1. Introduction

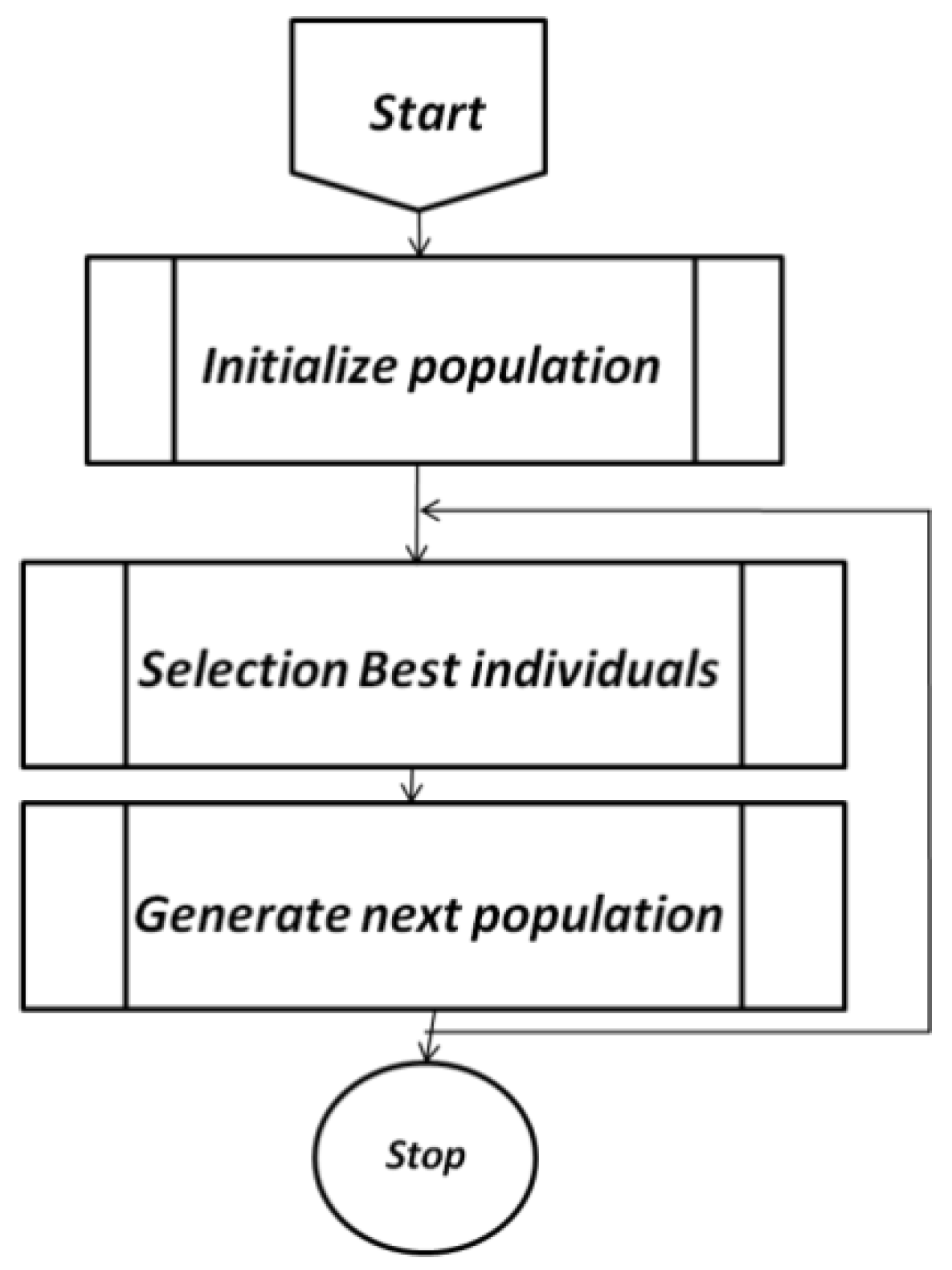

The ever-growing demand for computing power, storage services, and communication bandwidth brings evident challenges to the design of data centers and their constitutive parts. The server’s racks are made up of several trays, vertically stacked. They absorb electric power, part of which is dissipated in the form of heat, and need to be cooled. Among the design strategies for passive cooling, there is the tendency of reducing any unnecessary heat barriers, such as parts of the tray enclosure. This design trend shows some drawbacks from the electromagnetic compatibility point of view. In fact, the lack of parts of the metallic enclosure decreases the overall electromagnetic shielding of each tray, increasing its unwanted radiation toward the other trays of the same rack and toward the space external to the rack.

In modern data centers, in the aisles in between the racks, electronic devices such as personal computers or tablets of the maintenance personnel, or other electronic circuits used for different operations, are often present. Both classes of device are very sensitive to electromagnetic interference (EMI), and can be affected by the unwanted electromagnetic field radiated by the trays in the racks.

One more aspect to be considered is the high connectivity of the data center environment. Multiple wireless systems supervise the normal and maintenance operations of the center. The above-mentioned decreased shielding performance of the trays allow the trays’ electromagnetic fields to interact with the communication signals which, in turn, can be a source of interference for the trays’ electronic circuits.

In [

1], an efficient approach has been developed based on spherical wave expansion (SWE) theory [

2] to evaluate the total unwanted electromagnetic radiation of multiple stacked trays, considered as radiation sources, starting from the knowledge of the radiation characteristic of each single source considered isolated. The methodology in [

1] has been applied, in [

3], to the measured radiation pattern of a real rack. Each tray forming the rack has been characterized by the SWE coefficients, which are extracted by the direct measurements of its radiation fields when considered in isolation. These measurements consider each tray’s functionality and setting. From [

3], a sort of library of SWE coefficients for each tray typology is made available to reconstruct the total electromagnetic field, due to the stacking of the trays and for further elaboration.

