An IoT System for Real-Time Monitoring of DC Motor Overload

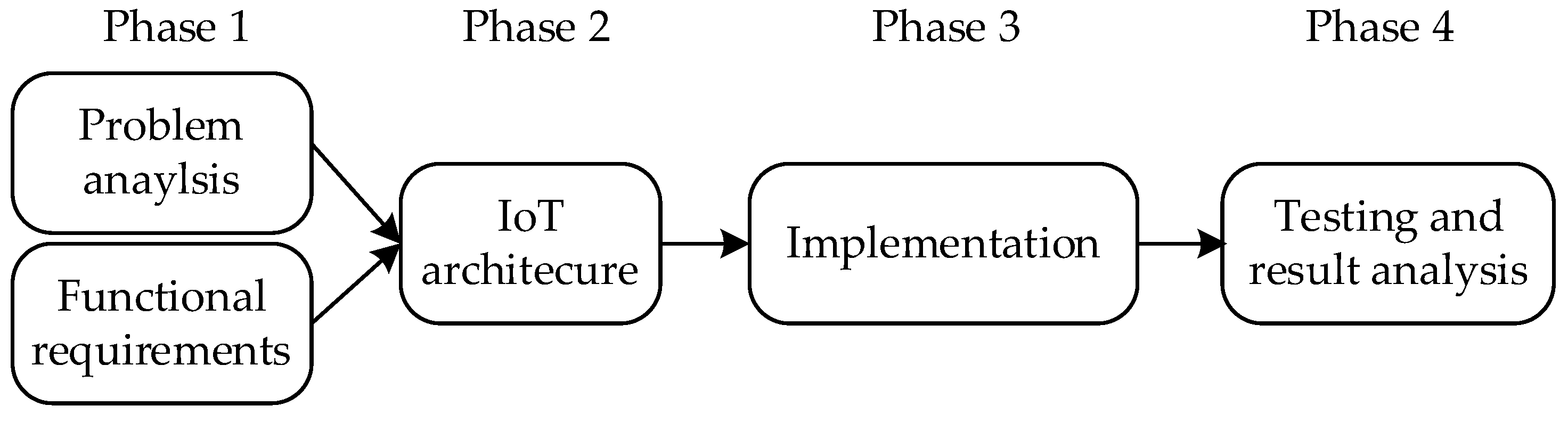

Abstract

:1. Introduction

2. Analysis of the Problem

2.1. The Case Study of the EKG-15 Excavator

2.2. Functional Requirements

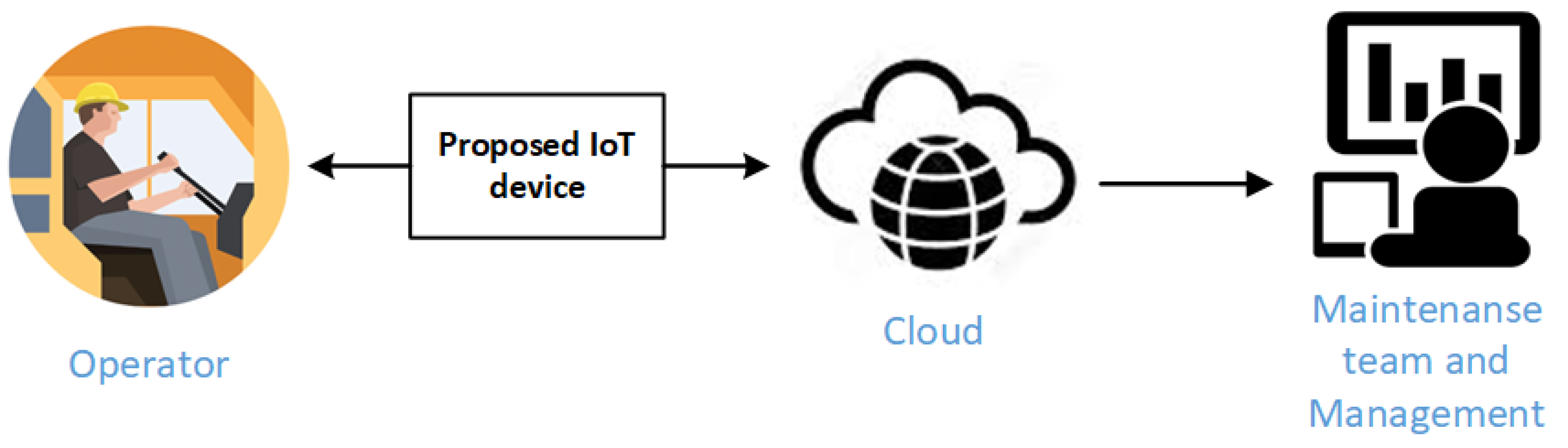

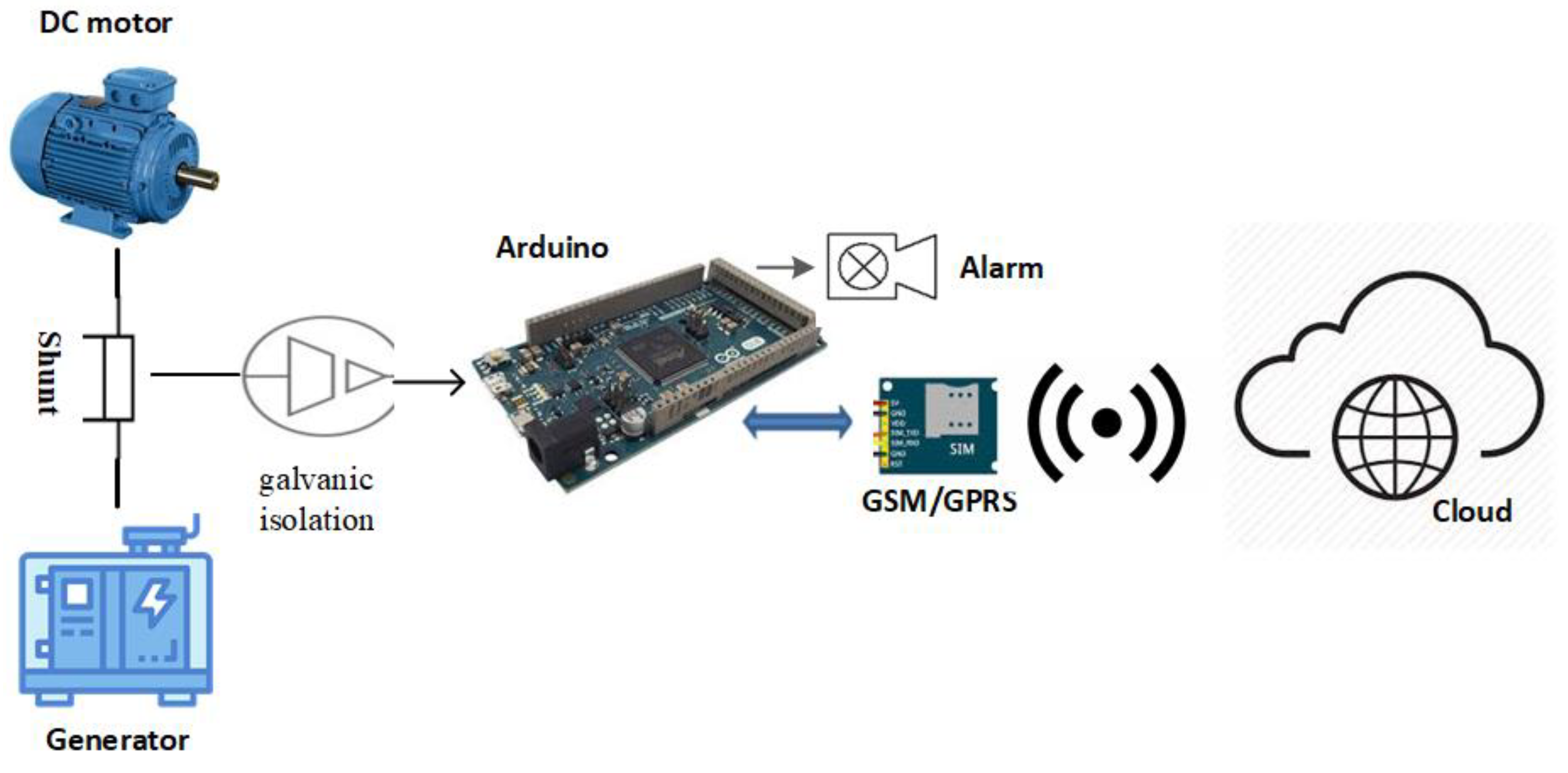

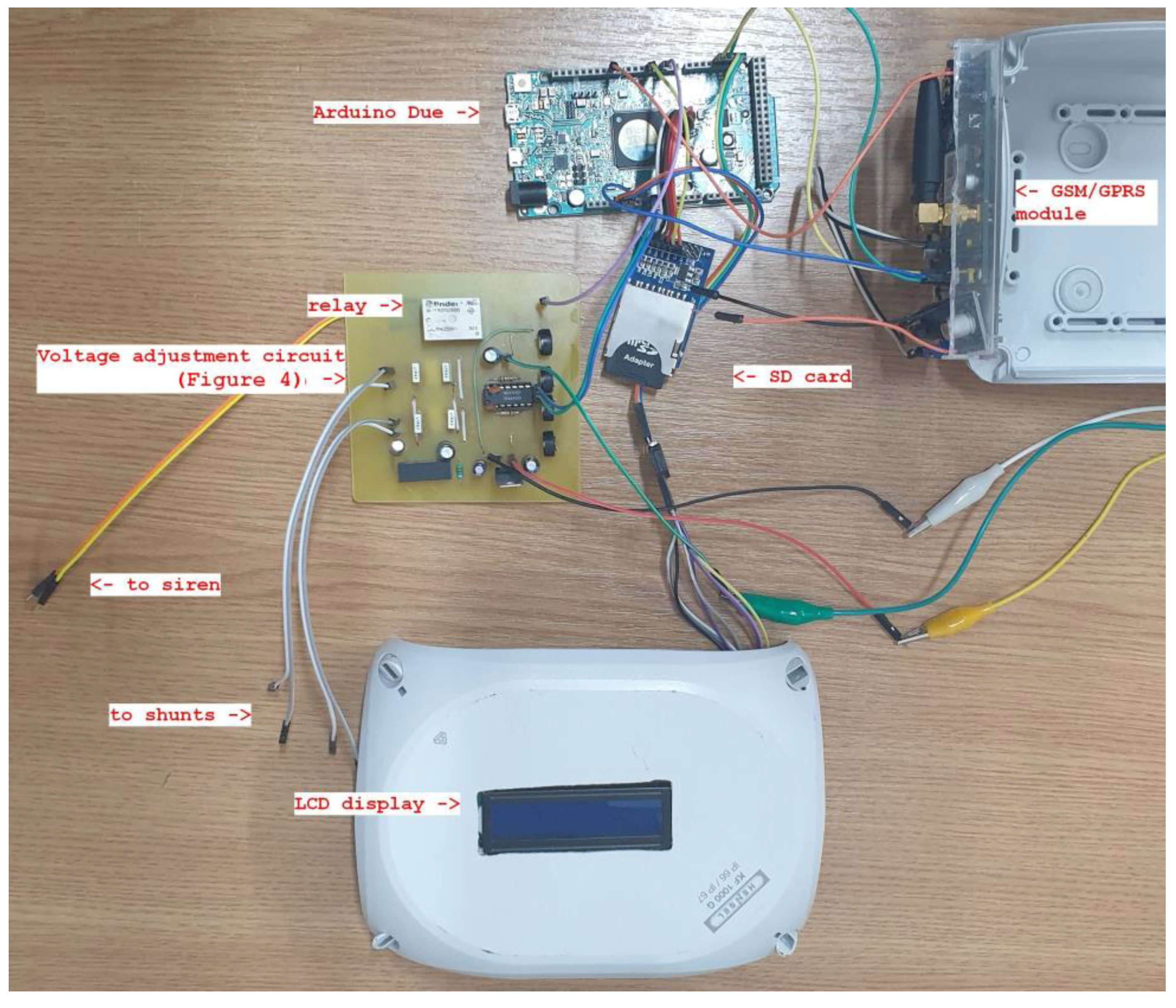

3. Architecture of the Proposed Solution

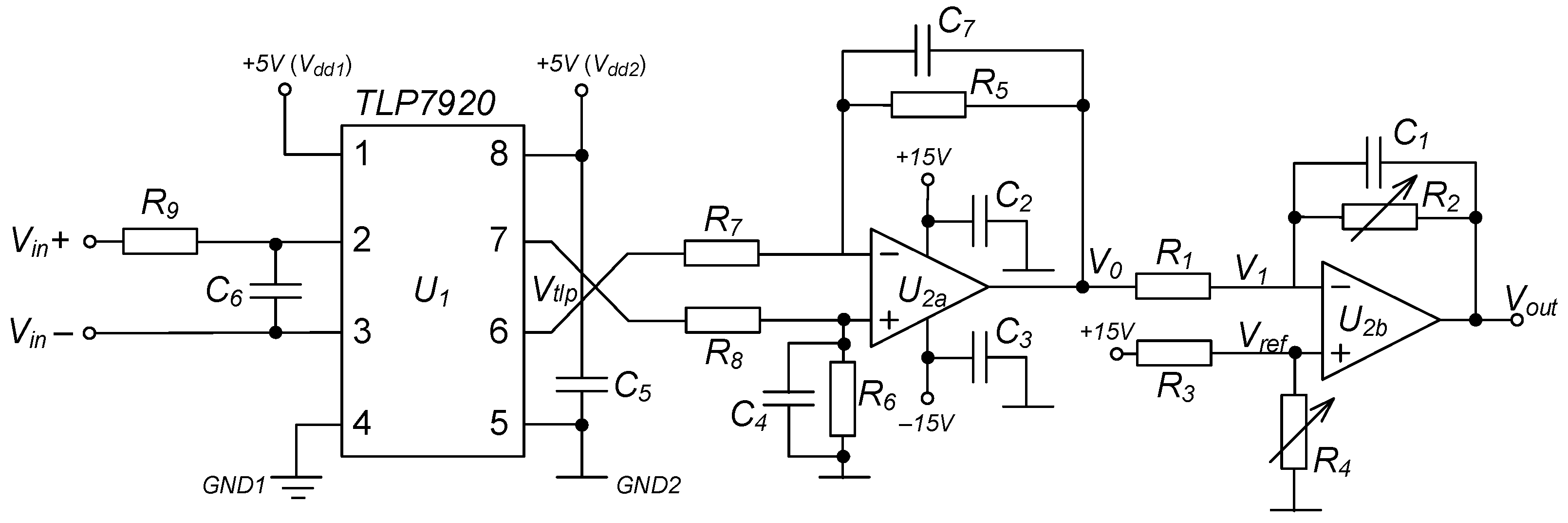

3.1. Short-Circuit Detection of Excavator’s DC Motor

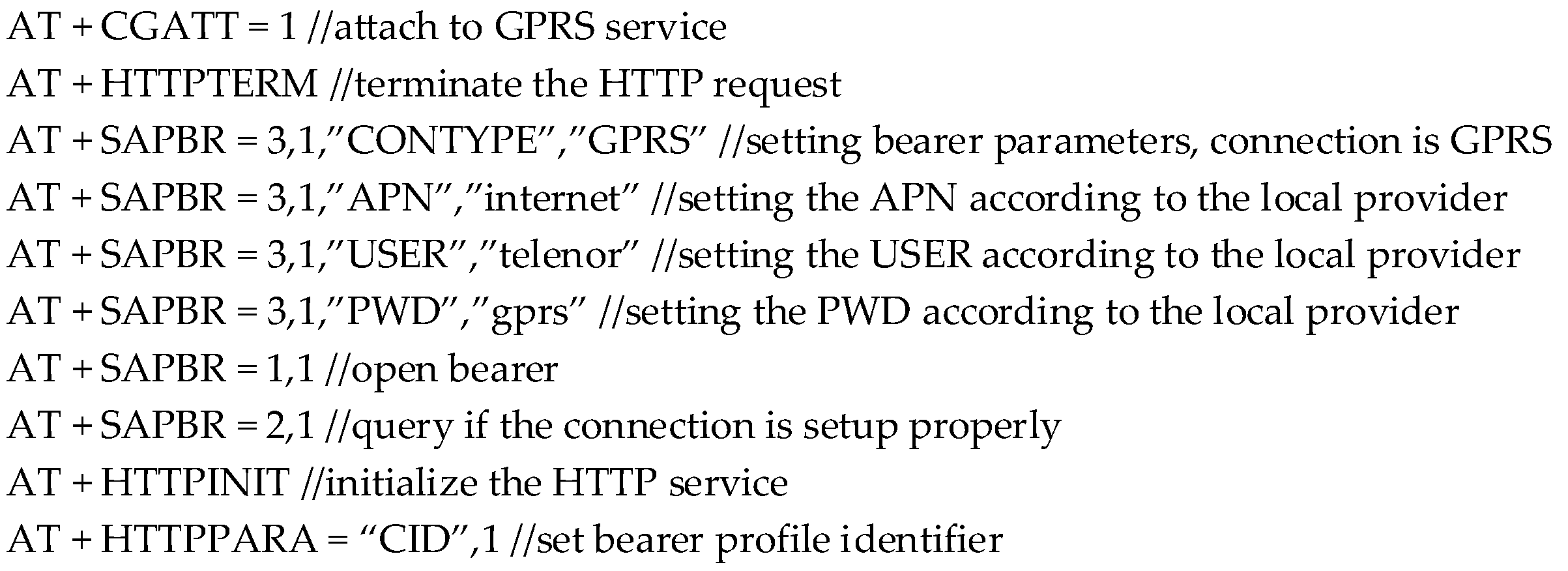

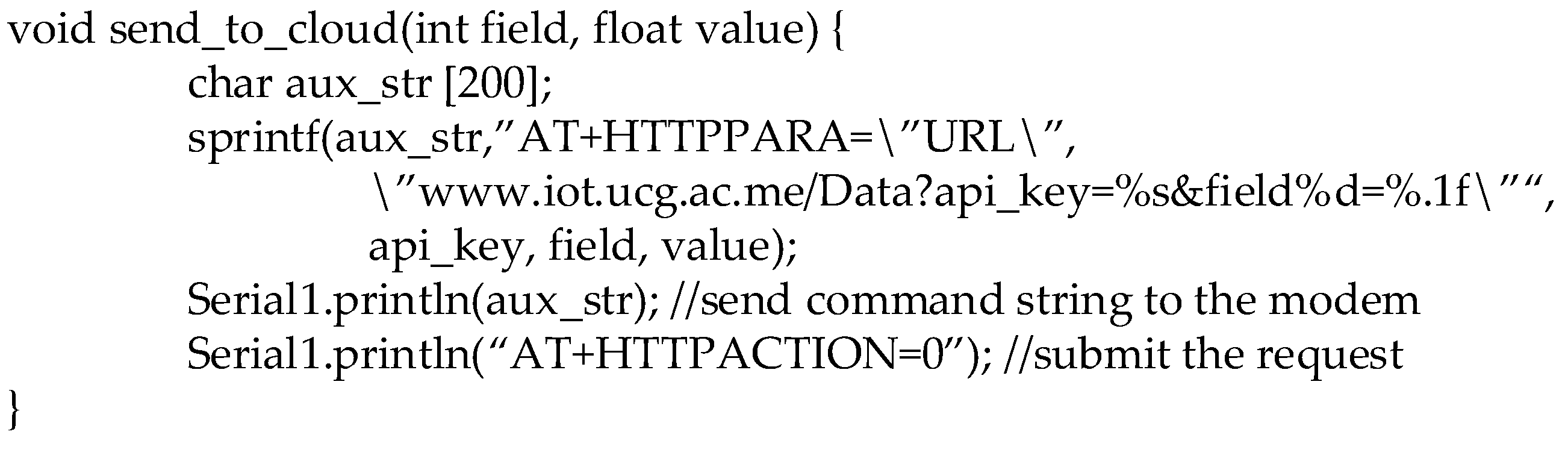

