Effect of Recycled Plastic Granules as a Partial Substitute for Natural Resource Sand on the Durability of SCC

Abstract

1. Introduction

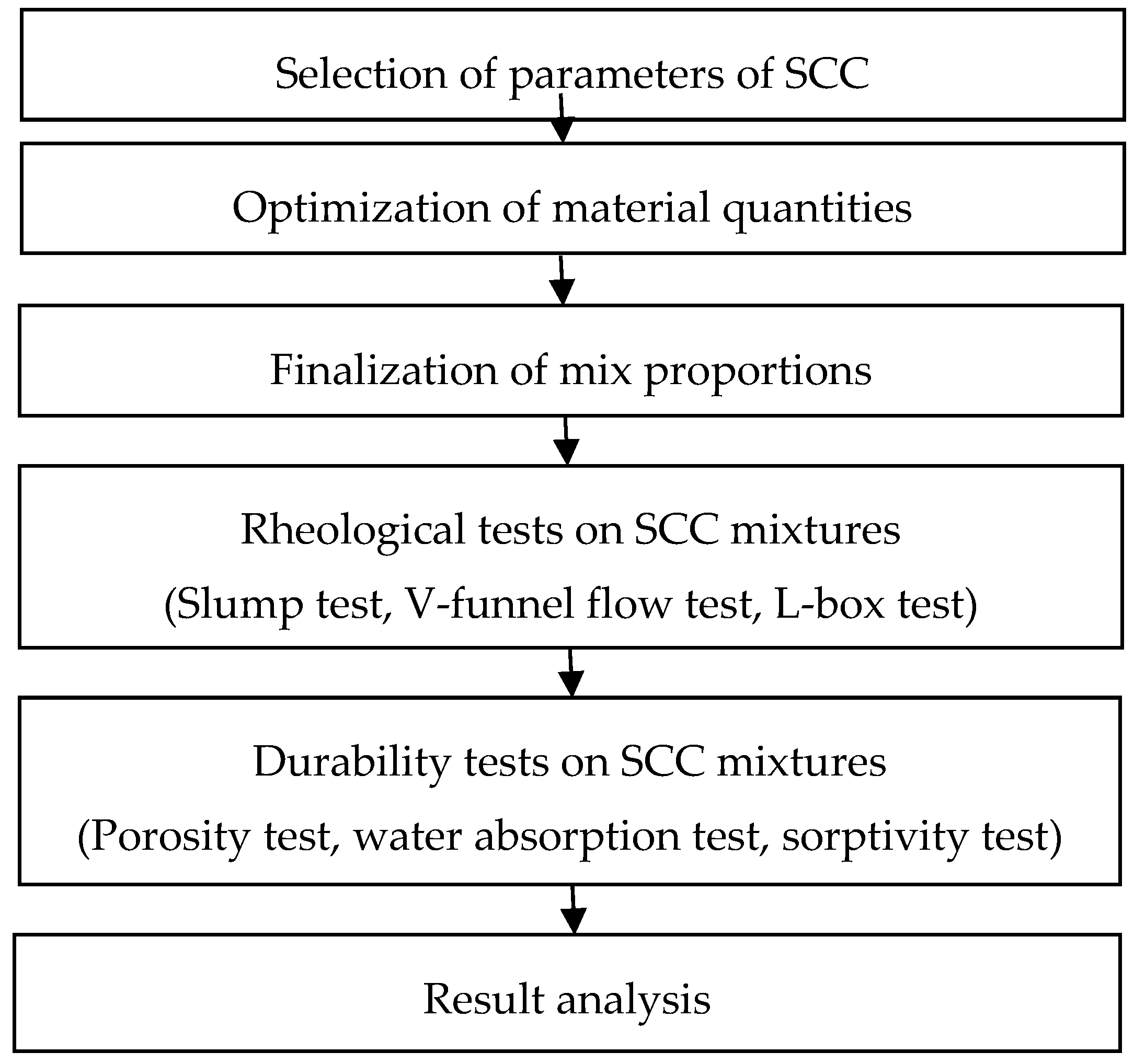

2. Materials and Methods

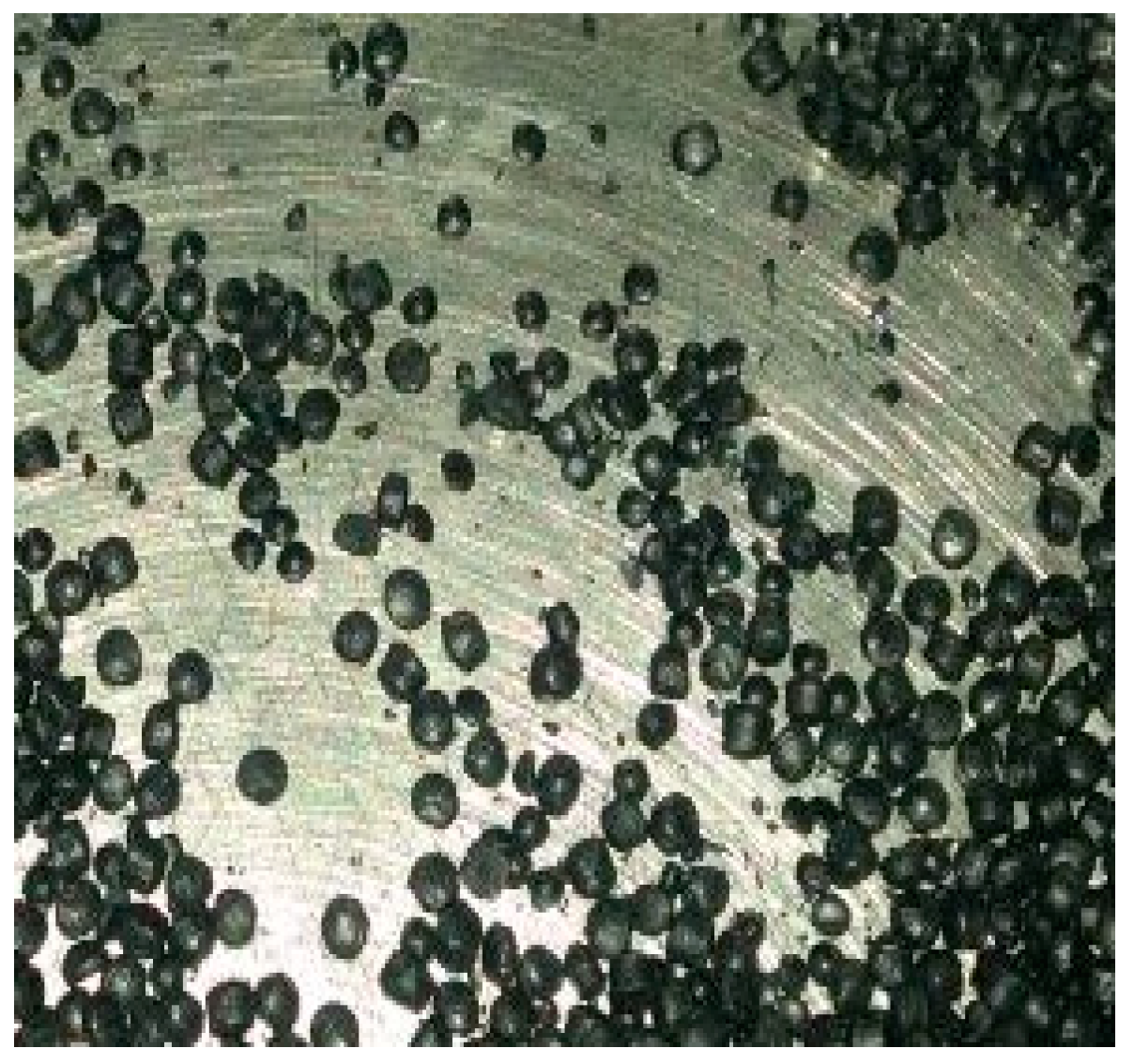

2.1. Materials Used for the Development of SCC

2.2. Mix Proportions

2.3. Test Procedure

2.3.1. Porosity Test on SCC Specimen

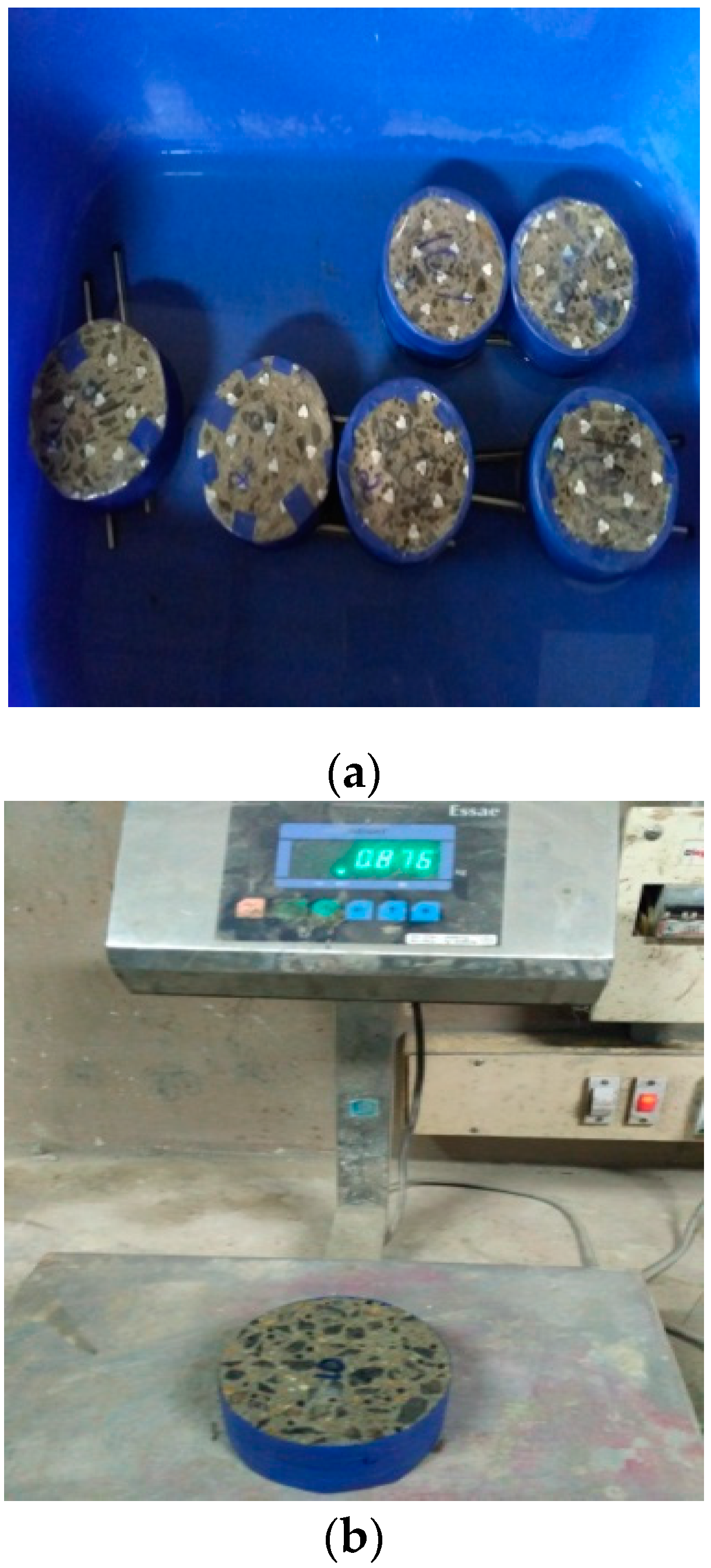

2.3.2. Water Absorption Test on SCC Specimen

2.3.3. Sorptivity Test on SCC Specimens

3. Result and Discussion

3.1. Effect of HIPS Aggregate on Porosity of SCC

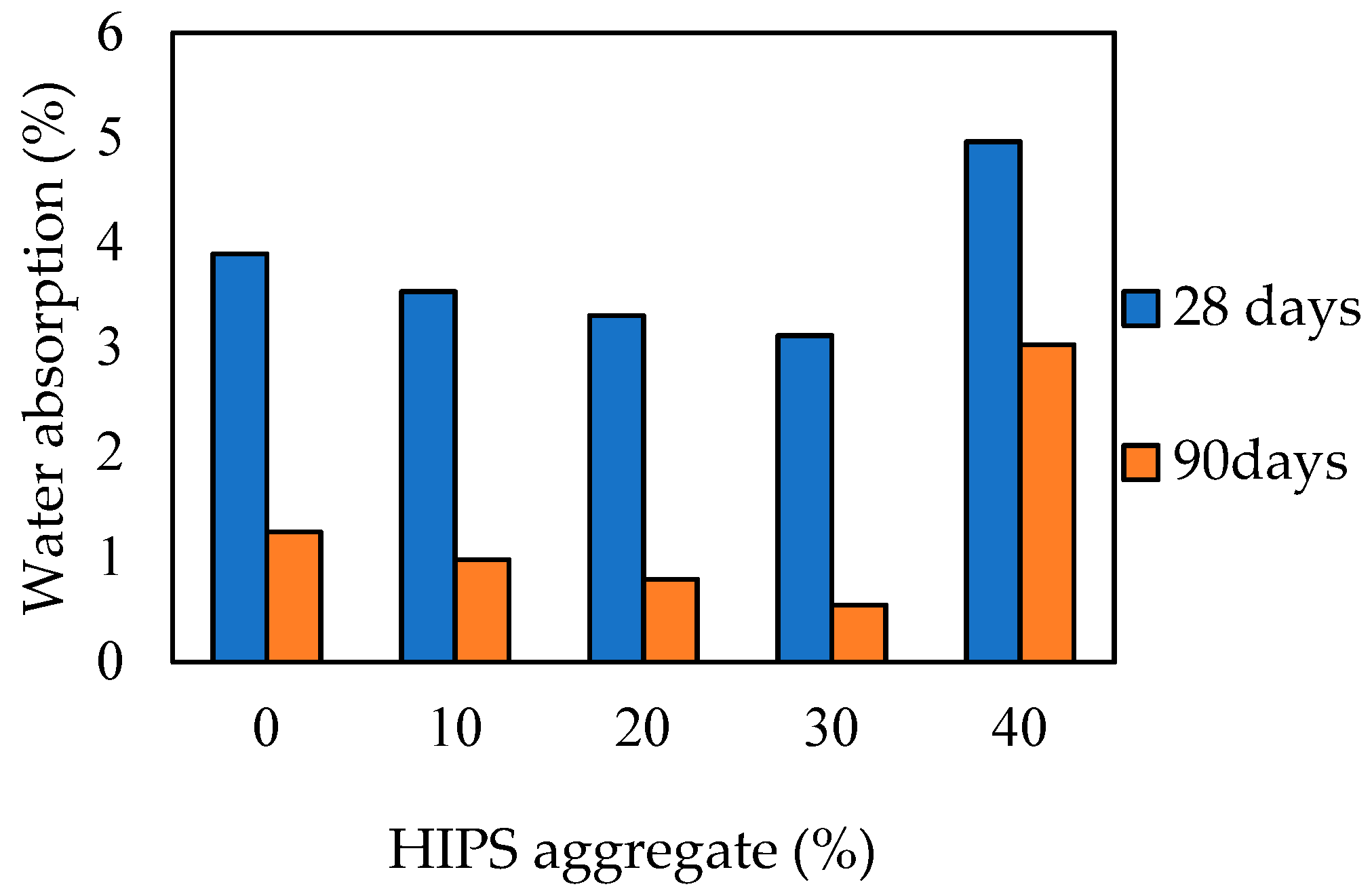

3.2. Effect of HIPS Granules in Water Absorption of SCC

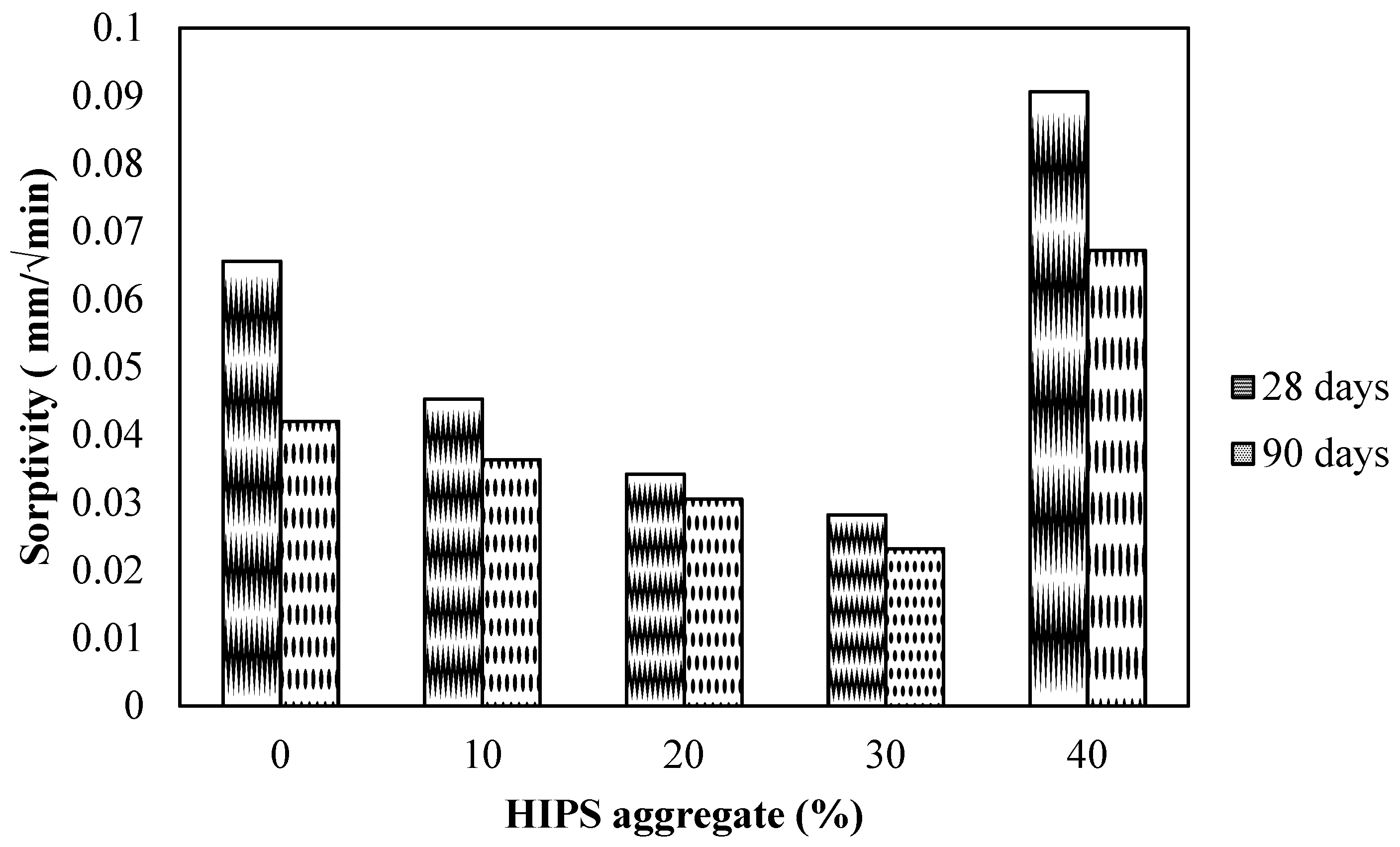

3.3. Effect of HIPS Granuleson Sorptivity of SCC

4. Conclusions

