A Segmented Preprocessing Method for the Vibration Signal of an On-Load Tap Changer

Abstract

1. Introduction

2. Vibration Signals of the OLTC

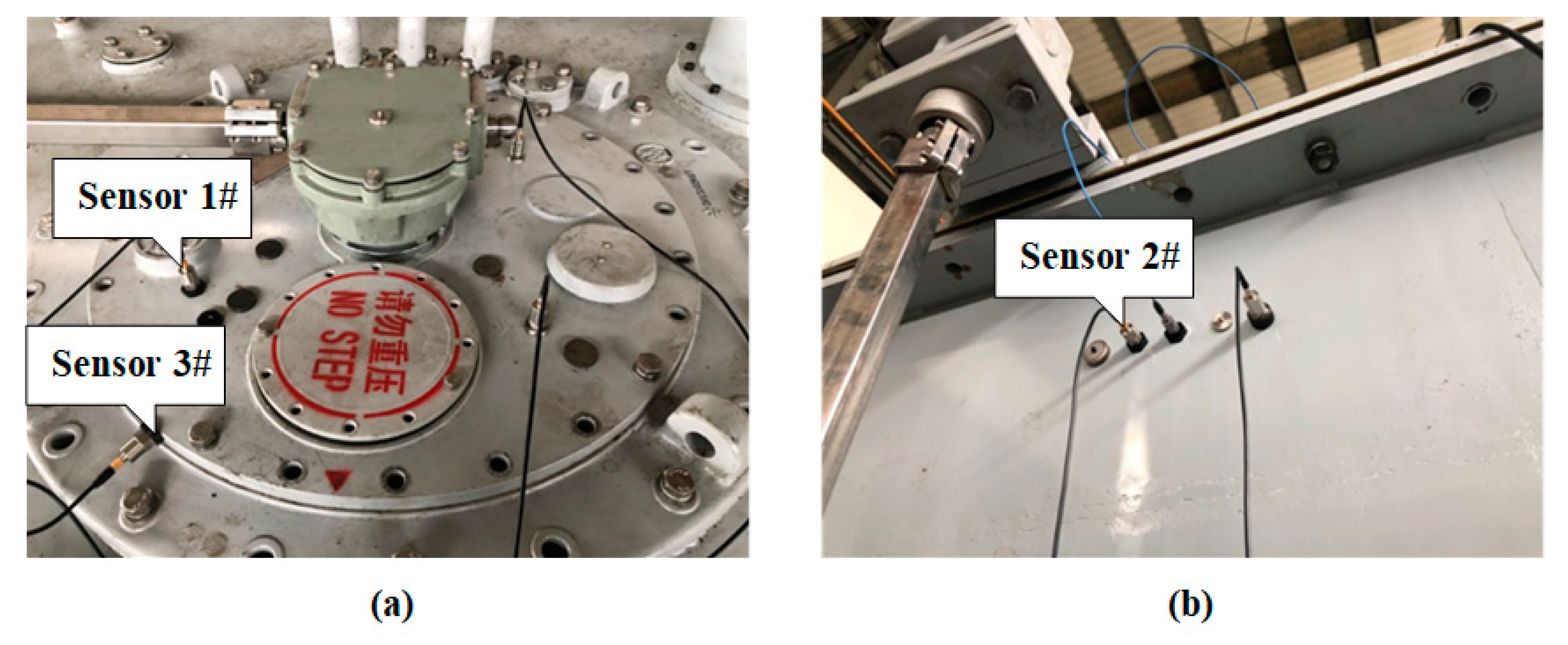

2.1. Collection of the Signal

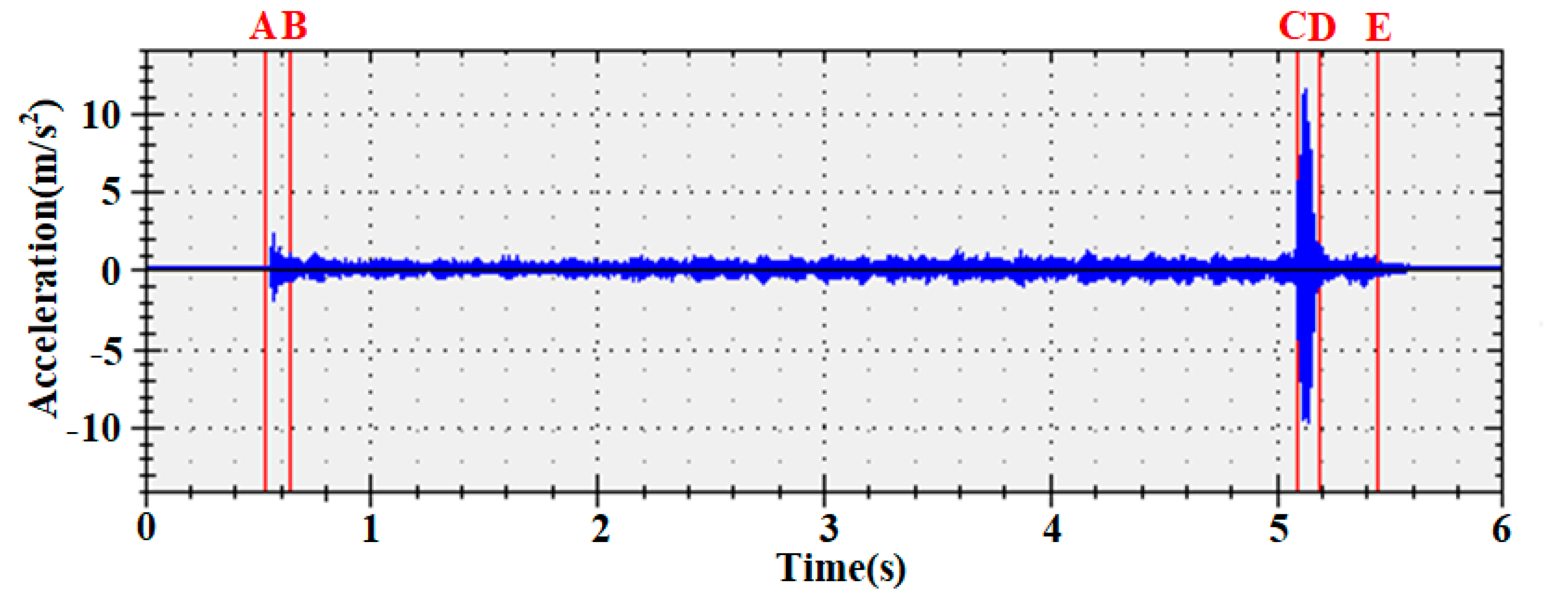

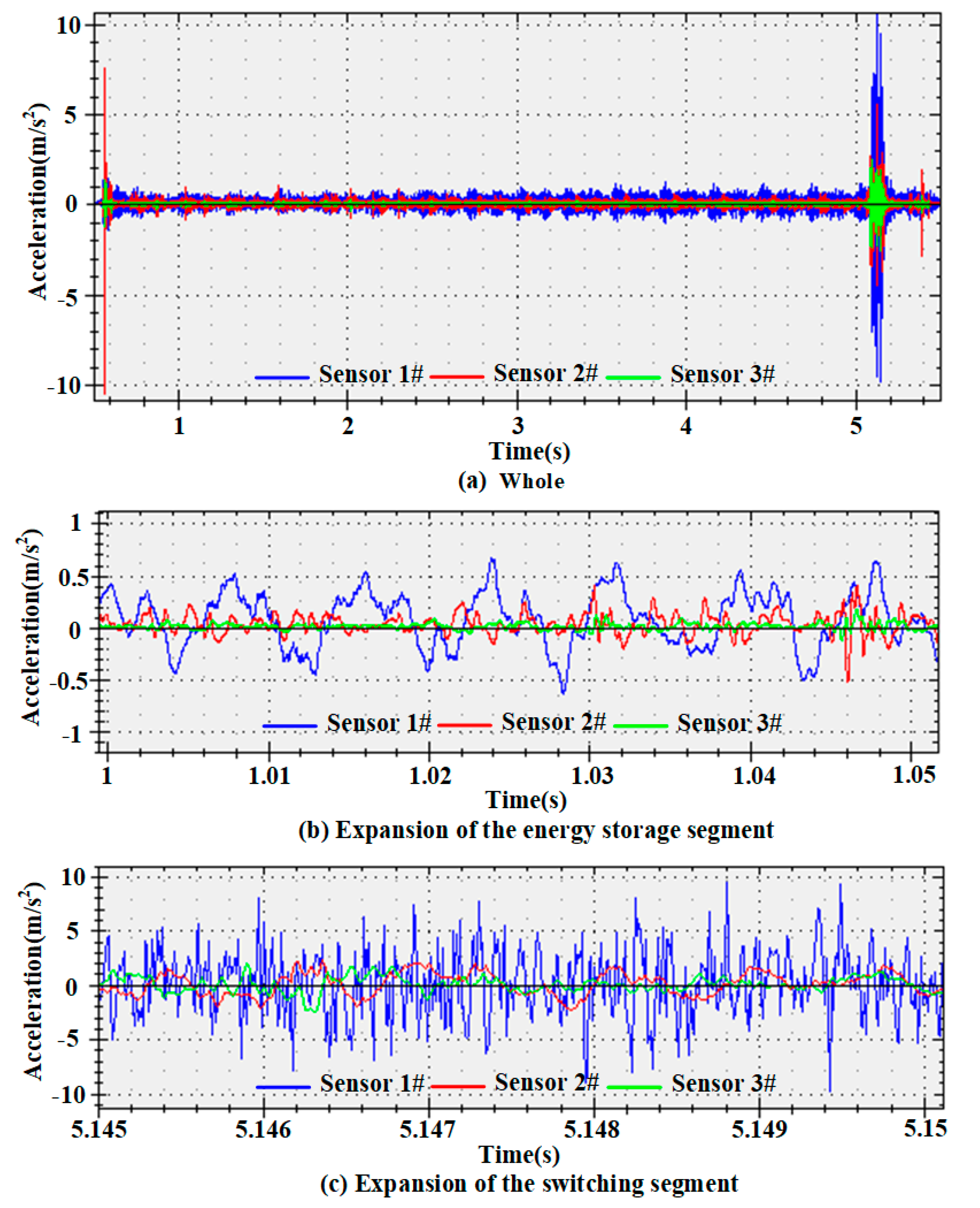

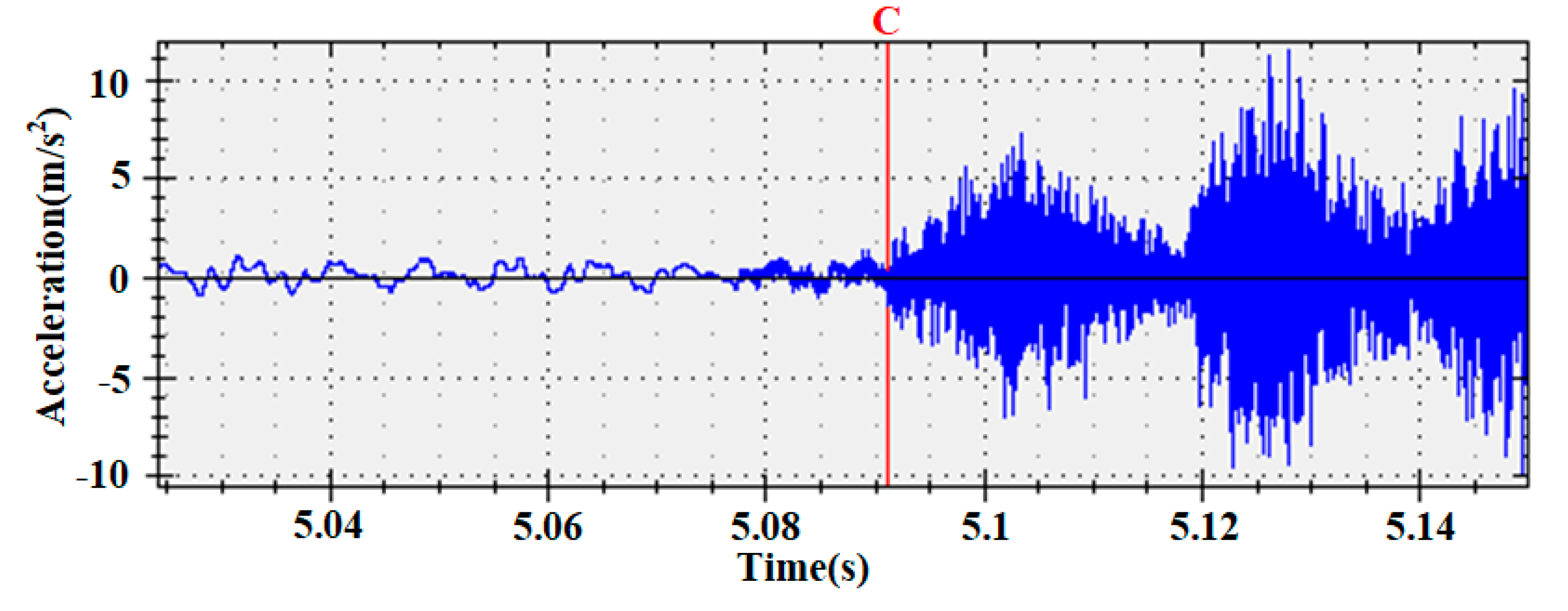

2.2. Waveform Characteristics of the Vibration Signals of the OLTC

2.3. Selection of the Vibration Signal of the OLTC

3. Segmentation Preprocessing

3.1. Necessity of Segmentation Preprocessing

3.1.1. Time Domain Characteristic Analysis

