Comparison of the Effectiveness of Selected Vibration Signal Analysis Methods in the Rotor Unbalance Detection of PMSM Drive System

Abstract

:1. Introduction

2. Rotor Unbalance in Electrical Machine

- Static unbalance occurs shaft rotational axis and weight distribution axis of the rotor are parallel but there is an offset. Static unbalance occurs more frequently in disk-shaped rotors due to uneven distribution of mass or in rotors with internal faults (e.g., broken rotor bars of a squirrel-cage motor or damaged permanent magnets of PMSM).

- Coupled unbalance occurs when two equal unbalances are 180 degrees out-of-phase. Under this condition, the shaft rotational axis and weight distribution axis of the rotor intersect at the centre of the rotor.

- Dynamic unbalance occurs when the shaft rotational axis and weight distribution axis of the rotor do not coincide.

3. Short Description of Selected Signal Analysis Methods

3.1. Fast Fourier Transform Analysis

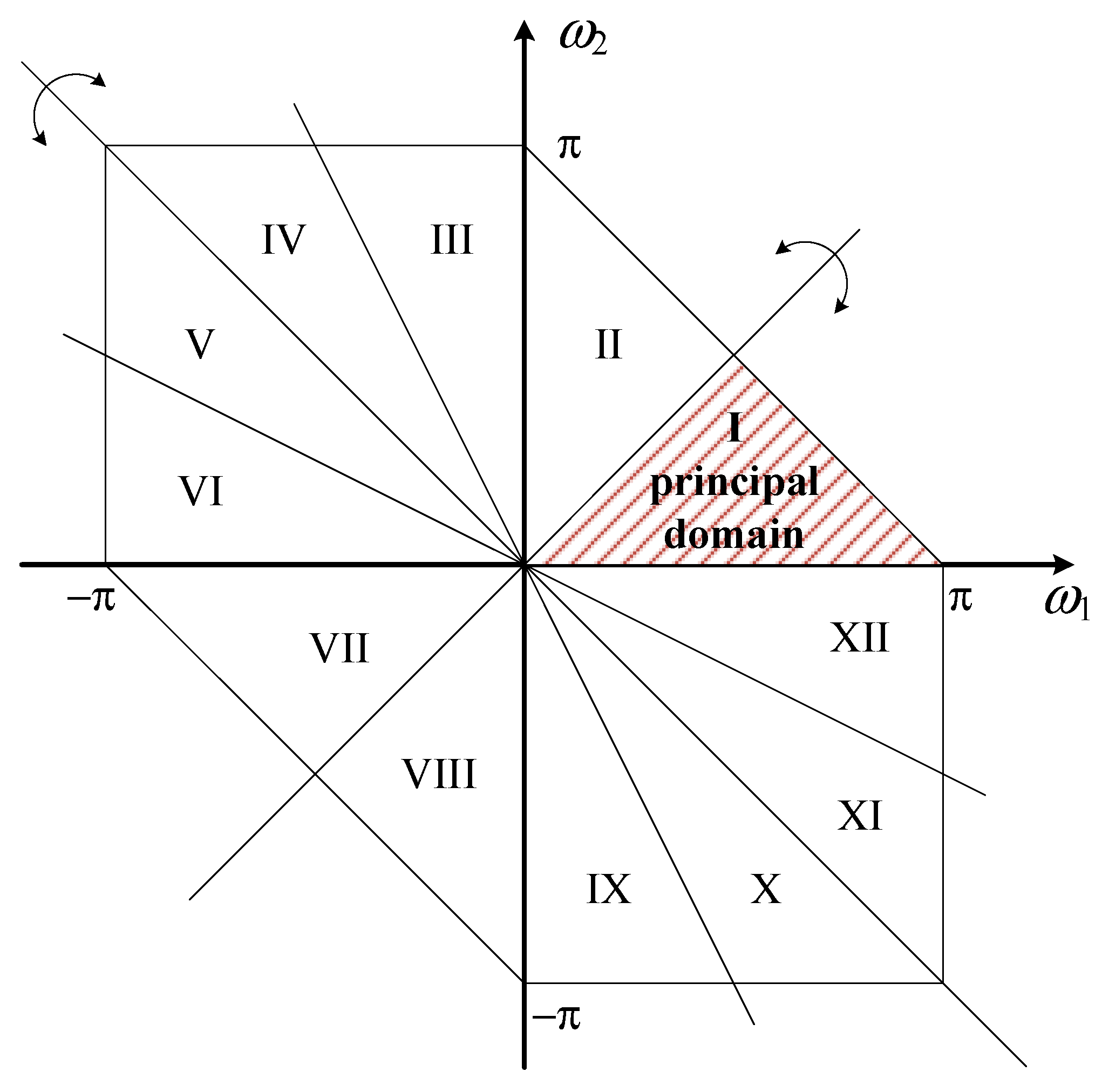

3.2. Bispectrum Analysis

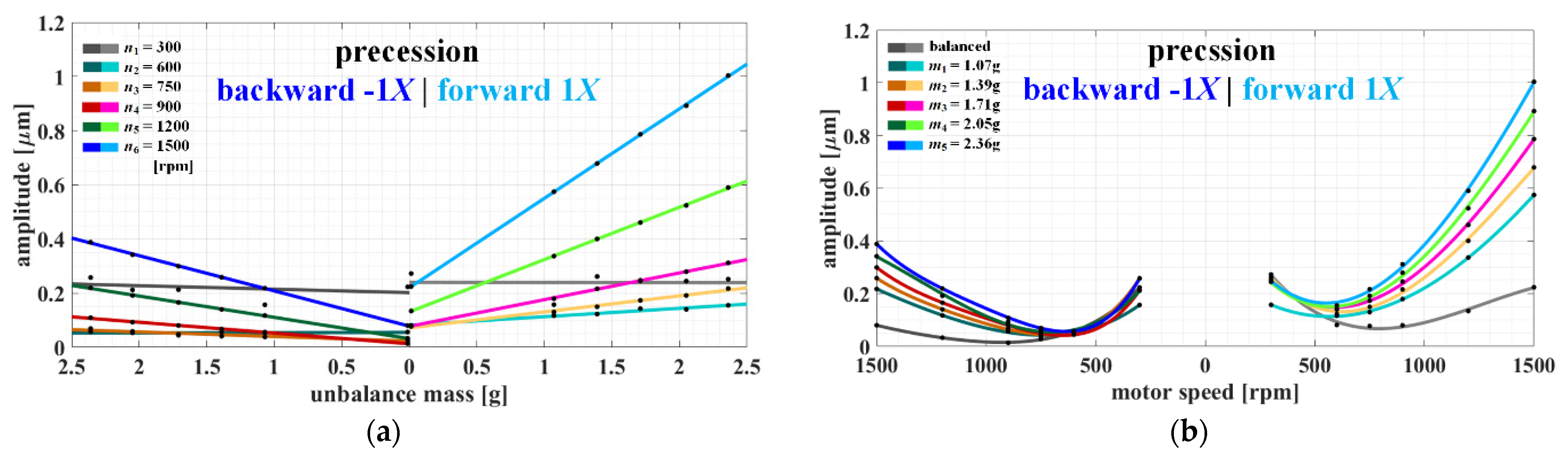

3.3. Full-Spectrum Analysis

- Amplitude of forward precession:

- Amplitude of backward precession:

