10.3390/electronics12122724