Resources Sustainability through Material Efficiency Strategies: An Insight Study of Electrical and Electronic Companies

Abstract

1. Introduction

2. Literature Analysis

2.1. Material Efficiency Considerations in Product Design

2.2. Material Efficiency during Material Sourcing

2.3. Material Efficiency Considerations during the Manufacturing Process

2.4. Material Efficiency during Product Distribution

3. Research Design

4. E&E’s Material Efficiency Strategies

5. Discussion and Research Implications

5.1. E&E Material Efficiency Strategy in Product Design and Material Sourcing

5.2. E&E Material Efficiency in Manufacturing Processes

5.3. E&E Material Efficiency Strategy in Product Distribution

5.4. Research Limitations

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

- Is your company aware of the importance of integrating a green or environmental strategy into the product design and manufacturing process?

- Does your company use any tactics or strategies to reduce material usage and waste in any way (material purchasing, design, manufacturing, and packaging and distribution)? If yes, please explain how?

- What is the common solid waste in your company? Are any strategies employed to reduce this waste?

- Does your company production line generate any toxic waste? What are the strategies being practiced by your company to reduce the toxic waste?

- How to make your product lighter?

- How to make your production line greener and sustainable?

- How to manage the generated waste along the production lines?

- How to control the scrap generation along the production lines?

