On the Optimal Selection of Flux Barrier Reconfiguration for a Five-Phase Permanent Magnet Assisted Synchronous Reluctance Machine for Low-Torque Ripple Application

Abstract

:1. Introduction

2. Material and Methods

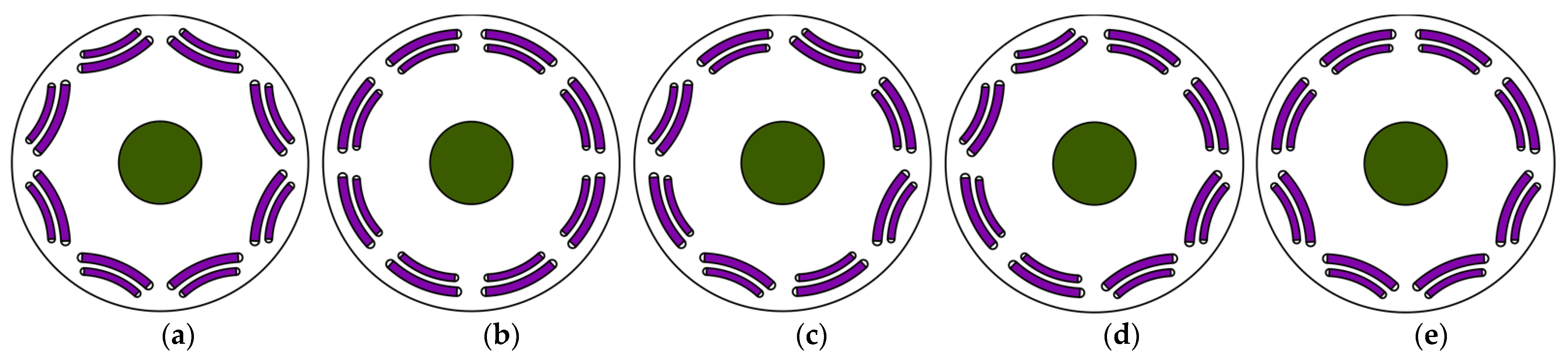

2.1. Proposed Design Scheme

