1. Introduction

In the course of vehicle electrification, a large part of the braking energy to be converted can be recovered. However, a mechanical brake is still required for safety reasons. One reason is the need for a redundant system. Another reason is that the maximum required braking torque cannot be achieved with the electric drive system. For example, an ordinary electric vehicle with a mass of 1700 kg at a speed of 140 km/h requires a braking power of 713 kW if, for safety reasons, a grip value between the tire and the road of 1.1 is fully utilised. Thus, the required brake power for normal powered vehicles is 3 to 8 times higher than the nominal propulsion power. One way to further reduce the use of a friction brake subject to wear is to use a wear-free eddy current brake (ECB). However, state-of-the-art eddy current brakes have the following disadvantages:

In [

1], it is shown that the disadvantage of a low power density can be compensated for by using a magnetoisotropic material structure. This structure allows the skin effect to be reduced and increases the free cooling area.

Figure 1 shows the braking torques in a braking process with a constant required torque

and linearly decreasing speed

n when using an eddy current brake. At lower speeds, an additional mechanical friction brake must supply the difference between the required torque and the torque of the eddy current brake

with a torque of

. Combinations of eddy current brakes and friction brakes have already been presented in other publications. In [

2,

3], concepts are presented in which the eddy current brake and the friction brake operate locally and separately. In other concepts [

4,

5], additional excitation poles are positioned on the brake disc to generate eddy currents and thus a wear-free portion of the braking torque. All of these concepts generate frictional torque via a classic brake caliper. However, the concept presented here and in a related patent [

6] uses the magnetic attraction between the rotor with exciter poles and the stator of an eddy current brake to generate additional frictional torque, such as an electromagnetic friction brake [

7,

8]. An additional actuator with power electronics or even a hydraulic system is therefore not required. This work demonstrates, for the first time, the use of magnetic attraction between the rotor and stator of an eddy current brake to decelerate to a standstill. In addition to the work of [

9], in this paper, measurement data for a functional demonstrator of the hybrid brake and the validation of the model are shown.

