Mandatory Recycling of Waste Cooking Oil from Residential and Commercial Sectors in Taiwan

Abstract

:1. Introduction

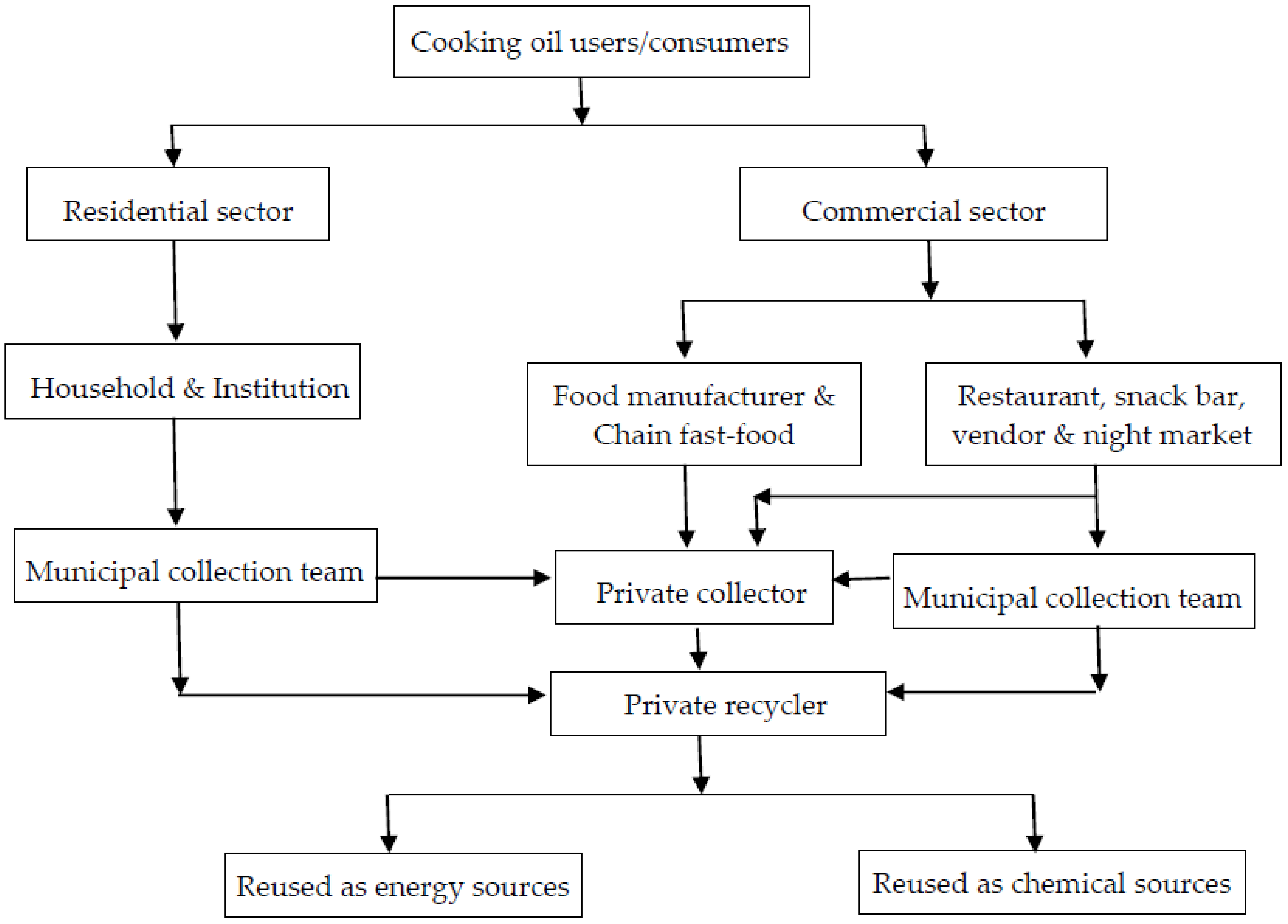

2. Literature Review of the Scientific Background for WCO Recycling

3. Recycling of Waste Cooking Oil in Taiwan

3.1. Waste Recycling Policies in Taiwan

- -

- which is discarded;

- -

- whose original purpose is lost, abandoned, not available, or unclear;

- -

- which is not deliberately produced during the constructing, manufacturing, processing, repairing, selling, or using processes;

- -

- which is generated from manufacturing processes, and is without feasible utilization technology or market economy value;

- -

- which is announced as “waste” by the central competent authority (i.e., EPA).

- -

- Be difficult to clear or disposal of.