Appendix B

| Area | Quotations | Final Theme |

|---|---|---|

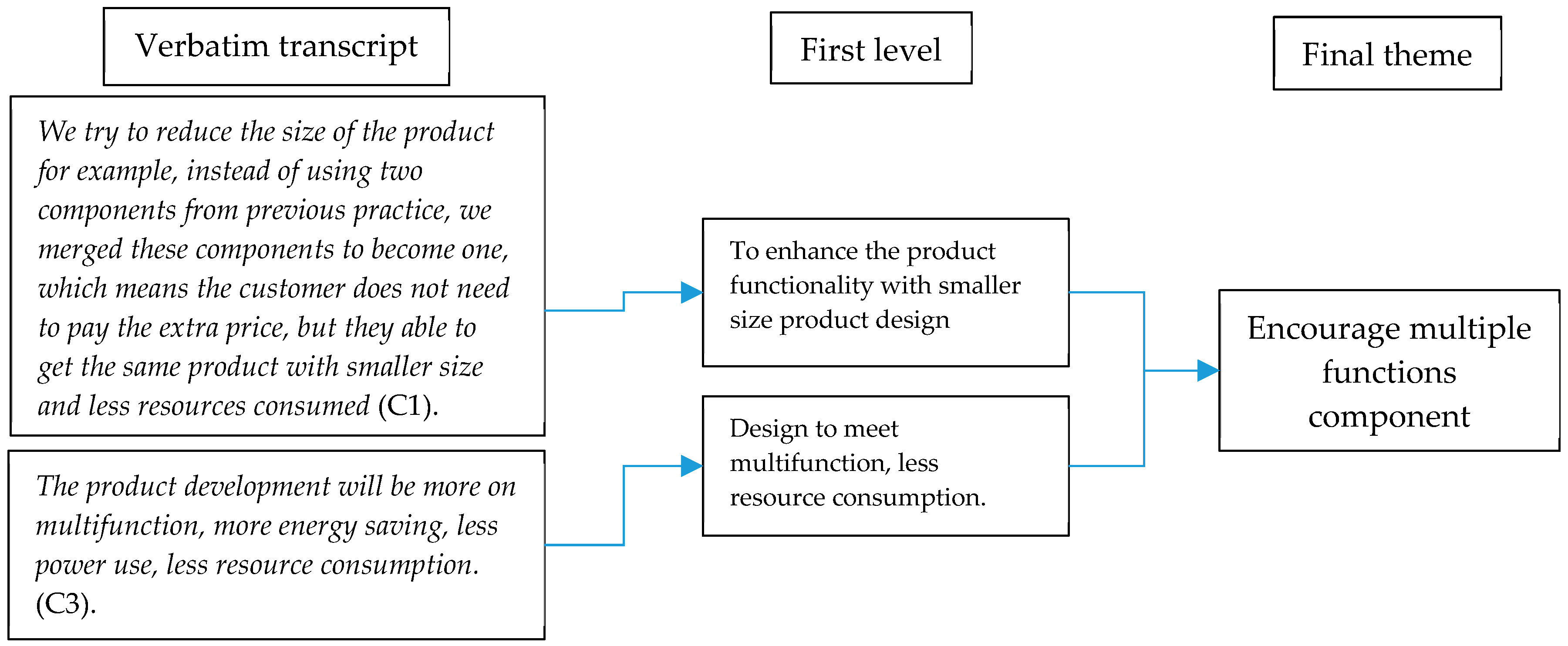

| Product design | “…what customer tries to do is to request a one off part to be integrated with other parts to make it more efficient and smaller, but the component generally can do two functions, compared to what we see previously they need two components to do it.” | Design for multiple purposes |

| “…the green compound used currently has to last at least 8 years. That’s why the material supplier has to come out with the component, parts, and the technology to make it longer life.” | Design for longer life | |

| “we already design to try to make it smaller, compared to last time, one wafer was possible to produce about 500 chips; however, now, because of better design, with the latest advanced technology, one wafer with same size they can produce 1000 chips.” | Less material per unit of function | |

| “if it is a recyclable part, we will put a recycle mark there, that is why we have a recycle mark on each of our parts,” | Design for material recovery | |

| Material sourcing | “We have to make all the part’s using green materials throughout. So far, we don’t have any issues to substitute green materials” | Material substitution |

| “We are buying wafers that are already in a sliced shape, which is a good wafer shape, Eventually, our waste would be the damaged wafer.” | Pre-fabricated part purchase | |

| Manufacturing process | “We try to reduce the copper usage, meaning that we have the print and same frame size, but want to produce more parts.” | Yield improvement |

| “...we try to simplify the design with less processes into our design, or in other words we try not to complicate the process in the manufacturing of our design.” | Process efficiency | |

| Product Distribution | “We have packaging specs such as the materials and the shape of packaging. So, the supplier of the packaging needs to comply with it” | Recyclable packaging |

| “In our packaging, we increased the quantity in our inner boxes. From 14,000 in a master box, we increase to 36,000. Eventually, it is material efficiency; we have increased the packaging in the inner boxes into a master box 2.5 times more. We save on our packaging and we also save on our transportation cost.” | Bulk packaging | |

| “We also try to reuse the plastic pallet packaging, because plastic pallets are tougher, but the cost is very high, you need to ensure they are returnable from your partners” | Returnable packaging |

References

- Moraga, G.; Huysveld, S.; Mathieux, F.; Blengini, G.A.; Alaerts, L.; Van Acker, K.; De Meester, S.; Dewulf, J. Circular economy indicators: What do they measure? Resour. Conserv. Recycl. 2019, 146, 452–461. [Google Scholar] [CrossRef]

- Abdel-Shafy, H.I.; Mansour, M.S. Solid waste issue: Sources, composition, disposal, recycling, and valorization. Egypt. J. Pet. 2018, 27, 1275–1290. [Google Scholar] [CrossRef]

- Utit, C.; Saari, M.Y.; Hassan, A.; Ismail, T.H.T. Measuring the embodied waste among industries in Malaysia. Procedia Environ. Sci. 2015, 30, 228–231. [Google Scholar] [CrossRef]

- Lovins, L.H. Rethinking production. In State of the World; Routledge: New York, NY, USA, 2008; pp. 32–44. [Google Scholar]

- Pariatamby, A.; Victor, D. Policy trends of e-waste management in Asia. J. Mater. Cycles Waste Manag. 2013, 15, 411–419. [Google Scholar] [CrossRef]

