Optimization for a Photovoltaic Pumping System Using Indirect Field Oriented Control of Induction Motor

Abstract

:1. Introduction

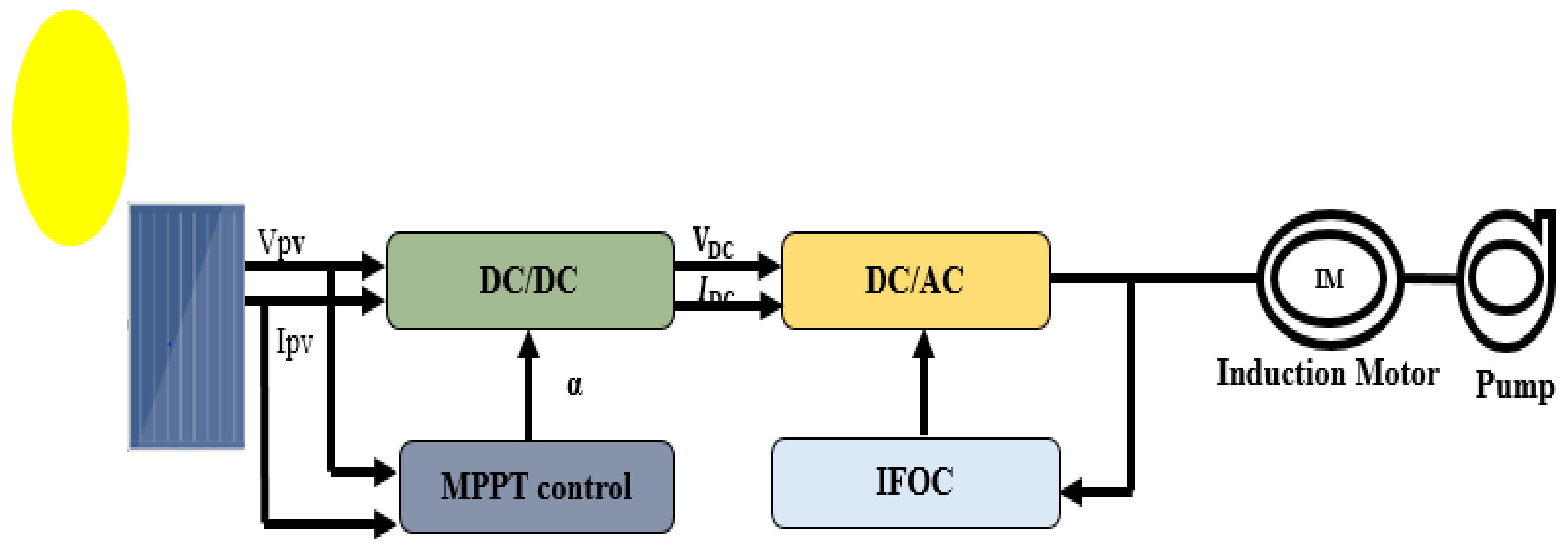

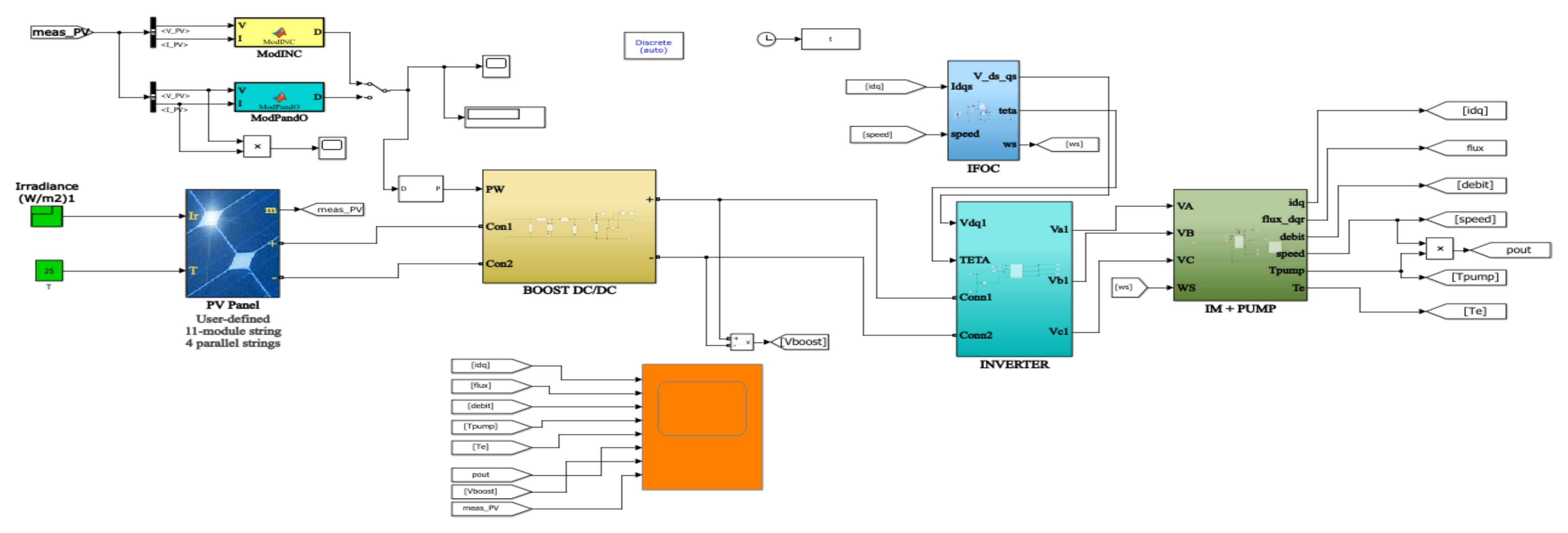

