A New Active Control Driver Circuit for Satellite’s Torquer System Using Second Generation Current Conveyor

Abstract

1. Introduction

2. Overview of the CCII, Torquer and the Control Arrangement

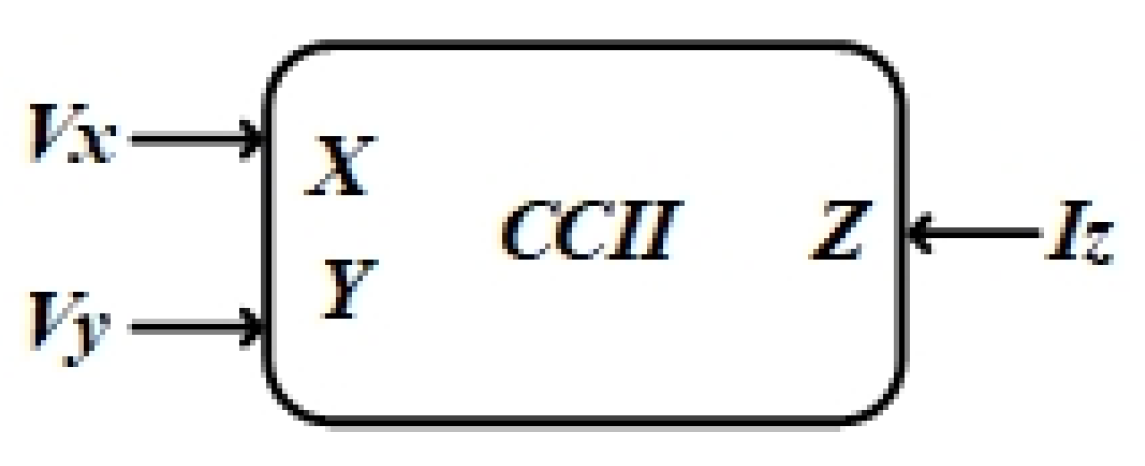

2.1. Second Generation Current Conveyor

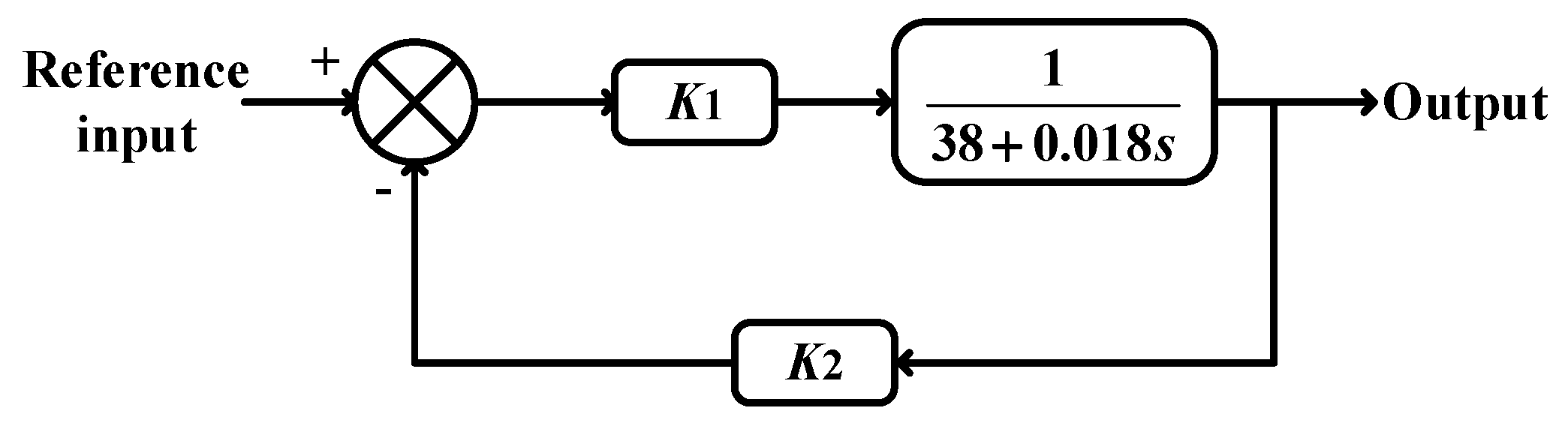

2.2. Torquer System and its Modeling

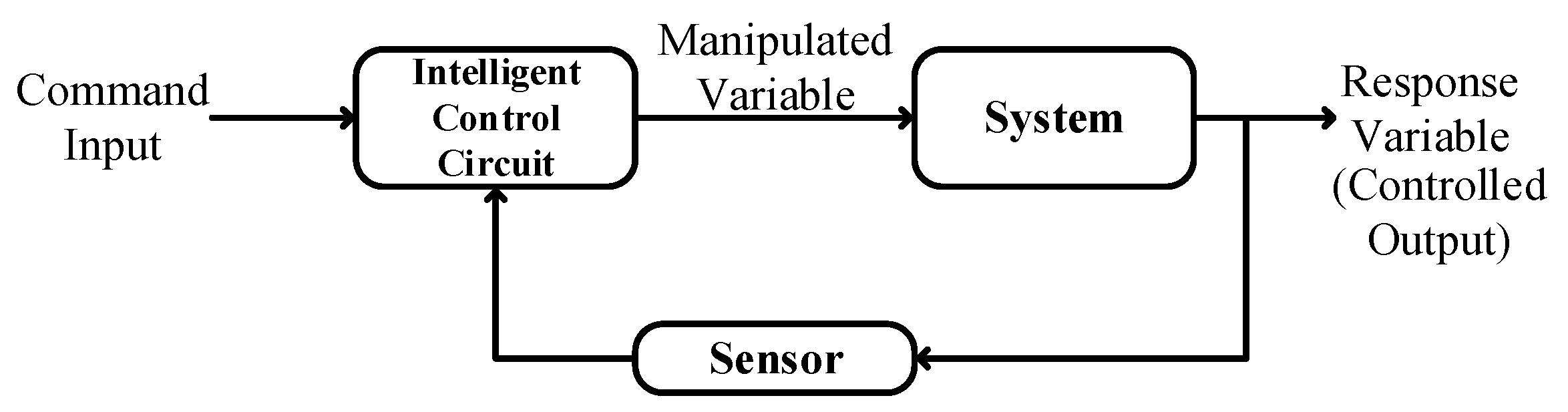

2.3. Generalized Control Block Diagram

- CCII architecture offers better performance, high linearity, and an exceptionally clean pulse response when compared to the OPAMP.

- With the CCII, the closed-loop bandwidth is determined primarily by the feedback resistor and is almost independent of the closed-loop gain. It is also free from the slew rate limitations inherent in traditional OPAMPs. Additionally, in the OPAMP, the bandwidth is limited by the gain.

- With CCII feedback is in the form of current. CCII responds to an error current at one of its input terminals, rather than an error voltage (as in OPAMP) and produces a corresponding output voltage.

3. Segmented Genetic Algorithm

- Selection: This is the first step in which few individuals are selected from the previous generation based on the fitness value. This fitness value is a measure of how close the individual is to the optimum value.

- Crossover: This is the second step in which the individuals selected in the previous step are used for generating the offspring.

- Mutation: This step is the last step in which the individuals are randomly mutated.