- Herat, S.; Agamuthu, P. E-waste: A problem or an opportunity? Review of issues, challenges and solutions in Asian countries. Waste Manag. Res. 2012, 30, 1113–1129. [Google Scholar] [CrossRef] [PubMed]

- Sahajwalla, V.; Gaikwad, V. The present and future of e-waste plastics recycling. Curr. Opin. Green Sustain. Chem. 2018, 13, 102–107. [Google Scholar] [CrossRef]

- Shumon, M.R.H.; Ahmed, S.; Islam, M.T. Electronic waste: Present status and future perspectives of sustainable management practices in Malaysia. Environ. Earth Sci. 2014, 72, 2239–2249. [Google Scholar] [CrossRef]

- Kumar, A.; Holuszko, M.; Espinosa, D.C.R. E-waste: an overview on generation, collection, legislation and recycling practices. Resour. Conserv. Recycl. 2017, 122, 32–42. [Google Scholar] [CrossRef]

- Awasthi, A.K.; Zeng, X.; Li, J. Environmental pollution of electronic waste recycling in India: A critical review. Environ. Pollut. 2016, 211, 259–270. [Google Scholar] [CrossRef] [PubMed]

- Tansel, B. From electronic consumer products to e-wastes: Global outlook, waste quantities, recycling challenges. Environ. Int. 2017, 98, 35–45. [Google Scholar] [CrossRef]

- Abdul Rashid, S.H.; Evans, S.; Longhurst, P. A comparison of four sustainable manufacturing strategies. Int. J. Sustain. Eng. 2008, 1, 214–229. [Google Scholar] [CrossRef]

- Allwood, J.M.; Ashby, M.F.; Gutowski, T.G.; Worrell, E. Material efficiency: A white paper. Resour. Conserv. Recycl. 2011, 55, 362–381. [Google Scholar] [CrossRef]

- Chan, C.W.; Huang, G.H. Artificial intelligence for management and control of pollution minimization and mitigation processes. Eng. Appl. Artif. Intell. 2003, 16, 75–90. [Google Scholar] [CrossRef]

- Neto, B.; Kroeze, C.; Hordijk, L.; Costa, C.; Pulles, T. Strategies to reduce the environmental impact of an aluminium pressure die casting plant: A scenario analysis. J. Environ. Manag. 2009, 90, 815–830. [Google Scholar] [CrossRef] [PubMed]

- Waage, S.A. Re-considering product design: A practical “road-map” for integration of sustainability issues. J. Clean. Prod. 2007, 15, 638–649. [Google Scholar] [CrossRef]

- Shahbazi, S.; Salloum, M.; Kurdve, M.; Wiktorsson, M. Material Efficiency Measurement: Empirical Investigation of Manufacturing Industry. Procedia Manuf. 2017, 8, 112–120. [Google Scholar] [CrossRef]

- Allwood, J.M.; Ashby, M.F.; Gutowski, T.G.; Worrell, E. Material efficiency: Providing material services with less material production. Philos. Trans. R. Soc. Lond. A Math. Phys. Eng. Sci. 2013, 371, 20120496. [Google Scholar] [CrossRef]

- Ho, F.H.; Abdul-Rashid, S.H.; Raja Ghazilla, R.A. Analytic Hierarchy Process-Based Analysis to Determine the Barriers to Implementing a Material Efficiency Strategy: Electrical and Electronics’ Companies in the Malaysian Context. Sustainability 2016, 8, 1035. [Google Scholar] [CrossRef]

- Walz, R. Employment and structural impacts of material efficiency strategies: Results from five case studies. J. Clean. Prod. 2011, 19, 805–815. [Google Scholar] [CrossRef]

- Worrell, E.; Faaij, A.P.C.; Phylipsen, G.J.M.; Blok, K. An approach for analysing the potential for material efficiency improvement. Resour. Conserv. Recycl. 1995, 13, 215–232. [Google Scholar] [CrossRef]

