Comparison of Different Large Signal Measurement Setups for High Frequency Inductors

Abstract

1. Introduction

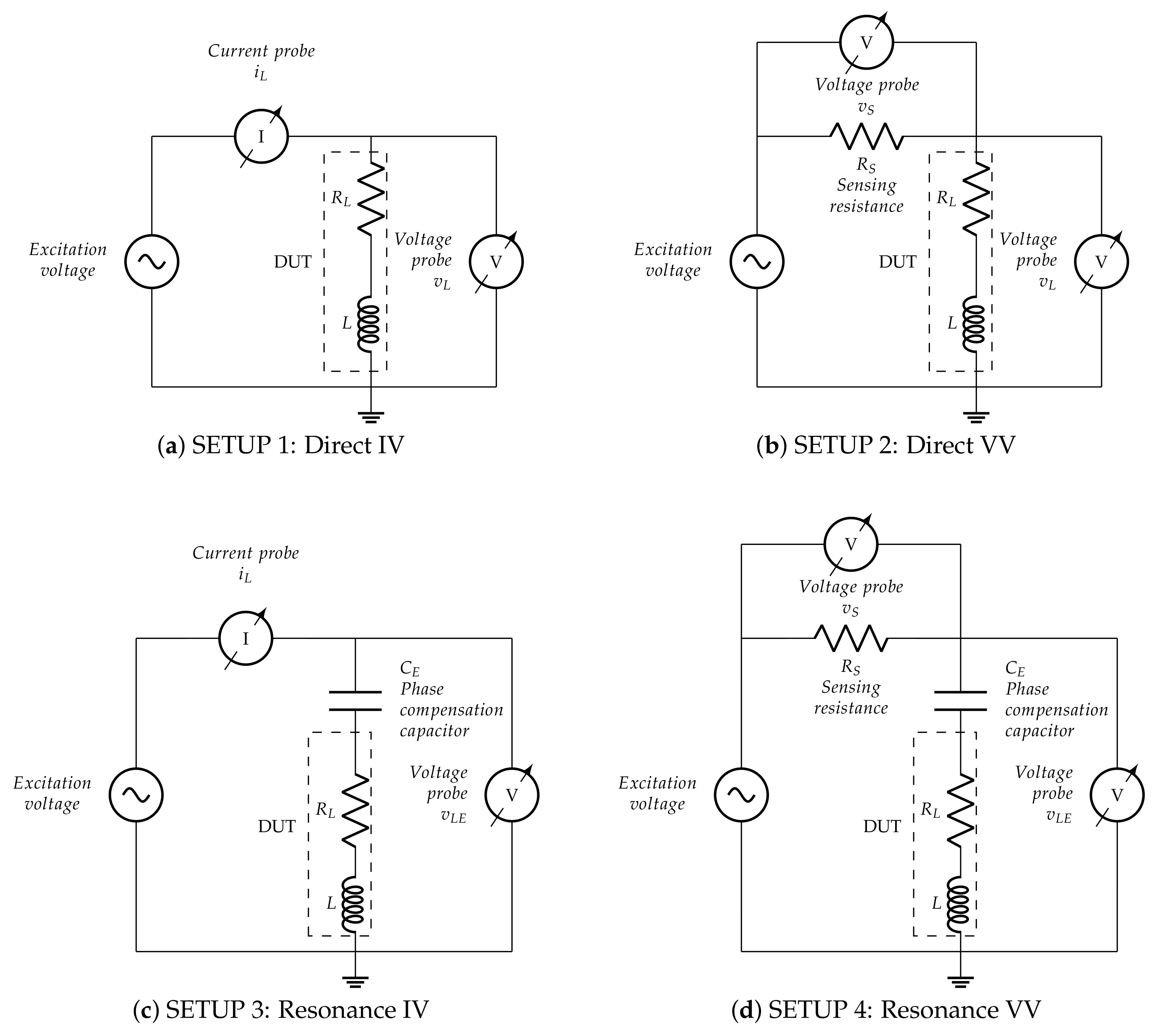

2. Measurement Setups

3. Modeling the Measurement Accuracy

4. Worst Case or Maximum Deviation of the Measurement

4.1. Deviation of Due to

4.2. Deviation of Due to

4.3. Discussion

- If º, for instance when measuring a high Q inductor without an additional capacitor, the main driver of the deviation on is the term related to the phase (19). The main contributor in that term is the sample rate of the oscilloscope () and the normalized deviation produced by it depends on the period T at which the inductor is being characterized. Therefore, to improve the results, the only options are either to measure at a lower frequency or to employ an oscilloscope with a higher sample rate.

