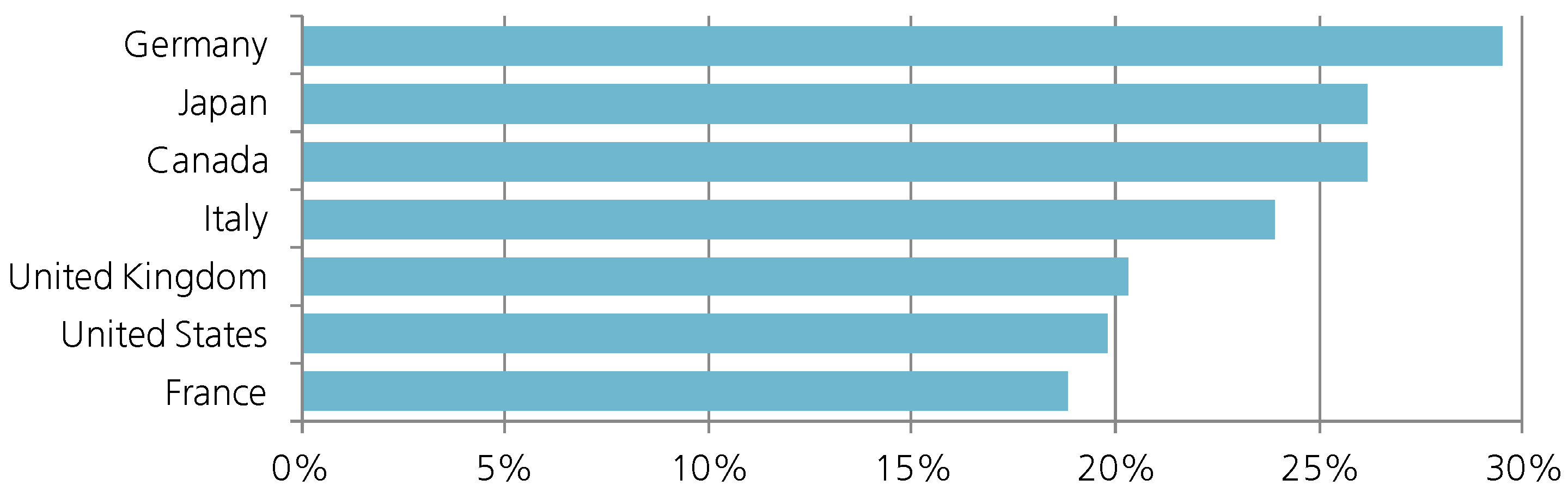

Taking the Step towards a More Dynamic View on Raw Material Criticality: An Indicator Based Analysis for Germany and Japan