- Peck, M.; Chipman, R. Industrial energy and material efficiency: What role for policies? In Industrial Development for the Twenty-first Century; United Nations Publications: New York, NY, USA, 2007; pp. 333–385. [Google Scholar]

- Braun, A.T.; Kleine-Moellhoff, P.; Reichenberger, V.; Seiter, S. Case study analysing potentials to improve material efficiency in manufacturing supply chains, considering circular economy aspects. Sustainability 2018, 10, 880. [Google Scholar] [CrossRef]

- Walker, S.; Coleman, N.; Hodgson, P.; Collins, N.; Brimacombe, L. Evaluating the Environmental Dimension of Material Efficiency Strategies Relating to the Circular Economy. Sustainability 2018, 10, 666. [Google Scholar] [CrossRef]

- Cooper, S.; Skelton, A.C.; Owen, A.; Densley-Tingley, D.; Allwood, J.M. A multi-method approach for analysing the potential employment impacts of material efficiency. Resour. Conserv. Recycl. 2016, 109, 54–66. [Google Scholar] [CrossRef]

- Dunant, C.F.; Skelton, A.C.; Drewniok, M.P.; Cullen, J.M.; Allwood, J.M. A marginal abatement cost curve for material efficiency accounting for uncertainty. Resour. Conserv. Recycl. 2019, 144, 39–47. [Google Scholar] [CrossRef]

- Horton, P.M.; Allwood, J.M.; Cleaver, C. Implementing material efficiency in practice: A case study to improve the material utilisation of automotive sheet metal components. Resour. Conserv. Recycl. 2019, 145, 49–66. [Google Scholar] [CrossRef]

- Azevedo, J.M.; Cabrera Serrenho, A.; Allwood, J.M. Energy and material efficiency of steel powder metallurgy. Powder Technol. 2018, 328, 329–336. [Google Scholar] [CrossRef]

- Levänen, J.; Eloneva, S. Fighting sustainability challenges on two fronts: Material efficiency and the emerging carbon capture and storage technologies. Environ. Sci. Policy 2017, 76, 131–138. [Google Scholar] [CrossRef]

- Lilja, R. From waste prevention to promotion of material efficiency: Change of discourse in the waste policy of Finland. J. Clean. Prod. 2009, 17, 29–136. [Google Scholar] [CrossRef]

- Ashby, M.F. Materials and the Environment: Eco-Informed Material Choice; Butterworth-Heinemann Publisher: Burlington, MA, USA, 2012; pp. 415–436. [Google Scholar]

- Cooper, T. Creating an economic infrastructure for sustainable product design. J. Sustain. Prod. Des. 1999, 8, 7–18. [Google Scholar]

- Zhong, R.; Wille, K.; Viegas, R. Material efficiency in the design of UHPC paste from a life cycle point of view. Constr. Build. Mater. 2018, 160, 505–513. [Google Scholar] [CrossRef]

- Hekkert, M.P.; van den Reek, J.; Worrell, E.; Turkenburg, W.C. The impact of material efficient end-use technologies on paper use and carbon emissions. Resour. Conserv. Recycl. 2002, 36, 241–266. [Google Scholar] [CrossRef]

- Osibanjo, O.; Nnorom, I.C. The challenge of electronic waste (e-waste) management in developing countries. Waste Manag. Res. 2007, 25, 489–501. [Google Scholar] [CrossRef] [PubMed]

- Subramoniam, R.; Huisingh, D.; Chinnam, R.B. Remanufacturing for the automotive aftermarket-strategic factors: Literature review and future research needs. J. Clean. Prod. 2009, 17, 1163–1174. [Google Scholar] [CrossRef]

- Gilbert, P.; Wilson, P.; Walsh, C.; Hodgson, P. The role of material efficiency to reduce CO2 emissions during ship manufacture: A life cycle approach. Mar. Policy 2017, 75, 227–237. [Google Scholar] [CrossRef]