- -

- Containing components that do not readily decompose over a long-term period.

- -

- Containing components that are hazardous substances.

- -

- Be valuable for recycling and reuse.

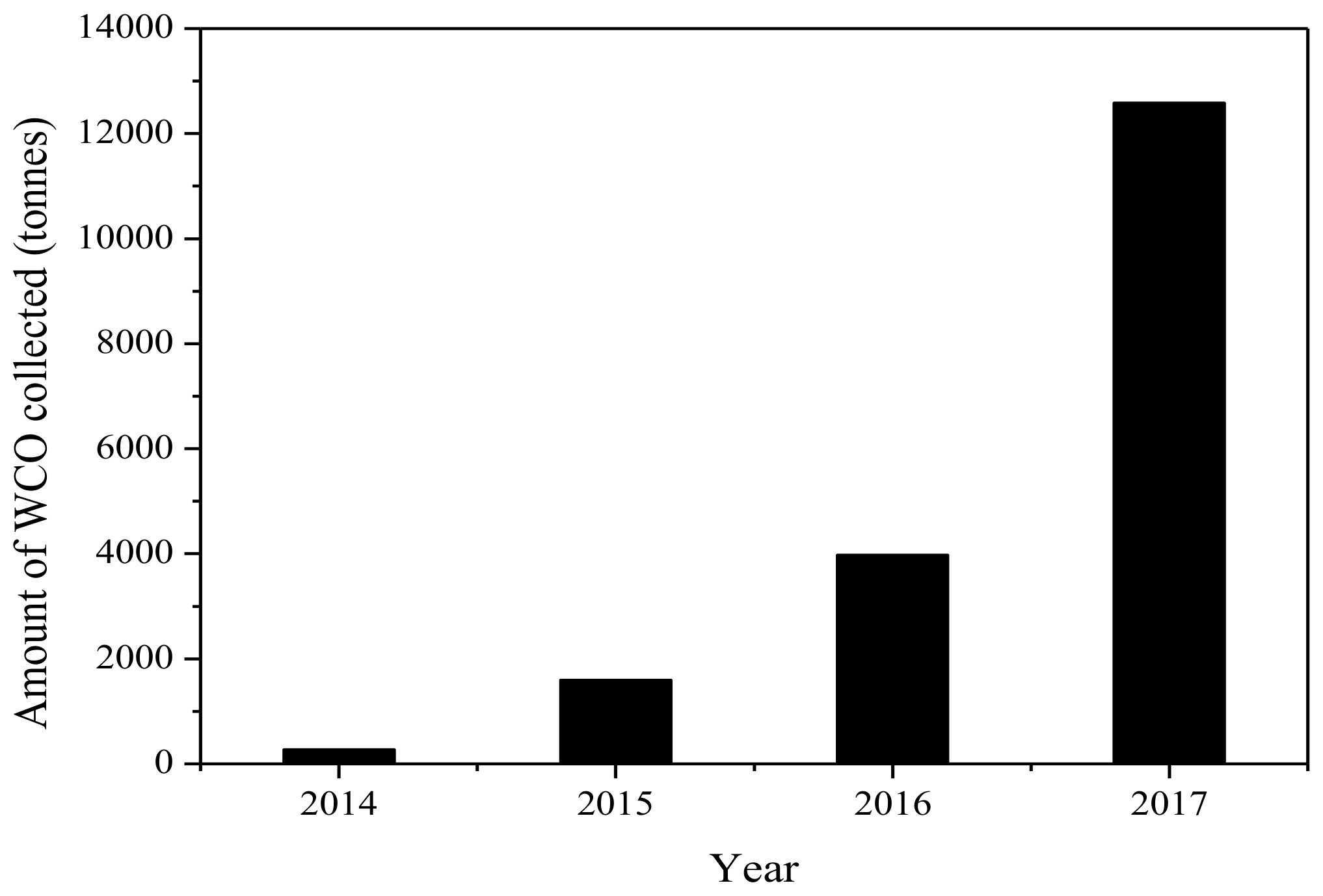

3.2. Waste Cooking Oil (WCO) Recycling Policies in Taiwan

- -

- Chain fast-food or restaurants (including branches and franchises) with a total capital of over NT$25 million.

- -

- Food manufacturers with a total capital of over NT$2.5 million.

- -

- Hotels (including branches) having more than 100 guest rooms.