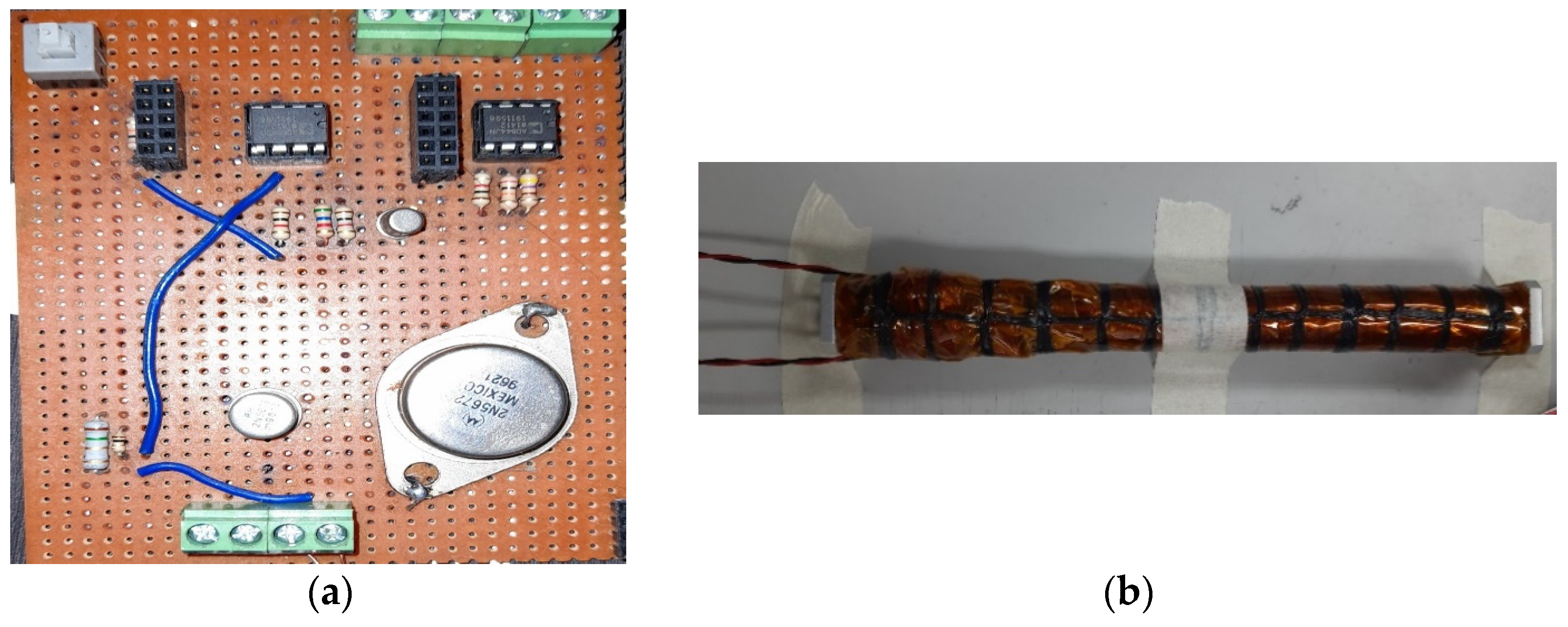

4. Control Driver Circuit Design

5. Simulations and Experimental Results

5.1. Results for 15 V, 400 mA

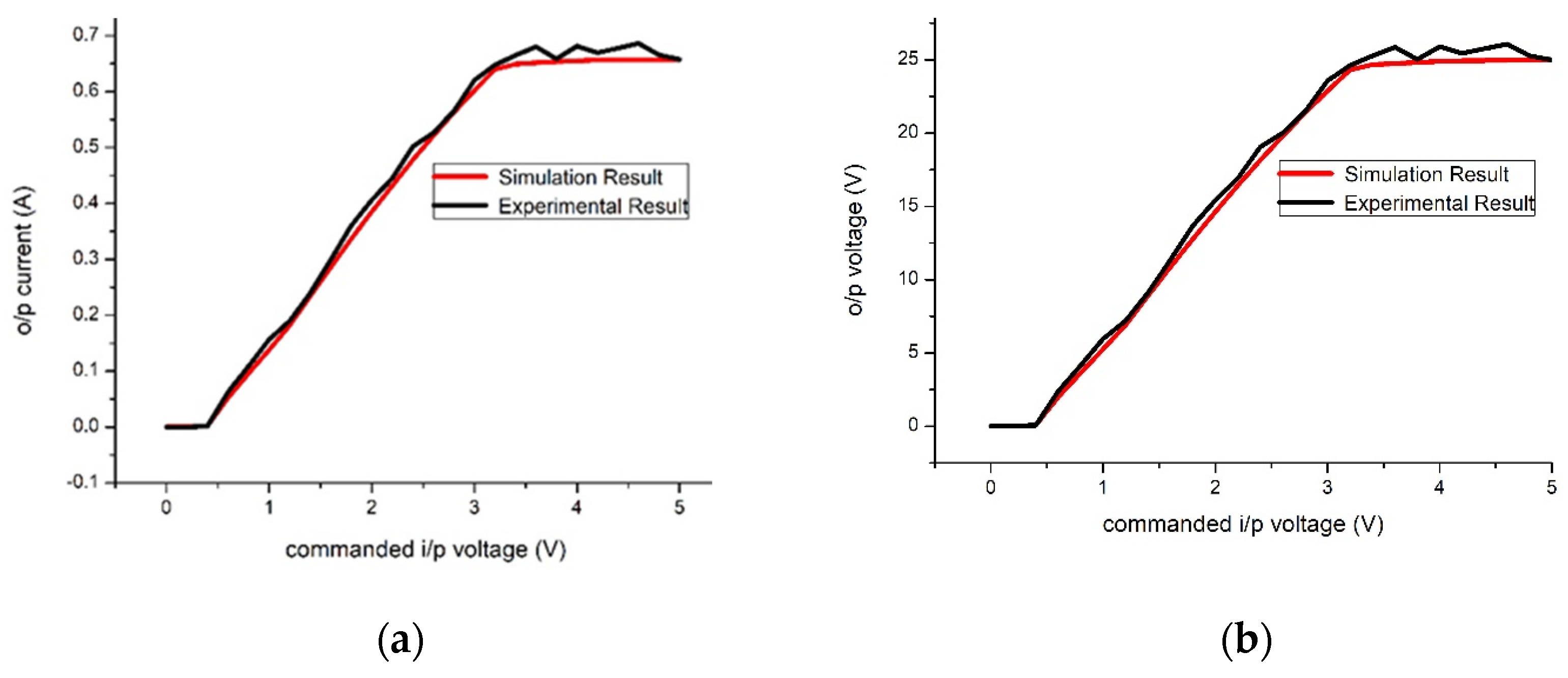

5.2. Results for 25 V, 650 mA

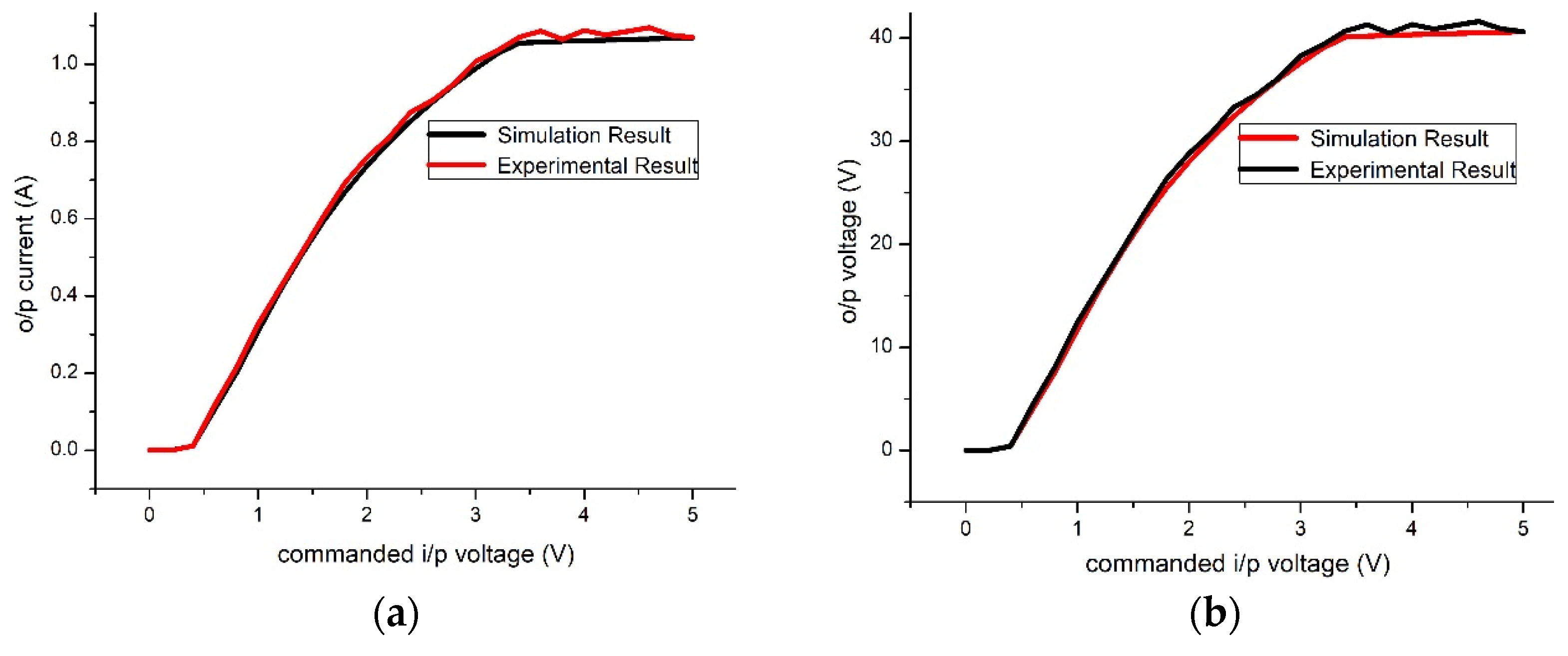

5.3. Results for 40 V, 1 A

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

References

- Duan, G.R.; Yu, H.H. LMIs in Control Systems—Analysis Design and Applications; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA, 2013; pp. 37–389. [Google Scholar]

- Wei, L.; Yongliang, X.; Haibo, Y. The effect of satellite movement on two-way time synchronization performance. In Proceedings of the 2012 IEEE International Frequency Control Symposium Proceedings, Baltimore, ML, USA, 21–24 May 2012; Institute of Electrical and Electronics Engineers (IEEE): Piscataway Township, NJ, USA, 2012; Volume 21, pp. 1–3. [Google Scholar]

