A Parallel Resonant Converter Polynomial Model Implemented in a Digital Signal Controller

Abstract

:1. Introduction

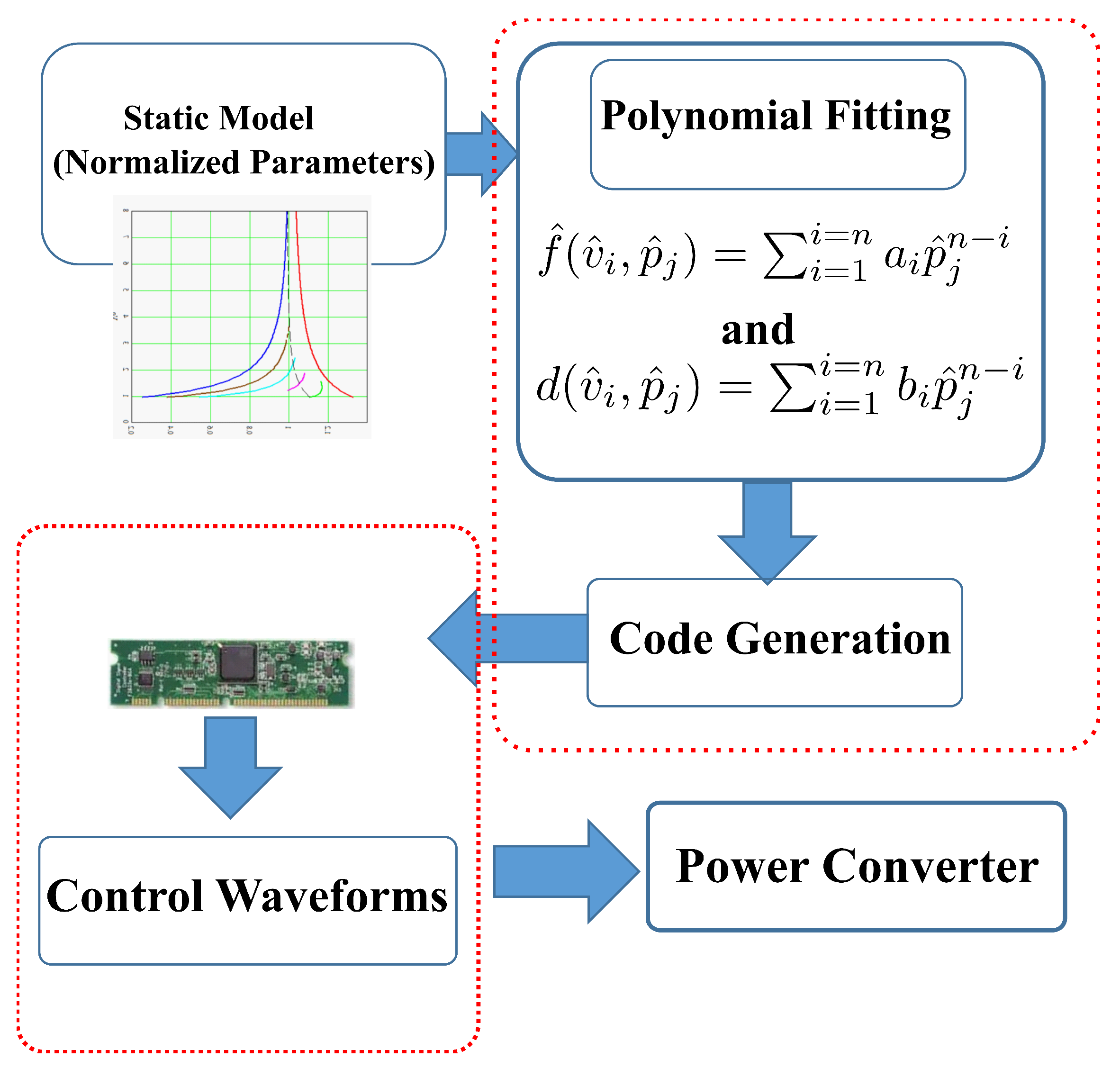

- First, the static model is developed in MathCad and its graphical representations are subsequently illustrated [14]. To extend the operational span and for ease of analysis, the normalized parameters are used. However, this model is complex in that it renders the implementation sophisticated;

- Second, the polynomial model is suggested [15]. It is an alternative to simplify the model and ease the implementation mostly in DSC. The polynomial model is developed by tuning the static model’s graphical representation in such away to generate the polynomic form through the numerical data-fitting method. The last gives the equivalent polynomic expression in graphic representation form;

- Third, the polynomial model is processed in MATLAB-Simulink to produce the program used for simulation and validation. The simulation is run for the validation of the polynomial model and to confirm the accuracy of the control codes’ output;

- Fourth, the DSC is configured to Simulink and the control codes are generated. They make the control program that fits in a DCS and give the adequate control waveforms to fire the power converter switches (IGBTs);

- Finally, the experimental results are used to confirm the polynomial model’s practicability and implementation feasibilities.