2. Modeling of The Parameter of The Pvwps

2.1. Description of the PUMP System

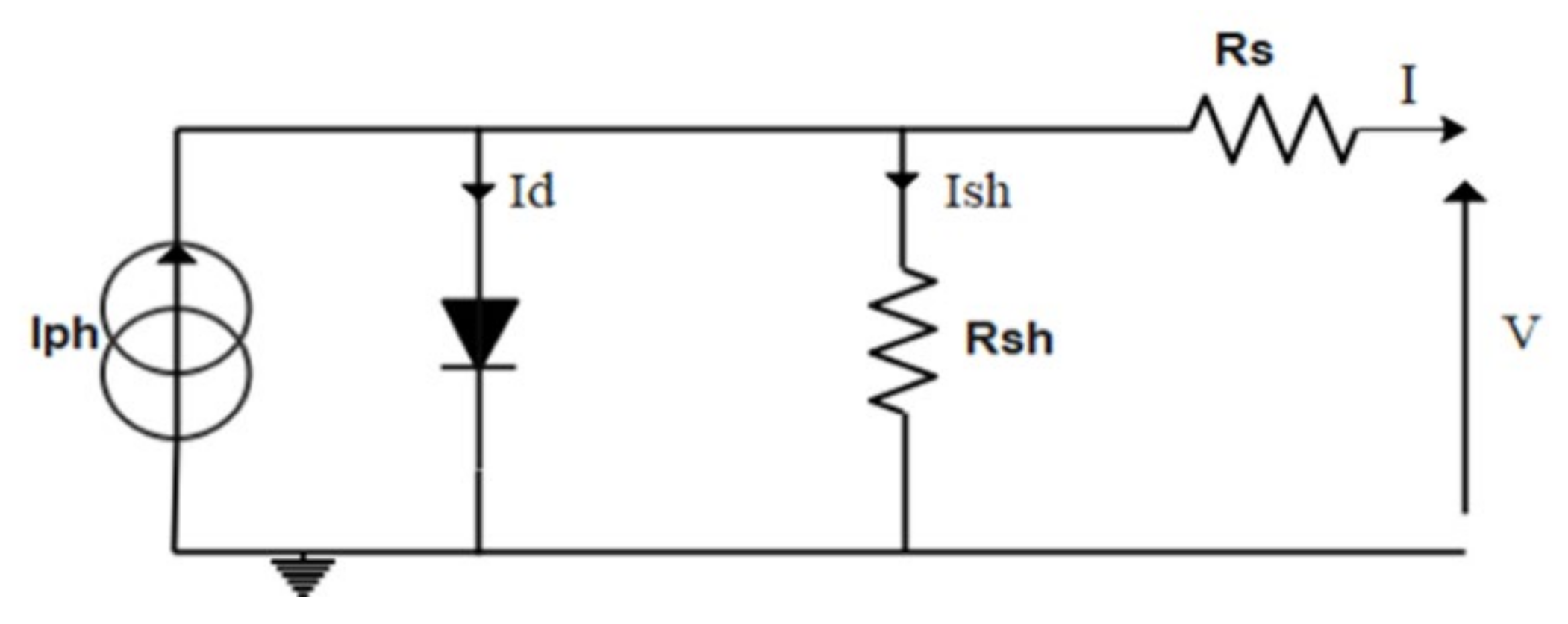

2.2. Equivalent Circuit of a Photovoltaic Cell

2.3. ”Boost Converter DC/DC”

