Managed Evolution of Automotive Software Product Line Architectures: A Systematic Literature Study

Abstract

1. Introduction

1.1. Research Approach and Contribution

1.2. Outline

2. Related Work and Background

2.1. Related Work

2.1.1. Automotive Software Engineering

2.1.2. Software Product Line Engineering

2.2. Conceptual Model for Managed Evolution of Automotive Software Product Line Architectures

3. Research Design

3.1. Research Method

- Step 1

- In the first step, we analyzed the scoping study [13] and carried out a data cleaning based on the inclusion/exclusion criteria resulting from the research questions.

- Step 2

- In the second step, we removed multiple occurrences of papers in the data set following the steps described in [37].

- Step 3

- On order to include further relevant papers from 2016 to 2021, we collected papers by defining and applying a search string. Similar to steps 1 and 2, we carried out a data cleaning on the collected papers.

- Step 4

- In the fourth step, we read the papers and applied the rigor-relevance model as proposed by Ivarsson and Gorschek [38].

- Step 5

- The fifth step comprised a quality assessment following the approach described in [39] (see also Appendix B).

- Step 6

- In the sixth step, we prepared the in-depth review. In this regard, we used a refined conceptual model for software product lines [34], which we used to further classify the papers in the data set.

- Step 7

- Finally, we used the aforementioned conceptual model and the categorized papers to conduct the in-depth review to answer the research questions.

3.2. Research Questions

3.3. Data Collection Procedures

3.3.1. Overview of the Scoping Study

3.3.2. Study Selection from the Scoping Study

- (1)

- Analyze the scoping study’s data and identify all papers on software product lines (incl. synonyms):

- (a)

- Selection of papers based on title and abstract;

- (b)

- Selection based on keywords (while testing the selection criteria, we decided to exclude the keywords reusability, reuse, derive, and feature, since they generated too many false positives) (incl. variants, upper/lower case, etc.): SPL, family, reference architecture, variability, variant model, variability management, feature model, feature tree, feature-oriented, derivate;

- (c)

- Result: This stage resulted into 87 paper (candidates); most of the papers selected are in the REU group (Table 3).

- (2)

- Rating of the study candidates (Section 3.3.2)

- (a)

- Application of the rigor-relevance model [38];

- (b)

- Definition of a threshold and selection of papers;

- (c)

- Final data cleaning and preparation of the in-depth analysis.

- (3)

- In-depth analysis (Section 3.4)

3.3.3. Collection and Selection of Papers from 2016 to 2021

- (1)

- Definition of a suitable search string.

- (2)

- Result:“automotive software” AND “software product line”.

- (3)

- Application of the search string to Google Scholar for the years 2016–2021.

- (4)

- Result: This stage resulted in 263 papers (candidates).

- (5)

- Selection of papers based on title and abstract, done by two reviewers.

- (6)

- Result: This stage resulted in 20 papers (candidates).

3.3.4. Final Paper Selection

- (1)

- All high-quality papers (i.e., high-scored papers) are in the result set;

- (2)

- Papers that have a high relevance score but a poor rigor score are included;

- (3)

- Medium-scored but balanced papers are included.

3.4. Analysis and Validity Procedures

- Category 1

- This category includes those papers for which all five researchers agreed that a study has a major contribution in a specific category. Finally, 8 papers were assigned to this category.

- Category 2

- This category includes those papers for which three or four researchers agreed that a study has a major contribution in a specific category. Finally, 30 papers were assigned to this category.

- Category 3

- This category includes those papers for which one or two researchers only agreed that a study has a major contribution in a specific category. Finally, 13 papers were assigned to this category.

4. Study Results and Discussion

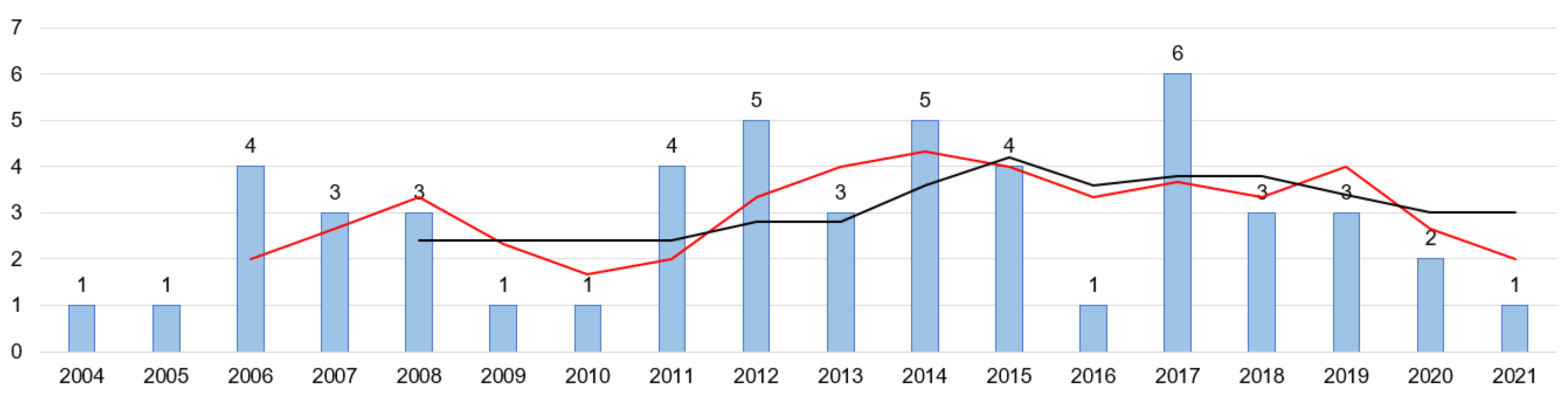

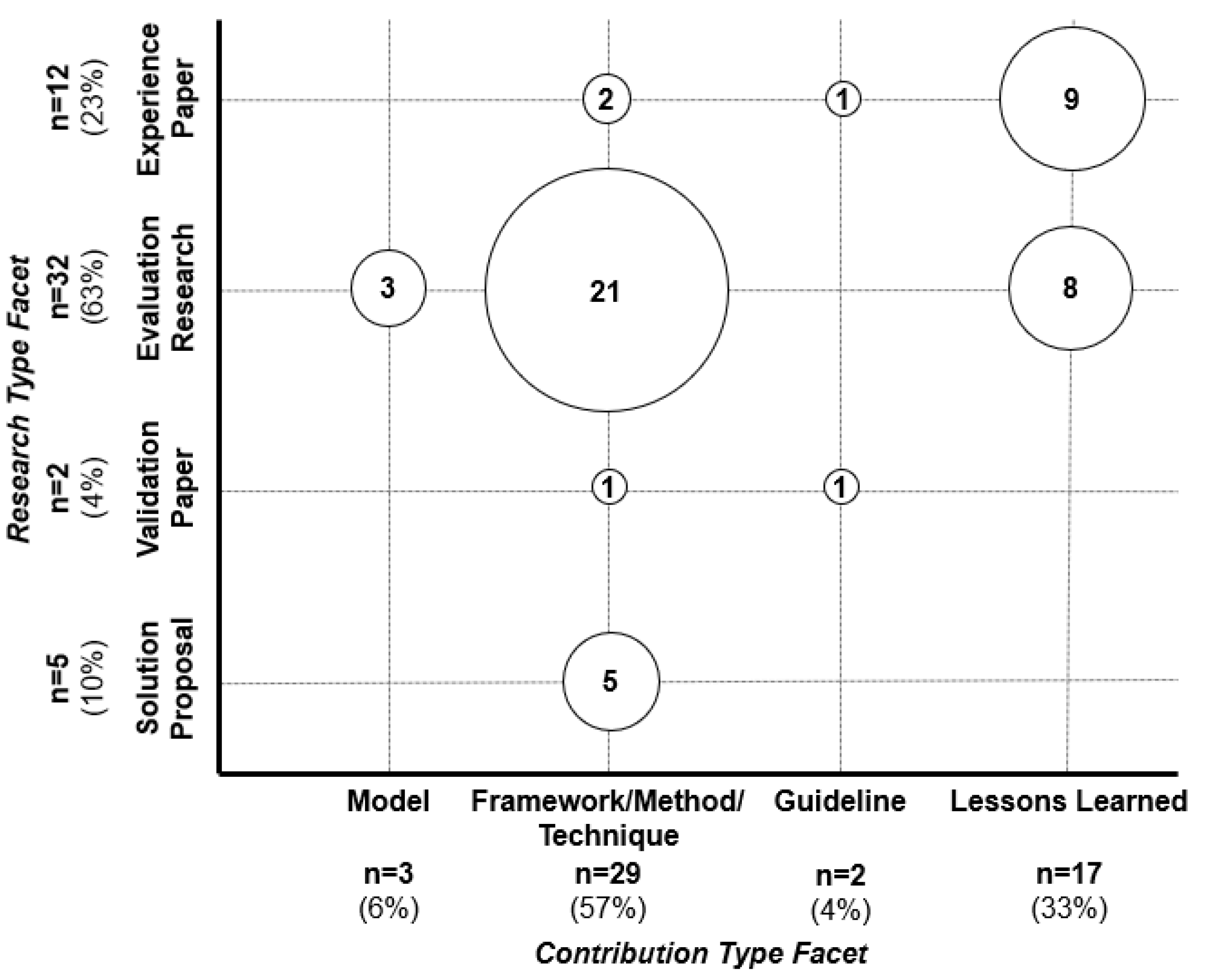

4.1. Result Overview

4.2. State of the Art in Holistic Approaches for Managed Evolution of Automotive Software Product Lines

4.3. Methods and Techniques to Implement Automotive Software Product Lines

4.3.1. Overview of Methods and Techniques Used for Automotive Software Product Lines

4.3.2. Architecture Evolution Process

4.3.3. Cost/Effort Estimation

4.3.4. Safety Analysis

4.3.5. Description Languages

4.3.6. Architecture Reengineering

4.3.7. Model Transformation

4.3.8. Model-Based Requirements Engineering

4.3.9. Overall Approach/Process

4.3.10. Reference Architectures

4.3.11. Software Product Line Merging

4.3.12. Testing/Verification

4.3.13. Variability Management

4.3.14. Agile Software Development

4.4. Discussion

4.4.1. RQ1: What Is the Current State of the Art in Holistic Approaches for Managed Evolution of Automotive Software Product Lines?

