Fault Detection of an Actuator with Dual Type Motors and One Common Motion Sensor

Abstract

:1. Introduction

1.1. Background

1.2. Literature Survey

1.3. Research Topic and Contributions

2. System Description and Problem Definition

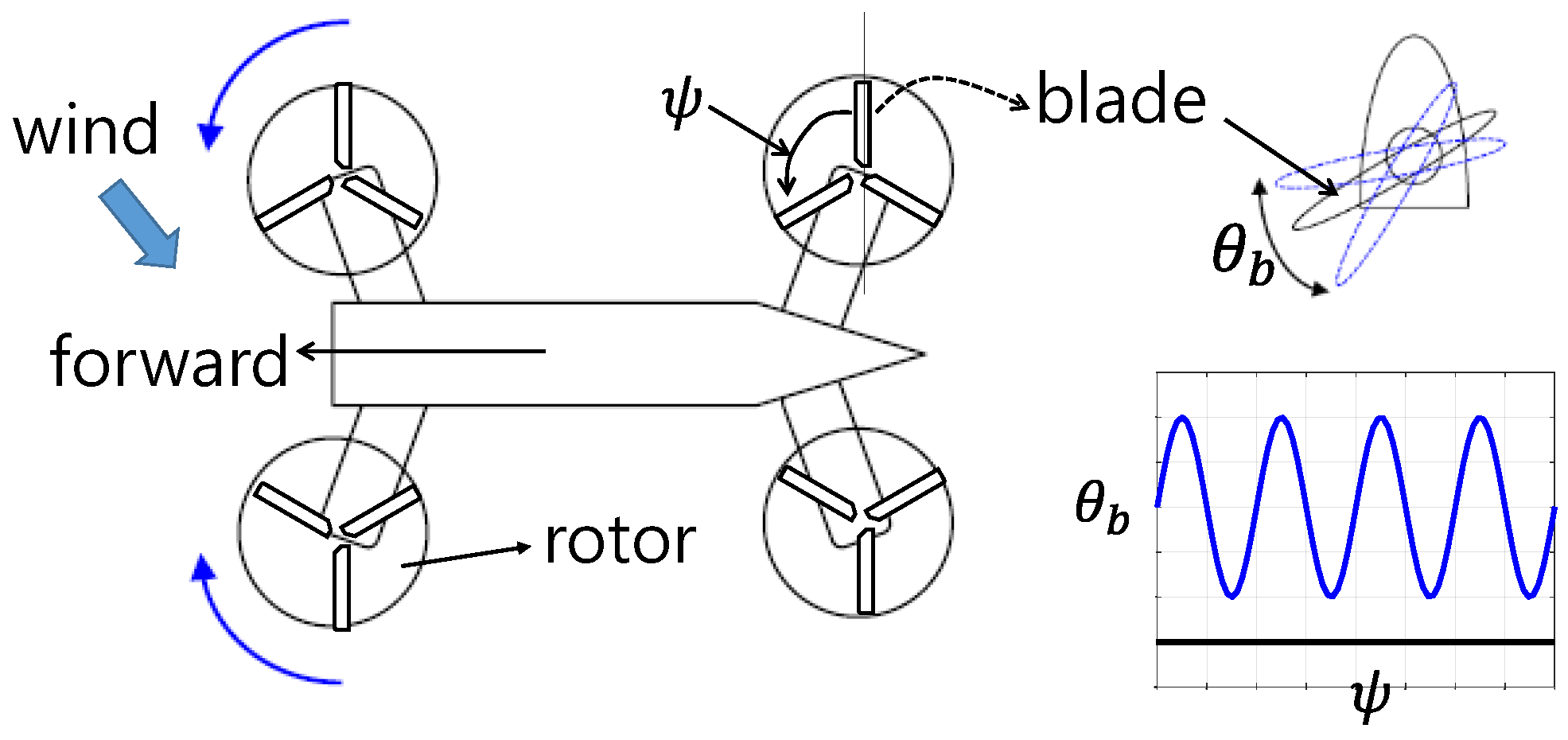

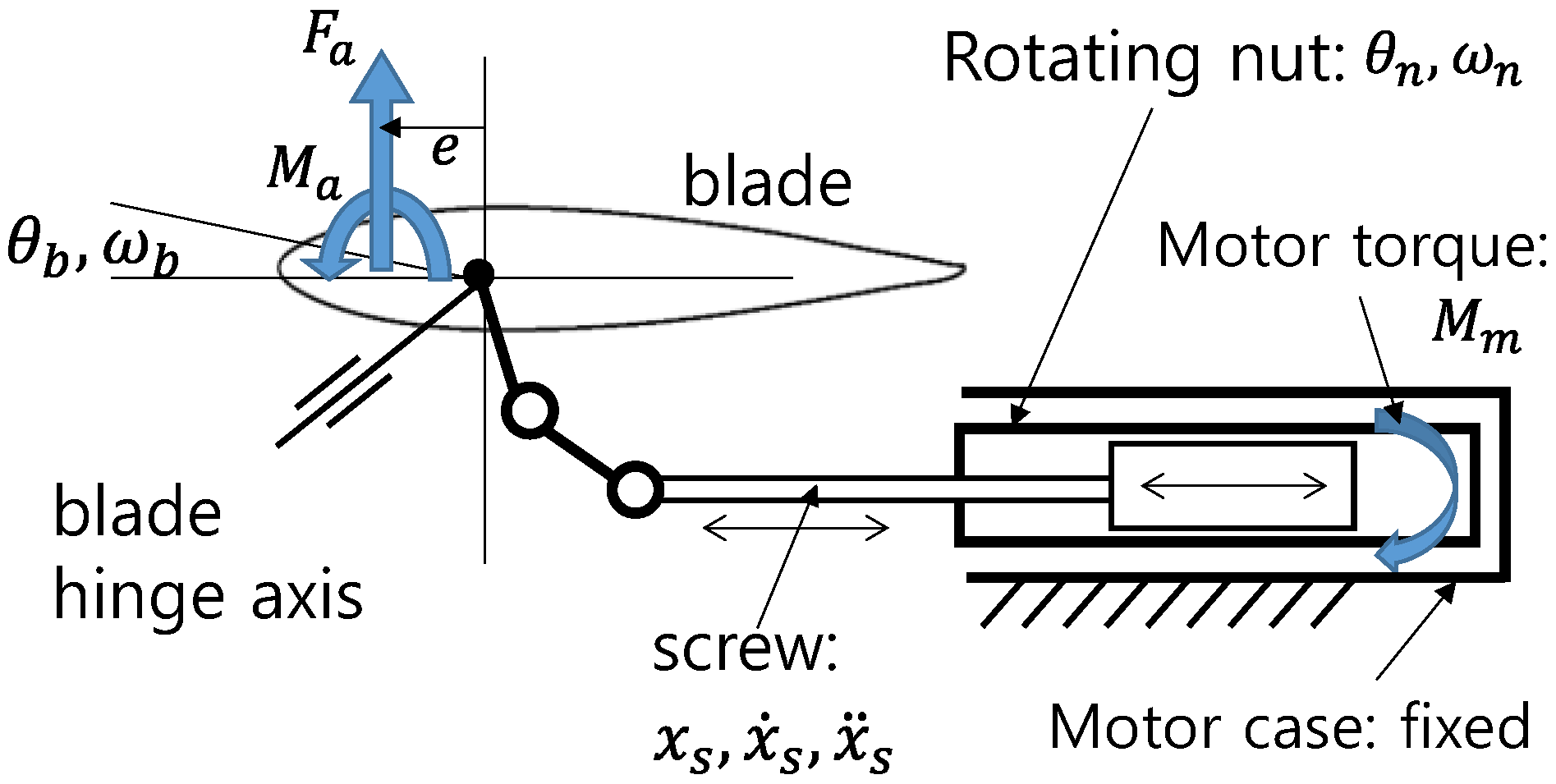

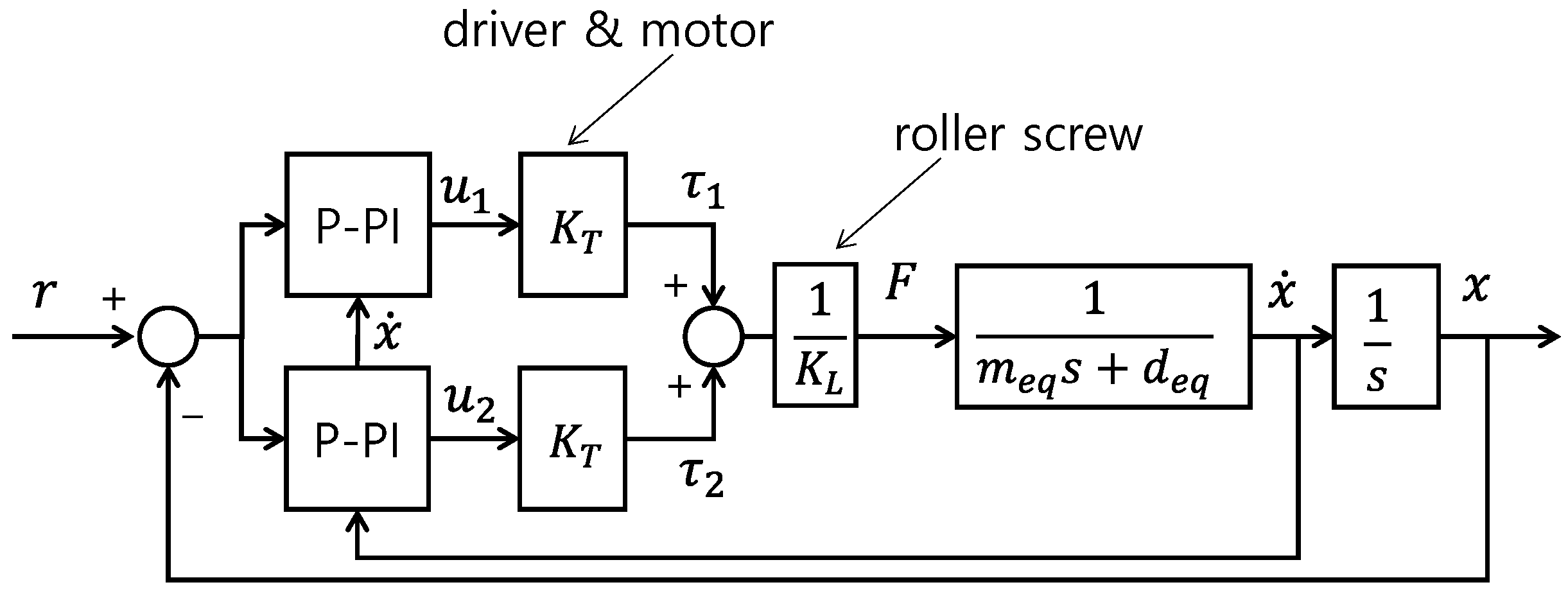

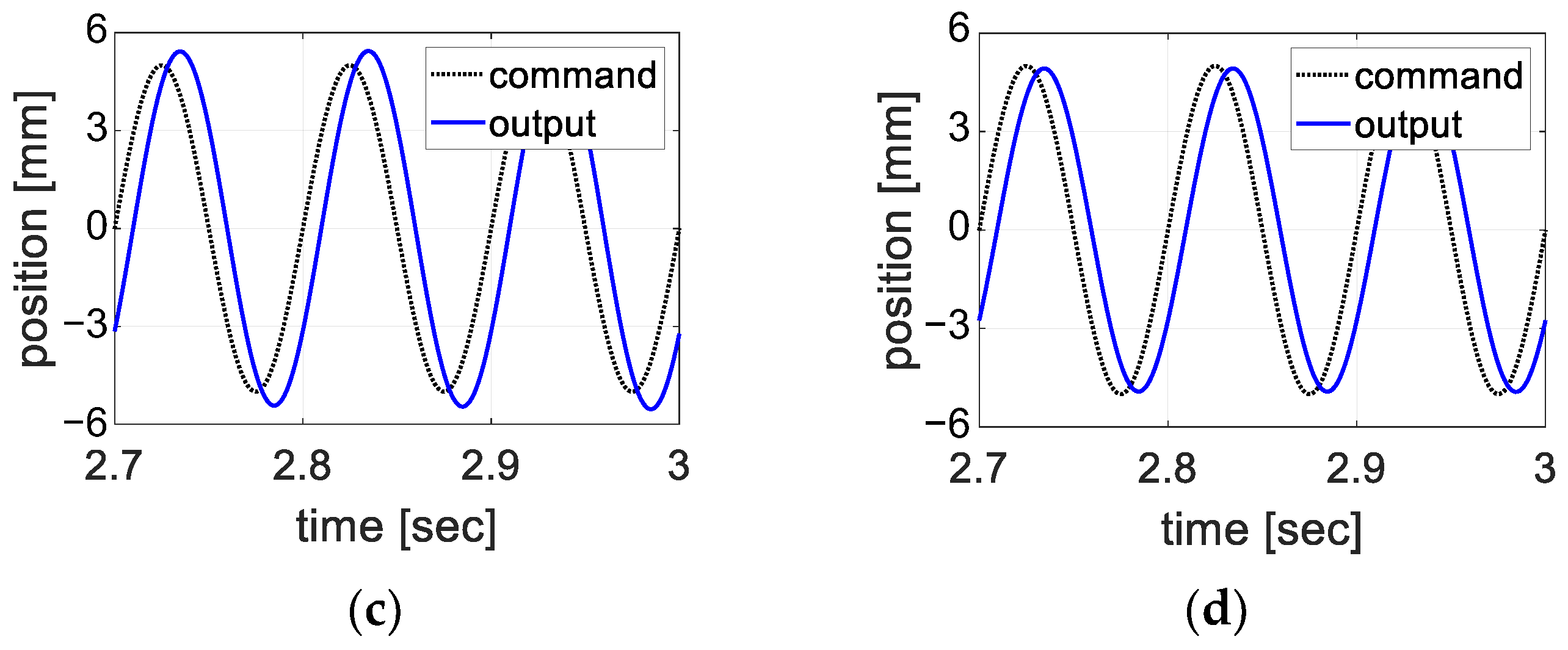