- Good compaction was attained with the existence of continuous gradation in the concrete matrix up to 30% HIPS replacement for fine aggregate in SCC. Hence, porosity was reduced about 30% due to enhanced rheology in SCC.

- Performance of HIPS in water absorption was found to be average and satisfactory (<5%). Only 20% of water absorption reduced at 30% of HIPS replacement in place of fine aggregate for SCC compared to reference concrete. Sorptivity values were reduced for concrete with 30% of HIPS replacement of fine aggregate for all curing ages. Reduction of water absorption and sorptivity values was higher for the 90 days compared to the 28 days curing period due to pozzolanic activity.

- The shape, size, and inert nature of HIPS aggregates resemble the properties of sand and it helps for SCC in achieving excellent durable performance. Recycled HIPS can be replaceable up to 30% for natural river sand for producing eco-friendly, durable, and flow-able concrete.

Author Contributions

Funding

Conflicts of Interest

References

- Mehta, P.K.; Monteiro, P. Concrete: Microstructure, Properties and Materials; McGraw-Hill: New York, NY, USA, 2006. [Google Scholar]

- Ramli, M.; Tabassi, A.A. Effects of polymer modification on the permeability of cement mortars under different curing conditions: A correlational study that includes pore distributions, water absorption and compressive strength. Constr. Build. Mater. 2012, 28, 561–570. [Google Scholar] [CrossRef]

- De Schutter, G. Evaluation of water absorption of concrete as a measure for resistance against carbonation and chloride migration. Mater. Struct. 2004, 37, 591–596. [Google Scholar] [CrossRef]

- Tasdemir, C. Combined effects of mineral admixtures and curing conditions on the sorptivity coefficient of concrete. Cem. Concr. Res. 2003, 33, 1637–1642. [Google Scholar] [CrossRef]

- Nik, A.S.; Omran, O.L. Estimation of compressive strength of self-compacted concrete with fibers consisting nano-SiO2 using ultrasonic pulse velocity. Constr. Build. Mater. 2013, 44, 654–662. [Google Scholar]

- Jacob-Vaillancourt, C.; Sorelli, L. Characterization of concrete composites with recycled plastic aggregates from postconsumer material streams. Constr. Build. Mater. 2018, 182, 561–572. [Google Scholar] [CrossRef]

- Gu, L.; Ozbakkaloglu, T. Use of recycled plastics in concrete: A critical review. Waste Manag. 2016, 51, 19–42. [Google Scholar] [CrossRef]