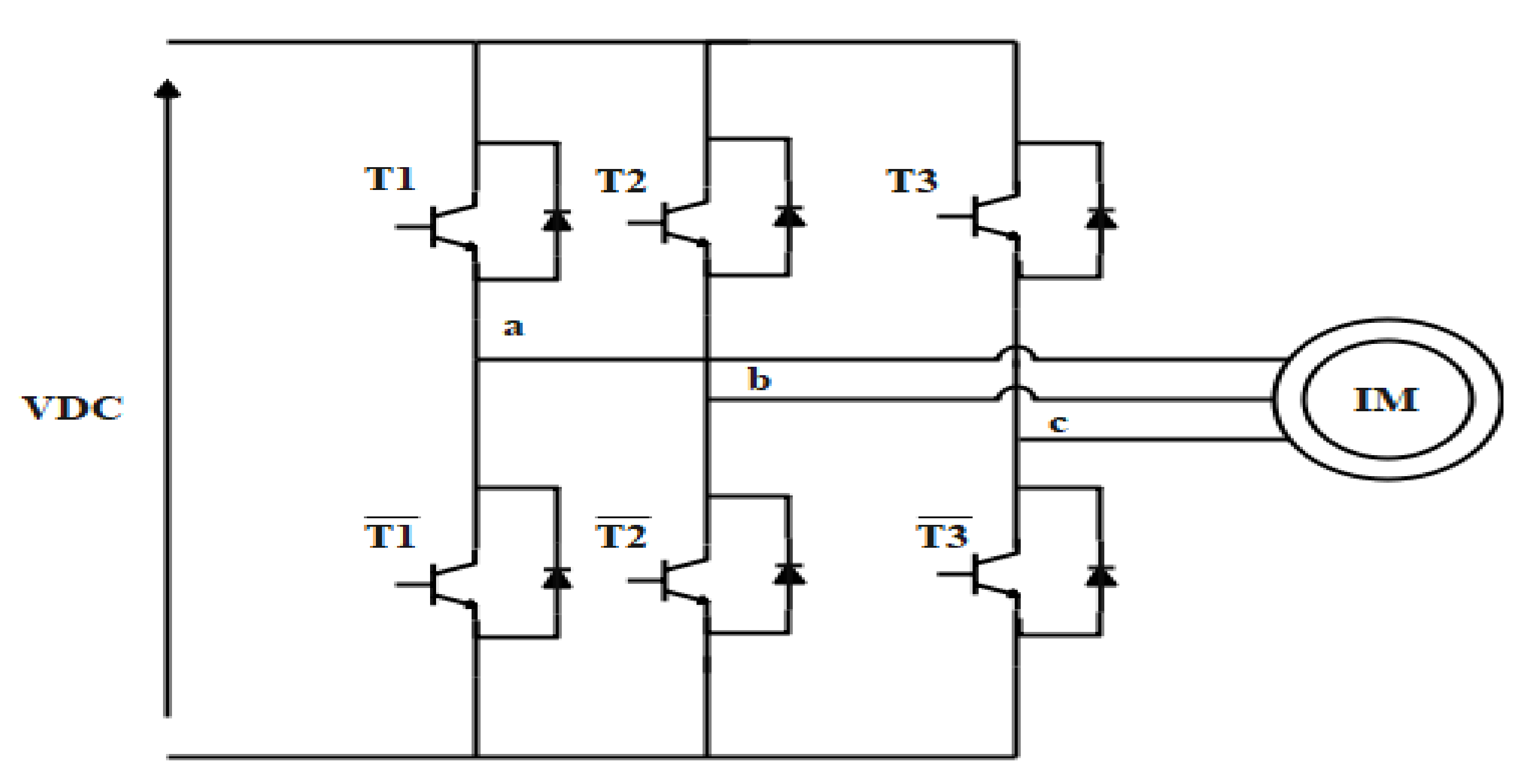

2.4. Inverter

2.5. Induction Motor

- is electromagnetic torque;

- is load torque; and

- is motor rotor speed.

2.6. Centrifugal PUMP

- is the power that the pump transmits to the fluid W(watt);

- is the total height (m);

- is the flow (m3/s);

- is the density of water (1000 kg/m3).

- is the maximum height (m);

- is the instantaneous speed (rpm);

- is the maximum speed (rpm);

- is the instantaneous flow (m3/s);

- is the maximum flow (m3/s).