2.1. System Description

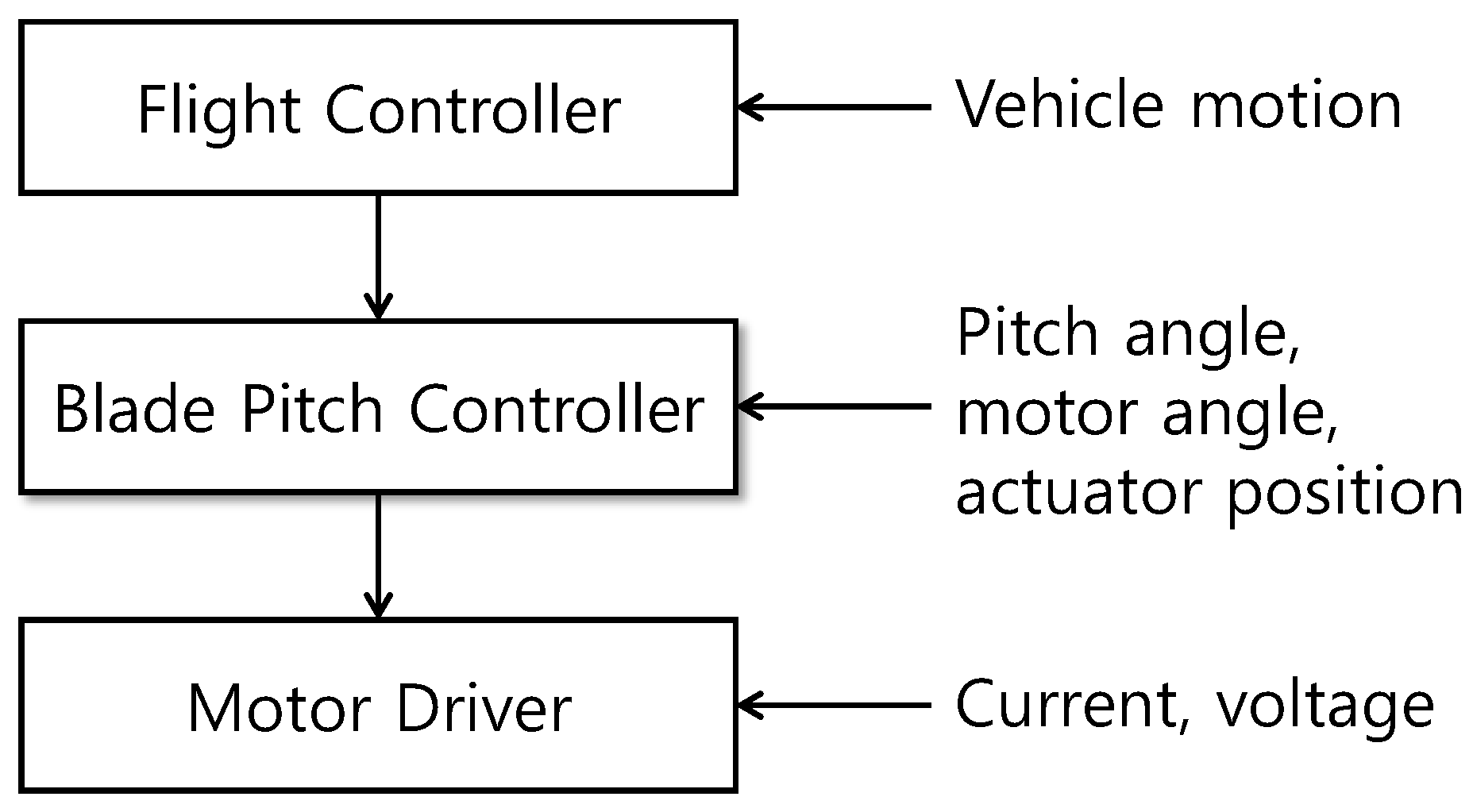

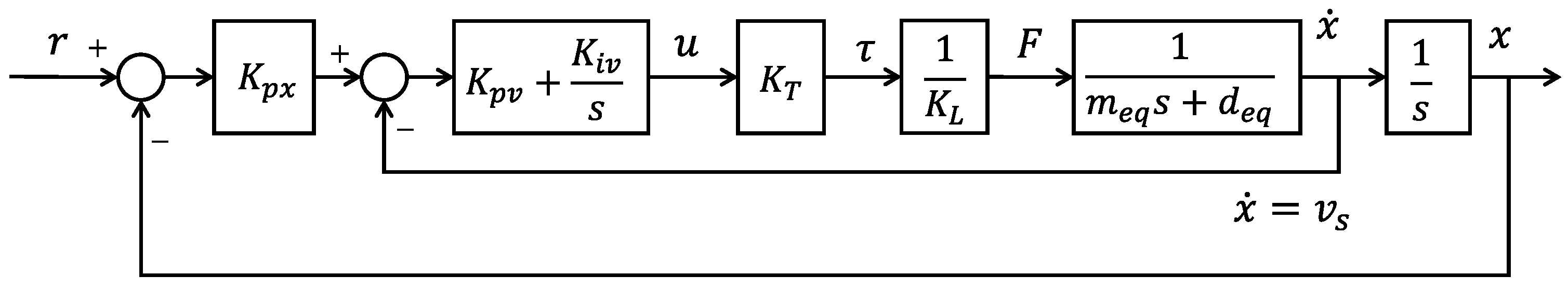

2.2. Controller and Driver

2.3. Problem Definition

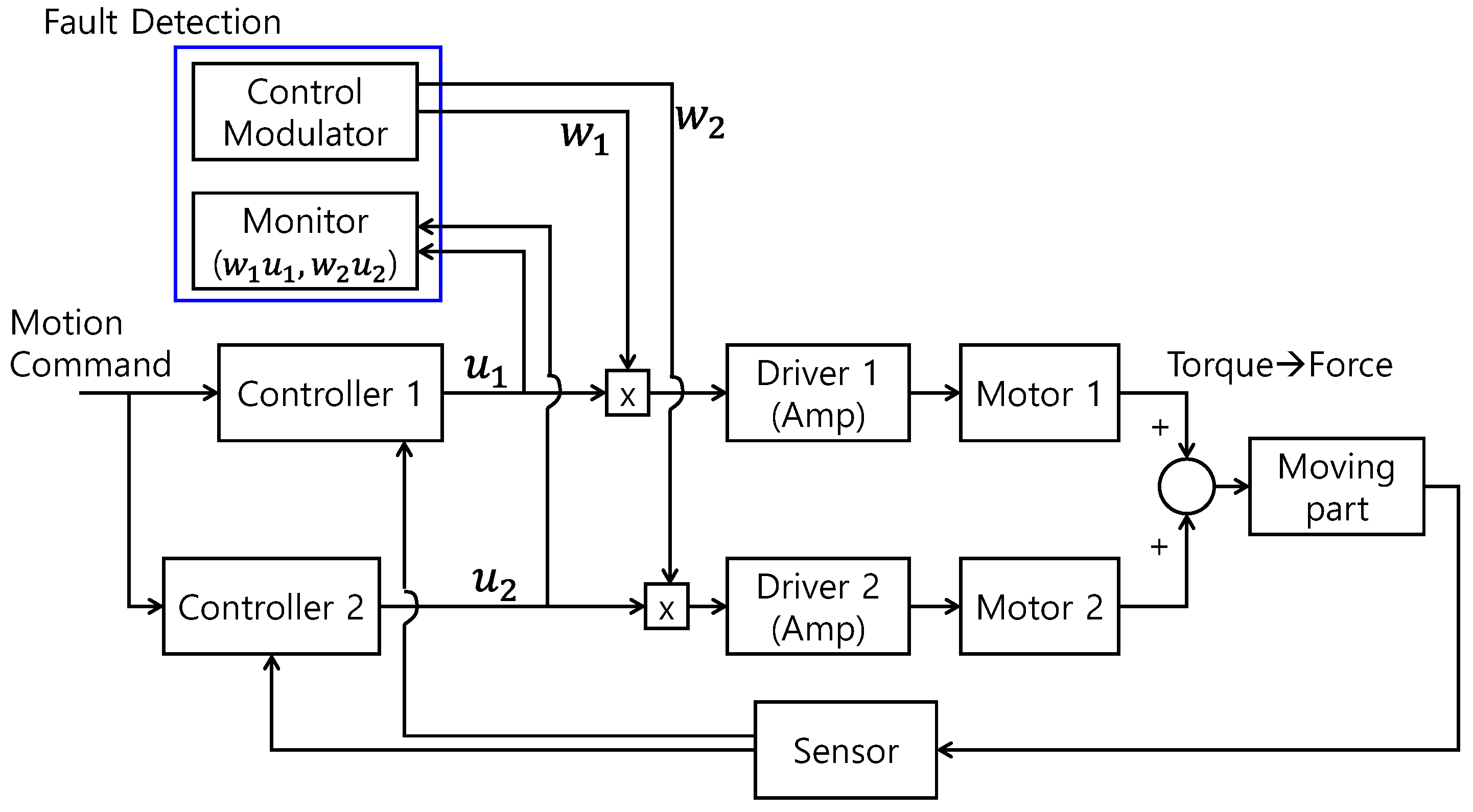