- Coppola, B.; Courard, L.; Michel, F.; Incarnato, L.; Scarfato, P.; Di Maio, L. Hygro-thermal and durability properties of a lightweight mortar made with foamed plastic waste aggregates. Constr. Build. Mater. 2018, 170, 200–206. [Google Scholar] [CrossRef]

- Záleská, M.; Pavlíková, M.; Pokorný, J.; Jankovský, O.; Pavlík, Z.; Černý, R. ´ Structural, mechanical and hygrothermal properties of lightweight concrete based on the application of waste plastics. Constr. Build. Mater. 2018, 180, 1–11. [Google Scholar] [CrossRef]

- Kumar, K.S.; Premalatha, P.V.; Baskar, K. Evaluation of Transport Properties of Concrete Made with E-Waste Plastic. J. Test. Eval. 2016, 45, 1849–1853. [Google Scholar]

- Lakshmi, R.; Nagan, S. Investigations on durability characteristics of e-plastic waste incorporated concrete. Asian J. Civ. Eng. 2011, 12, 773–787. [Google Scholar]

- Krishna, C.B.R.; Jagadeesh, P. Influence of Admixtures on Plastic Wastes in an Eco-Friendly Concrete A Review. Int. J. Civ. Eng. Technol. 2017, 8, 388–397. [Google Scholar]

- Krishna, C.B.R.; Jagadeesh, P. Durability studies on Self-Compacting Concrete replacing fine aggregate partially with High impact polystyrene. Int. J. Eng. Adv. Technol. 2019, 8, 75–79. [Google Scholar]

- Krishna, C.B.R.; Jagadeesh, P. Strength and Durability assessment of binary blended Self-Compacting Concrete replacing partial sand with electronic plastic waste. Int. J. Innov. Technol. Explor. Eng. 2019, 8, 107–111. [Google Scholar]

- Krishna, C.B.R.; Jagadeesh, P. Rheological and Strength Behavior of Binary Blended SCC Replacing Partial Fine Aggregate with Plastic E-Waste as High Impact Polystyrene. Buildings 2019, 9, 50. [Google Scholar]

- Krishna, C.B.R.; Jagadeesh, P. Fresh and Hardened Properties of Self-Compacting Concrete Replacing Fine Aggregate with High Impact Polystyrene Plastic Granules. Int. J. Civ. Eng. Technol. 2018, 9, 831–838. [Google Scholar]

- Yang, S.; Yue, X.; Liu, X.; Tong, Y. Properties of self-compacting lightweight concrete containing recycled plastic particles. Constr. Build. Mater. 2015, 84, 444–453. [Google Scholar] [CrossRef]

- Hama, S.M.; Hilal, N.N. Fresh properties of self-compacting concrete with plastic waste as partial replacement of sand. Int. J. Sustain. Built Environ. 2017, 6, 299–308. [Google Scholar] [CrossRef]

- Faraj, R.H.; Sherwan, A.F.H.; Daraei, A. Mechanical, fracture and durability properties of self-compacting high strength concrete containing recycled polypropylene plastic particles. J. Build. Eng. 2019, 25, 100808. [Google Scholar] [CrossRef]

- Alqahtani, F.K.; Ghataora, G.; Khan, M.I.; Dirar, S.; Kioul, A.; Al-Otaibi, M. Lightweight Concrete Containing Recycled Plastic Aggregates. In Proceedings of the 2015 International Conference on Electromechanical Control Technology and Transportation, Paris, France, 13–14 April 2015. [Google Scholar]

- Ranjbar, M.M.; Mousavi, S.Y. Strength and durability assessment of self-compacted lightweight concrete containing expanded polystyrene. Mater. Struct. 2015, 48, 1001–1011. [Google Scholar] [CrossRef]

- Sadrmomtazi, A.; Dolati-Milehsara, S.; Lotfi-Omran, O.; Sadeghi-Nik, A. The combined effects of waste Polyethylene Terephthalate (PET) particles and pozzolanic materials on the properties of self-compacting concrete. J. Clean. Prod. 2016, 112, 2363–2373. [Google Scholar] [CrossRef]

- Nikbin, I.M.; Rahimi, S.; Allahyari, H.; Fallah, F. Feasibility study of waste Poly-Ethylene Terephthalate (PET) particles as aggregate replacement for acid erosion of sustainable structural normal and lightweight concrete. J. Clean. Prod. 2016, 126, 108–117. [Google Scholar] [CrossRef]

- Akçaözoglu, S.; Ati¸s, C.D.; Akçaözoglu, K. An investigation on the use of shredded waste PET bottles as aggregate in lightweight concrete. Waste Manag. 2010, 30, 285–290. [Google Scholar] [CrossRef]

- Babafemi, A.; Branko, Š.; Suvash, C.P.; Vivi, A. Engineering Properties of Concrete with Waste Recycled Plastic: A Review. Sustainability. 2018, 10, 3875. [Google Scholar] [CrossRef]

- ASTM C642-13. Standard Test Method for Density, Absorption, and Voids in Hardened Concrete; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- ASTM C1585-13. Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic—Cement Concretes; ASTM International, West Conshohocken, PA, USA, 2013.