Abstract

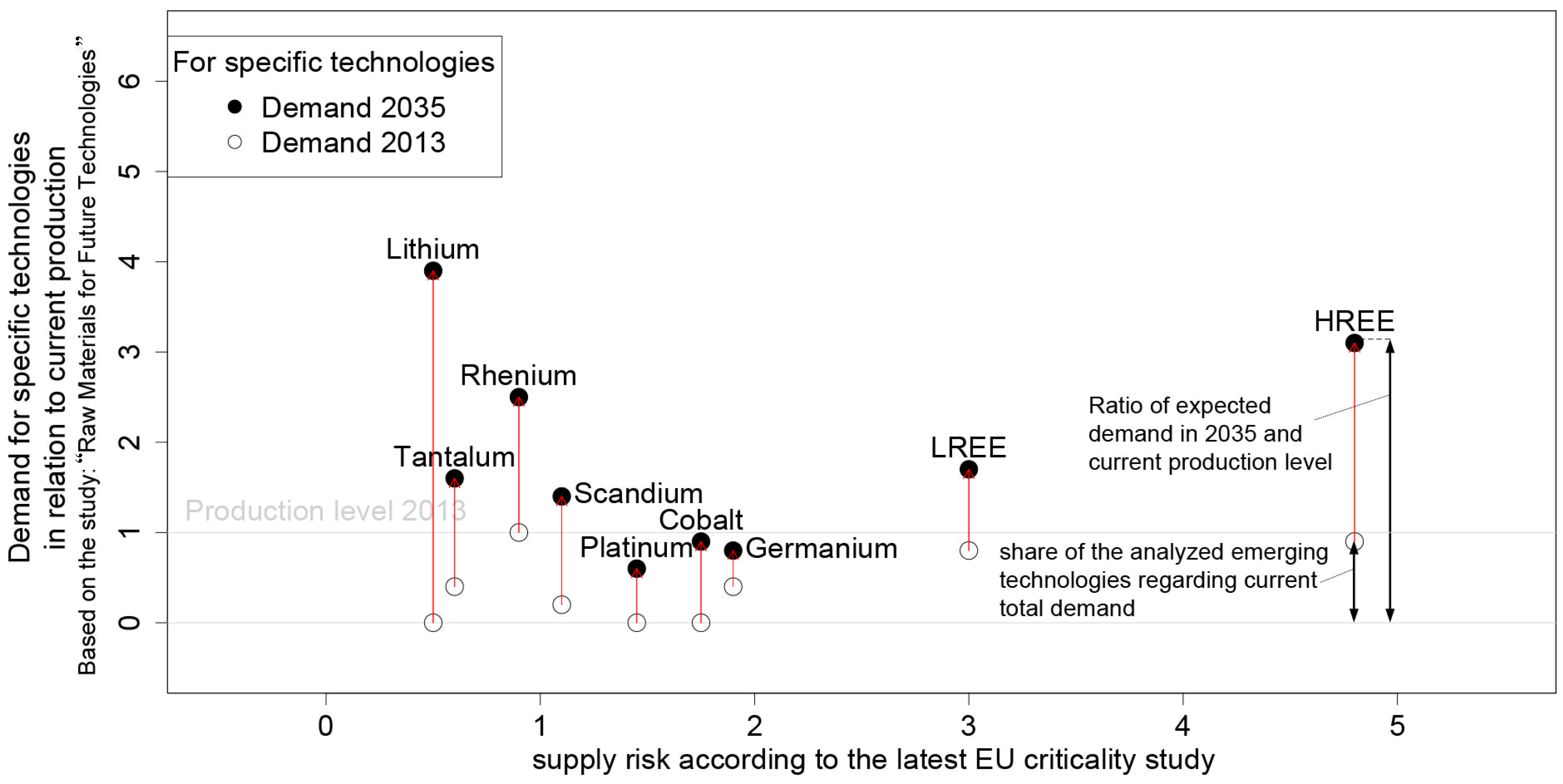

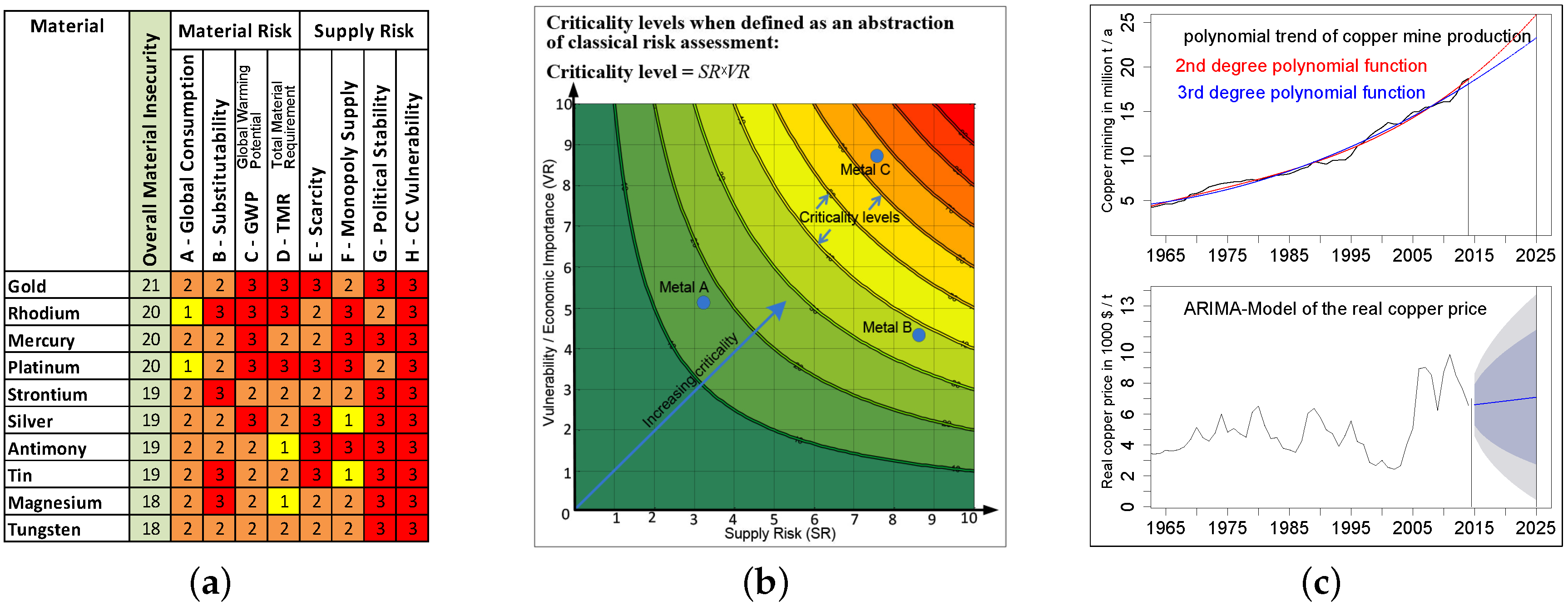

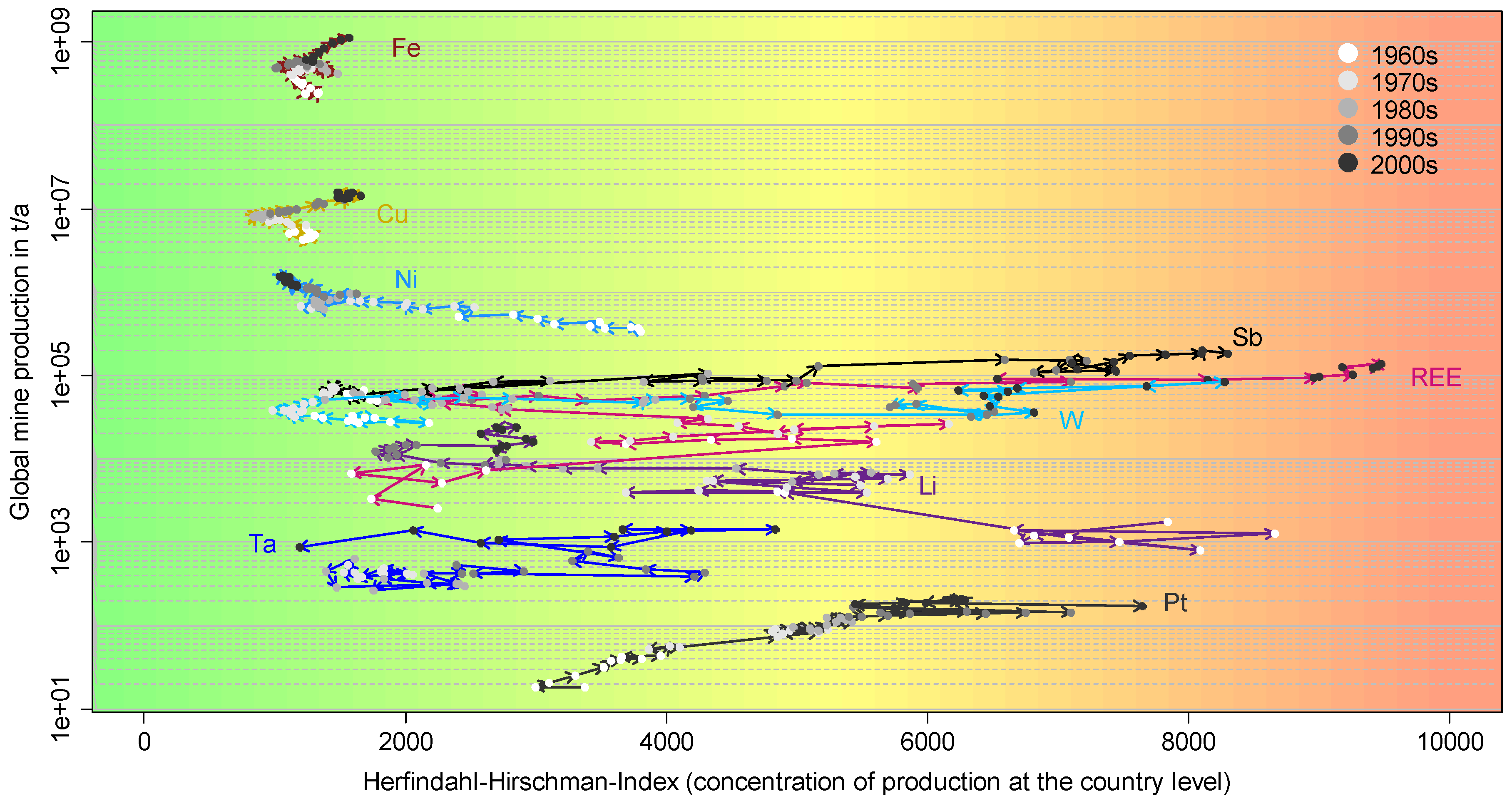

:1. Introduction

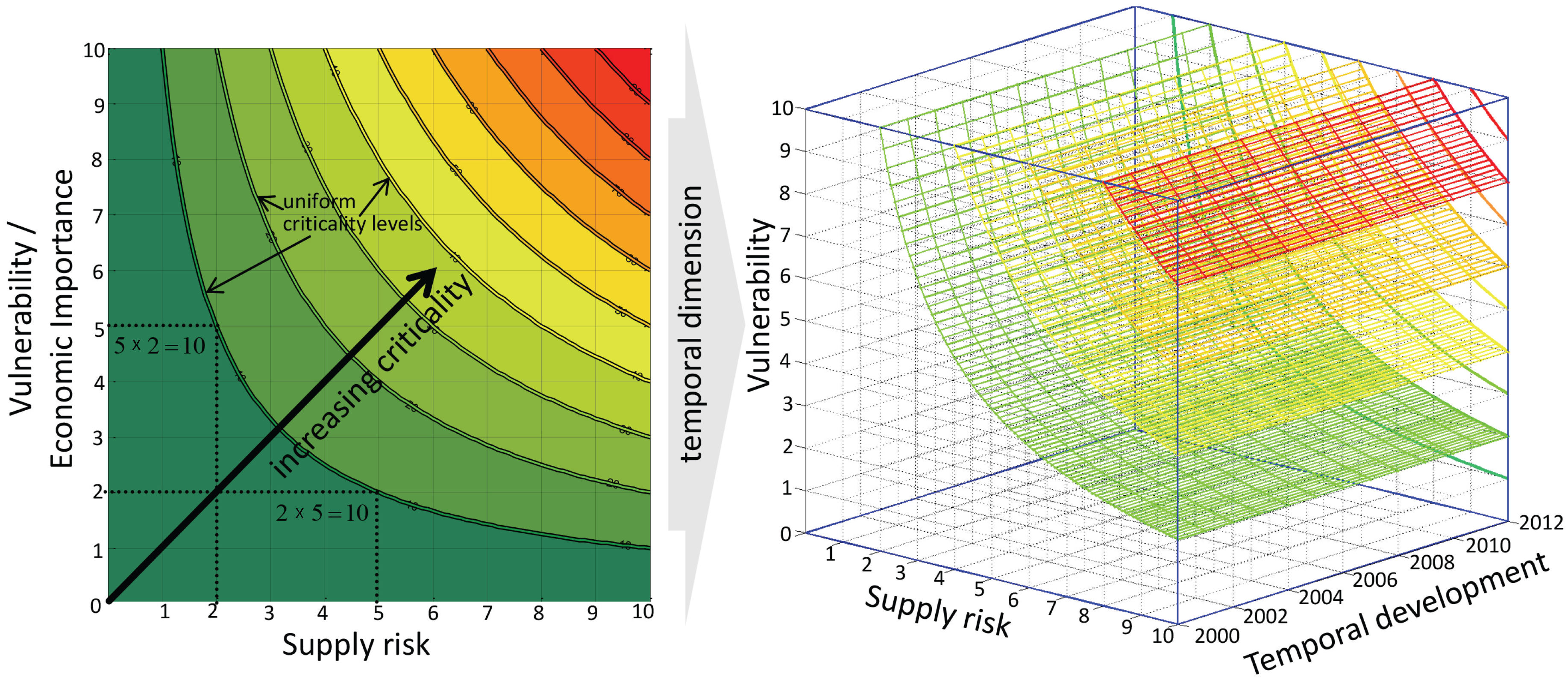

2. Methodology

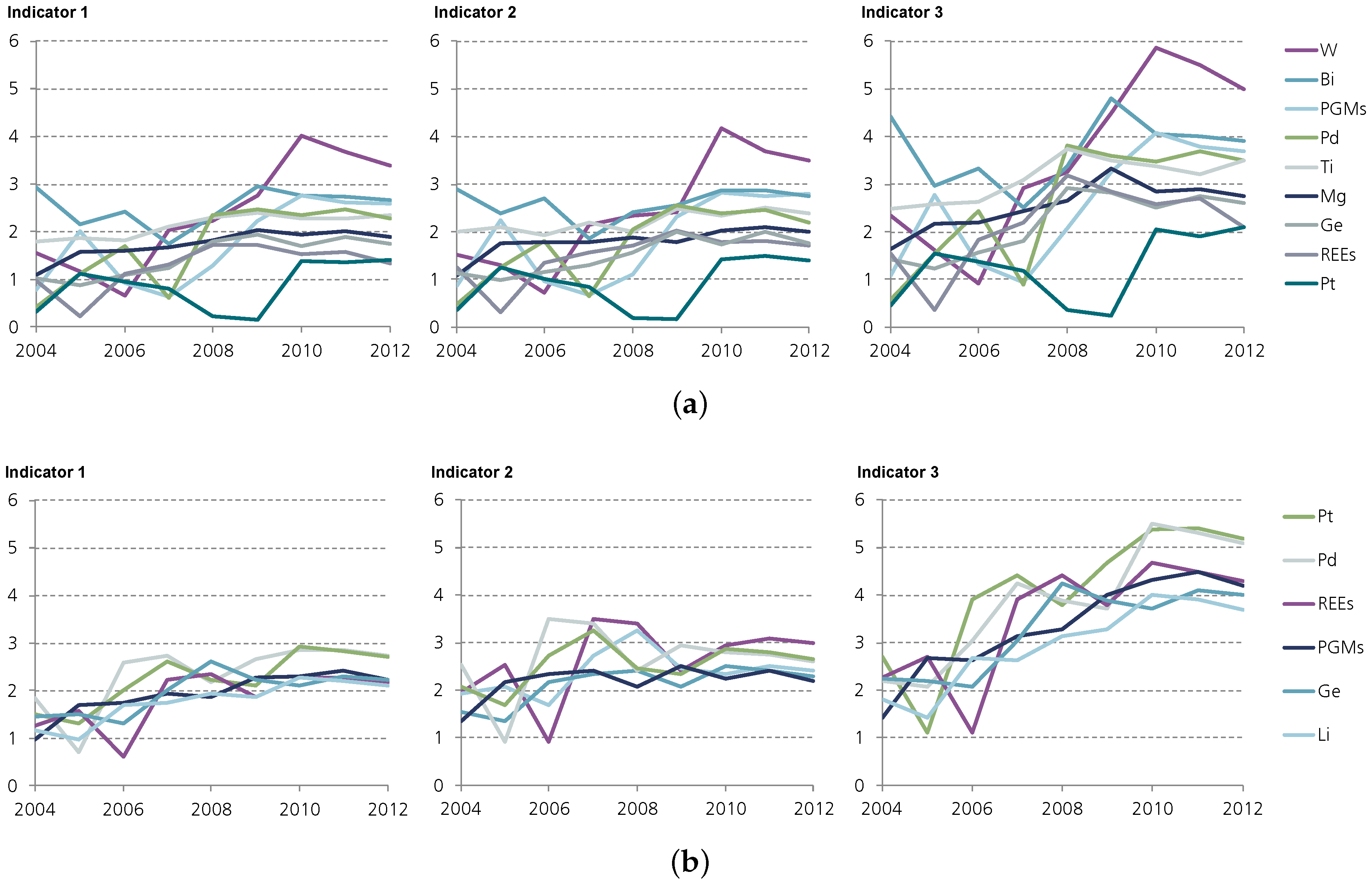

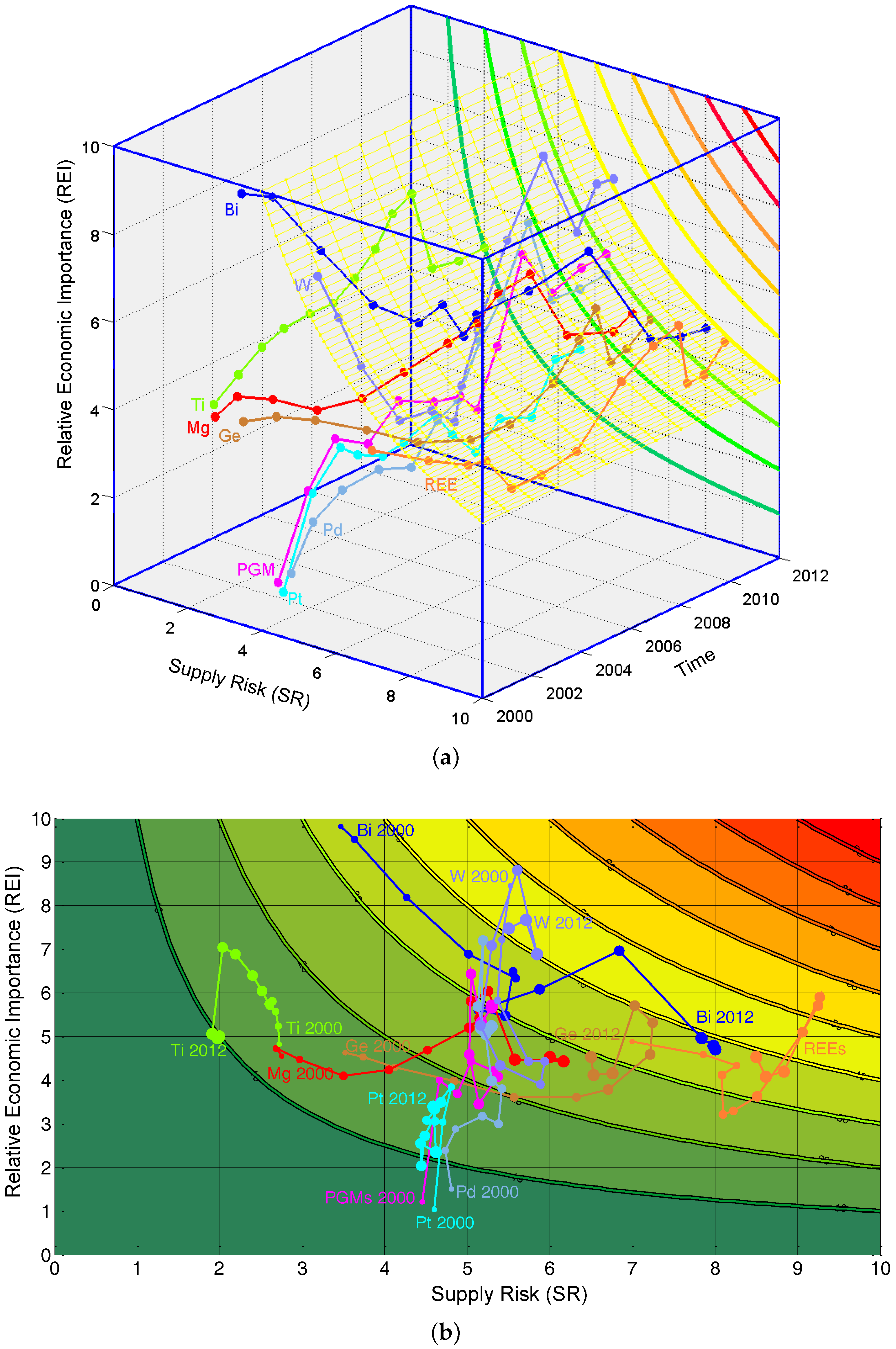

3. Results

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Erdmann, L.; Graedel, T.E. Criticality of Non-Fuel Minerals: A Review of Major Approaches and Analyses. Environ. Sci. Technol. 2011, 45, 7620–7630. [Google Scholar] [CrossRef] [PubMed]

- Speirs, J.; Houri, Y.; Gross, R. Materials Availability: Comparison of Material Criticality Studies: Methodologies and Results; Technical Report; UK Energy Research Centre: London, UK, 2013. [Google Scholar]

- Glöser, S.; Tercero Espinoza, L.; Gandenberger, C.; Faulstich, M. Raw material criticality in the context of classical risk assessment. Resour. Policy 2015, 44, 35–46. [Google Scholar] [CrossRef]

- Rosenau-Tornow, D.; Buchholz, P.; Riemann, A.; Wagner, M. Assessing the long-term supply risks for mineral raw materials—A combined evaluation of past and future trends. Resour. Policy 2009, 34, 161–175. [Google Scholar] [CrossRef]

- Tercero, L. The Role of Emerging Technologies in Rapidly Changing Demand for Mineral Raw Materials; Polinares Working Paper; European Commission: Brussels, Belgium, 2012. [Google Scholar]