3. Proposed Fault Detection Method

3.1. Fault Modes

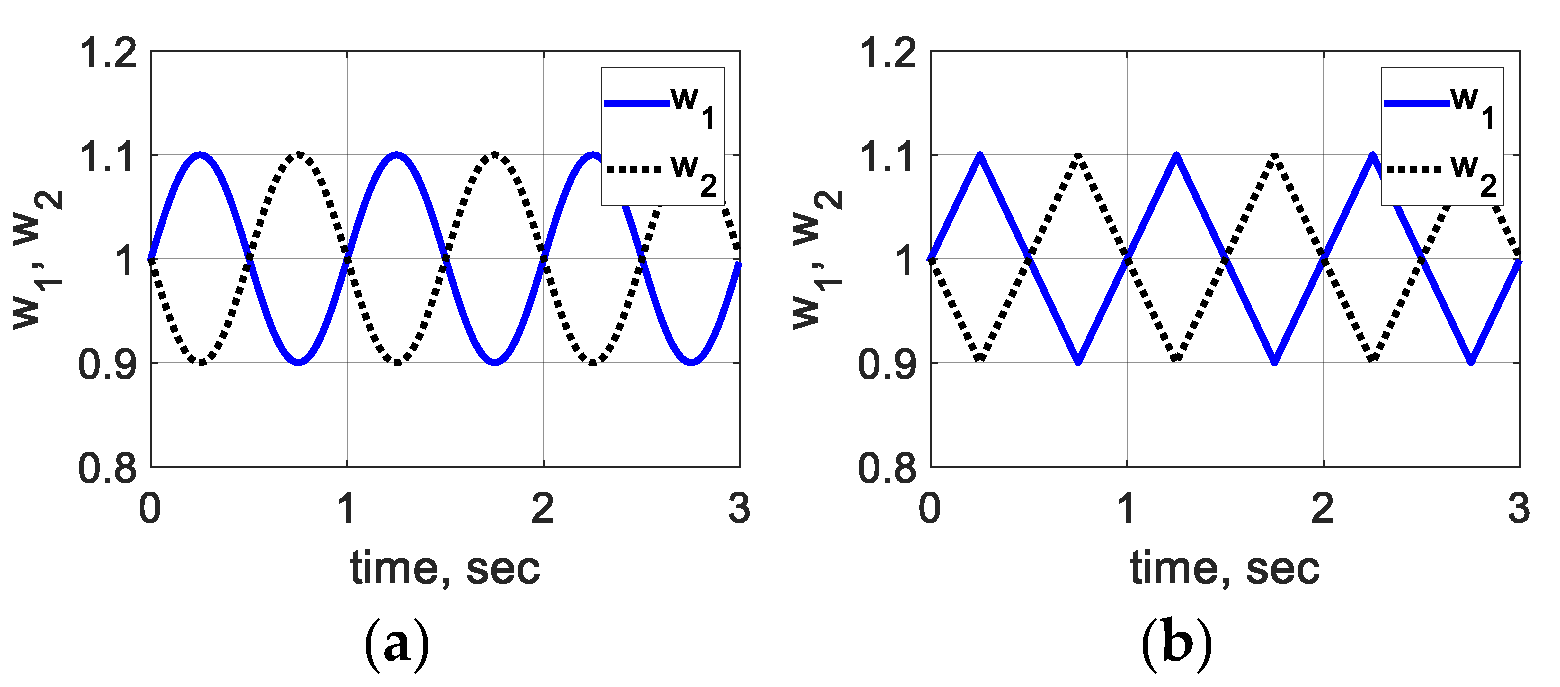

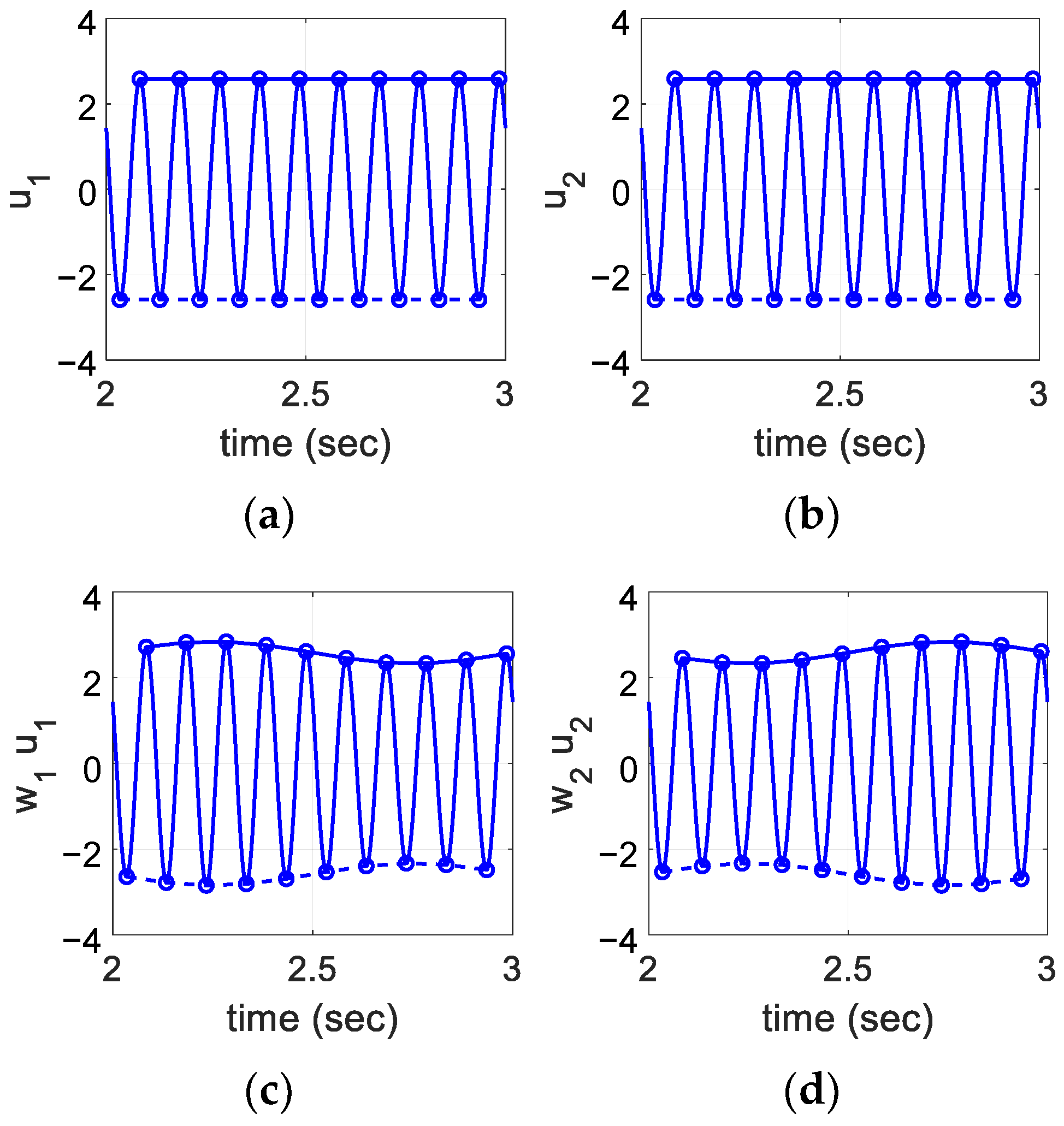

3.2. Proposed Method

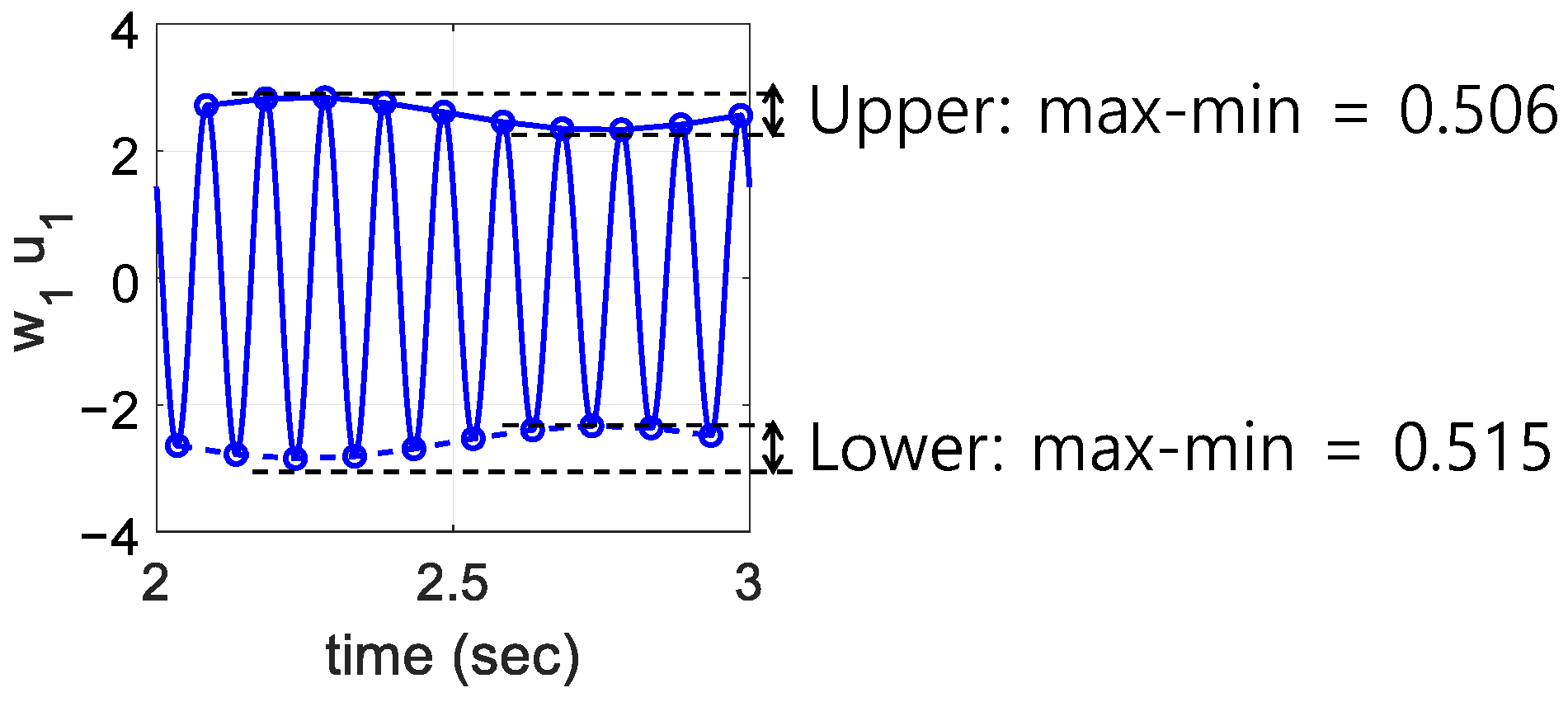

