Techno-Economic Evaluation of 5G-NSA-NPN for Networked Control Systems

Abstract

:1. Introduction

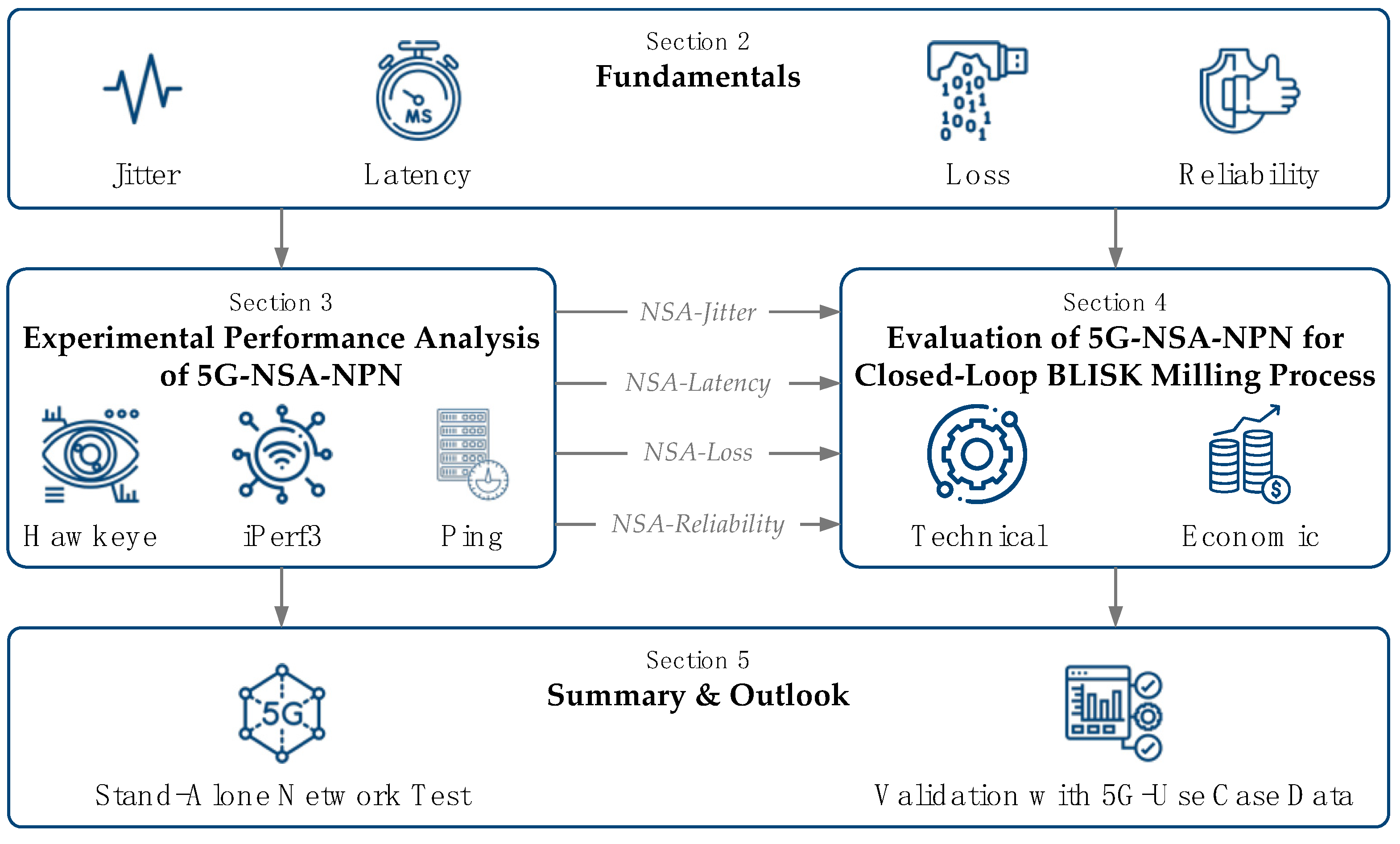

2. Fundamentals

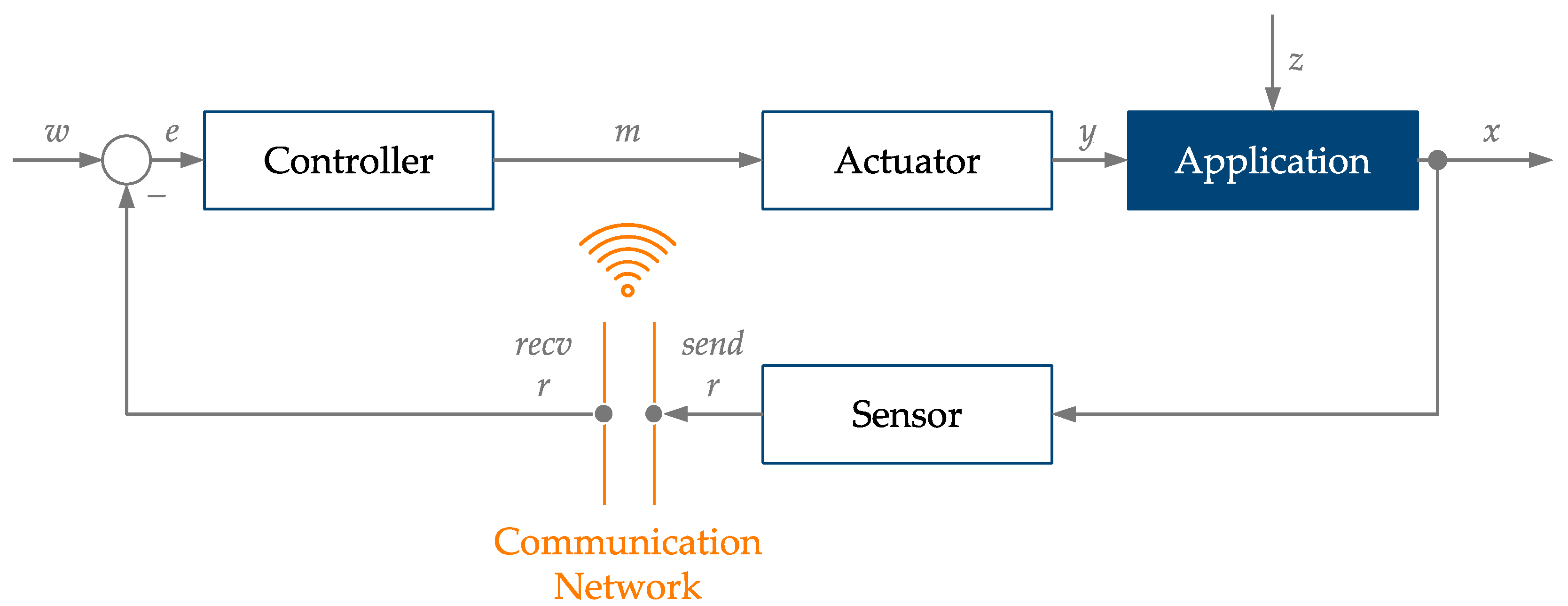

2.1. Networked Control System

2.2. Performance Characteristics of Wireless Communication Technologies

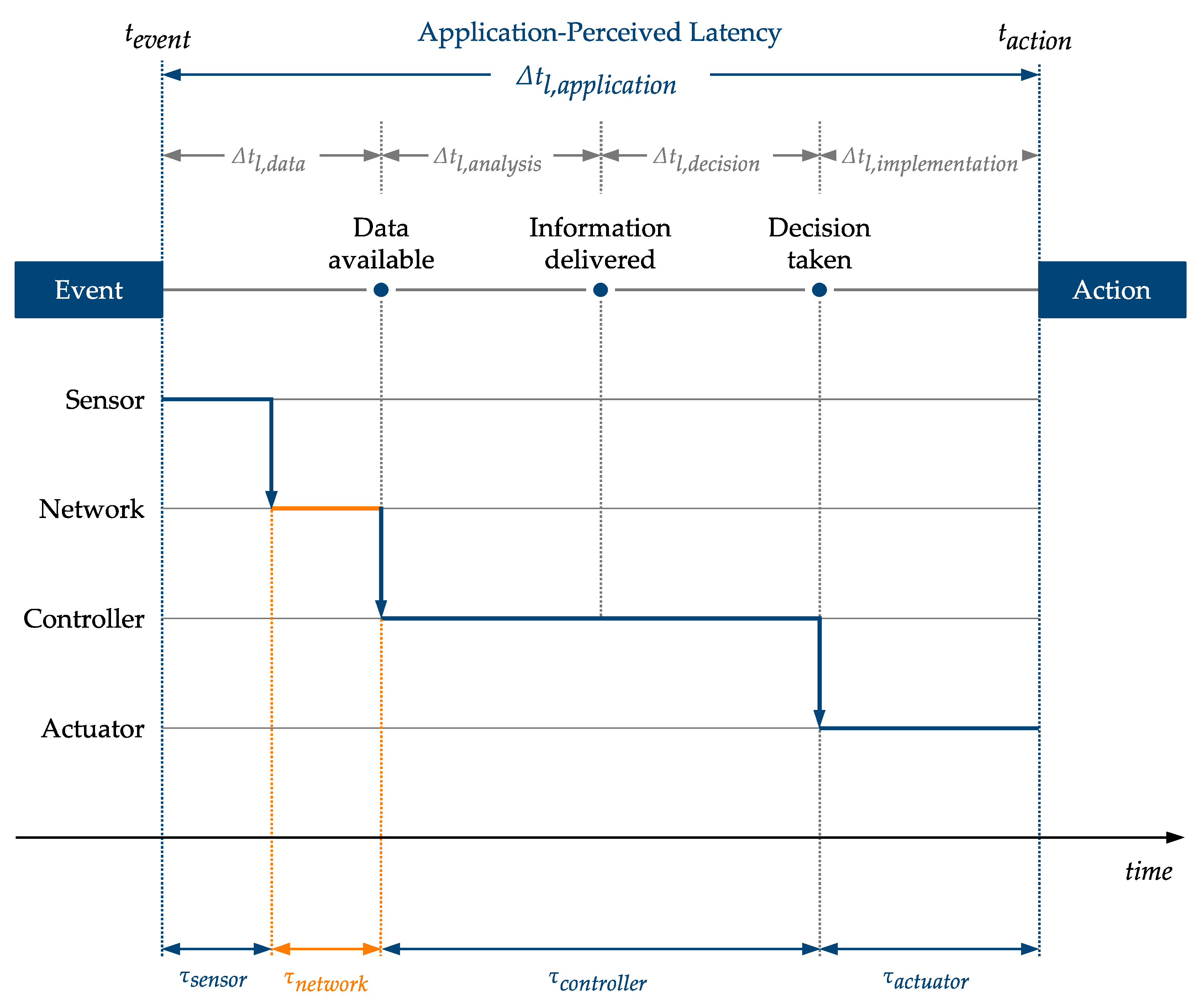

2.2.1. Latency

2.2.2. Jitter

2.2.3. Loss

