Revolutionizing Repairability of Industrial Electronics in Oil and Gas Sector: A Mathematical Model for the Index of Repairability (IOR) as a Novel Technique

Abstract

1. Introduction

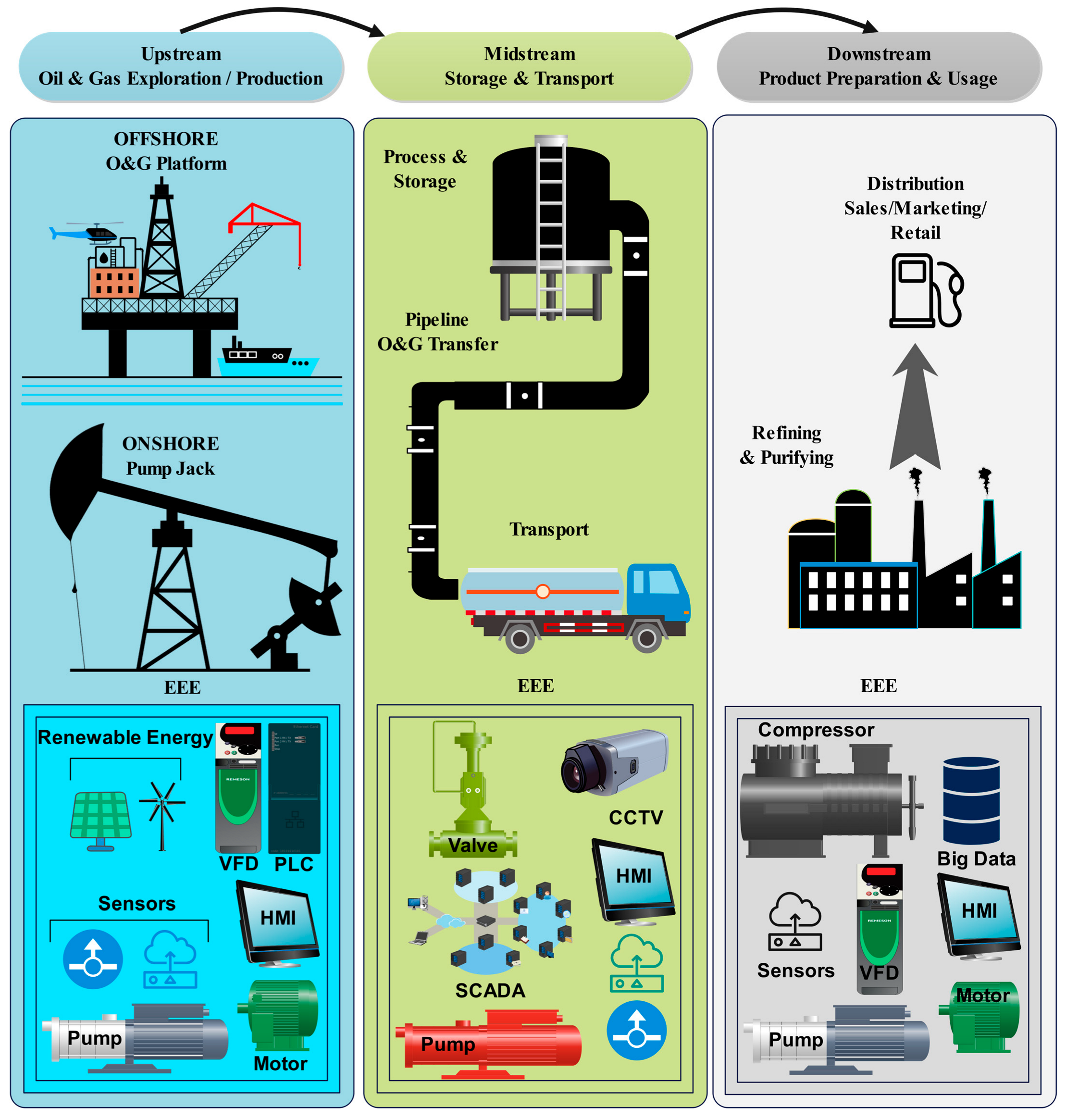

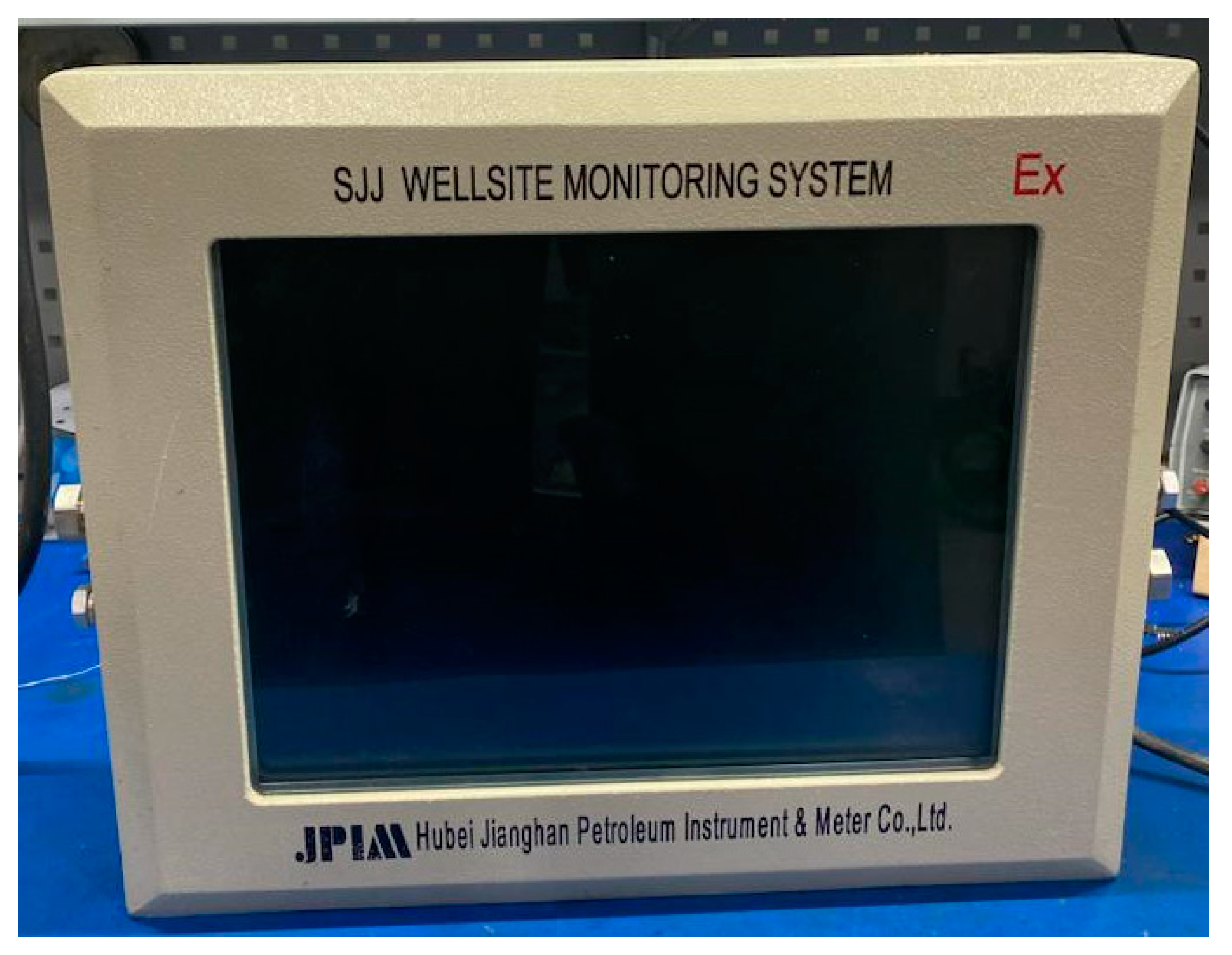

2. Application of Industrial Electronics in the O&G Field

2.1. Upstream Exploration

2.2. Midstream Operations

2.3. Downstream Refining

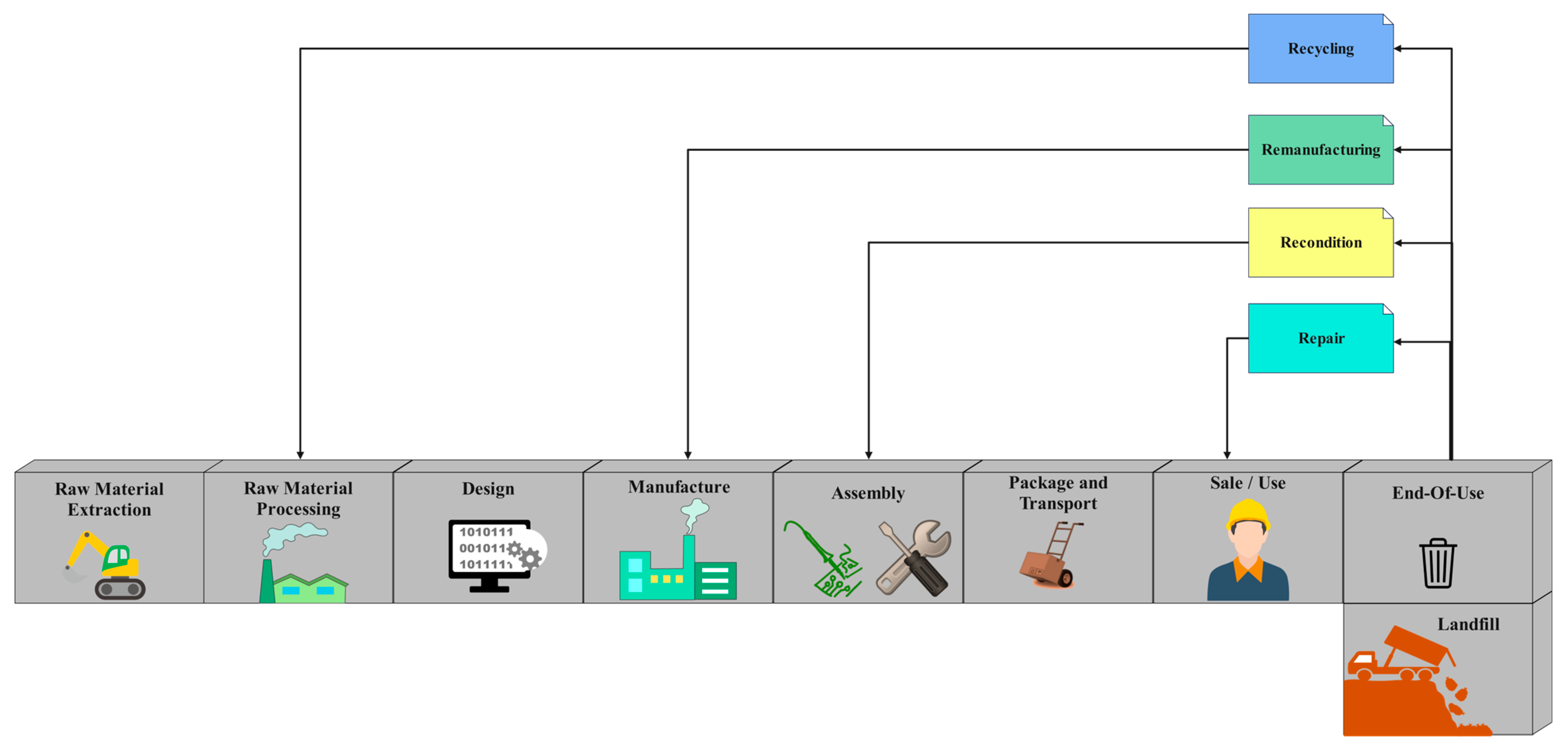