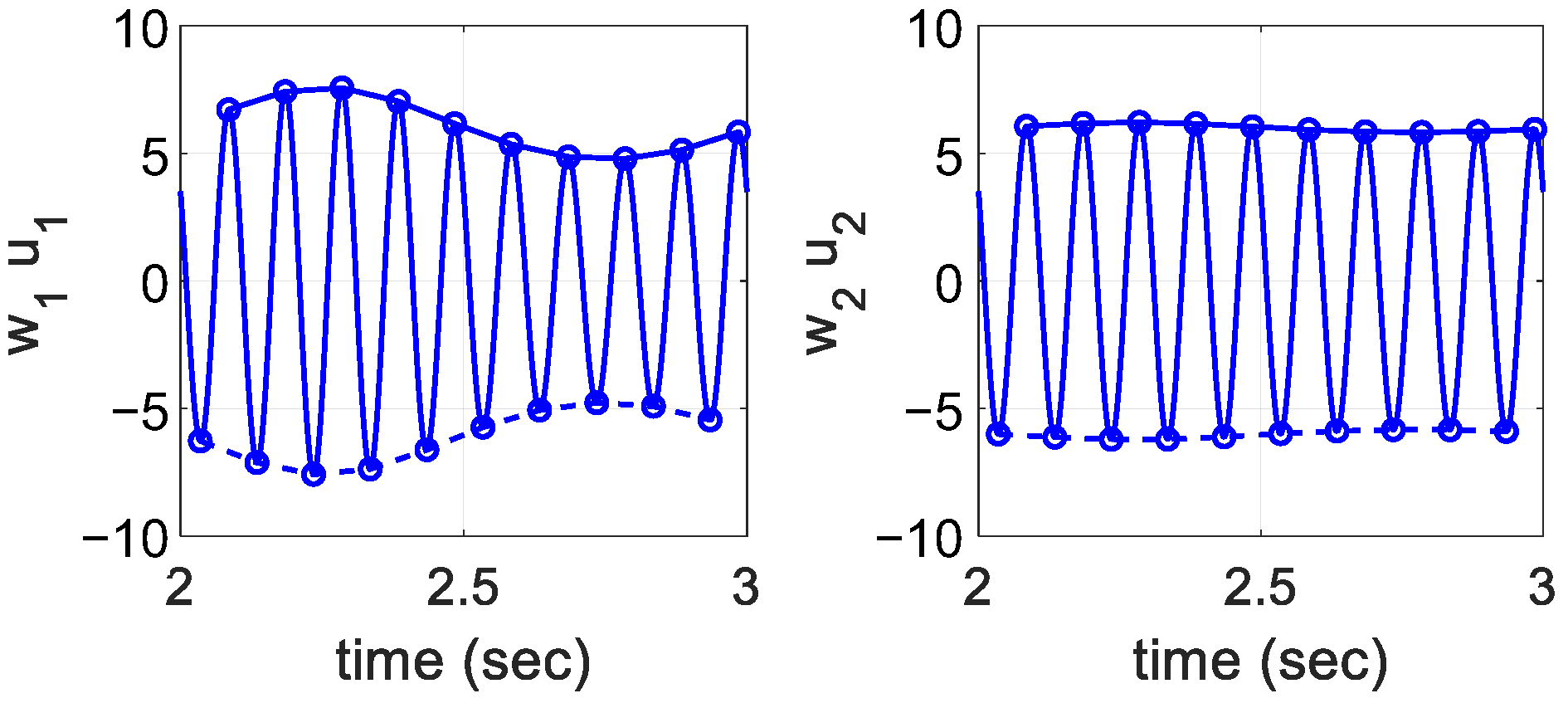

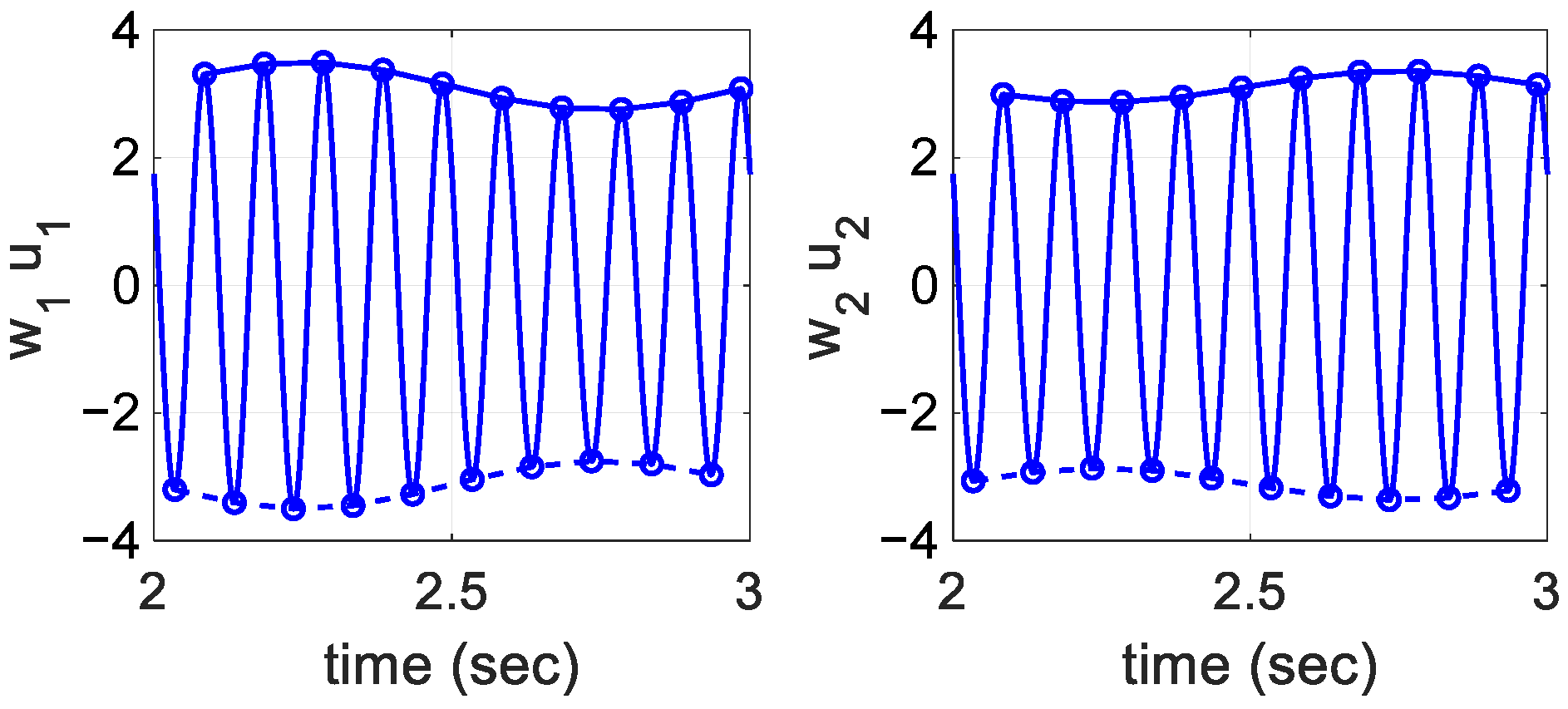

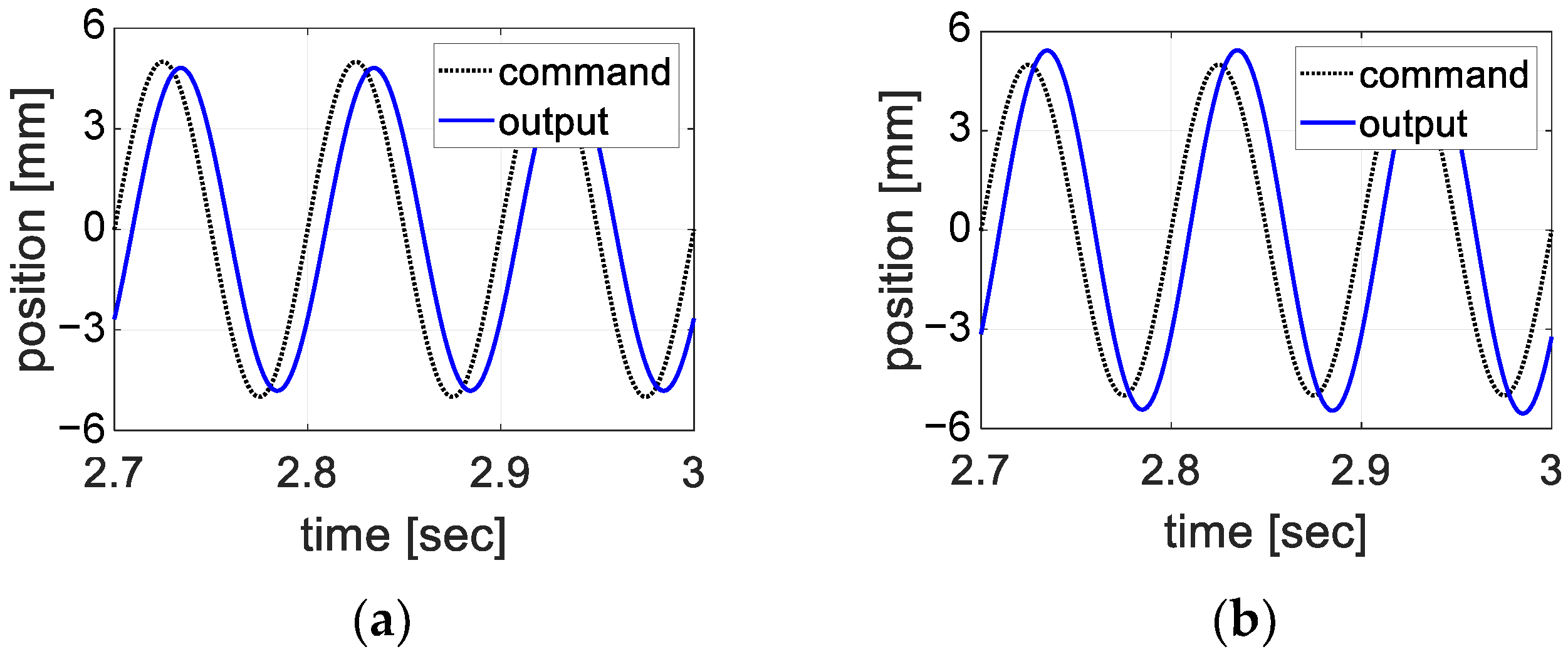

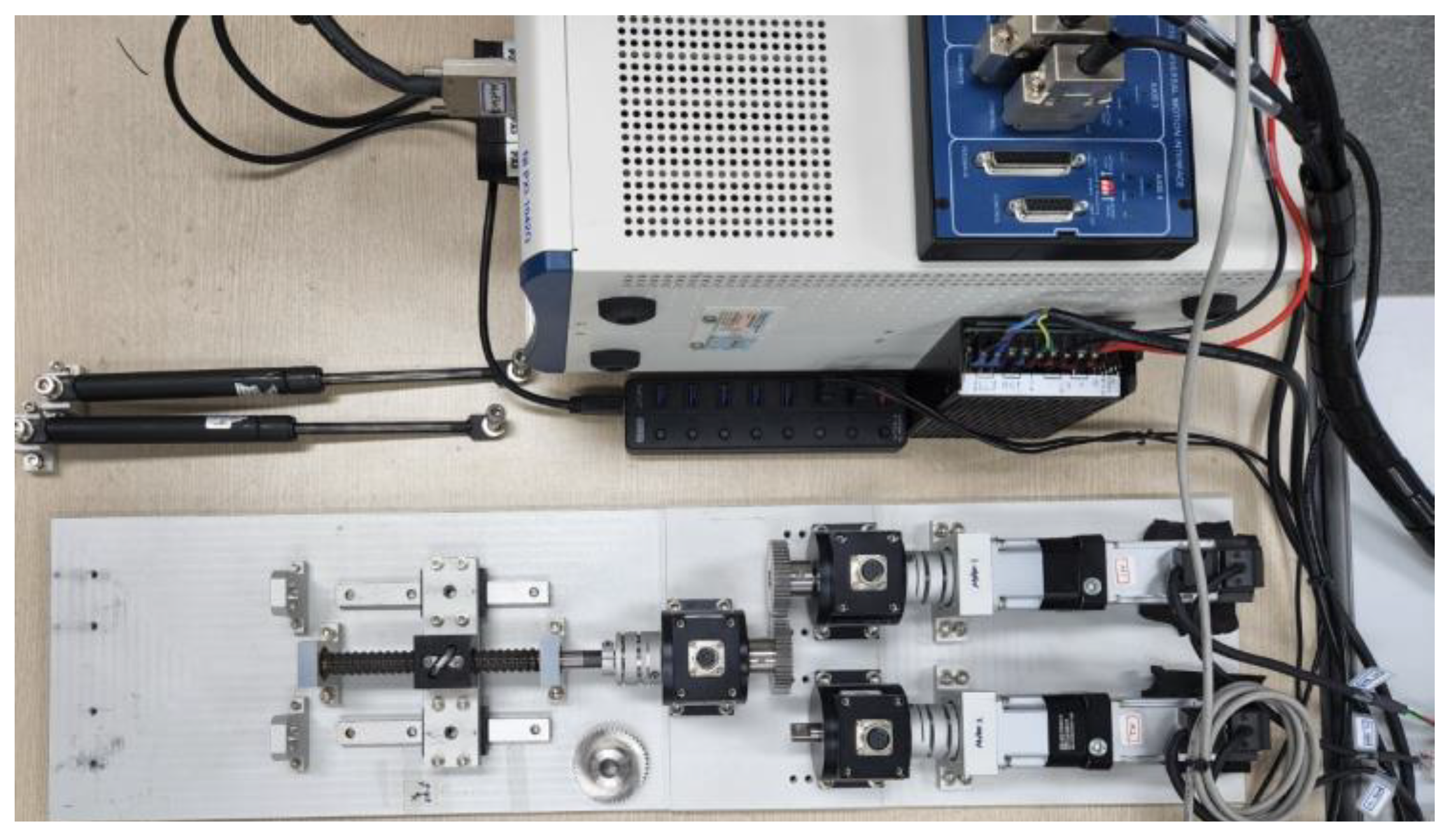

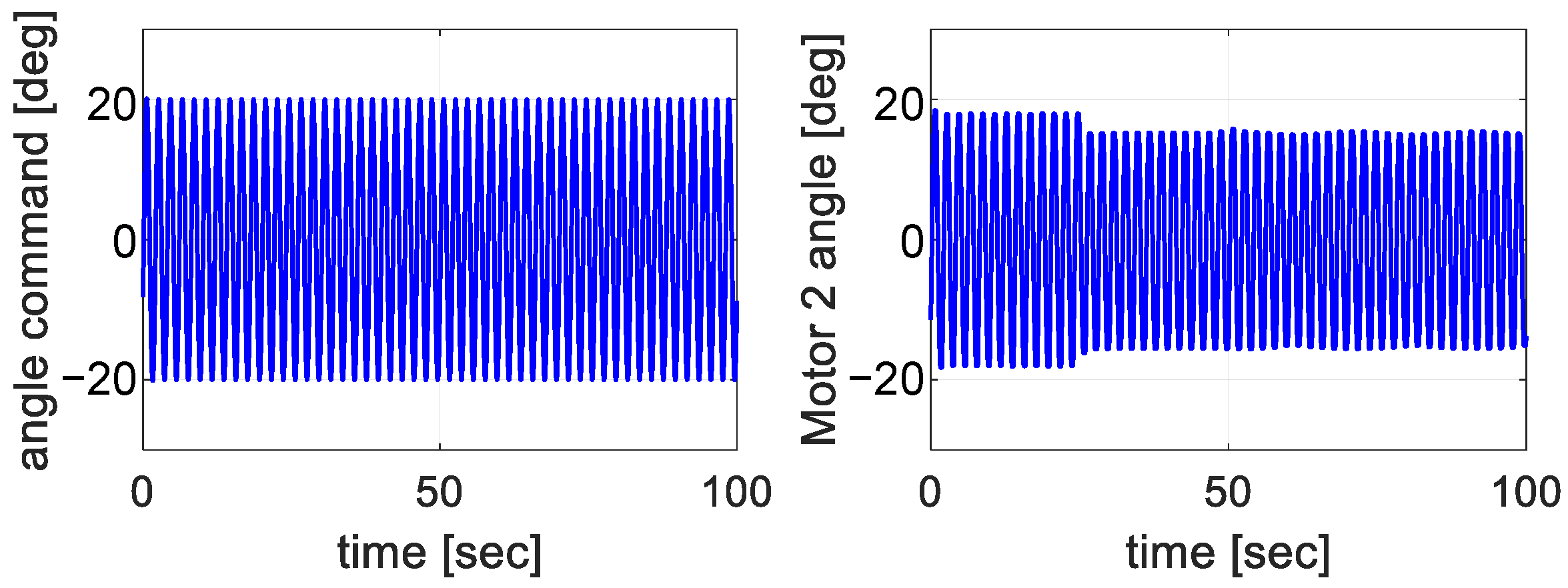