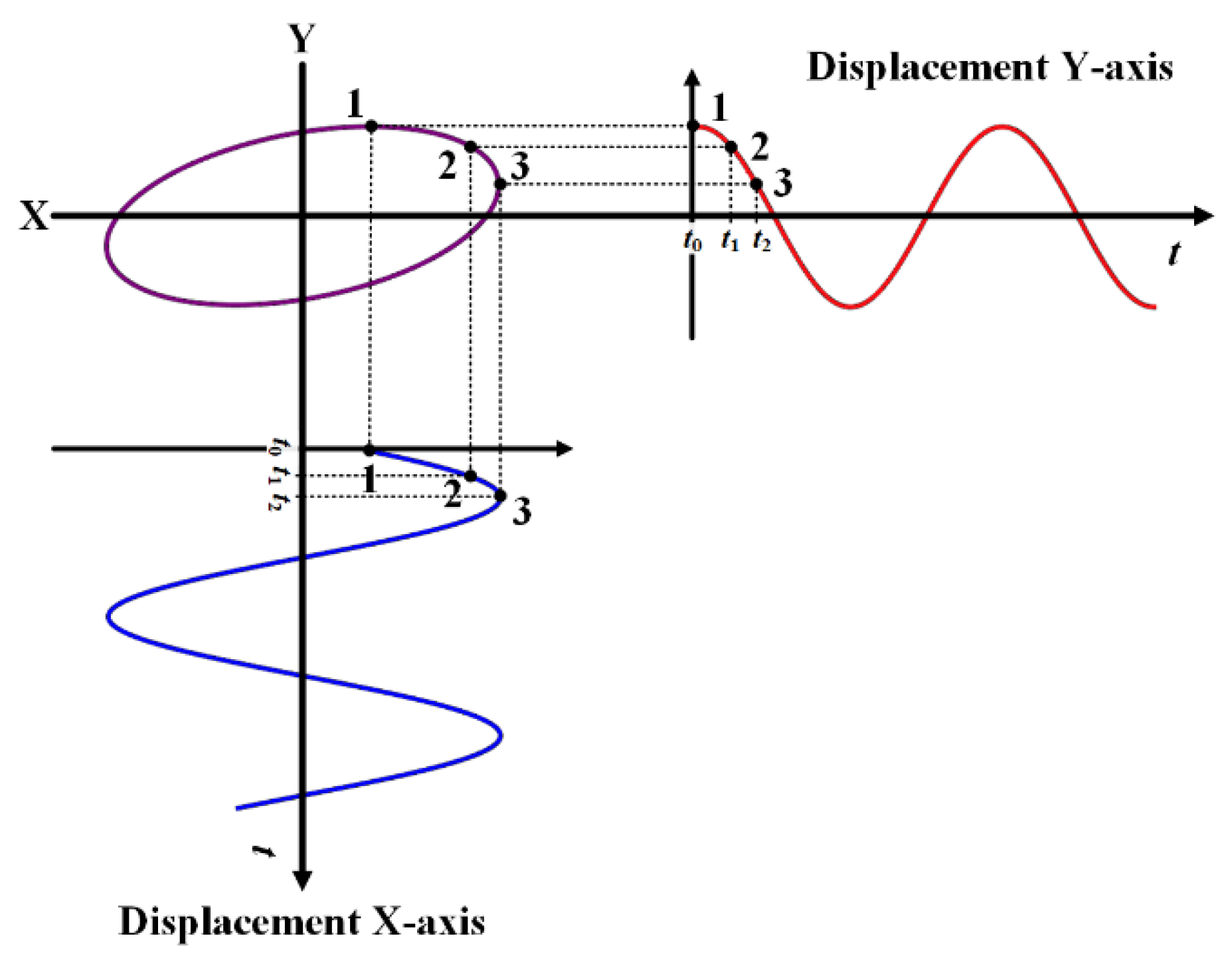

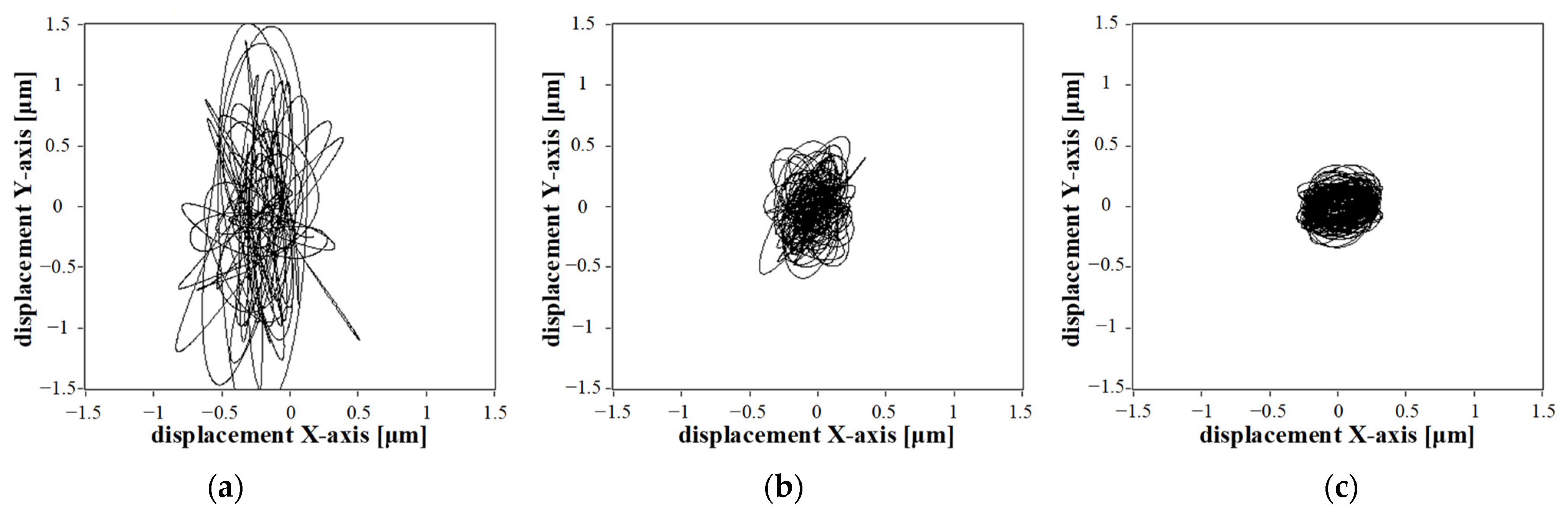

3.4. Orbit Shape Analysis

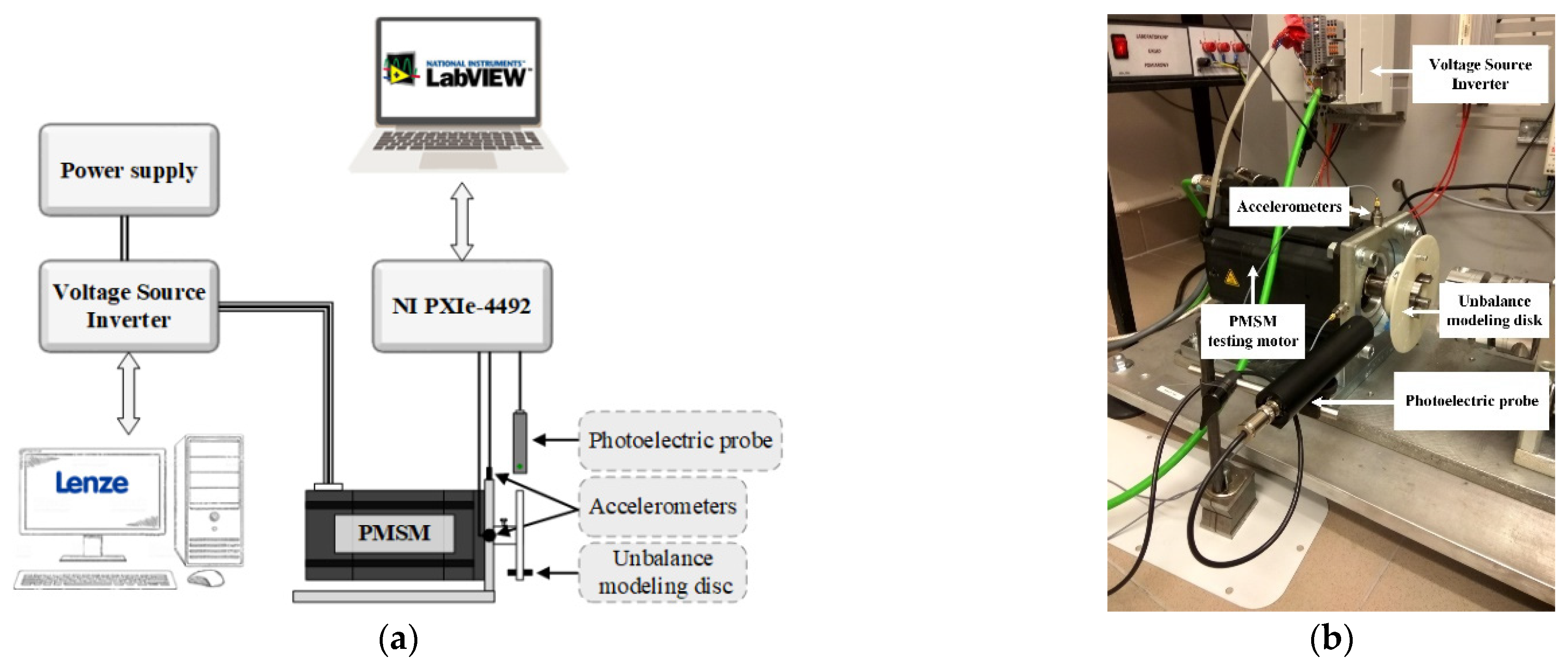

4. Experimental Setup and Test Scenario

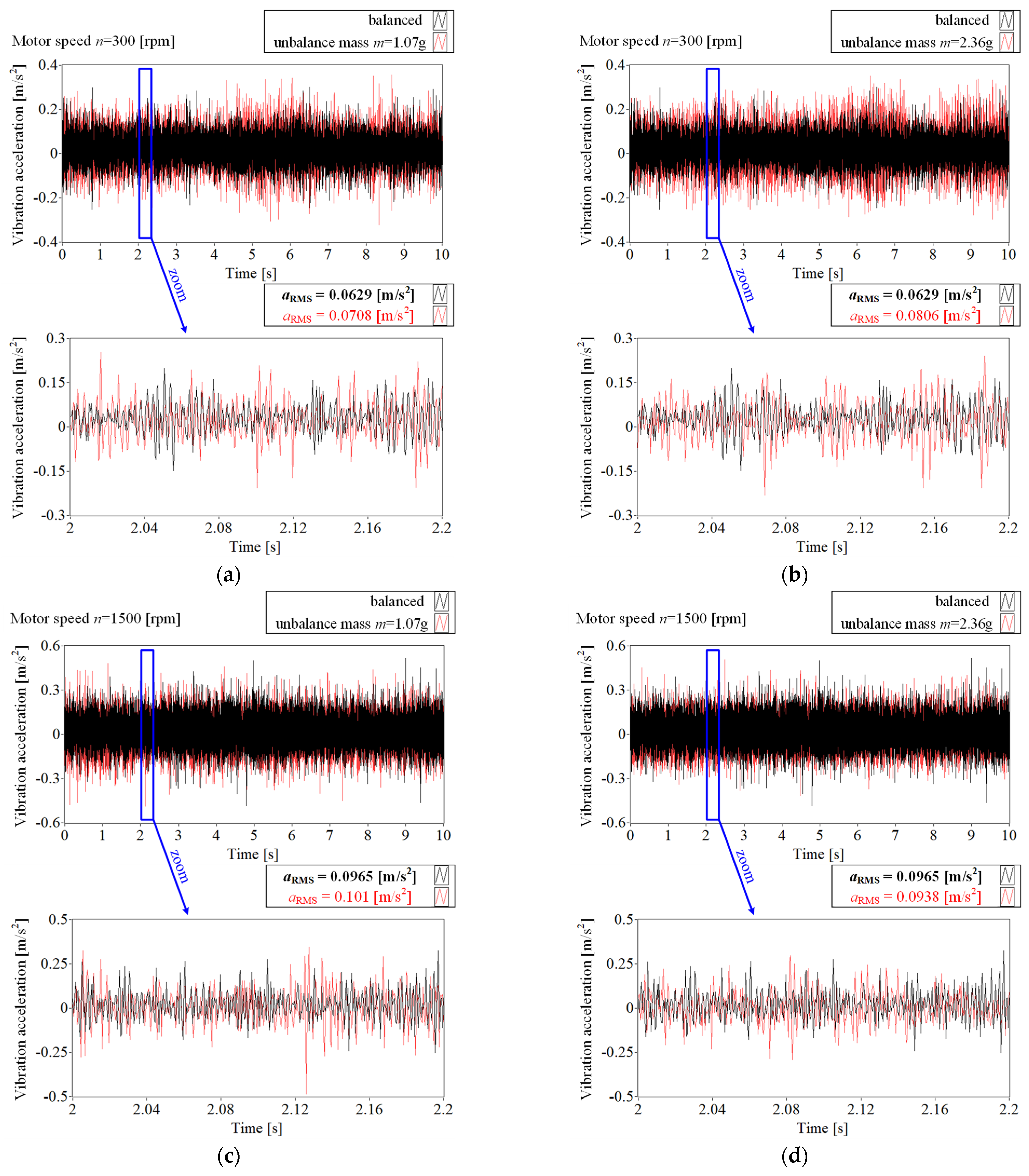

5. Analysis of Experimental Research Results

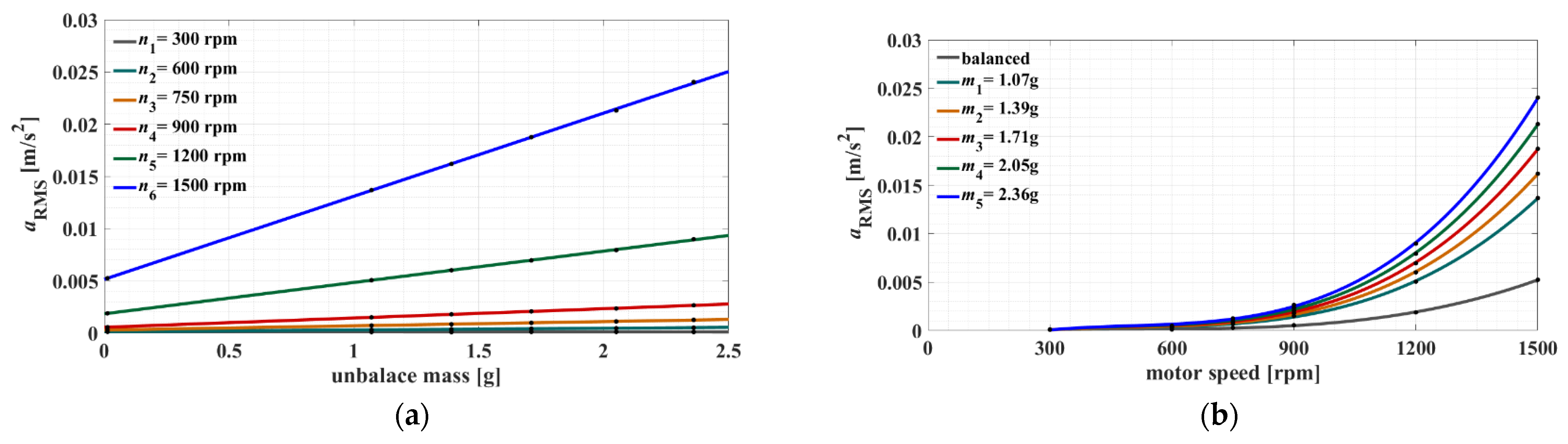