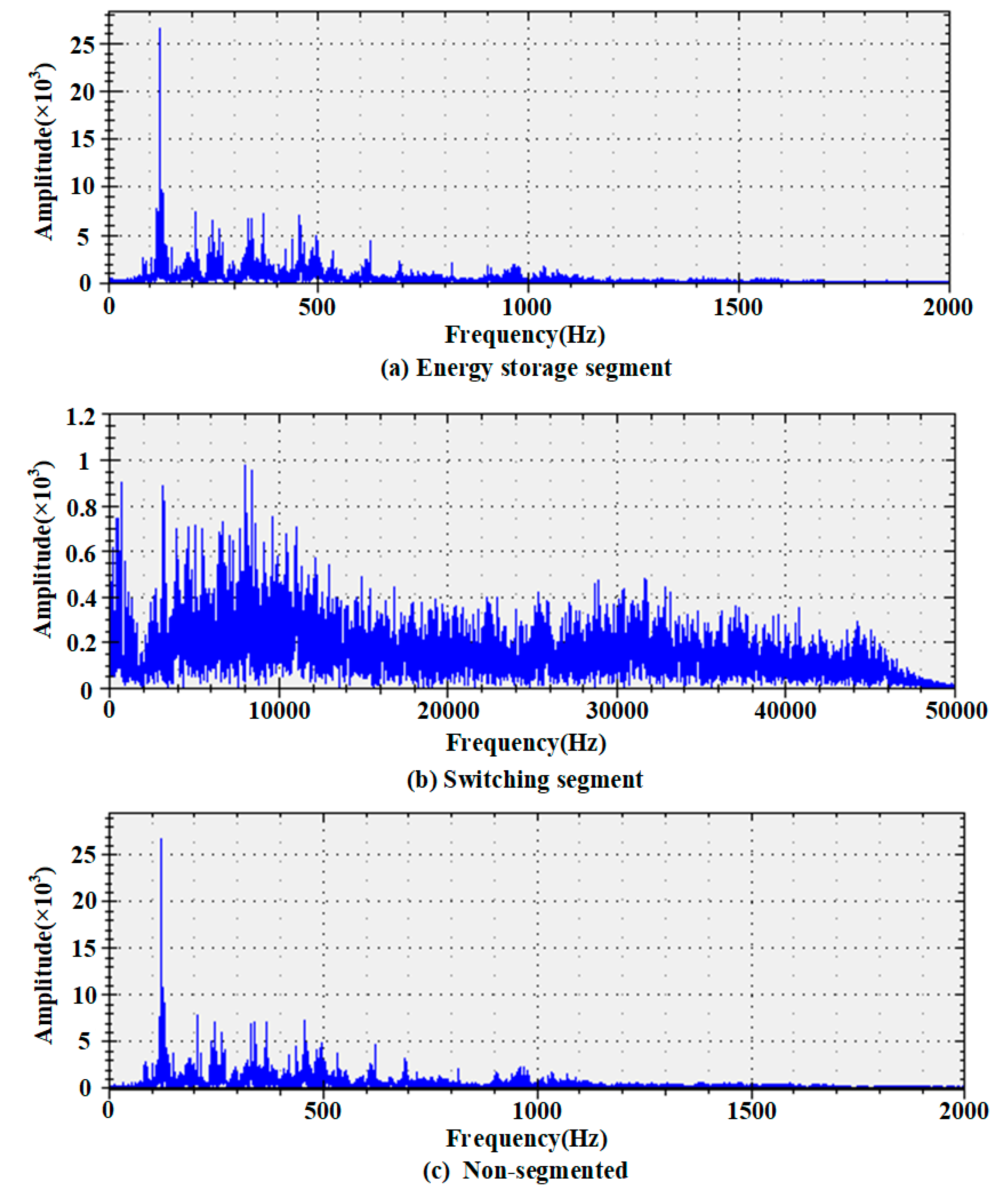

3.1.2. Frequency Spectrum Analysis

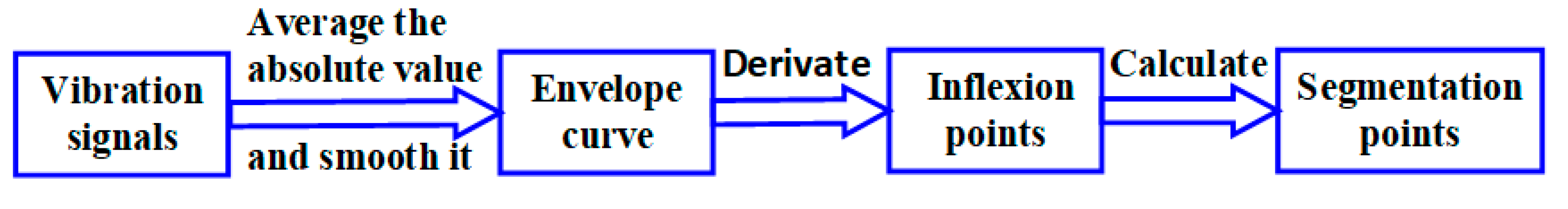

3.2. Method of Segmentation Preprocessing

4. Experiment

4.1. Sample Description

4.2. Diagnosis Results

5. Conclusions

- The vibration signal of the OLTC was divided into the starting segment, energy storage segment, switching segment, and stopping segment. The signals of the starting segment and the stopping segment were very random and generally not used for analysis;

- Whether from time domain analysis or frequency spectrum analysis, the difference between the energy storage segment and