- Shahbazi, S.; Wiktorsson, M.; Kurdve, M.; Jönsson, C.; Bjelkemyr, M. Material efficiency in manufacturing: Swedish evidence on potential, barriers and strategies. J. Clean. Prod. 2016, 127, 438–450. [Google Scholar] [CrossRef]

- Tecchio, P.; Ardente, F.; Marwede, M.; Clemm, C.; Dimitrova, G.; Mathieux, F. Ecodesign of personal computers: An analysis of the potentials of material efficiency options. Procedia CIRP 2018, 69, 716–721. [Google Scholar] [CrossRef]

- Hekkert, M.P.; Joosten, L.A.; Worrell, E.; Turkenburg, W.C. Reduction of CO2 emissions by improved management of material and product use: The case of primary packaging. Resour. Conserv. Recycl. 2000, 29, 33–64. [Google Scholar] [CrossRef]

- Hugo, A.; Ciumei, C.; Buxton, A.; Pistikopoulos, E.N. Environmental impact minimization through material substitution: A multi-objective optimization approach. Green Chem. 2004, 6, 407–417. [Google Scholar] [CrossRef]

- Lee, A.H.; Kang, H.Y.; Hsu, C.F.; Hung, H.C. A green supplier selection model for high-tech industry. Expert Syst. Appl. 2009, 36, 7917–7927. [Google Scholar] [CrossRef]

- Widmer, R.; Oswald-Krapf, H.; Sinha-Khetriwal, D.; Schnellmann, M.; Böni, H. Global perspectives on e-waste. Environ. Impact Assess. Rev. 2005, 25, 436–458. [Google Scholar] [CrossRef]

- Eveloy, V.; Ganesan, S.; Fukuda, Y.; Wu, J.; Pecht, M.G. Are you ready for lead-free electronics? IEEE Trans. Compon. Packag. Technol. 2005, 28, 884–894. [Google Scholar] [CrossRef]

- Riley, D.; Sanvido, V.; Horman, M.; McLaughlin, M.; Kerr, D. Lean and green: The role of design-build mechanical competencies in the design and construction of green buildings. In Construction Research Congress; Broadening Perspectives—Proc., Congress.; ASCE: San Diego, CA, USA, 2005; pp. 116–120. [Google Scholar]

- Ingarao, G.; Di Lorenzo, R.; Micari, F. Sustainability issues in sheet metal forming processes: An overview. J. Clean. Prod. 2011, 19, 337–347. [Google Scholar] [CrossRef]

- Münstermann, B.; Eckhardt, A.; Weitzel, T. The performance impact of business process standardization: An empirical evaluation of the recruitment process. Bus. Process Manag. J. 2010, 16, 29–56. [Google Scholar] [CrossRef]

- Rahimifard, S.; Seow, Y.; Childs, T. Minimising Embodied Product Energy to support energy efficient manufacturing. CIRP Ann. Manuf. Technol. 2010, 59, 25–28. [Google Scholar] [CrossRef]

- Sikdar, S.K. Sustainability and recycle–reuse in process systems. Clean Technol. Environ. Policy 2007, 9, 167–174. [Google Scholar] [CrossRef]

- Wiktorsson, M.; Bellgran, M.; Jackson, M. Sustainable Manufacturing-Challenges and Possibilities for Research and Industry from a Swedish perspective. In Manufacturing Systems and Technologies for the New Frontier; Springer: London, UK, 2008; pp. 119–122. [Google Scholar]

- Wu, M.C.; Chien, C.S.; Lu, K.S. Yield improvement planning for the recycle processes of test wafers. Int. J. Adv. Manuf. Technol. 2006, 27, 1228–1234. [Google Scholar] [CrossRef]

- Leal-Ayala, D.R.; Allwood, J.M.; Petavratzi, E.; Brown, T.J.; Gunn, G. Mapping the global flow of tungsten to identify key material efficiency and supply security opportunities. Resour. Conserv. Recycl. 2015, 103, 19–28. [Google Scholar] [CrossRef]