4.4.2. RQ2: What Particular Methods and Techniques Are Used to Implement a Managed Evolution of Automotive Software Product Lines?

4.5. Threats to Validity

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ADAS | Advanced Driver Assistant System |

| AGR | Agreement Processes |

| AORE | Aspect-Oriented Requirements Engineering |

| ATL | ATLAS Transformation Language |

| CBSD | Component-Based Software Development |

| CSP | Constraint Satisfaction Problems |

| CTF | Contribution Type Facet |

| CURE | Configuration Understanding and REmedy |

| DSE | Design Space Exploration |

| EAP | Evolutionary Architecture Processes |

| eCCS | Enhanced Cruise Control System |

| ECU | Electronic Control Unit |

| ETL | Epsilon Transformation Language |

| FBVM | Feature-Based Variability Management |

| FMEA | Failure Mode and Effects Analysis |

| FSMv | Finite State Machines with Variability |

| GReAT | Graph Rewrite And Transformation |

| MBT | Model-Based Testing |

| NFR | Non-Functional Requirements |

| OEM | Original Equipment Manufacturer |

| ORG | Organizational Project-Enabling Processes |

| P | Product |

| PFP | Process-Family-Points |

| PL | Product Line |

| PLA | Product Line Architecture |

| PLE | Product Line Engineering |

| PLP | Product Line Practice |

| PLUS | Product Line UML-Based Software Engineering |

| PRO | Project Processes |

| RAP | Revolutionary Architecture Processes |

| REU | Software Reuse Processes |

| RG | Research Question |

| ROI | Return on Investment |

| RTF | Research Type Facet |

| SBSE | Search-Based Software Engineering |

| SPL | Software Product Line |

| SRGM | Software Reliability Growth Model |

| SUP | Software Support Processes |

Appendix A. Primary Studies

| Id | Ref | Title | Summary |

|---|---|---|---|

| P8 | [40] | A component-based process for developing automotive ECU software | Definition of variability types and variation points for ECUs and a component based development process for developing ECUs. |

| P22 | [41] | A model-based approach to innovation management of automotive control systems | Model-based approach to innovation management of automotive systems focusing on requirements based innovation, and on technology based innovation. |

| P43 | [42] | A Survey on the Benefits and Drawbacks of AUTOSAR | Survey paper, which aims to gather evidence on AUTOSAR. |

| P71 | [43] | An unadjusted size measurement of embedded software system families and its validation | Metrics to measure the size of a system family oriented software development for estimation of development costs. |

| P72 | [44] | Analysing defect inflow distribution of automotive software projects | Approach for selecting the appropriate SRGM (software reliability growth model) from more than 100 possible SRGMs using statistical methods. |

| P79 | [45] | AORE (aspect-oriented requirements engineering) methodology for automotive software product lines | AORE (aspect-oriented requirements engineering) methodology to model functional and non-functional requirements of automotive software systems of multiple product lines aligned on a safety-critical distributed real-time architecture. |

| P86 | [46] | Architecting automotive product lines: Industrial practice | Study that shows how architects work with maintaining and changing PLA. |

| P90 | [47] | Architecture for embedded open software ecosystems | Open software ecosystems for embedded systems based on architectural cornerstones and continuous integration; reference architecture design. |

| P94 | [48] | Assessing merge potential of existing engine control systems into a product line | Approach to assess potential to merge existing systems into a product line. Procedure for performing the migration. |

| P100 | [49] | Automated diagnosis of feature model configurations | Constraint-based diagnostic approach for debugging errors in feature model configurations, and which can also be applied for software configuration evolution. |

| P129 | [50] | Automotive system development using reference architectures | Development process for E/E architectures using reference architectures: The process describes how to create and maintain the architecture and how to refine this into a product-specific architecture in product development projects. |

| P173 | [51] | Defining a strategy to introduce a software product line using existing embedded systems | Approach to assess potential to merge existing systems into a product line. |

| P215 | [52] | Evolutionary architecting of embedded automotive product lines: An industrial case study | Investigation of the evolutionary and revolutionary system architecture process in practice and the interplay between both. |

| P218 | [53] | Experience of Introducing Reference Architectures in the Development of Automotive Electronic Systems | They describe the evolution of the architecture development process at Volvo Cars. Specifically, they explain the background to why they introduced an architecture centred development process and how they apply this in practice. The result of the process is a reference architecture as a basis for the design of several projects. |

| P220 | [54] | Experience with variability management in requirement specifications | Feature-based variability management (FBVM) approach: The requirements are first mapped to features. Then, the specification author defines the product variants by selecting the relevant features. For a new specification document, the set of relevant product variants now defines all necessary requirements. |

| P221 | [55] | Experiences from a large scale software product line merger in the automotive domain | Experience report: Introduction of SPL approach at Bosch Gasoline Systems. |

| P223 | [56] | Experiences of applying model-based analysis to support the development of automotive software product lines | Prototypical framework for the analysis of embedded systems product lines, including view-supported analyses of Simulink models, evolution aspects of variability, and traceability. |

| P279 | [57] | IVaM: Implicit variant modeling and management for automotive embedded systems | Graph-based approach for the modeling and analysis of functional variants. They apply design space exploration (DSE) techniques and use knowledge based modeling approaches. |

| P281 | [58] | Lightweight introduction of EAST-ADL2 in an automotive software product line | Introduction of EAST-ADL2 in an automotive SPL, including mapping from AUTOSAR to EAST-ADL2, as well as implementation of a single point of control with respect to variability. |

| P285 | [59] | Managing complexity and variability of a model-based embedded software product line | Framework for model-based product lines of embedded systems, including the following methods: creation of a model-based PL from a historically grown product family, analyze information by context-specific views, and efficient product derivation. |

| P289 | [60] | Mastering Erosion of Software Architecture in Automotive Software Product Lines | Approach for architecture regeneration applied to a real world example. |

| P300 | [61] | Model transformation for high-integrity software development in derivative vehicle control system design | Study of applying model transformation to high-integrity software development for derivative vehicle systems. |

| P310 | [62] | Model-based pairwise testing for feature interaction coverage in software product line engineering | Pairwise testing in the SPL context: Mapping between feature models and a reusable test model in the form of statecharts. Investigation of the relationship between feature-based coverage criteria and model-based coverage criteria. |

| P332 | [63] | On hardware variability and the relation to software variability | Approach to relate a hardware variability and a software variability model using properties (hierarchically ordered name-value pairs) and a tool-based matching algorithm. |

| P343 | [64] | Optimizing the selection of representative configurations in verification of evolving product lines of distributed embedded systems | Method for determining a minimal set of configurations such that the successful verification of this small set implies the correctness of the entire product family. |

| P365 | [65] | Relating requirement and design variabilities | Method to relate the variability from design to requirement based on a conformance relation between design and requirement models of SPL’s features. |

| P377 | [66] | Reuse of Software in Distributed Embedded Automotive Systems | Framework for the reuse of application software components for automotive manufacturers, based on the PLP process model: Process part, development of modularized software components, and product development by using a standard software core. |

| P404 | [67] | Software behavior description of real-time embedded systems in component based software development | Concept to support the functional view (software behavior, e.g., “signal flows” and “mode dependent signal flows”) at the component level. |

| P468 | [68] | Towards integrated variant management in global software engineering: An experience report | Integrated variant management for building a common SPL by distributed teams. Parts of the method: Common development process with integrated feature model, and common configuration and revision control. |

| P493 | [69] | Variation management for software product lines with cumulative coverage of feature interactions | Variant management with respect to pair-wise feature interaction. |

| P503 | [70] | Why does it take that long? Establishing Product Lines in the Automotive Domain | Experience report: Introduction of SPL approach at Bosch Gasoline Systems, consisting of initial designing of the SPL, and long-term product line design and development including quality management. |

