Simulation of FDSOI-ISFET with Tunable Sensitivity by Temperature and Dual-Gate Structure

Abstract

:1. Introduction

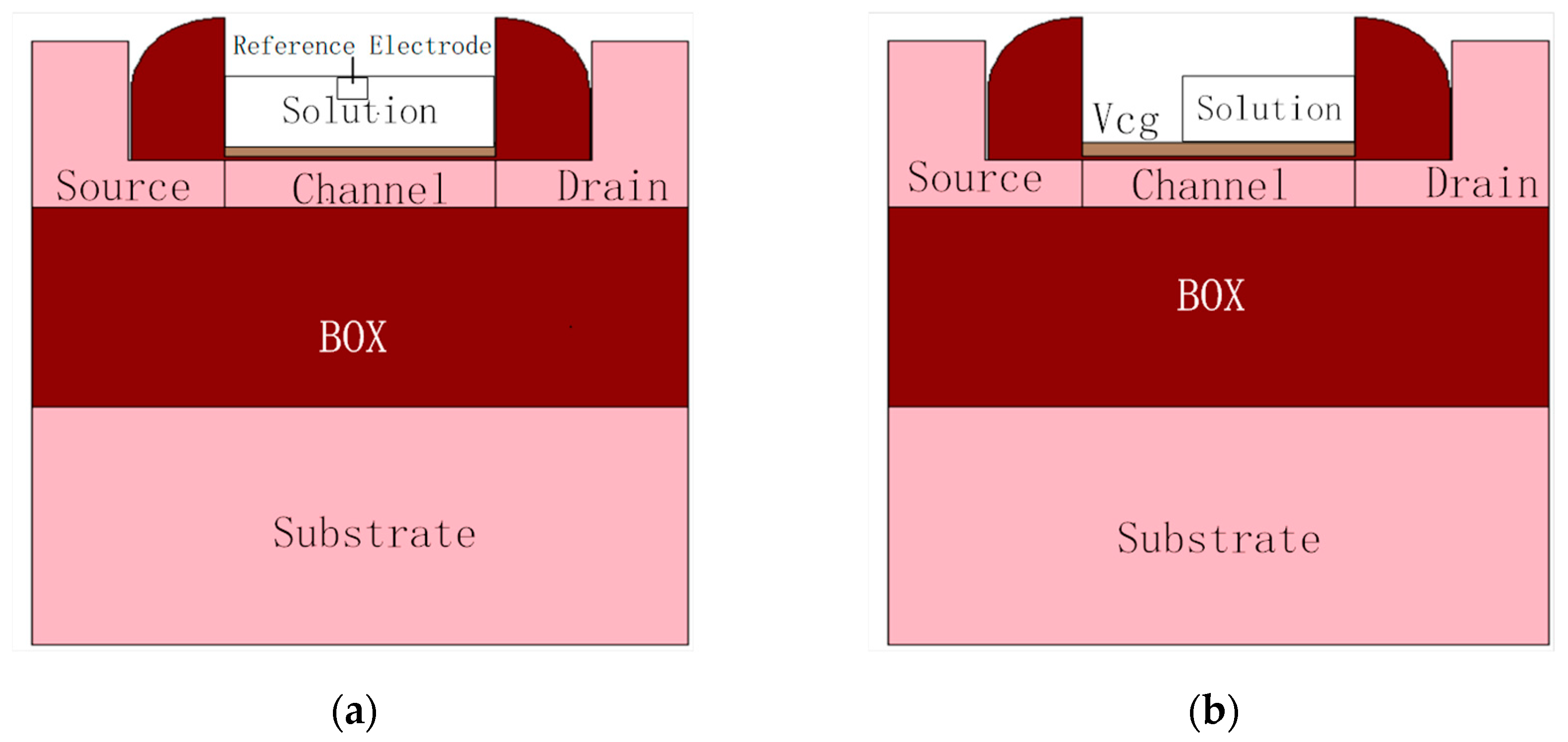

2. FDSOI ISFET Principle and Simulation Setup

2.1. Devices and Models

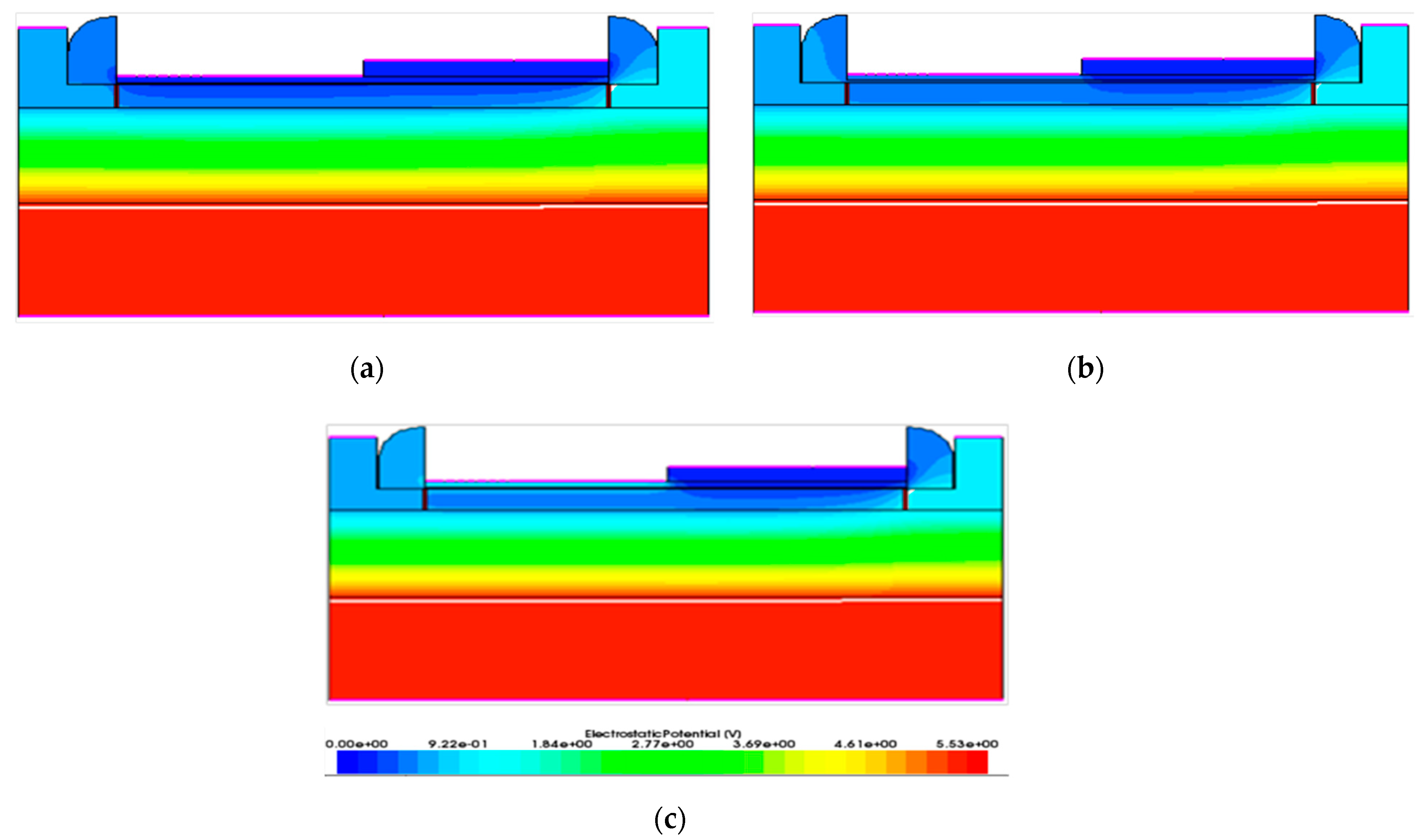

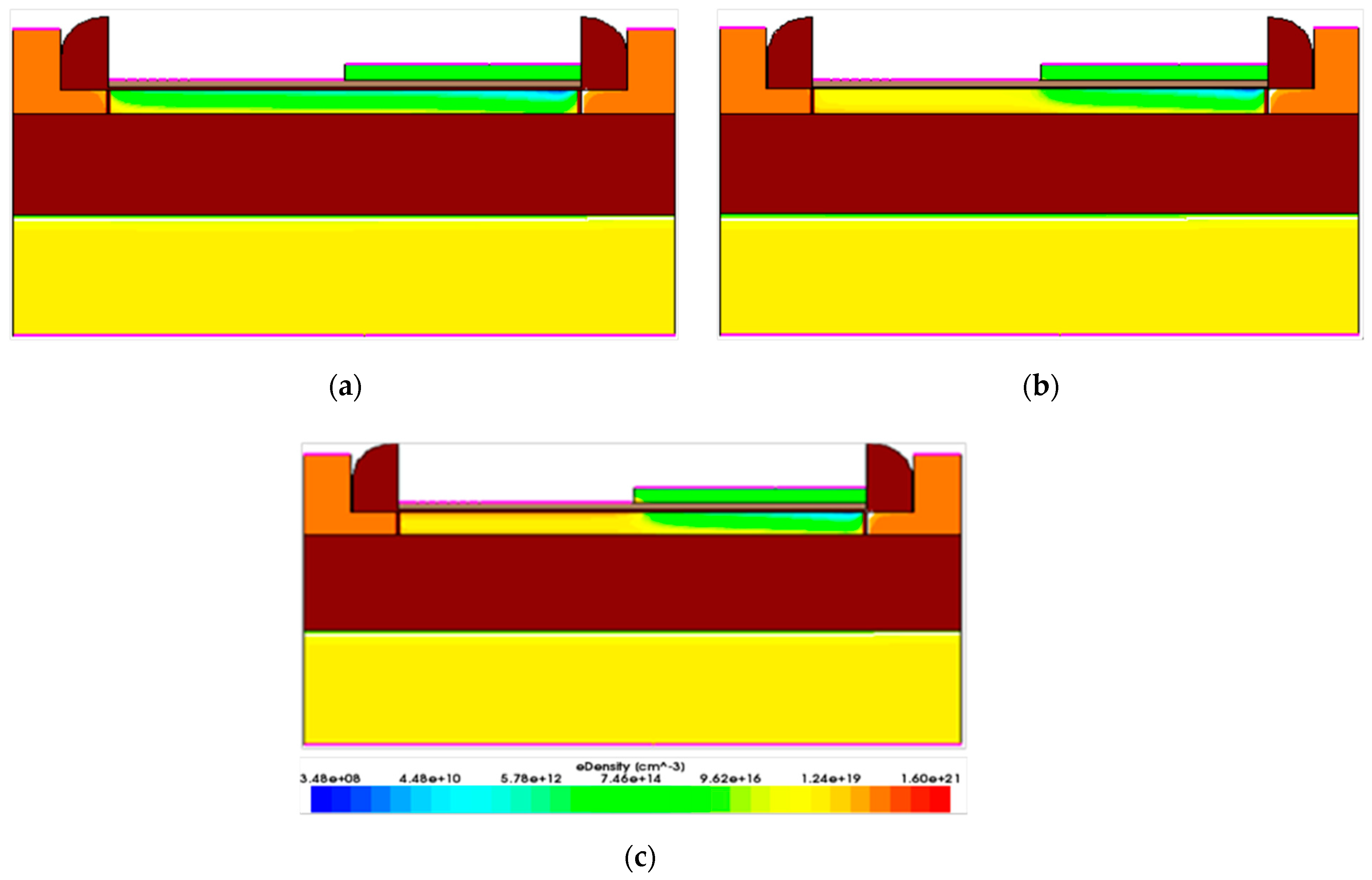

2.2. FDSOI ISFET Principle

3. Results and Discussion

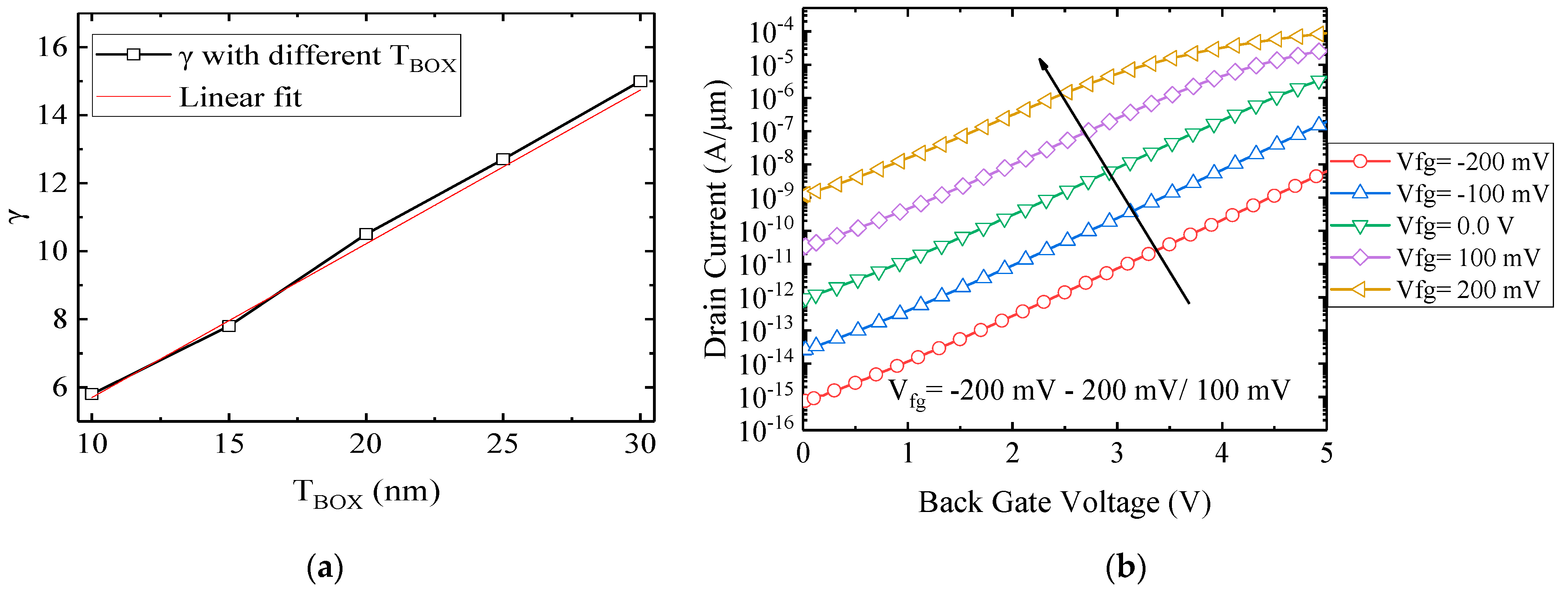