5.1. Fast Fourier Transform Analysis

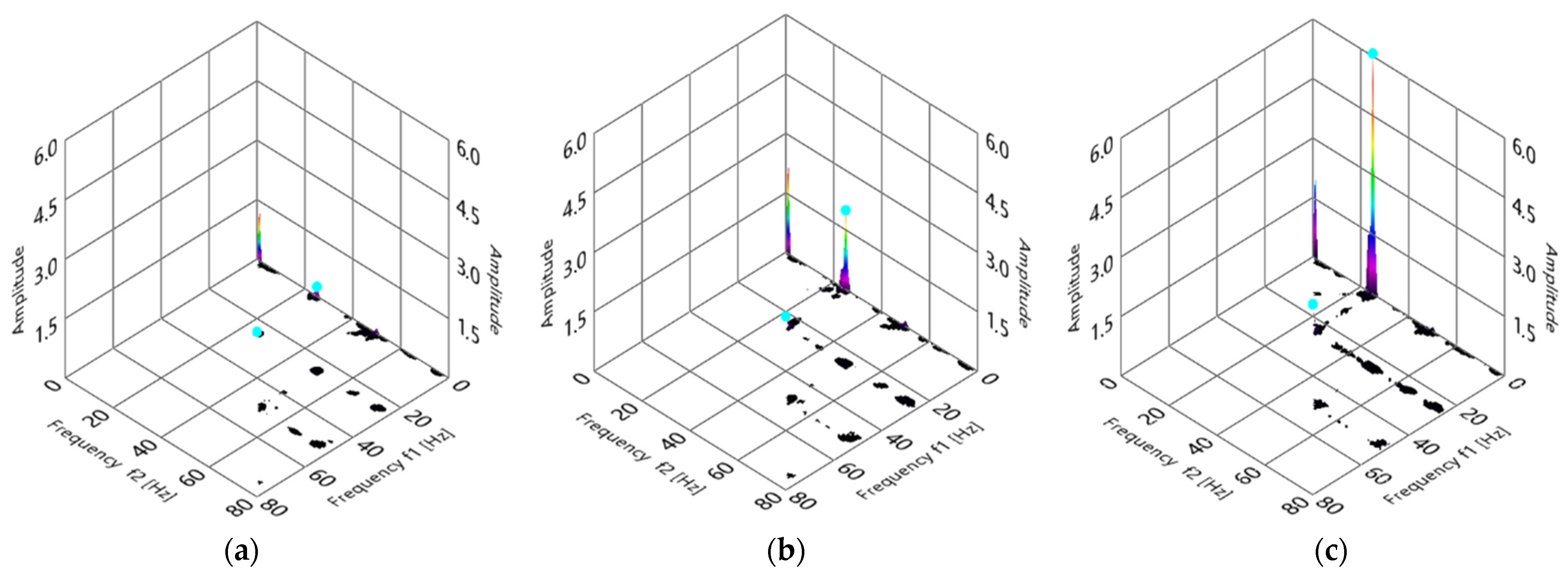

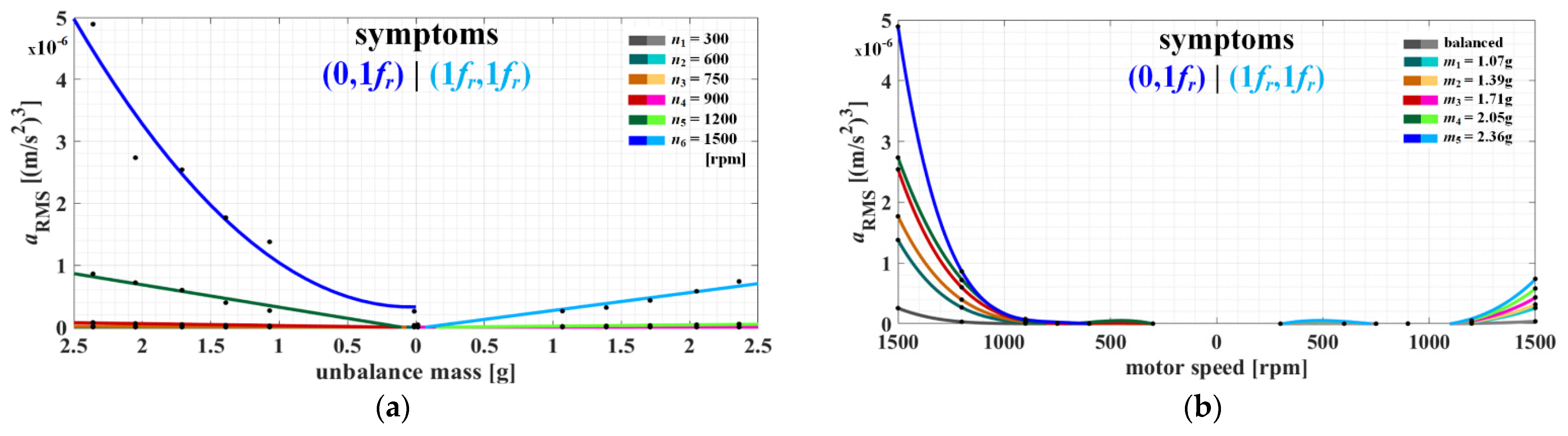

5.2. Bispectrum Analysis

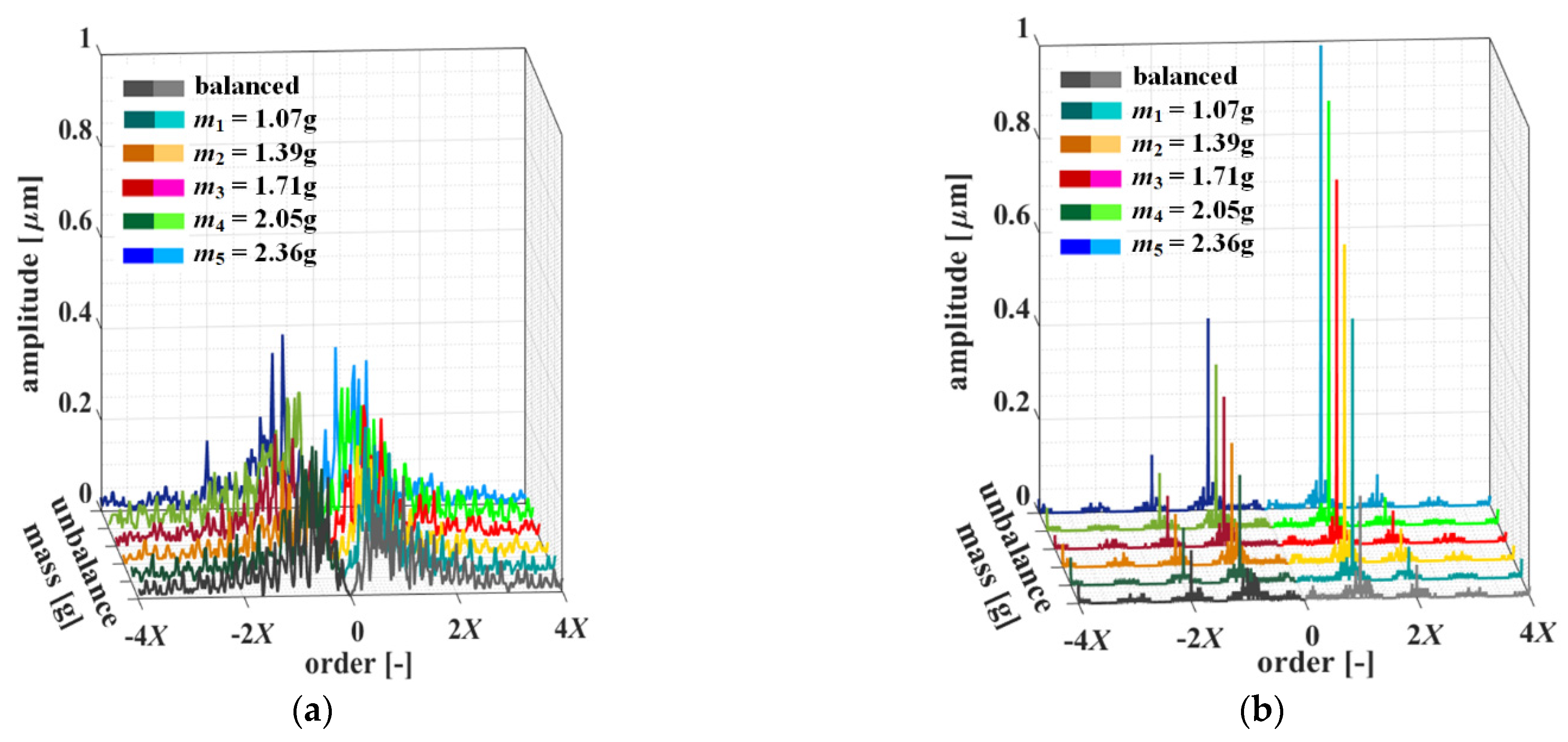

5.3. Full-Spectrum Analysis

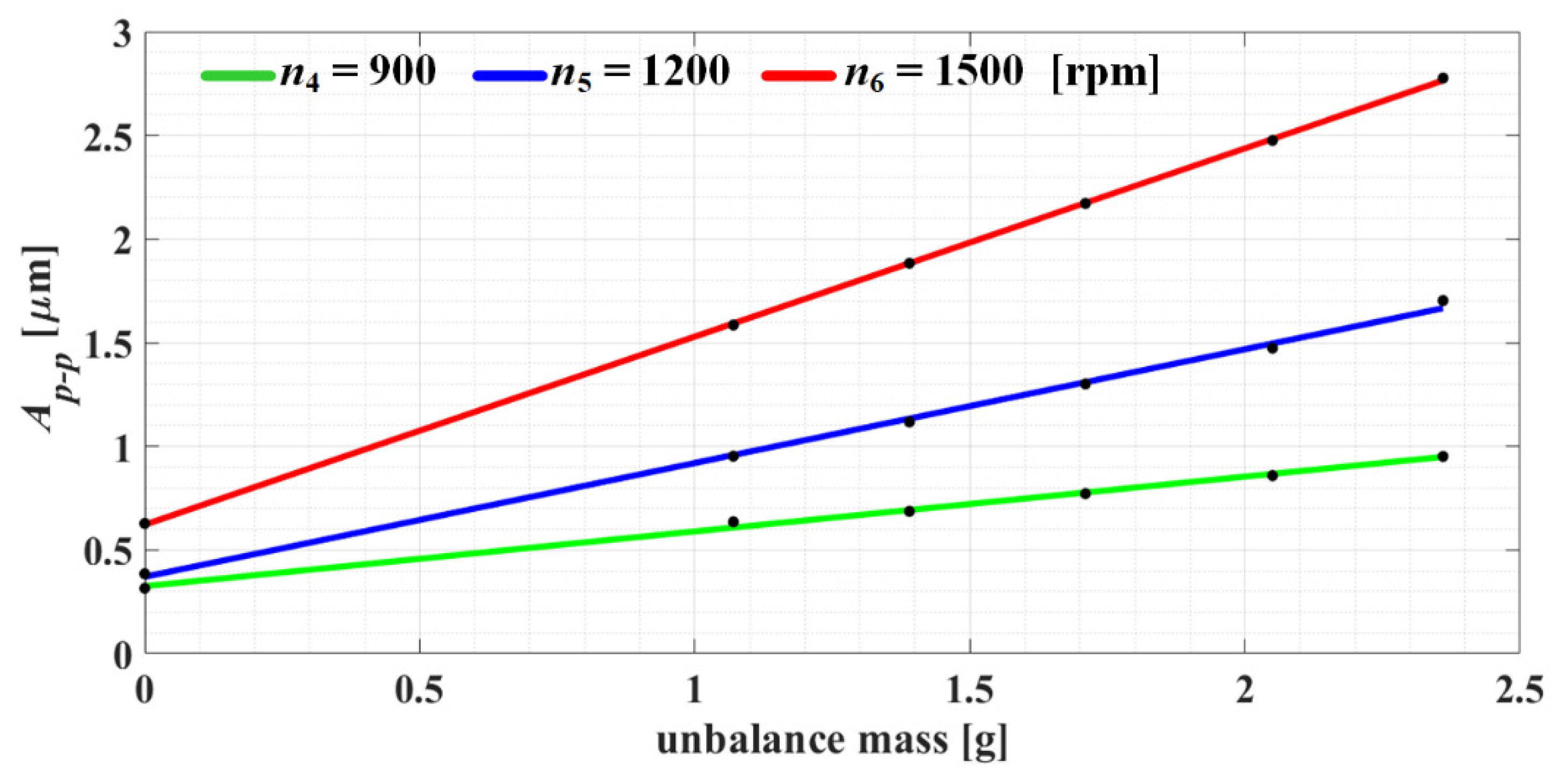

5.4. Orbit Shape Analysis

6. Comprehensive Comparison of the Effectiveness of the Tested Methods in Unbalance Detection

7. Summary

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| BS | Bispectrum |

| EMD | Empirical mode decomposition |

| FFT | Fast Fourier transform |

| FS | Full spectrum |

| FST | Full-spectrum transform |

| HHT | Hilbert–Huang transform |

| HOS | Higher-order spectra |

| IM | Induction motor |

| OS | Orbit shape |

| PMSM | Permanent magnet synchronous motor |

| PSD | Power spectral density |

| RMS | Root mean square |

| STFT | Short-time Fourier transform |

| TS | Trispectrum |

| WT | Wavelet transform |

| WVD | Wigner–Ville distribution |

References

- Wang, Z.; Yang, J.; Ye, H.; Zhou, W. A Review of Permanent Magnet Synchronous Motor Fault Diagnosis. In Proceedings of the 2014 IEEE Conference and Expo Transportation Electrification Asia-Pacific (ITEC Asia-Pacific), Beijing, China, 31 August–3 September 2014. [Google Scholar] [CrossRef]