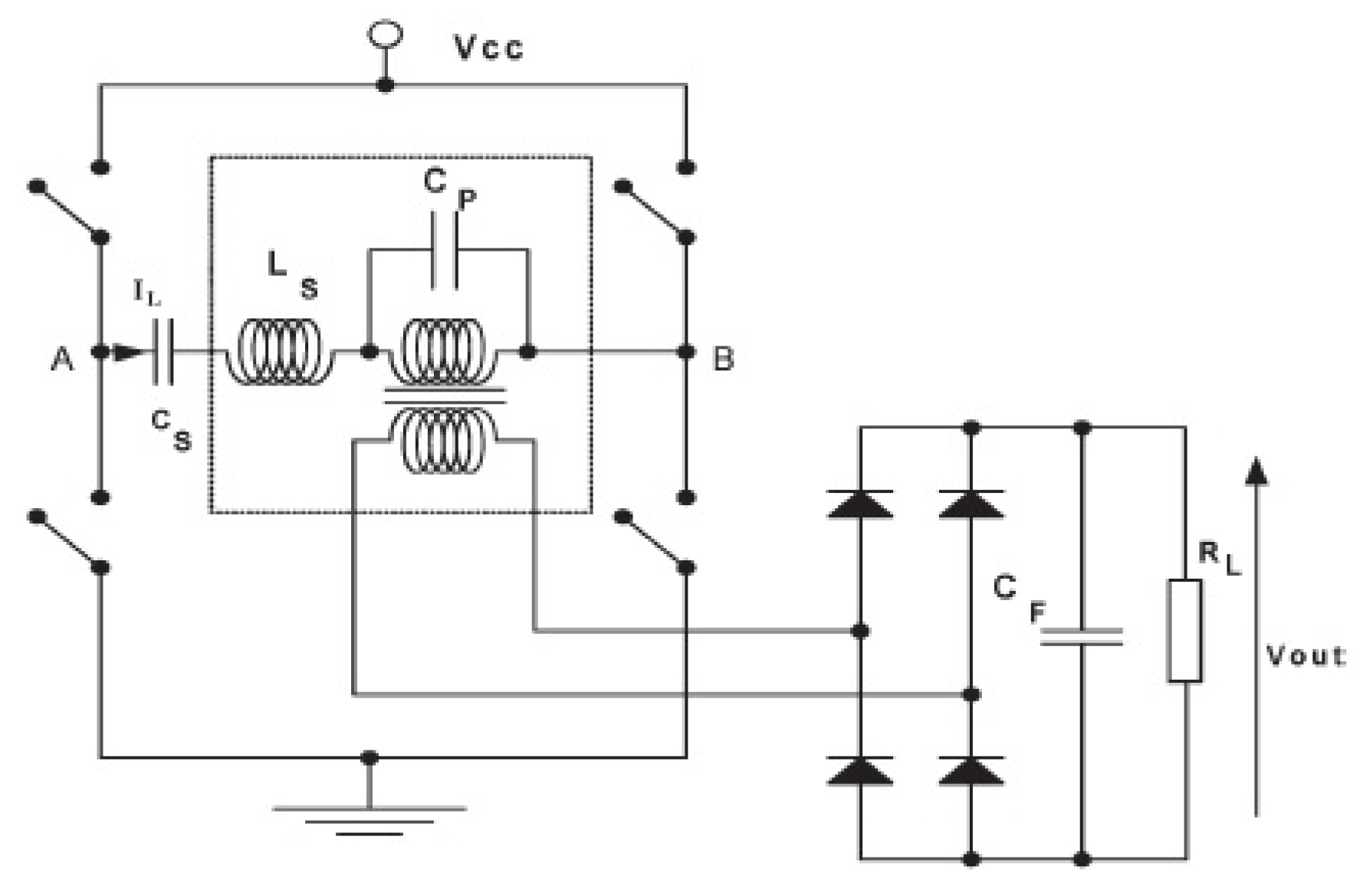

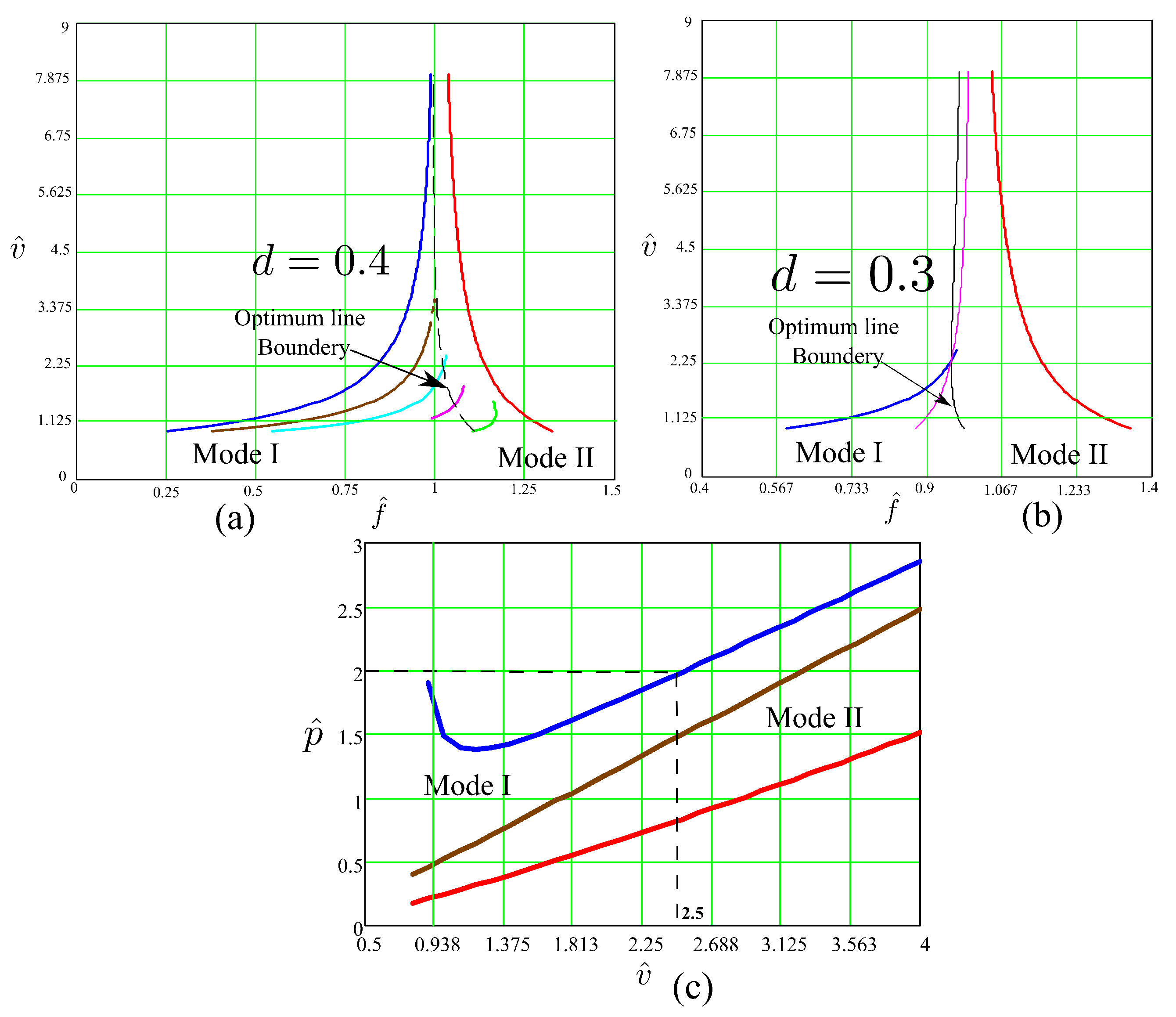

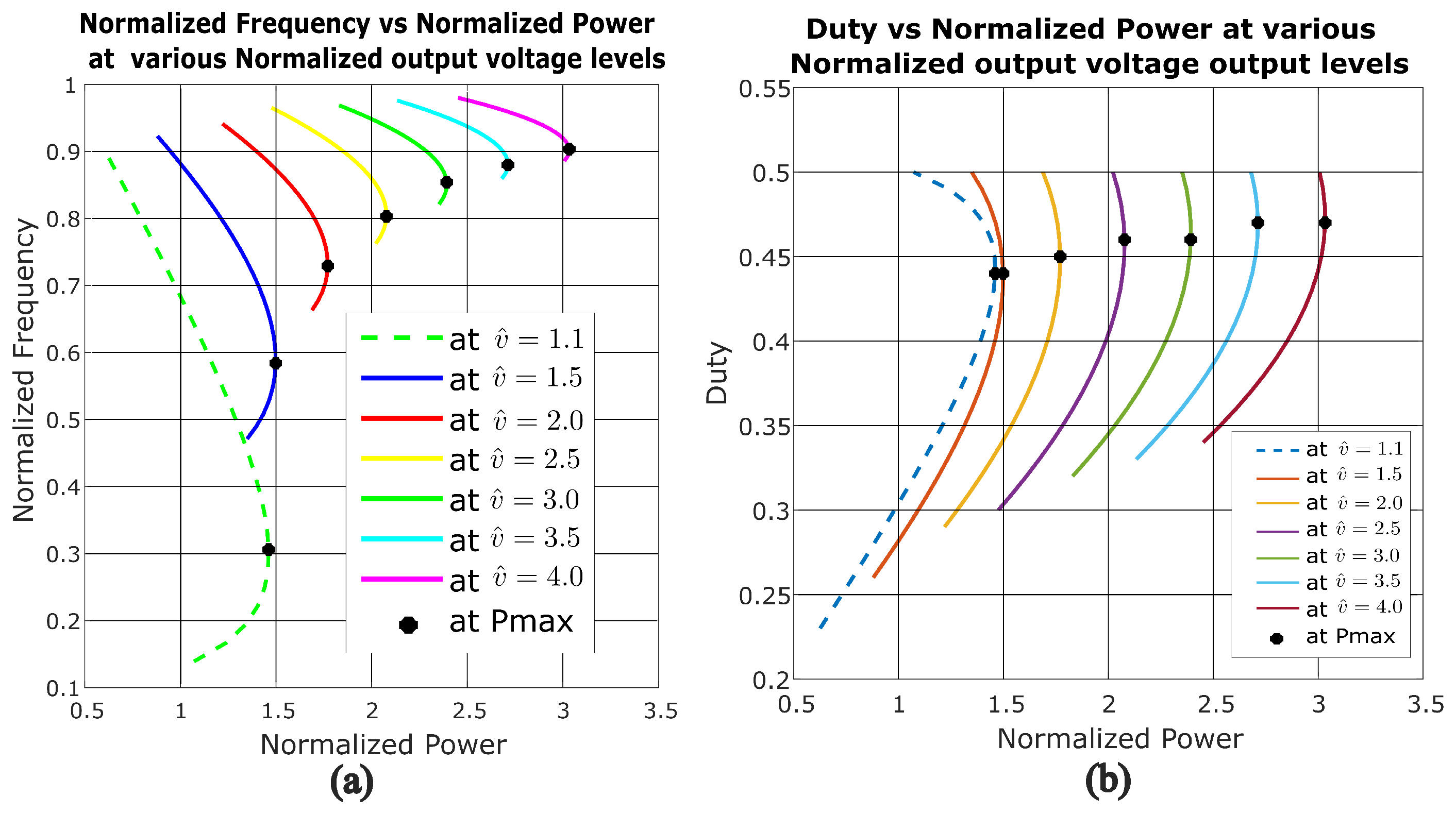

2. Grapical Representation of PRC Static Model

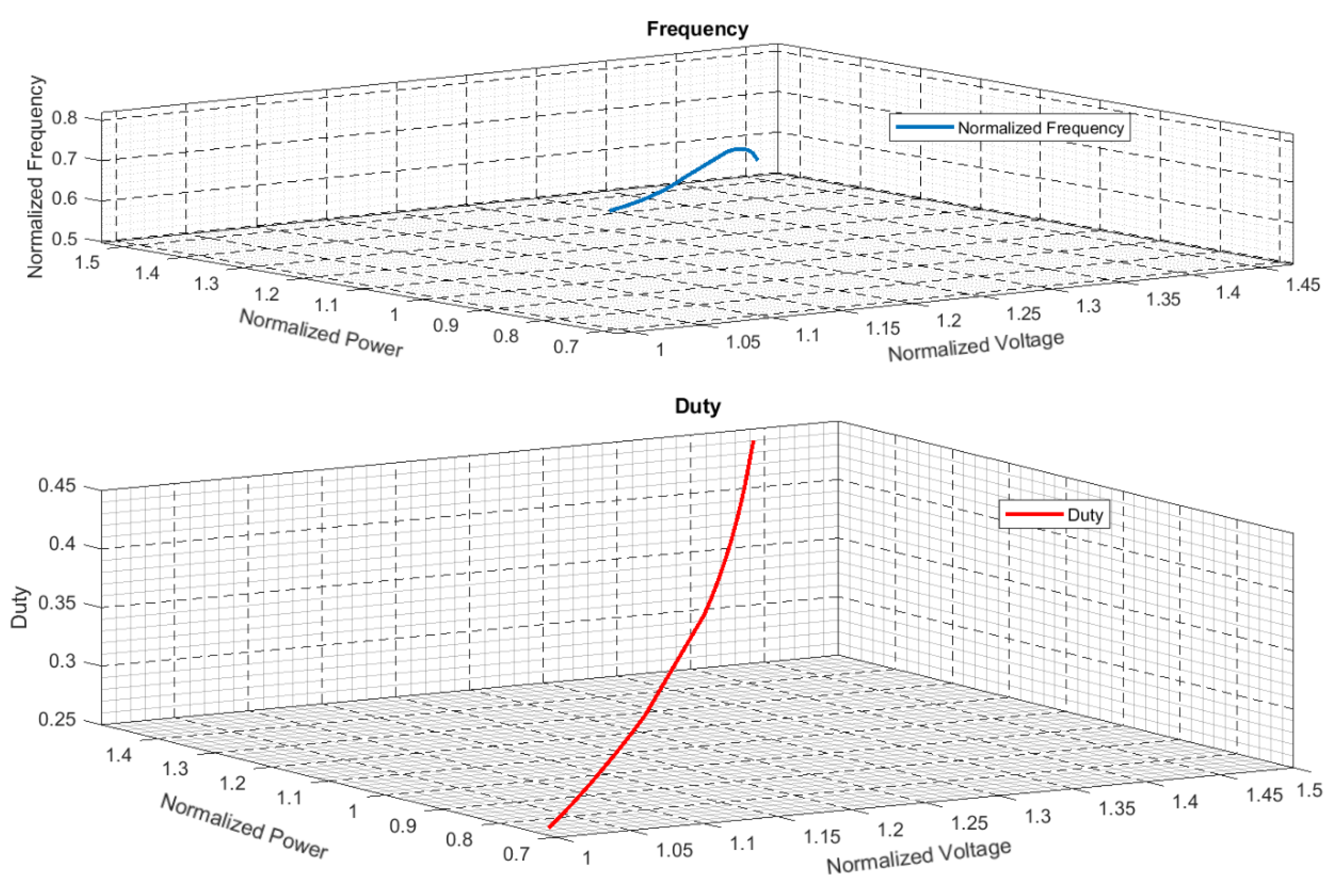

3. Polynomial Model of Parallel Resonant Converter

4. Model Building and Simulations

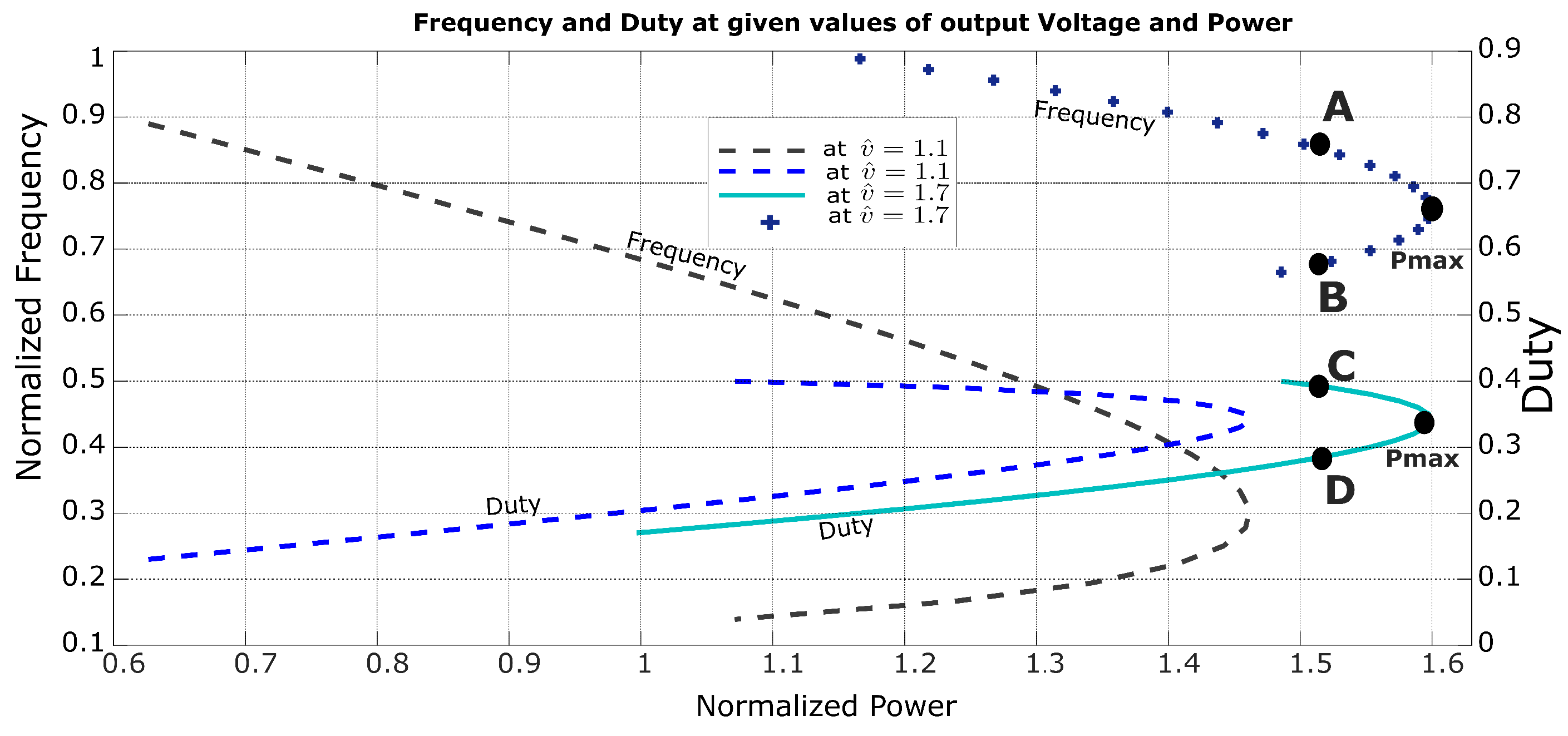

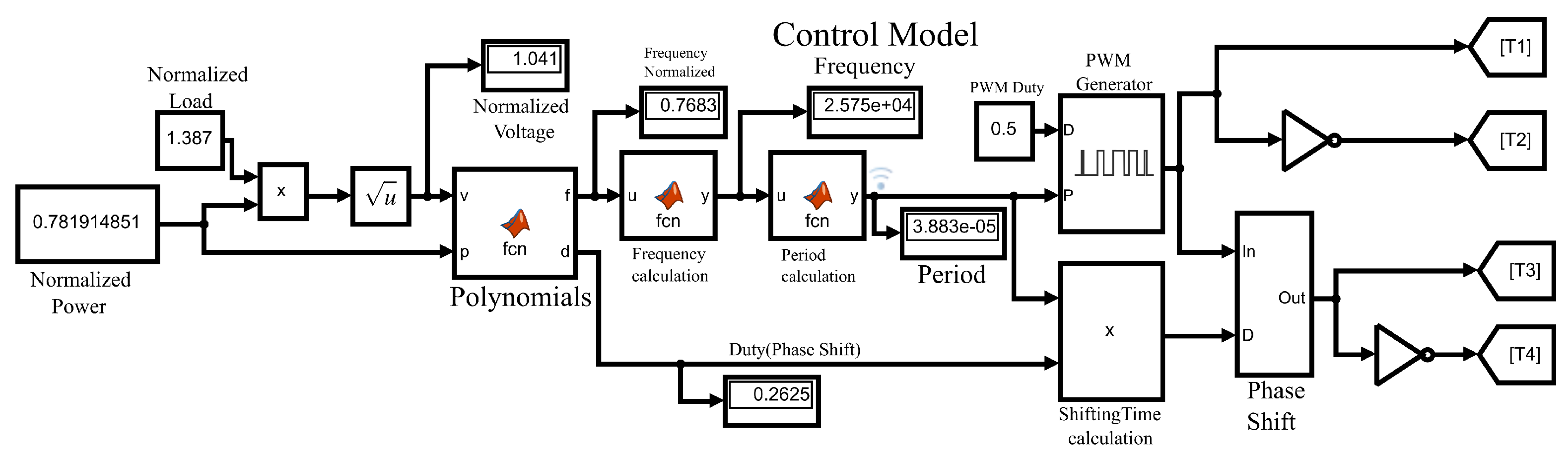

4.1. Two-Inputs Model Simulations

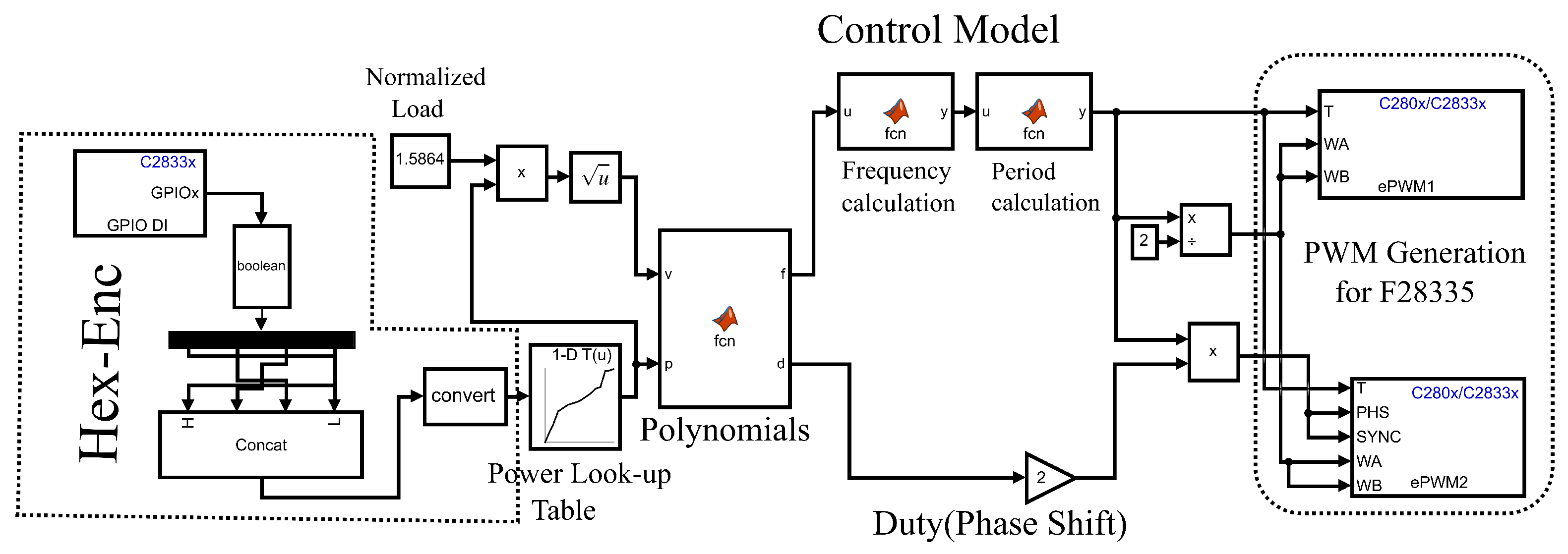

4.2. One-Input Model Simulations

5. DSC Configuration

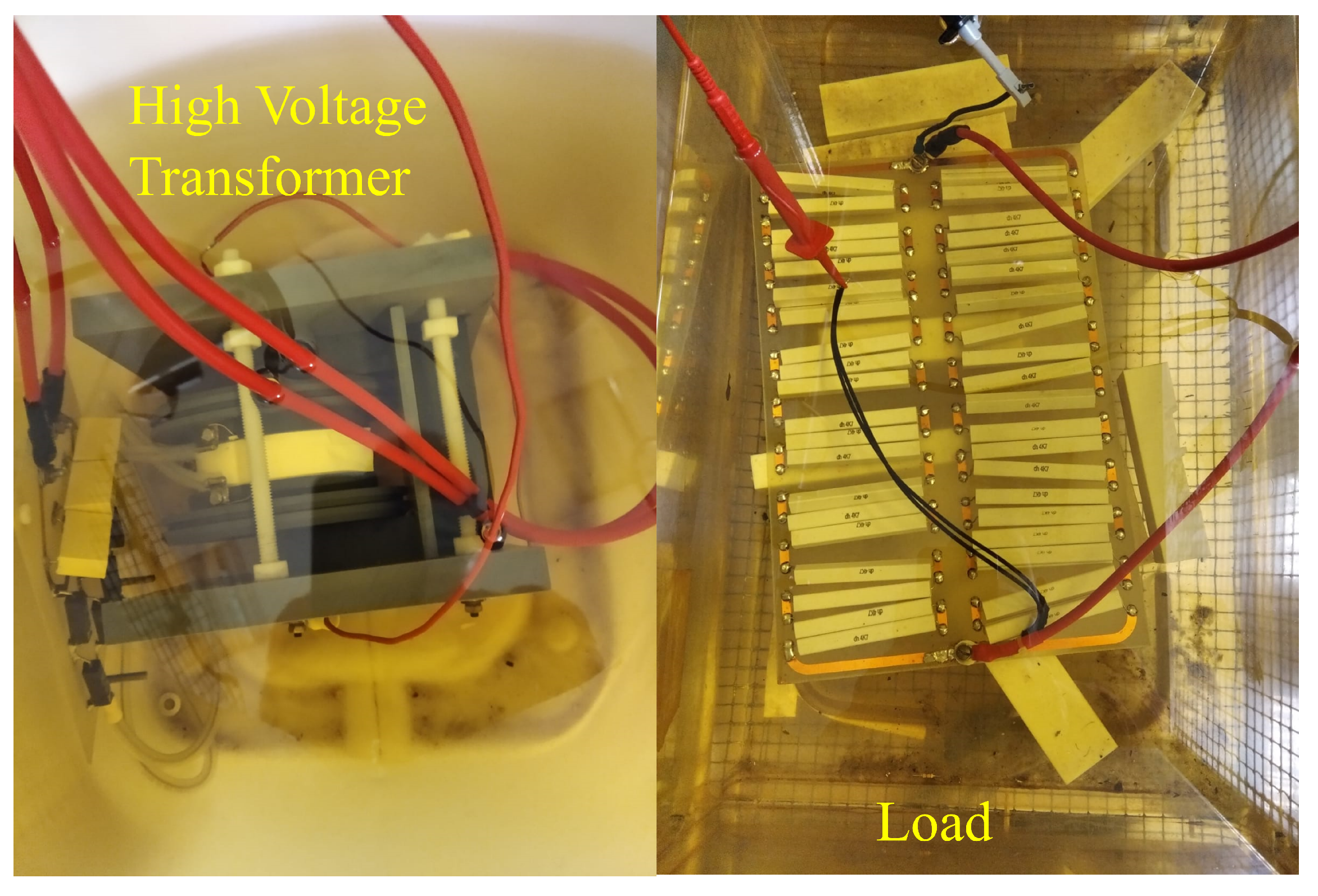

6. Experimental Prototype

6.1. Driver

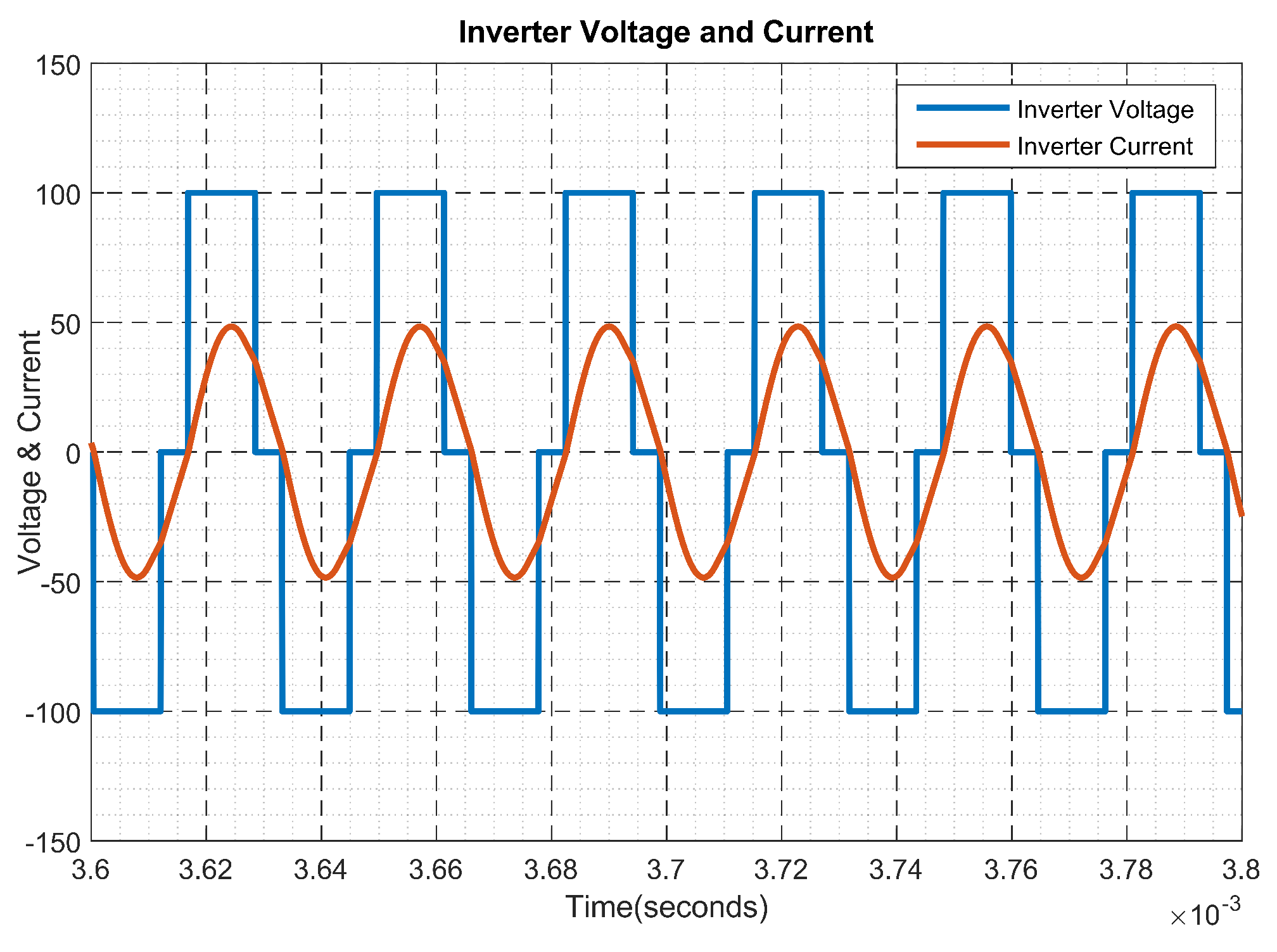

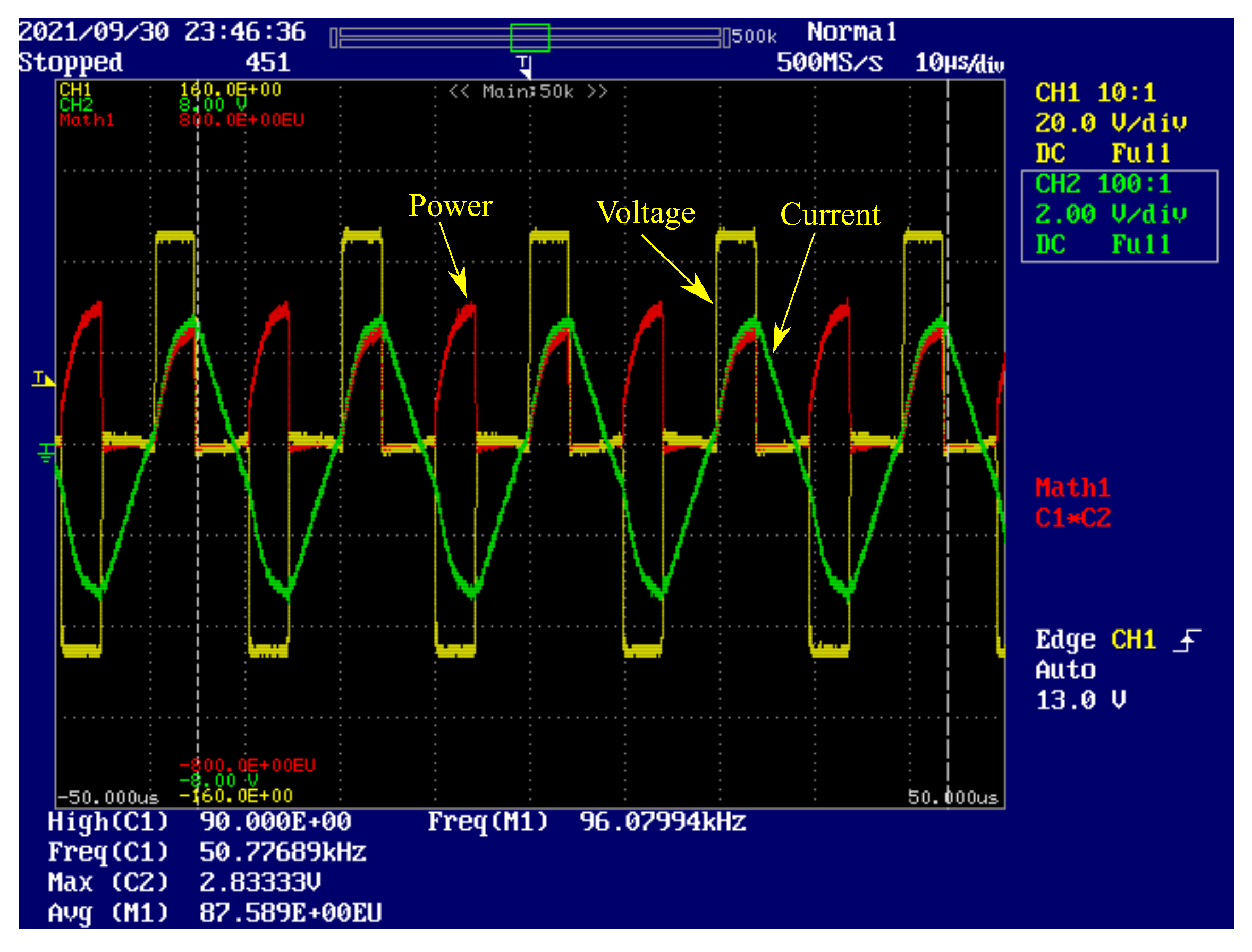

6.2. Low-Voltage Test

6.3. High-Voltage Test