2.2.4. Reliability

2.3. 5G-Technology Network Architecture

3. Performance Analysis of 5G-NSA-NPN

3.1. Experimental Setup and Test Methods

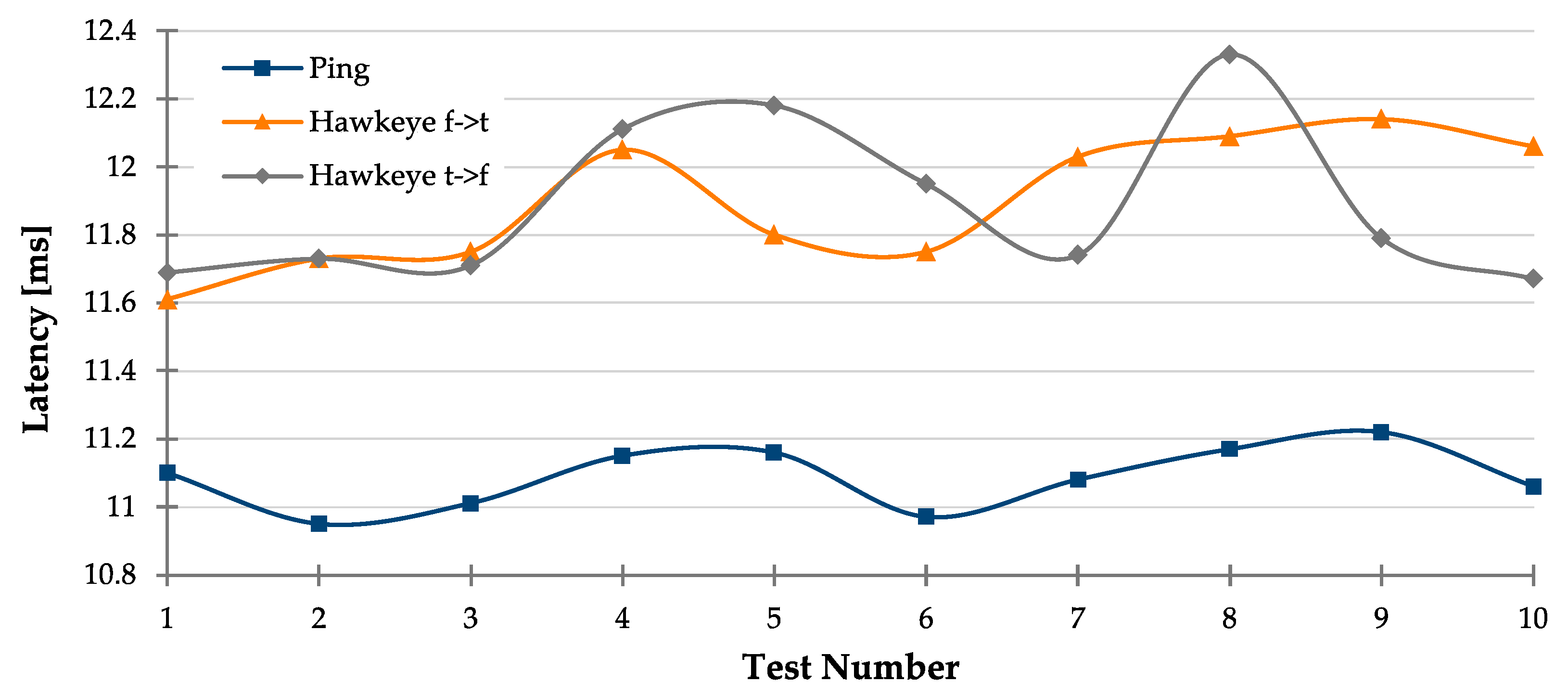

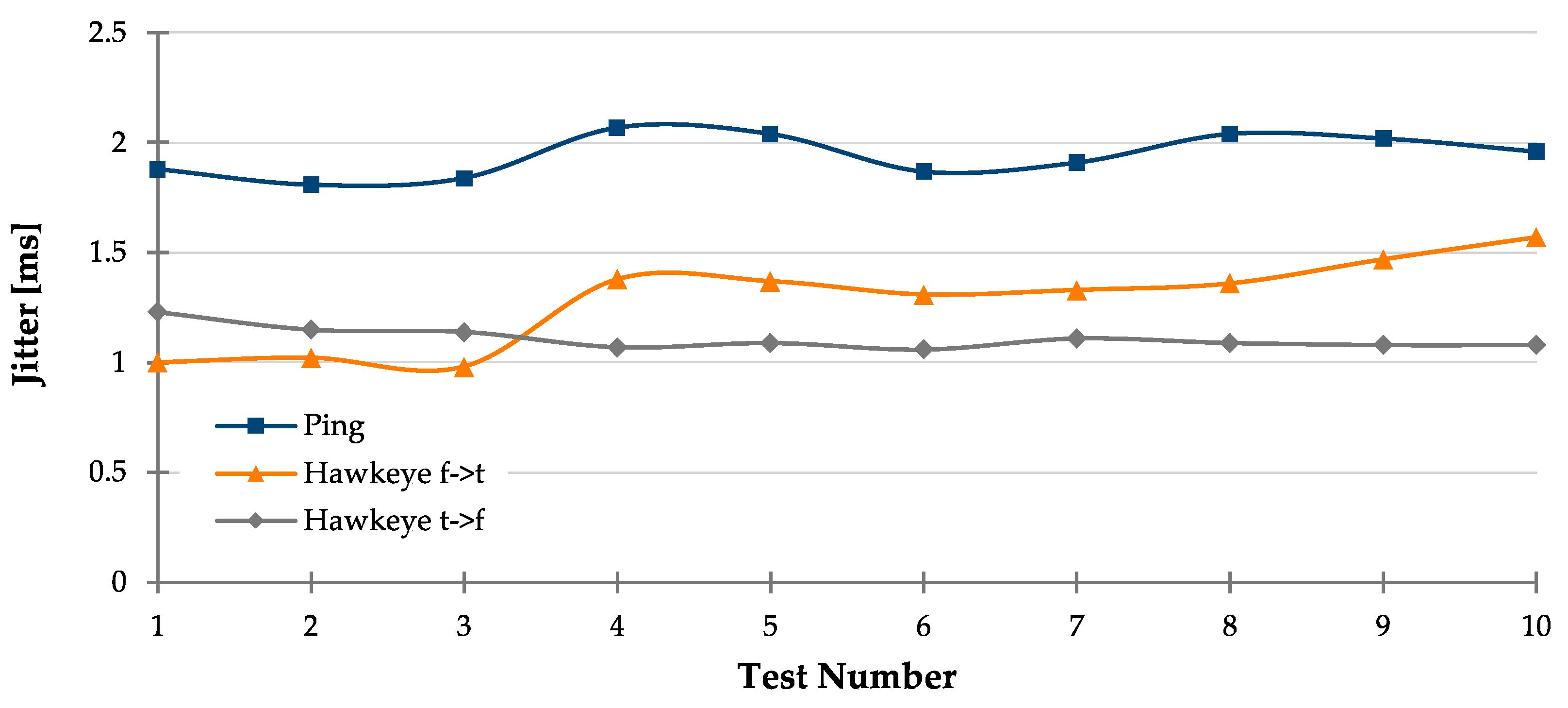

3.2. Experimental Results

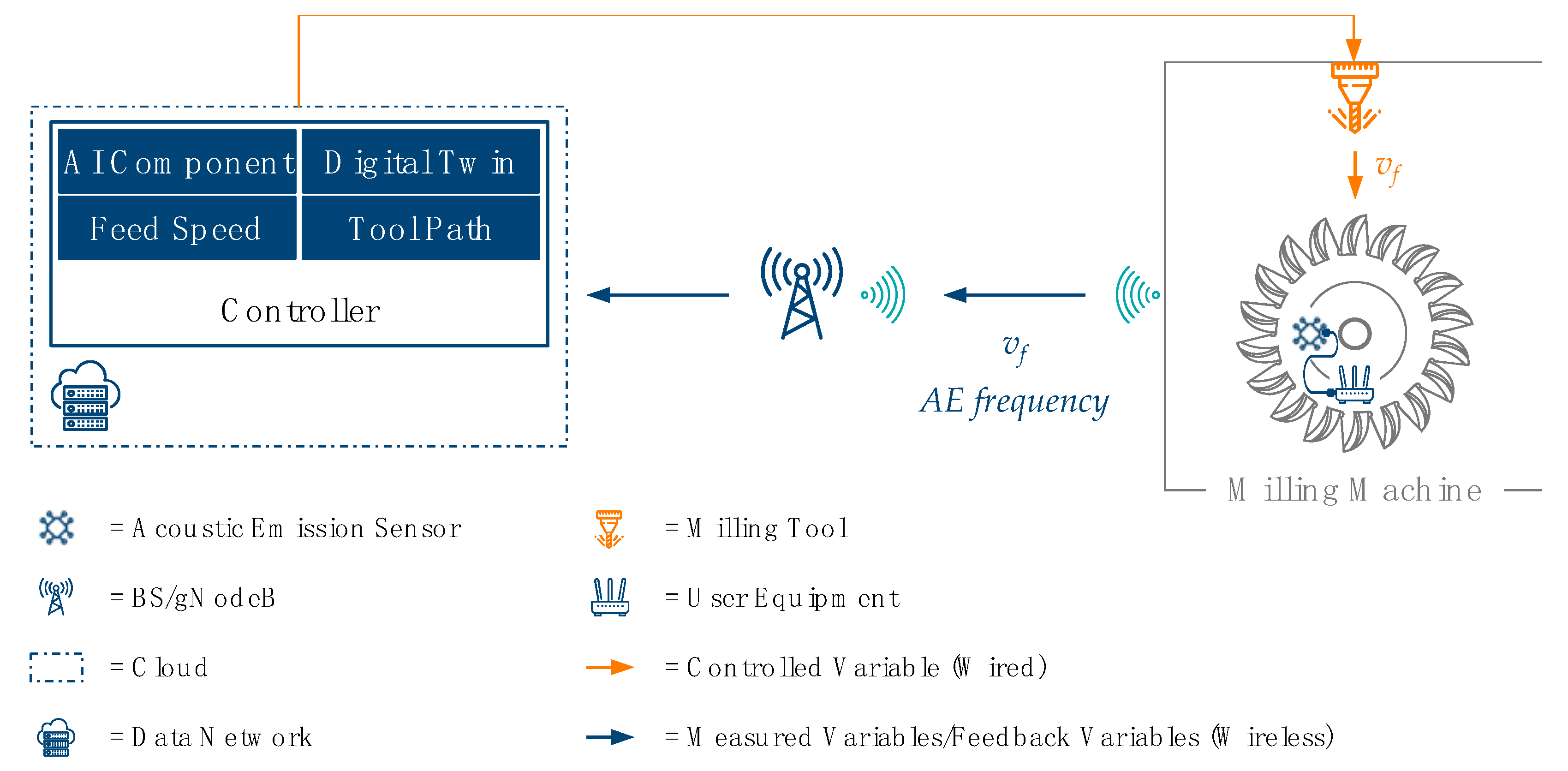

4. Evaluation of 5G-NSA-NPN for Closed-Loop BLISK Milling Process

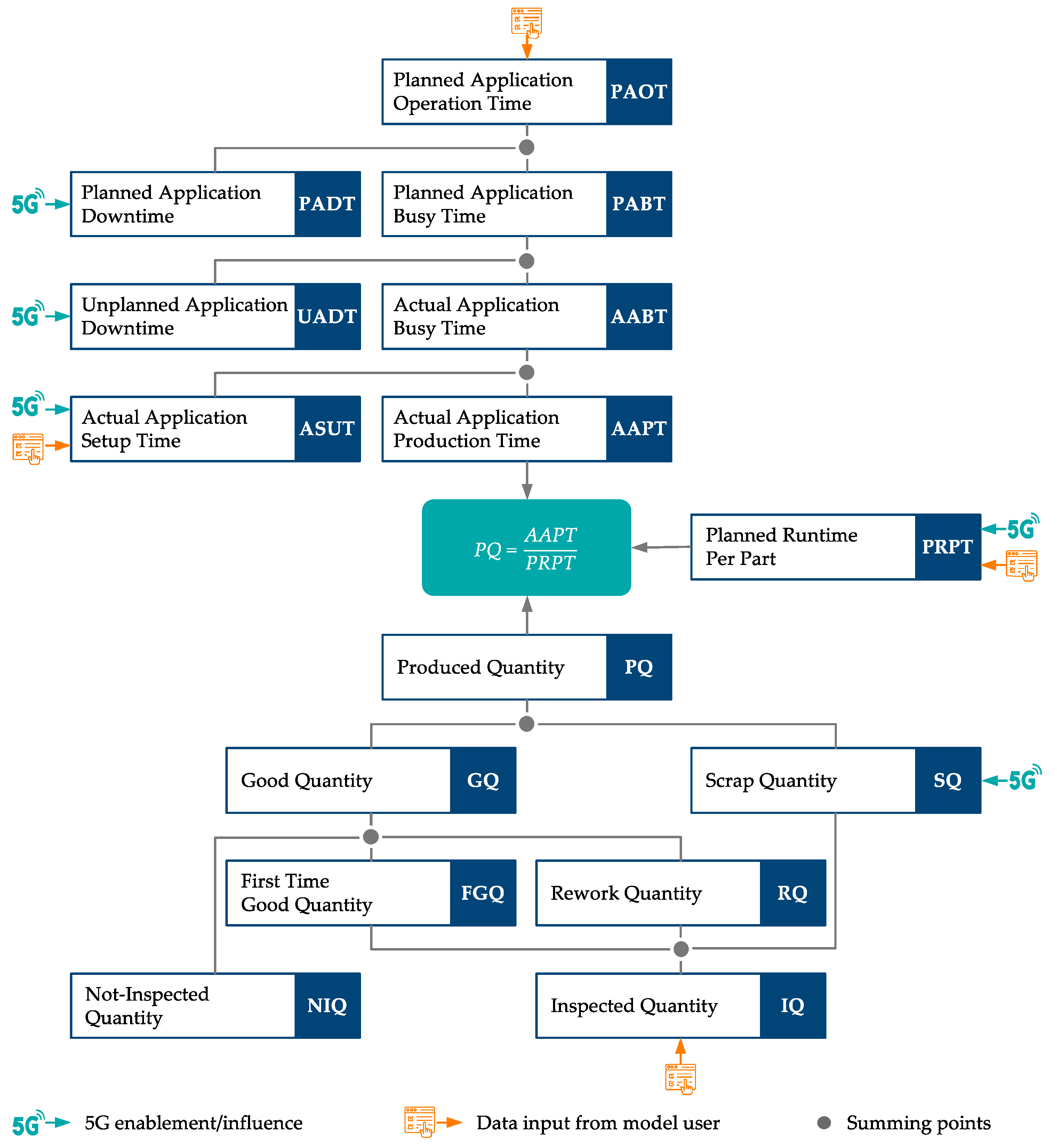

