A Product-Design-Change-Based Recovery Control Algorithm for Supply Chain Disruption Problem

Abstract

:1. Introduction

- Develop a two-layer model that considers product design change options and the abilities of alternative suppliers;

- Develop a computationally efficient algorithm to solve the mathematical model without sacrificing the optimal objective function value;

- Analyze the impact of the proposed decisions on the total profit of the supply chain after disruptions.

2. Literature Review

2.1. Supply Chain System Disruption Recovery Control Strategies

2.2. Product Design Change

2.3. Research Gap

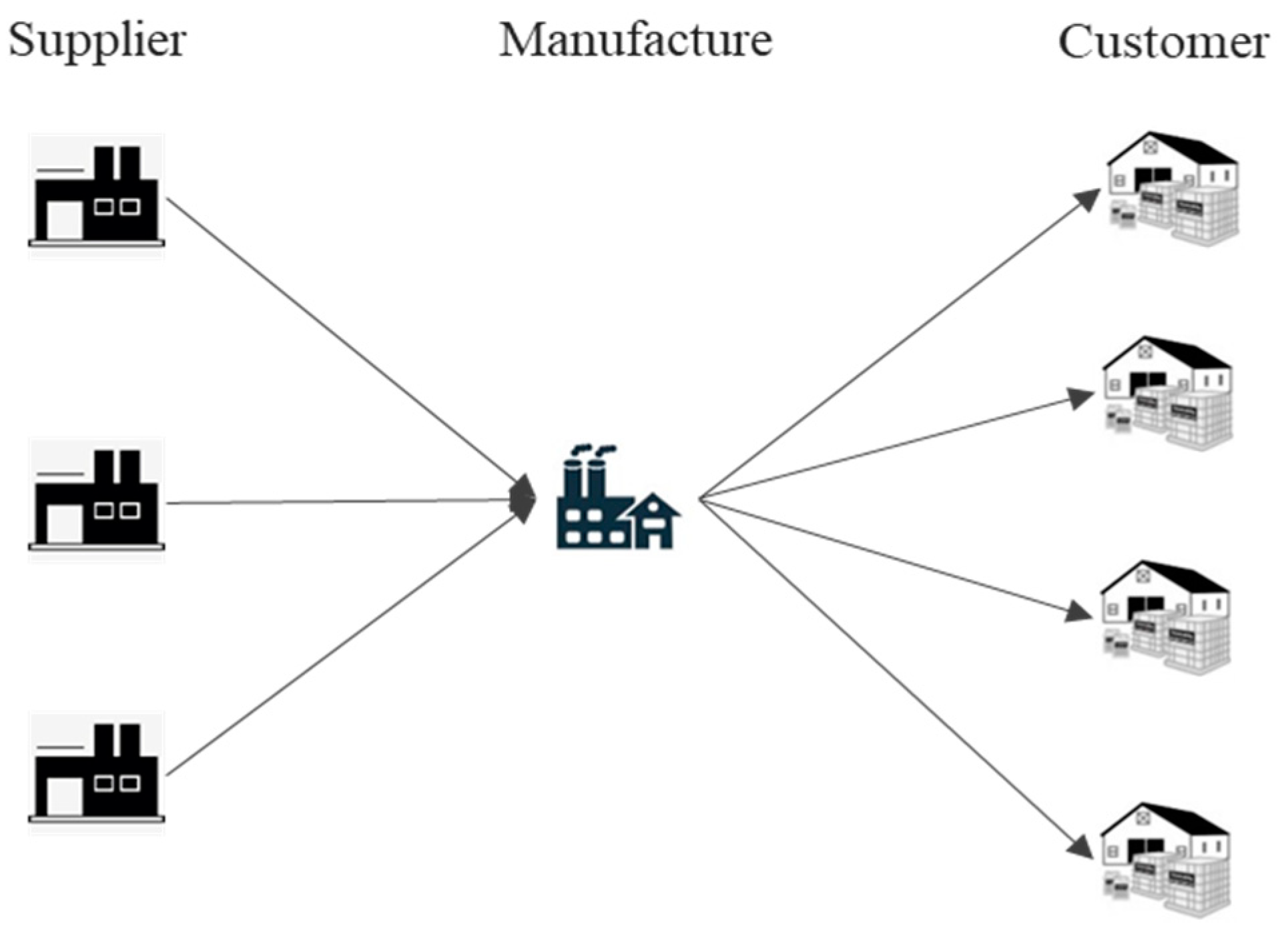

3. Problem Statement

3.1. Problem Definition

3.2. Assumptions

- All products require a core component, and only the supply disruption and impact of the component are considered. Product design changes adopt this component as the starting point for the change path.