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| CCS | Code Composer Studio |

| IGBT | Insulated Gate Bipolar Transistor |

| PRC | Parallel Resonant Converters |

| PWM | Pulse Width Modulation |

| TI | Texas Instrument |

References

- National Institute of Environmental Health Sciences; National Institutes of Health. Electric and magnetic fields associated with the use of electric power. In NIEHS/DOE EMF RAPID Program; 2002. [Google Scholar]

- Petri, A.K.; Schmiedchen, K.; Stunder, D.; Dechent, D.; Kraus, T.; Bailey, W.H.; Driessen, S. Biological effects of exposure to static electric fields in humans and vertebrates: A systematic review. Environ. Health 2017, 16, 41. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ahlbom, A.; Bridges, J.; De Seze, R.; Hillert, L.; Juutilainen, J.; Mattsson, M.O.; Neubauer, G.; Schüz, J.; Simko, M.; Bromen, K. Possible effects of electromagnetic fields (EMF) on human health–opinion of the scientific committee on emerging and newly identified health risks (SCENIHR). Toxicology 2008, 246, 248–250. [Google Scholar] [PubMed]

- Menke, M.F.; da Silva, M.F.; Bisogno, F.E.; Perdigao, M.S.; Saraiva, E.S.; Alonso, J.M.; Seidel, A.R. Comparative Analysis of Self-Oscillating Electronic Ballast Dimming Methods With Power Factor Correction for Fluorescent Lamps. IEEE Trans. Ind. Appl. 2015, 51, 770–782. [Google Scholar] [CrossRef]