4. Available Utilization of Waste Cooking Oil (WCO)

4.1. Biodiesel

4.2. Fuel Oils

4.3. Non-Fuel Related Uses

5. Conclusions and Prospects

Funding

Conflicts of Interest

References

- Gunstone, F.D. Composition and Properties of Edible Oils. In Edible Oil Processing, 2nd ed.; Hamm, W., Hamilton, R.J., Calliauw, G., Eds.; John Wiley & Sons: Oxford, UK, 2013; pp. 1–40. [Google Scholar]

- Wee, H.M.; Budiman, S.D.; Su, L.C.; Chang, M.; Chen, R. Responsible supply chain management—An analysis of Taiwanese gutter oil scandal using the theory of constraint. Int. J. Logist. Res. Appl. 2016, 19, 380–394. [Google Scholar] [CrossRef]

- Karmee, S.K. Fuel not food—Towards sustainable utilization of gutter oil. Biofuels 2017, 8, 339–7346. [Google Scholar] [CrossRef]

- Tsai, W.T.; Chou, Y.H.; Lin, C.M.; Hsu, H.C.; Lin, K.Y.; Chiu, C.S. Perspectives on resource recycling from municipal solid waste in Taiwan. Resour. Policy 2007, 32, 69–79. [Google Scholar] [CrossRef]

- Young, C.Y.; Ni, S.P.; Fan, K.S. Working towards a zero waste environment in Taiwan. Waste Manag. Res. 2009, 28, 236–244. [Google Scholar] [CrossRef] [PubMed]

- Tsai, W.T.; Lin, C.C.; Yeh, C.W. An analysis of biodiesel fuel from waste edible oil in Taiwan. Renew. Sustain. Energy Rev. 2007, 11, 838–857. [Google Scholar] [CrossRef]

- Panadare, D.C.; Rathod, V.K. Applications of waste cooking oil other than biodiesel: A review. Iran. J. Chem. Eng. 2015, 12, 55–76. [Google Scholar]

- Zhang, Y.; Dube, M.; McLean, D.; Kates, M. Biodiesel production from waste cooking oil. 1. Process design and technological assessment. Bioresour. Technol. 2003, 89, 1–13. [Google Scholar] [CrossRef]

- Kulkarni, M.G.; Dalai, A.K. Waste cooking oil: An economical source for biodiesel. Ind. Eng. Chem. Res. 2006, 45, 2901–2913. [Google Scholar] [CrossRef]

- Chhetri, A.B.; Watts, K.C.; Islam, M.R. Waste cooking oil as an alternate feedstock for biodiesel production. Energies 2008, 1, 3–18. [Google Scholar] [CrossRef]

- Math, M.C.; Kumar, S.P.; Chetty, S.V. Technologies for biodiesel production from used cooking oil—A review. Energy Sustain. Dev. 2010, 14, 339–345. [Google Scholar] [CrossRef]

- Singhabhandhu, A.; Tezuka, T. Prospective framework for collection and exploitation of waste cooking oil as feedstock for energy conversion. Energy 2010, 35, 1839–1847. [Google Scholar] [CrossRef]

- Balat, M. Potential alternatives to edible oils for biodiesel production—A review of current work. Energy Convers. Manag. 2011, 52, 1479–1492. [Google Scholar] [CrossRef]

- De Araujo, C.D.M.; de Andrade, C.C.; de Souza e Silva, E.; Dupas, F.A. Biodiesel production from used cooking oil: A review. Renew. Sustain. Energy Rev. 2013, 27, 445–452. [Google Scholar] [CrossRef]

- Mazubert, A.; Poux, M.; Aubin, J. Intensified processes for FAME production from waste cooking oil: A technological review. Chem. Eng. J. 2013, 233, 201–223. [Google Scholar] [CrossRef]

- Sheinbaum-Pardo, C.; Calderon-Irazoque, A.; Ramirez-Suarez, M. Potential of biodiesel from waste cooking oil in Mexico. Biomass Bioenergy 2013, 56, 230–238. [Google Scholar] [CrossRef]

- Talebian-Kiakalaieh, A.; Amin, N.A.S.; Mazaheri, H. A review on novel processes of biodiesel production from waste cooking oil. Appl. Energy 2013, 104, 683–710. [Google Scholar] [CrossRef]

- Yaakob, Z.; Mohammad, M.; Alherbawi, M.; Alam, Z.; Sopia, K. Overview of the production of biodiesel from Waste cooking oil. Renew. Sustain. Energy Rev. 2013, 18, 184–193. [Google Scholar] [CrossRef]