2.2. Design Differentiation

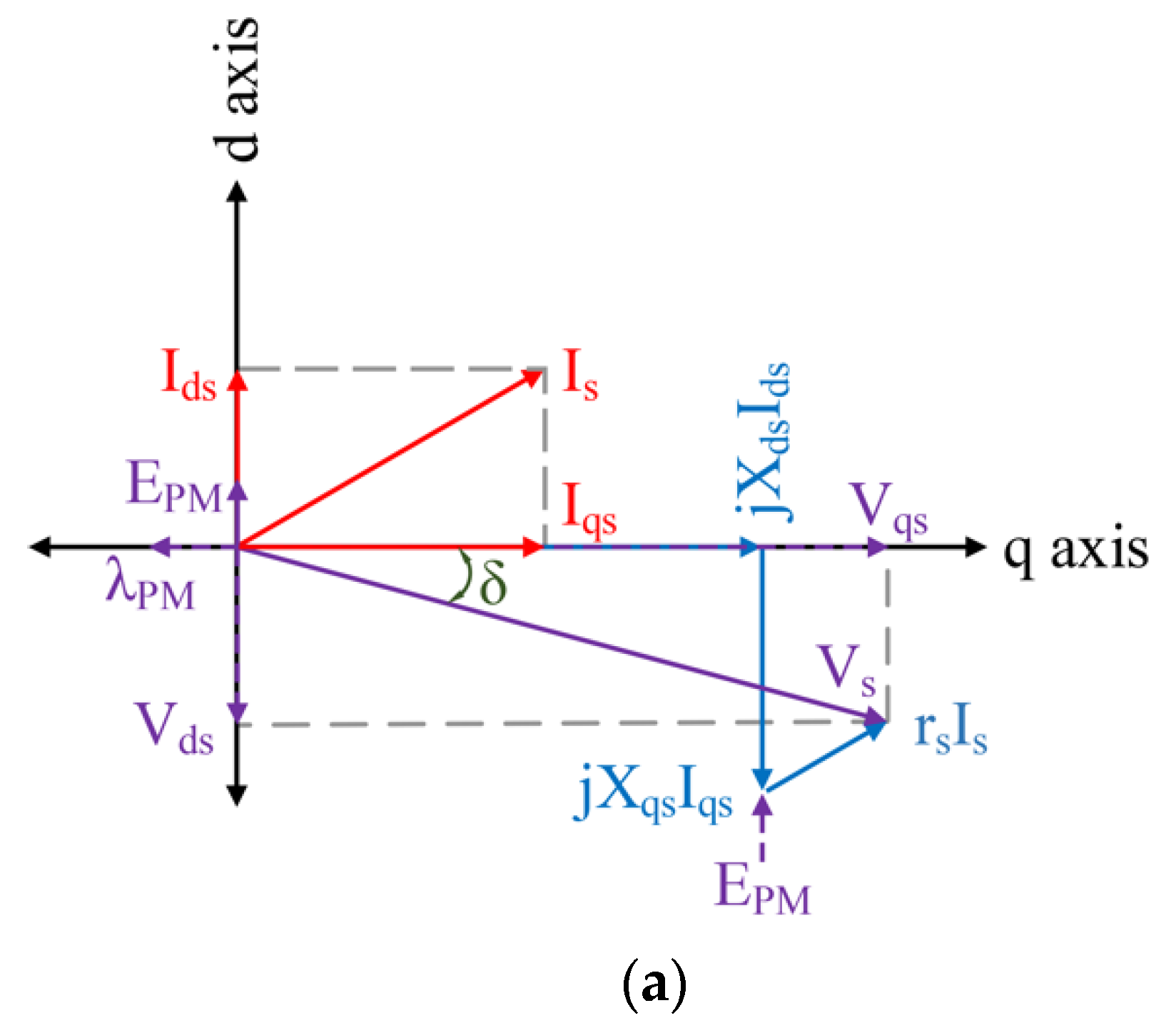

2.3. System Equations Review

2.4. LPM: Lumped Parameter Model

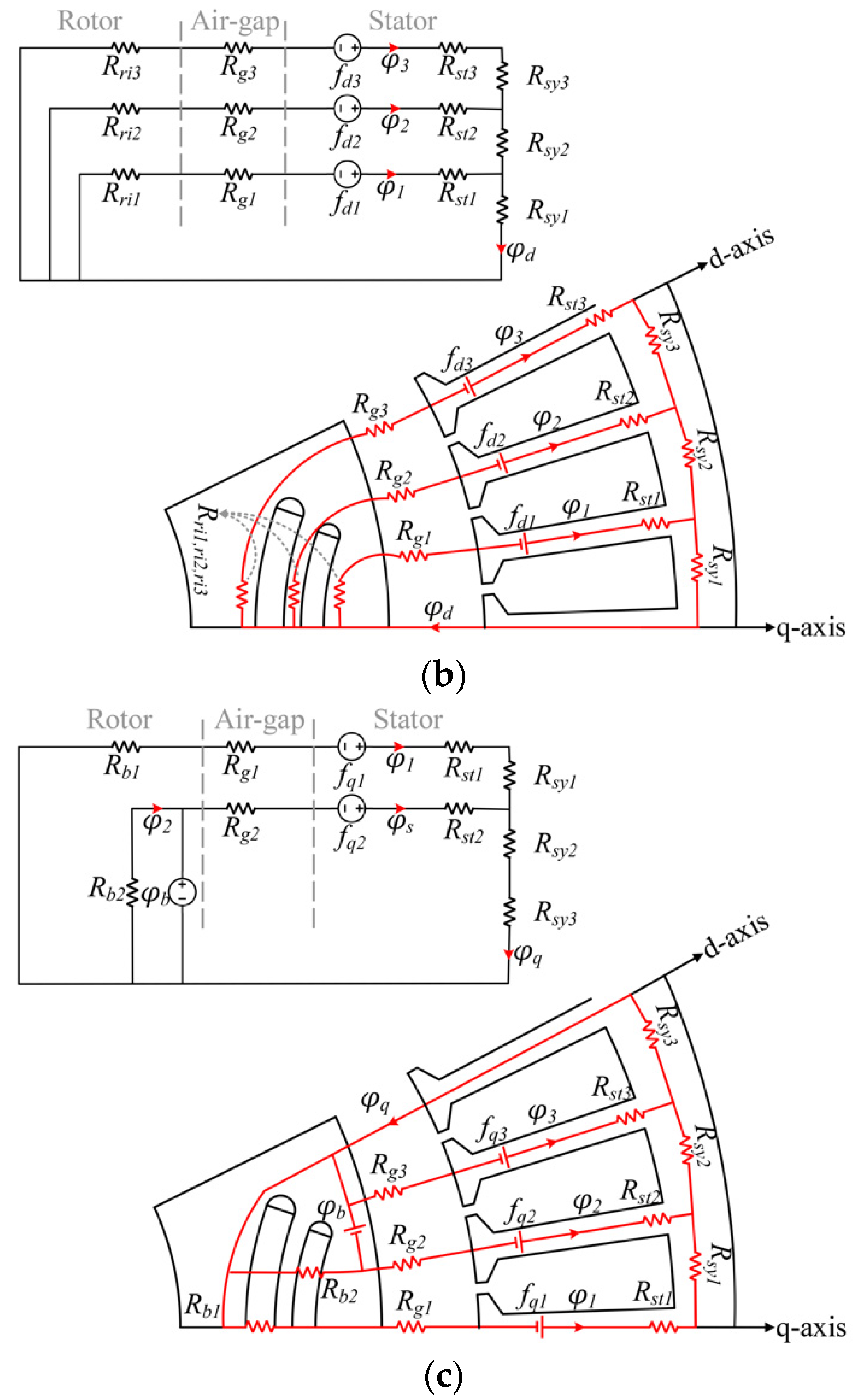

2.5. FEM: Finite Element Method

3. E-Magnetic FEM Results

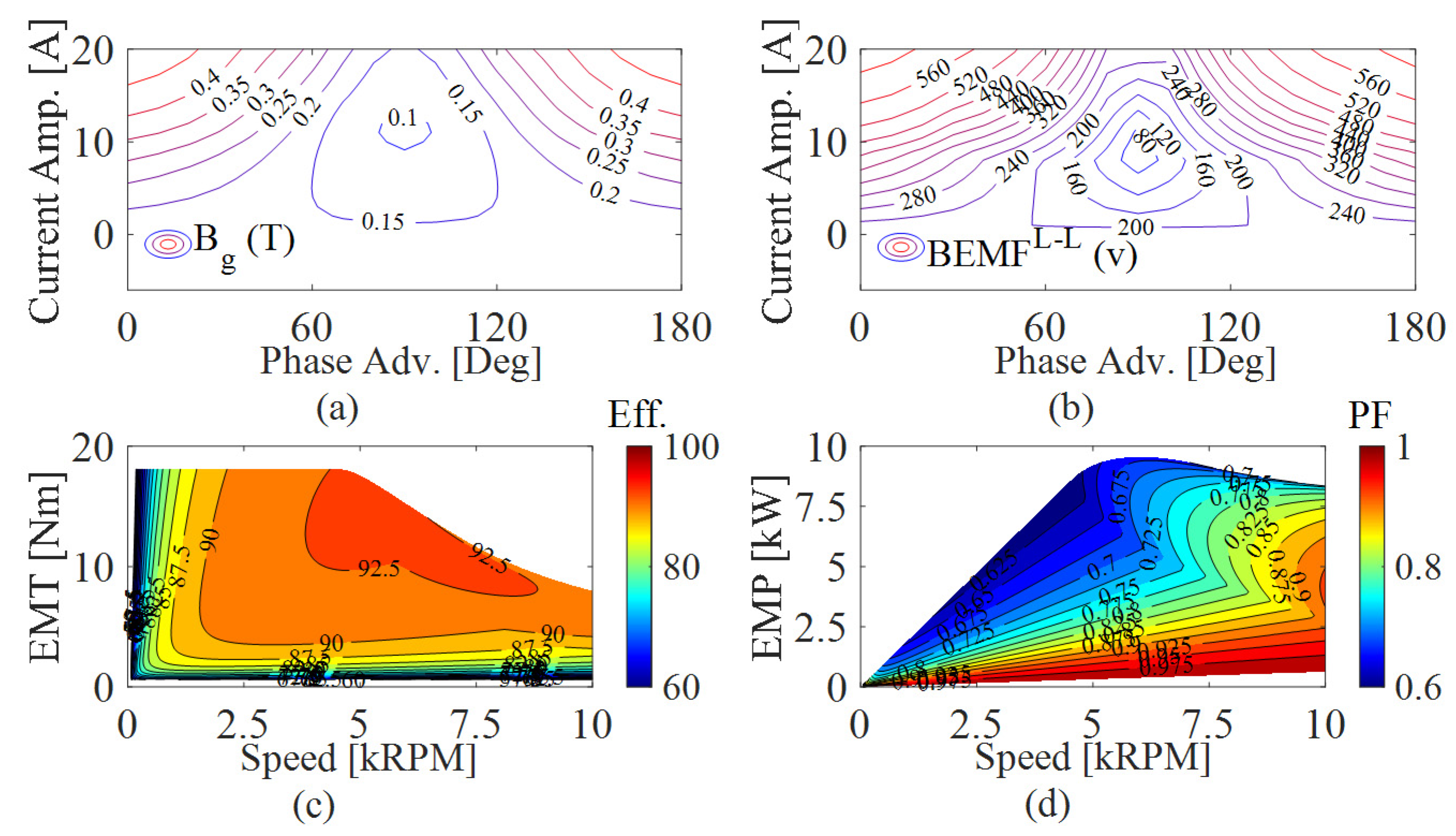