the switching segment of the vibration signals of the OLTC was obvious. Nonsegmented processing resulted in missing frequency characteristics for the switching segment. Hence, it was necessary to preprocess the vibration signal of the OLTC in segments;

- The segmented preprocessing method for the vibration signals of the OLTC was presented. The method was simple, practical, and highly accurate;

- The main mechanical faults of the OLTC were simulated, the vibration signals were collected, and OLTC fault diagnosis experiments were conducted. The experimental results showed that the accuracy of the fault diagnosis increased from 94.30% in the nonsegmented preprocessing to 98.46% in the segmented preprocessing. The increase was greater, especially for contact wear faults. The method was successfully applied to the actual project.

Author Contributions

Funding

Conflicts of Interest

References

- Yang, R.; Zhang, D.; Li, Z.; Yang, K.; Mo, S.; Li, L. Mechanical fault diagnostics of power transformer on-load tap changers using dynamic time warping. IEEE Trans. Instrum. Meas. 2019, 68, 3119–3127. [Google Scholar] [CrossRef]

- Riaz, F.; Wetzer, J.A.; Mor, R. Innovative approach toward an algorithm for automated defect recognition for on-load-tap changers. CIRED Open Access Proc. J. 2017, 2017, 246–250. [Google Scholar] [CrossRef][Green Version]

- Kang, P.J.; Birtwhistle, D. Condition monitoring of power transformer on-load tap-changers Part I: Automatic Condition diagnostic. Proc. Inst. Elect. Eng. Gener. Transmiss. Distrib. 2001, 148, 301–306. [Google Scholar] [CrossRef]

- Zhou, X.; Wang, F.H.; Fu, J.; Lin, J.; Jin, Z. Mechanical condition monitoring of on-load tap changers based on chaos theory and K-means clustering method. Proc. CSEE 2015, 35, 1541–1548. [Google Scholar]