3. Control Strategies of the PVWPS

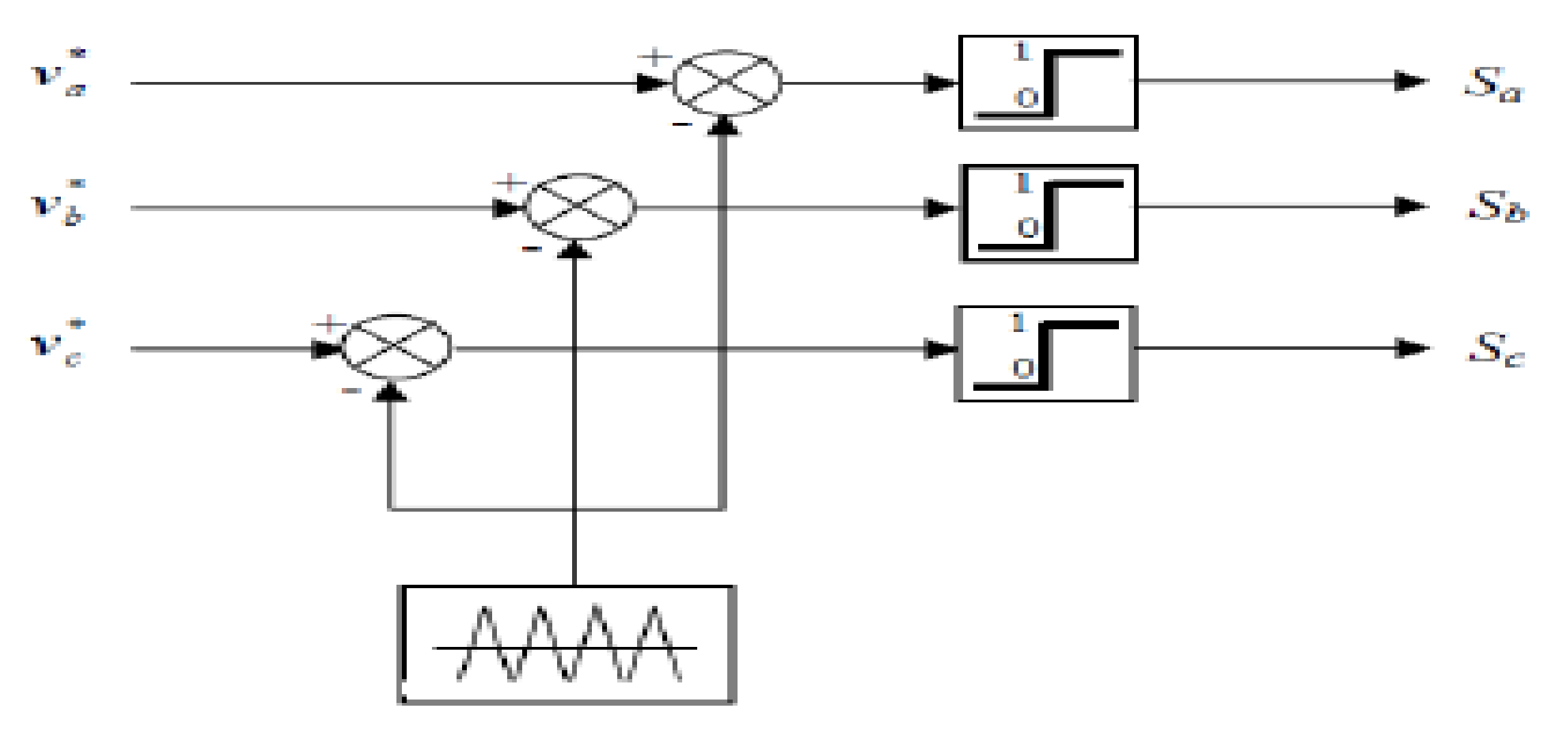

3.1. Control PWM

3.2. MPPT Control with variable step Incremental Conductance and Perturb and Observe Algorithms

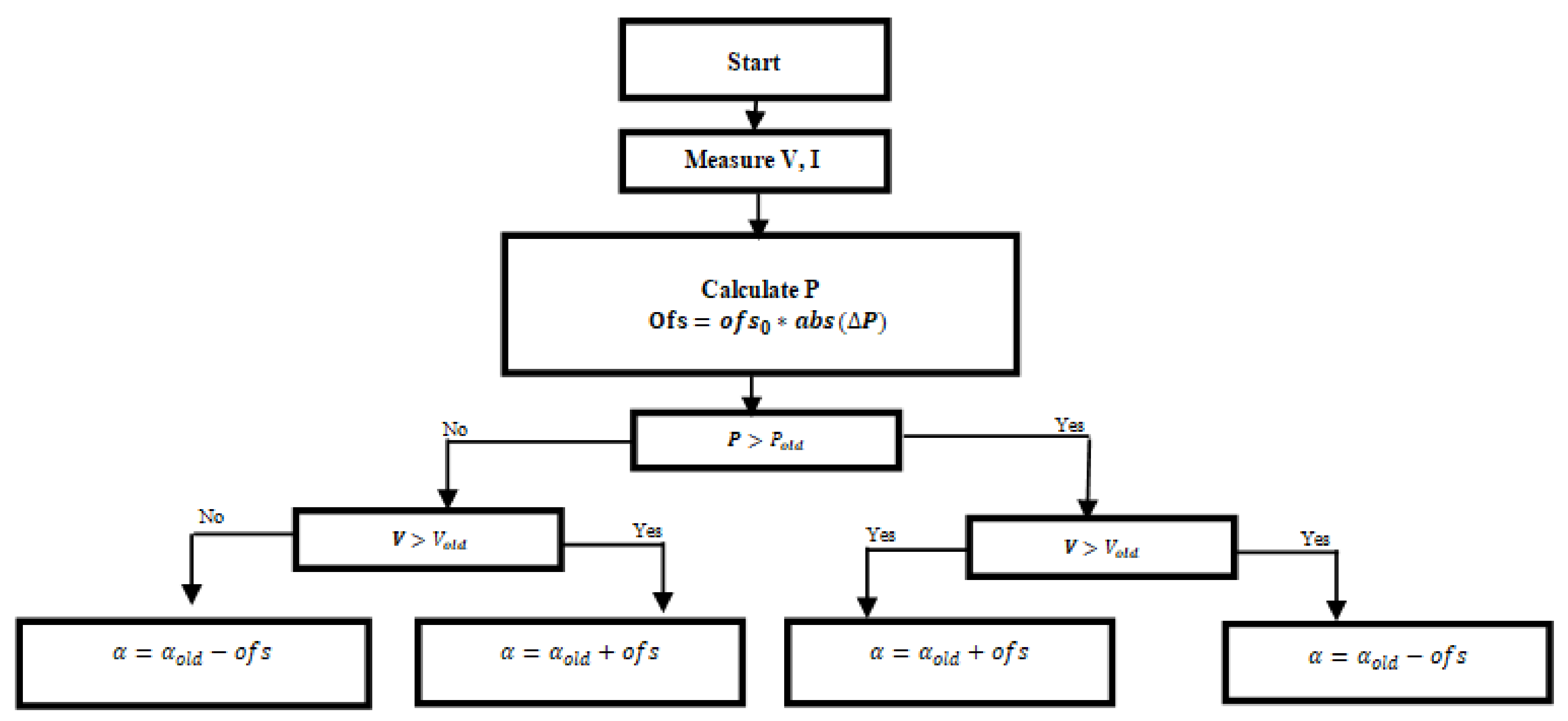

3.2.1. Variable step Perturb and Observe algorithm