3.1. Steady-State Analysis at Rated Current and Nominal Speed

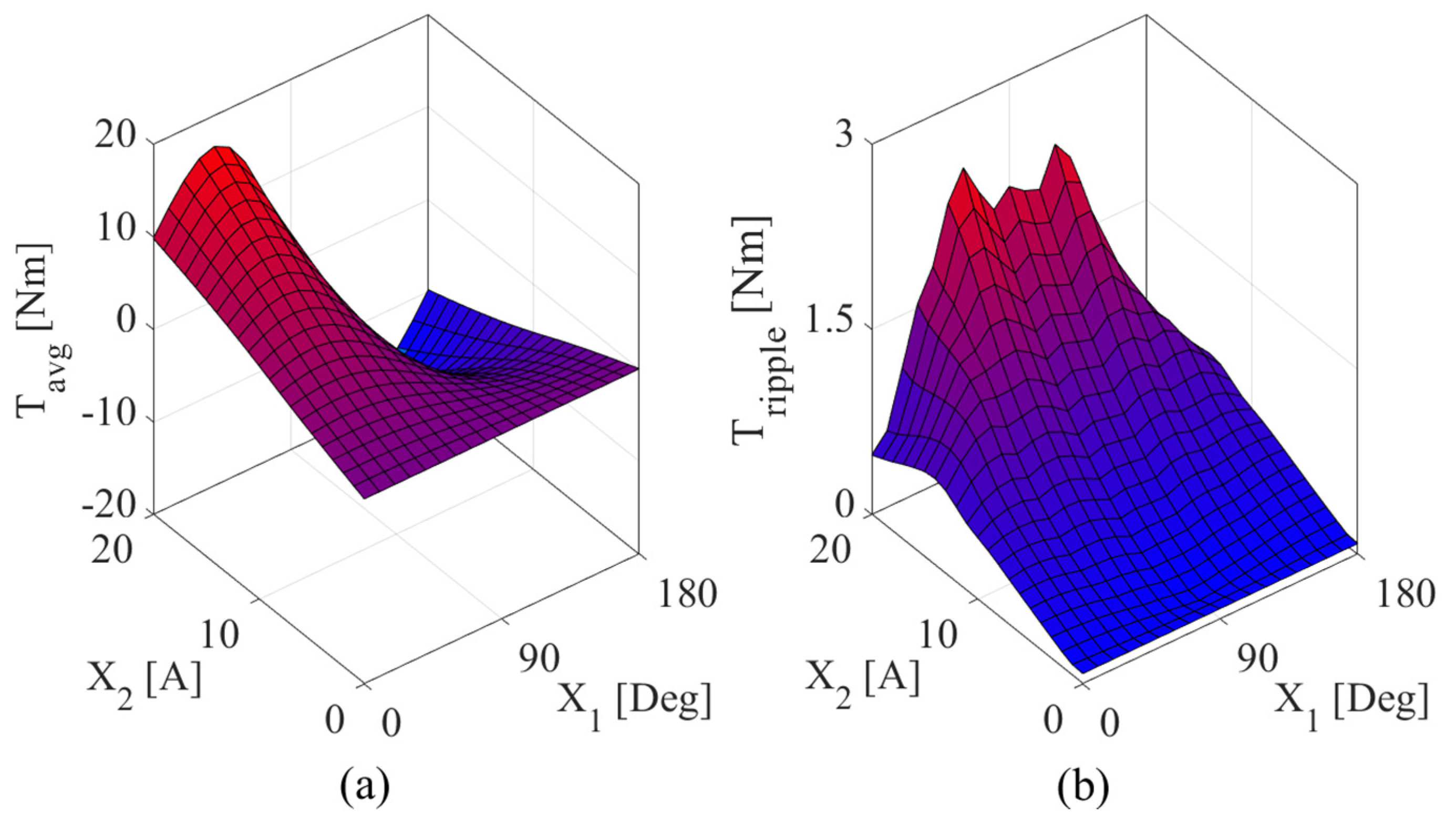

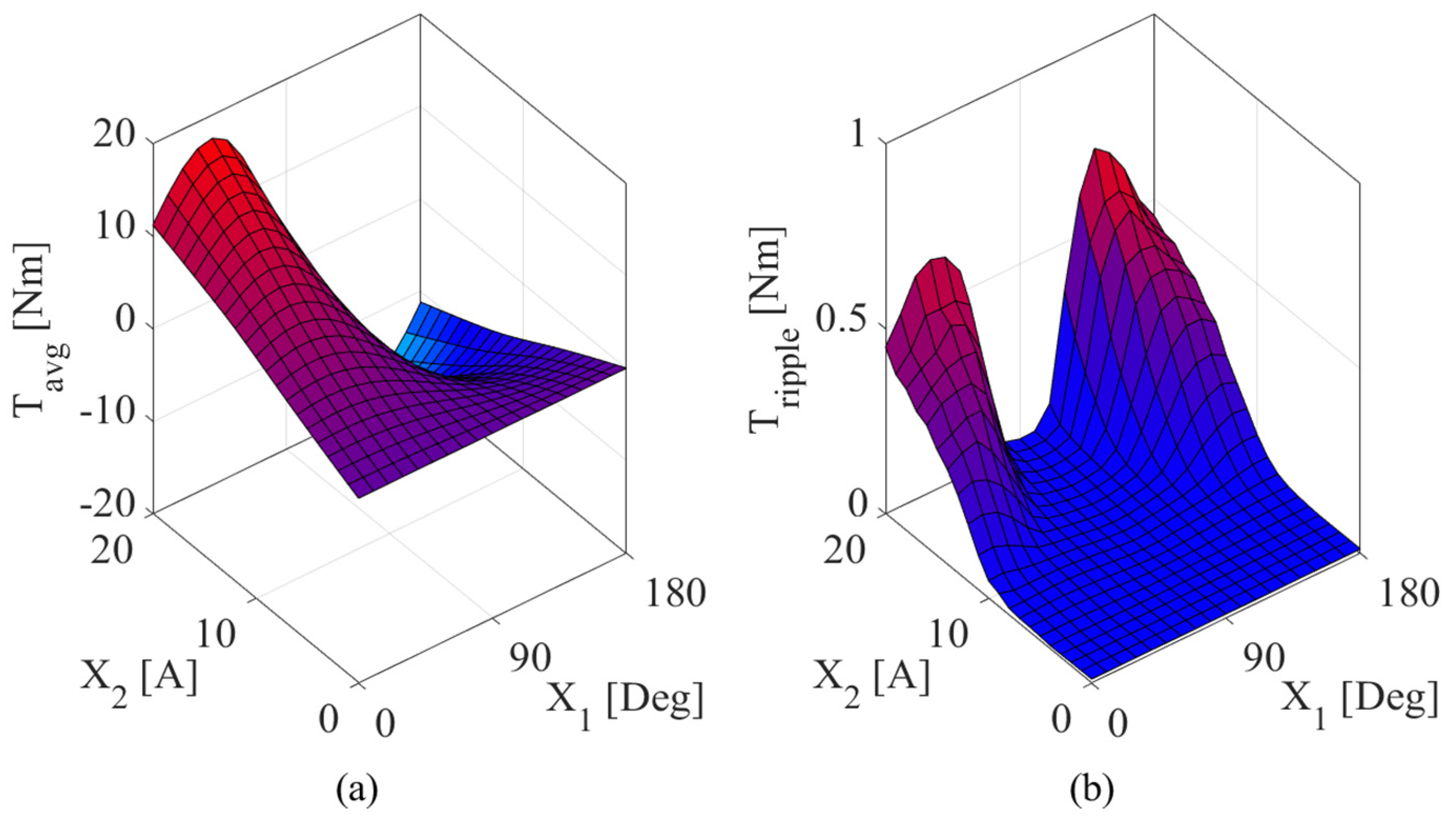

3.2. Optimization

3.3. Optimal Rotor Scheme

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Li, J.; Wang, K. A Novel Spoke-Type PM Machine Employing Asymmetric Modular Consequent-Pole Rotor. IEEE ASME Trans. Mechatron. 2019, 24, 2182–2192. [Google Scholar] [CrossRef]

- Heidari, H.R.; Andriushchenko, E.; Rassolkin, A.; Kallaste, A.; Vaimann, T.; Demidova, G.L. Comparison of Synchronous Reluctance Machine and Permanent Magnet-Assisted Synchronous Reluctance Machine Performance Characteristics. In Proceedings of the 27th International Workshop on Electric Drives: MPEI Department of Electric Drives 90th Anniversary (IWED), Moscow, Russia, 27–30 January 2020. [Google Scholar] [CrossRef]