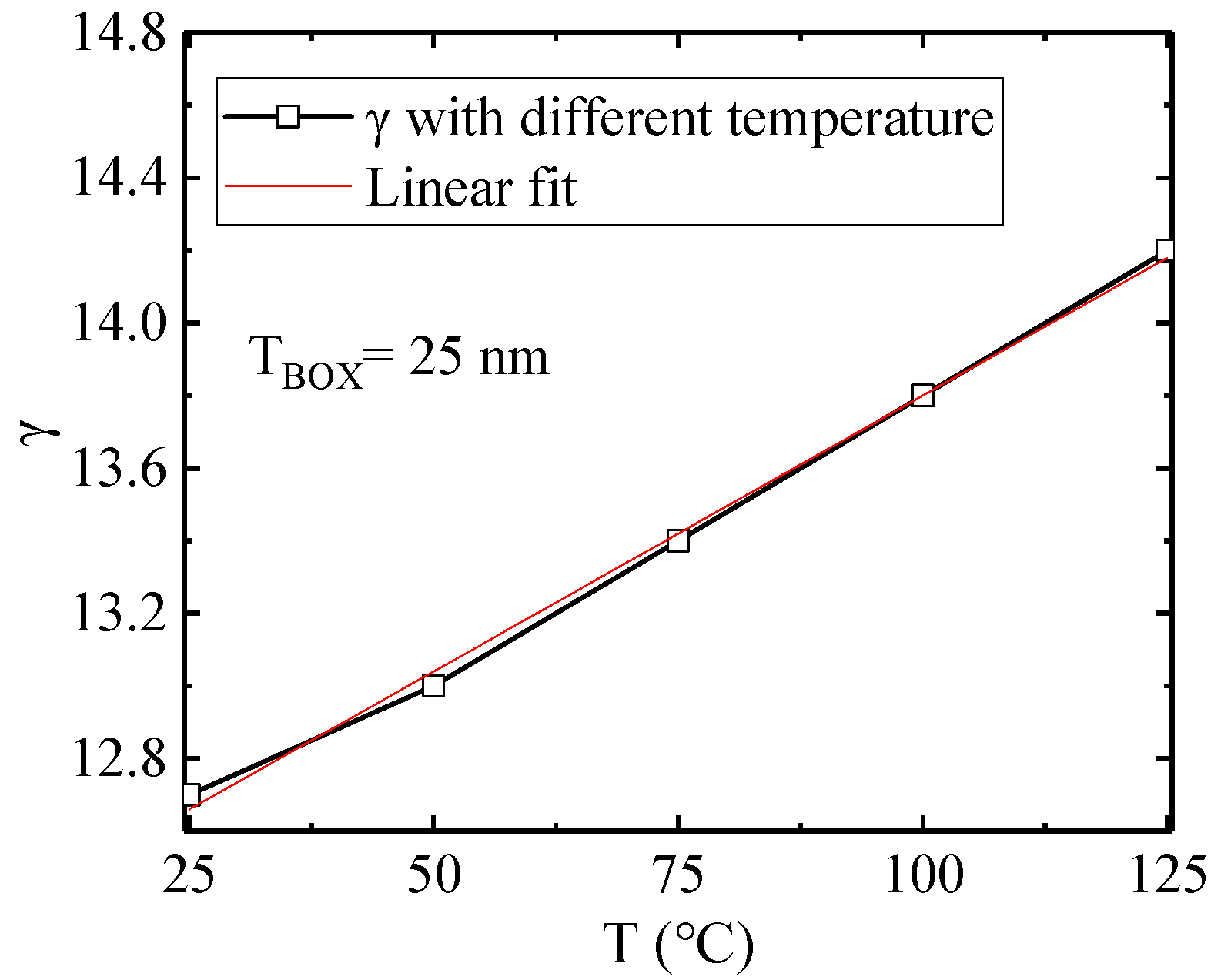

3.1. Influence of Temperature

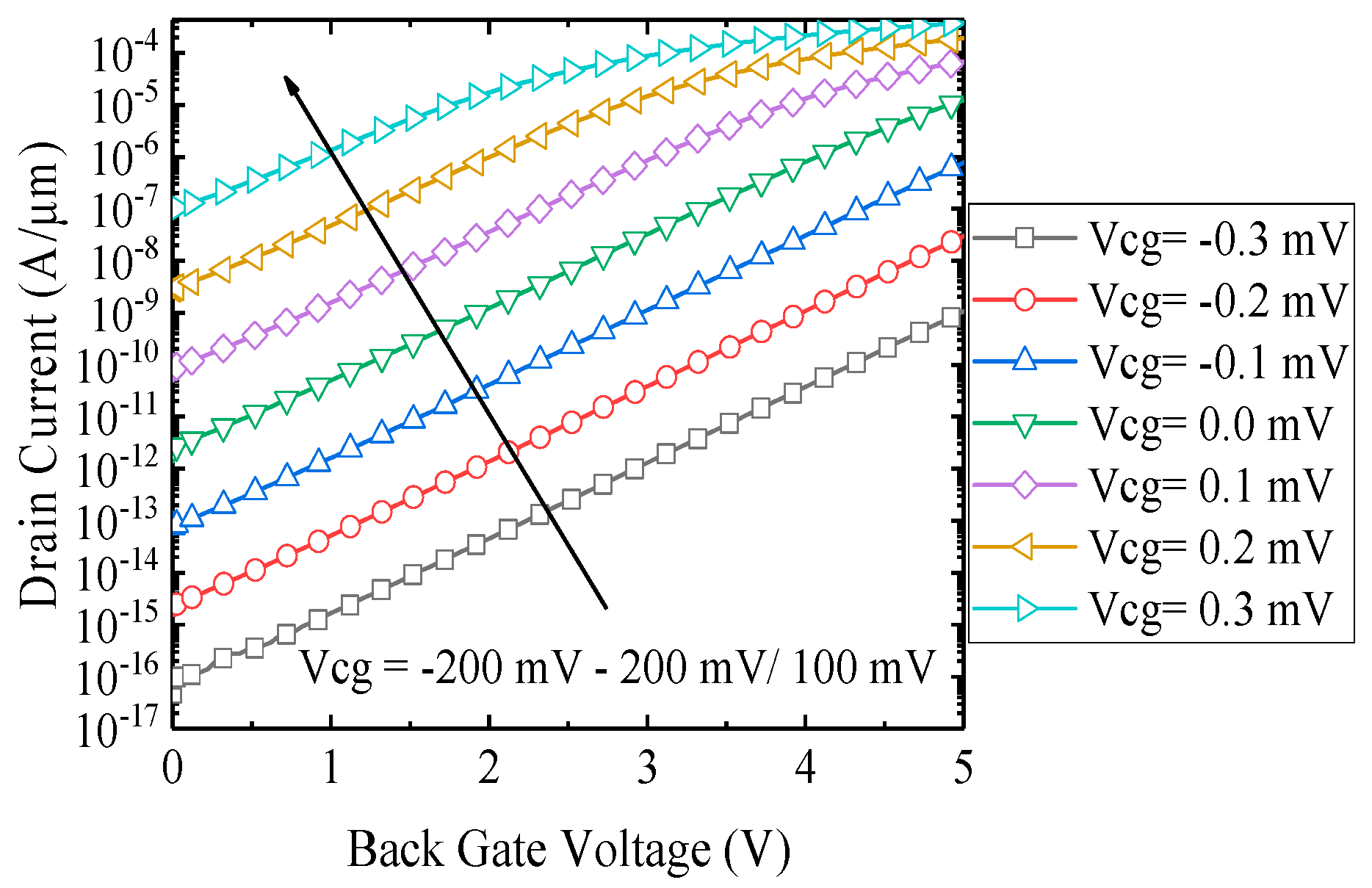

3.2. Influence of Dual-Gate Structure

3.3. Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bergveld, P. Development, Operation, and Application of the Ion-Sensitive Field-Effect Transistor as a Tool for Electrophysiology. IEEE Trans. Biomed. Eng. 1972, 5, 342–351. [Google Scholar] [CrossRef] [PubMed]