- Pajunen, N.; Watkins, G.; Wierink, M.; Heiskanen, K. Drivers and barriers of effective industrial material use. Miner. Eng. 2012, 29, 39–46. [Google Scholar] [CrossRef]

- Tien, S.W.; Chung, Y.C.; Tsai, C.H. Environmental design implementation in Taiwan’s industries. Environ. Impact Assess. Rev. 2002, 22, 685–702. [Google Scholar] [CrossRef]

- Hanssen, O.J.; Olsen, A.; Møller, H.; Rubach, S. National indicators for material efficiency and waste minimization for the Norwegian packaging sector 1995–2001. Resour. Conserv. Recycl. 2003, 38, 123–137. [Google Scholar] [CrossRef]

- Zhang, G.; Zhao, Z. Green Packaging Management of Logistics Enterprises. Phys. Procedia 2012, 24, 900–905. [Google Scholar] [CrossRef]

- Lee, S.G.; Lye, S.W. Design for manual packaging. Int. J. Phys. Distrib. Logist. Manag. 2003, 33, 163–189. [Google Scholar] [CrossRef]

- Kroon, L.; Vrijens, G. Returnable containers: An example of reverse logistics. Int. J. Phys. Distrib. Logist. Manag. 1995, 25, 56–68. [Google Scholar] [CrossRef]

- Jang, Y.C. Waste electrical and electronic equipment (WEEE) management in Korea: Generation, collection, and recycling systems. J. Mater. Cycles Waste Manag. 2010, 12, 283–294. [Google Scholar] [CrossRef]

- Perera, H.S.C.; Nagarur, N.; Tabucanon, M.T. Component part standardization: A way to reduce the life-cycle costs of product. Int. J. Prod. Econ. 1999, 60, 109–116. [Google Scholar] [CrossRef]

- Huang, M.S.; Hsu, M.K. Modular design applied to beverage-container injection molds. Int. J. Adv. Manuf. Technol. 2011, 53, 1–10. [Google Scholar] [CrossRef]

- Allwood, J.M.; Cullen, J.M.; Milford, R.L. Options for achieving a 50% cut in industrial carbon emissions by 2050. Environ. Sci. Technol. 2010, 44, 1888–1894. [Google Scholar] [CrossRef] [PubMed]

- Meier, H.; Völker, O.; Funke, B. Industrial Product-Service Systems (IPS2). Int. J. Adv. Manuf. Technol. 2011, 52, 1175–1191. [Google Scholar] [CrossRef]

- Rouw, M.; Worrell, E. Evaluating the impacts of packaging policy in The Netherlands. Resour. Conserv. Recycl. 2011, 55, 483–492. [Google Scholar] [CrossRef]

- Yin, R.K. Case Study Research: Design and Methods; Sage Publications: Thousand Oaks, CA, USA, 2009; Volume 5. [Google Scholar]

- Creswell, J.W.; Poth, C.N. Qualitative Inquiry and Research Design: Choosing among Five Approaches, 4th ed.; Sage Publications: Thousand Oaks, CA, USA, 2017. [Google Scholar]

- Ayres, L.; Kavanaugh, K.; Knafl, K.A. Within-case and across-case approaches to qualitative data analysis. Qual. Health Res. 2003, 13, 871–883. [Google Scholar] [CrossRef]

- Corbin, J.; Strauss, A. (Eds.) Basics of Qualitative Research: Techniques and Procedures for Developing Grounded Theory; Sage: Thousand Oaks, CA, USA, 2008. [Google Scholar]

- Huberman, M.; Miles, M.B. The Qualitative Researcher’s Companion; Sage: Thousand Oaks, CA, USA, 2002. [Google Scholar]

- Robson, C. Real World Research, 2nd ed.; Blackwell Publishing: Malden, MA, USA, 2002; pp. 455–497. [Google Scholar]