- Ruiz-Herrero, J.L.; Nieto, D.V.; López-Gil, A.; Arranz, A.; Fernández, A.; Lorenzana, A.; Merino, S.; De Saja, J.A.; Rodríguez-Pérez, M. Ángel Mechanical and thermal performance of concrete and mortar cellular materials containing plastic waste. Constr. Build. Mater. 2016, 104, 298–310. [Google Scholar] [CrossRef]

- CEB-FIP. Diagnosis and Assessment of Concrete Structures—State of Art Report; CEB Bulletin: Lausanne, Switzerland, 1989; Volume 192, pp. 83–85. [Google Scholar]

| Properties | Test Result | Test Method | IS 12269 (1987) Requirements |

|---|---|---|---|

| Normal consistency | 31% | IS 4031 (1988)—part 4 | - |

| Initial setting time (min) | 60 | IS 4031 (1988)—part 5 | Minimum time is 30 min |

| Final setting time (min) | 320 | IS 4031 (1988)—part 5 | Maximum time is 600 min |

| Specific gravity | 3.15 | IS 4031(1988)—part 11 | - |

| Compressive strength (MPa) | IS 4031 (1988)—part 6 | ||

| 3 days | 30.82 MPa | 27 MPa | |

| 7 days | 49.50 MPa | 37 MPa | |

| 28 days | 58.34 MPa | 53 MPa |

| Particulars | Percentage of Chemical Composition (%) | IS:12269-1987Recommendations |

|---|---|---|

| Lime (CaO) | 61.85 | |

| Silica (SiO2) | 20.07 | |

| Iron oxide (Fe2O3) | 4.62 | |

| Alumina (Al2O3) | 5.32 | |

| Magnesia (MgO) | 0.83 | Not more than 6.0% |

| Sulfuric anhydride (SO3) | 2.50 | Maximum content is 3.0% when C3A >5.0; Maximum content is 2.5% when C3A <5.0 |

| Lime saturation factor CaO-0.7SO3/2.8SiO2+1.2Al2O3+0.65Fe2O3 | 0.91 | 0.80 to 1.02 |

| Ratio of alumina/iron oxide | 1.18 | Minimum is 0.66 |

| Chloride content | 0.0028 | Maximum content is 0.1% |

| Aggregate Property | Aggregate Type | ||

|---|---|---|---|

| Coarse Aggregate | Fine Aggregate | HIPS Aggregate | |

| Specific gravity | 2.7 | 2.6 | 1.04 |

| Water absorption (%) | 0.3% | 1% | Negligible |

| Bulk density (kg/m3) | 1656 | 1609 | 650 |

| Size of aggregate (mm) | 12 mm and 10 mm in 60:40 ratio | Less than 4.75 | 1 mm–4 mm |