- Sidi, M.J. Spacecraft Dynamics and Control—A Practical Engineering Approach; Cambridge University Press: England, UK, 1997; pp. 64–111. [Google Scholar]

- Söken, H.E. An Attitude Filtering and Magnetometer Calibration Approach for Nanosatellites. Int. J. Aeronaut. Space Sci. 2018, 19, 164–171. [Google Scholar] [CrossRef]

- Wisniewski, R. Linear Time-Varying Approach to Satellite Attitude Control Using Only Electromagnetic Actuation. J. Guid. Control. Dyn. 2000, 23, 640–647. [Google Scholar] [CrossRef]

- Psiaki, M.L. Magnetic Torquer Attitude Control via Asymptotic Periodic Linear Quadratic Regulation. J. Guid. Control. Dyn. 2001, 24, 386–394. [Google Scholar] [CrossRef]

- Lovera, M.; De Marchi, E.; Bittanti, S. Periodic attitude control techniques for small satellites with magnetic actuators. IEEE Trans. Control. Syst. Technol. 2002, 10, 90–95. [Google Scholar] [CrossRef]

- Challa, M.; Kotaru, S.; Natanson, G. Magnetometer-only attitude and rate estimates during the Earth Radiation Budget Satellite 1987 control anomaly. In Proceedings of the Guidance, Navigation, and Control Conference, Hilton Head, SC, USA, 10–12 August 1997; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 1997; Volume 2, pp. 830–840. [Google Scholar]

- Challa, M.; Natanson, G.; Ottenstein, N. Magnetometer-only attitude and rate estimates for spinning spacecraft. In Proceedings of the Astrodynamics Specialist Conference, Denver, CO, USA, 14–17 August 2000; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2000; pp. 311–321. [Google Scholar]

- Crassidis, J.L.; Markley, F.L. Predictive Filtering for Attitude Estimation Without Rate Sensors. J. Guid. Control. Dyn. 1997, 20, 522–527. [Google Scholar] [CrossRef]

- Abdelrahman, M.; Park, S.-Y. Integrated attitude determination and control system via magnetic measurements and actuation. Acta Astronaut. 2011, 69, 168–185. [Google Scholar] [CrossRef]