- Newman, I. Qualitative-Quantitative Research Methodology: Exploring the Interactive Continuum; SIU Press: Carbondale, IL, USA, 1998. [Google Scholar]

- Burla, L.; Knierim, B.; Barth, J.; Liewald, K.; Duetz, M.; Abel, T. From text to codings: Intercoder reliability assessment in qualitative content analysis. Nurs. Res. 2008, 57, 113–117. [Google Scholar] [CrossRef] [PubMed]

- Gehin, A.; Zwolinski, P.; Brissaud, D. A tool to implement sustainable end-of-life strategies in the product development phase. J. Clean. Prod. 2008, 16, 566–576. [Google Scholar] [CrossRef]

- Asante, K.A.; Amoyaw-Osei, Y.; Agusa, T. E-waste recycling in Africa: Risks and opportunities. Curr. Opin. Green Sustain. Chem. 2019, 18, 109–117. [Google Scholar] [CrossRef]

- Rochman, F.F.; Ashton, W.S.; Wiharjo, M.G. E-waste, money and power: Mapping electronic waste flows in Yogyakarta, Indonesia. Environ. Dev. 2017, 24, 1–8. [Google Scholar] [CrossRef]

- Herat, S. Sustainable Management of Electronic Waste (e-Waste). Clean Soil Air Water 2007, 35, 305–310. [Google Scholar] [CrossRef]

- Chapple, W.; Paul, C.J.M.; Harris, R. Manufacturing and corporate environmental responsibility: Cost implications of voluntary waste minimisation. Struct. Chang. Econ. Dyn. 2005, 16, 347–373. [Google Scholar] [CrossRef]

- Wath, S.B.; Vaidya, A.N.; Dutt, P.S.; Chakrabarti, T. A roadmap for development of sustainable E-waste management system in India. Sci. Total Environ. 2010, 409, 19–32. [Google Scholar] [CrossRef] [PubMed]

| Material Efficiency Area | Strategy | Benefit | Reference |

|---|---|---|---|

| Product design | Less material per unit functions; Design for multiple purposes; Doing with less/doing without; Product light weighting | Reduce material intake; Reduce product size; Reduce product weight; Reduce material intake; Shorten manufacturing and product assembly time | [13,22,30,31,32,33] |

| Design for longer life | Extend product life cycle; Reduce virgin material extraction | [13,30,31,34] | |

| Design for remanufacturing | Reduce energy use during manufacturing; Reduce virgin material use | [13,35,36] | |

| Design for reuse | Extend product life cycle; Reduce energy usage in manufacturing process | [13,22,30,37] | |

| Design for recycling | Recover material from obsolete product; Reduce virgin material extraction | [13,17,30,31,38,39] | |

| Material sourcing | Material substitution/green material purchase | Ease the manufacturing process; Reduce energy consumption; Ease the material recovery; Reduce manufacturing cost; Reduce solid waste generation | [13,22,30,35,40,41,42,43,44] |

| Pre-manufacture part | Reduce machining time; Reduce solid waste generation; Reduce energy consumption; | [30,45] | |

| Manufacturing process | Process efficiency | Reduce solid waste generation; Reduce manufacturing time; Eliminate unnecessary processes; Reduce energy usage | [46,47,48,49,50] |

| Yield improvement | Reduce solid waste generation from manufacturing process; Reduce reprocess activities | [13,28,30,51] | |

| By-product recycling | Recover the solid waste into resource | [30,52,53] | |

| Product Distribution | Green packaging | Recovery material from packaging | [22,54,55,56] |

| Bulk packaging | Reduce packaging material use | [57] | |

| Lightweight packaging | Reduce packaging material use | [57] | |

| Returnable packaging | Extend product life cycle; Reduce packaging waste | [22,58] |

| Case Study Company | ISO14001 Compliance | Product/ Service | Key-Informant (Experiences) | Origin Country, Size | Department/Unit |