- Kadota, M.; Shoji, H.; Furuya, S. A Dimming Method for Hot Cathode Fluorescent Lamp Using a Resonant Inverter Operating at Fixed Switching Frequency. IEEE Trans. Power Electron. 2015, 30, 2253–2261. [Google Scholar] [CrossRef]

- Sarnago, H.; Lucia, O.; Mediano, A.; Burdio, J.M. Design and Implementation of a High-Efficiency Multiple-Output Resonant Converter for Induction Heating Applications Featuring Wide Bandgap Devices. IEEE Trans. Power Electron. 2014, 29, 2539–2549. [Google Scholar] [CrossRef]

- Kundu, U.; Sensarma, P. Gain-Relationship-Based Automatic Resonant Frequency Tracking in Parallel LLC Converter. IEEE Trans. Ind. Electron. 2015, 63, 874–883. [Google Scholar] [CrossRef]

- Garcia, V.; Rico, M.; Sebastian, J.; Hernando, M.; Uceda, J. Study of an optimized resonant converter for high-voltage applications. In Proceedings of the 3rd International Power Electronic Congress. Technical Proceedings (CIEP’94), Puebla, Mexico, 21–25 August 1994; pp. 114–121. [Google Scholar]

- Luo, W.; Wang, X. Development of electric control high power medical-use X-ray generator. In Proceedings of the 2009 International Conference on Information Engineering and Computer Science, Wuhan, China, 19–20 December 2009; pp. 1–5. [Google Scholar]

- Cavalcante, F. High Output Voltage Series-Parallel Resonant dc-dc Converter for Medical X-ray Imaging Applications. Ph.D. Thesis, These de la Swiss Federal Institute of Technology Zurich, Zurich, Switzerland, 2006. [Google Scholar]