- Moradian, M.R.; Soltani, J.; Najjar-Khodabakhsh, A.; Arab Markadeh, G.R. Adaptive Torque and Flux Control of Sensorless IPMSM Drive in the Stator Flux Field Oriented Reference Frame. IEEE Trans. Ind. Inform. 2019, 15, 205–212. [Google Scholar] [CrossRef]

- Moradian, M.R.; Soltani, J.; Benbouzid, M.; Najjar-Khodabakhsh, A. A Parameter Independent Stator Current Space-Vector Reference Frame-Based Sensorless IPMSM Drive Using Sliding Mode Control. Energies 2021, 14, 2365. [Google Scholar] [CrossRef]

- Ghorbani, H.R.; Majidi, B. Power Density Optimization through Optimal Selection of PM properties in a PM-SyncRM Using FEM Analysis. In Proceedings of the 2019 10th International Power Electronics, Drive Systems and Technologies Conference (PEDSTC), Shiraz, Iran, 12–14 February 2019. [Google Scholar] [CrossRef]

- Ghorbani, H.; Moradian, M. Torque pulsation reduction in five-phase PMASyncRMs. J. Power Electron. 2021, 1–10. [Google Scholar] [CrossRef]

- Krichen, M.; Elbouchikhi, E.; Benhadj, N.; Chaieb, M.; Benbouzid, M.; Neji, R. Motor Current Signature Analysis-Based Permanent Magnet Synchronous Motor Demagnetization Characterization and Detection. Machines 2020, 8, 35. [Google Scholar] [CrossRef]

- Agarlita, S.; Ursu, D.; Tutelea, L.; Boldea, I.; Fahimi, B. BLDC multiphase reluctance machines: A revival attempt with 2D FEM investigation and standstill tests. In Proceedings of the IEEE Energy Conversion Congress and Exposition, Denver, CO, USA, 15–19 September 2013. [Google Scholar] [CrossRef]

- Maroufian, S.S.; Pillay, P. Design and Analysis of a Novel PM-Assisted Synchronous Reluctance Machine Topology with AlNiCo Magnets. IEEE Trans. Ind. App. 2019, 55, 4733–4742. [Google Scholar] [CrossRef]

- Chen, K.; Yu, W.; Wen, C. Rotor Optimization for Synchronous Reluctance Motors. CES Trans. Electr. Mach. Syst. 2019, 3, 279–284. [Google Scholar] [CrossRef]

- Jurca, F.N.; Inte, R.; Martis, C. Optimal rotor design of novel outer rotor reluctance synchronous machine. Electr. Eng. 2020, 102, 107–116. [Google Scholar] [CrossRef]

- Inte, R.A.; Jurca, F.N.; Martis, C. Design and Analysis of Outer Rotor Permanent Magnet Assisted Synchronous Reluctance Machine with Concentrated Winding for Small Electric Propulsion. In Proceedings of the AEIT International Annual Conference (AEIT), Florence, Italy, 18–20 September 2019. [Google Scholar] [CrossRef]

- Mohanarajah, T.; Nagrial, M.; Rizk, J.; Hellany, A. A Novel Method to Optimize Permanent Magnet Assisted Synchronous Reluctance Machines. Electr. Power Comp. Syst. 2020, 48, 933–944. [Google Scholar] [CrossRef]

- Zeraoulia, M.; Benbouzid, M.; Diallo, D. Electric Motor Drive Selection Issues for HEV Propulsion Systems: A Comparative Study. IEEE Trans. Veh. Tech. 2006, 55, 1756–1764. [Google Scholar] [CrossRef] [Green Version]

- Aryasomayajula, S.B.; Banerjee, R.; Sensarma, P. Effect of Magnets and Diamagnetic Material on Performance of SynRM with Novel Rotor Structure. In Proceedings of the National Power Electronics Conference (NPEC), Tiruchirappalli, India, 13–15 December 2019. [Google Scholar] [CrossRef]

- Hezzi, A.; Elghali, S.B.; Bensalem, Y.; Zhou, Z.; Benbouzid, M.; Abdelkrim, M.N. ADRC-Based Robust and Resilient Control of a 5-Phase PMSM Driven Electric Vehicle. Machines 2020, 8, 17. [Google Scholar] [CrossRef]

- Wang, S.; Ma, J.; Liu, C.; Wang, Y.; Lei, G.; Guo, Y.; Zhu, J. Design and performance analysis of a novel synchronous reluctance machine. Int. J. Appl. Electromagn. Mech. 2020, 63, 249–265. [Google Scholar] [CrossRef]