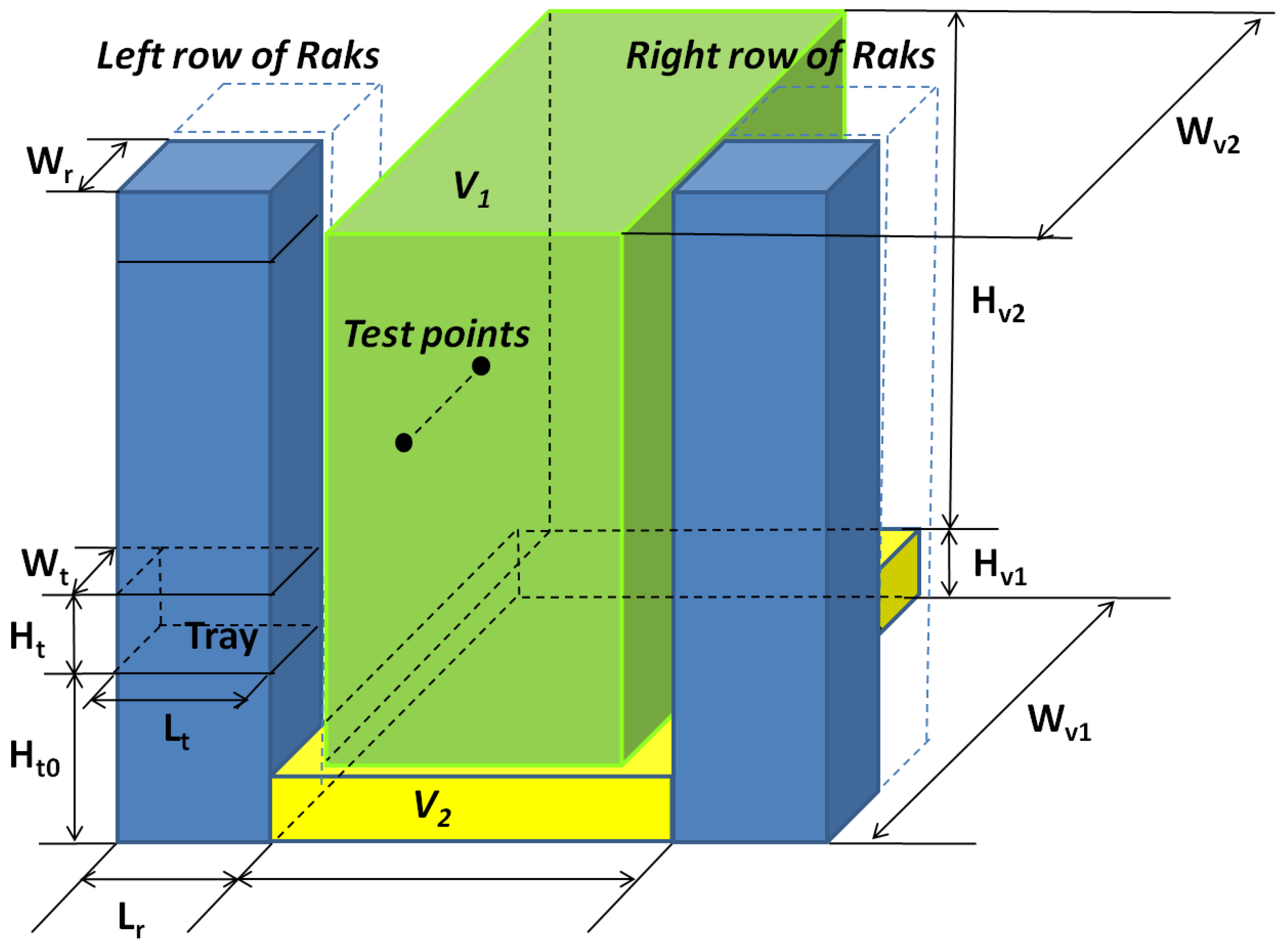

The target of this paper is to develop a procedure to find the optimal position of the trays in the vertical stack of a rack, in order to minimize their total physical electromagnetic radiation in a volume of space outside the rack. This procedure, formally set as a minimization problem, will resort to the SWE coefficients of the trays for the efficient computation of their radiation, and to a multi-objective optimization approach based on a genetic algorithm (MOGA) [

4].

Section 2 illustrates the physical model of the trays and racks, briefly recalls the extraction and use of the associated SWE coefficients, and describes the target volume of space for which the cost functions are defined. The implemented MOGA and some constraints set on the formation of the chromosomes, in order to take into account the actual design of a rack (aka

rackification), are introduced in

Section 3. The results, all in terms of electromagnetic fields, their comparison with those obtained by other methods, and the practical implications of multiple solutions that are not optimal, with respect to all objectives, are discussed in

Section 4. Finally,

Section 5 offers some concluding remarks.

3. Constrained Multiple Objective Genetic Algorithm

Genetic algorithms (GA) follow a heuristic procedure to solve the research problems of the optimal solution(s). They consider a set of solutions (called chromosomes or individuals) that evolve in intervals of time called generations. Evolution is driven by the comparison of the values of cost (or

objective or

fitness) functions [

5], evaluated for each chromosome of the population. These functions are a sort of measure of quality, with respect to the problem considered. By means of these values, individuals of one generation are compared, selected, and used to create the population of the next one, which is formed by individuals with better cost function values. The basic structure of a genetic algorithm is cyclic and is shown in

Figure 3. Each cycle represents a generation, and within it, operations are carried out to generate a newly formed population with increasingly better chromosomes.