|---|---|---|---|---|---|

| C1 | Yes | Integrated Circuit | Senior Engineer (Quality control) (8 years) | Germany, Large (>4000 employees) | Production; Quality control unit |

| C2 | Yes | Circuit design, mechanical design and assembly | Material Specialist (9 years) | USA, Large (>2000 employees) | Research and Development unit; Design |

| C3 | Yes | Integrated circuit | Packaging Department Director (10 years), Senior engineer (8 years) | USA, Large (>1000 employees) | Management; Design unit; packaging unit |

| C4 | Yes | Integrated circuit, circuit design and assembly | EHS Manager (12 years) | Malaysia, Large (>1000 employees) | Environmental and safety unit |

| C5 | Yes | Solar cell, solar panel | Packaging manager (10 years) | USA, Large (>1500 employees) | Production unit;Packaging unit |

| C6 | Yes | TV (video and audio system), LED display unit | Senior engineer (7 years) | Japan, Large (>1500 employees) | Design unit; |

| C7 | Yes | TV (video and audio system), LED display unit | Principal designer (10 years) | Netherlands, Large (>500 employees) | Research and Development unit; Design unit |

| Step | Data Analysis Process | Activity |

|---|---|---|

| 1 | Transcribe Data | Researcher transcribes verbatim the recorded interview data. Repeated reading of the transcripts in order to become familiar with the transcripts. |

| 2 | Generate code | Researcher codes the interesting and relevant data (short phrases, sentences, or the entire dataset). |

| 3 | Build Theme | Researcher searches for and reviews the available themes to be used to describe the identified codes. |

| 4 | Define Theme | Researcher clarifies the themes to be used by presenting the clear relationship to the data codes. |

| 5 | Produce Findings | Researcher analyses the results from the themes and codes, and relates these discoveries to scholarly findings. |

| Semi-Structured Interview | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Area | Criteria | Example of Activities | C1 | C2 | C3 | C4 | C5 | C6 | C7 |

| Product design | Fabricate with less components |

| x | x | x | x | x | ||

| Design for ease recovery |

| x | |||||||

| Design with longer life components |

| x | |||||||

| Encourage multiple functions component |

| x | x | x | x | ||||

| Material sourcing | Low environmental impacts material substitution |

| x | x | x | x | x | x | x |

| Pre-manufactured part purchase |

| x | x | x | |||||

| Manufacturing process | Close to tolerance machining |

| x | x | x | x | x | x | |

| Reduce production changeover |

| x | x | x | x | x | |||

| Product Distribution | Green packaging |

| x | x | x | x | |||

| Returnable packaging |

| x | |||||||

| Bulk packaging for non-critical components |

| x | |||||||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ho, F.H.; Abdul-Rashid, S.H.; Raja Ghazilla, R.A.; Woo, Y.L. Resources Sustainability through Material Efficiency Strategies: An Insight Study of Electrical and Electronic Companies. Resources 2019, 8, 117. https://doi.org/10.3390/resources8020117

Ho FH, Abdul-Rashid SH, Raja Ghazilla RA, Woo YL. Resources Sustainability through Material Efficiency Strategies: An Insight Study of Electrical and Electronic Companies. Resources. 2019; 8(2):117. https://doi.org/10.3390/resources8020117

Chicago/Turabian StyleHo, Fu Haw, Salwa Hanim Abdul-Rashid, Raja Ariffin Raja Ghazilla, and Yoke Ling Woo. 2019. "Resources Sustainability through Material Efficiency Strategies: An Insight Study of Electrical and Electronic Companies" Resources 8, no. 2: 117. https://doi.org/10.3390/resources8020117

APA StyleHo, F. H., Abdul-Rashid, S. H., Raja Ghazilla, R. A., & Woo, Y. L. (2019). Resources Sustainability through Material Efficiency Strategies: An Insight Study of Electrical and Electronic Companies. Resources, 8(2), 117. https://doi.org/10.3390/resources8020117