- Yang, Q.; Ruan, J.; Zhuang, Z.; Huang, D. Condition evaluation for opening damper of spring operated high-voltage circuit breaker using vibration time-frequency image. IEEE Sens. J. 2019, 19, 8116–8126. [Google Scholar] [CrossRef]

- Seo, J.; Ma, H.; Saha, T.K. A joint vibration and arcing measurement system for online condition monitoring of on-load tap changer of the power transformer. IEEE Trans. Power Deliv. 2017, 32, 1031–1038. [Google Scholar] [CrossRef]

- Yang, Q.; Ruan, J.; Zhuang, Z. Fault diagnosis of circuit breakers based on time–frequency and chaotic vibration analysis. IET Gener. Transm. Distrib. 2020, 14, 1214–1221. [Google Scholar] [CrossRef]

- Wang, C.L.; Li, K.; Ma, H.Z.; Wang, A.Q. Feature recognition of OLTC vibration signal based on WP_SVD denoising method. Proc. CSU-EPSA 2012, 24, 36–41. [Google Scholar]

- Lu, L.; Cui, Y.H. Diagnosis of transformer tap changer contact fault based on vibration signal. Electr. Power Autom. Equip. 2012, 32, 93–97. [Google Scholar]

- Duan, X.; Zhao, T.; Li, T.; Liu, J.; Zou, L.; Zhang, L. Method for diagnosis of on-load tap changer based on wavelet theory and support vector machine. J. Eng. 2017, 2017, 2193–2197. [Google Scholar] [CrossRef]

- Gao, S.; Zhou, C.; Zhang, Z.; Geng, J.; He, R.; Yin, Q.; Xing, C. Mechanical fault diagnosis of an on-load tap changer by applying cuckoo search algorithm-based fuzzy weighted least squares support vector machine. Math. Probl. Eng. 2020. [Google Scholar] [CrossRef]

- Gao, S.G.; Yue, G.L.; Zhou, C.; Geng, J.H.; Xing, C.; Ding, Y.; Meng, L.H. Applying Hilbert-Huang transform of the Volterra model to diagnosing mechanical fault for on-load tap changer. High Volt. Appar. 2020, 56, 173–180. [Google Scholar]

- Duan, R.C.; Wang, F.H. Fault diagnosis of on-load tap-changer in converter transformer based on time–frequency vibration analysis. IEEE Trans. Ind. Electron. 2016, 63, 3815–3823. [Google Scholar] [CrossRef]

- Duan, R.C.; Wang, F.H.; Zhou, L.D. Mechanical condition detection of on-load tap-changer in converter transformer based on narrowband noise assisted multivariate empirical mode decomposition algorithm. Trans. China Electrotech. Soc. 2017, 32, 182–189. [Google Scholar]

- Duan, R.C.; Wang, F.H.; Zhou, L.D. Mechanical features extraction of on-load tap-changer in converter transformer based on optimized HHT algorithm and Lorentz information measure. Proc. CSEE 2016, 36, 3101–3109. [Google Scholar]

- Xu, Y.; Zhou, C.; Geng, J.; Gao, S.; Wang, P. A method for diagnosing mechanical faults of on-load tap changer based on ensemble empirical mode decomposition, Volterra model and decision acyclic graph support vector machine. IEEE Access 2019, 7, 84803–84816. [Google Scholar] [CrossRef]

- Liu, J.; Wang, G.; Zhao, T.; Zhang, L. Fault diagnosis of on-load tap-changer based on variational mode decomposition and relevance vector machine. Energies 2017, 10, 946. [Google Scholar] [CrossRef]

- Li, Q.M.; Zhao, T.; Zhang, L.; Lou, J. Mechanical fault diagnostics of on-load tap changer within power transformers based on hidden Markov model. IEEE Trans. Power Deliv. 2012, 27, 596–601. [Google Scholar] [CrossRef]

- Wang, F.H.; Zeng, Q.H.; Zheng, Y.M.; Qian, Y. A mechanical fault diagnosis of on-load tap-changers based on phase space fusion of Bayes estimation and CM-SVDD. Proc. CSEE 2020, 40, 358–368. [Google Scholar]

- Zeng, Q.H.; Wang, F.H.; Zheng, Y.M.; He, W.L. Fault recognition of on-load tap-changer in power transformer based on convolutional neural network. Autom. Electr. Power Syst. 2020, 44, 144–151. [Google Scholar]