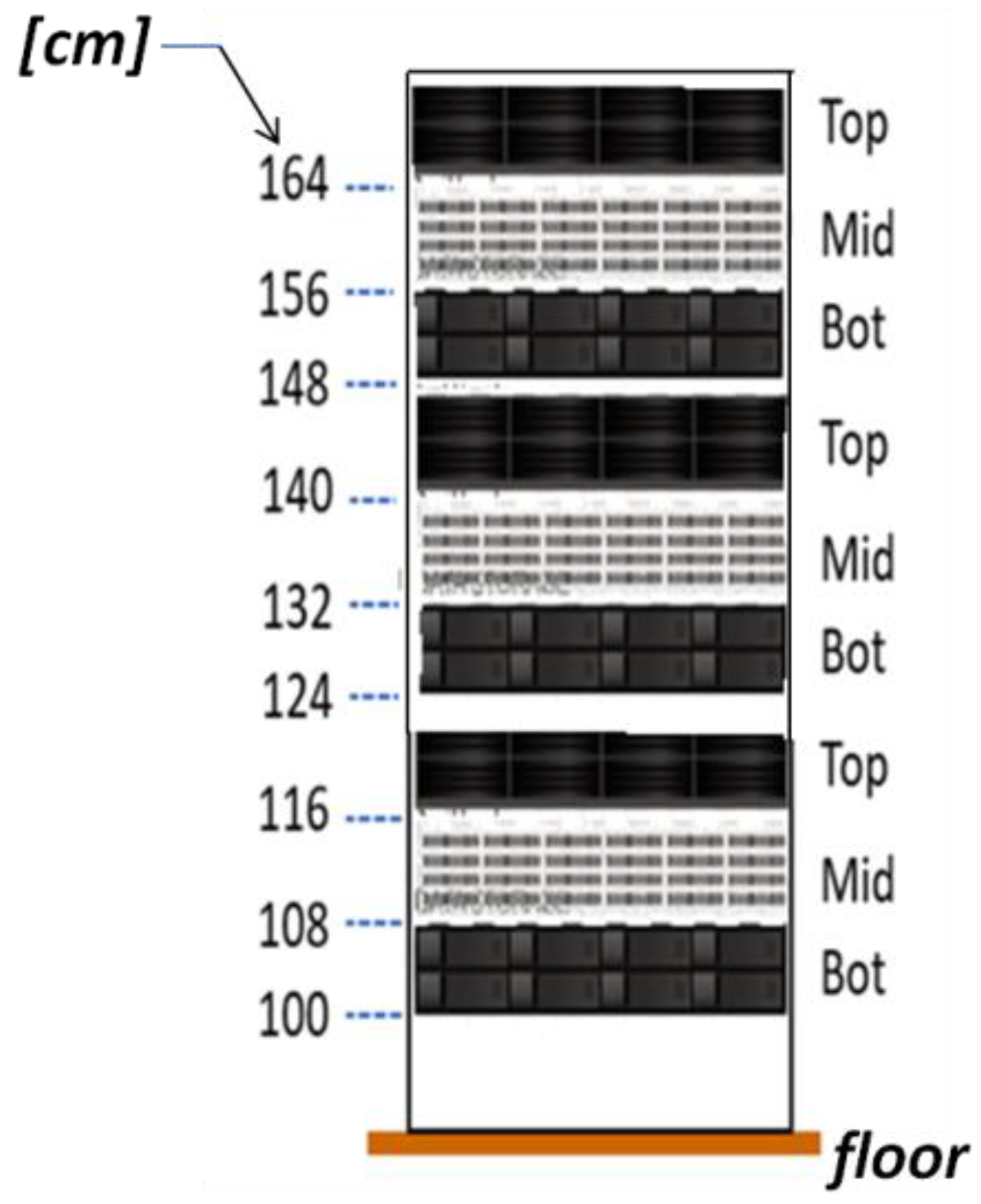

The first step of the algorithm is to create a random population of chromosomes. The following phases are repeated with each generation, and are associated with the principle of natural selection: the early stages are concerned with selecting the best individuals in the population, while the others generate new individuals.

Chromosomes are the basis of the functioning of the genetic algorithm, and they represent possible solutions to the problem. In our case, each chromosome is built up by N

g = nine genes. Each gene represents one of the nine trays of the rack, as in

Figure 1. The first gene is associated with the bottom-most tray at h

t0 = 100 cm, the second gene with the tray at h

t = 108 cm, and so on. The value of a gene can have only three integer values (1, 2, or 3), which are associated with the proper set of SWE coefficients of the Bot, Mid, and Top trays, respectively. The number of chromosomes in the population is N

c = 500.

At this stage of the algorithm, new chromosomes are generated from other chromosomes bypassing their own genetic heritage, so that the new solutions are similar but not equal to the parent ones. This aspect is fundamental for the convergence of the algorithm; in fact, every new population is built with better individuals than the previous one. This is the crossover phase. In this work, the whole arithmetic crossover has been used [

6], where the new chromosomes (or

offsprings) are a linear combination of the two parent chromosomes. In this technique, a pair of chromosomes are selected randomly for crossover, and by a linear combination, two new ones are produced. This linear combination can be described as:

where

offspringi is the

i-th offspring (

i = 1, 2),

Parentsij is the

j-th part (

j = 1 corresponds to the first

m genes of the

i-th chromosome

Parentsi,

j = 2 corresponds to the remaining 9-

m genes of the

i-th chromosome

Parentsi), and

m is a random number, such that 2 <

m < 8.

The next step is the application of the mutation operator. The effect of this operator is to deeply modify the chromosome so that the mutated individual explores areas of the space of solutions not yet observed. This phase is introduced to avoid convergence towards local optimal minima or maxima, thus favoring a global search. In this work, a mutation rate of μ = 20% has been used, which corresponds to about 900 gene mutations. Random numbers, chosen from a Gaussian distribution, are chosen to select the gene to mutate, and its value is replaced by another random value between 1 and 3.