3.2. Communication between IoT Device and the Cloud

4. Experimental Results

Performance Analysis

5. Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Park, H.-S. Conceptual framework of construction productivity estimation. KSCE J. Civ. Eng. 2006, 10, 311–317. [Google Scholar] [CrossRef]

- Ng, F.; Harding, J.A.; Glass, J. An eco-approach to optimise efficiency and productivity of a hydraulic excavator. J. Clean. Prod. 2016, 112, 3966–3976. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Q.; Chen, G.; Jiang, W.; Li, K.; Li, K. Automatically Detecting Excavator Anomalies Based on Machine Learning. Symmetry 2019, 11, 957. [Google Scholar] [CrossRef] [Green Version]

- Donnelly, G. Infrastructure Spending Could Be Hindered by a Shortage of Skilled Labor. Available online: https://finance.yahoo.com/news/infrastructure-spending-could-hindered-shortage-192951287.html (accessed on 27 April 2022).

- Ho, P.H.K. Labour and skill shortages in Hong Kong’s construction industry. Eng. Constr. Archit. Manag. 2016, 23, 533–550. [Google Scholar] [CrossRef]

- Juricic, B.B.; Galic, M.; Marenjak, S. Review of the Construction Labour Demand and Shortages in the EU. Buildings 2021, 11, 17. [Google Scholar] [CrossRef]