- Each customer’s demand for products is constant, and customer order requirements are independent of each other.

- Whether a supplier will be disrupted is independent of the circumstances of the other suppliers. Supply disruptions occur at zero, after which point no new disruptions occur during the production planning, and the disrupted supplier cannot resume the production plan.

- Orders from customer j are produced in one cycle and shipped immediately after production, and products produced in cycle t are delivered in cycle t + 1, regardless of product inventory.

- The manufacturers choose only one design change option to produce substitute products to deal with disruptions.

- Substitute products and backorders are available to all customers. The manufacturer needs to compensate for delivering substitute products to customers.

- Exceeding the customer’s latest delivery period Tj will result in backorder costs, while exceeding the customer’s latest cancellation period Uj will result in lost sales costs.

- The emergency sourcing of raw materials is implemented immediately after supply disruptions, regardless of delays in production caused by emergency sourcing.

- The transportation time and cost of raw materials and products between suppliers, manufacturers, and retailers are not considered.

4. Mathematical Model

Model Development

5. Solution Approach

5.1. Solution Construction

5.2. Path Selection Process

5.3. Local Search Method

5.4. Pheromone Update Rules

5.4.1. Adaptive Pheromone Volatility Factor

5.4.2. Elitist Ant System

5.4.3. Maximum and Minimum Pheromone Strategy

| Algorithm 1: HACO. |

| Input: Initial point change intensity , point change cost , point change time , change impact intensity , and a termination condition. |

| Output: The obtained best solution. |

| Begin |

| for each edge in pheromoneGraph do |

| Set initial pheromone. |

| end for |

| for each iteration do |

| for each initial point do |

| → changeIntensity |

| for each ant do |

| Initialize ant with starting at initial point. |

| while changeIntensity > 0 do |

| Roulette selects next point |

| if next point is not null then |

| Update changeIntensity |

| Update route, length by |

| Update ant current Point |

| else |

| Initialize ant, changeIntensity, route, length |

| end if |

| end while |

| Update inputRoutes, inputLengths |

| end for |

| Local search with inputting inputRoutes, inputLengths, initPoint |

| Obtain the best route and length for this iteration by local search |

| Calculate the change cost and time based on the best route |

| Obtain profit by using Gurobi with the and |

| for each edge in pheromoneGraph do |

| Update pheromone using the pheromone update rules |

| end for |

| if profit > maxProfit then |

| Update minRoute, minLength, maxProfit, initPoint |

| end if |

| end for |

| end for |

| End. |

6. Numerical Experiments

6.1. Parameter Setting and Sensitivity Analysis

6.2. Comparison of Algorithms

6.3. Scenario-Based Analysis

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Notations and Variables

| List of indices: | ||

| Index for original suppliers; | ||

| Index for alternative suppliers; | ||

| Index for product part nodes; | ||

| Index for initial change nodes; | ||

| Index for customers; | ||

| Index for production periods. | ||

| List of decision variables: | ||

| 1 if changed from node to node and 0 otherwise; | ||

| 1 if node is changed and 0 otherwise; | ||

| 1 if the initial change node is selected and 0 otherwise; | ||

| Quantity to be procured in period from supplier after disruptions; | ||

| Quantity to be procured in period from alternative supplier after product change; | ||