- Moser, N.; Lande, T.S.; Toumazou, C.; Georgiou, P. ISFETs in CMOS and Emergent Trends in Instrumentation: A Review. IEEE Sens. J. 2016, 16, 6496–6514. [Google Scholar] [CrossRef]

- Passeri, D.; Morozzi, A.; Kanxheri, K.; Scorzoni, A. Numerical simulation of ISFET structures for biosensing devices with TCAD tools. Biomed. Eng. Online 2015, 14, 1–16. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tarasov, A.; Wipf, M.; Stoop, R.L.; Bedner, K.; Fu, W.; Guzenko, V.A.; Knopfmacher, O.; Calame, M.; Schönenberger, C. Understanding the Electrolyte Background for Biochemical Sensing with Ion-Sensitive Field-Effect Transistors. ACS Nano 2012, 6, 9291. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Q.; Wang, M.; Tao, M.; Yin, R.; Li, Y.; Yang, N.; Xu, W.; Gao, C.; Hao, Y.; Yang, Z. Planar Dual Gate GaN HEMT Cascode Amplifier as a Voltage Readout pH Sensor With High and Tunable Sensitivities. IEEE Electron Device Lett. 2020, 41, 485–488. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, J.; Li, Y.; Shuang, Z.; Zhao, Y. Carbon Dots Based Photoelectrochemical Sensors for Ultrasensitive Detection of Glutathione and Its Applications in Probing of Myocardial Infarction. Biosensors Bioelectron. 2017, 99, 251. [Google Scholar] [CrossRef] [PubMed]

- Shuang, Z.A.; Cong, S.A.; Hha, B.; Zl, A.; Gang, X.A.; Qy, A.; Peng, S.A.; Lc, A.; Wn, A.; Jb, B. ISFET and Dex-AgNPs based portable sensor for reusable and real-time determinations of concanavalin A and glucose on smartphone. Biosensors Bioelectron. 2020, 151, 111962. [Google Scholar]