| P580 | [71] | A process to support a systematic change impact analysis of variability and safety in automotive functions | Process of an integrated, model-based change impact analysis. This process is integrating model-based development, SPL engineering, and safety engineering. |

| P588 | [72] | A model-based approach to support the automatic safety analysis of multiple product line products | Model-based approach to support the generation of safety analysis assets (fault trees and FMEA analysis) addressing multiple SPL products. |

| P589 | [73] | Supporting the automated generation of modular product line safety cases | Approach for supporting largely automated generation of modular and reusable PL safety case architectures from the information provided by SPL feature modeling and model-based safety analysis. |

| P660 | [74] | Evaluating flexibility in embedded automotive product lines using real options | Evaluation process for practitioners using Real Options Theory that provides a way of valuing system designs and enables to think about the future in a systematic manner. |

| E8 | [75] | Automotive Software Product Line Architecture Evolution: Extracting, Designing and Managing Architectural Concepts | A method that combines the following techniques: architectural concept; quality measurement technique; evolutionary incremental development process. Goal: Overall development cycle for managed evolution of automotive PLAs. |

| E53 | [76] | Control Mechanisms for Managed Evolution of Automotive Software Product Line Architectures | (1) Description language and its meta model for the specification of the software product line architecture and the software architecture of the corresponding products. Goal: Architecture conformance checking. |

| E59 | [77] | Towards a Model-Driven Product Line Engineering Process – An Industrial Case Study | They identify and define a product line engineering process that is aligned with model-based systems engineering activities at the engines control department of Volvo CE; Discuss the implications of the migration from the current development process to a model-based product line engineering-oriented process. |

| E66 | [78] | Extractive Software Product Line Engineering Using Model-Based Delta Module Generation | Procedure that uses the extracted variability information to generate a transformational delta-oriented SPL fully automatically. |

| E127 | [79] | A Multiple Product Line Development Method Based on Variability Structure Analysis | Structural analysis method of variability for multiple product lines using an extended model of OVM. Agile application development method to refine development items according to variability dependency based on the analysis. |

| E130 | [80] | Agile Tames Product Line Variability: An Agile Development Method for Multiple Product Lines of Automotive Software Systems | Agile development method for multiple product lines by iteratively reusing process assets in application engineering. |

| E132 | [81] | An Industrial Case Study for Adopting Software Product Lines in Automotive Industry | A practical evolution-based approach to migrate and evolve a set of variants of a given product into an SPL. |

| E173 | [82] | Structuring automotive product lines and feature models: an exploratory study at Opel | Guidance to practitioners how to structure automotive product lines and their feature models. |

| E175 | [83] | Real-life Challenges on Agile Software Product Lines in Automotive | Survey based on 16 semi-structured interviews from the automotive domain, an internal workshop with 40 participants and a discussion round on ESE congress 2016. |

| E177 | [84] | Combining Agile Development and Software Product Lines in Automotive: Challenges and Recommendations | Combines the results of two previous publications and extends them by recommendations to combine agile software development and SPLs. |

| E178 | [85] | Mapping Agility to Automotive Software Product Line Concerns | Based on previous work and two workshops, agility is mapped to software product line concerns. |

| E179 | [86] | Interface-Based Similarity Analysis of Software Components for the Automotive Industry | An automated syntactical similarity analysis for software component interfaces is proposed to support the software product line extraction and maintenance. |

| E183 | [87] | Applying Product Line Testing for the Electric Drive System | They present the TIGRE methodology. Goal: Reduce redundant testing effort by intelligent planning and reporting of the test execution. |

| E187 | [88] | Applying Declarative Analysis to Software Product Line Models: An Industrial Study | Approach to lifting behavior alteration analysis, including configurable visualization of analysis results. |

| E224 | [89] | Risk-Based Compatibility Analysis in Automotive Systems Engineering | Risk-based change-impact analysis to identify system variants relevant for retesting after an update. |

| E230 | [90] | Exploring Automotive Stakeholder Requirements for Architecture Optimization Support | Interviews with the automotive industry experts. Goal: Research the usefulness (or necessity) of automated PLA design space exploration for current industrial practice. |

Appendix B. Data Extraction and Dataset Quality Assessment

| Category | Questions |

|---|---|

| Data Extraction | The data extraction was performed using the following key questions:

|

| Quality Assessment | The quality assessment was carried out following the list of questions from Kitchenham and Charters ([39], p. 28). Each question was rated on a 5-point scale with: 1 = not fulfilled at all, 2 = partially fulfilled, 3 = basically fulfilled, 4 = fulfilled to a large extent, and 5 = completely fulfilled and very well implemented/documented. Please note that the numbers for the individual questions are taken from ([39], p. 28). In Table A3, we refer to these numbers to present the quality assessment for the particular studies. |

| Paper | Ref | 1 | 1.1 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 18 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P8 | [40] | 3 | 3 | 3 | 3 | 4 | 3 | 4 | 4 | 3 | 3 | 3 | 2 | 2 | 3 | 4 | 3 | 3 |

| P22 | [41] | 4 | 4 | 5 | 3 | 3 | 3 | 2 | 3 | 2 | 3 | 3 | 3 | 3 | 4 | 4 | 3 | 4 |

| P43 | [42] | 5 | 5 | 5 | 4 | 5 | 5 | 4 | 4 | 5 | 5 | 5 | 3 | 4 | 4 | 4 | 4 | 5 |

| P71 | [43] | 5 | 4 | 4 | 3 | 4 | 4 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 4 | 4 | 3 | 4 |

| P72 | [44] | 5 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 5 | 4 | 4 | 5 | 4 | 4 |

| P79 | [45] | 3 | 3 | 3 | 3 | 3 | 2 | 3 | 3 | 2 | 3 | 3 | 2 | 2 | 3 | 3 | 3 | 3 |

| P86 | [46] | 4 | 4 | 4 | 4 | 4 | 4 | 3 | 3 | 4 | 4 | 3 | 3 | 3 | 4 | 4 | 4 | 4 |

| P90 | [47] | 5 | 4 | 4 | 3 | 3 | 4 | 3 | 3 | 4 | 4 | 4 | 4 | 3 | 4 | 4 | 4 | 4 |

| P94 | [48] | 4 | 3 | 4 | 3 | 3 | 3 | 3 | 3 | 2 | 2 | 3 | 2 | 2 | 3 | 3 | 3 | 3 |

| P100 | [49] | 4 | 3 | 4 | 4 | 4 | 5 | 4 | 4 | 5 | 4 | 4 | 4 | 4 | 5 | 5 | 4 | 4 |

| P129 | [50] | 4 | 4 | 5 | 4 | 4 | 5 | 4 | 4 | 4 | 4 | 4 | 4 | 3 | 4 | 4 | 3 | 4 |

| P173 | [51] | 4 | 3 | 4 | 3 | 3 | 3 | 3 | 2 | 2 | 2 | 3 | 3 | 2 | 3 | 3 | 3 | 3 |

| P215 | [52] | 4 | 4 | 5 | 4 | 5 | 4 | 3 | 3 | 4 | 4 | 3 | 4 | 3 | 4 | 4 | 4 | 4 |

| P218 | [53] | 4 | 4 | 4 | 3 | 2 | 3 | 2 | 2 | 3 | 2 | 3 | 4 | 2 | 3 | 3 | 2 | 3 |

| P220 | [54] | 4 | 4 | 4 | 3 | 3 | 2 | 2 | 2 | 3 | 2 | 3 | 3 | 2 | 3 | 3 | 3 | 2 |

| P221 | [55] | 4 | 4 | 3 | 3 | 3 | 3 | 2 | 3 | 2 | 3 | 3 | 2 | 3 | 3 | 3 | 3 | 3 |

| P223 | [56] | 4 | 4 | 3 | 2 | 3 | 3 | 2 | 2 | 2 | 2 | 3 | 3 | 2 | 3 | 3 | 3 | 3 |

| P279 | [57] | 4 | 3 | 4 | 3 | 2 | 3 | 2 | 2 | 2 | 2 | 2 | 3 | 2 | 3 | 3 | 2 | 3 |

| P281 | [58] | 3 | 3 | 3 | 2 | 2 | 3 | 2 | 2 | 2 | 2 | 3 | 3 | 2 | 3 | 3 | 2 | 3 |

| P285 | [59] | 4 | 4 | 4 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 2 | 2 | 3 | 4 | 3 | 3 |

| P289 | [60] | 4 | 4 | 4 | 3 | 2 | 3 | 2 | 3 | 2 | 2 | 3 | 3 | 2 | 3 | 3 | 3 | 3 |

| P300 | [61] | 4 | 3 | 4 | 3 | 3 | 3 | 4 | 3 | 3 | 3 | 3 | 2 | 2 | 3 | 3 | 3 | 3 |

| P310 | [62] | 4 | 4 | 4 | 4 | 3 | 3 | 3 | 3 | 3 | 3 | 2 | 2 | 2 | 3 | 4 | 4 | 3 |

| P332 | [63] | 4 | 4 | 4 | 3 | 4 | 3 | 3 | 3 | 2 | 3 | 3 | 3 | 2 | 3 | 4 | 4 | 3 |

| P343 | [64] | 4 | 4 | 4 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 4 | 3 | 4 |