The part of the algorithm inspired by the principle of natural selection deals with the classification of chromosomes, and ranks and selects the best solutions within the population. The cost functions

fc1 and

fc2 for volumes V

1 and V

2, as defined in Equation (1), are used as measures of the fitness of the solutions. Different from a single-objective GA, in a multi-objective approach, the two cost functions are not combined into one [

3,

7], but are considered separate.

Once the fitness of each chromosome is calculated, a subpopulation is chosen to generate new solutions. There are various techniques for selecting the set of solutions, named the mating pool, for reproduction. Due to the large number of the population used in this work (the size is N

p = 500 chromosomes), the tournament selection technique has been chosen [

8]: a small subset of chromosomes (in this work, the size of this subset is 4) is randomly picked up from the mating pool, and the chromosomes with the lowest

fci in the subset become parents. The tournament repeats for every offspring needed. In the tournament selection, the whole population never needs to be sorted; this is a clear advantage because it is known that sorting is a time-consuming action for large populations.

The multi-objective nature of the developed algorithm is shown by evaluating the

fc1 for volume 1 and the

fc2 for volume 2 (

fci is defined in Equation (1)) separately for each chromosome of the population, instead of merging them in a single weighted cost function [

9]. At each chromosome, both values of

fci are associated, forming a point of coordinates (

fc1,

fc2) in the cost function Cartesian plane. At each chromosome (at each point on the plane), the concept of dominance is applied, and only the non-dominated chromosomes belonging to the Pareto front [

10] are retained as optimal solutions.

Figure 4 qualitatively shows six solutions, of which only four are non-dominated, forming the optimal solutions’ Pareto fronts. Without adding additional information, all four solutions are equally satisfactory. This flexibility is one of the strengths of the MOGA.

In order to make the MOGA implementation more suitable for its use in the design of the stack of trays from the point of view of the unwanted radiation, the presence of a specific design constraint is considered. In the real design of a rack, there is a limit on the repetition of the same tray in the stack. A rack cannot be formed by trays of the same type. This constraint is introduced in the algorithm in the form of a soft constrained technique [

11,

12] that is considered more valid for real and complex problems than a hard one. The soft constrained technique implemented is the penalty function method. This method penalizes the cost functions of solutions that are not eligible. In this way, chromosomes are moved to areas of the space of the goals that the ranking considers worse. This is completed in two simple steps: first, whether the chromosomes respect the constraint (i.e., the number of genes with the same value is less than a given constrain value

K) is checked. Subsequently, the values of the cost functions associated with these individuals are increased by a factor

Rc that moves their chromosomes far from the optimal region, and then excludes them from participating in the new generations. In the next section, a systematic analysis of the impact of the constraint value

K on the optimal solutions will be carried out.

4. Results and Discussion

As the first step for a critical discussion of the numerical output, a set of reference results needs to be compared with those stemming from the proposed MOGA. These reference results are found by using the analytical procedures developed in [

3,

4], where a single-objective GA (SOGA) has been developed. The implemented SOGA finds the minimum unwanted radiated EMI in volumes V

1 and V

2 at a specific frequency that is considered critical for the applications considered. As mentioned, the results obtained by the SOGA are considered as a sort of reference for those stemming from the MOGA, either to show the similarities or to show the differences, advantages, and drawbacks. For the SOGA, the two cost functions

fc1 and

fc2 (defined in Equation (1)) are combined into the single

fcSOGA:

ensuring similar conditions between the SOGA and the MOGA.