- Chang-Richards, Y.; Wilkinson, S.; Seville, E.; Brunsdon, D. Effects of a major disaster on skills shortages in the construction industry: Lessons learned from New Zealand. Eng. Constr. Archit. Manag. 2017, 24, 2–20. [Google Scholar] [CrossRef]

- Web Page of “Rudnik Uglja Pljevlja”. Available online: https://www.rupv.me/en (accessed on 1 May 2021).

- Sandzimier, R.J.; Asada, H.H. A Data-Driven Approach to Prediction and Optimal Bucket-Filling Control for Autonomous Excavators. IEEE Robot. Autom. Lett. 2020, 5, 2682–2689. [Google Scholar] [CrossRef]

- Chayama, K.; Fujioka, A.; Kawashima, K.; Yamamoto, H.; Nitta, Y.; Ueki, C.; Yamashita, A.; Asama, H. Technology of Unmanned Construction System in Japan. J. Robot. Mechatron. 2014, 26, 403–417. [Google Scholar] [CrossRef]

- Haga, M.; Hiroshi, W.; Fujishima, K. Digging control system for hydraulic excavator. Mechatronics 2001, 11, 665–676. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, J.; Zhang, Y.; Luo, C. A Novel Method of Soil Parameter Identification and Force Prediction for Automatic Excavation. IEEE Access 2020, 8, 11197–11207. [Google Scholar] [CrossRef]

- Tan, C.P.; Zweiri, Y.H.; Althoefer, K.; Seneviratne, L.D. Online soil parameter estimation scheme based on Newton-Raphson method for autonomous excavation. IEEE/ASME Trans. Mechatron. 2005, 10, 221–229. [Google Scholar] [CrossRef]

- Jud, D.; Hottiger, G.; Leemann, P.; Hutter, M. Planning and Control for Autonomous Excavation. IEEE Robot. Autom. Lett. 2017, 2, 2151–2158. [Google Scholar] [CrossRef]

- Azulay, O.; Shapiro, A. Wheel Loader Scooping Controller Using Deep Reinforcement Learning. IEEE Access 2021, 9, 24145–24154. [Google Scholar] [CrossRef]