| P365 | [65] | 4 | 4 | 3 | 3 | 2 | 3 | 2 | 3 | 3 | 3 | 2 | 3 | 3 | 3 | 3 | 3 | 3 |

| P377 | [66] | 4 | 4 | 3 | 2 | 2 | 3 | 3 | 2 | 2 | 3 | 3 | 3 | 2 | 3 | 4 | 3 | 3 |

| P404 | [67] | 4 | 4 | 4 | 3 | 3 | 3 | 3 | 3 | 2 | 3 | 2 | 2 | 2 | 3 | 4 | 3 | 3 |

| P468 | [68] | 4 | 4 | 4 | 4 | 4 | 4 | 3 | 3 | 4 | 3 | 3 | 3 | 2 | 3 | 4 | 3 | 3 |

| P493 | [69] | 4 | 4 | 4 | 3 | 4 | 4 | 3 | 3 | 3 | 4 | 3 | 3 | 4 | 4 | 4 | 4 | 4 |

| P503 | [70] | 3 | 2 | 3 | 2 | 2 | 2 | 1 | 1 | 2 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 2 |

| P580 | [71] | 4 | 4 | 3 | 4 | 4 | 3 | 3 | 4 | 3 | 3 | 3 | 3 | 3 | 3 | 4 | 4 | 4 |

| P588 | [72] | 4 | 4 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 2 | 3 | 3 | 3 | 3 | 3 |

| P589 | [73] | 4 | 4 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 2 | 2 | 3 | 3 | 3 | 3 |

| P660 | [74] | 3 | 3 | 3 | 2 | 3 | 3 | 3 | 3 | 2 | 3 | 2 | 2 | 2 | 3 | 3 | 2 | 3 |

| E8 | [75] | 4 | 4 | 3 | 4 | 3 | 3 | 4 | 2 | 2 | 3 | 3 | 3 | 4 | 3 | 3 | 3 | 4 |

| E53 | [76] | 4 | 4 | 3 | 4 | 3 | 3 | 3 | 4 | 4 | 4 | 3 | 3 | 4 | 4 | 4 | 4 | 4 |

| E59 | [77] | 4 | 3 | 4 | 3 | 3 | 3 | 3 | 3 | 2 | 2 | 3 | 3 | 3 | 3 | 3 | 3 | 4 |

| E66 | [78] | 4 | 3 | 4 | 3 | 2 | 3 | 3 | 3 | 3 | 3 | 3 | 2 | 3 | 3 | 3 | 3 | 4 |

| E127 | [79] | 3 | 3 | 4 | 3 | 2 | 3 | 3 | 4 | 3 | 4 | 3 | 4 | 3 | 4 | 3 | 3 | 4 |

| E130 | [80] | 4 | 4 | 4 | 3 | 3 | 3 | 2 | 2 | 3 | 4 | 3 | 4 | 3 | 3 | 3 | 3 | 3 |

| E132 | [81] | 3 | 3 | 3 | 3 | 2 | 3 | 3 | 4 | 3 | 3 | 3 | 2 | 3 | 2 | 3 | 3 | 3 |

| E173 | [82] | 3 | 4 | 4 | 2 | 3 | 2 | 3 | 3 | 3 | 3 | 3 | 4 | 3 | 3 | 4 | 3 | 3 |

| E175 | [83] | 4 | 4 | 5 | 2 | 3 | 4 | 3 | 2 | 3 | 3 | 3 | 4 | 3 | 3 | 4 | 3 | 3 |

| E177 | [84] | 4 | 4 | 4 | 3 | 2 | 3 | 2 | 2 | 3 | 3 | 2 | 2 | 1 | 3 | 3 | 2 | 3 |

| E178 | [85] | 4 | 4 | 4 | 2 | 3 | 2 | 2 | 3 | 3 | 2 | 3 | 4 | 2 | 3 | 3 | 3 | 3 |

| E179 | [86] | 4 | 4 | 4 | 3 | 2 | 3 | 2 | 2 | 3 | 3 | 2 | 2 | 3 | 3 | 4 | 4 | 3 |

| E183 | [87] | 4 | 5 | 4 | 4 | 4 | 4 | 3 | 4 | 3 | 3 | 3 | 3 | 2 | 2 | 3 | 3 | 3 |

| E187 | [88] | 4 | 4 | 4 | 3 | 3 | 3 | 3 | 4 | 3 | 4 | 3 | 3 | 3 | 4 | 4 | 4 | 4 |

| E224 | [89] | 5 | 4 | 5 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 3 | 4 | 3 | 4 | 4 | 4 | 4 |

| E230 | [90] | 4 | 4 | 4 | 3 | 3 | 4 | 3 | 3 | 4 | 3 | 3 | 3 | 3 | 3 | 4 | 3 | 4 |

References

- Schäuffele, J.; Zurawka, T. Automotive Software Engineering: Grundlagen, Prozesse, Methoden und Werkzeuge Effizient Einsetzen, 4th ed.; Vieweg+Teubner: Berlin, Germany, 2010. [Google Scholar]

- Broy, M.; Pretschner, A.; Salzmann, C.; Stauner, T. Software-Intensive Systems in the Automotive Domain: Challenges for Research and Education; Technical Report 2006-01-1458, SAE Technical Paper; SAE International: Warrendale, PA, USA, 2006. [Google Scholar]

- Bernard, M.; Buckl, C.; Döricht, V.; Fehling, M.; Fiege, L.; von Grolman, H.; Ivandic, N.; Janello, C.; Klein, C.; Kuhn, K.J.; et al. Mehr Software (im) Wagen: Informations-und Kommunikationstechnik (IKT) als Motor der Elektromobilität der Zukunft; fortiss GmbH: München, Germany, 2011. [Google Scholar]

- Broy, M. Challenges in Automotive Software Engineering. In Proceedings of the 28th International Conference on Software Engineering, Shanghai, China, 20–28 May 2006; ACM: New York, NY, USA, 2006; pp. 33–42. [Google Scholar]

- Schulte-Coerne, V.; Thums, A.; Quante, J. Automotive Software: Characteristics and Reengineering Challenges. Softwaretechnik-Trends 2009, 29, 2–40. [Google Scholar]

- Pretschner, A.; Broy, M.; Krüger, I.H.; Stauner, T. Software Engineering for Automotive Systems: A Roadmap. In Proceedings of the FOSE ’07: IEEE Computer Society, 2007 Future of Software Engineering, Washington, DC, USA, 23–25 May 2007; pp. 55–71. [Google Scholar]

- Thiel, S.; Babar, M.A.; Botterweck, G.; O’Brien, L. Software Product Lines in Automotive Systems Engineering. SAE Int. J. Passeng. Cars-Electron. Electr. Syst. 2008, 1, 531–543. [Google Scholar] [CrossRef]

- Macala, R.R.; Stuckey, L.D.; Gross, D.C. Managing Domain-specific, Product-line Development. IEEE Softw. 1996, 13, 57–67. [Google Scholar] [CrossRef]

- Meyer, M.H.; Lehnerd, A.P. The Power of Product Platforms; Free Press: New York, NY, USA, 1997. [Google Scholar]

- Weiss, D.M.; Lai, C.T.R. Software Product-Line Engineering: A Family-Based Software Development Process; Addison-Wesley Longman Publishing Co., Inc.: Boston, MA, USA, 1999. [Google Scholar]

- Clements, P.; Northrop, L. Software Product Lines: Practices and Patterns; Addison Wesley: Boston, MA, USA, 2001. [Google Scholar]

- Pohl, K.; Böckle, G.; Linden, F.v.d. Software Product Line Engineering: Foundations, Principles and Techniques; Springer: New York, NY, USA, 2005. [Google Scholar]

- Haghighatkhah, A.; Banijamali, A.; Pakanen, O.P.; Oivo, M.; Kuvaja, P. Automotive software engineering: A systematic mapping study. J. Syst. Softw. 2017, 128, 25–55. [Google Scholar] [CrossRef]

- Raatikainen, M.; Tiihonen, J.; Männistö, T. Software product lines and variability modeling: A tertiary study. J. Syst. Softw. 2019, 149, 485–510. [Google Scholar] [CrossRef]

- Kitchenham, B.A.; Budgen, D.; Brereton, P. Evidence-Based Software Engineering and Systematic Reviews; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- Petersen, K.; Vakkalanka, S.; Kuzniarz, L. Guidelines for Conducting Systematic Mapping Studies in Software Engineering: An Update. Inf. Softw. Technol. 2015, 64, 1–18. [Google Scholar] [CrossRef]

- Petersen, K.; Feldt, R.; Mujtaba, S.; Mattson, M. Systematic mapping studies in software engineering. In Proceedings of the International Conference on Evaluation and Assessment in Software Engineering, Bari, Italy, 26–27 June 2008; pp. 68–77. [Google Scholar]