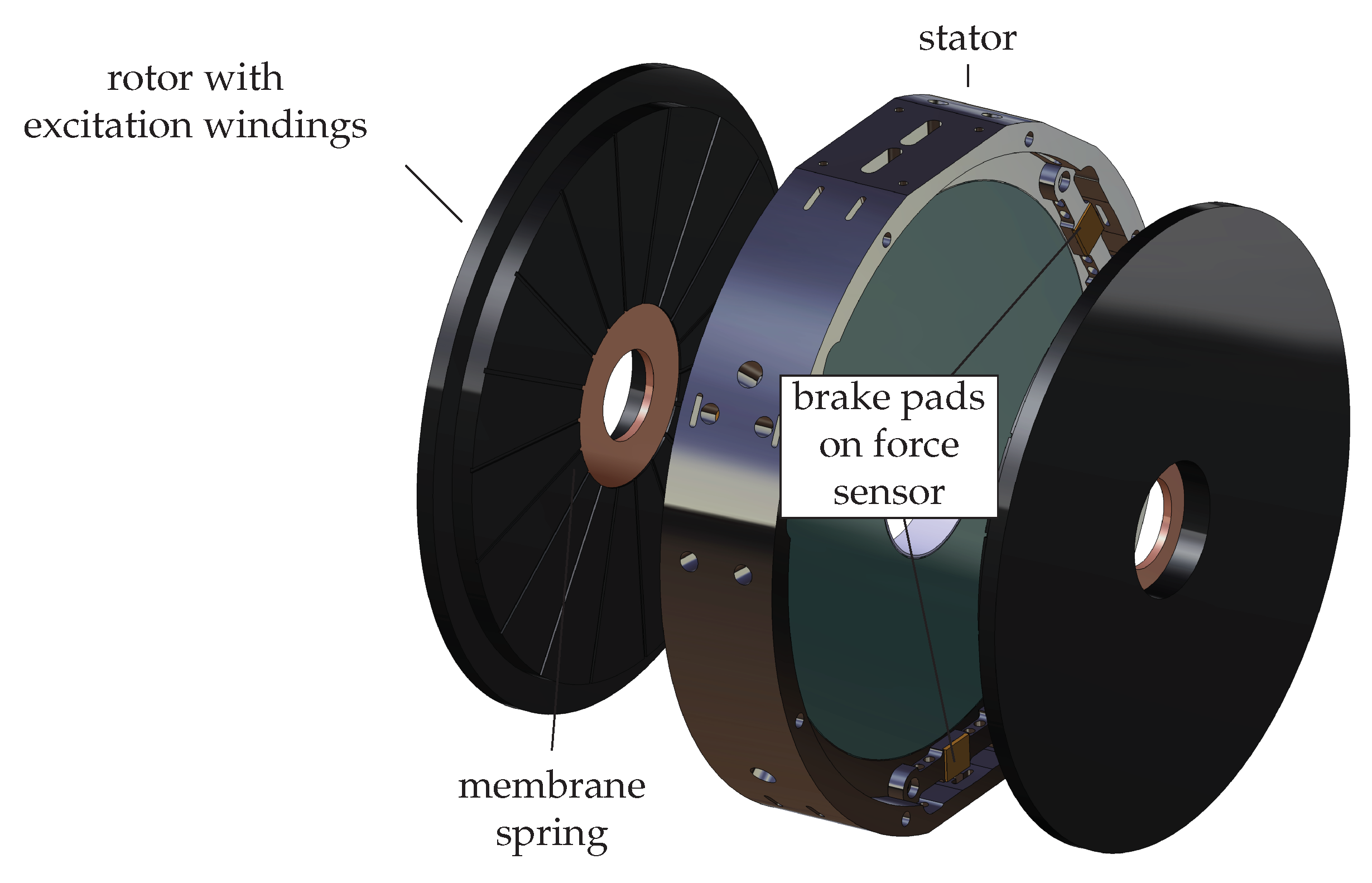

2. Concept of the Hybrid Brake

Figure 2a shows an exemplary cad model, and

Figure 2b shows the superordinate operating principle of the hybrid brake. The current in the excitation windings on the rotor excites eddy currents in the stator, which generate an eddy current torque

during the rotary motion.

At low speeds, the induction effect decreases sharply until, at zero speed, no braking torque is generated by eddy currents.

At these low speeds, the magnetic attraction force between the rotor and stator is used to generate a frictional torque to brake to a stop. Since contact between the rotor and stator is necessary for the frictional action, a spring is used to ensure that contact is not present when the hybrid brake is not required to provide a braking torque. Since the torque must be transmitted from the rotor to the hub and the rotor must be axially displaceable at the same time, a diaphragm spring is used.

3. Design Method

As with the eddy current brake, the hybrid brake is optimised for maximum wear reduction in the event of emergency braking compared with the use of a conventional friction brake. Since the wear of a mechanical friction brake is approximately proportional to the converted braking energy [

10], the wear reduction factor is defined as

where

is the wear-free torque due to eddy currents, and

is the total required torque (see

Figure 1). In the first step, the active magnetic geometry is optimised exactly according to the method presented in [

1], neglecting the additional frictional torque. At best, a hybrid brake with this geometry can achieve the wear reduction factor from optimisation in which the frictional torque is neglected. The friction torque

of the hybrid brake results from the normal force

acting on the surface with the mean radius

and the corresponding friction coefficient

.

Using a spring with a stiffness close to zero, the normal force between the surfaces

corresponds to the magnetic normal force

between the rotor and stator. To give a direct example, the torques in this case are shown in

Figure 3. In this case, the maximum excitation current results in a normal force and thus a frictional torque, which is represented by the red dashed line. Therefore, the excitation current must be reduced until the total torque is equal to the required torque. This means that the maximum excitation current must also be reduced at speeds where the torque due to eddy currents is lower than the required torque. As a result, the torque of the eddy currents is also greatly reduced, and the wear reduction factor of the previous optimisation cannot be achieved.

Ideally, the excitation current should be set so that the torques of the eddy currents, taking into account the boundary conditions

and

are as high as possible (see

Figure 1). Thus, the spring mechanism must be designed to reduce the normal force

so that the wear reduction is as close as possible to the value of the previous optimisation.

In detail, this means that the spring characteristic should be optimised so that the time until the rotor contacts the stator

is as long as possible so that the frictional torque is zero in this time range, which is the first quality factor for the spring parameter analyses. For stability reasons, the rotors should behave stably at a constant required torque. This means that the axial velocity should be mainly in one direction, i.e., as aperiodic as possible. An aperiodic factor is defined as a second quality parameter with

where

is the velocity of the rotor or the first derivative of the rotor position

s in

Figure 4b. The aperiodic factor is one when the rotor moves in only one direction and goes to zero when it oscillates back and forth for a long time. Since a high impact velocity of the rotors on the stator would result in a high peak normal force and thus a high peak mechanical torque, which is probably higher than the required torque, the impact velocity should be as low as possible. To provide an additional degree of freedom to meet these requirements, the hub of the rotor has a contour against which the spring can rest during compression. This contour can be used to influence the characteristics of the spring curve. The given parameters for the optimisation are the allowable design space for the spring, the outer radius

, its inner radius

, its total thickness

, and the allowable mechanical stress.