- Cordero-Ravelo, V.; Schallenberg-Rodriguez, J. Cordiodiesel production as a solution to waste cooking oil (WCO) disposal. Will any type of WCO do for a transesterification process? A quality assessment. J. Environ. Manag. 2018, 228, 117–129. [Google Scholar] [CrossRef]

- Sahar; Sadaf, S.; Iqbal, J.; Ullah, I.; Bhatti, H.N.; Nouren, S.; Habib-ur-Rehman; Nisar, J.; Iqbal, M. Biodiesel production from waste cooking oil: An efficient technique to convert waste into biodiesel. Sustain. Cities Soc. 2018, 41, 220–226. [Google Scholar] [CrossRef]

- Zhang, H.; Ozturk, U.A.; Zhou, D.; Qiu, Y.; Wu, Q. How to increase the recovery rate for waste cooking oil-to-biofuel conversion: A comparison of recycling modes in China and Japan. Ecol. Indic. 2015, 51, 146–150. [Google Scholar] [CrossRef]

- Laws and Regulation Retrieving System (Environmental Protection Administration, Taiwan). Available online: https://oaout.epa.gov.tw/law/EngLawContent.aspx?lan=E&id=174 (accessed on 10 February 2019).

- Tchobanoglous, G.; Theisen, H.; Vigil, S.A. Integrated Solid Waste Management: Engineering Principles and Management Issues; McGraw-Hill: New York, NY, USA, 1993; pp. 39–68. [Google Scholar]

- Rhyner, C.R.; Schwartz, L.J.; Wenger, R.B.; Kohrell, M.G. Waste Management and Resource Recovery; CRC Press: Boca Raton, FL, USA, 1995; pp. 26–34. [Google Scholar]

- Fan, K.S.; Lin, C.H.; Chang, T.C. Management and performance of Taiwan’s waste recycling fund. J. Air Waste Manag. Assoc. 2005, 55, 574–582. [Google Scholar] [CrossRef] [PubMed]

- Sachs, N. Planning the funeral at the birth: Extended producer responsibility in the European Union and the United States. Harv. Environ. Law Rev. 2006, 30, 51–98. [Google Scholar]

- Gupt, Y.; Sahay, S. Review of extended producer responsibility: A case study approach. Waste Manag. Res. 2015, 33, 595–611. [Google Scholar] [CrossRef] [PubMed]

- Environmental Protection Administration (EPA, Taiwan). Yearbook of Environmental Protection Statistics 2017; EPA: Taipei, Taiwan, 2018. [Google Scholar]

- Elder, M.; Hayashi, S. A Regional Perspective on Biofuels in Asia. In Biofuels and Sustainability; Takeuchi, K., Shiroyama, H., Saito, O., Matsuura, M., Eds.; Springer: Tokyo, Japan, 2018; pp. 223–246. [Google Scholar]

- Hoekman, S.K.; Robbins, C. Review of the effects of biodiesel on NOx emissions. Fuel Process. Technol. 2012, 96, 237–249. [Google Scholar] [CrossRef]

- Susmozas, A.; Iribarren, D.; Dufour, J. Assessing the life-cycle performance of hydrogen production via biofuel reforming in Europe. Resources 2015, 4, 398–411. [Google Scholar] [CrossRef]

- Asian-Pacific Economic Cooperation (APEC). Establishment of the Guidelines for the Development of Biodiesel Standards in the APEC Region; APEC: Singapore, 2009. [Google Scholar]

- Wang, T. Soybean Oil. In Vegetable Oils in Food Technology: Composition, Properties, and Uses; Gunstone, F.D., Ed.; CRC Press: Boca Raton, FL, USA, 2002; pp. 18–58. [Google Scholar]

- Chen, C.Y.; Lee, W.J.; Mwangi, J.K.; Wang, L.C.; Wu, J.L.; Lin, S.L. Reduction of persistent organic pollutant emissions during incinerator start-up. Air Air Qual. Res. 2017, 17, 899–912. [Google Scholar] [CrossRef]

- Van Ruth, S.M.; Rozijn, M.; Koot, A.; Perez Garcia, R.; van der Kamp, H.; Codony, R. Authentication of feeding fats: Classification of animal fats, fish oils and recycled cooking oils. Anim. Feed Sci. Technol. 2010, 155, 65–73. [Google Scholar] [CrossRef]

- Sanaguano, H.; Tigre-Leon, A.; Bayas-Morejon, I.F. Use of waste cooking oil in the manufacture of soaps. Int. J. Ecol. Dev. 2018, 33, 19–27. [Google Scholar]