3. Dealing with Failed EEE in O&G Industry

3.1. Replacement of Failed EEE Products

3.1.1. E-Waste

3.1.2. Cost

3.2. Remanufacturing of Failed EEE Products

3.2.1. Feasibility

3.2.2. Time

3.2.3. Quality and Reliability

3.2.4. Skilled Labor

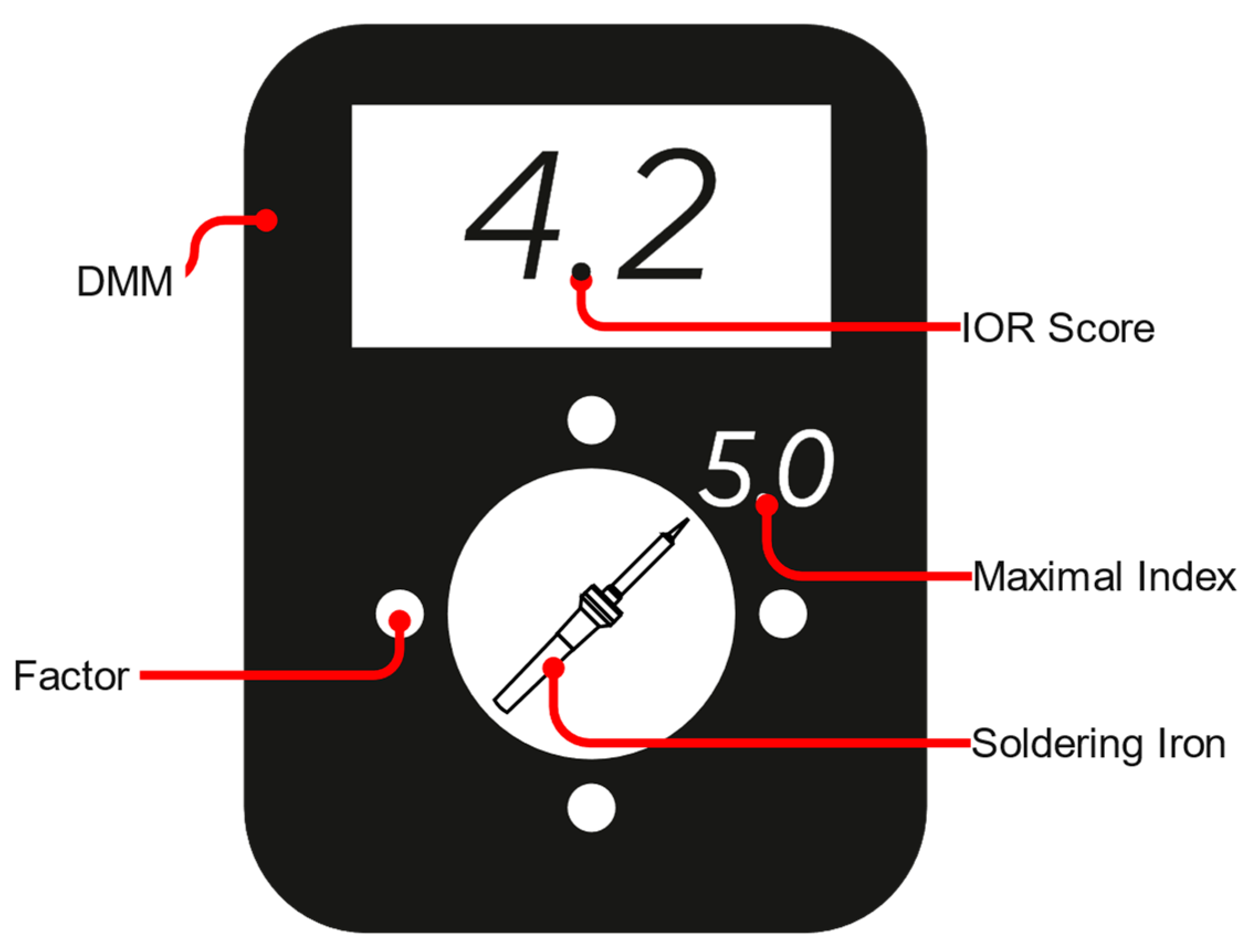

4. Index of Repairability (IOR) for EEE in Oil and Gas Industry: A Novel Solution

4.1. Scoring Systems for Repairability