4. System Model

Figure 4a shows the block diagram of the hybrid brake system model. With the input voltage

, the excitation current in the excitation windings is calculated as a function of time

t with

where

is the resistance, and

is the inductance of the excitation windings. The required input voltage

is calculated in a model predictive control loop, which is not part of this work. The torque due to eddy currents

as well as the magnetic normal force

due to field coupling are described in lookup tables as a function of the excitation current

, the speed

n, and the magnetic air gap

. For this purpose, the electromagnetic model of [

11], which is extended by a co-energetic approach [

12,

13,

14] to calculate the normal force, is used.

In

Figure 4b, the model of the mechanical domain of the dynamic model is shown. The equation of the motion of the rotor with the mass

is

where the forces of the stop limits are a combination of an elastic force expressed with a stiffness

c and damping force.

In reality, the elastic force is the result of the deformation of the stator and the rotor. However, the deformation is represented by the overlap

of solids. In the case of the stop acting against the stator, the intersection can be expressed by

as can be seen in

Figure 4b, where

is the maximum mechanical air gap and

is the predeformation of the spring. It is always

. The second term in Equation (

6) is the damping force. The damping force is a mixture of the damping due to a squeezed flow when the air gap becomes very small and the damping due to the internal friction of the bodies. The first damping phenomenon is described in [

15]. With respect to the internal friction, the damping is inherently modelled with the squeezed damping equation by modifying Equation (

1) in [

15] and choosing the parameters

a and

appropriately.

5. Electromagnetic Model

The main goal of the electromagnetic model is to determine the induced eddy currents and the resulting wear-free torque as a function of the speed

n for different excitation currents

and magnetic air gaps

[

11]. In context of the hybrid brake, the normal force

also needs to be calculated with the electromagnetic model which is designed for the eddy currend brake with the magneto-isotropic material structure shown in

Figure 5. The model is based on the following assumptions and simplifications:

The model is a reluctance network;

The model is a quasi static model;

The magnetic circuit is modelled two-dimensionally in a pole cross-section at the mean effective radius in order to calculate the mean eddy current across all pin columns in the radial direction.

Because the model is quasi stationary, only the average torque over one revolution at a constant angular speed , constant excitation current , and constant temperature of an ECB can be determined from the energy balance of the ECB, including the mechanical power , the average ohmic losses in the active material as a result of the eddy currents , the average hysteresis losses , and the mechanical friction losses . The hysteresis losses are only taken into account in the pins and mixed with eddy current losses in the pins to compute the pin iron losses .

Figure 6 shows the reluctance network with

pins in one pole pitch

. The excitation current

and the eddy currents

in the material structure cause a magnetic flux

in each pin segment, where

i is the pin index in the tangential (movement) direction, and

j is the index of the pin segment with the length

(see right side in

Figure 5b) in the axial direction.

The reluctance network results in the mesh equation

where

is mesh flux of the mesh

, which is analogous to the vector potential

A in the transient magnetic field diffusion equation [

16]. Further,

are the path reluctances of one mesh

to neighboured meshes with the flux

. Corresponding to

Figure 6, the sum of the reluctances in the first term is

is the electric resistance of one eddy current path, and

is the external applied excitation current, which only exists in the meshes with excitation windings. The first term on the right represents the eddy currents

as a result of the mesh flux change and is the outcome of applying the chain rule to the flux change over time due to the speed of the rotor

v at the mean effective radius and the discretisation by the central difference, where

is the distance between two adjacent pins in the direction of movement.

To transform Equation (

8) into a system of equations that can be solved numerically, the first term on the right side is moved to the left, and some entries of the resulting system matrix contain

. This equation system, with the solution vector containing the mesh fluxes, is solved iteratively considering the nonlinear magnetisation curve of the excitation system as well of the steel pins in the magnetoisotropic material structure which, in this case, is also a function of the frequency

. The average power in joules over one revolution as a result of the eddy currents is computed from the resulting mesh fluxes

with

The floor function

and second term of this equation consider the symmetry boundary condition in the axial direction if the number of sheets

is a odd number. Due to the antisymmetric boundary conditions for

, the mesh flux is

and for

From the energy balance of the eddy current brake, the average torque over one revolution is calculated with

The magnetic attraction force between the rotor and stator is calculated with a co-energy approach [

12,

13,

14]. At a constant excitation current

and constant speed

n, the magnetic attraction force is determined with the derivative of the co-energy

with respect to the magnetic air gap

.

The total co-energy is the sum of the co-energy of every domain that is penetrated by a magnetic flux. For the flux path’s trough air, the co-energy is simply

where

is the magnetic flux penetrating the flux path which has the reluctance

. In flux paths with nonlinear magnetisation curves, the co-energy is computed from the material’s specific co-energy as a function of the flux density and the volume of the flux path.

