Interference Signal Identification of Sensor Array Based on Convolutional Neural Network and FPGA Implementation

Abstract

:1. Introduction

- i.

- We established a simple mechanical structure model to analyze the generation mechanism of interference signals in the MEMS sensor array acquisition system;

- ii.

- We designed a CNN model with fewer parameters to identify the interference wave;

- iii.

- We implemented the CNN model a on field-programmable gate array (FPGA).

2. Materials and Methods

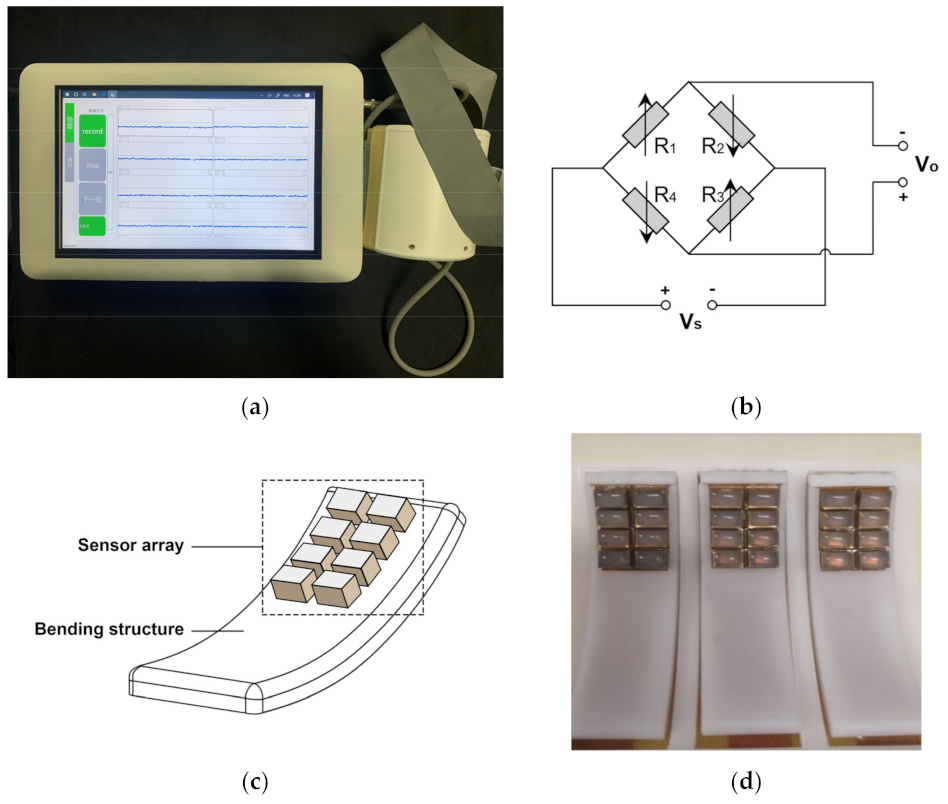

2.1. MEMS Sensor Array Acquisition System

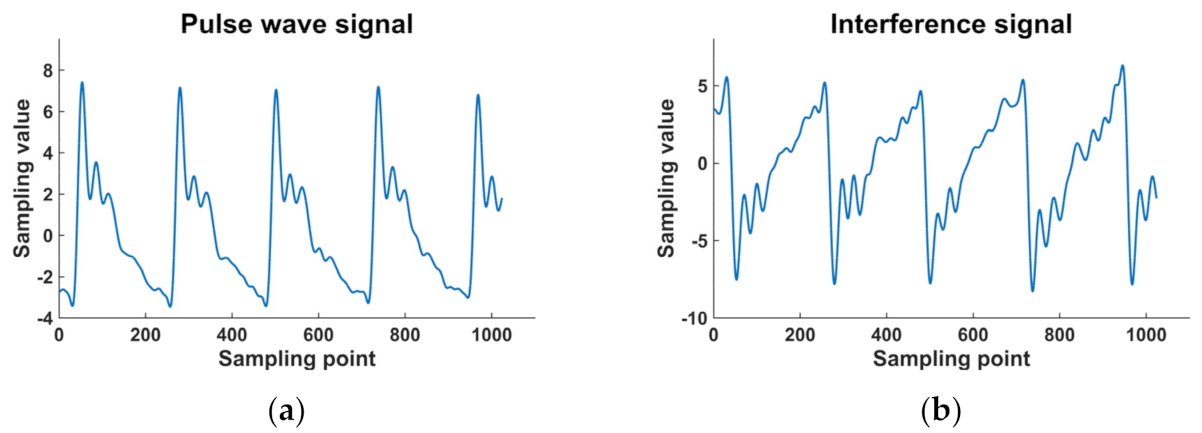

2.2. Mechanical Analysis of Interference Signals

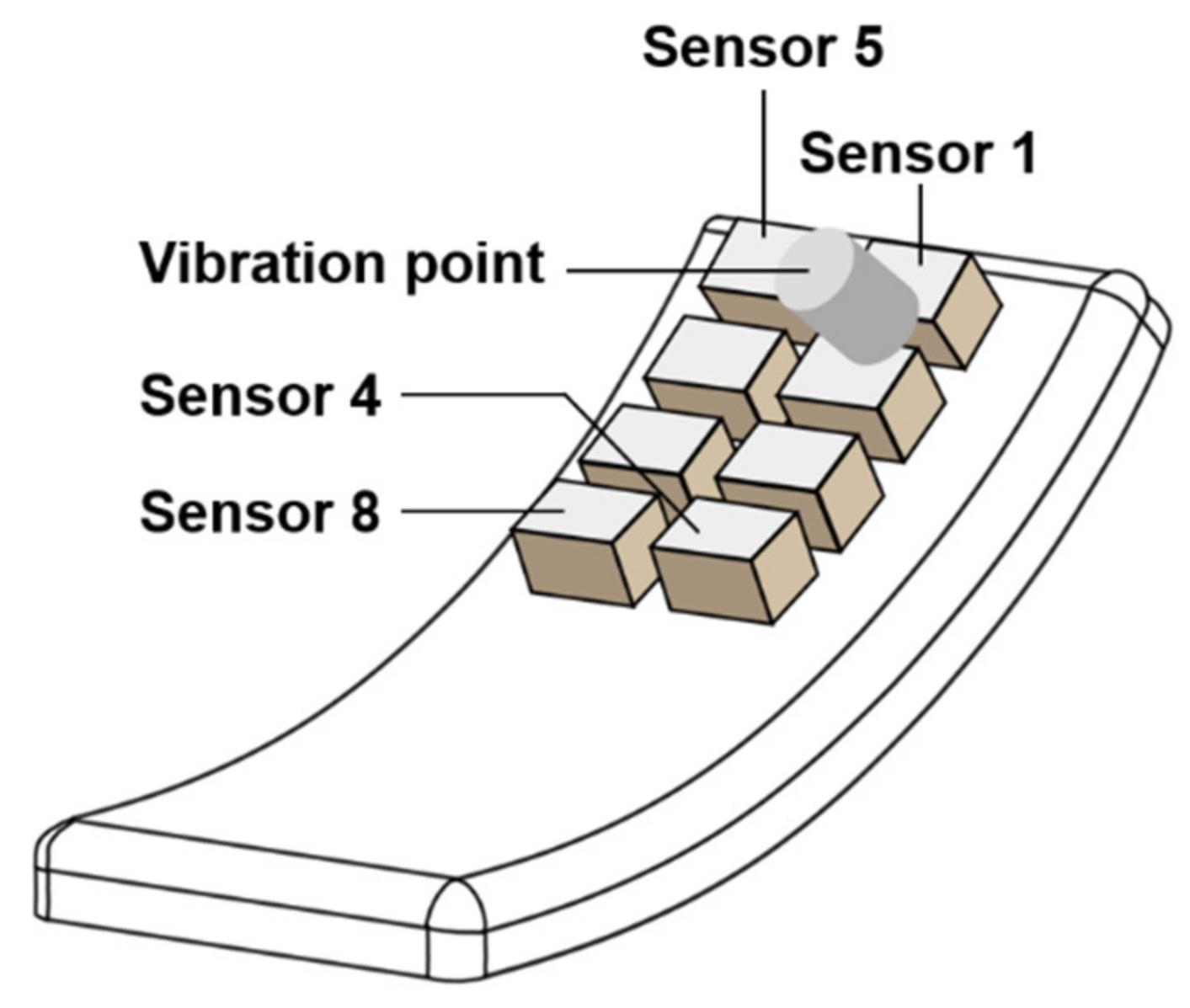

2.2.1. Single-Point Vibration Signal Generator

2.2.2. Mechanical Analysis of Interference Signals

2.3. Interference Signal Recognition Based on CNN

2.3.1. Signal Preprocessing

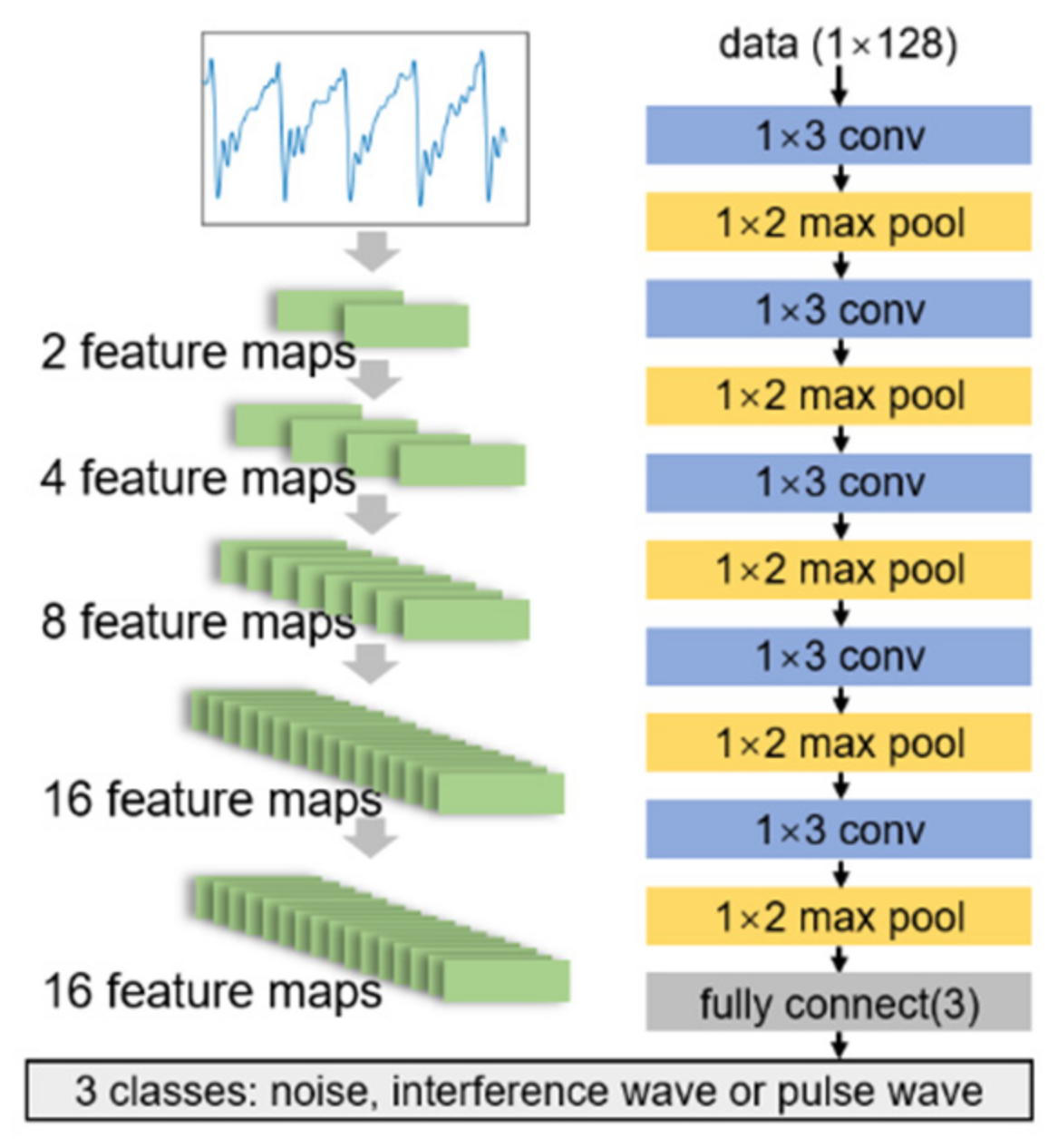

2.3.2. CNN Model