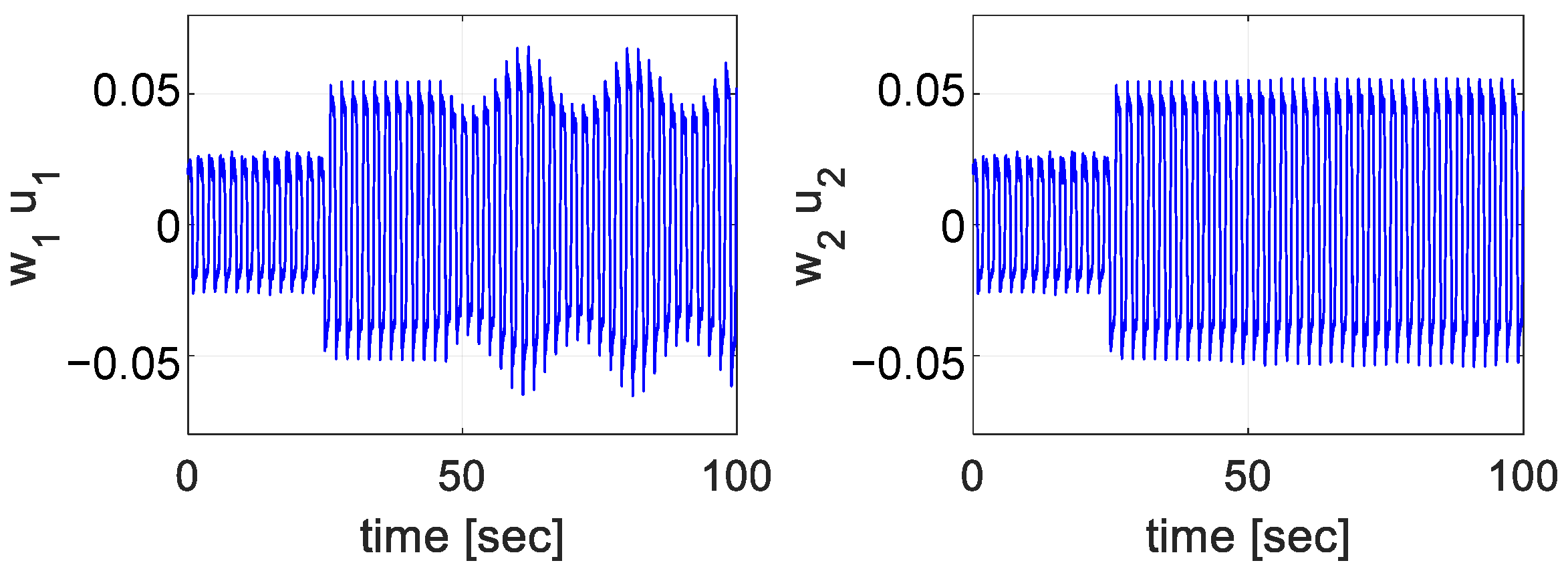

3.3. Simulation Studies

- For C, if |A − B| exceeds a threshold, a fault has occurred. For D, if A/B or B/A is above a threshold, a fault has occurred.