- If the measurement is done by adding a capacitor to compensate the reactance º. In this case, the main driver of the deviation on is related to the module, and the three terms that have to be taken into account are the ones shown in (22):

- -

- The vertical resolution of the oscilloscope, given by the number of bits of its ADC () is always present, whether the current measurement is done using a current probe or a voltage one. To minimize its impact, a high number of bits is required.

- -

- The nominal deviation on the gain of the probes used to measure the voltage () and current () has the same impact. However, active voltage probes usually have a better performance than current ones (), but the impact on the deviation of a sensing resistor () can increase the deviation , and even make it a worse option.

5. Results

5.1. Validation by Simulation

- The tolerances in the value of and ( and , respectively) are accounted for by adding or subtracting its value to the nominal one.

- The tolerance in the gain of the probes and the deviation due to the bit resolution of the oscilloscope ( and in (22)) are lumped together in and , the values of which are added or subtracted to the measurement of every probe.

- The time deviation due to the sample rate of the oscilloscope has two different effects (18): the deviation of the real period of the measured waves, which is modeled as a deviation of the generator period (), and the deviation of the phase of the two probes, modeled by a delay block in each of them.

5.2. Experimental Validation

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sullivan, C.R.; Harburg, D.V.; Qiu, J.; Levey, C.G.; Yao, D. Integrating magnetics for on-chip power: A perspective. IEEE Trans. Power Electron. 2013, 28, 4342–4353. [Google Scholar] [CrossRef]

- Mathúna, C.; Kulkarni, S.; Pavlovic, Z.; Casey, D.; Rohan, J.; Kelleher, A.M.; Maxwell, G.; O’Brien, J.; McCloskey, P. Power inside—Applications and technologies for integrated power in microelectronics. In Proceedings of the 2017 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 2–6 December 2017; pp. 331–334. [Google Scholar] [CrossRef]

- Fernandez, C.; Pavlovic, Z.; Kulkarni, S.; McCloskey, P.; O’Mathuna, C. Novel High-Frequency Electrical Characterization Technique for Magnetic Passive Devices. IEEE J. Emerg. Sel. Top. Power Electron. 2018, 6, 621–628. [Google Scholar] [CrossRef]

- Gutierrez, F. Fully-Integrated Converter for Low-Cost and Low-Size Power Supply in Internet-of-Things Applications. Electronics 2017, 6, 38. [Google Scholar] [CrossRef]

- Lee, D. Energy harvesting chip and the chip based power supply development for a wireless sensor network. Sensors 2008, 8, 7690–7714. [Google Scholar] [CrossRef] [PubMed]

- Bajwa, R.; Yapici, M.K. Integrated On-Chip Transformers: Recent Progress in the Design, Layout, Modeling and Fabrication. Sensors 2019, 19, 3535. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Wang, Z.J.; Zhu, B.H.; Kim, E.S.; Kim, N.Y. Fabrication of QFN-packaged miniaturized GaAs-based bandpass filter with intertwined inductors and dendritic capacitor. Materials 2020, 13, 1932. [Google Scholar] [CrossRef] [PubMed]

- Qian, K.; Qian, L. Inductance Model of a Backside Integrated Power Inductor in 2.5D/3D Integration. Appl. Sci. 2020, 10, 8275. [Google Scholar] [CrossRef]

- Mu, M. High Frequency Magnetic Core Loss Study. Ph.D. Thesis, Virginia Polytechnic Institute and State University, Blacksburg, VA, USA, 2013; pp. 1–52. [Google Scholar]

- Mu, M.; Li, Q.; Gilham, D.J.; Lee, F.C.; Ngo, K.D. New core loss measurement method for high-frequency magnetic materials. IEEE Trans. Power Electron. 2014, 29, 4374–4381. [Google Scholar] [CrossRef]

- Han, Y.; Cheung, G.; Li, A.; Sullivan, C.R.; Perreault, D.J. Evaluation of magnetic materials for very high frequency power applications. IEEE Trans. Power Electron. 2012, 27, 425–435. [Google Scholar] [CrossRef]

- Kolar, J.; Krismer, F.; Lobsiger, Y.; Muhlethaler, J.; Nussbaumer, T.; Minibock, J. Extreme efficiency power electronics. In Proceedings of the 7th International Conference on Integrated Power Electronics Systems, CIPS 2012, Nuremberg, Germany, 6–8 March 2012. [Google Scholar]

- Javidi, N.F.; Nymand, M.; Forsyth, A.J. New method for error compensation in high frequency loss measurement of powder cores. In Proceedings of the 2017 IEEE Applied Power Electronics Conference and Exposition (APEC), Tampa, FL, USA, 26–30 March 2017; pp. 876–881. [Google Scholar] [CrossRef]