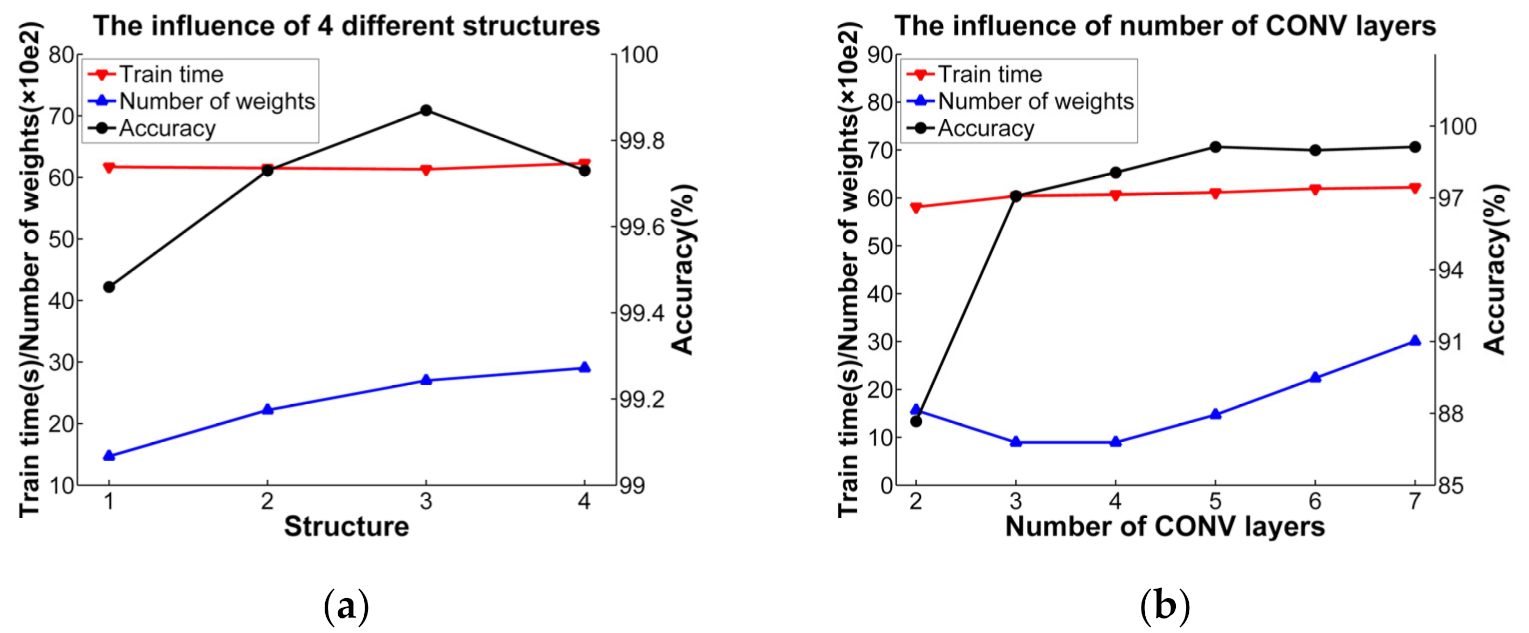

2.3.3. CNN Model Design

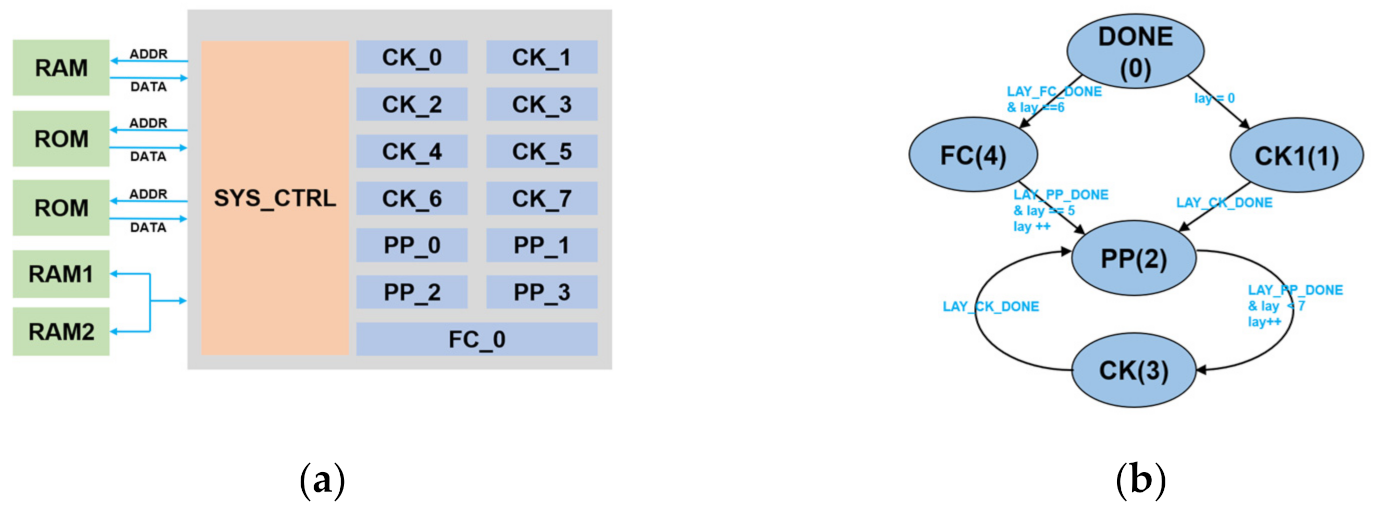

2.4. Design of CNN Accelerator Based on FPGA

2.4.1. Overall Architecture

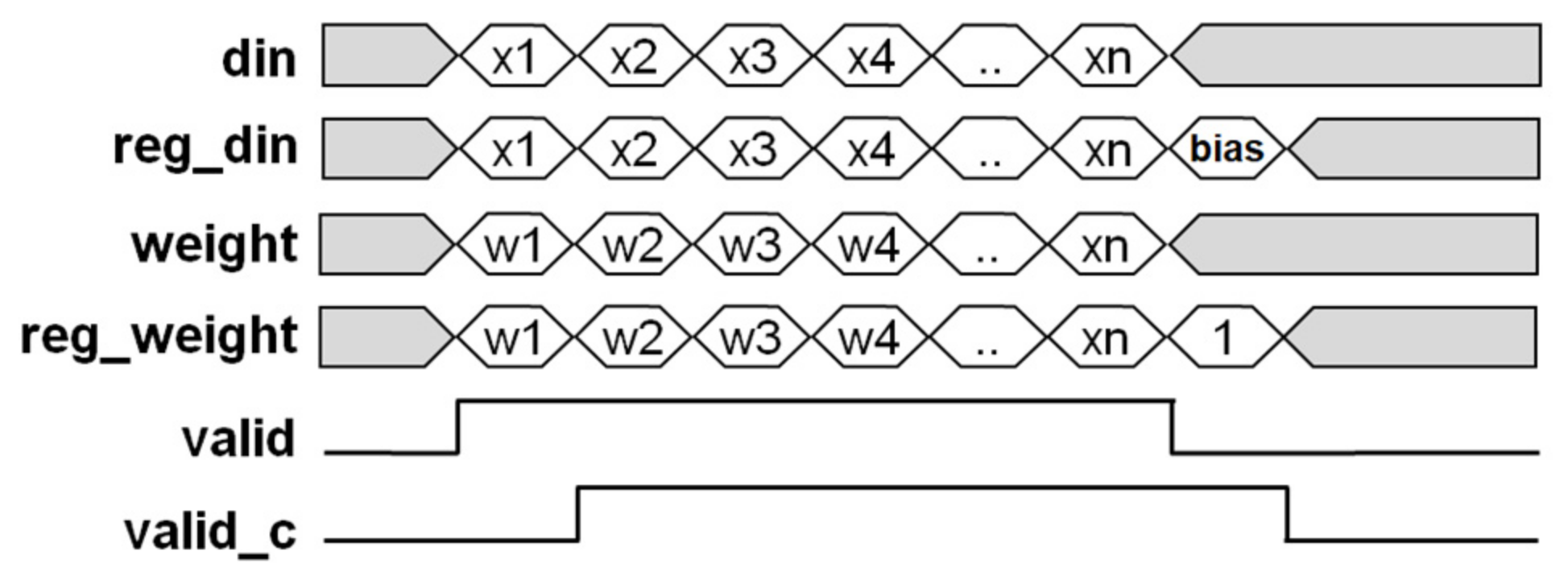

2.4.2. Computing Module Design

3. Results

3.1. Interference Signal Recognition Based on CNN

3.1.1. Data Sources

3.1.2. Model Training

3.1.3. Test Results

3.2. FPGA Simulation and Testing

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Che, X.S.; Xu, X.Q.; Sun, J.; Xu, H. Research