In the system model (see

Figure 4b), the electromagnetic model contains lookup tables with precomputed values for the eddy current torque

and the magnetic attraction force

as a function of the excitation current

, the magnetic air gap

, and the speed

n.

Figure 7 shows the eddy current torque

and the normal force

as a function of the magnetic air gap

and the excitation current

for speeds of

n = 1000 min

−1 and

n = 8000 min

−1.

6. Spring Model

The main task for the spring is to decrease the normal force such that the wear reduction is as high as possible under the requirement that the brake torque can be generated. Additionally, the spring provides a reset of the axial rotor position and transfers the torque from the rotor to the shaft. The first approach to the spring is to design it as a wave spring. The spring lies against a tangential contour during compression, as shown in

Figure 8a. Due to the limited design space, the mean spring diameter

, the width

, and the total height of the spring

are given. The parameters to be optimized are the spring wavenumber

, the thickness of a spring leaf

, and the contour radius

.

The model is based on the Euler–Bernoulli beam theory with the governing equation for the deflection

w along the path

x

where

E is the Young’s modulus,

I is the second moment of the area, and

q is the specific surface load, which is zero in this case. Due to symmetry, a spring leaf is divided over

quarter sections of length

as shown in

Figure 8b. Further, the model is related to the middle spring sheet. When the spring comes into contact with the contour, the bending moment remains constant up to the end point of the contact due to the radius of curvature

.

If the force

F is given, the point at which the contact ends can be determined with

Due to the strong deflection along the contour, the deflection of the free beam length is calculated in a separate coordinate system that is rotated by the angle

and shifted by the vector

with respect to the main coordinate system. The force

F acts with its component

in the coordinate system on a free bar of length

and leads to a free deflection of

The reverse transformation to the main coordinate system then leads to the deflection of the spring

7. Spring Parameter Analysis

After a transient simulation of the system model, the quality criteria are evaluated by varying the spring parameters, each of which leads to different spring characteristics.

Figure 9 shows different design points in the space of the quality criteria.

For a better understanding of the system, the behaviour is analysed in detail for three different design points. The red, green, and blue design points (design 1–3) are each a result of spring parameters that produce the spring characteristics shown in

Figure 10.

Each of these spring characteristics results in a different dynamic behaviour, illustrated by the state trajectories in

Figure 11. It is evident that design 2, with the green spring curve, results in the lowest time to rotor contact with the stator and the highest impact velocity, because it has the lowest stiffness and preload. Design 1, with the red spring curve, gives the highest time to impact, a very low impact velocity, but also, a dynamic behaviour with a high number of periodic oscillations (see

Figure 11). At some point, the spring force exceeds the magnetic attraction force, slowing the axial motion of the rotor and causing it to move back. Design 3 offers a tradeoff between a lower time to impact and a lower oscillation rate. In

Figure 12, it is clear that designs that result in a higher time to contact also have a higher wear reduction factor, because the frictional torque stays at zero longer. Design 1 has the highest wear reduction factor of

, but also results in torque oscillations due to the unstable motion of the rotor. Design 3 is the design with the next highest wear reduction factor of

and an acceptable aperiodic factor of

. This design, which yields the blue spring curve, will be selected to build a functional demonstrator for future experiments. To ensure that the spring design will result in the desired spring curve in reality, an finite element method (FEM) analysis is performed.

11. Discussion

In this work, the model and design method of a hybrid brake were presented. Finally, a working demonstrator was tested. Most importantly, the results show that it is possible to use the magnetic attraction of an eddy current brake to brake to a stop at very low speeds. The spring that enables the axial movement of the rotors was optimised for high wear reduction as well as stable dynamic behaviour. Due to the friction in the bushing, no axial vibrations were detected or measured during the tests. Therefore, it should be possible to use a spring design that leads to a higher wear reduction, which was assumed in the design process to lead to strong vibrations (see design 1 in the spring parameter analysis section). The wear reduction has not yet been analysed because the torque–speed map has not yet been fully measured. Furthermore, the measurement data show strong deformation of the rotor, so the air gap is inhomogeneous along the radius. The validation of the subsystems was successful. Both the electromagnetic model for calculating the primary magnetic flux and the FEM model of the spring deviate from the experimental results by less than 10%. The proposed method for calculating the eddy current moment from the measured magnetic fluxes was also successfully tested. The final validation of the overall system was only partially possible due to the deformation of the rotor, which resulted in an inhomogeneous air gap. Even if the air gap had been measured at more points, validation of the model would also not have been possible, because the electromagnetic model is a two-dimensional model. Therefore, the electromagnetic model must be extended to a three-dimensional model, and the laser distance sensors should be positioned at different radial locations for complete model validation. Since the material structure of the active element is probably not suitable for mass production, the magneto-isotropic material structure must be improved in terms of it’s cost-effective manufacturability.