- Ovchinnikov, M.; Roldugin, D.; Penkov, V. Three-axis active magnetic attitude control asymptotical study. Acta Astronaut. 2015, 110, 279–286. [Google Scholar] [CrossRef]

- Ivanov, D.; Ovchinnikov, M.; Penkov, V.; Roldugin, D.; Doronin, D.; Ovchinnikov, A. Advanced numerical study of the three-axis magnetic attitude control and determination with uncertainties. Acta Astronaut. 2017, 132, 103–110. [Google Scholar] [CrossRef]

- Xiang, T.; Meng, T.; Wang, H.; Han, K.; Jin, Z.-H. Design and on-orbit performance of the attitude determination and control system for the ZDPS-1A pico-satellite. Acta Astronaut. 2012, 77, 182–196. [Google Scholar] [CrossRef]

- Celani, F. Spacecraft Attitude Stabilization Using Magnetorquers with Separation Between Measurement and Actuation. J. Guid. Control. Dyn. 2016, 39, 2184–2191. [Google Scholar] [CrossRef]

- Carletta, S.; Teofilatto, P. Design and Numerical Validation of an Algorithm for the Detumbling and Angular Rate De-termination of a CubeSat Using Only Three-Axis Magnetometer Data. Int. J. Aerosp. Eng. 2018, 3, 1–12. [Google Scholar] [CrossRef]

- Giri, D.K.; Sinha, M. Robust Backstepping Magnetic Attitude Control of Satellite Subject to Unsymmetrical Mass Properties. J. Spacecr. Rocket. 2019, 56, 298–305. [Google Scholar] [CrossRef]

- Safari, L.; Minaei, S. A simple low voltage, high output impedance resistor based current mirror with extremely low input and output voltage requirements. In Proceedings of the 2016 39th International Conference on Telecommunications and Signal Processing (TSP), Vienna, Austria, 27–29 June 2016; Institute of Electrical and Electronics Engineers (IEEE): Piscataway Township, NJ, USA, 2016; pp. 254–256. [Google Scholar]

- Sedra, A.S. The current conveyor: History and progress. In Proceedings of the 2015 IEEE International Symposium on Circuits and Systems (ISCAS), Lisbon, Portugal, 24–27 May 2015; Institute of Electrical and Electronics Engineers (IEEE): Piscataway Township, NJ, USA, 2015; pp. 1567–1571. [Google Scholar]

- Toumazou, C.; Lidgey, F.J.; Haigh, D.G. Analogue IC Design: The Current Mode Approach; Peter Peregrinus Ltd.: London, UK, 1992. [Google Scholar]

- Aronhime, P. Transfer-function synthesis using a current conveyor. IEEE Trans. Circuits Syst. 1974, 21, 312–313. [Google Scholar] [CrossRef]

- Abdalla, K.K.; Bhaskar, D.R.; Senani, R. Configuration for Realizing a Current-Mode Universal Filter and Dual-Mode Quadrature Single Resistor Controlled Oscillator. IET Circuits Devices Syst. 2012, 6, 159–167. [Google Scholar] [CrossRef]

- Senani, R.; Bhaskar, D.R.; Singh, V.K.; Sharma, R.K. Sinusoidal Oscillators and Waveform Generators using Modern Electronic Circuit Building Blocks; Springer: Cham, Switzerland, 2016; pp. 175–209. [Google Scholar]

- Gupta, P.; Verma, V.K.; Ranjan, R.K.; Appasani, B.; Priyadarshini, B.; Nath, V. A series expansion method aided design of current mode second generation current conveyor based active control circuit. Microsyst. Technol. 2018, 25, 2323–2330. [Google Scholar] [CrossRef]

- Verma, V.K.; Ranjan, R.K.; Gupta, P.; Priyadarshini, B.; Nath, V. A Series Expansion Method Aided Design of CCII Controller for a Tito System. Microsyst. Technol. 2018, 24, 3843–3849. [Google Scholar] [CrossRef]

- Gupta, P.; Appasani, B.; Verma, V.K.; Ranjan, R.K. PSO based CCII PID controller for a continuous stirred tank reactor system. In Proceedings of the 2017 IEEE International Conference on Power, Control, Signals and Instrumentation Engineering (ICPCSI), Chennai, India, 21–22 September 2017; Institute of Electrical and Electronics Engineers (IEEE): Piscataway Township, NJ, USA, 2017; pp. 2786–2789. [Google Scholar]