| 1 if customer’s order is produced in period and 0 otherwise. | ||

| List of product change path planning model parameters: | ||

| Weight coefficient; | ||

| N | Maximum number of nodes in the product network; | |

| Intensity of change impact from node to node ; | ||

| Functional relevance of node with node | ||

| Change propagation impact of node ; | ||

| In-degree of node ; | ||

| Out-degree of node ; | ||

| Probability of change of node ; | ||

| Probability of simultaneous change of node and node ; | ||

| Propagation probability of node to node ; | ||

| Change time of node ; | ||

| Change cost of node ; | ||

| Initial change impact intensity of the initial change node ; | ||

| Change impact intensity of node covered by change propagation path; | ||

| Reliability coefficient of initial node . | ||

| List of supply chain disruption recovery model parameters: | ||

| 1 if the original supplier has not been disrupted and 0 otherwise; | ||

| Quantity to be procured in period from supplier without disruptions; | ||

| Unit cost of raw materials from supplier | ||

| Unit emergency cost of raw materials from supplier | ||

| Unit cost of alternative raw materials from alternative supplier | ||

| Maximum supply capacity of supplier in period; | ||

| Maximum supply capacity of alternative supplier in period; | ||

| Maximum production capacity in period; | ||

| Unit cost of production; | ||

| Inventory in period; | ||

| Quantity of order demand from customer ; | ||

| Delivery lead time for customer ; | ||

| Last time for customer to cancel the order; | ||

| Unit cost of backorder for customer’s order after delayed delivery; | ||

| Unit cost of lost sales for customer’s order after order cancellation; | ||

| Product change cost; | ||

| Product change time; | ||

| Unit compensation cost of substitution products; | ||

| Unit price of the order. | ||

References

- Dolgui, A.; Ivanov, D.; Sokolov, B. Ripple effect in the supply chain: An analysis and recent literature. Int. J. Prod. Res. 2018, 56, 414–430. [Google Scholar] [CrossRef] [Green Version]

- Friesz, T.L.; Lee, I.; Lin, C.-C. Competition and disruption in a dynamic urban supply chain. Transp. Res. Part B Methodol. 2011, 45, 1212–1231. [Google Scholar] [CrossRef]

- Torabi, S.; Baghersad, M.; Mansouri, S. Resilient Supplier Selection and Order Allocation under Operational and Disruption Risks. Transp. Res. Part E Logist. Transp. Rev. 2015, 79, 22–48. [Google Scholar] [CrossRef]

- Tang, C.; Tomlin, B. The power of flexibility for mitigating supply chain risks. Int. J. Prod. Econ. 2008, 116, 12–27. [Google Scholar] [CrossRef] [Green Version]

- Tomlin, B. On the value of mitigation and contingency strategies for managing supply chain disruption risks. Manag. Sci. 2006, 52, 639–657. [Google Scholar] [CrossRef] [Green Version]

- Ivanov, D.; Dolgui, A.; Sokolov, B.; Ivanova, M. Literature review on disruption recovery in the supply chain. Int. J. Prod. Res. 2017, 55, 6158–6174. [Google Scholar] [CrossRef]

- Hosseini, S.; Morshedlou, N.; Ivanov, D.; Sarder, M.; Barker, K.; Al Khaled, A. Resilient supplier selection and optimal order allocation under disruption risks. Int. J. Prod. Econ. 2019, 213, 124–137. [Google Scholar] [CrossRef]

- Kim, S.H.; Tomlin, B. Guilt by association: Strategic failure prevention and recovery capacity investments. Manag. Sci. 2013, 59, 1631–1649. [Google Scholar] [CrossRef] [Green Version]

- Lu, M.; Huang, S.; Shen, Z.-J.M. Product substitution and dual sourcing under random supply failures. Transp. Res. Part B Methodol. 2011, 45, 1251–1265. [Google Scholar] [CrossRef]

- Chen, J.; Wang, H.; Zhong, R.Y. A supply chain disruption recovery strategy considering product change under COVID-19. J. Manuf. Syst. 2021, 60, 920–927. [Google Scholar] [CrossRef]

- Chen, C.-Y.; Liao, G.-Y.; Lin, K.-S. An attribute-based and object-oriented approach with system implementation for change impact analysis in variant product design. CAD Comput. Aided Des. 2015, 62, 203–217. [Google Scholar] [CrossRef]

- Lin, Y.; Zhou, L. The impacts of product design changes on supply chain risk: A case study. Int. J. Phys. Distrib. Logist. Manag. 2011, 41, 162–186. [Google Scholar] [CrossRef]

- Ma, S.H.; Jiang, Z.L.; Liu, W.P. Evaluation of a design property network-based change propagation routing approach for mechanical product development. Adv. Eng. Inform. 2016, 30, 633–642. [Google Scholar] [CrossRef]

- Namdar, J.; Li, X.P.; Sawhney, R.; Pradhan, N. Supply chain resilience for single and multiple sourcing in the presence of disruption risks. Int. J. Prod. Res. 2018, 56, 2339–2360. [Google Scholar] [CrossRef] [Green Version]