- Tan, F.D.; Vollin, J.L.; Cuk, S.M. Practical approach for magnetic core-loss characterization. IEEE Trans. Power Electron. 1995, 10, 124–130. [Google Scholar] [CrossRef]

- Joint Committee For Guides In Metrology. Evaluation of Measurement Data—Guide to the Expression of Uncertainty in Measurement; International Organization for Standardization: Geneva, Switzerland, 2008; Volume 50, p. 134. [Google Scholar]

- Elison, S.; Williams, A. (Eds.) Quantifying Uncertainty in Analytical Measurement EURACHEM/CITAC Guide CG 4, 3rd ed.; Eurachem/Citac: Teddington, UK, 2011. [Google Scholar]

- Bertocco, M.; Sona, A.; Zanchetta, P. An improved method for the evaluation of uncertainty of channel power measurement with a spectrum analyzer. IEEE Trans. Instrum. Meas. 2006, 56, 1479–1483. [Google Scholar] [CrossRef]

- Huang, H. A unified theory of measurement errors and uncertainties. Meas. Sci. Technol. 2018, 29. [Google Scholar] [CrossRef]

- Witkovsky, V.; Wimmer, G.; Durisova, Z.; Duris, S.; Palencar, R. Brief overview of methods for measurement uncertainty analysis: GUM uncertainty framework, Monte Carlo method, characteristic function approach. In Proceedings of the 2017 11th International Conference on Measurement, Smolenice, Slovakia, 29–31 May 2017; pp. 35–38. [Google Scholar] [CrossRef]

- Von Martens, H.J. Evaluation of uncertainty in measurements—Problems and tools. Opt. Lasers Eng. 2002, 38, 185–206. [Google Scholar] [CrossRef]

- Gapinski, B.; Rucki, M. The roundness deviation measurement with CMM. In Proceedings of the 2008 IEEE International Workshop on Advanced Methods for Uncertainty Estimation in Measurement, Sardinia, Italy, 21–22 July 2008; pp. 108–111. [Google Scholar] [CrossRef]

- Shahanaghi, K.; Nakhjiri, P. A new optimized uncertainty evaluation applied to the Monte-Carlo simulation in platinum resistance thermometer calibration. Meas. J. Int. Meas. Conf. 2010, 43, 901–911. [Google Scholar] [CrossRef]

- Li, Y.; Xuwei, H.; Haibin, J. Uncertainty evaluation for a precision phase measurement system at power frequency. In Proceedings of the 2019 14th IEEE International Conference on Electronic Measurement and Instruments, (ICEMI 2019), Changsha, China, 1–3 November 2019; pp. 1867–1872. [Google Scholar] [CrossRef]

- Hou, D.; Mu, M.; Lee, F.C.; Li, Q. New high-frequency core loss measurement method with partial cancellation concept. IEEE Trans. Power Electron. 2017, 32, 2987–2994. [Google Scholar] [CrossRef]

- Northrop, R. Introduction to Instrumentation and Measurements, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

| Deviation Component | ||||||

|---|---|---|---|---|---|---|

| Value |

| Model | Inductance | Q Factor (@13.45 MHz) | (@13.45 MHz) |

|---|---|---|---|

| 2014VS-251ME | 257 nH | 116.56 | 186.3 m |

| Component | Model | Parameter | Value |

|---|---|---|---|

| Oscilloscope | R&S©RTM3000 | 10 | |

| Oscilloscope | R&S©RTM3000 | 5 Gs/s | |

| Passive voltage probe | R&S©RT-ZP10 | ||

| Active voltage probe | R&S©RT-ZD10 | ||

| Current probe | R&S©RT-ZC20 | ||

| Current sensing resistor | SR732ARTTD1R00F | ||

| Series added capacitor | 08051A561F4T2A |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lopez-Lopez, J.; Fernandez, C.; Barrado, A.; Zumel, P. Comparison of Different Large Signal Measurement Setups for High Frequency Inductors. Electronics 2021, 10, 691. https://doi.org/10.3390/electronics10060691

Lopez-Lopez J, Fernandez C, Barrado A, Zumel P. Comparison of Different Large Signal Measurement Setups for High Frequency Inductors. Electronics. 2021; 10(6):691. https://doi.org/10.3390/electronics10060691

Chicago/Turabian StyleLopez-Lopez, Jaime, Cristina Fernandez, Andrés Barrado, and Pablo Zumel. 2021. "Comparison of Different Large Signal Measurement Setups for High Frequency Inductors" Electronics 10, no. 6: 691. https://doi.org/10.3390/electronics10060691

APA StyleLopez-Lopez, J., Fernandez, C., Barrado, A., & Zumel, P. (2021). Comparison of Different Large Signal Measurement Setups for High Frequency Inductors. Electronics, 10(6), 691. https://doi.org/10.3390/electronics10060691