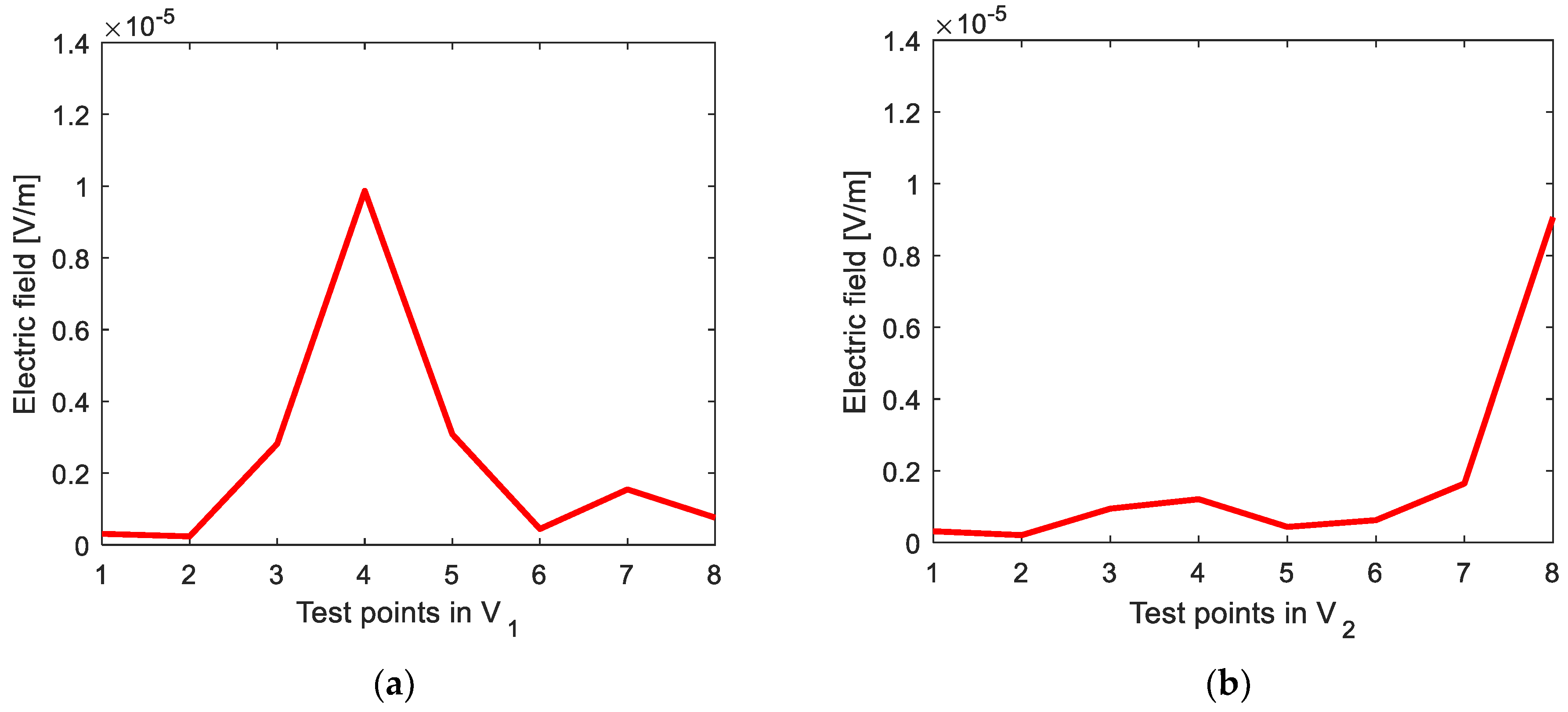

Figure 5a,b reports the magnitude of the computed radiated electric field in each of the N

1 and N

2 test points in the volumes, due to the configuration of the trays in the rack that minimizes Equation (5), according to the SOGA. Such optimal configuration is represented by the chromosome C

SOGA:

in which:

Figure 5.

The magnitude of the electric field in (a) the N1 test points of volume V1 and (b) the N2 test points of volume V2, due to the optimal SOGA solution CSOGA in Equation (6).

Figure 5.

The magnitude of the electric field in (a) the N1 test points of volume V1 and (b) the N2 test points of volume V2, due to the optimal SOGA solution CSOGA in Equation (6).

The structure of the SOGA chromosome is the same as the structure of the MOGA one. The results in

Figure 5 are considered as the reference results for all the subsequent structures.