- Allain, M.; Konduri, S.; Maske, H.; Pagilla, P.R.; Chowdhary, G. Blended Shared Control of a Hydraulic Excavator. IFAC-PapersOnLine 2017, 50, 14928–14933. [Google Scholar] [CrossRef]

- Davila Delgado, J.M.; Oyedele, L.; Ajayi, A.; Akanbi, L.; Akinade, O.; Bilal, M.; Owolabi, H. Robotics and automated systems in construction: Understanding industry-specific challenges for adoption. J. Build. Eng. 2019, 26, 100868. [Google Scholar] [CrossRef]

- Dadhich, S.; Bodin, U.; Andersson, U. Key challenges in automation of earth-moving machines. Autom. Constr. 2016, 68, 212–222. [Google Scholar] [CrossRef] [Green Version]

- Lee, J.S.; Ham, Y.; Park, H.; Kim, J. Challenges, tasks, and opportunities in teleoperation of excavator toward human-in-the-loop construction automation. Autom. Constr. 2022, 135, 104119. [Google Scholar] [CrossRef]

- Dubois, A.; Gadde, L.E. The construction industry as a loosely coupled system: Implications for productivity and innovation. Constr. Manag. Econ. 2010, 20, 621–631. [Google Scholar] [CrossRef]

- Hemami, A.; Hassani, F. An overview of autonomous loading of bulk material. In Proceedings of the 2009 26th International Symposium on Automation and Robotics in Construction, ISARC 2009, Austin, TX, USA, 24–27 June 2009; pp. 405–411. [Google Scholar]

- Bogue, R. What are the prospects for robots in the construction industry? Ind. Robot 2018, 45, 1–6. [Google Scholar] [CrossRef]

- Park, S.; Kim, J.; Lee, S.; Seo, J. A Comparative Analysis of Automated Machine Guidance and Control Systems for Trench Excavation. KSCE J. Civ. Eng. 2021, 25, 4065–4074. [Google Scholar] [CrossRef]

- Radonjić, M.; Vujnovic, S.; Krstić, A.; Zečević, Ž. IoT System for Detecting the Condition of Rotating Machines Based on Acoustic Signals. Appl. Sci. 2022, 12, 4385. [Google Scholar] [CrossRef]

- Ciancetta, F.; Fiorucci, E.; Ometto, A.; Fioravanti, A.; Mari, S.; Segreto, M.A. A Low-Cost IoT Sensors Network for Monitoring Three-Phase Induction Motor Mechanical Power Adopting an Indirect Measuring Method. Sensors 2021, 21, 754. [Google Scholar] [CrossRef] [PubMed]

- Loukatos, D.; Androulidakis, N.; Arvanitis, K.G.; Peppas, K.P.; Chondrogiannis, E. Using Open Tools to Transform Retired Equipment into Powerful Engineering Education Instruments: A Smart Agri-IoT Control Example. Electronics 2022, 11, 855. [Google Scholar] [CrossRef]

- Radonjić, M.; Zečevic, Ž.; Krstajić, B. Iot System for Short-Circuit Detection of Dc Motor at Ekg-15 Excavator. In Proceedings of the First International Conference ETIMA 2021, Štip, North Macedonia, 19–21 October 2021; pp. 222–230. [Google Scholar]

- Gardašević, G.; Veletić, M.; Maletić, N.; Vasiljević, D.; Radusinović, I.; Tomović, S.; Radonjić, M. The IoT Architectural Framework, Design Issues and Application Domains. Wirel. Pers. Commun. 2016, 92, 127–148. [Google Scholar] [CrossRef]

- Arduino. Available online: https://www.arduino.cc (accessed on 12 May 2021).

- UoM IoT Platform. Available online: http://www.iot.ucg.ac.me/ (accessed on 10 February 2022).

- NI4OS-Europe Project (National Initiatives for Open Science in Europe). Available online: https://ni4os.eu/ (accessed on 23 December 2021).