- Li, W.; Wang, X. Bio-lubricants derived from waste cooking oil with improved oxidation stability and low-temperature properties. J. Oleo Sci. 2015, 64, 367–374. [Google Scholar] [CrossRef]

- Kumar, S.; Negi, S. Transformation of waste cooking oil into C-18 fatty acids using a novel lipase produced by Penicillium chrysogenum through solid state fermentation. 3 Biotech 2015, 5, 847–851. [Google Scholar] [CrossRef]

| Location | Company No. | Reuse Method | Reuse Treatment Capacity (Tonne/Month) |

|---|---|---|---|

| Northern Taiwan | A | Feedstock for biodiesel Feedstock for stearic acid Feedstock for fatty acid methyl ester (blending with fuel oil) | 4800 |

| B | Feedstock for stearic acid | 600 | |

| Central Taiwan | C | Feedstock for biodiesel | 162.4 |

| D | Feedstock for biodiesel Feedstock for fatty acid methyl ester (blending with fuel oil) | 3000 | |

| Southern Taiwan | E | Feedstock for biodiesel Feedstock for fatty acid methyl ester (blending with fuel oil) | 1803.1 |

| F | Feedstock for biodiesel Feedstock for fatty acid methyl ester (blending with fuel oil) | 2600 | |

| G | Feedstock for soap | 520 | |

| H | Feedstock for soap | 80 |

| Property | Units | CNS-15072 (Taiwan) | EN 14214 (Europe) | ||

|---|---|---|---|---|---|

| Lower Limit | Upper Limit | Lower Limit | Upper Limit | ||

| Ester content | %(m/m) | 96.5 | - | 96.5 | - |

| Density at 15 °C | kg/m3 | 860 | 900 | 860 | 900 |

| Viscosity at 40 °C | mm2/s | 3.5 | 5.0 | 3.5 | 5.0 |

| Flash point | °C | 120 | - | 101 | - |

| Sulfur content | mg/kg | - | 10 | - | 10 |

| Carbon residue (at 10% distillation residue) | %(m/m) | - | 0.3 | - | 0.3 |

| Cetane Number | - | 51.0 | - | 51.0 | - |

| Sulfated ash content | %(m/m) | - | 0.02 | - | 0.02 |

| Water content | mg/kg | - | 500 | - | 500 |

| Total contamination | mg/kg | - | 24 | - | 24 |

| Copper band corrosion (3 h/50 °C) | rating | Class 1 | Class 1 | ||

| Oxidation stability, 110 °C | hours | 6 | - | 6 | - |

| Acid value | mg KOH/g | - | 0.5 | - | 0.5 |

| Iodine value | - | - | 120 | - | 120 |

| Linolenic acid methyl ester | %(m/m) | - | 12 | - | 12 |

| Polyunsaturated (≥4 Double bonds) methyl ester | %(m/m) | - | 1 | - | 1 |

| Methanol content | %(m/m) | - | 0.2 | - | 0.2 |

| Monoglyceride content | %(m/m) | - | 0.8 | - | 0.8 |

| Diglyceride content | %(m/m) | - | 0.2 | - | 0.2 |

| Triglyceride content | %(m/m) | - | 0.2 | - | 0.2 |

| Free glycerine | %(m/m) | - | 0.02 | - | 0.02 |

| Total glycerine | %(m/m) | - | 0.25 | - | 0.25 |

| Alkali Metals (Na + K) | mg/kg | - | 5 | - | 5 |

| Alkali Metals (Ca + Mg) | mg/kg | - | 5 | - | 5 |

| Phosphorus content | mg/kg | - | 10 | - | 10 |

| Cold filter plugging point (CFPP) | °C | - | 0 (B class) | - | +5~−26 2 |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsai, W.-T. Mandatory Recycling of Waste Cooking Oil from Residential and Commercial Sectors in Taiwan. Resources 2019, 8, 38. https://doi.org/10.3390/resources8010038

Tsai W-T. Mandatory Recycling of Waste Cooking Oil from Residential and Commercial Sectors in Taiwan. Resources. 2019; 8(1):38. https://doi.org/10.3390/resources8010038

Chicago/Turabian StyleTsai, Wen-Tien. 2019. "Mandatory Recycling of Waste Cooking Oil from Residential and Commercial Sectors in Taiwan" Resources 8, no. 1: 38. https://doi.org/10.3390/resources8010038

APA StyleTsai, W.-T. (2019). Mandatory Recycling of Waste Cooking Oil from Residential and Commercial Sectors in Taiwan. Resources, 8(1), 38. https://doi.org/10.3390/resources8010038