- Clarke, S.; Fitzgerald, B.; Nixon, P.; Pohl, K.; Ryan, K.; Sinclair, D.; Thiel, S. The Role of Software Engineering in Future Automotive Systems Development. SAE Int. J. Passeng. Cars-Electron. Electr. Syst. 2008, 1, 544–552. [Google Scholar] [CrossRef]

- Grimm, K. Software technology in an automotive company: Major challenges. In Proceedings of the 25th international conference on Software Engineering, IEEE Computer Society, Portland, OR, USA, 3–10 May 2003; pp. 498–503. [Google Scholar]

- Gruszczynski, B. An overview of the current state of software engineering in embedded automotive electronics. In Proceedings of the 2006 IEEE International Conference on Electro/information Technology, East Lansing, MI, USA, 7–10 May 2006; pp. 377–381. [Google Scholar]

- Fabbrini, F.; Fusani, M.; Lami, G.; Sivera, E. Software engineering in the european automotive industry: Achievements and challenges. In Proceedings of the COMPSAC’08: 32nd Annual IEEE International, Computer Software and Applications, Turku, Finland, 28 July–1 August 2008; pp. 1039–1044. [Google Scholar]

- Antinyan, V. Revealing the complexity of automotive software. In Proceedings of the 28th ACM Joint Meeting on European Software Engineering Conference and Symposium on the Foundations of Software Engineering, Virtual, 8–13 November 2020; Devanbu, P., Ed.; ACM Digital Library; Association for Computing Machinery: New York, NY, USA, 2020; pp. 1525–1528. [Google Scholar] [CrossRef]

- Schmid, K.; Rabiser, R.; Grünbacher, P. A Comparison of Decision Modeling Approaches in Product Lines. In Proceedings of the 5th International Workshop on Variability Modeling of Software-intensive Systems (VaMoS’11), Namur, Belgium, 27–29 January 2011; Heymans, P., Czarnecki, K., Eisenecker, U.W., Eds.; ACM: New York, NY, USA, 2011; pp. 119–126. [Google Scholar]

- Czarnecki, K.; Grünbacher, P.; Rabiser, R.; Schmid, K.; Wasowski, A. Cool Features and Tough Decisions: A Comparison of Variability Modeling Approaches. In Proceedings of the VaMoS ’12: Sixth International Workshop on Variability Modeling of Software-Intensive Systems, Leipzig, Germany, 25–27 January 2012; ACM: New York, NY, USA, 2012; pp. 173–182. [Google Scholar]

- Harman, M.; Jia, Y.; Krinke, J.; Langdon, W.B.; Petke, J.; Zhang, Y. Search Based Software Engineering for Software Product Line Engineering: A Survey and Directions for Future Work. In Proceedings of the SPLC’14: 18th International Software Product Line Conference, Florence, Italy, 15–19 September 2014; ACM: New York, NY, USA, 2014; Volume 1, pp. 5–18. [Google Scholar] [CrossRef]

- Engström, E.; Runeson, P. Software product line testing–A systematic mapping study. Inf. Softw. Technol. 2011, 53, 2–13. [Google Scholar] [CrossRef]

- Lee, J.; Kang, S.; Lee, D. A Survey on Software Product Line Testing. In Proceedings of the 16th International Software Product Line Conference, Salvador, Brazil, 2–7 September 2012; Volume 1, pp. 31–40. [Google Scholar]

- Oster, S.; Wübbeke, A.; Engels, G.; Schürr, A. A Survey of Model-Based Software Product Lines Testing. In Model-Based Testing for Embedded Systems; CRC Press: Boca Raton, FL, USA, 2011; pp. 338–381. [Google Scholar]

- Thüm, T.; Apel, S.; Kästner, C.; Schaefer, I.; Saake, G. A Classification and Survey of Analysis Strategies for Software Product Lines. ACM Comput. Surv. (CSUR) 2014, 47, 6. [Google Scholar] [CrossRef]

- Chen, L.; Ali Babar, M.; Ali, N. Variability Management in Software Product Lines: A Systematic Review. In Proceedings of the SPLC ’09: 13th International Software Product Line Conference, San Francisco, CA, USA, 24–28 August 2009; Carnegie Mellon University: Pittsburgh, PA, USA, 2009; pp. 81–90. [Google Scholar]

- Schobbens, P.Y.; Heymans, P.; Trigaux, J.C. Feature Diagrams: A Survey and a Formal Semantics. In Proceedings of the 14th IEEE International Conference Requirements Engineering, St. Paul, MN, USA, 11–15 September 2006; pp. 139–148. [Google Scholar]

- Chacón-Luna, A.E.; Gutiérrez, A.M.; Galindo, J.A.; Benavides, D. Empirical software product line engineering: A systematic literature review. Inf. Softw. Technol. 2020, 128, 106389. [Google Scholar] [CrossRef]

- Marques, M.; Simmonds, J.; Rossel, P.O.; Bastarrica, M.C. Software product line evolution: A systematic literature review. Inf. Softw. Technol. 2019, 105, 190–208. [Google Scholar] [CrossRef]

- Knieke, C.; Körner, M.; Rausch, A.; Schindler, M.; Strasser, A.; Vogel, M. A Holistic Approach for Managed Evolution of Automotive Software Product Line Architectures. In Proceedings of the ADAPTIVE 2017: Special Track: Managed Adaptive Automotive Product Line Development (MAAPL), Athens, Greece, 19–23 February 2017; pp. 43–52. [Google Scholar]

- Cool, B.; Knieke, C.; Rausch, A.; Schindler, M.; Strasser, A.; Vogel, M.; Brox, O.; Jauns-Seyfried, S. From Product Architectures to a Managed Automotive Software Product Line Architecture. In Proceedings of the SAC’16: 31st Annual ACM Symposium on Applied Computing, Pisa, Italy, 4–8 April 2016; ACM: New York, NY, USA, 2016; pp. 1350–1353. [Google Scholar] [CrossRef]

- de Silva, L.; Balasubramaniam, D. Controlling Software Architecture Erosion: A Survey. J. Syst. Softw. 2012, 85, 132–151. [Google Scholar] [CrossRef]

- Kuhrmann, M.; Fernández, D.M.; Daneva, M. On the pragmatic design of literature studies in software engineering: An experience-based guideline. Empir. Softw. Eng. 2017. [Google Scholar] [CrossRef]

- Ivarsson, M.; Gorschek, T. A method for evaluating rigor and industrial relevance of technology evaluations. Empir. Softw. Eng. 2011, 16, 365–395. [Google Scholar] [CrossRef]

- Kitchenham, B.; Charters, S. Guidelines for Performing Systematic Literature Reviews in Software Engineering; Technical Report EBSE-2007-01; Keele University: Keele, UK, 2007. [Google Scholar]

- Her, J.S.; Choi, S.W.; Cheun, D.W.; Bae, J.S.; Kim, S.D. A Component-Based Process for Developing Automotive ECU Software. Lect. Notes Comput. Sci. 2007, 4589, 358. [Google Scholar]

- Gleirscher, M.; Vogelsang, A.; Fuhrmann, S. A Model-Based Approach to Innovation Management of Automotive Control Systems. In Proceedings of the 2014 IEEE IWSPM 8th International Workshop on Software Product Management (IWSPM), Karlskrona, Sweden, 26 August 2014; pp. 1–10. [Google Scholar]

- Martínez-Fernández, S.; Ayala, C.P.; Franch, X.; Nakagawa, E.Y. A Survey on the Benefits and Drawbacks of AUTOSAR. In Proceedings of the First International Workshop on Automotive Software Architecture, Montreal, QC, Canada, 4 May 2015; pp. 19–26. [Google Scholar]

- Kiebusch, S.; Franczyk, B.; Speck, A. An Unadjusted Size Measurement of Embedded Software System Families and its Validation. Softw. Process. Improv. Pract. 2006, 11, 435–446. [Google Scholar] [CrossRef]

- Rana, R.; Staron, M.; Berger, C.; Hansson, J.; Nilsson, M. Analysing defect inflow distribution of automotive software projects. In Proceedings of the 10th International Conference on Predictive Models in Software Engineering, Turin, Italy, 17 September 2014; pp. 22–31. [Google Scholar]

- Aoyama, M.; Yoshino, A. AORE (Aspect-Oriented Requirements Engineering) Methodology for Automotive Software Product Lines. In Proceedings of the APSEC’08: 15th Asia-Pacific, Software Engineering Conference, Beijing, China, 3–5 December 2008; pp. 203–210. [Google Scholar]

- Gustavsson, H.; Eklund, U. Architecting Automotive Product Lines: Industrial Practice. In Software Product Lines: Going Beyond; Springer: Berlin/Heidelberg, Germany, 2010; pp. 92–105. [Google Scholar]

- Eklund, U.; Bosch, J. Architecture for Embedded Open Software Ecosystems. J. Syst. Softw. 2014, 92, 128–142. [Google Scholar] [CrossRef][Green Version]

- Yoshimura, K.; Ganesan, D.; Muthig, D. Assessing Merge Potential of Existing Engine Control Systems into a Product Line. In Proceedings of the 2006 International Workshop on Software Engineering for Automotive Systems, Shanghai, China, 20–28 May 2006; pp. 61–67. [Google Scholar]