- When , the working point is on the left of the MPP;

- When , the working point is on the MPP;

- When , the working point is on the right of the MPP.

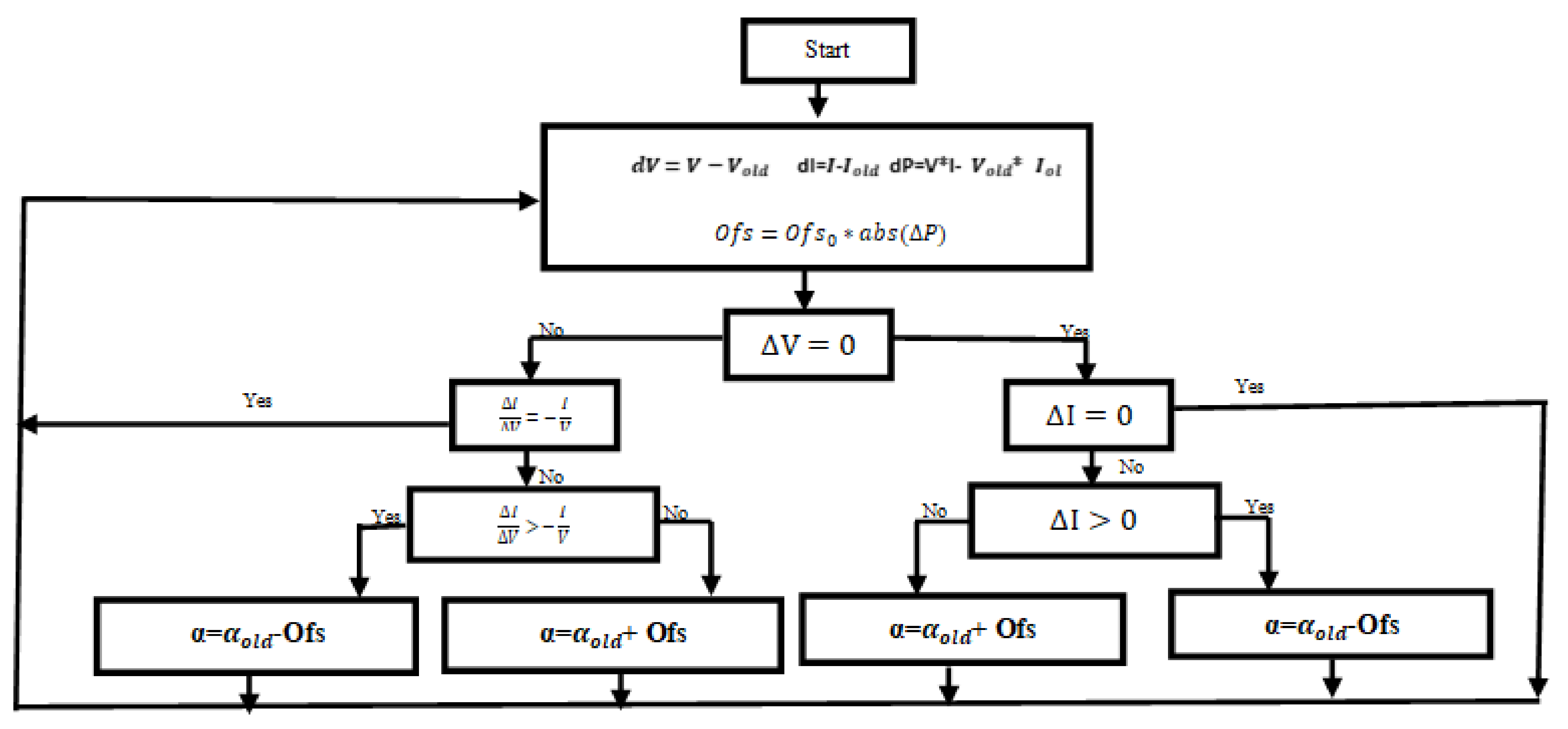

3.2.2. Variable step Incremental Conductance algorithm

- at MPP;

- Right to MPP;

- Left to MPP.