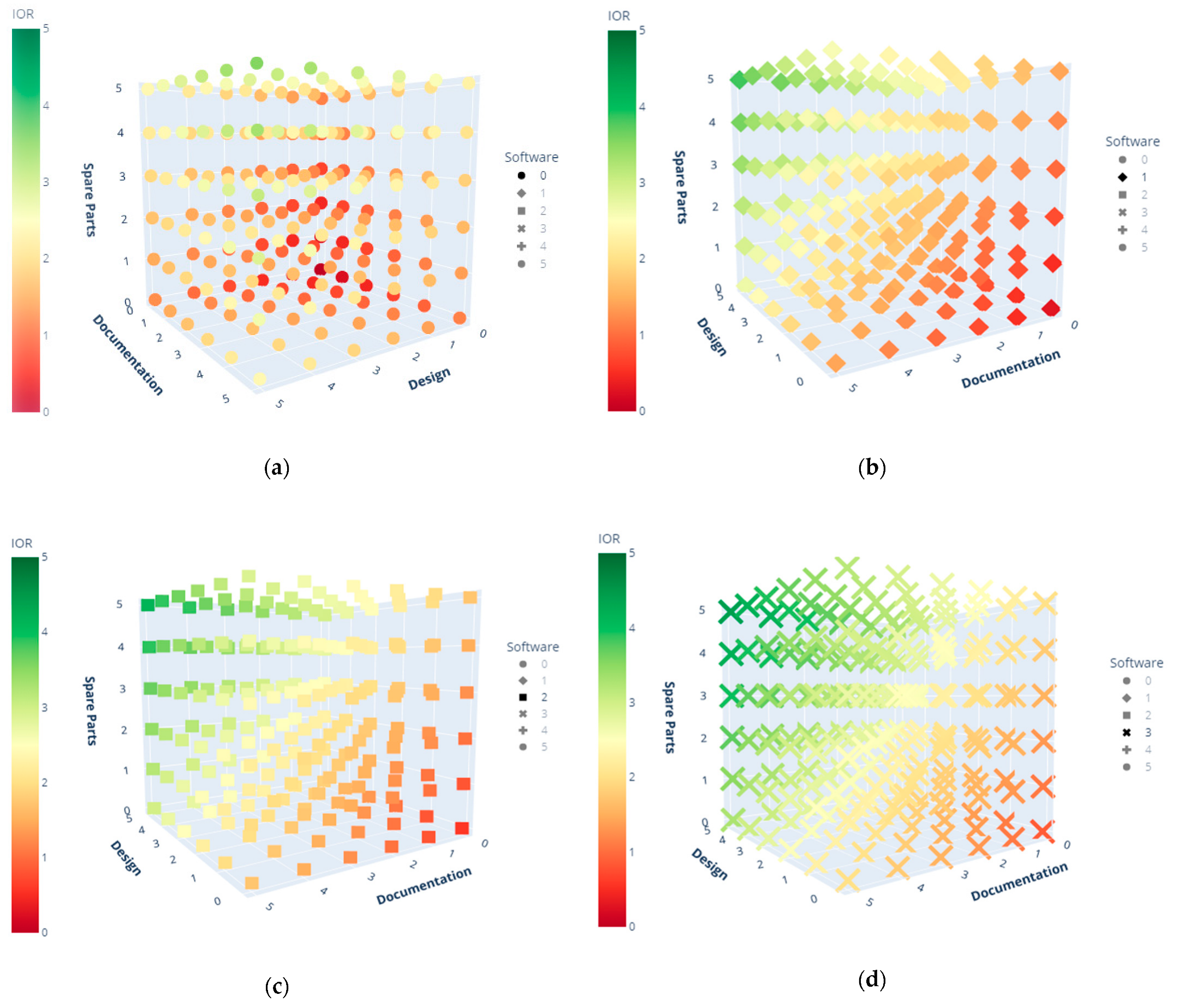

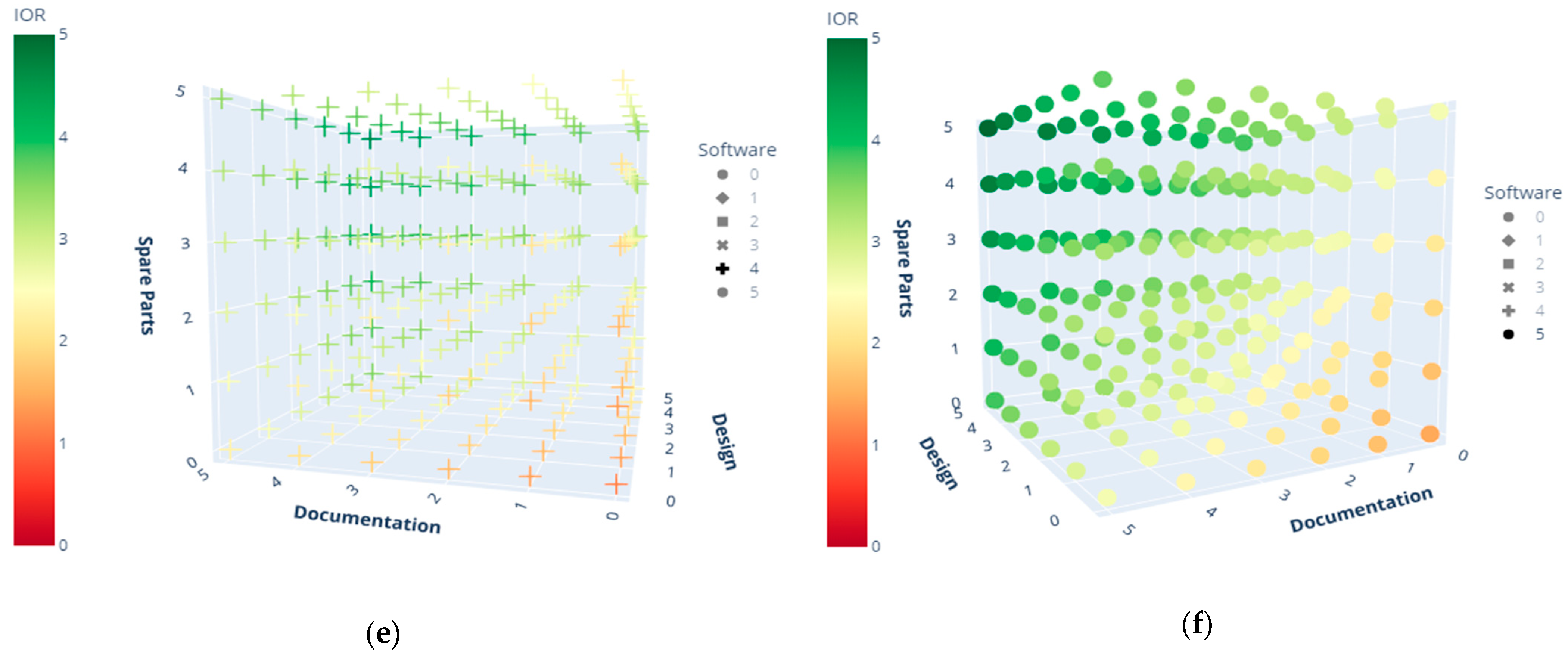

4.2. Mathematical Modeling

4.3. Pictogram Logo and Graphical Charter for the IOR

4.4. Procedure for Calculating the IOR

5. Impact of IOR on O&G Sector

5.1. Reactive or Run-to-Failure (RtF) Maintenance

5.2. Preventive or Time-Based Maintenance (PM or TbM)

5.3. Condition-Based Maintenance (CbM)

5.4. Predictive Maintenance (PdM)

5.5. Risk-Based Maintenance (RbM)

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Al-Khodiry, A. The economic and monetary union of the Gulf Cooperation Council. J. World Trade 2012, 46, 121–154. [Google Scholar] [CrossRef]

- Qudah, A.A.; Badawi, A.; AboElsoud, M.E. The Impact of Oil Sector on the Global Competitiveness of the GCC Countries: Panel Data Approach. Res. J. Financ. Account. 2016, 7, 32–39. [Google Scholar]

- Choi, Y.; Lee, C.; Song, J. Review of renewable energy technologies utilized in the oil and gas industry. Int. J. Renew. Energy Res. 2017, 7, 592–598. [Google Scholar] [CrossRef]

- Elijah, O.; Ling, P.A.; Rahim, S.K.A.; Geok, T.K.; Arsad, A.; Kadir, E.A.; Abdurrahman, M.; Junin, R.; Agi, A.; Abdulfatah, M.Y. A Survey on Industry 4.0 for the Oil and Gas Industry: Upstream Sector. IEEE Access 2021, 9, 144438–144468. [Google Scholar] [CrossRef]