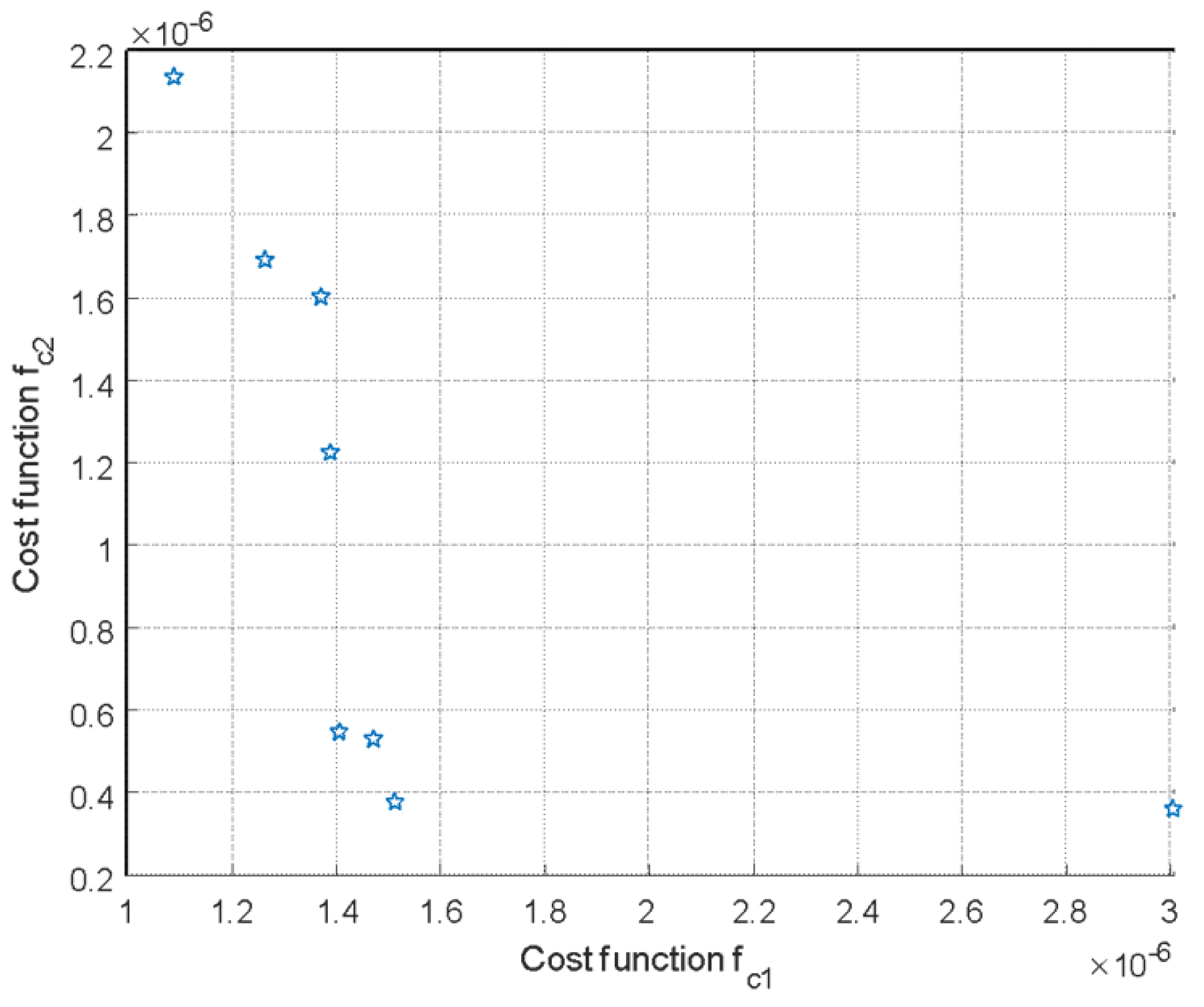

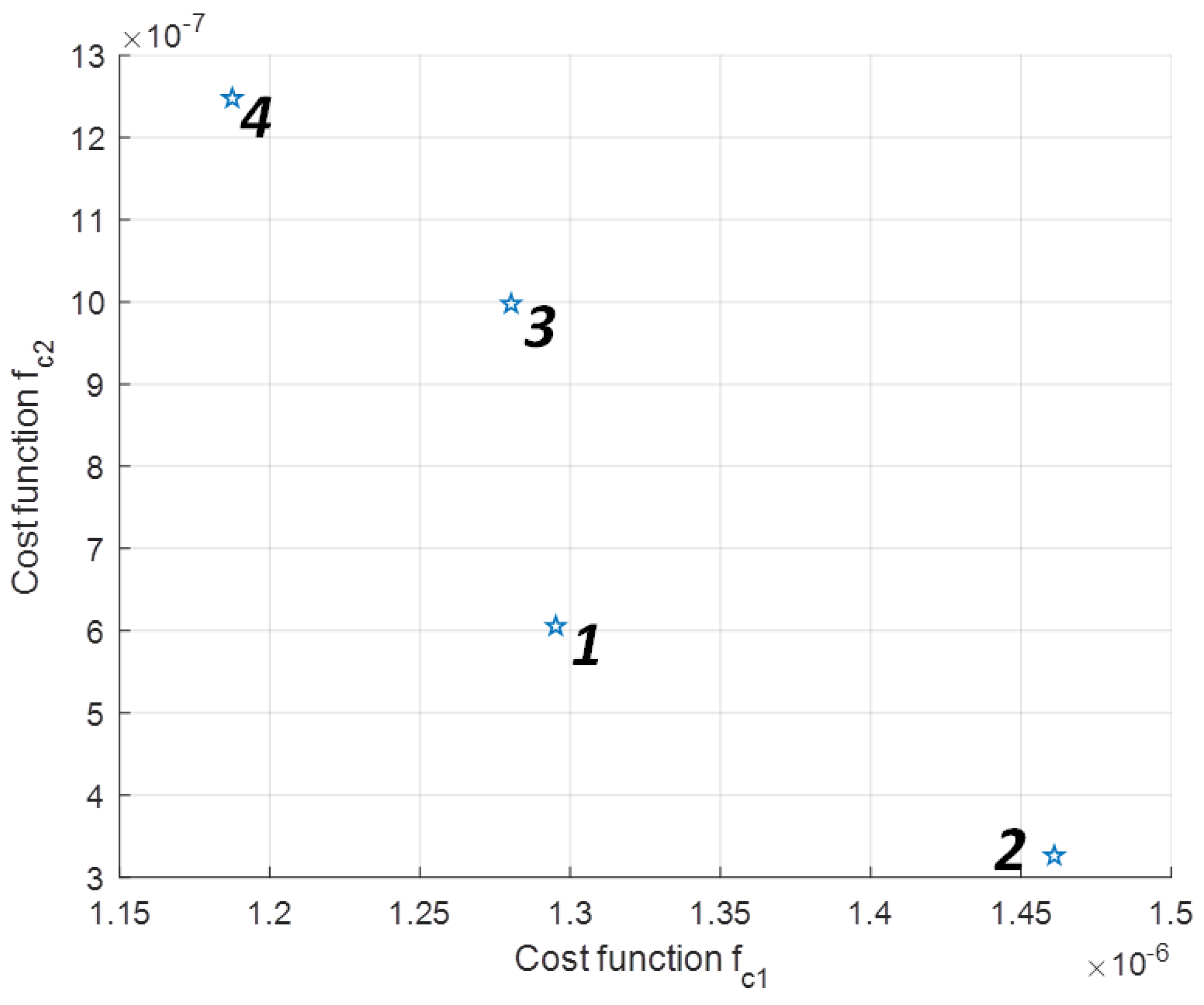

The second step considers the MOGA’s optimal solutions. As mentioned in

Section 3, the output of a MOGA procedure is a set of solutions (in our case, a set of tray configurations), each one non-dominated by the others: they form the optimal Pareto front. The optimal Pareto front obtained for the problem at hand, characterized by the same variables of the SOGA, is given in

Figure 6.

In

Figure 6, each starlet indicates a chromosome, or a tray configuration. The eight chromosomes, from C

MOGA1 to C

MOGA8, of the optimal Pareto front in

Figure 6 are reported, by row, in

Table 1.

At each of the rack’s configurations, described in

Table 1, and belonging to the optimal Pareto front, corresponds a value of the magnitude of the computed electromagnetic radiated field in the N

1 and N

2 points of volumes V

1 and V

2, respectively.