3.3. Field-Oriented Control

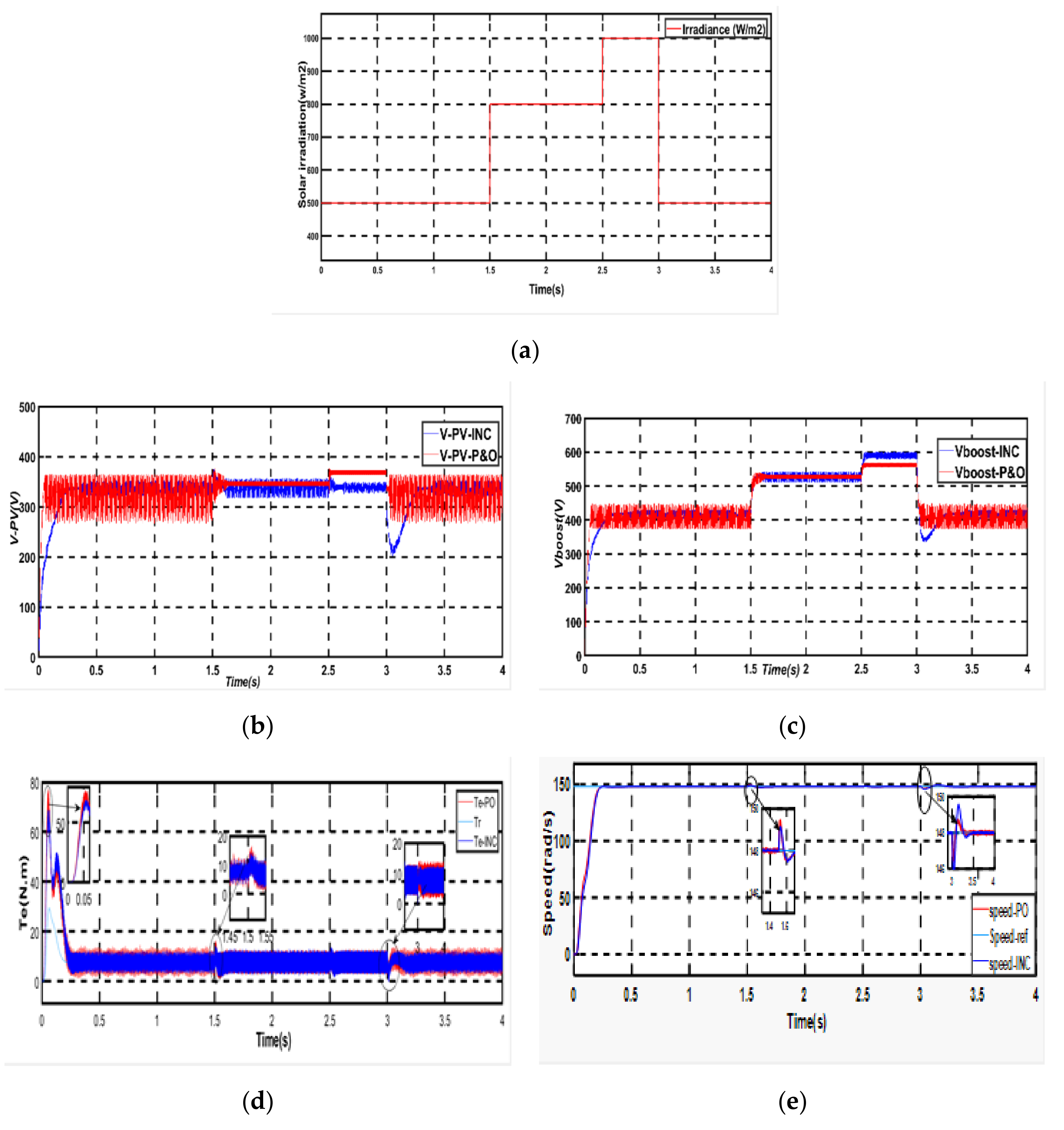

4. Simulation Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| PV Parameters | Symbol | Values |

|---|---|---|

| Maximum Power | Pmp | 270,116 W |

| Open circuit Voltage | Voc | 37.9 V |

| Voltage at MPPT Short-circuit current Cells per module | Vmp Isc Ncell | 30.8 V 9.07 A 8.7 A |

| Boost Parameters | Symbol | Values |

|---|---|---|

| Input voltage | Vin | 338.8 V |

| Output voltage | Vout | 600 V |

| Duty cycle Inductance Output and input capacitor | D L Cin = Cout | 0.43 3 mh 6 × 10−4 F |

| IM Parameters | Symbol | Values |

|---|---|---|

| Nominal power | Pn | 1.5 kw |

| Nominal voltage | Vn | 220/380 |

| Rated speed | Ω | 1420 rpm |

| Nominal frequency | fn | 50 Hz |

| Stator resistance | Rs | 4.850 Ω |

| Rotor resistance | Rr | 3.805 Ω |

| Stator inductance | Ls | 0.274 H |

| Rotor inductance | Lr | 0.274 H |

| Mutual induction | Lm | 0.258 H |

| Number of pole pairs | p | 2 |

References

- Feraga, C.-E.; Bouldjedri, A. Performance of a Photovoltaic Pumping System Driven by a Single Phase Induction Motor Connected to a Photovoltaic Generator. Autom. Časopis Autom. Mjer. Elektron. Računarstvo Komun. 2016, 57, 163–172. [Google Scholar] [CrossRef] [Green Version]