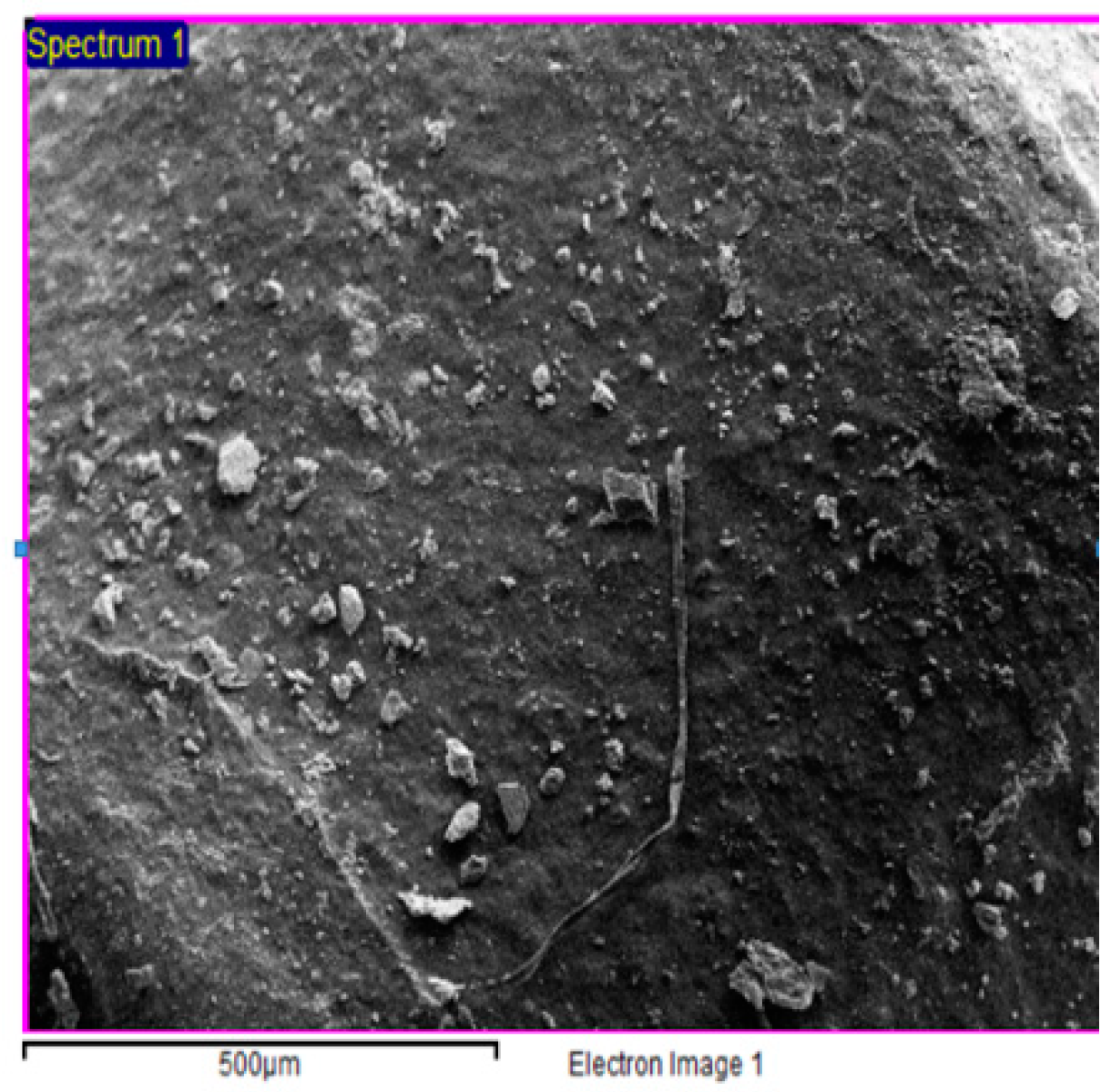

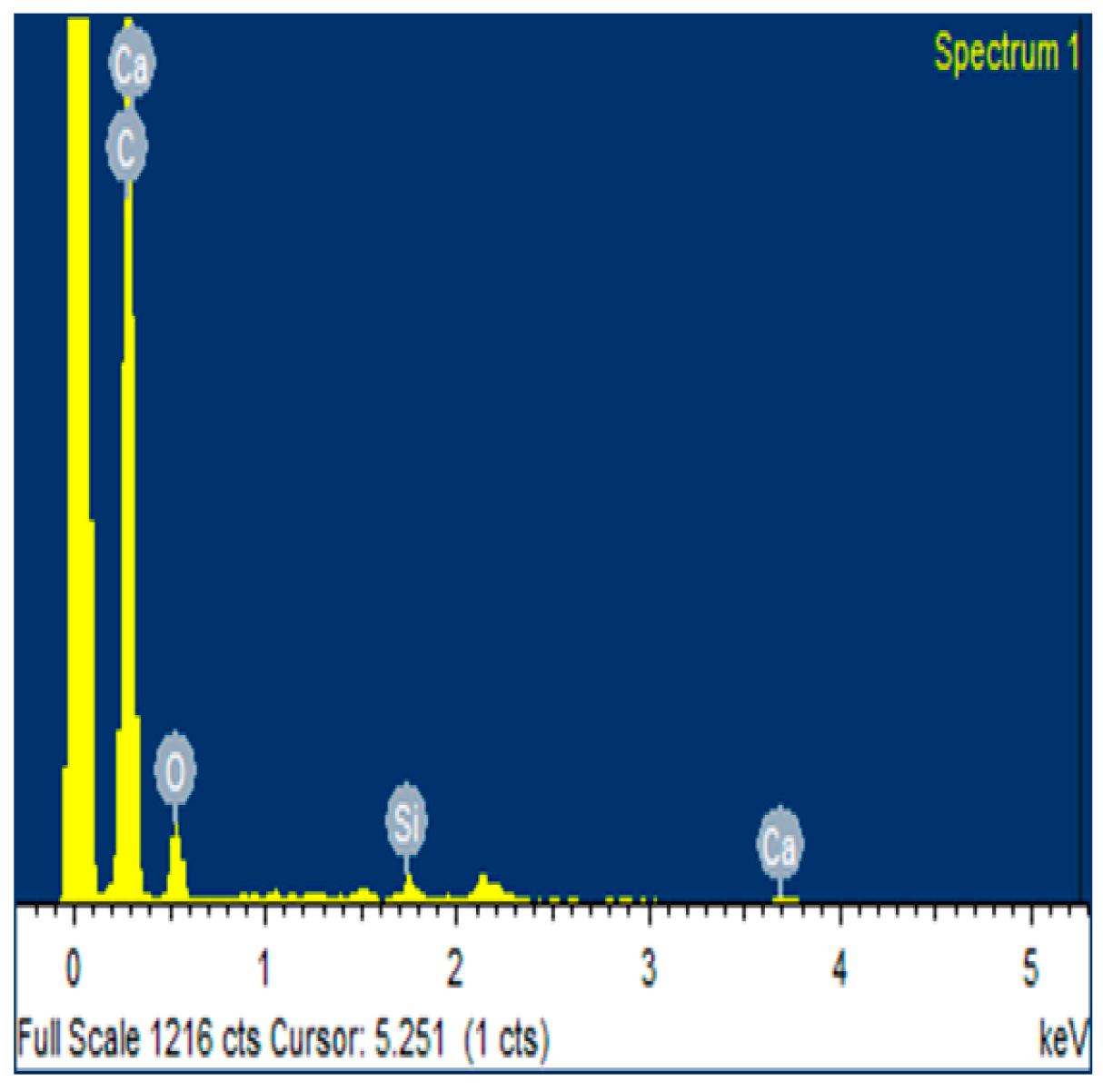

| Element | Weight% | Atomic% |

|---|---|---|

| C K | 82.13 | 87.10 |

| O K | 14.73 | 11.73 |

| Si K | 1.32 | 0.60 |

| Ca K | 1.82 | 0.58 |

| Total | 100.00 |

| Chemical Properties | ||

|---|---|---|

| Class F Fly Ash Particulars | Chemical Composition (%) | Recommendations According to ASTM C 618 |

| Silica (SiO2) | 60.5 | |

| Alumina (Al2O3) | 30.8 | |

| Iron oxide (Fe2O3) | 3.6 | SiO2+ Al2O3+ Fe2O3>70 |

| Lime (CaO) | 1.4 | |

| Magnesia (MgO) | 0.91 | |

| Sulfuric anhydride (SO3) | 0.14 | |

| K2O + Na2O | 1.1 | Maximum of 5.0 |

| Loss on ignition | 0.29 | Maximum of 6.0 |

| Physical Properties | ||

| Specific gravity | 2.2 | |

| Fineness (m2/kg) | 320 | Minimum of 225 m2/kg |

| Particulars | Test Results of Super-Plasticizer FOSROC Conplast SP430 | Test Results of FOSROC Viscosity Modifying Agent |