- White, J.; Benavides, D.; Schmidt, D.; Trinidad, P.; Dougherty, B.; Ruiz-Cortés, A. Automated Diagnosis of Feature Model Configurations. J. Syst. Softw. 2010, 83, 1094–1107. [Google Scholar] [CrossRef]

- Lind, K.; Heldal, R. Automotive System Development using Reference Architectures. In Proceedings of the 2012 35th Annual IEEE, Software Engineering Workshop (SEW), Heraclion, Greece, 12–13 October 2012; pp. 42–51. [Google Scholar]

- Yoshimura, K.; Ganesan, D.; Muthig, D. Defining a Strategy to Introduce a Software Product Line Using Existing Embedded Systems. In Proceedings of the 6th ACM & IEEE International Conference on Embedded Software, Seoul, Korea, 22–25 October 2006; pp. 63–72. [Google Scholar]

- Axelsson, J. Evolutionary Architecting of Embedded Automotive Product Lines: An Industrial Case Study. In Proceedings of the Joint Working IEEE/IFIP Conference on Software Architecture, 2009 & European Conference on Software Architecture, WICSA/ECSA 2009, Cambridge, UK, 14–17 September 2009; pp. 101–110. [Google Scholar]

- Eklund, U.; Askerdal, O.; Granholm, J.; Alminger, A.; Axelsson, J. Experience of Introducing Reference Architectures in the Development of Automotive Electronic Systems. In Proceedings of the SEAS ’05: Second International Workshop on Software Engineering for Automotive Systems, St. Louis, MI, USA, 21 May 2005; ACM: New York, NY, USA, 2005; pp. 1–6. [Google Scholar] [CrossRef]

- Boutkova, E. Experience with Variability Management in Requirement Specifications. In Proceedings of the 2011 15th International Software Product Line Conference (SPLC), Munich, Germany, 22–26 August 2011; pp. 303–312. [Google Scholar]

- Tischer, C.; Muller, A.; Mandl, T.; Krause, R. Experiences from a Large Scale Software Product Line Merger in the Automotive Domain. In Proceedings of the 2011 15th International Software Product Line Conference (SPLC), Munich, Germany, 22–26 August 2011; pp. 267–276. [Google Scholar]

- Merschen, D.; Polzer, A.; Botterweck, G.; Kowalewski, S. Experiences of Applying Model-based Analysis to Support the Development of Automotive Software Product Lines. In Proceedings of the 5th Workshop on Variability Modeling of Software-Intensive Systems, Namur, Belgium, 27–29 January 2011; pp. 141–150. [Google Scholar]

- Graf, S.; Glaß, M.; Wintermann, D.; Teich, J.; Lauer, C. IVaM: Implicit Variant Modeling and Management for Automotive Embedded Systems. In Proceedings of the 2013 International Conference on Hardware/Software Codesign and System Synthesis (CODES+ ISSS), Montréal, QC, Canada, 29 September–4 October 2013; pp. 1–10. [Google Scholar]

- Leitner, A.; Kajtazovic, N.; Mader, R.; Kreiner, C.; Steger, C.; Weiß, R. Lightweight introduction of EAST-ADL2 in an automotive software product line. In Proceedings of the 2012 45th Hawaii International Conference on System Science (HICSS), Maui, HI, USA, 4–7 January 2012; pp. 5526–5535. [Google Scholar]

- Polzer, A.; Merschen, D.; Botterweck, G.; Pleuss, A.; Thomas, J.; Hedenetz, B.; Kowalewski, S. Managing complexity and variability of a model-based embedded software product line. Innov. Syst. Softw. Eng. 2012, 8, 35–49. [Google Scholar] [CrossRef]

- Strasser, A.; Cool, B.; Gernert, C.; Knieke, C.; Körner, M.; Niebuhr, D.; Peters, H.; Rausch, A.; Brox, O.; Jauns-Seyfried, S.; et al. Mastering Erosion of Software Architecture in Automotive Software Product Lines. In Proceedings of the SOFSEM 2014: Theory and Practice of Computer Science, Nový Smokovec, Slovakia, 26–29 January 2014; Geffert, V., Preneel, B., Rovan, B., Stuller, J., Tjoa, A.M., Eds.; Springer: New York, NY, USA, 2014; Volume 8327, pp. 491–502. [Google Scholar]

- Wang, S. Model Transformation for High-Integrity Software Development in Derivative Vehicle Control System Design. In Proceedings of the HASE’07: 10th IEEE High Assurance Systems Engineering Symposium, Dallas, TX, USA, 14–16 November 2007; pp. 227–234. [Google Scholar]

- Lochau, M.; Oster, S.; Goltz, U.; Schürr, A. Model-based pairwise testing for feature interaction coverage in software product line engineering. Softw. Qual. J. 2012, 20, 567–604. [Google Scholar] [CrossRef]

- Brink, C.; Kamsties, E.; Peters, M.; Sachweh, S. On Hardware Variability and the Relation to Software Variability. In Proceedings of the 2014 40th EUROMICRO Conference on Software Engineering and Advanced Applications (SEAA), Verona, Italy, 27–29 August 2014; pp. 352–355. [Google Scholar]

- Scheidemann, K.D. Optimizing the Selection of Representative Configurations in Verification of Evolving Product Lines of Distributed Embedded Systems. In Proceedings of the 2006 10th International Software Product Line Conference, Baltimore, Maryland, 21–24 August 2006; pp. 75–84. [Google Scholar]

- Millo, J.V.; Ramesh, S. Relating Requirement and Design Variabilities. In Proceedings of the 2012 19th Asia-Pacific Software Engineering Conference (APSEC), Hong Kong, China, 4–7 December 2012; Volume 2, pp. 35–42. [Google Scholar]

- Hardung, B.; Kölzow, T.; Krüger, A. Reuse of Software in Distributed Embedded Automotive Systems. In Proceedings of the 4th ACM international Conference on Embedded Software, Pisa, Italy, 27–29 September 2004; pp. 203–210. [Google Scholar]

- Kim, J.E.; Kapoor, R.; Herrmann, M.; Haerdtlein, J.; Grzeschniok, F.; Lutz, P. Software Behavior Description of Real-Time Embedded Systems in Component Based Software Development. In Proceedings of the 2008 11th IEEE International Symposium on Object Oriented Real-Time Distributed Computing (ISORC), Orlando, FL, USA, 5–7 May 2008; pp. 307–311. [Google Scholar]

- Manz, C.; Stupperich, M.; Reichert, M. Towards Integrated Variant Management in Global Software Engineering: An Experience Report. In Proceedings of the 2013 IEEE 8th International Conference on Global Software Engineering (ICGSE), Bari, Italy, 26–29 August 2013; pp. 168–172. [Google Scholar]

- Kato, S.; Yamaguchi, N. Variation Management for Software Product Lines with Cumulative Coverage of Feature Interactions. In Proceedings of the 2011 15th International Software Product Line Conference (SPLC), Munich, Germany, 21–26 August 2011; pp. 140–149. [Google Scholar]

- Tischer, C.; Muller, A.; Ketterer, M.; Geyer, L. Why does it take that long? Establishing Product Lines in the Automotive Domain. In Proceedings of the SPLC 2007, 11th International Software Product Line Conference, Kyoto, Japan, 10–14 September 2007; pp. 269–274. [Google Scholar]

- Käßmeyer, M.; Schulze, M.; Schurius, M. A process to support a systematic change impact analysis of variability and safety in automotive functions. In Proceedings of the 19th International Conference on Software Product Line, Nashville, TN, USA, 20–24 July 2015; pp. 235–244. [Google Scholar]

- de Oliveira, A.L.; Braga, R.T.; Masiero, P.C.; Papadopoulos, Y.; Habli, I.; Kelly, T. A Model-Based Approach to Support the Automatic Safety Analysis of Multiple Product Line Products. In Proceedings of the 2014 Brazilian Symposium on Computing Systems Engineering (SBESC), Manaus, Brazil, 3–7 November 2014; pp. 7–12. [Google Scholar]

- de Oliveira, A.L.; Braga, R.T.; Masiero, P.C.; Papadopoulos, Y.; Habli, I.; Kelly, T. Supporting the Automated Generation of Modular Product Line Safety Cases. In Theory and Engineering of Complex Systems and Dependability; Springer: New York, NY, USA, 2015; pp. 319–330. [Google Scholar]

- Gustavsson, H.; Axelsson, J. Evaluating Flexibility in Embedded Automotive Product Lines Using Real Options. In Proceedings of the SPLC’08: 12th International Software Product Line Conference, Limerick, Ireland, 8–12 September 2008; pp. 235–242. [Google Scholar]

- Grewe, A.; Knieke, C.; Körner, M.; Rausch, A.; Schindler, M.; Strasser, A.; Vogel, M. Automotive Software Product Line Architecture Evolution: Extracting, Designing and Managing Architectural Concepts. Int. J. Adv. Intell. Syst. 2017, 10, 203–222. [Google Scholar]