- Singla, C.; Pahwa, V.; Kumar, D. Optimum MPPT Technique for the PV based Field Oriented Control of Induction Motor Feeding Centrifugal Pump. Indian J. Sci. Technol. 2016, 9, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Moubarak, A.; El-Saady, G.; Ibrahim, E.N. Variable Speed Photovoltaic Water Pumping Using Affinity Laws. J. Power Energy Eng. 2017, 5, 50–71. [Google Scholar] [CrossRef] [Green Version]

- Khlifi, M.A. Study and Control of Photovoltaic Water Pumping System. J. Electr. Eng. Technol. 2016, 10, 350–371. [Google Scholar] [CrossRef] [Green Version]

- Amir, A.; Selvaraj, J.; Rahim, N.A. Study of the MPP tracking algorithms: Focusing the numerical method techniques. Renew. Sustain. Energy Rev. 2016, 62, 350–371. [Google Scholar] [CrossRef]

- Gupta, A.; Chauhan, Y.K.; Pachauri, R.K. A comparative investigation of maximum power point tracking methods for solar PV system. Sol. Energy 2016, 136, 236–253. [Google Scholar] [CrossRef]

- Anna, M.; Immanuel, S. MPPT based stand-alone water pumping system. In Proceedings of the International Conference on Computer, Communication and Electrical Technology (ICCCET), Tirunelveli, India, 18–19 March 2011. [Google Scholar]

- Motahhir, A.S.; Ghzizal, E.; Sebti, S.; Derouich, A. Modeling of Photovoltaic System with modified Incremental Conductance Algorithm for fast changes of irradiance. Int. J. Photoenergy 2018, 2018, 13. [Google Scholar] [CrossRef]

- Saidi, K.; Maamoun, M.; Bounekhla, M. A new high performance variable step size perturb-and-observe MPPT algorithm for photovoltaic system. Int. J. Power Electron. Drive Syst. 2019, 10, 1662–1674. [Google Scholar] [CrossRef]

- Li, C.; Chen, Y.; Zhou, D.; Liu, J.; Zeng, J. A High-Performance Adaptive Incremental Conductance MPPT Algorithm for Photovoltaic Systems. J. Energ. 2016, 9, 288. [Google Scholar] [CrossRef] [Green Version]

- Poompavai, T.; Kowsalya, M. Control and energy management strategies applied for solar photovoltaic and wind energy fed water pumping system: A review. Renew. Sustain. Energy Rev. 2018, 107, 108–122. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, B. BLDC motor-driven solar PVArray-fed water pumping system employing zeta converter. IEEE Trans. Ind. Appl. 2016, 52, 2315–2322. [Google Scholar] [CrossRef]

- Mudlapur, A.; Ramana, V.V.; Damodaran, R.V.; Balasubramanian, V.; Mishra, S. Effect of partial shading on PV fed induction motor water pumping systems. IEEE Trans. Energy Convers. 2019, 34, 530–539. [Google Scholar] [CrossRef]

- Kiran, N. Indirect Vector Control of Three Phase Induction Motor using PSIM. Bull. Electr. Eng. Inform. 2014, 3, 15–24. [Google Scholar] [CrossRef]

- Saeed, M.A.; Kim, S.H.; Kim, H.; Liang, J.; Woo, H.Y.; Kim, T.G.; Yan, H.; Shim, J.W. Indoor Organic Photovoltaics: Optimal Cell Design Principles with Synergistic Parasitic Resistance and Optical Modulation Effect. Adv. Energy Mater. 2021, 11, 2003103. [Google Scholar] [CrossRef]

- Errouha, M.; Derouich, A.; Motahir, S.; Zamzoum, O. Optimal Control of Induction Motor for Photovoltaic Water Pumping System. Technol. Econ. Smart Grids Sustain. Energy 2020, 5, 6. [Google Scholar] [CrossRef] [Green Version]

- Yahyaoui, I. Specifications of Photovoltaic Pumping Systems Sizing, Fuzzy Energy Management Specifications of Photovoltaic Pumping Systems; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Wang, F.; Zhang, Z.; Mei, X.; Rodríguez, J.; Kennel, R. Advanced control strategies of induction machine: Field oriented control, direct torque control and model predictive control. Energies 2018, 11, 120. [Google Scholar] [CrossRef] [Green Version]

- Rawat, R.; Kaushik, S.C.; Lamba, R. A review on modeling, design methodology and size optimization of photovoltaic based water pumping, standalone and grid connected system. Renew Sustain. Energy Rev. 2016, 57, 1506–1519. [Google Scholar] [CrossRef]