- Agamy, M.; Dame, M.; Dai, J.; Li, X.; Cioffi, P.; Sellick, R.; Gupta, R. Resonant converter building blocks for high power, high voltage applications. In Proceedings of the 2015 IEEE Applied Power Electronics Conference and Exposition (APEC), Charlotte, NC, USA, 15–19 March 2015; pp. 2116–2121. [Google Scholar]

- Wang, H. Design and Control of Series Resonant Converters for dc Current Power Distribution Applications. Ph.D. Thesis, Utah State University, Logan, UT, USA, 2018. [Google Scholar]

- Juan, D.; Villegas, P.J.; Alberto, M.P.; Martín-Ramos, J.A.; Jose-Prieto, M.A. High-voltage DC/DC converter 10KV, 600W with digital output voltage monitoring. In Proceedings of the 2013 IEEE Industry Applications Society Annual Meeting, Lake Buena Vista, FL, USA, 6–11 October 2013; pp. 1–6. [Google Scholar]

- Diaz, J.; Saiz, P.J.V.; Martin-Ramos, J.A.; Martin-Pernia, A.; Martinez, J.A. A high-voltage ac/dc resonant converter based on prc with single capacitor as an output filter. IEEE Trans. Ind. Appl. 2010, 46, 2134–2142. [Google Scholar] [CrossRef]

- Martin-Ramos, J.A.; Díaz, J.; Nuño, F.; Villegas, P.J.; López-Hernández, A.; Gutiérrez-Delgado, J.F. A polynomial model to calculate steady-state set point in the PRC-LCC topology with a capacitor as output filter. IEEE Trans. Ind. Appl. 2014, 51, 2520–2527. [Google Scholar] [CrossRef]

- Martín-Ramos, J.A.; Sáiz, P.J.V.; Pernía, A.M.; Díaz, J.; Martínez, J.A. Optimal control of a high-voltage power supply based on the PRC-LCC topology with a capacitor as output filter. IEEE Trans. Ind. Appl. 2013, 49, 2323–2329. [Google Scholar] [CrossRef]

- Yang, R.; Ding, H.; Xu, Y.; Yao, L.; Xiang, Y. An analytical steady state model of LCC type series–parallel resonant converter with capacitive output filter. IEEE Trans. Power Electron. 2014, 29, 328–338. [Google Scholar] [CrossRef]

- Sun, J.M.; Wang, S.P.; Nishimura, T.; Nakaoka, M. Resonant mode PWM DC–DC converter with a high-voltage transformer link and its control methods for medical-use X-ray power supply. In Proceedings of the 8th European Conference on Power Electronics and Applications, Lausanne, Switzerland, 7–9 September 1999; pp. 7–9. [Google Scholar]

- Shafiei, N.; Pahlevaninezhad, M.; Farzanehfard, H.; Motahari, S.R. Analysis and implementation of a fixed-frequency LCLC resonant converter with capacitive output filter. IEEE Trans. Ind. Electron. 2011, 58, 4773–4782. [Google Scholar] [CrossRef]

- Nguyen, B.; Zhang, X.; Ferencz, A.; Takken, T.; Senger, R.; Coteus, P. Analytic model for power MOSFET turn-off switching loss under the effect of significant current diversion at fast switching events. In Proceedings of the 2018 IEEE Applied Power Electronics Conference and Exposition (APEC), San Antonio, TX, USA, 4–8 March 2018; pp. 287–291. [Google Scholar] [CrossRef]

- Locorotondo, E.; Pugi, L.; Corti, F.; Becchi, L.; Grasso, F. Analytical Model of Power MOSFET Switching Losses due to Parasitic Components. In Proceedings of the 2019 IEEE 5th International forum on Research and Technology for Society and Industry (RTSI), Florence, Italy, 9–12 September 2019; pp. 331–336. [Google Scholar] [CrossRef] [Green Version]

- Dobrescu, L.; Smeu, R.; Dobrescu, D. Load switch power MOSFET SPICE model. In Proceedings of the 2016 International Conference and Exposition on Electrical and Power Engineering (EPE), Iasi, Romania, 20–22 October 2016; pp. 644–647. [Google Scholar] [CrossRef]

- Yang, Y.; Ma, D.; Yu, T. Interpolation by nonuniform b-spline through uniform b-spline filter banks. In Proceedings of the 2016 IEEE International Conference on Digital Signal Processing (DSP), Beijing, China, 16–18 October 2016; pp. 375–378. [Google Scholar]

- Ferrer-Arnau, L.; Parisi-Baradad, V.; Soria, J.; Nasreddine, K.; Benzinou, A. A comparative study between elliptic fourier and b-spline descriptors for object contour representation. In Proceedings of the International Image Processing, Applications and Systems Conference, Sfax, Tunisia, 5–7 November 2014; pp. 1–5. [Google Scholar]

- Che, X.; Zong, S.; Che, N.; Gao, Z. The product calculation of linear polynomial and b-spline curve. In Proceedings of the 2009 IEEE 10th International Conference on Computer-Aided Industrial Design & Conceptual Design, Wenzhou, China, 26–29 November 2009; pp. 991–994. [Google Scholar]

- Malkowski, M.; Ufnalski, B.; Grzesiak, L.M. B-spline based repetitive controller revisited: Error shift, higher-order polynomials and smooth pass-to-pass transition. In Proceedings of the 2015 19th International Conference on System Theory, Control and Computing (ICSTCC), Cheile Gradistei, Romania, 14–16 October 2015; pp. 19–25. [Google Scholar]

- Texas Instrument. TMS320F2833x, TMS320F2823x Digital Signal Controllers (DSCs); Texas Instrument: Brussels Belgium, 2007. [Google Scholar]

| 1.0 | 0 | 0 | −0.61102 | 1.222 |

| 1.1 | −0.70602 | 1.9259 | −2.2687 | 1.7354 |

| 1.2 | −1.288 | 3.6637 | −3.9182 | 2.2918 |

| 1.3 | −1.3247 | 3.9212 | −4.2784 | 2.4819 |

| 1.4 | −1.5175 | 4.6649 | −5.1259 | 2.8205 |

| . | . | . | . | . |

| . | . | . | . | . |

| . | . | . | . | . |

| 3.6 | −0.59499 | 4.2475 | −10.184 | 9.1596 |

| 3.7 | −0.74666 | 5.5661 | −13.909 | 12.606 |

| 3.8 | −0.65556 | 4.9904 | −12.737 | 11.858 |

| 3.9 | −0.57735 | 4.486 | −11.689 | 11.175 |

| 4.0 | −0.51036 | 4.0457 | −10.758 | 10.559 |

| 1.0 | 0 | 0 | 0.19449 | 0.11102 |

| 1.1 | 0.25389 | −0.69256 | 0.81585 | −0.07406 |

| 1.2 | 0.51726 | −1.4713 | 1.5735 | −0.32038 |

| 1.3 | 0.58838 | −1.7417 | 1.9003 | −0.45238 |

| 1.4 | 0.74316 | −2.2865 | 2.5136 | −0.68055 |

| . | . | . | . | . |

| . | . | . | . | . |

| . | . | . | . | . |

| 3.6 | 0.89738 | −6.408 | 15.368 | −12.018 |

| 3.7 | 1.1575 | −8.6289 | 21.562 | −17.693 |

| 3.8 | 1.048 | −7.9784 | 20.364 | −17.059 |

| 3.9 | 0.95176 | −7.3958 | 19.273 | −16.475 |

| 4.0 | 0.86674 | −6.872 | 18.276 | −15.935 |

| 1.0–1.2 | −6.4400 | 6.4193 | 18.3190 | −18.2870 | −16.5360 | 15.9240 | 5.3490 | −4.1342 |