- Krichen, M.; Ben hadj, N.; Chaeib, M.; Neji, R. Fault Detection and Diagnosis Methods in Permanent Magnet Synchronous Machines: A Review. In Proceedings of the International Conference on Recent Advances in Electrical Systems, Hammamet, Tunisia, 22–24 December 2017. [Google Scholar]

- Chen, Y.; Liang, S.; Li, W.; Liang, H.; Wang, C. Faults and Diagnosis Methods of Permanent Magnet Synchronous Motors: A Review. Appl. Sci. 2019, 9, 2116. [Google Scholar] [CrossRef] [Green Version]

- Moosavi Anchehpoli, S.S. Analysis and Diagnosis of Faults in the PMSM Drivetrains for Series Hybrid Electrical Vehicles (SHEVs); Electric power; Université de Technologie de Belfort-Montbeliard: Sevenans, France, 2013. [Google Scholar]

- Gomaa, F.R.; Khader, K.M.; Eissa, M.A. Fault Diagnosis of Rotating Machinery based on vibration analysis. Int. J. Adv. Eng. Glob. Technol. 2016, 4, 1571–1586. [Google Scholar]

- Faiz, J.; Takbash, A.M.; Mazaheri-Tehrani, E. A Review of Application of Signal Processing Techniques for Fault Diagnosis of Induction Motors—Part I. AUT J. Electr. Eng. 2017, 49, 109–122. [Google Scholar] [CrossRef]

- Ribeiro Junior, R.F.; de Almeida, F.A.; Gomes, G.F. Fault classification in three-phase motors based on vibration signal analysis and artificial neural networks. Neural. Comput. Applic. 2020, 32, 15171–15189. [Google Scholar] [CrossRef]

- Liang, H.; Chen, Y.; Liang, S.; Wang, C. Fault Detection of Stator Inter-Turn Short-Circuit in PMSM on Stator Current and Vibration Signal. Appl. Sci. 2018, 8, 1677. [Google Scholar] [CrossRef] [Green Version]

- Lipus, J.; Jankovych, R.; Hammer, M.; Lipus, T. Vibration and related diagnostics of motors and generators. MM Sci. J. 2016, 2016, 1639–1642. [Google Scholar] [CrossRef]

- Czmochowski, J.; Moczko, P.; Odyjas, P.; Pietrusiak, D. Tests of rotary machines vibrations in steady and unsteady states on the basis of large diameter centrifugal fans. Eksploat. Niezawodn.—Maint. Reliab. 2014, 16, 211–216. [Google Scholar]

- Ghazali, M.H.M.; Rahiman, W. Vibration Analysis for Machine Monitoring and Diagnosis: A Systematic Review. Shock. Vib. 2021, 2021, 9469318. [Google Scholar] [CrossRef]

- Jardine, A.K.; Lin, D.; Banjevic, D. A review on machinery diagnostics and prognostics implementing condition-based maintenance. Mech. Syst. Signal Process. 2006, 20, 1483–1510. [Google Scholar] [CrossRef]

- Li, Z.; Yan, X.; Yuan, C.; Zhao, J.; Peng, Z. Fault detection and diagnosis of a gearbox in marine propulsion systems using bispectrum analysis and artificial neural networks. J. Mar. Sci. Appl. 2011, 10, 17–24. [Google Scholar] [CrossRef] [Green Version]

- Guoji, S.; McLaughlin, S.; Yongcheng, X.; White, P. Theoretical and experimental analysis of bispectrum of vibration signals for fault diagnosis of gears. Mech. Syst. Signal Process. 2014, 43, 76–89. [Google Scholar] [CrossRef]

- Yunusa-Kaltungo, A.; Sinha, J.K. Combined bispectrum and trispectrum for faults diagnosis in rotating machines. Proc. Inst. Mech. Eng. Part O J. Risk Reliab. 2014, 228, 419–428. [Google Scholar] [CrossRef]

- Saidi, L.; Fnaiech, F.; Henao, H.; Capolino, G.-A.; Cirrincione, G. Diagnosis of broken-bars fault in induction machines using higher order spectral analysis. ISA Trans. 2013, 52, 140–148. [Google Scholar] [CrossRef] [PubMed]

- Saidi, L.; Ali, J.B.; Fnaiech, F. Bi-spectrum based-EMD applied to the non-stationary vibration signals for bearing faults diagnosis. ISA Trans. 2014, 53, 1650–1660. [Google Scholar] [CrossRef]

- Bently, D.; Hatch, C. Fundamentals of Rotating Machinery Diagnostics; Bently Pressurized Bearing Company: Minden, NV, USA, 2002. [Google Scholar]

- Goldman, P.; Muszynska, A. Application of Full Spectrum to Rotating Machinery Diagnostics. Orbit 1999, 20, 17–21. [Google Scholar]

- Muszynska, A. Rotordynamics, 1st ed.; Taylor & Francis Group, CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar] [CrossRef]

- Patel, T.H.; Darpe, A.K. Experimental investigations on vibration response of misaligned rotors. Mech. Syst. Signal Process. 2009, 23, 2236–2252. [Google Scholar] [CrossRef]

- Patel, T.H.; Darpe, A.K. Vibration response of misaligned rotors. J. Sound Vib. 2009, 325, 609–628. [Google Scholar] [CrossRef]

- Silva, R.R.; Costa, E.S.; Oliveira, R.; Mesquita, A. Fault diagnosis in rotating machine using full spectrum of vibration and fuzzy logic. J. Eng. Sci. Technol. 2017, 12, 2952–2964. [Google Scholar]