- Gulyaev, A.; Fokin, D.; Ten, E.; Vlasyevsky, V. PWM algorithms synthesis. Procedia Eng. 2016, 165, 1529–1535. [Google Scholar] [CrossRef]

- Motahhir, S.; El Hammoumi, A.; El Ghzizal, A. The Most Used MPPT Algorithms: Review and the Suitable Low-cost Embedded Board for Each Algorithm. J. Clean Prod. 2019, 246, 118983. [Google Scholar] [CrossRef]

- Motahhir, S.; El Hammoumi, A.; El Ghzizal, A. Photovoltaic system with quantitative comparative between an improved MPPT and existing INC and P&O methods under fast varying of solar irradiation. Energy Rep. 2018, 4, 341–350. [Google Scholar]

- Hiware, R.S.; Chaudhari, J.G. Indirect Field Oriented Control for Induction Motor. In Proceedings of the International Conference on Emerging Trends in Engineering Technology, Port Louis, Mauritius, 18–20 November 2011. [Google Scholar]

- Bossoufi, B.; Karim, M.; Lagrioui, A.; Mohammed, T.; EL Hafyani, M.L. Backstepping control of DFIG Generators for Wide-Range Variable-Speed Wind Turbines. IJAAC Int. J. Autom. Control 2014, 8, 122–140. [Google Scholar] [CrossRef]

- Bossoufi, B.; Karim, M.; Lagrioui, A.; Mohammed, T. FPGA-Based Implementation nonlinear backstepping control of a PMSM Drive. IJPEDS Int. J. Power Electron. Drive Syst. 2014, 4, 12–23. [Google Scholar] [CrossRef]

- Bossoufi, B.; Karim, M.; Lagrioui, A. FPGA-Based Implementation Sliding Mode Control and nonlinear Adaptive Backstepping control of a Permanent Magnet Synchronous Machine Drive. Wseas Trans. Syst. Control. 2014, 9, 86–100. [Google Scholar]

- Narjess, S.; Trabelsi, R.; Gdaim, S.; Bossoufi, B.; Mimouni, M.F. Backstepping control of induction motor using Xilinx System Generator: FPGA-based implementation. Int. J. Emerg. Sci. 2013, 3, 289–302. [Google Scholar]

- Bossoufi, B.; Karim, M.; Ionita, S.; Lagrioui, A. Nonlinear Non Adaptive Backstepping with Sliding-Mode Torque Control Approach for PMSM Motor. J. Electr. Syst. 2012, 8, 236–248. [Google Scholar]

- Bossoufi, B.; Karim, M.; Ionita, S.; Lagrioui, A. The Optimal Direct Torque Control of a PMSM drive: FPGA-Based Implementation with Matlab & Simulink Simulation. J. Theor. Appl. Inf. Technol. 2011, 28, 63–72. [Google Scholar]

- Bossoufi, B.; Karim, M.; Ionita, S.; Lagrioui, A.; Gabriel, I. Matlab & Simulink Simulation with FPGA-Based Implementation Sliding Mode Control of a Permanent Magnet Synchronous Machine Drive. Wseaa Trans. Syst. Control 2011, 6, 92–103. [Google Scholar]

- Bossoufi, B.; Karim, M.; Ionita, S.; Lagrioui, A. Indirect Sliding Mode Control of a Permanent Magnet Synchronous Machine: FPGA-Based Implementation with Matlab & Simulink Simulation. J. Theor. Appl. Inf. Technol. 2011, 29, 32–42. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saady, I.; Karim, M.; Bossoufi, B.; Motahhir, S.; Adouairi, M.s.; Majout, B.; Lamnadi, M.; Masud, M.; Al-Amri, J.F. Optimization for a Photovoltaic Pumping System Using Indirect Field Oriented Control of Induction Motor. Electronics 2021, 10, 3076. https://doi.org/10.3390/electronics10243076

Saady I, Karim M, Bossoufi B, Motahhir S, Adouairi Ms, Majout B, Lamnadi M, Masud M, Al-Amri JF. Optimization for a Photovoltaic Pumping System Using Indirect Field Oriented Control of Induction Motor. Electronics. 2021; 10(24):3076. https://doi.org/10.3390/electronics10243076

Chicago/Turabian StyleSaady, Ikram, Mohammed Karim, Badre Bossoufi, Saad Motahhir, Mohamed said Adouairi, Btissam Majout, Mouna Lamnadi, Mehedi Masud, and Jehad F. Al-Amri. 2021. "Optimization for a Photovoltaic Pumping System Using Indirect Field Oriented Control of Induction Motor" Electronics 10, no. 24: 3076. https://doi.org/10.3390/electronics10243076

APA StyleSaady, I., Karim, M., Bossoufi, B., Motahhir, S., Adouairi, M. s., Majout, B., Lamnadi, M., Masud, M., & Al-Amri, J. F. (2021). Optimization for a Photovoltaic Pumping System Using Indirect Field Oriented Control of Induction Motor. Electronics, 10(24), 3076. https://doi.org/10.3390/electronics10243076