- Knieke, C.; Körner, M.; Rausch, A.; Schindler, M.; Strasser, A.; Vogel, M. Control Mechanisms for Managed Evolution of Automotive Software Product Line Architectures. Int. J. Adv. Softw. 2017, 10, 191–210. [Google Scholar]

- Bilic, D.; Sundmark, D.; Afzal, W.; Wallin, P.; Causevic, A.; Amlinger, C.; Barkah, D. Towards a Model-Driven Product Line Engineering Process. In Proceedings of the 13th Innovations in Software Engineering Conference on Formerly known as India Software Engineering Conference, Jabalpur, India, 27–29 February 2020; Jain, S., Ed.; ACM Digital Library; Association for Computing Machinery: New York, NY, USA, 2020; pp. 1–11. [Google Scholar] [CrossRef]

- Wille, D.; Runge, T.; Seidl, C.; Schulze, S. Extractive software product line engineering using model-based delta module generation. In Proceedings of the Eleventh International Workshop on Variability Modelling of Software-intensive Systems, Eindhoven, The Netherlands, 1–3 February 2017; Schaefer, I., Ed.; ACM Digital Library; ACM: New York, NY, USA, 2017; pp. 36–43. [Google Scholar] [CrossRef]

- Hayashi, K.; Aoyama, M. A multiple product line development method based on variability structure analysis. In Proceedings of the 22nd International Systems and Software Product Line Conference, Gothenburg, Sweden, 10–14 September 2018; Berger, T., Ed.; ACM: New York, NY, USA, 2018; Volume 1, pp. 160–169. [Google Scholar] [CrossRef]

- Hayashi, K.; Aoyama, M.; Kobata, K. Agile Tames Product Line Variability. In Proceedings of the 21st International Systems and Software Product Line Conference, Sevilla, Spain, 25–29 September 2017; Cohen, M., Ed.; ACM: New York, NY, USA, 2017; Volume A, pp. 180–189. [Google Scholar] [CrossRef]

- Ignaim, K.; Fernandes, J.M. An industrial case study for adopting software product lines in automotive industry. In Proceedings of the 23rd International Systems and Software Product Line Conference volume B–SPLC ’19, Paris, France, 9–13 September 2019; Salinesi, C., Ziadi, T., Eds.; ACM Press: New York, New York, USA, 2019; pp. 1–8. [Google Scholar] [CrossRef]

- Oliinyk, O.; Petersen, K.; Schoelzke, M.; Becker, M.; Schneickert, S. Structuring automotive product lines and feature models: An exploratory study at Opel. Requir. Eng. 2017, 22, 105–135. [Google Scholar] [CrossRef]

- Hohl, P.; Münch, J.; Schneider, K.; Stupperich, M. Real-Life Challenges on Agile Software Product Lines in Automotiv. In Proceedings of the International Conference on Product-Focused Software Process Improvement, Innsbruck, Austria, 29 November–1 December 2017; pp. 28–36. [Google Scholar]

- Hohl, P.; Stupperich, M.; Munch, J.; Schneider, K. Combining Agile Development and Software Product Lines in Automotive: Challenges and Recommendations. In Proceedings of the 2018 International Conference on Development and Application Systems (DAS), Suceava, Romania, 24–26 May 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1–10. [Google Scholar] [CrossRef]

- Hohl, P.; Theobald, S.; Becker, M.; Stupperich, M.; Münch, J. Mapping Agility to Automotive Software Product Line Concerns. In Product-Focused Software Process Improvement; Kuhrmann, M., Ed.; Lecture Notes in Computer Science; Springer: Cham, Switzerland, 2018; Volume 11271, pp. 409–421. [Google Scholar] [CrossRef]

- Kehrbusch, P.; Richenhagen, J.; Rumpe, B.; Schloßer, A.; Schulze, C. Interface-based similarity analysis of software components for the automotive industry. In Proceedings of the 20th International Systems and Software Product Line Conference, Beijing, China, 16–23 September 2016; Mei, H., Ed.; ACM Digital Library; ACM: New York, NY, USA, 2016; pp. 99–108. [Google Scholar] [CrossRef]

- Ebert, R.; Jolianis, J.; Kriebel, S.; Markthaler, M.; Pruenster, B.; Rumpe, B.; Salman, K.S. Applying Product Line Testing for the Electric Drive System. In Proceedings of the 23rd International Systems and Software Product Line Conference, Paris, France, 9–13 September 2019; Berger, T., Ed.; ACM Digital Library; Association for Computing Machinery: New York, NY, USA, 2019; Volume A, pp. 14–24. [Google Scholar] [CrossRef]

- Shahin, R.; Hackman, R.; Toledo, R.; Ramesh, S.; Atlee, J.M.; Chechik, M. Applying Declarative Analysis to Software Product Line Models: An Industrial Study. In Proceedings of the 2021 24th International Conference on Model Driven Engineering Languages and Systems, Fukuoka, Japan, 10–15 October 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 145–155. [Google Scholar] [CrossRef]

- Pett, T.; Eichhorn, D.; Schaefer, I. Risk-based compatibility analysis in automotive systems engineering. In Proceedings of the 23rd ACM/IEEE International Conference on Model Driven Engineering Languages and Systems: Companion Proceedings; Guerra, E., Ed.; ACM Digital Library; Association for Computing Machinery: New York, NY, USA, 2020; pp. 1–10. [Google Scholar] [CrossRef]

- Wägemann, T.; Tavakoli Kolagari, R.; Schmid, K. Exploring Automotive Stakeholder Requirements for Architecture Optimization Support. In Proceedings of the 2019 IEEE International Conference on Software Architecture Companion, Hamburg, Germany, 25–26 March 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 37–44. [Google Scholar] [CrossRef]

- Wieringa, R.; Maiden, N.; Mead, N.; Rolland, C. Requirements Engineering Paper Classification and Evaluation Criteria: A Proposal and a Discussion. Requir. Eng. 2005, 11, 102–107. [Google Scholar] [CrossRef]

- Fleiss, J.L. Measuring nominal scale agreement among many raters. Psychol. Bull. 1971, 76, 378–382. [Google Scholar] [CrossRef]

- Amram, M.; Kulatilaka, N. Real Options; Harvard Business School Press: Boston, MA, USA, 1999. [Google Scholar]

- Copeland, T.; Antikarov, V. Real Options: A Practitioner’s Guide; TEXERE: New York, NY, USA, 2001. [Google Scholar]

- Gomaa, H. Designing Software Product Lines with UML: From Use Cases to Pattern-Based Software Architectures; Addison-Wesley Professional: Boston, MA, USA, 2004. [Google Scholar]

| Activity | Objective | Input/Output |

|---|---|---|

| Recovery and Discovery | Recovery of the implemented PLA from the source artifacts (developed products) and discovery of the intended PLA. | Input: Source artifacts (developed products). Output: Implemented and intended PLA. |

| PL-Requirements | Specification and validation of software system and software component requirements by requirements engineering. | Input: Requirements. Output: Software system and software component requirements. |

| PL-Design | Further development of PLA with consideration of design principles. Application of measuring techniques to assess quality of PLA. | Input: Software system/component requirements and documentation from product development. Output: New PLA (called “PLA vision”). |

| PL-Plan | Planning of a set of iterations of further development toward the PLA vision taking all affected projects into account. | Input: PLA vision. Output: Development plan including the planned order of module implementations and the planned related projects. |

| PL-Implement | Implementation including testing as specified by the development plan for product line development. | Input: Development plan for product line. Output: Implemented module versions. |

| PL-Check | Minimization of product architecture erosion by architecture conformance checking based on architecture rules. | Input: Architecture rules and set of implemented modules to be checked. Output: Check results. |

| PL to P | Defining a project plan by selecting a project from the the product line. | Input: Development plan for product line. Output: Project plan. |

| P-Requirements | Specification of special requirements for a certain vehicle product including vehicle related parameter settings. | Input: Requirements in particular from calibration engineers. Output: Vehicle related requirements. |

| P-Design | Designing product architecture and performing architecture adaptations taking product specific requirements into account. Compliance checking with PLA to minimize erosion. | Input: Project plan and product specific requirements. Output: Planned product architecture. |

| P-Plan | Definition of iterations to be performed on product level toward the planned product architecture. | Input: Product architecture. Output: Development plan for product development. |

| P-Implement | Product specific implementations including testing as specified by the development plan for product development. | Input: Development plan for product development. Output: Implemented module versions. |

| P-Check | Architecture conformance checking between PLA and PA. | Input: Architecture rules and set of implemented modules to be checked. Output: Check results. |

| P to PL | Providing product related information of developed product for integration into product line development. | Input: Developed product. Output: Product documentation and implementation artifacts of developed products. |

| Research Question and Rationale | |

|---|---|

| RQ | What Is the current state of the art in holistic approaches for managed evolution of automotive software product lines? We aim at collecting information about such holistic approaches and use our conceptual model (cf. Section 2.2) as a reference model to evaluate the current state of the art. Specifically, we are interested into the coverage of the particular aspects of the conceptual model and, thus, the fields covered in current research and research gaps, respectively. |