4.1. Approach for Techno-Economic Evaluation

4.2. Application of Approach to Evaluate the Impact of 5G-NSA-NPN on BLISK Milling Process

4.2.1. Application Specification

4.2.2. 5G-Deployment Goal Selection

4.2.3. 5G-Control Task Selection

4.2.4. Data Entry

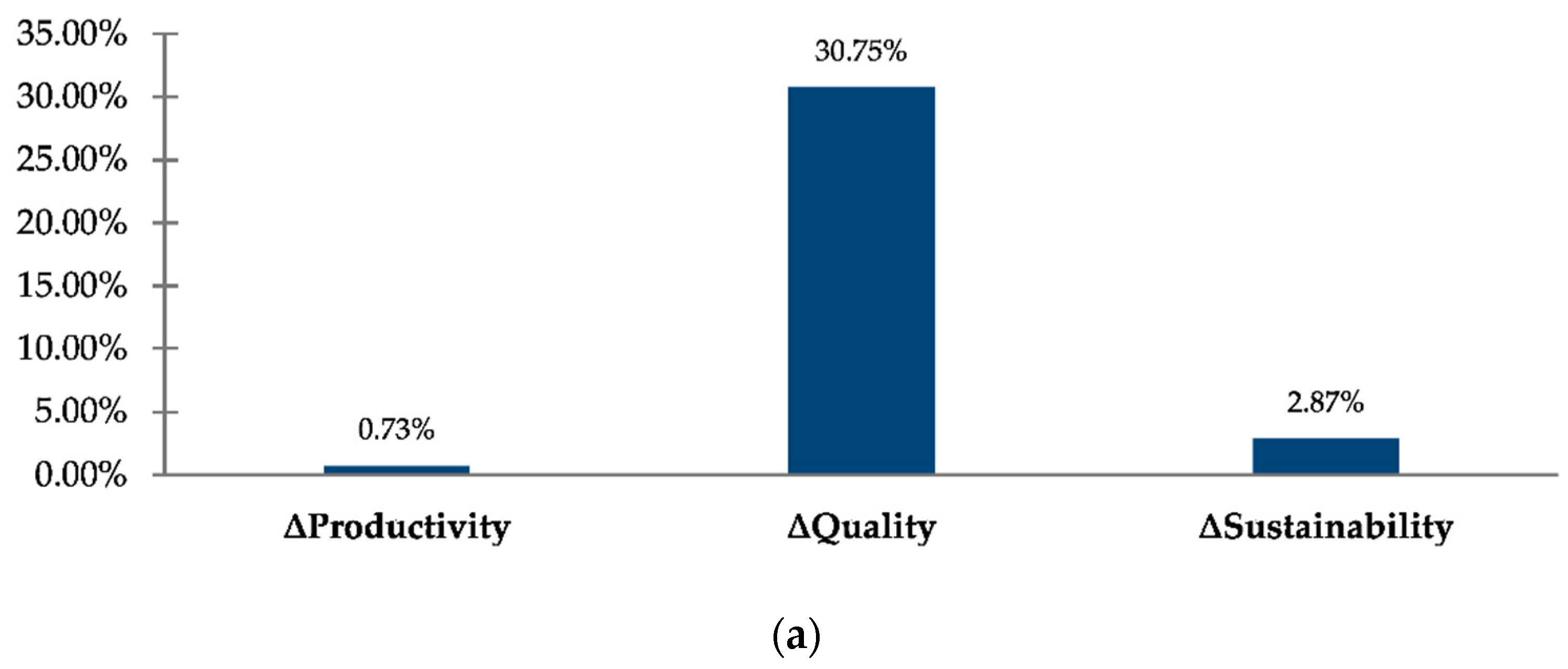

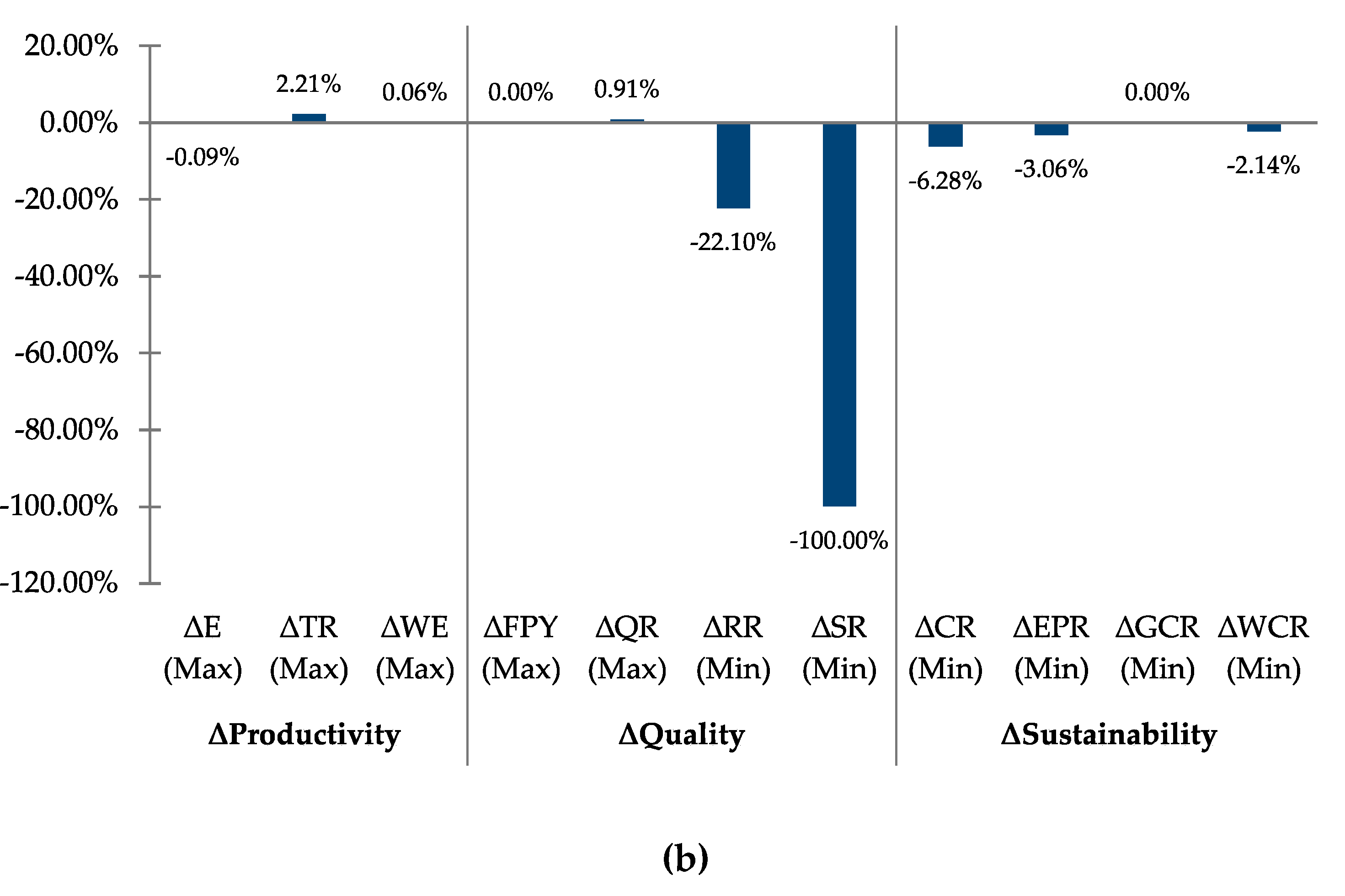

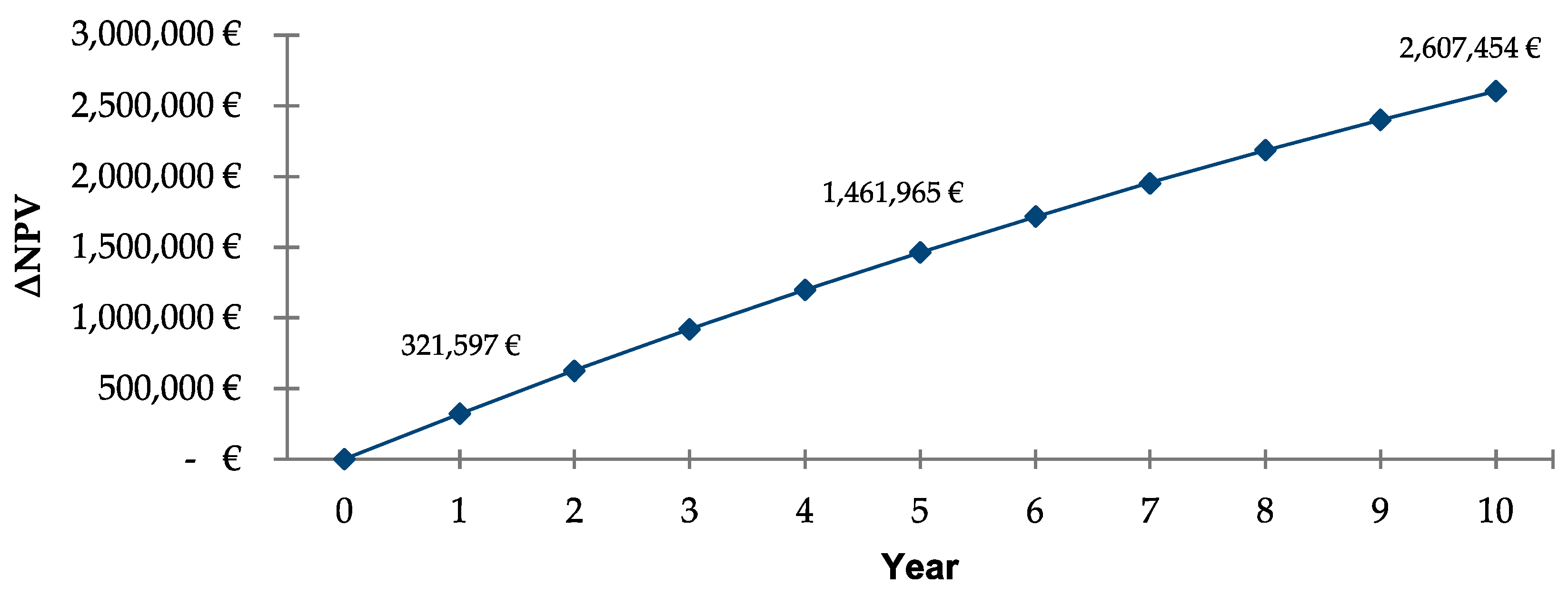

4.2.5. Goal Evaluation

5. Conclusions and Outlook

Author Contributions

Funding

Conflicts of Interest

Appendix A. Mathematical Model Explanations

Appendix B. Use Case Data

| Data | Unit | Value | Data Type | Data Source | Goal | |||

|---|---|---|---|---|---|---|---|---|

| Productivity | Quality | Sustainability | NPV and RoI | |||||

| Application—Total Number | [ ] | 1 | Application | U | x | |||

| Application—Lifetime | y | 10 | Application | U | x | |||

| Tool Change—Duration | h | 0.166 | Application | U | x | x | x | x |

| Tool Change—Number of Change per BLISK | [ ] | 1 | Application | U | x | x | x | x |

| Workpiece Change—Duration | h | 0.166 | Facility | U | x | x | x | x |

| Compressed Air—Consumption of Application | L/min | 150 | Facility | U | x | x | ||