- Ayele, G.T.; Monfray, S.; Ecoffey, S.; Boeuf, F.; Cloarec, J.; Drouin, D.; Souifi, A. Ultrahigh-Sensitive CMOS pH Sensor Developed in the BEOL of Standard 28 nm UTBB FDSOI. IEEE J. Electron Devices Soc. 2018, 6, 1026–1032. [Google Scholar] [CrossRef]

- Wang, L.; Bu, Y.; Ao, J.-P. Effect of oxygen plasma treatment on the performance of AlGaN/GaN ion-sensitive field-effect transistors. Diam. Relat. Mater. 2017, 73, 1–6. [Google Scholar] [CrossRef]

- Yusof, K.A.; Noh, N.I.M.; Herman, S.H.; Abdullah, A.Z.; Zolkapli, M.; Abdullah, W.F.H. pH sensing characteristics of silicon nitride thin film and silicon nitride-based ISFET sensor. In Proceedings of the 2013 IEEE 4th Control and System Graduate Research Colloquium, Shah Alam, Malaysia, 19–20 August 2013; pp. 132–135. [Google Scholar]

- Chou, J.-C.; Weng, C.-Y.; Tsai, H.-M. Study on the temperature effects of Al2O3 gate pH-ISFET. Sens. Actuators B Chem. 2002, 81, 152–157. [Google Scholar] [CrossRef]

- Gimmel, P.; Schierbaum, K.D.; Göpel, W.; Vlekkert, H.; Rooij, N. Reduced light sensibility in optimized Ta2O5-ISFET structures. Sens. Actuators B Chem. 1991, 4, 135–140. [Google Scholar] [CrossRef]

- Poghossian, A.S. The super-Nernstian pH sensitivity of Ta2O5-gate ISFETs. Sens. Actuators B Chem. 1992, 7, 367–370. [Google Scholar] [CrossRef]

- Bausells, J.; Carrabina, J.; Errachid, A.; Merlos, A. Ion-sensitive field-effect transistors fabricated in a commercial CMOS technology. Sens. Actuators B Chem. 1999, 57, 56–62. [Google Scholar] [CrossRef] [Green Version]

- Rahhal, L.; Ayele, G.T.; Monfray, S.; Cloarec, J.-P.; Fornacciari, B.; Pardoux, E.; Chevalier, C.; Ecoffey, S.; Drouin, D.; Morin, P.; et al. High sensitivity pH sensing on the BEOL of industrial FDSOI transistors. Solid-State Electron. 2017, 134, 22–29. [Google Scholar] [CrossRef]

- Ayele, G.T.; Monfray, S.; Ecoffey, S.; Boeuf, F.; Bon, R.; Cloarec, J.P.; Drouin, D. Ultrahigh-Sensitive and CMOS Compatible ISFET Developed in BEOL of Industrial UTBB FDSOI. In Proceedings of the 2018 IEEE Symposium on VLSI Technology, Honolulu, HI, USA, 18–22 June 2018. [Google Scholar]

- Ayele, G.T.; Monfray, S.; Boeuf, F.; Cloarec, J.P.; Ecoffey, S.; Drouin, D.; Puyoo, E.; Souifi, A. Development of ultrasensitive extended-gate Ion-sensitive-field-effect-transistor based on industrial UTBB FDSOI transistor. In Proceedings of the 2017 47th European Solid-State Device Research Conference (ESSDERC), Leuven, Belgium, 11–14 September 2017; pp. 264–267. [Google Scholar]

- Pfattner, R.; Foudeh, A.M.; Chen, S.; Niu, W.; Matthews, J.R.; He, M.; Bao, Z. Dual-Gate Organic Field-Effect Transistor for pH Sensors with Tunable Sensitivity. Adv. Electron. Mater. 2019, 5, 1800381. [Google Scholar] [CrossRef] [Green Version]

- Son, T.; Le, S.C.; Curt, A. Richter, Arvind Balijepalli. Optimal field-effect transistor operation for high-resolution biochemical measurements. Rev. Sci. Instrum. 2021, 92, 030901. [Google Scholar]

- Dai, Y.; Huang, D.; Xing, J.; Pan, Z.; Zhang, B. Temperature Characteristics of an All-Solid-State Ion-Sensitive Field Effect Transistor pH Sensor. Semicond. Technol. 2018, 43, 734–739. [Google Scholar]

- Synopsys TCAD Tools. Available online: http://www.synopsys.com/Tools/TCADU (accessed on 25 January 2013).