on Pulse Power Spectrum Calculation Method Based on TCM. In Proceedings of the IEEE International Conference on Communication Software and Networks (ICCSN), Chengdu, China, 6–7 June 2015; pp. 333–337. [Google Scholar]

- Khandai, S.K.; Jain, S.K. Comparison of Sensors Performance for the Development of Wrist Pulse Acquisition System. In Proceedings of the IEEE Region 10 Conference (TENCON), Penang, Malaysia, 5–8 November 2017; pp. 2870–2875. [Google Scholar]

- Thakker, B.; Vyas, A.L. Frequency domain analysis of radial pulse in abnormal health conditions. In Proceedings of the IEEE EMBS Conference on Biomedical Engineering and Sciences (IECBES), Kuala Lumpur, Malaysia, 30 November–2 December 2010; pp. 227–231. [Google Scholar] [CrossRef]

- Hu, C.-S.; Chung, Y.-F.; Yeh, C.-C.; Luo, C.-H. Temporal and Spatial Properties of Arterial Pulsation Measurement Using Pressure Sensor Array. Evid. Based Complement. Altern. Med. 2012, 2012, 1–9. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Peng, J.-Y.; Lu, M.S.C. A Flexible Capacitive Tactile Sensor Array with CMOS Readout Circuits for Pulse Diagnosis. IEEE Sens. J. 2015, 15, 1170–1177. [Google Scholar] [CrossRef]

- Ji, M.N.; Meng, X.F.; Nie, J.; Wang, Y.Q.; Lin, L.W. A new type of bionics based piezoelectric heartbeat sensor used in pulse-taking for health warning. In Proceedings of the 17th IEEE SENSORS Conference, New Delhi, India, 28–31 October 2018; pp. 752–755. [Google Scholar]