- Huang, H.; Zeng, N.; Xu, H. Procurement mechanism for dual sourcing and emergency production under capacity constraint. Comput. Ind. Eng. 2018, 119, 204–218. [Google Scholar] [CrossRef]

- Bottani, E.; Murino, T.; Schiavo, M.; Akkerman, R. Resilient food supply chain design: Modelling framework and metaheuristic solution approach. Comput. Ind. Eng. 2019, 135, 177–198. [Google Scholar] [CrossRef]

- Simchi-Levi, D.; Wang, H.; Wei, Y.H. Increasing Supply Chain Robustness through Process Flexibility and Inventory. Prod. Oper. Manag. 2018, 27, 1476–1491. [Google Scholar] [CrossRef]

- Lucker, F.; Seifert, R.W.; Bicer, I. Roles of inventory and reserve capacity in mitigating supply chain disruption risk. Int. J. Prod. Res. 2019, 57, 1238–1249. [Google Scholar] [CrossRef] [Green Version]

- Lucker, F.; Chopra, S.; Seifert, R.W. Mitigating Product Shortage Due to Disruptions in Multi-Stage Supply Chains. Prod. Oper. Manag. 2021, 30, 941–964. [Google Scholar] [CrossRef]

- Shahed, K.S.; Azeem, A.; Ali, S.M.; Moktadir, M.A. A supply chain disruption risk mitigation model to manage COVID-19 pandemic risk. Environ. Sci. Pollut. Res. 2021. [Google Scholar] [CrossRef]

- Katsaliaki, K.; Galetsi, P.; Kumar, S. Supply chain disruptions and resilience: A major review and future research agenda. Ann. Oper. Res. 2021, 319, 965–1002. [Google Scholar] [CrossRef] [PubMed]

- Paul, S.K.; Sarker, R.; Essam, D. A reactive mitigation approach for managing supply disruption in a three-tier supply chain. J. Intell. Manuf. 2018, 29, 1581–1597. [Google Scholar] [CrossRef]

- Paul, S.K.; Sarker, R.; Essam, D.; Lee, P.T.-W. A mathematical modelling approach for managing sudden disturbances in a three-tier manufacturing supply chain. Ann. Oper. Res. 2019, 280, 299–335. [Google Scholar] [CrossRef]

- Malik, A.I.; Sarkar, B. Disruption management in a constrained multi-product imperfect production system. J. Manuf. Syst. 2020, 56, 227–240. [Google Scholar] [CrossRef] [PubMed]

- Paul, S.K.; Chowdhury, P. A production recovery plan in manufacturing supply chains for a high-demand item during COVID-19. Int. J. Phys. Distrib. Logist. Manag. 2021, 51, 104–125. [Google Scholar] [CrossRef]

- Gupta, V.; Ivanov, D.; Choi, T.M. Competitive pricing of substitute products under supply disruption. Omega 2021, 101, 102279. [Google Scholar] [CrossRef]

- Khalilabadi, S.M.G.; Zegordi, S.H.; Nikbakhsh, E. A multi-stage stochastic programming approach for supply chain risk mitigation via product substitution. Comput. Ind. Eng. 2020, 149, 106786. [Google Scholar] [CrossRef]

- Saha, A.K.; Paul, A.; Azeem, A.; Paul, S.K. Mitigating partial-disruption risk: A joint facility location and inventory model considering customers’ preferences and the role of substitute products and backorder offers. Comput. Oper. Res. 2020, 117, 104884. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, W.; Zhang, J. Resource constrained scheduling of design changes based on simulation of change propagation process in the complex engineering design. Res. Eng. Des. 2019, 30, 21–40. [Google Scholar] [CrossRef]

- Shivankar, S.D.; Deivanathan, R. Product design change propagation in automotive supply chain considering product life cycle. CIRP J. Manuf. Sci. Technol. 2021, 35, 390–399. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, W. An integrated change propagation scheduling approach for product design. Concurr. Eng. 2014, 22, 347–360. [Google Scholar] [CrossRef]

- Uckun, S.; Mackey, R.; Do, M.; Zhou, R.; Huang, E.; Shah, J. Measures of product design adaptability for changing requirements. Artif. Intell. Eng. Des. Anal. Manuf. 2014, 28, 353–368. [Google Scholar] [CrossRef]