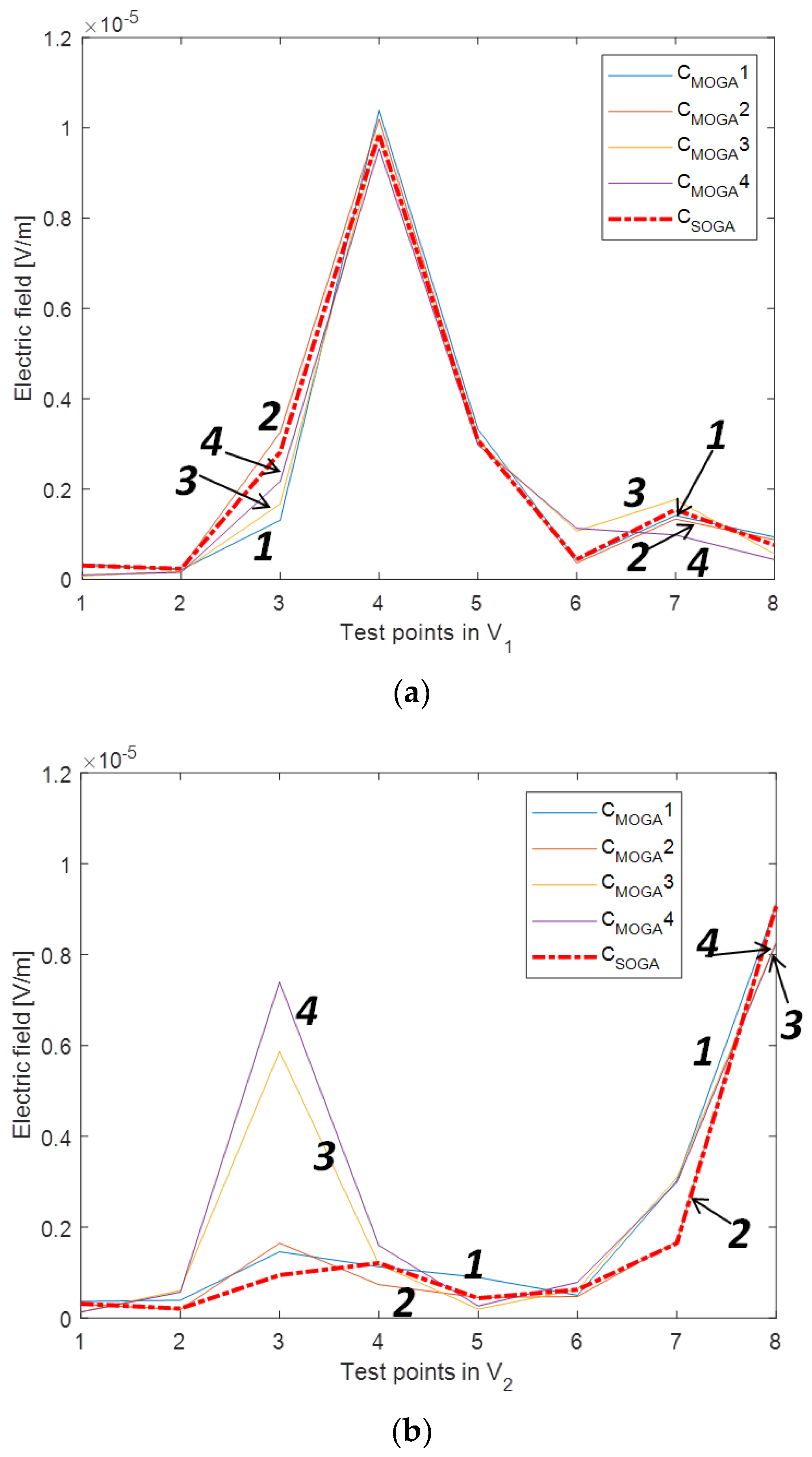

Figure 7a,b shows these magnitudes in these test points radiated by the configurations of the trays in

Table 1 that minimize Equation (5), according to the proposed MOGA. They are also compared, as reference, with the field distribution in the same test points, due to the chromosome C

SOGA in Equation (6).

In general, as expected, the spatial distribution of the radiated field estimated by the SOGA and MOGA algorithms are similar but not identical. The values of the electric field, due to the configurations C

MOGA1, C

MOGA4, and C

MOGA8 (those with the starlets close to the origin of the axis in

Figure 6), are closer to C

SOGA. The others have higher magnitudes, but still belong to the optimal Pareto front and are an option if other design limitations or constraints must be taken into account.

In the design process of a server rack, there is a great number of logical and physical constraints to consider when positioning the trays. In the logical class fall those related to the functionality and principal operations for which the rack is targeted (processing, storage, switching, etc.); to the physical class belongs those limits such as overall weight, length of the interconnection cables/fibers, and total heat dissipated. For this reason, as the third step of the analysis of the results, a procedure to limit the number of repetitions N

r of trays of the same type in the rack has been added to the proposed MOGA without constraints. This constraint is an indirect but efficient way to consider either the logical or functional design limits [

11,

12]. The value N

r ranges from N

g (a rack of all equal trays) to N

r = 3, which is the minimum number of tray repetitions given the three different types of trays (Top, Mid, and Bot). Based on this, the impact of several values of the constraint N