- Nguyen, T.V.; Mizuki, Y.; Tsukagoshi, T.; Takahata, T.; Ichiki, M.; Shimoyama, I. MEMS-Based Pulse Wave Sensor Utilizing a Piezoresistive Cantilever. Sensors 2020, 20, 1052. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Loukogeorgakis, S.; Dawson, R.; Phillips, N.; Martyn, C.N.; Greenwald, S.E. Validation of a device to measure arterial pulse wave velocity by a photoplethysmographic method. Physiol. Meas. 2002, 23, 581–596. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.Y.; Zhang, L.; Zhang, D.; Zheng, Y.P. Wavelet based analysis of Doppler ultrasonic wrist-pulse signals. In Proceedings of the 1st International Conference on Biomedical Engineering and Informatics, Sanya, China, 27–30 May 2008; p. 539. [Google Scholar]

- Zhang, H.; An, M.; Bu, Z.; Zheng, Z. Fingertip pulse wave extraction based on ultrasonic echo signal. Chin. J. Med. Phys. 2020, 37, 1306–1311. [Google Scholar]

- Liu, S.; Zhang, S.; Zhang, Y.; Geng, X.; Zhang, J.; Zhang, H. A novel flexible pressure sensor array for depth information of radial artery. Sens. Actuators Phys. 2018, 272, 92–101. [Google Scholar] [CrossRef]

- Wang, P.; Zuo, W.M.; Zhang, D. A Compound Pressure Signal Acquisition System for Multichannel Wrist Pulse Signal Analysis. IEEE Trans. Instrum. Meas. 2014, 63, 1556–1565. [Google Scholar] [CrossRef]

- Shin, K.Y.; Jeon, S.C.; Nam, K.C.; Huh, Y. Implementation of Array Sensor Module for a Radial Artery Tonometry. In Proceedings of the 32nd Annual International Conference of the IEEE Engineering-in-Medicine-and-Biology-Society (EMBC 10), Buenos Aires, Argentina, 30 August–4 September 2010; pp. 6397–6400. [Google Scholar]

- Wang, D.M.; Zhang, D. Analysis of pulse waveforms preprocessing. In Proceedings of the International Conference on Computerized Healthcare (ICCH), Hong Kong, China, 17–18 December 2012; pp. 174–179. [Google Scholar]

- Katsuura, T.; Izumi, S.; Yoshimoto, M.; Kawaguchi, H.; Yoshimoto, S.; Sekitani, T. Wearable pulse wave velocity sensor using flexible piezoelectric film array. In Proceedings of the IEEE Biomedical Circuits and Systems Conference (BioCAS), Turin, Italy, 19–21 October 2017; pp. 1–4. [Google Scholar] [CrossRef]

- Wang, D.M.; Zhang, D.; Lu, G.M. An Optimal Pulse System Design by Multichannel Sensors Fusion. IEEE J. Biomed. Health Inform. 2016, 20, 450–459. [Google Scholar] [CrossRef] [PubMed]

- Kaisti, M.; Leppanen, J.; Lahdenoja, O.; Kostiainen, P.; Pankaala, M.; Meriheina, U.; Koivisto, T.; IEEE. Wearable Pressure Sensor Array for Health Monitoring. In Proceedings of the 44th Computing in Cardiology Conference (CinC), Rennes, France, 24–27 September 2017. [Google Scholar]

- Chen, J.Z.; Sun, K.; Zheng, R.; Sun, Y.; Yang, H.; Zhong, Y.F.; Li, X.X. Three-Dimensional Arterial Pulse Signal Acquisition in Time Domain Using Flexible Pressure-Sensor Dense Arrays. Micromachines 2021, 12, 569. [Google Scholar] [CrossRef] [PubMed]