- Yu, G.; Yu, Y.; Aijun, L. Joint optimization of complex product variant design responding to customer requirement changes. J. Intell. Fuzzy Syst. 2016, 30, 397–408. [Google Scholar]

- Yu, G.; Yang, Y.; Zhang, X.; Li, C. Network-based analysis of requirement change in customized complex product development. Int. J. Inform. Tec. Dec. Mak. 2017, 16, 1125–1149. [Google Scholar]

- Li, Y.; Zhao, W.; Tong, S. Simulation based scheduling of multiple change propagations in multistage product development processes. Expert Syst. Appl. 2017, 89, 1–19. [Google Scholar] [CrossRef]

- Stefansdottir, B.; Grunow, M. Selecting new product designs and processing technologies under uncertainty: Two-stage stochastic model and application to a food supply chain. Int. J. Prod. Econ. 2018, 201, 89–101. [Google Scholar] [CrossRef]

- Li, R.M.; Yang, N.D.; Zhang, Y.L.; Liu, H. Risk propagation and mitigation of design change for complex product development (CPD) projects based on multilayer network theory. Comput. Ind. Eng. 2020, 142, 106370. [Google Scholar] [CrossRef]

- Rostami, A.; Paydar, M.M.; Asadi-Gangraj, E. A hybrid genetic algorithm for integrating virtual cellular manufacturing with supply chain management considering new product development. Comput. Ind. Eng. 2020, 145, 106565. [Google Scholar] [CrossRef]

- Dorigo, M.; Maniezzo, V.; Colorni, A. Ant system: Optimization by a colony of cooperating agents. IEEE Trans. Syst. Man Cybern. Part B Cybern. 1996, 26, 27–41. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Patriarca, R.; Simone, F.; Di Gravio, G. Modelling cyber resilience in a water treatment and distribution system. Reliab. Eng. Syst. Saf. 2022, 226, 108653. [Google Scholar] [CrossRef]

- Hu, H.T.; Guo, S.Y.; Qin, Y.C.; Lin, W.J. Two-stage stochastic programming model and algorithm for mitigating supply disruption risk on aircraft manufacturing supply chain network design. Comput. Ind. Eng. 2023, 175, 108880. [Google Scholar] [CrossRef]