- Liu, Z.; Hu, Y.; Wu, J.; Zhang, B.; Feng, G. A Novel Modular Permanent Magnet-Assisted Synchronous Reluctance Motor. IEEE Access 2021, 9, 19947–19959. [Google Scholar] [CrossRef]

- Zhao, W.; Shen, H.; Lipo, T.A.; Wang, X. A New Hybrid Permanent Magnet Synchronous Reluctance Machine with Axially Sandwiched Magnets for Performance Improvement. IEEE Trans. Energy Convers. 2018, 33, 4. [Google Scholar] [CrossRef]

- Cai, W.; Wu, X.; Zhou, M.; Liang, Y.; Wang, Y. Review and Development of Electric Motor Systems and Electric Powertrains for New Energy Vehicles. Automot. Innov. 2021, 4, 3–22. [Google Scholar] [CrossRef]

- Cui, W.; Hu, B.; Pan, T. A Novel PMSM with Optimized Asymmetric Eccentric Air-Gap for High-Power Electric Motorcycle. Electr. Power Compon. Syst. 2019, 47, 1854–1863. [Google Scholar] [CrossRef]

- Momen, F.; Rahman, K.; Son, Y. Electrical Propulsion System Design of Chevrolet Bolt Battery Electric Vehicle. IEEE Tran. Ind. App. 2018, 55, 376–384. [Google Scholar] [CrossRef]

- Tawfiq, K.B.; Ibrahim, M.N.; El-Kholy, E.E.; Sergeant, P. Performance Improvement of Existing Three Phase Synchronous Reluctance Machine: Stator Upgrading to 5-Phase with Combined Star-Pentagon Winding. IEEE Access 2020, 8, 143569–143583. [Google Scholar] [CrossRef]

- Toliyat, H.A.; Waikar, S.P.; Lipo, T.A. Analysis and simulation of five-phase synchronous reluctance machines including third harmonic of air gap MMF. IEEE Trans. Industry App. 1998, 34, 332–339. [Google Scholar] [CrossRef] [Green Version]

- Shen, J.-X.; Lin, Y.-Q.; Sun, Y.; Qin, X.-F.; Wan, W.-J.; Cai, S. Permanent Magnet Synchronous Reluctance Machines with Axially Combined Rotor Structure. IEEE Tran. Magn. 2021. [Google Scholar] [CrossRef]

- Mohammadi, A.; Mirimani, S.M. Design of a Novel PM-Assisted Synchronous Reluctance Motor Topology Using V-Shape Permanent Magnets for Improvement of Torque Characteristic. IEEE Tran. Energy Convers. 2021. [Google Scholar] [CrossRef]

- Korman, O.; Degano, M.; Nardo, M.D.; Gerada, C. A Novel Flux Barrier Parametrization for Synchronous Reluctance Machine. IEEE Tran. Energy Convers. 2021. [Google Scholar] [CrossRef]

- Wang, K.; Zhu, Z.Q.; Ombach, G.; Koch, M.; Zhang, S.; Xu, J. Optimal slot/pole and flux-barrier layer number combinations for synchronous reluctance machines. In Proceedings of the Eighth International Conference and Exhibition on Ecological Vehicles and Renewable Energies (EVER), Monte Carlo, Monaco, 27–30 March 2013. [Google Scholar] [CrossRef]

- Scmidt, E.; Brandl, W. Comparative finite element analysis of synchronous reluctance machines with internal rotor flux barriers. In Proceedings of the IEEE International Electric Machines and Drives Conference (IEMDC), Cambridge, MA, USA, 17–20 June 2001. [Google Scholar] [CrossRef]

- Wang, Y.; Ionel, D.; Dorrell, D.G.; Stretz, S. Establishing the power factor limitations for synchronous reluctance machines. IEEE Trans. Magn. 2015, 51, 8111704. [Google Scholar] [CrossRef]

- Bianchi, N.; Bolognani, S.; Bon, D.; Pre, M.D. Torque harmonic compensation in a synchronous reluctance motor. IEEE Trans. Energy Convers. 2008, 23, 466–473. [Google Scholar] [CrossRef]

- Moghaddam, R.; Gyllensten, F. Novel high-performance SynRM design method: An easy approach for a complicated rotor topology. IEEE Trans. Ind. Electron. 2014, 61, 5058–5065. [Google Scholar] [CrossRef]

- Baek, J.; Bonthu, S.S.R.; Choi, S. Design of five-phase permanent magnet assisted synchronous reluctance motor for low output torque ripple applications. IET Electr. Power App. 2016, 10, 339–346. [Google Scholar] [CrossRef]