- For C, Motor 1 is faulty if A > B, and Motor 2 is faulty if otherwise. For D, Motor 1 is faulty if A/B > 1, and Motor 2 is faulty if otherwise.

3.4. Discussion

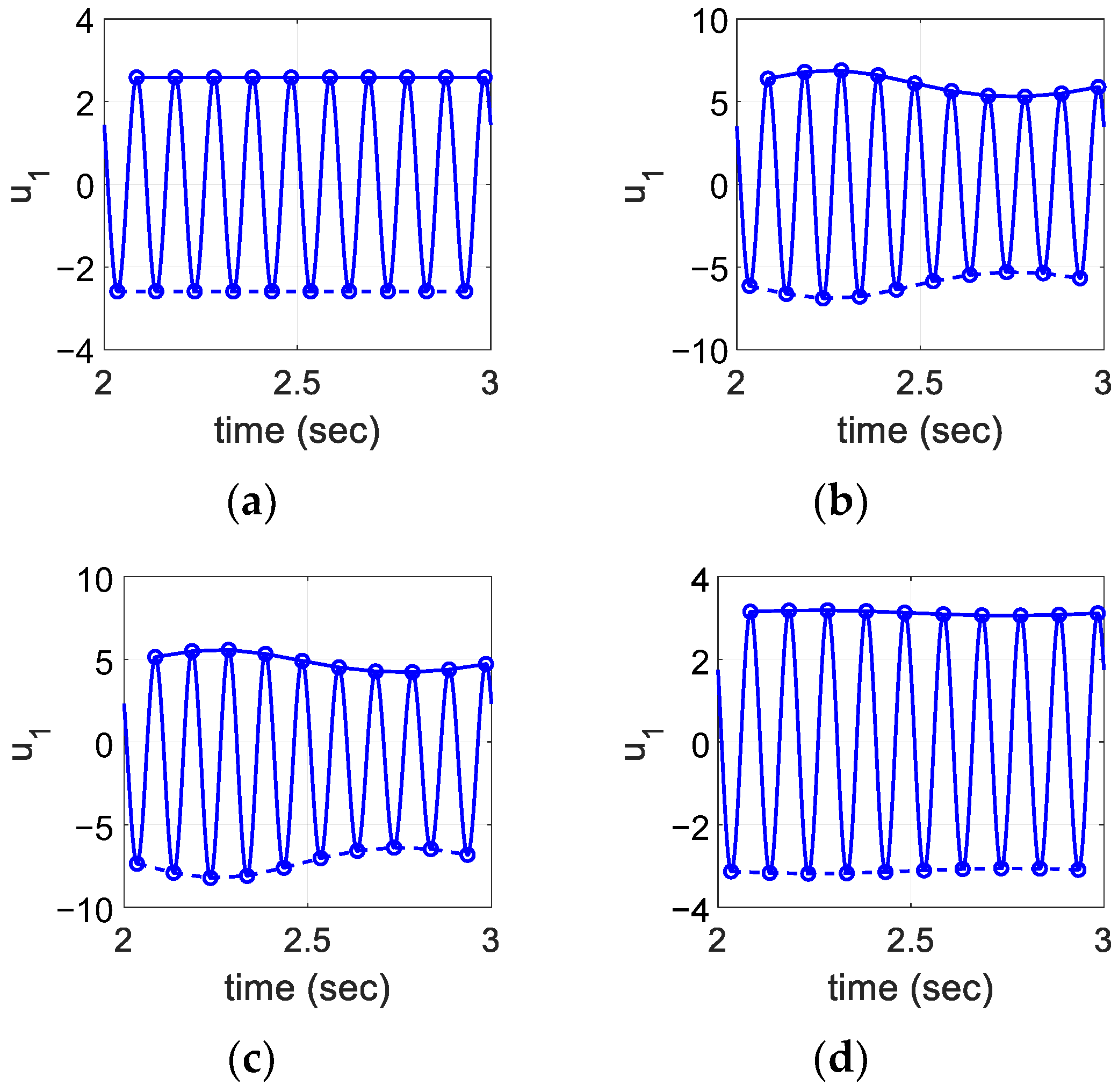

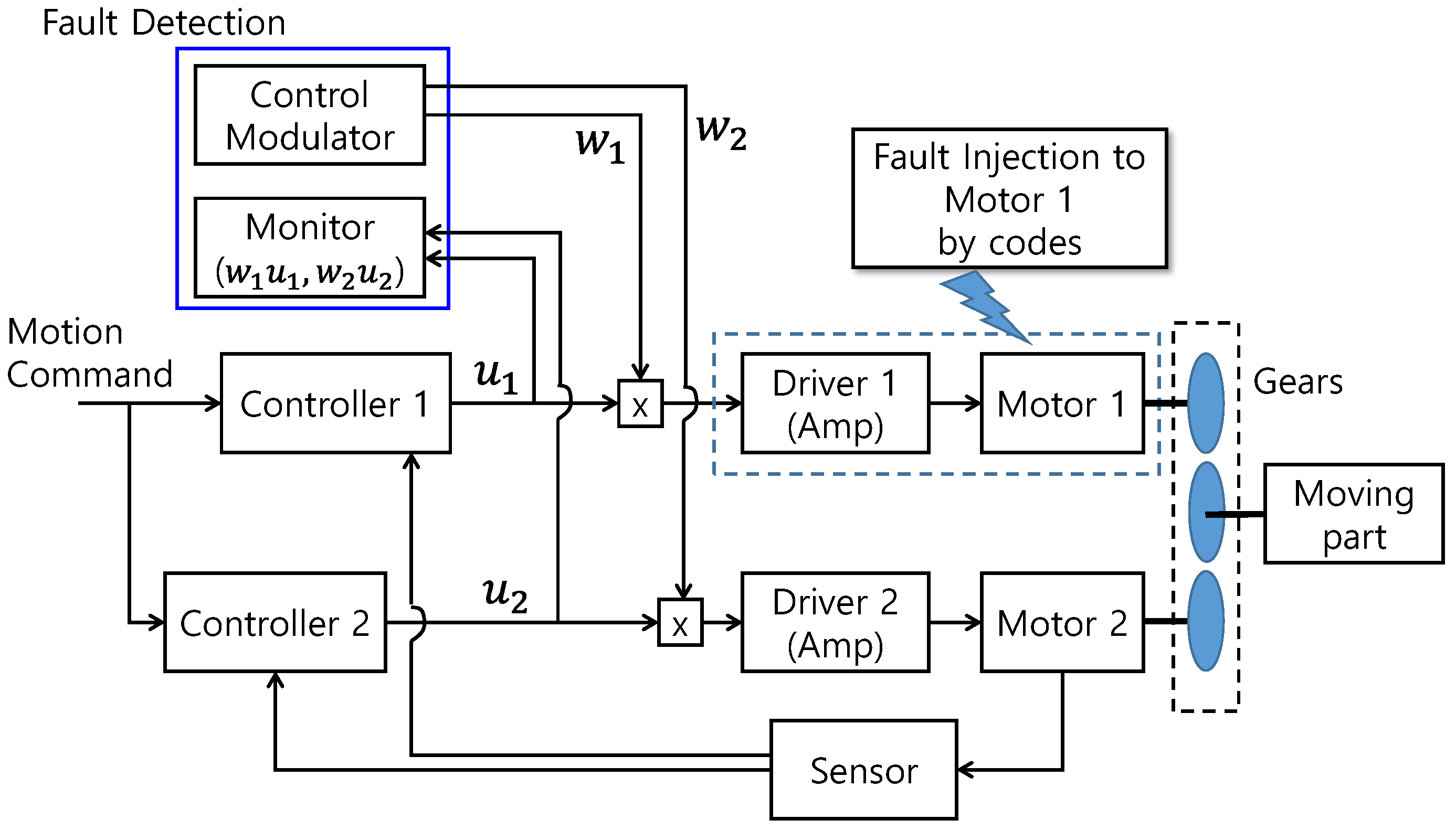

4. Experiments with Servo Motors

4.1. Test Equipment and Conditions

4.2. Test Results

4.3. Discussion

5. Conclusions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zolghadri, A.; Henry, D.; Cieslak, J.; Efimov, D.; Goupil, P. Fault Diagnosis and Fault-Tolerant Control and Guidance for Aerospace Vehicles; Springer: London, UK, 2014; pp. 1–27. [Google Scholar]