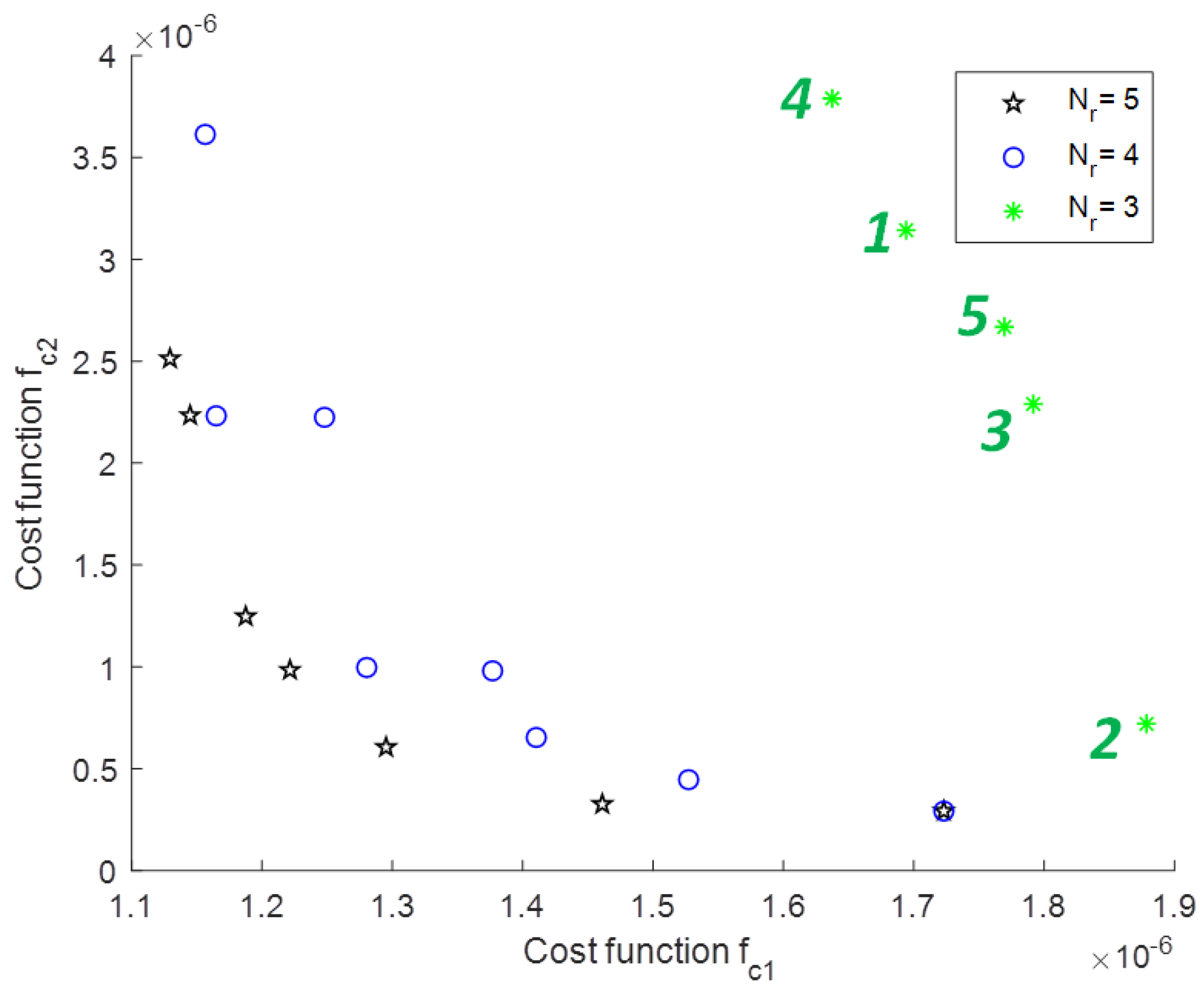

r is considered, and is shown in the following figures and tables.

Setting N

r = 5 yields the optimal solutions obtained by the proposed constrained MOGA, shown in

Figure 8 (obtained by [

13]), to which the chromosomes in

Table 2 correspond.

The spatial distributions of the magnitude of the electric field in the N

1 and N

2 test points in volumes V

1 and V

2, due to the four optimal configurations in

Figure 8 and obtained by imposing the constrain N

r = 5, are shown in

Figure 9, along with, as reference, the values of the electric field in the same points obtained by the configuration in C

SOGA in Equation (6).

As the N

r decreases (from 9 to 3), the constraint becomes stricter, the number of possible tray repetitions decreases and, hence, the performance of the optimal solutions that show an increase in the values of the cost functions also decreases. This is visible in

Figure 10, where the optimal solutions for N

r = 5, 4, and 3 move from the region close to the origin of the axis to regions with larger values of

fc1 and

fc2, respectively.

Table 3 connects the solutions in

Figure 10 with the disposition of the trays in the rack fulfilling the stricter constraint of N

r = 3.

The inherent statistical nature of a GA calls, at least, for the evaluation of its performance for multiple runs to test the convergence of the computed output. For the specific physical problem considered up to now, the optimal Pareto front for seven cases has been computed: the unconstrained MOGA (or N

r = 0), and the MOGA with N

r = 3, 4, 5, 6, 7, and 8. Each case has been run 100 times, and the 100 optimal Pareto fronts for each case have been plotted in

Figure 11. The runs for N

r = 8 (purple circles) are very close to the unconstrained case, as expected. As the constraints become stricter (N

r decreases), the cluster of fronts moves forward from the origin of the axis toward regions of higher values of the cost functions. Please note that different runs can produce chromosomes with the same structure, so some symbols are overlapped.

From a visual inspection of

Figure 11, the self-consistency of the results and the accuracy of the MOGA is evident: the less stringent the constraint, the more solutions with low cost function values are available, giving rise to a cluster of symbols close to the origin of the axis. As the constraint becomes more stringent, less configurations are available, so the optimal solutions move far from the low values of the

fci that also spread on the

fc1–

fc2 plane. This is confirmed as a proper quantitative measure of the Cartesian distance of each solution from the origin of the axis. For the generic

i-th solution, the distance

di is defined as:

For each set of constraints, N

r, one can compute the average distance D and the standard deviation σ of all the solutions belonging to that constraint.

Table 4 reports the results. The qualitative trends are confirmed by the values in the table.

As final consideration, it is worthy to quantify the radiated field attenuation obtained by the optimal configuration of the trays in the stack of the rack.

Figure 12a,b shows the spatial distribution of the magnitude of the electric field in the test points of V

1 and V

2, due to the complete population of chromosomes (100 curves).

In the entire population, the distribution due to one of the optimal MOGA solutions belonging to the Pareto front is highlighted in red. The attenuation between the overall maximum value in the population and the maximum of the optimal solution is around 6 dB for V1 and around 4.8 for V2.