| Compressed Air—Consumption of Rework | L/min | 260 | Facility | U | x | x | ||

| Compressed Air—Cost | €/L | 0.01 | Facility | U | x | |||

| Convergence Factor from kWh to CO2 | kg CO2/kWh | 3 | Facility | L | x | x | ||

| Electric Power—Cost | €/kWh | 0.319 | Facility | U | x | |||

| Electric Power—Hourly Appl. Consumption | kW | 13 | Facility | U | x | x | ||

| Electric Power—Hourly Network Consumption | kW | 1 | Facility | L | x | x | ||

| Electric Power—Hourly Rework Consumption | kW | 1 | Facility | U | x | x | ||

| Energy—CO2 Tax | €/t | 30 | Facility | U | x | |||

| Gas—Consumption | BTU | 0 | Facility | U | x | x | ||

| Water—Consumption | l/h | 50 | Facility | U | x | x | ||

| Water—Cost | €/L | 0.05 | Facility | U | x | |||

| Failure Events—Accidents per Day | [ ] | 0 | Failure | U | x | |||

| Failure Events—Costs for Tool Breakage | € | 1000 | Failure | U | x | |||

| Failure Events—TTR per Tool Breakage | h | 2 | Failure | U | x | x | x | x |

| Failure Events—Wage of Repairment Staff | €/h | 35 | Failure | U | x | |||

| Application Downtime—Planned—Cost | €/h | 180 | Process | U | x | |||

| Application Downtime—Unplanned—Cost | €/h | 1500 | Process | U | x | |||

| Application Maintenance—Time per Operation | h | 2 | Process | U | x | x | x | x |

| Application Maintenance—Operations per Day | [ ] | 0.2 | Process | U | x | x | x | x |

| Application Operation Time—Planned per Day | h | 16 | Process | U | x | x | x | x |

| Application Setup—Number per Day | [ ] | 1 | Process | U | x | x | x | x |

| Application Setup—Time per Setup | h | 0.5 | Process | U | x | x | x | x |

| Application Setup—Wage of Setup Staff | €/h | 35 | Process | U | x | |||

| Batch Size | [ ] | 1 | Process | U | x | x | x | x |

| Human Operation—Operator per Shift | [ ] | 1 | Process | U | x | |||

| Human Operation—Planned Break Time/Shift | h | 0.5 | Process | U | x | x | ||

| Human Operation—Planned Work Time/Shift | h | 8 | Process | U | x | x | ||

| Human Operation—Shifts per Day | [ ] | 2 | Process | U | x | x | ||

| Human Operation—Wage of Staff | €/h | 35 | Process | U | x | |||

| Production—Days per Year | d | 250 | Process | U | x | x | x | x |

| Disposal—Cost per Part | € | 5000 | Product | U | x | |||

| Individualization—Additional Profit | € | 0 | Product | U | x | |||

| Individualization—Percentage | % | 0 | Product | U | x | |||

| Material—Cost per Part | € | 1500 | Product | U | x | |||

| Material—Cost for Rework per Part | € | 0 | Product | U | x | |||

| Products—Selling Price per Part | € | 27,500 | Product | U | x | |||

| Quality Control—Inspection Percentage | % | 100 | Product | U | x | x | x | |

| Quality Control—Inspection Time per Part | h | 4 | Product | U | x | x | ||

| Quality Control—Cost per Part | € | 1000 | Product | U | x | |||

| Rework—Duration—Basic for one Part | h | 4 | Product | U | x | x | x | |

| Rework—Duration—Per Vibration | s | 60 | Product | U | x | x | x | |

| Rework—Wage of Staff | €/h | 35 | Product | U | x | |||

| Rework—Percentage | % | 100 | Product | U | x | x | ||

| Annual Interest Rate | % | 5 | Additional | U | x | |||

References

- Aijaz, A.; Stanoev, A. Closing the Loop: A High-Performance Connectivity Solution for Realizing Wireless Closed-Loop Control in Industrial IoT Applications. IEEE Internet Things J. 2021, 8, 11860–11876. [Google Scholar] [CrossRef]

- Jeschke, S.; Brecher, C.; Meisen, T.; Özdemir, D.; Eschert, T. Industrial Internet of Things and Cyber Manufacturing Systems. In Industrial Internet of Things; Springer: Berlin/Heidelberg, Germany, 2017; pp. 3–19. [Google Scholar]

- Lyczkowski, E.; Wanjek, A.; Sauer, C.; Kiess, W. Wireless Communication in Industrial Applications. In Proceedings of the 2019 24th IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Zaragoza, Spain, 10–13 September 2019; pp. 1392–1395. [Google Scholar]

- Åkerberg, J.; Gidlund, M.; Björkman, M. Future Research Challenges in Wireless Sensor and Actuator Networks Targeting Industrial Automation. In Proceedings of the 2011 9th IEEE International Conference on Industrial Informatics, Lisbon, Portugal, 26–29 July 2011; pp. 410–415. [Google Scholar]

- Baumann, D.; Mager, F.; Wetzker, U.; Thiele, L.; Zimmerling, M.; Trimpe, S. Wireless Control for Smart Manufacturing: Recent Approaches and Open Challenges. Proc. IEEE 2020, 109, 441–467. [Google Scholar] [CrossRef]

- Siegl, S. Networked Control Systems: Ein Überblick; Universität der Bundeswehr München: Munich, Germany, 2017. [Google Scholar]

- Zuehlke, D. SmartFactory—Towards a Factory-of-Things. Annu. Rev. Control 2010, 34, 129–138. [Google Scholar] [CrossRef]

- Scheuvens, L.; Simsek, M.; Noll-Barreto, A.; Franchi, N.; Fettweis, G.P. Framework for Adaptive Controller Design Over Wireless Delay-Prone Communication Channels. IEEE Access 2019, 7, 49726–49737. [Google Scholar] [CrossRef]

- Schulz, P.; Matthe, M.; Klessig, H.; Simsek, M.; Fettweis, G.; Ansari, J.; Ashraf, S.A.; Almeroth, B.; Voigt, J.; Riedel, I. Latency Critical IoT Applications in 5G: Perspective on the Design of Radio Interface and Network Architecture. IEEE Commun. Mag. 2017, 55, 70–78. [Google Scholar] [CrossRef]

- Varghese, A.; Tandur, D. Wireless Requirements and Challenges in Industry 4.0. In Proceedings of the 2014 International Conference on Contemporary Computing and Informatics (IC3I), Mysore, India, 27–29 November 2014; pp. 634–638. [Google Scholar]

- Stefanović, Č. Industry 4.0 from 5G Perspective: Use-Cases, Requirements, Challenges and Approaches. In Proceedings of the 2018 11th CMI International Conference: Prospects and Challenges towards Developing a Digital Economy within the EU, Copenhagen, Denmark, 29–30 November 2018; pp. 44–48. [Google Scholar]

- Aijaz, A. Private 5G: The Future of Industrial Wireless. arXiv 2020, arXiv:2006.01820. [Google Scholar] [CrossRef]

- Adib, D.; Barraclough, C. 5G’s Impact on Manufacturing-$740 BN of Benefits in 2030. STL Partn. Exec. Brief 2019, 1, 1–40. [Google Scholar]

- Boston Consulting Group. 5G Promises Massive Job and GDP Growth in the US. 2021. Available online: https://www.bcg.com/publications/2021/5g-economic-impact-united-states (accessed on 27 April 2022).