- TLP 7920 Datasheet, Toshiba Electronic Devices & Storage Corporation. Available online: https://toshiba.semicon-storage.com/ap-en/semiconductor/product/optoelectronics/isolation-amplifiers-isolated-delta-sigma-modulators/detail (accessed on 12 May 2021).

- Pmod SD: Full-Sized SD Card Slot. Available online: https://store.digilentinc.com/pmod-sd-full-sized-sd-card-slot (accessed on 15 November 2021).

- SIM808 GPRS/GSM+GPS Shield v1.1. Available online: https://www.elecrow.com/wiki/index.php?title=SIM808_GPRS/GSM%2BGPS_Shield_v1.1 (accessed on 15 November 2021).

- Telenor Montenegro, Device Settings, GPRS Settings. Available online: https://www.telenor.rs/en/consumer/support/device-settings/ (accessed on 8 November 2021).

|

|

|

|

| Vin [mV] | −80 | −60 | −40 | −20 | 20 | 40 | 60 | 80 |

| Vtlp [mV] | −605 | −453 | −301 | −152 | 158 | 308 | 460 | 612 |

| Vin [mV] | −80 | −60 | −40 | −20 | 20 | 40 | 60 | 80 |

| Vout [V] | 0.13 | 0.48 | 0.83 | 1.19 | 1.9 | 2.26 | 2.62 | 2.98 |

| Component | Specification |

|---|---|

| Arduino Due | MicrocontrollerAT91SAM3X8E, operating voltage 3.3 V, input voltage 7–12 V, digital I/O pins 54 (of which 12 provide PWM output), analog input pins 12, analog output pins 2 (DAC), flash memory 512 KB, SRAM 96 KB (two banks: 64 KB and 32 KB), clock speed 84 MHz. |

| SD card | 32 GB, micro SD card Class 10 |

| SD card adapter | PmodSD by Digilent, Full-sized SD card slot, No limitation on file system or memory size of SD card used, 1-bit and 4-bit communication, 12-pin Pmod connector with SPI interface. |

| GSM-GPRS modem | Quad-band 850/900/1800/1900 MHz, GPRS multi-slot class12 connectivity: max. 85.6 kbps(down-load/up-load), Controlled by AT Command, Supply voltage range 5 V ~ 12 V, Supports 3.0 V to 5.0 V logic level, Low power consumption, 1 mA in sleep mode, Standard Micro SIM Card. |

| LCD | 16 character × 2 lines; 5 × 8 dots; single power supply (5 V ± 10%); I2C interface |

| TLP7920 optically isolated amplifier | Sigma-delta (Σ-Δ) analog-to-digital converter technology/Optical coupled isolation amplifier |

| Real-Time Clock DS3231 RTC chip | Real-Time Clock Counts Seconds, Minutes, Hours, Date of the Month, Month, Day of the Week, and Year, with Leap-Year Compensation Valid Up to 2100, Accuracy ± 2 ppm from 0 °C to +40 °C, Accuracy ± 3.5 ppm from −40 °C to + 85 °C, Fast (400 kHz) I2C Interface, Battery-Backup Input for Continuous Timekeeping, 3.3 V Operation |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Radonjić, M.; Zečević, Ž.; Krstajić, B. An IoT System for Real-Time Monitoring of DC Motor Overload. Electronics 2022, 11, 1555. https://doi.org/10.3390/electronics11101555

Radonjić M, Zečević Ž, Krstajić B. An IoT System for Real-Time Monitoring of DC Motor Overload. Electronics. 2022; 11(10):1555. https://doi.org/10.3390/electronics11101555

Chicago/Turabian StyleRadonjić, Milutin, Žarko Zečević, and Božo Krstajić. 2022. "An IoT System for Real-Time Monitoring of DC Motor Overload" Electronics 11, no. 10: 1555. https://doi.org/10.3390/electronics11101555

APA StyleRadonjić, M., Zečević, Ž., & Krstajić, B. (2022). An IoT System for Real-Time Monitoring of DC Motor Overload. Electronics, 11(10), 1555. https://doi.org/10.3390/electronics11101555