- Alajmi, S.; Altaweel, B. Challenges and Proposed Solutions toward Successful Dealing with E-Waste in Kuwait. Int. J. Energy Environ. Eng. 2023, 17, 6–12. [Google Scholar]

- Alghazo, J.; Ouda, O.K.M.; El Hassan, A. E-waste environmental and information security threat: GCC countries vulnerabilities. Euro-Mediterr. J. Environ. Integr. 2018, 3, 13. [Google Scholar] [CrossRef]

- Shahbazi, S.; Johansen, K.; Sundin, E. Product design for automated remanufacturing—A case study of electric and electronic equipment in Sweden. Sustainability 2021, 13, 9039. [Google Scholar] [CrossRef]

- Lu, H.; Guo, L.; Azimi, M.; Huang, K. Oil and Gas 4.0 era: A systematic review and outlook. Comput. Ind. 2019, 111, 68–90. [Google Scholar] [CrossRef]

- Shukla, A.; Karki, H. Application of robotics in onshore oil and gas industry—A review Part I. Robot. Auton. Syst. 2016, 75, 490–507. [Google Scholar] [CrossRef]

- Shukla, A.; Karki, H. Application of robotics in offshore oil and gas industry—A review Part II. Robot. Auton. Syst. 2016, 75, 508–524. [Google Scholar] [CrossRef]

- Morsi, I.; El-Din, L.M. SCADA system for oil refinery control. Measurement 2014, 47, 5–13. [Google Scholar] [CrossRef]

- Ganapathy, M. Electronics Instruments & Control for Oil Exploration. IETE J. Res. 1981, 27, 45–52. [Google Scholar] [CrossRef]

- Pinkse, J.; Buuse, D.V.D. The development and commercialization of solar PV technology in the oil industry. Energy Policy 2012, 40, 11–20. [Google Scholar] [CrossRef]

- Saadallah, N.; Heggelund, Y. Electrification of Oil and Gas Platforms by Wind Energy. Energies 2023, 16, 3062. [Google Scholar] [CrossRef]

- Syed, F.I.; Alshamsi, M.; Dahaghi, A.K.; Neghabhan, S. Artificial lift system optimization using machine learning applications. Petroleum 2022, 8, 219–226. [Google Scholar] [CrossRef]

- Alakbarov, R.G.; Hashimovm, M.A. Application Of The Internet Of Things In Oil-Gas Industry. In Proceedings of the 6th International Conference on Control and Optimization with Industrial Applications, Baku, Azerbaijan, 11–13 July 2018; pp. 11–13. [Google Scholar]

- Baudoin, C.R. Deploying the industrial internet in oil & gas: Challenges and opportunities. In Proceedings of the SPE Intelligent Energy International Conference and Exhibition, Aberdeen, UK, 6–8 September 2016; OnePetro: Aberdeen, UK, 2016. [Google Scholar] [CrossRef]

- Olaizola, I.G.; Quartulli, M.; Unzueta, E.; Goicolea, J.I.; Flórez, J. Refinery 4.0, a Review of the Main Challenges of the Industry 4.0 Paradigm in Oil & Gas Downstream. Sensors 2022, 22, 9164. [Google Scholar] [CrossRef]

- Abalansa, S.; El Mahrad, B.; Icely, J.; Newton, A. Electronic Waste, an Environmental Problem Exported to Developing Countries: The GOOD, the BAD and the UGLY. Sustainability 2021, 13, 5302. [Google Scholar] [CrossRef]

- Selin, H.; Vandeveer, S.D. Raising Global Standards: Hazardous Substances and E-Waste Management in the European Union. Environ. Sci. Policy Sustain. Dev. 2006, 48, 6–18. [Google Scholar] [CrossRef]

- Alghazo, J.; Ouda, O.K.M. Electronic waste management and security in GCC countries: A growing challenge. In Proceedings of the ICIEM International Conference, Sousse, Tunisia, 27–30 October 2016. [Google Scholar]

- Gregory, J. E-Waste Take-Back System Design and Policy Approaches; StEP Initiative; United Nations University: Tokyo, Japan, 2009. [Google Scholar]

- Alkouh, A.; Keddar, K.A.; Alatefi, S. Remanufacturing of Industrial Electronics: A Case Study from the GCC Region. Electronics 2023, 12, 1960. [Google Scholar] [CrossRef]

- Hatcher, G.D.; Ijomah, W.L.; Windmill, J.F.C. Design for remanufacturing in China: A case study of electrical and electronic equipment. J. Remanuf. 2013, 3, 3. [Google Scholar] [CrossRef]

- Shao, J.; Huang, S.; Lemus-Aguilar, I.; Ünal, E. Circular business models generation for automobile remanufacturing industry in China: Barriers and opportunities. J. Manuf. Technol. Manag. 2020, 31, 542–571. [Google Scholar] [CrossRef]