- Mohammadi, E.; Manavizadeh, N. An Accurate TCAD-Based Model for ISFET Simulation. IEEE Trans. Electron Devices 2018, 65, 3950–3956. [Google Scholar] [CrossRef]

- Bandiziol, A.; Palestri, P.; Pittino, F.; Esseni, D.; Selmi, L. A TCAD-Based Methodology to Model the Site-Binding Charge at ISFET/Electrolyte Interfaces. IEEE Trans. Electron Devices 2015, 62, 3379–3386. [Google Scholar] [CrossRef]

- Chung, I.Y.; Jang, H.; Lee, J.; Moon, H.; Seo, S.M.; Kim, D.H. Simulation study on discrete charge effects of SiNW biosensors according to bound target position using a 3D TCAD simulator. Nanotechnology 2012, 23, 123–133. [Google Scholar] [CrossRef] [Green Version]

- Esseni, D.; Abramo, A.; Selmi, L.; Sangiorgi, E. Physically based modeling of low field electron mobility in ultrathin single- and double-gate SOI n-MOSFETs. IEEE Trans. Electron Devices 2003, 50, 2445–2455. [Google Scholar] [CrossRef]

- Poljak, M.; Jovanovic, V.; Grgec, D.; Suligoj, T. Assessment of Electron Mobility in Ultrathin-Body InGaAs-on-Insulator MOSFETs Using Physics-Based Modeling. IEEE Trans. Electron Devices 2012, 59, 1636–1643. [Google Scholar] [CrossRef]

- Lyumkis, E.; Mickevicius, R.; Penzin, O.; Polsky, B.; El Sayed, K.; Wettstein, A. Simulations of ultrathin SOI with quantum transport models. In Proceedings of the 2001 IEEE International SOI Conference, Durango, CO, USA, 1–4 October 2001; pp. 49–50. [Google Scholar]

- Poiroux, T.; Widiez, J.; Lolivier, J.; Vinet, M.; Casse, M.; Prévitali, B.; Deleonibus, S. New and accurate method for electrical extraction of silicon film thickness on fully-depleted SOI and double gate transistors. In Proceedings of the 2004 IEEE International SOI Conference (IEEE Cat. No.04CH37573), Charleston, SC, USA, 4–7 October 2004; pp. 73–74. [Google Scholar]

| Parameters | Values |

|---|---|

| Top Silicon Thickness | 6 nm |

| Buried Oxide Thickness | 25 nm |

| Length of Sensing Area | 50 nm |

| Doping Concentration of Source and Drain Area | 1 × 1020 cm−3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Bi, J.; Liu, M.; Han, T. Simulation of FDSOI-ISFET with Tunable Sensitivity by Temperature and Dual-Gate Structure. Electronics 2021, 10, 1585. https://doi.org/10.3390/electronics10131585

Wang H, Bi J, Liu M, Han T. Simulation of FDSOI-ISFET with Tunable Sensitivity by Temperature and Dual-Gate Structure. Electronics. 2021; 10(13):1585. https://doi.org/10.3390/electronics10131585

Chicago/Turabian StyleWang, Hanbin, Jinshun Bi, Mengxin Liu, and Tingting Han. 2021. "Simulation of FDSOI-ISFET with Tunable Sensitivity by Temperature and Dual-Gate Structure" Electronics 10, no. 13: 1585. https://doi.org/10.3390/electronics10131585

APA StyleWang, H., Bi, J., Liu, M., & Han, T. (2021). Simulation of FDSOI-ISFET with Tunable Sensitivity by Temperature and Dual-Gate Structure. Electronics, 10(13), 1585. https://doi.org/10.3390/electronics10131585