- MHP Management und IT-Beratung. Industrie 4.0 Barometer 2020; MHP Management und IT-Beratung: Munich, Germany, 2021. [Google Scholar]

- Digital Catapult. Made in 5G—5G for the UK Manufacturing Sector; UK5G: London, UK, 2019. [Google Scholar]

- 5G Alliance for Connected Industries and Automation. 5G Non-Public Networks for Industrial Scenarios; ZVEI–German Electrical and Electronic Manufacturers’ Association: Frankfurt am Main, Germany, 2019. [Google Scholar]

- Gupta, R.A.; Chow, M.-Y. Networked Control System: Overview and Research Trends. IEEE Trans. Ind. Electron. 2010, 57, 2527–2535. [Google Scholar] [CrossRef]

- Xia, F.; Tian, Y.-C.; Li, Y.; Sung, Y. Wireless Sensor/Actuator Network Design for Mobile Control Applications. Sensors 2007, 7, 2157–2173. [Google Scholar] [CrossRef] [PubMed]

- Chow, M.-Y.; Tipsuwan, Y. Network-Based Control Systems: A Tutorial. In Proceedings of the IECON’01. 27th Annual Conference of the IEEE Industrial Electronics Society (Cat. No. 37243), Denver, CO, USA, 29 November–2 December 2001; pp. 1593–1602. [Google Scholar]

- Kiesel, R.; Jakob, F.; Vollmer, T.; Schmitt, R.H. Evaluation of ICT for Networked Control Systems of Latency-Critical Applications in Production. In Proceedings of the 15th CIRP Conference on Intelligent Computation in Manufacturing Engineering, Gulf of Naples, Italy, 13–15 July 2022. (currently being published). [Google Scholar]

- Ploplys, N.J.; Kawka, P.A.; Alleyne, A.G. Closed-Loop Control over Wireless Networks. IEEE Control Syst. Mag. 2004, 24, 58–71. [Google Scholar]

- Kartashevskiy, V.; Buranova, M. Analysis of packet jitter in multiservice network. In Proceedings of the 2018 International Scientific-Practical Conference Problems of Infocommunications. Science and Technology (PIC S&T), Kharkiv, Ukraine, 9–12 October 2018; pp. 797–802. [Google Scholar]

- Leng, Q.; Wei, Y.-H.; Han, S.; Mok, A.K.; Zhang, W.; Tomizuka, M. Improving control performance by minimizing jitter in RT-WiFi networks. In Proceedings of the 2014 IEEE Real-Time Systems Symposium, Rome, Italy, 2–5 December 2014; pp. 63–73. [Google Scholar]

- She, C.; Yang, C.; Quek, T.Q. Radio resource management for ultra-reliable and low-latency communications. IEEE Commun. Mag. 2017, 55, 72–78. [Google Scholar] [CrossRef]

- Dahlman, E.; Parkvall, S.; Skold, J. 5G NR: The Next Generation Wireless Access Technology; Academic Press: Cambridge, MA, USA, 2020. [Google Scholar]

- Ericsson. 5G Deployment Considerations; Ericsson: Stockholm, Sweden, 2018; Available online: https://www.ericsson.com/en/reports-and-papers/5g-deployment-considerations (accessed on 27 April 2022).

- Siddiqi, M.A.; Yu, H.; Joung, J. 5G Ultra-Reliable Low-Latency Communication Implementation Challenges and Operational Issues with IoT Devices. Electronics 2019, 8, 981–998. [Google Scholar] [CrossRef] [Green Version]

- NGMN Alliance. 5G E2E Technology to Support Verticals URLLC Requirements. 2019. Available online: https://www.ngmn.org/wp-content/uploads/200210-Verticals-URLLC-Requirements-v2.5.4.pdf (accessed on 27 April 2022).

- International Telecommunication Union. Recommendation ITU-R M.2083-0: IMT Vision—Framework and Overall Objectives of the Future Development of IMT for 2020 and Beyond; International Telecommunication Union: Geneva, Switzerland, 2015. [Google Scholar]

- Ghosh, A.; Maeder, A.; Baker, M.; Chandramouli, D. 5G Evolution: A View on 5G Cellular Technology beyond 3GPP Release 15. IEEE Access 2019, 7, 127639–127651. [Google Scholar] [CrossRef]

- Lennvall, T.; Gidlund, M.; Åkerberg, J. Challenges when Bringing IoT into Industrial Automation. In Proceedings of the 2017 IEEE AFRICON, Cape Town, South Africa, 18–20 September 2017; pp. 905–910. [Google Scholar]

- Kiesel, R.; Böhm, F.; Pennekamp, J.; Schmitt, R.H. Development of a Model to Evaluate the Potential of 5G Technology for Latency-Critical Applications in Production. In Proceedings of the IEEE International Conference on Industrial Engineering and Engineering Management (IEEM) 2021, Singapore, 13–16 December 2021; pp. 739–744. [Google Scholar]

- Kiesel, R.; Henke, L.; Mann, A.; Renneberg, F.; Stich, V.; Schmitt, R.H. Techno-Economic Evaluation of 5G Technology for Automated Guided Vehicles in Production. Electronics 2022, 11, 192. [Google Scholar] [CrossRef]

- Kiesel, R.; Stichling, K.; Hemmers, P.; Vollmer, T.; Schmitt, R.H. Quantification of Influence of 5G Technology Implementation on Process Performance in Production. In Proceedings of the 54th CIRP Conference on Manufacturing Systems, Athen, Greece, 22–24 September 2021; pp. 104–109. [Google Scholar]

- Klocke, F.; Zeis, M.; Klink, A.; Veselovac, D. Technological and Economical Comparison of Roughing Strategies via Milling, EDM and ECM for Titanium-and Nickel-Based BLISKs. Procedia Cirp 2012, 2, 98–101. [Google Scholar] [CrossRef]

- Ericsson. 5G Business Value—A Case Study on Real-Time Control in Manufacturing; Ericsson: Stockholm, Sweden, 2018; Available online: https://www.ericsson.com/en/reports-and-papers/consumerlab/reports/5g-business-value-to-industry-blisk (accessed on 27 April 2022).

- Kehl, P.; Lange, D.; Maurer, F.K.; Németh, G.; Overbeck, D.; Jung, S.; König, N.; Schmitt, R.H. Comparison of 5G Enabled Control Loops for Production. In Proceedings of the 2020 IEEE 31st Annual International Symposium on Personal, Indoor and Mobile Radio Communications, London, UK, 31 August–3 September 2020; pp. 1–6. [Google Scholar]

- Pike, R.; Neale, B.; Linsley, P. Corporate Finance and Investment: Decisions & Strategies; Pearson Education Limited: Harlow, UK, 2015. [Google Scholar]

- Klocke, F.; Zeis, M.; Klink, A.; Veselovac, D. Technological and Economical Comparison of Roughing Strategies via Milling, Sinking-EDM, Wire-EDM and ECM for Titanium- and Nickel-Based Blisks. CIRP J. Manuf. Sci. Technol. 2013, 6, 198–203. [Google Scholar] [CrossRef]

- Klocke, F. Fertigungsmesstechnik und Werkstückqualität. In Fertigungsverfahren 1; Springer: Berlin/Heidelberg, Germany, 2018; pp. 5–45. [Google Scholar]

- Fricke, K.; Gierlings, S.; Ganser, P.; Venek, T.; Bergs, T. Geometry Model and Approach for Future Blisk LCA. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Chennai, India, 16–17 September 2020. [Google Scholar] [CrossRef]