| RV | ||||

|---|---|---|---|---|

| 1 | 1 | 0.4 | 20 | 3,808,061 |

| 1 | 2 | 0.5 | 30 | 3,804,925 |

| 1 | 3 | 0.6 | 40 | 3,809,832 |

| 1 | 4 | 0.7 | 50 | 3,816,376 |

| 1 | 5 | 0.8 | 60 | 3,810,651 |

| 2 | 1 | 0.5 | 40 | 3,807,243 |

| 2 | 2 | 0.6 | 50 | 3,804,925 |

| 2 | 3 | 0.7 | 60 | 3,810,651 |

| 2 | 4 | 0.8 | 20 | 3,813,105 |

| 2 | 5 | 0.4 | 30 | 3,808,743 |

| 3 | 1 | 0.6 | 60 | 3,809,015 |

| 3 | 2 | 0.7 | 20 | 3,811,469 |

| 3 | 3 | 0.8 | 30 | 3,809,833 |

| 3 | 4 | 0.4 | 40 | 3,809,697 |

| 3 | 5 | 0.5 | 50 | 3,809,697 |

| 4 | 1 | 0.7 | 30 | 3,811,333 |

| 4 | 2 | 0.8 | 40 | 3,804,790 |

| 4 | 3 | 0.4 | 50 | 3,807,925 |

| 4 | 4 | 0.5 | 60 | 3,808,197 |

| 4 | 5 | 0.6 | 20 | 3,808,879 |

| 5 | 1 | 0.8 | 50 | 3,815,422 |

| 5 | 2 | 0.4 | 60 | 3,807,243 |

| 5 | 3 | 0.5 | 20 | 3,808,879 |

| 5 | 4 | 0.6 | 30 | 3,816,240 |

| 5 | 5 | 0.7 | 40 | 3,816,376 |

| Instance | HACO | GA | MA |

|---|---|---|---|

| scp_10_20 | 6,693,096 ± 0 | 6,693,096 ± 0 | 6,693,096 ± 0 |

| scp_10_40 | 6,693,998 ± 3810 | 6,691,328 ± 7350 | 6,695,629 ± 5465 |

| scp_10_60 | 6,693,845 ± 8146 | 6,653,189 ± 10,483 | 6,665,607 ± 7949 |

| scp_15_20 | 8,061,226 ± 0 | 8,061,226 ± 0 | 8,061,226 ± 0 |

| scp_15_40 | 8,062,048 ± 2524 | 8,049,030 ± 2396 | 8,048,161 ± 8463 |

| scp_15_60 | 8,054,094 ± 3495 | 8,027,927 ± 2476 | 8,042,458 ± 8018 |

| scp_20_20 | 9,941,884 ± 0 | 9,941,884 ± 0 | 9,941,884 ± 0 |

| scp_20_40 | 9,983,068 ± 7902 | 9,983,197 ± 8804 | 9,988,197 ± 11,218 |

| scp_20_60 | 9,957,946 ± 6725 | 9,821,165 ± 18,917 | 9,902,341 ± 20,915 |

| Instance | HACO | ACO | ACO_APF | ACO_LS |

|---|---|---|---|---|

| scp_10_20 | 6,693,096 ± 0 | 6,693,096 ± 0 | 6,693,096 ± 0 | 6,693,096 ± 0 |

| scp_10_40 | 6,693,998 ± 3810 | 6,679,116 ± 3293 | 6,691,292 ± 2016 | 6,693,193 ± 3817 |

| scp_10_60 | 6,693,845 ± 8146 | 6,642,138 ± 6863 | 6,643,189 ± 4584 | 6,657,470 ± 10,045 |

| scp_15_20 | 8,061,226 ± 0 | 8,061,226 ± 0 | 8,061,226 ± 0 | 8,061,226 ± 0 |

| scp_15_40 | 8,062,048 ± 2524 | 8,025,500 ± 7759 | 8,034,780 ± 2930 | 8,047,006 ± 6259 |

| scp_15_60 | 8,054,094 ± 3495 | 7,957,927 ± 8632 | 8,001,549 ± 2376 | 8,048,161 ± 9463 |

| scp_20_20 | 9,941,884 ± 0 | 9,941,884 ± 0 | 9,941,884 ± 0 | 9,941,884 ± 0 |

| scp_20_40 | 9,983,068 ± 902 | 9,905,811 ± 3264 | 9,933,217 ± 1609 | 9,975,491 ± 11,211 |

| scp_20_60 | 9,957,946 ± 6725 | 9,811,579 ± 12,405 | 9,811,852 ± 3077 | 9,878,767 ± 19,978 |

| Parameter | Value |

|---|---|

| Number of original suppliers | 10 |

| Number of customers | 10 |

| Number of alternative suppliers | 5 |

| Number of selectable change nodes | 40 |

| Set of values concerning whether to adopt a product design change strategy |

| Number of Disruptions | Total Profit | |

|---|---|---|

| 0 | 6,999,975 | 6,999,975 |

| 4 | 6,696,798 | 5,467,688 |

| 6 | 3,797,728 | 1,567,682 |

| 8 | 1,382,646 | −1,532,377 |

| Number of Disruptions | Delivered on Schedule | Delayed Delivery | Undelivered | |||

|---|---|---|---|---|---|---|

| 0 | 10 | 10 | 0 | 0 | 0 | 0 |

| 4 | 10 | 8 | 0 | 2 | 0 | 0 |

| 6 | 6 | 3 | 4 | 3 | 0 | 4 |

| 8 | 3 | 0 | 5 | 4 | 2 | 6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Kang, H.; Wang, H. A Product-Design-Change-Based Recovery Control Algorithm for Supply Chain Disruption Problem. Electronics 2023, 12, 2552. https://doi.org/10.3390/electronics12122552

Chen J, Kang H, Wang H. A Product-Design-Change-Based Recovery Control Algorithm for Supply Chain Disruption Problem. Electronics. 2023; 12(12):2552. https://doi.org/10.3390/electronics12122552

Chicago/Turabian StyleChen, Jingze, Haodong Kang, and Hongfeng Wang. 2023. "A Product-Design-Change-Based Recovery Control Algorithm for Supply Chain Disruption Problem" Electronics 12, no. 12: 2552. https://doi.org/10.3390/electronics12122552

APA StyleChen, J., Kang, H., & Wang, H. (2023). A Product-Design-Change-Based Recovery Control Algorithm for Supply Chain Disruption Problem. Electronics, 12(12), 2552. https://doi.org/10.3390/electronics12122552