- Verma, V.K.; Ranjan, R.K.; Lekshmi, V.; Azad, A.K.; Appasani, B.; Nath, V. A second generation current conveyor based PID controller optimized using a crossover improved genetic algorithm. Microsyst. Technol. 2020, 26, 1449–1454. [Google Scholar] [CrossRef]

- Smith, K.; Sedra, A. The current conveyor—A new circuit building block. In Proceedings of the Proceedings of the IEEE; Institute of Electrical and Electronics Engineers (IEEE): Piscataway Township, NJ, USA, 1968; Volume 56, pp. 1368–1369. [Google Scholar]

- Wilson, B. Recent developments in current conveyors and current-mode circuits. IEE Proc. G Circuits, Devices Syst. 1990, 137, 63. [Google Scholar] [CrossRef]

- Svoboda, J.A.; McGory, L.; Webb, S. Applications of a commercially available current conveyor. Int. J. Electron. 1991, 70, 159–164. [Google Scholar] [CrossRef]

- Goldberg, D.E. Genetic Algorithms; Pearson Education: New Delhi, India, 2006; pp. 1–25. [Google Scholar]

- Appasani, B.; Gupta, N. A Novel Segmentation Approach in GA and its Applications in Antenna Arrays. Microw. Rev. 2017, 23, 8–14. [Google Scholar]

- Smeresky, B.; Rizzo, A.; Sands, T. Optimal Learning and Self-Awareness Versus PDI. Algorithms 2020, 13, 23. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Magnetic dipole moment, Am2 | 0.15 |

| Coil resistance, Ohm | 38 |

| Coil inductance, mH | 18 |

| Number of turns | 370 |

| Optimization Technique | Settling Time (ms) | Steady-State Error (%) |

|---|---|---|

| GA | 0.186 | 10% |

| SGA (2 segments) | 0.203 | 10.9% |

| SGA (6 segments) | 0.141 | 7.6% |

| SGA (10 segments) | 0.122 | 6.6% |

| PSO | 0.151 | 8.1% |

| FA | 0.16 | 8.6% |

| BA | 0.227 | 12.3% |

| Resistance | Value | ||

|---|---|---|---|

| 15 Volt Operation | 25 Volt Operation | 40 Volt Operation | |

| R1 | 6.8 kΩ | 6.8 kΩ | 6.8 kΩ |

| R2 | 32 kΩ | 32 kΩ | 32 kΩ |

| R3 | 100 Ω | 220 Ω | 500 Ω |

| R4 | 6.8 kΩ | 6.8 kΩ | 6.8 kΩ |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Verma, V.K.; Ranjan, R.K.; Prince, P.; Appasani, B.; Bizon, N.; Thounthong, P. A New Active Control Driver Circuit for Satellite’s Torquer System Using Second Generation Current Conveyor. Electronics 2021, 10, 911. https://doi.org/10.3390/electronics10080911

Verma VK, Ranjan RK, Prince P, Appasani B, Bizon N, Thounthong P. A New Active Control Driver Circuit for Satellite’s Torquer System Using Second Generation Current Conveyor. Electronics. 2021; 10(8):911. https://doi.org/10.3390/electronics10080911

Chicago/Turabian StyleVerma, Vijay Kumar, Rajeev Kumar Ranjan, Pallav Prince, Bhargav Appasani, Nicu Bizon, and Phatiphat Thounthong. 2021. "A New Active Control Driver Circuit for Satellite’s Torquer System Using Second Generation Current Conveyor" Electronics 10, no. 8: 911. https://doi.org/10.3390/electronics10080911

APA StyleVerma, V. K., Ranjan, R. K., Prince, P., Appasani, B., Bizon, N., & Thounthong, P. (2021). A New Active Control Driver Circuit for Satellite’s Torquer System Using Second Generation Current Conveyor. Electronics, 10(8), 911. https://doi.org/10.3390/electronics10080911