- Dangal, S.; Faludi, J.; Balkenende, R. Design Aspects in Repairability Scoring Systems: Comparing Their Objectivity and Completeness. Sustainability 2022, 14, 8634. [Google Scholar] [CrossRef]

- Bracquene, E.; Peeters, J.R.; Burez, J.; De Schepper, K.; Duflou, J.R.; Dewulf, W. Repairability evaluation for energy related products. Procedia CIRP 2019, 80, 536–541. [Google Scholar] [CrossRef]

- Sanfelix, F.J.V.; Cordella, M.; Alfieri, F. Methods for the Assessment of the Reparability and Upgradability of Energy-Related Products: Application to TVs; Joint Research Centre (Seville Site): Seville, Spain, 2019. [Google Scholar]

- Flipsen, B.; Huisken, M.; Opsomer, T.; Depypere, M. Smartphone reparability scoring: Assessing the self-repair potential of mobile ICT devices. In Proceedings of the PLATE 2019, Berlin, Germany, 18–20 September 2019; European Union: Berlin, Germany, 2019. [Google Scholar]

- CEN-CENELEC, EN45554; General Methods for the Assessment of the Ability to Repair, Reuse and Upgrade Energy-Related Products. European Committee for Electrotechnical Standardization: Brussels, Belgium, 2020.

- ONR 192102; Label of Excellence for Durable, Repair Friendly, Designed Electrical and Electronic Appliances. Beuth Publishing: Berlin, Germany, 2014.

- Indice de Réparabilité. 2021. Available online: https://www.ecologie.gouv.fr/indice-reparabilite (accessed on 16 March 2023).

- Sharma, G.; Rai, R.N. Modified Repair Quality Index for Complex Repairable Systems. In Proceedings of the 30th European Safety and Reliability Conference and the 15th Probabilistic Safety Assessment and Management Conference, Venice, Italy, 1–5 November 2020; pp. 2851–2858. [Google Scholar] [CrossRef]

- Saaty, T.L. Decision making with the analytic hierarchy process. Int. J. Serv. Sci. 2008, 1, 83–98. [Google Scholar] [CrossRef]

- McInerney, M.; Impallari, P.; Rodrigo, F. Raleway. Google Fonts. Available online: https://fonts.google.com/specimen/Raleway (accessed on 1 April 2023).

- Lindkvist Haziri, L.; Sundin, E. Supporting design for remanufacturing-A framework for implementing information feedback from remanufacturing to product design. J. Remanuf. 2020, 10, 57–76. [Google Scholar] [CrossRef]

- Kuo, T.-C.; Huang, S.H.; Zhang, H.-C. Design for manufacture and design for ‘X’: Concepts, applications, and perspectives. Comput. Ind. Eng. 2001, 41, 241–260. [Google Scholar] [CrossRef]

- Go, T.; Wahab, D.; Hishamuddin, H. Multiple generation life-cycles for product sustainability: The way forward. J. Clean. Prod. 2015, 95, 16–29. [Google Scholar] [CrossRef]

- Battaïa, O.; Dolgui, A.; Heragu, S.S.; Meerkov, S.M.; Tiwari, M.K. Design for manufacturing and assembly/disassembly: Joint design of products and production systems. Int. J. Prod. Res. 2018, 56, 7181–7189. [Google Scholar] [CrossRef]

- Soh, S.; Ong, S.K.; Nee, A.Y.C. Design for assembly and disassembly for remanufacturing. Assem. Autom. 2016, 36, 12–24. [Google Scholar] [CrossRef]

- Boks, C.; McAloone, T.C. Transitions in sustainable product design research. Int. J. Prod. Dev. 2009, 9, 429. [Google Scholar] [CrossRef]

- Rodrigues, V.P.; Pigosso, D.C.; McAloone, T.C. Measuring the implementation of ecodesign management practices: A review and consolidation of process-oriented performance indicators. J. Clean. Prod. 2017, 156, 293–309. [Google Scholar] [CrossRef]

- Shahbazi, S.; Jönbrink, A.K. Design Guidelines to Develop Circular Products: Action Research on Nordic Industry. Sustainability 2020, 12, 3679. [Google Scholar] [CrossRef]

- Sundin, E.; Elo, K.; Mien Lee, H. Design for automatic end-of-life processes. Assem. Autom. 2012, 32, 389–398. [Google Scholar] [CrossRef]

- Telford, S.; Mazhar, M.I.; Howard, I. Condition based maintenance (CBM) in the oil and gas industry: An overview of methods and techniques. In Proceedings of the 2011 International Conference on Industrial Engineering and Operations Management, Kuala Lumpur, Malaysia, 22–24 January 2011; pp. 22–24. [Google Scholar]