- Calleja, A.; González, H.; Polvorosa, R.; Gómez, G.; Ayesta, I.; Barton, M.; de Lacalle, L.L. Blisk Blades Manufacturing Technologies Analysis. Procedia Manuf. 2019, 41, 714–722. [Google Scholar] [CrossRef]

| Frequency Range Designation | Frequency Band | Existing/New | Frequency Range [MHz] |

|---|---|---|---|

| FR1 | Low Bands | Existing/New | 410–960 |

| Mid Bands I | Existing | 1000–2600 | |

| Mid Bands II | New | 3300–7125 | |

| FR2 | High Bands | New | 24,250–52,600 |

| Ping Test | Hawkeye [from → to] | Hawkeye [to → from] | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Latency [ms] | Jitter [ms] | Latency [ms] | Jitter [ms] | Latency [ms] | Jitter [ms] | |||||||

| Nr. | Avg. | Min. | Max. | Avg. | Avg. | Min. | Max. | Avg. | Avg. | Min. | Max. | Avg. |

| 1 | 11.10 | 7.66 | 18.70 | 1.88 | 11.61 | 7 | 16 | 1 | 11.69 | 7 | 16 | 1.23 |

| 2 | 10.95 | 7.47 | 17.32 | 1.81 | 11.73 | 7 | 17 | 1.02 | 11.73 | 8 | 15 | 1.15 |

| 3 | 11.01 | 7.76 | 16.68 | 1.84 | 11.75 | 8 | 16 | 0.98 | 11.71 | 7 | 16 | 1.14 |

| 4 | 11.15 | 7.09 | 20.43 | 2.07 | 12.05 | 8 | 16 | 1.38 | 12.11 | 8 | 18 | 1.07 |

| 5 | 11.16 | 7.36 | 17.31 | 2.04 | 11.80 | 6 | 15 | 1.37 | 12.18 | 7 | 17 | 1.09 |

| 6 | 10.97 | 7.27 | 17.20 | 1.87 | 11.75 | 8 | 16 | 1.31 | 11.95 | 8 | 18 | 1.06 |

| 7 | 11.08 | 7.52 | 19,21 | 1.91 | 12.03 | 7 | 15 | 1.33 | 11.74 | 8 | 19 | 1.11 |

| 8 | 11.17 | 7.46 | 19.91 | 2.04 | 12.09 | 7 | 16 | 1.36 | 12.33 | 8 | 16 | 1.09 |

| 9 | 11.22 | 7.41 | 17.80 | 2.02 | 12.14 | 7 | 17 | 1.47 | 11.79 | 8 | 17 | 1.08 |

| 10 | 11.06 | 7.43 | 18.19 | 1.96 | 12.06 | 5 | 17 | 1.57 | 11.67 | 8 | 16 | 1.08 |

| Nr. | Loss [%] | Reliability [%] |

|---|---|---|

| 1 | 0.0027 | 99.9973 |

| 2 | 0.0013 | 99.9987 |

| 3 | 0.0027 | 99.9973 |

| 4 | 0.0040 | 99.9960 |

| 5 | 0.0027 | 99.9973 |

| 6 | 0.0027 | 99.9973 |

| 7 | 0.0013 | 99.9987 |

| 8 | 0.0047 | 99.9953 |

| 9 | 0.0013 | 99.9987 |

| 10 | 0.0040 | 99.9960 |

| Performance Characteristic | Test Method | Nominal Value According to ITU Specifications | Measured Mean-Value at IPT NSA-NPN |

|---|---|---|---|

| Jitter [ms] | Hawkeye/Ping | n/a | 1.19/1.94 |

| Latency [ms] | Hawkeye/Ping | 1.0 | 11.89/11.09 |

| Loss [%] | iperf3 | 0.001 | 0.003 |

| Reliability [%] | Iperf3 | 99.999 | 99.997 |

| Goal | Description | Key Performance Indicator | Trend |

|---|---|---|---|

| Productivity | Output per unit of input over a specific period; also: production efficiency | Effectiveness (E) | Max |

| Throughput Ratio (TR) | Max | ||

| Worker Efficiency (WE) | Max | ||

| Quality | Degree to which the output of the production process meets the requirements | First Pass Yield (FPY) | Max |

| Quality Ratio (QR) | Max | ||

| Rework Ratio (RR) | Min | ||

| Scrap Ratio (SR) | Min | ||

| Sustainability | Level to which the creation of manufactured products is fulfilled by processes that are nonpolluting | Compressed Air Consumption Ratio (ACR) | Min |

| Electric Power Consumption Ratio (ECR) | Min | ||

| Gas Consumption Ratio (GCR) | Min | ||

| Water Consumption Ratio (WCR) | Min |

| Control Task Property | Unit | Roughing i = r | Pre-Finishing i = p | Finishing (Blade) i = f,b | Finishing (Hub) i = f,h |

|---|---|---|---|---|---|

| Cutting Depth (Axial) | mm | ||||

| Cutting Depth (Radial) | mm | ||||

| Feed Speed | mm/s | ||||

| Feed Speed Adoption Time | s | ||||

| Surface Thickness | mm | ||||

| Tool Breakage | n°/h | ||||

| Tool Damage | n°/h | ||||

| Vibrations causing Marks | n°/min |

| Control Task Property | Unit | Roughing i = r | Pre-Finishing i = p | Finishing (Blade) i = f,b | Finishing (Hub) i = f,h |

|---|---|---|---|---|---|

| Cutting Depth (Axial) | mm | 7.5 | 5.0 | 0.6 | 0.6 |

| Cutting Depth (Radial) | mm | 2.0 | 2.0 | 0.5 | 1.0 |

| Feed Speed (without 5G) | mm/min | 1200 | 730 | 350 | 450 |

| Feed Speed (with 5G) | mm/min | 1250 | 750 | 360 | 460 |

| Feed Speed Adoption Time | s | 0.00 | 0.25 | 5.00 | 1.00 |

| Surface Thickness | mm | 10.0 | 5.0 | 0.011 | 0.017 |

| Tool Breakage | n°/h | 1/10,000 | 1/10,000 | 1/100,000 | 1/100,000 |

| Tool Damage | n°/h | 1/100,000 | 1/100,000 | 1/100,000 | 1/100,000 |

| Vibrations causing Marks | n°/min | 0.00 | 0.01 | 0.20 | 0.10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kiesel, R.; Schmitt, S.; König, N.; Brochhaus, M.; Vollmer, T.; Stichling, K.; Mann, A.; Schmitt, R.H. Techno-Economic Evaluation of 5G-NSA-NPN for Networked Control Systems. Electronics 2022, 11, 1736. https://doi.org/10.3390/electronics11111736

Kiesel R, Schmitt S, König N, Brochhaus M, Vollmer T, Stichling K, Mann A, Schmitt RH. Techno-Economic Evaluation of 5G-NSA-NPN for Networked Control Systems. Electronics. 2022; 11(11):1736. https://doi.org/10.3390/electronics11111736

Chicago/Turabian StyleKiesel, Raphael, Sarah Schmitt, Niels König, Maximilian Brochhaus, Thomas Vollmer, Kirstin Stichling, Alexander Mann, and Robert H. Schmitt. 2022. "Techno-Economic Evaluation of 5G-NSA-NPN for Networked Control Systems" Electronics 11, no. 11: 1736. https://doi.org/10.3390/electronics11111736

APA StyleKiesel, R., Schmitt, S., König, N., Brochhaus, M., Vollmer, T., Stichling, K., Mann, A., & Schmitt, R. H. (2022). Techno-Economic Evaluation of 5G-NSA-NPN for Networked Control Systems. Electronics, 11(11), 1736. https://doi.org/10.3390/electronics11111736