- Monte, M.; Verbelen, F.; Vervisch, B. The Use of Orbitals and Full Spectra to Identify Misalignment. In Structural Health Monitoring; Springer International Publishing: Cham, Switzerland, 2014; pp. 215–222. [Google Scholar] [CrossRef] [Green Version]

- Jeong, H.; Park, S.; Woo, S.; Lee, S. Rotating Machinery Diagnostics Using Deep Learning on Orbit Plot Images. Procedia Manuf. 2016, 5, 1107–1118. [Google Scholar] [CrossRef] [Green Version]

- Rafaq, M.S.S.; Lee, H.; Park, Y.; Lee, S.B.; Fernandez, D.; Diaz-Reigosa, D.; Briz, F. A Simple Method for Identifying Mass Unbalance using Vibration Measurement in Permanent Magnet Synchronous Motors. IEEE Trans. Ind. Electron. 2021, 69, 6441–6444. [Google Scholar] [CrossRef]

- Zhang, J.; Hang, J.; Cheng, M. Diagnosis of mechanical unbalance fault in permanent magnet synchronous machine drives. Electr. Power Comp. Syst. 2016, 44, 1408–1417. [Google Scholar] [CrossRef]

- Hang, J.; Zhang, J.; Cheng, M.; Wang, Z. Fault diagnosis of mechanical unbalance for permanent magnet synchronous motor drive system under nonstationary condition. In Proceedings of the 2013 IEEE Energy Conversion Congress and Exposition, Denver, CO, USA, 15–19 September 2013; pp. 3556–3562. [Google Scholar] [CrossRef]

- Park, C.H.; Lee, J.; Ahn, G.; Youn, M.; Youn, B.D. Fault detection of PMSM under non-stationary conditions based on wavelet transformation combined with distance approach. In Proceedings of the 2019 IEEE 12th International Symposium on Diagnostics for Electric Machines, Power Electronics and Drives (SDEMPED), Toulouse, France, 27–30 August 2019; pp. 88–93. [Google Scholar] [CrossRef]

- Corbalan, P.; Chiang, L.E. Rotor Unbalance Fault Diagnosis in Wind Turbine by Markov Chain Monte Carlo Method. Res. Sq. Platf. 2021; preprint. [Google Scholar] [CrossRef]

- Xie, T.; Wang, T.; He, Q.; Diallo, D.; Claramunt, C. A review of current issues of marine current turbine blade fault detection. Ocean. Eng. 2020, 218, 108194. [Google Scholar] [CrossRef]

- Yinquan, Y. Fault Diagnosis of Permanent Magnet Synchronous Motor Based on Mechanical and Magnetic Characteristic Analysis. Ph.D. Thesis, Department of Electrical and Computer Engineering, National University of Singapore, Singapore, 2014. [Google Scholar]

- Ewert, P.; Jaworski, M. Application of selected higher-order methods to detect rotor unbalance of drive system with PMSM. In Proceedings of the 2021 IEEE 19th International Power Electronics and Motion Control Conference (PEMC), Gliwice, Poland, 25–29 April 2021; pp. 874–879. [Google Scholar] [CrossRef]

- Smith, S.W. Digital Signal Processing: A Practical Guide for Engineers and Scientists; Elsevier Science: Burlington, VT, USA, 2002. [Google Scholar] [CrossRef]

- Mendel, J.M. Tutorial on Higher-Order Statistic (Spectra) in Signal Processing and System Theory: Theoretical Results and Some Applications. Proc. IEEE 1991, 79, 278–305. [Google Scholar] [CrossRef]

- Nikias, C.L.; Petropulu, A. Higher-Order Spectra Analysis: A Nonlinear Signal Processing Framework; Prentice-Hall: Hoboken, NJ, USA, 1993. [Google Scholar]

- Piñeyro, J.; Klempnow, A.; Lescano, J. Effectiveness of new spectral tools in the anomaly detection of rolling element bearings. J. Alloy. Compd. 2000, 310, 276–279. [Google Scholar] [CrossRef]

- Matsuoka, T.; Ulrych, T.J. Phase estimation using the bispectrum. Proc. IEEE 1984, 72, 1403–1411. [Google Scholar] [CrossRef]

| Feature | Method | |||

|---|---|---|---|---|

| FFT | BS | OS | FS | |

| Symptom | 1fr | (0,1fr); (1fr,1fr) | Ap–p | 1X |

| Effectiveness | 2.5 ÷ 4.5 | 6 ÷ 20 | 2.5 ÷ 4 | 2.5 ÷ 4.5 |

| Computational complexity | Low | High | Low | High |

| Total number of signals | 1 | 1 | 2 | 3 |

| Process | Stationary | Stationary | Stationary | Non-stationary |

| Signal recording time | 10 s | 1 s | 1 revolution | 1 revolution |

| Constraint | — | — | n > 900 rpm | n > 750 rpm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ewert, P.; Kowalski, C.T.; Jaworski, M. Comparison of the Effectiveness of Selected Vibration Signal Analysis Methods in the Rotor Unbalance Detection of PMSM Drive System. Electronics 2022, 11, 1748. https://doi.org/10.3390/electronics11111748

Ewert P, Kowalski CT, Jaworski M. Comparison of the Effectiveness of Selected Vibration Signal Analysis Methods in the Rotor Unbalance Detection of PMSM Drive System. Electronics. 2022; 11(11):1748. https://doi.org/10.3390/electronics11111748

Chicago/Turabian StyleEwert, Pawel, Czeslaw T. Kowalski, and Michal Jaworski. 2022. "Comparison of the Effectiveness of Selected Vibration Signal Analysis Methods in the Rotor Unbalance Detection of PMSM Drive System" Electronics 11, no. 11: 1748. https://doi.org/10.3390/electronics11111748

APA StyleEwert, P., Kowalski, C. T., & Jaworski, M. (2022). Comparison of the Effectiveness of Selected Vibration Signal Analysis Methods in the Rotor Unbalance Detection of PMSM Drive System. Electronics, 11(11), 1748. https://doi.org/10.3390/electronics11111748