- Hu, X.; Zhu, H.; Xu, J.; Xu, D.; Dong, J.; IEEE. Wrist Pulse Signals Analysis based on Deep Convolutional Neural Networks. In Proceedings of the IEEE Conference on Computational Intelligence in Bioinformatics and Computational Biology, Honolulu, HI, USA, 21–24 May 2014. [Google Scholar]

- Chen, C.L.; Li, Z.Q.; Zhang, Y.T.; Zhang, S.L.; Hou, J.N.; Zhang, H.Y. A 3D Wrist Pulse Signal Acquisition System for Width Information of Pulse Wave. Sensors 2020, 20, 11. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zou, H.; Zhang, Y.; Zhang, J.; Chen, C.; Geng, X.; Zhang, S.; Zhang, H. A Novel Multi-Dimensional Composition Method Based on Time Series Similarity for Array Pulse Wave Signals Detecting. Algorithms 2020, 13, 297. [Google Scholar] [CrossRef]

| Structure of FC Layers | Accuracy (%) | Train Time(s) | Number of Weights |

|---|---|---|---|

| FC1 (20) + FC2 (3) | 99.8 | 61.5 | 3848 |

| FC1 (3) | 99.87 | 61.3 | 2700 |

| Structure | CONV1 | CONV2 | CONV3 | CONV4 | CONV5 |

|---|---|---|---|---|---|

| 1 | (1-2) | (2-4) | (4-8) | (8-16) | (16-16) |

| 2 | (1-4) | (4-8) | (8-16) | (16-16) | (16-16) |

| 3 | (1-4) | (4-16) | (16-16) | (16-16) | (16-16) |

| 4 | (1-8) | (1-16) | (16-16) | (16-16) | (16-16) |

| Parameter Name | Value |

|---|---|

| Kernel size | 1 × 3 |

| Pooling size | 1 × 2 |

| Loss function | CrossEntropyLoss |

| Optimizer | Adam |

| Learning rate | 0.001 |

| Batch size | 100 |

| epochs | 50 |

| Predicted Class | ||||

|---|---|---|---|---|

| Interference | Pulse | Noise | ||

| Actual class | Interference | 50 | 0 | 0 |

| Pulse | 0 | 50 | 0 | |

| Noise | 1 | 0 | 49 | |

| Resource | Utilization | Available | Utilization% |

|---|---|---|---|

| LUT | 18,761 | 63,400 | 29.59 |

| FF | 30,063 | 126,800 | 23.71 |

| BRAM | 53.50 | 135 | 39.63 |

| DSP | 147 | 240 | 61.25 |

| BUFG | 2 | 32 | 6.25 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, L.; Geng, X.; Xu, H.; Zhang, Y.; Li, Z.; Zhang, J.; Zhang, H. Interference Signal Identification of Sensor Array Based on Convolutional Neural Network and FPGA Implementation. Electronics 2021, 10, 2867. https://doi.org/10.3390/electronics10222867

Huang L, Geng X, Xu H, Zhang Y, Li Z, Zhang J, Zhang H. Interference Signal Identification of Sensor Array Based on Convolutional Neural Network and FPGA Implementation. Electronics. 2021; 10(22):2867. https://doi.org/10.3390/electronics10222867

Chicago/Turabian StyleHuang, Lin, Xingguang Geng, Hao Xu, Yitao Zhang, Zhiqiang Li, Jun Zhang, and Haiying Zhang. 2021. "Interference Signal Identification of Sensor Array Based on Convolutional Neural Network and FPGA Implementation" Electronics 10, no. 22: 2867. https://doi.org/10.3390/electronics10222867

APA StyleHuang, L., Geng, X., Xu, H., Zhang, Y., Li, Z., Zhang, J., & Zhang, H. (2021). Interference Signal Identification of Sensor Array Based on Convolutional Neural Network and FPGA Implementation. Electronics, 10(22), 2867. https://doi.org/10.3390/electronics10222867