| 1.3–1.5 | −1.5900 | 0.7310 | 7.2865 | −5.5462 | −9.5360 | 8.1538 | 4.2220 | −3.0346 |

| 1.6–1.8 | −0.6750 | −0.2770 | 5.6585 | −4.4915 | −10.4860 | 11.3930 | 5.8700 | −6.3060 |

| 1.9–2.0 | −1.0950 | 0.5737 | 8.3280 | −9.8350 | −16.5230 | 23.2470 | 10.0220 | −14.3620 |

| 2.1–2.2 | 2.4240 | −6.4033 | −9.1850 | 24.9940 | 11.4450 | −32.4880 | −4.4950 | 14.6110 |

| 2.3–2.4 | −0.3650 | −0.3347 | 3.7960 | −3.1700 | −9.1530 | 12.1060 | 6.5700 | −9.3089 |

| 2.5–2.6 | −1.3930 | 2.4775 | 10.2110 | −20.4600 | −22.7860 | 48.3120 | 16.1910 | −34.5450 |

| 2.7–2.8 | 1.5088 | −5.0318 | −7.1010 | 24.4050 | 10.8790 | −39.0250 | −5.2610 | 21.150 |

| 2.9–3.0 | 1.4187 | −5.0571 | −7.1910 | 26.4110 | 11.8340 | −45.3510 | −6.1590 | 26.1780 |

| 3.1–3.2 | 1.2073 | −4.6060 | −6.4090 | 25.2430 | 11.0000 | −45.3490 | −5.9280 | 27.2370 |

| 3.3–3.4 | 1.2193 | −4.9297 | −6.9400 | 28.9530 | 12.7600 | −55.6680 | −7.3800 | 35.5000 |

| 3.5–3.6 | 0.8654 | −3.7104 | −5.1330 | 22.7260 | 9.8200 | −45.5360 | −5.8950 | 30.3820 |

| 3.7–3.8 | 0.9110 | −4.1174 | −5.7570 | 26.8670 | 11.7200 | −57.2730 | −7.4800 | 40.2820 |

| 3.9–4.0 | 0.6699 | −3.1900 | −4.4030 | 21.6580 | 9.3100 | −47.9980 | −6.1600 | 35.1990 |

| 1.0–1.2 | 2.5863 | −2.5879 | −7.3565 | 7.3709 | 6.8951 | −6.7233 | −2.1570 | 2.2782 |

| 1.3–1.5 | 1.4197 | −1.2530 | −5.5730 | 5.5074 | 6.9235 | −7.1266 | −2.8196 | 3.2310 |

| 1.6–1.8 | 1.0212 | −0.8488 | −5.6690 | 6.4327 | 9.2140 | −11.6320 | −4.7130 | 6.5631 |

| 1.9–2.0 | 1.4800 | −1.7409 | −8.8670 | 12.5890 | 15.9650 | −24.5400 | −9.0870 | 14.8890 |

| 2.1–2.2 | −1.4155 | 4.0245 | 4.9870 | −15.0450 | −5.5260 | 18.3800 | 1.7760 | −6.8231 |

| 2.3–2.4 | 0.9160 | −1.0600 | −6.2970 | 9.5256 | 13.0150 | −21.9590 | −8.5190 | 15.5710 |

| 2.5–2.6 | 1.8546 | −3.6424 | −12.6150 | 26.5220 | 27.0250 | −58.9940 | −18.6480 | 42.0000 |

| 2.7–2.8 | −1.2309 | 4.3582 | 5.4290 | −20.3120 | −7.4930 | 30.6620 | 3.0070 | −14.2730 |

| 2.9–3.0 | −1.2665 | 4.7769 | 6.0270 | −23.9850 | −8.970 | 38.9310 | 3.9060 | −19.6160 |

| 3.1–3.2 | −1.1662 | 4.7107 | 5.7960 | −24.7890 | −8.9300 | 41.9620 | 3.9460 | −21.9280 |

| 3.3–3.4 | −1.2710 | 5.4262 | 6.7870 | −30.6250 | −11.2500 | 55.5640 | 5.3800 | −31.2600 |

| 3.5–3.6 | −0.9676 | 4.3807 | 5.3780 | −25.7690 | −9.2600 | 48.7040 | 4.5600 | −28.4340 |

| 3.7–3.8 | −1.0950 | 5.2090 | 6.5050 | −32.6970 | −11.9800 | 65.8880 | 6.3400 | −41.1510 |

| 3.9–4.0 | −0.8502 | 4.2675 | 5.2380 | −27.8240 | −9.9700 | 58.1560 | 5.4000 | −37.5350 |

| Item | Value | Unit |

|---|---|---|

| 100 | V | |

| 34.232 | uH | |

| 658.7 | nF | |

| 30 | uF | |

| 7.209 | ||

| 33.527 | kHz |

| d | |||

|---|---|---|---|

| 1.00664 | 0.730587 | 0.780201 | 0.2535 |

| 1.041401 | 0.781915 | 0.768267 | 0.2625 |

| 1.074677 | 0.832682 | 0.757526 | 0.2716 |

| 1.120123 | 0.904597 | 0.74589 | 0.2842 |

| 1.150194 | 0.953819 | 0.74052 | 0.2925 |

| 1.172152 | 0.990585 | 0.737835 | 0.2985 |

| 1.30065 | 1.219677 | 0.695766 | 0.3417 |

| 1.316569 | 1.249714 | 0.685622 | 0.3488 |

| 1.332491 | 1.280124 | 0.673986 | 0.3567 |

| 1.348824 | 1.311699 | 0.661157 | 0.3656 |

| 1.359014 | 1.331593 | 0.652206 | 0.3716 |

| 1.372422 | 1.357997 | 0.639675 | 0.3801 |

| 1.389738 | 1.392481 | 0.621476 | 0.3924 |

| 1.403329 | 1.419851 | 0.605663 | 0.4032 |

| 1.412658 | 1.438791 | 0.593729 | 0.4112 |

| 1.441706 | 1.498569 | 0.550467 | 0.4404 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rwamurangwa, E.; González, J.D.; Villegas Saiz, P.J.; Martín-Ramos, J.A.; Pernía, A.M. A Parallel Resonant Converter Polynomial Model Implemented in a Digital Signal Controller. Electronics 2022, 11, 1085. https://doi.org/10.3390/electronics11071085

Rwamurangwa E, González JD, Villegas Saiz PJ, Martín-Ramos JA, Pernía AM. A Parallel Resonant Converter Polynomial Model Implemented in a Digital Signal Controller. Electronics. 2022; 11(7):1085. https://doi.org/10.3390/electronics11071085

Chicago/Turabian StyleRwamurangwa, Evode, Juan Díaz González, Pedro José Villegas Saiz, Juan Antonio Martín-Ramos, and Alberto Martin Pernía. 2022. "A Parallel Resonant Converter Polynomial Model Implemented in a Digital Signal Controller" Electronics 11, no. 7: 1085. https://doi.org/10.3390/electronics11071085

APA StyleRwamurangwa, E., González, J. D., Villegas Saiz, P. J., Martín-Ramos, J. A., & Pernía, A. M. (2022). A Parallel Resonant Converter Polynomial Model Implemented in a Digital Signal Controller. Electronics, 11(7), 1085. https://doi.org/10.3390/electronics11071085