- Monteriù, A.; Freddi, A.; Longhi, S. (Eds.) Fault Diagnosis and Fault-Tolerant Control of Robotic and Autonomous Systems; IET: London, UK, 2020. [Google Scholar]

- Huang, C.; Naghdy, F.; Du, H.; Huang, H. Fault tolerant steer-by-wire systems: An overview. Annu. Rev. Contr. 2019, 47, 98–111. [Google Scholar] [CrossRef]

- Zhang, W.; Yang, X.; Xu, Z.; Zhang, W.; Yang, L.; Liu, X. An adaptive fault-tolerant control method for robot manipulators. Int. J. Control. Autom. Syst. 2021, 19, 3983–3995. [Google Scholar] [CrossRef]

- Maré, J.; Fu, J. Review on signal-by-wire and power-by-wire actuation for more electric aircraft. Chin. J. Aeronaut. 2017, 30, 857–870. [Google Scholar] [CrossRef]

- Song, K.; Yeo, H.; Moon, J. Approach control concepts and optimal vertiport airspace design for urban air mobility (UAM) operation. Int. J. Aeronaut. Space Sci. 2021, 22, 982–994. [Google Scholar] [CrossRef]

- Jiang, X.; Wang, S.; Li, Q.; Gao, Y. Design and optimization of dual-winding fault-tolerant permanent magnet motor. CES Trans. Electr. Mach. Syst. 2019, 3, 45–53. [Google Scholar] [CrossRef]

- Jiang, X.; Huang, W.; Cao, R.; Hao, Z.; Jiang, W. Electric drive system of dual winding fault tolerant permanent magnet motor for aerospace applications. IEEE Trans. Ind. Electron. 2015, 62, 7322–7330. [Google Scholar] [CrossRef]

- Gao, Y.; Ma, J.; Chen, Q.; Wu, Y. Characteristic model-based adaptive fault tolerant control for four motor synchronization systems considering actuator failure. Int. J. Control. Autom. Syst. 2021, 19, 4010–4024. [Google Scholar] [CrossRef]

- Ferdowsi, H.; Cai, J.; Jagannathan, S. Actuator and sensor fault detection and failure prediction for systems with multi-dimensional nonlinear partial differential equations. Int. J. Control. Autom. Syst. 2022, 20, 789–802. [Google Scholar] [CrossRef]

- Xu, Q.; Lee, K.-M.; Zhou, H.; Yang, H.-Y. Model-based fault detection and isolation scheme for a rudder servo system. IEEE Trans. Ind. Electron. 2015, 62, 2384–2396. [Google Scholar] [CrossRef]

- Park, B.; Park, B.G.; Kim, T.S.; Ryu, J.S.; Lee, B.K.; Hyun, D.S. Fault tolerant system under open phase fault for BLDC motor drives. In Proceedings of the 2006 37th IEEE Power Electronics Specialists Conference, Jeju, Korea, 18–22 June 2006; pp. 1–6. [Google Scholar]

- Aqil, M.; Hur, J. Multiple sensor fault detection algorithm for fault tolerant control of BLDC motor. Electronics 2021, 10, 1038. [Google Scholar] [CrossRef]

- Kim, Y.; Bae, H.; Kim, S.; Vachtsevanos, G. Fault diagnosis of ac servo motor with current signals based on wavelet decomposition and template matching methods. In Proceedings of the 17th World Congress IFAC, Seoul, Korea, 6–11 July 2008; pp. 7239–7244. [Google Scholar]

- Purbowaskito, W.; Wu, P.; Lan, C. Permanent magnet synchronous motor driving mechanical transmission fault detection and identification: A model-based diagnosis approach. Electronics 2022, 11, 1356. [Google Scholar] [CrossRef]

- He, L.; Chen, G.Y.; Zheng, H.Y. Fault tolerant control method of dual steering actuator motors for steer-by-wire system. Int. J. Automot. Technol. 2015, 16, 977–987. [Google Scholar] [CrossRef]

- Zou, Y.; Zhang, Y.; Mao, H. Fault diagnosis on the bearing of traction motor in high-speed trains based on deep learning. Alex. Eng. J. 2021, 60, 1209–1219. [Google Scholar] [CrossRef]

- Zhao, H.; Liu, J.; Chen, H.; Chen, J.; Li, Y.; Xu, J.; Deng, W. Intelligent diagnosis using continuous wavelet transform and gauss convolutional deep belief network. IEEE Trans. Reliab. 2022, 1–11. [Google Scholar] [CrossRef]

- Zhaoyang, F.; Jinglin, L. Fault diagnosis of dual-redundancy BLDC motor. In Proceedings of the 2015 18th International Conference on Electrical Machines and Systems, Pattaya, Thailand, 25–28 October 2015; pp. 1209–1213. [Google Scholar]

- Guo, F.; Ren, X.; Li, Z.; Han, C. Kalman filter based fault detection of dual motor systems. In Proceedings of the 36th Chinese Control Conference, Dalian, China, 26–28 July 2017. [Google Scholar]

- Jiang, X.; Huang, W.; Cao, R.; Zhu, P.; Jiang, W. Open-circuit fault diagnosis of a dual-winding fault-tolerant permanent magnet motor drive for aerospace applications. In Proceedings of the 2015 18th International Conference on Electrical Machines and Systems, Pattaya, Thailand, 25–28 October 2015; pp. 1204–1208. [Google Scholar]

- Noh, Y.; Kim, W.; Lee, J. The optimal current ratio control of redundant electric drive systems and diagnostic strategies for disagreement. IEEE Access 2021, 9, 32115–32130. [Google Scholar] [CrossRef]

- Kim, Y.; Heo, H.; Park, J.; Kim, J. Fault tolerant control methods for dual type independent multi-phase bldc motor under the open-switch fault conditions. J. Electr. Eng. Technol. 2018, 13, 722–732. [Google Scholar]

- Jin, J. Dynamic models of blade pitch control system driven by electro-mechanical actuator. J. Korean Soc. Aeronaut. Space Sci. 2022, 50, 111–118. [Google Scholar]

- Available online: https://en.wikipedia.org/wiki/Roller_screw (accessed on 1 October 2022).

- Kim, S. Electric Motor Control—DC, AC, and BLDC Motors; Elsevier Science: Amsterdam, The Netherlands, 2017. [Google Scholar]

| Parameters | Values | Unit | Parameters | Values | Unit |

|---|---|---|---|---|---|

| 114 | kg | 100 | - | ||

| 11.4 | kg/s | 34.2 | - | ||

| rad/s | 859.5 | - | |||

| 1 | Nm/A | 0.0024 | m |

| Cases | Boundary | (A) | (B) | |A − B| (C) | A/B (D) |

|---|---|---|---|---|---|

| Normal | U | 0.506 | 0.506 | 0 | 1.00 |

| L | 0.515 | 0.515 | 0 | 1.00 | |

| (U + L)/2 | 0.510 | 0.510 | 0 | 1.00 | |

| Zero output | U | 2.775 | 0.393 | 2.38 | 7.06 |

| L | 2.808 | 0.378 | 2.43 | 7.43 | |

| (U + L)/2 | 2.791 | 0.386 | 2.41 | 7.23 | |

| Fixed output | U | 2.304 | 0.393 | 1.91 | 5.86 |

| L | 3.288 | 0.378 | 2.91 | 8.70 | |

| (U + L)/2 | 2.796 | 0.386 | 2.41 | 7.24 | |

| Scaled -down | U | 0.736 | 0.484 | 0.25 | 1.52 |

| L | 0.748 | 0.494 | 0.25 | 1.51 | |

| (U + L)/2 | 0.742 | 0.489 | 0.25 | 1.52 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, J. Fault Detection of an Actuator with Dual Type Motors and One Common Motion Sensor. Electronics 2022, 11, 3338. https://doi.org/10.3390/electronics11203338

Jin J. Fault Detection of an Actuator with Dual Type Motors and One Common Motion Sensor. Electronics. 2022; 11(20):3338. https://doi.org/10.3390/electronics11203338

Chicago/Turabian StyleJin, Jaehyun. 2022. "Fault Detection of an Actuator with Dual Type Motors and One Common Motion Sensor" Electronics 11, no. 20: 3338. https://doi.org/10.3390/electronics11203338

APA StyleJin, J. (2022). Fault Detection of an Actuator with Dual Type Motors and One Common Motion Sensor. Electronics, 11(20), 3338. https://doi.org/10.3390/electronics11203338