- Wang, G.; Liu, J.; Zhao, T.; Zhang, L. Mechanical Condition Monitoring of On-load Tap Changers Based on Improved Variational Mode Decomposition. J. Hunan Univ. (Nat. Sci.) 2017, 44, 75–83. [Google Scholar]

- Zhang, Z.X.; Chen, W.G.; Tang, S.R.; Wang, Y.Y.; Wan, F. State feature extraction and anomaly diagnosis of on-load tap-changer based on complementary ensemble empirical mode decomposition and local outlier factor. Trans. China Electrotech. Soc. 2019, 34, 4508–4518. [Google Scholar]

- Zhang, Z.X.; Gao, T.Y.; Lei, J.L. Vibration signal preprocessing method of OLTC for converter transformer. Electr. Power Eng. Technol. 2020, 39, 120–125. [Google Scholar]

- Zhang, Z.X. Research on Vibration Signal Analysis and State Diagnosis Method of Transformer On-Load Tap Changer. Ph.D. Thesis, Chongqing University, Chongqing, China, 2019. [Google Scholar]

- Seshadrinath, J.; Singh, B.; Panigrahi, B.K. Vibration analysis based interturn fault diagnosis in induction machines. IEEE Trans. Ind. Inf. 2014, 10, 340–350. [Google Scholar] [CrossRef]

- Zheng, J.; He, T.T.; Guo, J.; Huang, H.; Chen, X.X. Adaptive separation of vibration signal of on-load tap changer based on independent component analysis and endpoint detection. Power Syst. Technol. 2010, 34, 208–213. [Google Scholar]

- Zhao, M.; Xu, G. Feature extraction of power transformer vibration signals based on empirical wavelet transform and multiscale entropy. IET Sci. Meas. Technol. 2018, 12, 63–71. [Google Scholar] [CrossRef]

- Rivas, E.; Burgos, J.C.; García-Prada, J.C. Vibration analysis using envelope wavelet for detecting faults in the OLTC tap selector. IEEE Trans. Power Deliv. 2010, 25, 1629–1636. [Google Scholar] [CrossRef]

- Xu, Y.; Chen, B.B.; Ma, H.Z.; Xu, H.H.; Wang, L. Vibration signal feature extraction method of the on-load tap changer based on EMD-PSD. J. Electr. Power Sci. Technol. 2020, 35, 3–10. [Google Scholar]

- Castro, J.C.; Lagos, G.S.; Gonzalez, O.A. Simulation and measuring transients in on-load tap changers. IEEE. Lat. Am. Trans. 2017, 15, 1901–1907. [Google Scholar] [CrossRef]

- Chen, M.; Ma, H.Z.; Xu, Y. Design of monitoring system for on-load tap changer of transformer based on data acquisition card. Transformer 2019, 56, 30–34. [Google Scholar]

- Fan, J.H.; Wang, W.G.; Wang, F.H.; Qian, Y. Vibration characteristic analysis of vacuum interrupter on-load tap-changer. Power Syst. Technol. 2019, 43, 4425–4432. [Google Scholar]

- Wang, K.M.; Shu, H.C.; Cao, L.P.; Dong, J.; Su, Y.G. Study of OLTC running state evaluation method based on correlation analysis. Power Syst. Prot. Control 2015, 43, 54–59. [Google Scholar]

- Chen, M.; Ma, H.Z.; Xu, Y.; Pan, X.C.; Chen, B.B. Mechanical fault diagnosis of on-load tap changer based on empirical mode decomposition algorithm for improved mask signal. Smart Power 2019, 47, 88–94. [Google Scholar]

- Liu, Z.Y.; Chen, H.J.; Yu, X.J.; Xia, X.Q. Research progress and prospects on fault diagnosis method for transformer on-load tap. High Volt. Appar. 2019, 55, 18–25, 33. [Google Scholar]