- Poór, P.; Basl, J. Predictive maintenance as an intelligent service in Industry 4.0. J. Syst. Integr. 2019, 10, 3–10. [Google Scholar]

| Repairability Assessment Systems | Products Eligible for Testing | Criteria |

|---|---|---|

| Assessment Matrix for Ease of Repair (AsMeR) [27] | All EEE | The repair process comprises five key stages: identifying the product, determining the cause of failure, disassembling and reassembling, replacing any necessary parts, and restoring the product to a functional state. In addition, it considers three crucial repairability factors: providing information, designing the product for ease of repair, and offering adequate service support, catering to both professional repair technicians and DIY repair enthusiasts. |

| Joint Research Centre Repair Scoring System (RSS) [28] | Vacuum cleaners, laptops, TVs, mobile phones, washing machines, and dishwashers | This model is designed for professional repair specialists to evaluate repairability, reusability, and upgradability. |

| iFixit 2019 Smartphone Repairability Scoring System [29] | Mobile phones | This model emphasizes eight criteria aimed at evaluating the simplicity of self-repair. |

| General Methods for the Assessment of the Ability to Repair, Reuse, and Upgrade Energy-Related Products (EN 45554) [30] | All EEE | A universal assessment method for repair, reuse, and upgrade, this approach offers a generic set of tools without focusing on specific products. It is designed for use by both professional repairers and self-repair enthusiasts. |

| Label of Excellence for Durable, Repair-Friendly Designed Electrical and Electronic Appliances (ONR:192012) [31] | Brown goods and white goods | This evaluation encompasses durability and repairability, with criteria focusing on product design, information provision, and services. This approach is intended for professional repairers. |

| French Reparability Index (FRI) [32] | Washing machines, TVs, laptops, smartphones, and lawnmowers | This model is centered around five criteria: documentation, disassembly, replacement part availability, replacement part cost, and other device-specific factors. It caters to both professional repairers and self-repair enthusiasts. |

| Factor | Normalized Weight | Weight Factor Using Geometric Mean |

|---|---|---|

| Design | 0.251303742 | 0.25 |

| Documentation | 0.228457947 | 0.23 |

| Spare parts | 0.231313671 | 0.23 |

| Software | 0.294139607 | 0.29 |

| Cumulative Score Factor | Criterion |

|---|---|

| Design | Modularity |

| Clear labeling | |

| Ease of disassembly | |

| Safety considerations | |

| Testing points and waveforms | |

| Documentation | Availability of service/user manuals |

| Online documentation | |

| Documentation in multiple languages | |

| Troubleshooting and maintenance guidelines | |

| User/technician feedback | |

| Spare parts | Replacement parts availability |

| Spare parts cost | |

| Spare parts reliability and quality | |

| Spare parts datasheets | |

| Spare parts warranty | |

| Software | Software updates availability |

| Original firmware availability | |

| Remote/online technical support | |

| Reset/data recovery | |

| Access to the software tools |

| IOR Category | Score Range | Design | Documentation | Spare Parts | Software |

|---|---|---|---|---|---|

| Very low repairability | Non-modular and inaccessible | Inadequate | Poor quality and not available | No access | |

| Low repairability | Minimal modularity and accessibility | Lacking | Low quality and rarely available | Restricted access | |

| Moderate repairability | Some modularity and accessibility | Sufficient | Average quality and limited availability | Some restrictions | |

| High repairability | Modular and accessible | Detailed | Good quality and widely available | Limited restrictions | |

| Very high repairability | Highly modular and accessible | Comprehensive | High-quality and easily available | Open and easy access |

| IOR Pictogram Logo | Range | Color RGB (CMYB%) |

|---|---|---|

|  217-22-39 (7-98-86-1) | |

|  254-116-27 (0-64-89-0) | |

|  255-201-1 (0-22-93-0) | |

|  158-204-0 (84-13-94-2) | |

|  0-148-67 (84-13-94-2) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alkouh, A.; Keddar, K.A.; Alatefi, S. Revolutionizing Repairability of Industrial Electronics in Oil and Gas Sector: A Mathematical Model for the Index of Repairability (IOR) as a Novel Technique. Electronics 2023, 12, 2461. https://doi.org/10.3390/electronics12112461

Alkouh A, Keddar KA, Alatefi S. Revolutionizing Repairability of Industrial Electronics in Oil and Gas Sector: A Mathematical Model for the Index of Repairability (IOR) as a Novel Technique. Electronics. 2023; 12(11):2461. https://doi.org/10.3390/electronics12112461

Chicago/Turabian StyleAlkouh, Ahmad, Kamel Abderrazak Keddar, and Saad Alatefi. 2023. "Revolutionizing Repairability of Industrial Electronics in Oil and Gas Sector: A Mathematical Model for the Index of Repairability (IOR) as a Novel Technique" Electronics 12, no. 11: 2461. https://doi.org/10.3390/electronics12112461

APA StyleAlkouh, A., Keddar, K. A., & Alatefi, S. (2023). Revolutionizing Repairability of Industrial Electronics in Oil and Gas Sector: A Mathematical Model for the Index of Repairability (IOR) as a Novel Technique. Electronics, 12(11), 2461. https://doi.org/10.3390/electronics12112461