- Bilyi, V.; Bilyi, D.; Oleg, M.; Dajaku, G.; Gerling, D. Synchronous reluctance machine with multiphase stator cage winding. In Proceedings of the 20th International Conference on Electrical Machines and Systems (ICEMS), Sydney, Australia, 11–14 August 2017. [Google Scholar] [CrossRef]

| Parameter | Sym. | Value | Unit |

|---|---|---|---|

| Number of Phases | m | 5 | - |

| Number of Stator Slots | NS | 40 | - |

| Number of Rotor Poles | NP | 8 | - |

| Rated Speed | nr | 5 | krpm |

| Input Current | In | 15 | A |

| DC Bus Voltage | VDC | 400 | v |

| Stator Outer Diameter | DSO | 160 | mm |

| Stator Inner Diameter | DSI | 90 | mm |

| Rotor Outer Diameter | DRO | 89.15 | mm |

| Shaft Diameter | DSh | 29 | mm |

| Stack Length | Lm | 90 | mm |

| PM Arc | LPM | 35 | °Mech. |

| Air-Gap Length | Lg | 0.85 | mm |

| Steel Material | - | M800-50A | - |

| PM Material | - | N42SH | - |

| PM Mass | - | 0.5 | kg |

| Steel Laminations Mass (Rotor & Stator) | - | 11.16 | kg |

| Copper Wire Mass (AWG 18) | - | 3.35 | kg |

| Total Mass (Excluding the Shaft) | - | 15 | kg |

| Model/Parameter | K | Wb1 | Wb2 | Wi1 | Wi2 | Wrib | dr | Unit |

|---|---|---|---|---|---|---|---|---|

| Model-I | 0.47 | 3 | 4 | 6 | 2 | 3 | 30 | mm |

| Model-II | 0.54 | 4 | 4 |

| Parameter | Unit | I | II | III | IV | V |

|---|---|---|---|---|---|---|

| Tavg | Nm | 11.02 | 11.6 | 11.4 | 11.37 | 11.35 |

| TCog | Nm | 0.1 | 0.05 | 0.025 | 0.035 | 0.022 |

| TRipple | % | 5.9 | 2.95 | 2.8 | 2.93 | 2.85 |

| η | % | 93.8 | 94.75 | 93.94 | 94.2 | 94.1 |

| PF | - | 0.65 | 0.77 | 0.71 | 0.71 | 0.71 |

| Ld | mH | 6.07 | 5.944 | 6.03 | 5.99 | 6 |

| Lq | mH | 11.04 | 10.87 | 10.98 | 10.97 | 10.97 |

| Model-I | Model-II | Model-III | Model-IV | Model-V | |

|---|---|---|---|---|---|

| Tmax [Nm] | 16.5 | 18.13 | 17.66 | 17.6 | 17.7 |

| Tripple [Nm] | 1.77 | 0.8 | 0.85 | 0.83 | 0.6 |

| X1 [Deg] | 40 | 40 | 40 | 40 | 40 |

| X2 [A] | 20 | 20 | 20 | 20 | 20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghorbani, H.; Moradian, M.; Benbouzid, M. On the Optimal Selection of Flux Barrier Reconfiguration for a Five-Phase Permanent Magnet Assisted Synchronous Reluctance Machine for Low-Torque Ripple Application. Electronics 2022, 11, 41. https://doi.org/10.3390/electronics11010041

Ghorbani H, Moradian M, Benbouzid M. On the Optimal Selection of Flux Barrier Reconfiguration for a Five-Phase Permanent Magnet Assisted Synchronous Reluctance Machine for Low-Torque Ripple Application. Electronics. 2022; 11(1):41. https://doi.org/10.3390/electronics11010041

Chicago/Turabian StyleGhorbani, Hamidreza, Mohammadreza Moradian, and Mohamed Benbouzid. 2022. "On the Optimal Selection of Flux Barrier Reconfiguration for a Five-Phase Permanent Magnet Assisted Synchronous Reluctance Machine for Low-Torque Ripple Application" Electronics 11, no. 1: 41. https://doi.org/10.3390/electronics11010041

APA StyleGhorbani, H., Moradian, M., & Benbouzid, M. (2022). On the Optimal Selection of Flux Barrier Reconfiguration for a Five-Phase Permanent Magnet Assisted Synchronous Reluctance Machine for Low-Torque Ripple Application. Electronics, 11(1), 41. https://doi.org/10.3390/electronics11010041