| RQ | What particular methods and techniques are used to implement a managed evolution of automotive software product lines? We aim to identify the methods and techniques used to implement automotive software product lines in general, and their usage scope in particular. For this, we analyze the available literature and categorize and evaluate the contributions found according to a given schema (Section 2.2). |

| Research Area and Topics | Studies Per Area |

|---|---|

Agreement Processes (AGR)

| 5 |

Organizational Project-Enabling Processes (ORG)

| 48 |

Project Processes (PRO)

| 14 |

Technical and Software Implementation Processes a (ENG/DEV)

| 439 |

Software Support Processes (SUP)

| 122 |

Software Reuse Processes (REU)

| 72 |

| Id | Ref | RTF a | CTF b | Rigor | Relevance |

|---|---|---|---|---|---|

| P8 | [40] | Evaluation | Model | 1.0 | 2.0 |

| P22 | [41] | Solution Proposal | Framework/Method/Technique | 1.5 | 2.0 |

| P43 | [42] | Evaluation | Lessons Learned | 3.0 | 3.0 |

| P71 | [43] | Evaluation | Framework/Method/Technique | 1.5 | 2.0 |

| P72 | [44] | Evaluation | Lessons Learned | 3.0 | 3.0 |

| P79 | [45] | Evaluation | Framework/Method/Technique | 1.0 | 2.0 |

| P86 | [46] | Evaluation | Lessons Learned | 2.0 | 4.0 |

| P90 | [47] | Evaluation | Model | 2.0 | 3.0 |

| P94 | [48] | Evaluation | Framework/Method/Technique | 1.0 | 2.0 |

| P100 | [49] | Validation | Framework/Method/Technique | 2.5 | 1.0 |

| P129 | [50] | Evaluation | Model | 2.0 | 4.0 |

| P173 | [51] | Evaluation | Framework/Method/Technique | 1.0 | 2.0 |

| P215 | [52] | Evaluation | Lessons Learned | 2.5 | 4.0 |

| P218 | [53] | Experience Paper | Lessons Learned | 0.5 | 2.0 |

| P220 | [54] | Experience Paper | Lessons Learned | 0.5 | 2.0 |

| P221 | [55] | Experience Paper | Lessons Learned | 0.5 | 2.0 |

| P223 | [56] | Experience Paper | Framework/Method/Technique | 1.0 | 2.0 |

| P279 | [57] | Evaluation | Framework/Method/Technique | 1.0 | 3.0 |

| P281 | [58] | Validation | Guideline | 1.0 | 2.0 |

| P285 | [59] | Evaluation | Framework/Method/Technique | 1.5 | 4.0 |

| P289 | [60] | Evaluation | Framework/Method/Technique | 1.0 | 2.0 |

| P300 | [61] | Evaluation | Lessons Learned | 1.0 | 2.0 |

| P310 | [62] | Evaluation | Framework/Method/Technique | 1.0 | 2.0 |

| P332 | [63] | Evaluation | Framework/Method/Technique | 1.0 | 1.0 |

| P343 | [64] | Evaluation | Framework/Method/Technique | 1.0 | 2.0 |

| P365 | [65] | Evaluation | Framework/Method/Technique | 1.0 | 1.0 |

| P377 | [66] | Solution Proposal | Framework/Method/Technique | 1.0 | 1.0 |

| P404 | [67] | Evaluation | Lessons Learned | 0.5 | 2.0 |

| P468 | [68] | Experience Paper | Lessons Learned | 1.0 | 3.0 |

| P493 | [69] | Experience Paper | Framework/Method/Technique | 2.0 | 3.0 |

| P503 | [70] | Experience Paper | Lessons Learned | 0.0 | 2.0 |

| P580 | [71] | Solution Proposal | Framework/Method/Technique | 1.0 | 3.0 |

| P588 | [72] | Evaluation | Framework/Method/Technique | 1.0 | 3.0 |

| P589 | [73] | Evaluation | Framework/Method/Technique | 1.0 | 2.0 |

| P660 | [74] | Evaluation | Framework/Method/Technique | 1.0 | 2.0 |

| P580 | [71] | Solution Proposal | Framework/Method/Technique | 1.0 | 3.0 |

| P588 | [72] | Evaluation | Framework/Method/Technique | 1.0 | 3.0 |

| P589 | [73] | Evaluation | Framework/Method/Technique | 1.0 | 2.0 |

| P660 | [74] | Evaluation | Framework/Method/Technique | 1.0 | 2.0 |

| E8 | [75] | Evaluation | Framework/Method/Technique | 1.0 | 2.0 |

| E53 | [76] | Evaluation | Framework/Method/Technique | 1.0 | 3.0 |

| E59 | [77] | Evaluation | Lessons Learned | 2.0 | 4.0 |

| E66 | [78] | Evaluation | Framework/Method/Technique | 2.0 | 2.0 |

| E127 | [79] | Evaluation | Framework/Method/Technique | 1.0 | 4.0 |

| E130 | [80] | Evaluation | Framework/Method/Technique | 1.0 | 4.0 |

| E132 | [81] | Evaluation | Framework/Method/Technique | 2.0 | 2.0 |

| E173 | [82] | Experience Paper | Guideline | 3.0 | 2.0 |

| E175 | [83] | Experience Paper | Lessons Learned | 2.5 | 2.0 |

| E177 | [84] | Experience Paper | Lessons Learned | 2.0 | 2.0 |

| E178 | [85] | Experience Paper | Lessons Learned | 2.0 | 2.0 |

| E179 | [86] | Evaluation | Framework/Method/Technique | 1.0 | 1.0 |

| E183 | [87] | Solution Proposal | Framework/Method/Technique | 1.0 | 3.0 |

| E187 | [88] | Evaluation | Lessons Learned | 1.0 | 2.0 |

| E224 | [89] | Solution Proposal | Framework/Method/Technique | 2.0 | 1.0 |

| E230 | [90] | Experience Paper | Lessons Learned | 2.5 | 2.0 |

| Activity | Papers | % |

|---|---|---|

| Recovery and Discovery | [40,48,50,51,53,59,60,70,75,78,81,88] | 13 |

| PL-Requirements | [41,45,53,54,65,66,77,81] | 9 |

| PL-Design | [40,41,42,43,45,46,47,50,51,52,53,55,56,57,58,59,61,63,65,66,67,69,70,71,72,74,75,77,82] | 32 |

| PL-Plan | [47,50,52,66,68,71,75,87,89] | 10 |

| PL-Implement | [56,62,66,69,72,76,77,87,88,89] | 11 |

| PL-Check | [49,65,69,76] | 4 |

| PL to P | [41,54,57,59,61,66,87] | 8 |

| P-Requirements | [66] | 1 |

| P-Design | [50,66,67] | 3 |

| P-Plan | [66] | 1 |

| P-Implement | [62,66,76,87] | 4 |

| P-Check | [44,76] | 2 |

| P to PL | [41,48] | 2 |

| Rest (unassigned) | [64,73,83,84,85] |

| No. | Methods and/or Techniques | Papers | PL a | P b |

|---|---|---|---|---|

| 1 | Architecture evolution process | [46,50,52] | x | x |

| 2 | Cost/effort estimation | [43,48,51,74] | x | |

| 3 | Safety analysis | [44,71,72,73,89] | x | |

| 4 | Description languages | [67,76] | x | x |

| 5 | Architecture reengineering | [60] | x | |

| 6 | Model transformation | [49,56,58,59,61,78,86] | x | |

| 7 | Model-based requirements engineering | [41,45] | x | x |

| 8 | Overall approach/process | [50,53,59,66,70,75,77] | x | x |

| 9 | Reference architectures | [42,47,50,53,82] | x | x |

| 10 | SPL merging | [48,51,55,81,86] | x | |

| 11 | Testing/verification | [62,64,87,88] | x | x |

| 12 | Variability management | [40,54,57,63,65,68,69,71,72,73,79,90] | x | x |

| 13 | Agile software development | [79,80,83,84,85,87] | x |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Knieke, C.; Rausch, A.; Schindler, M.; Strasser, A.; Vogel, M. Managed Evolution of Automotive Software Product Line Architectures: A Systematic Literature Study. Electronics 2022, 11, 1860. https://doi.org/10.3390/electronics11121860

Knieke C, Rausch A, Schindler M, Strasser A, Vogel M. Managed Evolution of Automotive Software Product Line Architectures: A Systematic Literature Study. Electronics. 2022; 11(12):1860. https://doi.org/10.3390/electronics11121860

Chicago/Turabian StyleKnieke, Christoph, Andreas Rausch, Mirco Schindler, Arthur Strasser, and Martin Vogel. 2022. "Managed Evolution of Automotive Software Product Line Architectures: A Systematic Literature Study" Electronics 11, no. 12: 1860. https://doi.org/10.3390/electronics11121860

APA StyleKnieke, C., Rausch, A., Schindler, M., Strasser, A., & Vogel, M. (2022). Managed Evolution of Automotive Software Product Line Architectures: A Systematic Literature Study. Electronics, 11(12), 1860. https://doi.org/10.3390/electronics11121860