- Fang, Y.H. Brief analysis of on-load tap changer faults in transformer. Transformer 2011, 48, 62–65. [Google Scholar]

| Fault Code | Fault Type | Number of Continuous Samples | Number of Supplementary Samples | Number of Training Samples | Number of Extended Samples |

|---|---|---|---|---|---|

| 0 | Normal (1) | 28 | 0 | 20 | 8 |

| Normal (2) | 28 | 0 | 20 | 8 | |

| Normal (3) | 28 | 6 | 20 | 14 | |

| 1 | Contact wear (1) | 28 | 0 | 20 | 8 |

| Contact wear (2) | 28 | 16 | 20 | 24 | |

| NA | Spring fatigue and contact wear | 28 | 4 | 0 | 32 |

| 2 | Curved plate falling off | 28 | 0 | 20 | 8 |

| 3 | Curved plate loosening | 28 | 0 | 20 | 8 |

| 4 | Jamming (1) | 12 | 0 | 10 | 2 |

| Jamming (2) | 28 | 10 | 20 | 18 | |

| 5 | Abnormal switching | 28 | 0 | 20 | 8 |

| 6 | Contact loosening | 28 | 0 | 20 | 8 |

| 7 | Contact falling off | 28 | 0 | 20 | 8 |

| 8 | Main spring fatigue (1) | 28 | 0 | 20 | 8 |

| Main spring fatigue (2) | 28 | 16 | 20 | 24 | |

| Total | 404 | 52 | 270 | 186 |

| Fault Type | Description |

|---|---|

| Normal (1) | No fault. Data were obtained on different dates. The OLTC was detachable; therefore, the data might be different. |

| Normal (2) | |

| Normal (3) | |

| Contact wear (1) | The surface of a group of four moving and static transition contacts were artificially roughened to simulate the fault that the contacts were burned by the arc. |

| Contact wear (2) | The surface of 16 A-phase moving contacts were artificially roughened to simulate the fault that the contacts were burned by the arc. |

| Spring fatigue and contact wear | The main spring was shortened by two turns, and the surface of the 16 A-phase moving contacts was artificially roughened. |

| Curved plate falling off | The entire curved plate of phase A was removed. |

| Curved plate loosening | The screws of the A-phase curved plate were loosened. |

| Jamming (1) | Sawdust was added to the gearbox. Jamming (1) and Jamming (2) were different in the position and quantity of sawdust. |

| Jamming (2) | |

| Abnormal switching | The position of the switch was adjusted so that it was offset by a certain angle. |

| Contact loosening | The pressure spring of the selector switch contact was cut off for one turn. |

| Contact falling off | One set of three selector switch contacts was removed. |

| Main spring fatigue (1) | The main spring was shortened by four turns. |

| Main spring fatigue (2) | The main spring was shortened by two turns. |

| Fault Type | Total Number of Samples | Segmented | Nonsegmented | ||||

|---|---|---|---|---|---|---|---|

| Error | Miss | Mistake | Error | Miss | Mistake | ||

| Normal | 90 | 1 | / | / | 2 | / | / |

| Contact wear | 72 | / | 3 | / | 3 | ||

| Curved plate falling off | 28 | / | / | ||||

| Curved plate loosening | 28 | / | / | 1 | |||

| Jamming | 50 | / | / | ||||

| Abnormal switching | 28 | / | / | ||||

| Contact loosening | 28 | / | 1 | / | 2 | ||

| Contact falling off | 28 | / | / | ||||

| Main spring fatigue | 72 | / | 1 | / | 3 | ||

| Spring fatigue and contact wear | 32 | / | 1 | / | 3 | 12 | |

| Total | 456 | 1 | 2 | 4 | 2 | 3 | 21 |

| Correct rate | 98.46% | 94.30% | |||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shang, R.; Peng, C.; Fang, R. A Segmented Preprocessing Method for the Vibration Signal of an On-Load Tap Changer. Electronics 2021, 10, 131. https://doi.org/10.3390/electronics10020131

Shang R, Peng C, Fang R. A Segmented Preprocessing Method for the Vibration Signal of an On-Load Tap Changer. Electronics. 2021; 10(2):131. https://doi.org/10.3390/electronics10020131

Chicago/Turabian StyleShang, Rongyan, Changqing Peng, and Ruiming Fang. 2021. "A Segmented Preprocessing Method for the Vibration Signal of an On-Load Tap Changer" Electronics 10, no. 2: 131. https://doi.org/10.3390/electronics10020131

APA StyleShang, R., Peng, C., & Fang, R. (2021). A Segmented Preprocessing Method for the Vibration Signal of an On-Load Tap Changer. Electronics, 10(2), 131. https://doi.org/10.3390/electronics10020131