|---|---|---|

| Specific gravity | 1.20 | 1.09 |

| Color | Brown | White |

| Solid content (%) | 40 | 40 |

| Quantity (%) by cementitious weight | 0.9 | 0.2 |

| Main component | Sulfonated naphthalene polymers | Poly-carboxylate ether |

| Material Data | Coarse Aggregate (CA) Optimization | Constituent Materials for Concrete | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Material | Specific Gravity | % Absorption | Material | % by Weight | Material (kg/m3) | Initial | Adjusted | Per 1 m3 | ||||

| Cement | 3.15 | N/A | CA 10 mm | 40 | Cement | 347.90 | 347.90 | 347.90 | ||||

| Fly ash | 2.20 | N/A | CA 12 mm | 60 | Fly ash | 149.10 | 149.10 | 149.10 | ||||

| CA 12 mm | 2.70 | 0.3 | Water | 178.90 | 186.50 | 186.50 | ||||||

| CA10 mm | 2.70 | 0.3 | CA (kg/m3) | 758.44 | Sand | 861.90 | 861.90 | 861.90 | ||||

| Sand | 2.60 | 1.0 | % of CA | 28.09 | CA 12 mm | 455.00 | 455.00 | 455.00 | ||||

| Input parameters | Concrete mix proportions by volume (lit/m3) | Aggregate proportions | CA 10 mm | 303.30 | 303.30 | 303.30 | ||||||

| Dry-Rodded Unit Weight DRUW (kg/m3) | 1656 | CA | 280.91 | Material | % Vol. | % Wt. | VMA (lit) | 0.99 | 0.99 | 0.99 | ||

| % ofCA in DRUW | 45.80 | Mortar | 719.00 | CA 12 mm | 27.50 | 28.00 | SP (lit) | 4.47 | 4.47 | 4.47 | ||

| % of sand | 46.10 | Sand | 331.50 | CA 10 mm | 18.30 | 18.70 | Unit wt. | 2152 | Total(kg) | 2159.60 | ||

| % of fly ash | 30 | Paste | 387.50 | FA | 54.10 | 53.10 | ||||||

| Total | 100 | 100 | ||||||||||

| Wt. water/binder | 0.36 | Total aggregates (kg/m3) | 1620.35 | |||||||||

| Binder (kg/m3) | 497.00 | Sand(kg/m3) | 861.90 | |||||||||

| Super plasticizer (% wt. of binder) | 0.90 | Vol. water/powder | 1.00 | |||||||||

| Viscosity modifying agent (% wt. of binder) | 0.20 | Paste composition | ||||||||||

| % of air content | 2.00 | kg/m3 | lit/m3 | |||||||||

| % of dry material (SP) | 40 | Cement | Fly ash | Water | SP | VMA | Paste | |||||

| % of dry material (VMA) | 40 | 347.90 | 149.10 | 178.90 | 4.47 | 0.99 | 382.60 | |||||

| Cement (kg/m3) | Fly Ash (30% by Wt. of Cement) (kg/m3) | Coarse Aggregate (kg/m3) | Sand (kg/m3) | HIPS (%) | HIPS (kg/m3) | Flow-Ability | |||

|---|---|---|---|---|---|---|---|---|---|

| 12 mm | 10 mm | Slump (mm) | V-Funnel Flow Time (sec) | L-Box (h2/h1) ratio | |||||

| 347.90 | 149.10 | 455.07 | 303.38 | 861.69 | 0 | 0.00 | 598 | 9.80 | 0.83 |

| 347.90 | 149.10 | 455.07 | 303.38 | 776.18 | 10 | 34.48 | 659 | 9.20 | 0.86 |

| 347.90 | 149.10 | 455.07 | 303.38 | 690.13 | 20 | 69.01 | 690 | 8.60 | 0.88 |

| 347.90 | 149.10 | 455.07 | 303.38 | 603.85 | 30 | 103.51 | 723 | 8.00 | 0.89 |

| 347.90 | 149.10 | 455.07 | 303.38 | 517.53 | 40 | 138.00 | 642 | 10.3 | 0.78 |

| Time (sec) | Tolerance (+/−) |

|---|---|

| 60 s | 2 s |

| 5 min | 10 s |

| 10 min | 2 min |

| 20 min | 2 min |

| 30 min | 2 min |

| 60 min | 2 min |

| Every hour, up to 6 h measurement on first day | 5 min |

| Once a day, up to 3 days | 2 h |

| Day 4 to 7, three measurements 24 h apart | 2 h |

| Day 7 to 9, one measurement | 2 h |

| Water Absorption (%) | Performance |

|---|---|

| >5% | Poor |

| 3%–5% | Average |

| <3% | Good |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chunchu, B.R.K.; Putta, J. Effect of Recycled Plastic Granules as a Partial Substitute for Natural Resource Sand on the Durability of SCC. Resources 2019, 8, 133. https://doi.org/10.3390/resources8030133

Chunchu BRK, Putta J. Effect of Recycled Plastic Granules as a Partial Substitute for Natural Resource Sand on the Durability of SCC. Resources. 2019; 8(3):133. https://doi.org/10.3390/resources8030133

Chicago/Turabian StyleChunchu, Bala Rama Krishna, and Jagadeesh Putta. 2019. "Effect of Recycled Plastic Granules as a Partial Substitute for Natural Resource Sand on the Durability of SCC" Resources 8, no. 3: 133. https://doi.org/10.3390/resources8030133

APA StyleChunchu, B. R. K., & Putta, J. (2019). Effect of Recycled Plastic Granules as a Partial Substitute for Natural Resource Sand on the Durability of SCC. Resources, 8(3), 133. https://doi.org/10.3390/resources8030133