- Morley, N.; Eatherley, D. Material Security—Ensuring Resource Availability for the UK Economy: UK Environment Agency and Department for Business Enterprise; Technical Report; Oakdene Hollins Ltd.: Aylesbury, UK, 2008. [Google Scholar]

- National Research Council (NRC). Minerals, Critical Minerals, and the U.S. Economy: Committee on Critical Mineral Impacts of the U.S. Economy; Technical Report; Committee on Earth Resources, National Research Council: Washington, DC, USA, 2008. [Google Scholar]

- Achzet, B.; Helbig, C. How to evaluate raw material supply risks—An overview. Resour. Policy 2013, 38, 435–447. [Google Scholar] [CrossRef]

- Scholz, R.W.; Wellmer, F.W. Approaching a dynamic view on the availability of mineral resources: What we may learn from the case of phosphorus? Glob. Environ. Chang. 2013, 23, 11–27. [Google Scholar] [CrossRef]

- Habib, K.; Wenzel, H. Reviewing resource criticality assessment from a dynamic and technology specific perspective—Using the case of direct-drive wind turbines. J. Clean. Prod. 2016, 112, 3852–3863. [Google Scholar] [CrossRef]

- Knoeri, C.; Wäger, P.A.; Stamp, A.; Althaus, H.J.; Weil, M. Towards a dynamic assessment of raw materials criticality: Linking agent-based demand—With material flow supply modelling approaches. Sci. Total Environ. 2013, 461–462, 808–812. [Google Scholar] [CrossRef] [PubMed]

- Glöser, S.; Faulstich, M. Quantitative Analysis of the Criticality of Mineral and Metallic Raw Materials Based on a System Dynamics Approach. In Proceedings of the 30th International Conference of the System Dynamics Society, St. Gallen, Switzerland, 22–26 July 2012.

- European Commission. Critical Raw Materials for the EU; Technical Report; European Commission (Enterprise and Industry): Brussels, Belgium, 2010. [Google Scholar]

- European Commission. Report on Critical Raw Materials for the EU; Technical Report; European Commission (Enterprise and Industry): Brussels, Belgium, 2014. [Google Scholar]

- Ciacci, L.; Nuss, P.; Reck, B.; Werner, T.; Graedel, T. Metal Criticality Determination for Australia, the US, and the Planet—Comparing 2008 and 2012 Results. Resources 2016, 5, 29. [Google Scholar] [CrossRef]

- Gandenberger, C.; Glöser, S.; Marscheider-Weidemann, F.; Ostertag, K.; Walz, R. Die Versorgung der Deutschen Wirtschaft mit Roh- und Werkstoffen für Hochtechnologien: Präzisierung und Weiterentwicklung der Deutschen Rohstoffstrategie: Innovationsreprot; Technical Report; Büro für Technikfolgen-Abschätzung beim Deutschen Bundestag (TAB): Berlin, Germany, 2012. [Google Scholar]

- Buijs, B.; Sievers, H.; Tercero Espinoza, L.A. Limits to the critical raw materials approach. Proc. ICE Waste Resour. Manag. 2012, 165, 201–208. [Google Scholar] [CrossRef]

- Olivetti, E.; Field, F.; Kirchain, R. Understanding dynamic availability risk of critical materials: The role and evolution of market analysis and modeling. MRS Energy Sustain. 2015, 2. [Google Scholar] [CrossRef]

- Mancini, L.; Sala, S.; Recchioni, M.; Benini, L.; Goralczyk, M.; Pennington, D. Potential of life cycle assessment for supporting the management of critical raw materials. Int. J. Life Cycle Assess. 2015, 20, 100–116. [Google Scholar] [CrossRef]

- Dewulf, J.; Blengini, G.A.; Pennington, D.; Nuss, P.; Nassar, N.T. Criticality on the international scene: Quo vadis? Resour. Policy 2016, 50, 169–176. [Google Scholar] [CrossRef]

- Graedel, T.E.; Reck, B.K. Six Years of Criticality Assessments: What Have We Learned So Far? J. Ind. Ecol. 2016, 20, 692–699. [Google Scholar] [CrossRef]

- Jin, Y.; Kim, J.; Guillaume, B. Review of critical material studies. Resour. Conserv. Recycl. 2016, 113, 77–87. [Google Scholar] [CrossRef]

- U.S. Department of Energy. Critical Materials Strategy: 2010; Technical Report; U.S. Department of Energy: Washington, DC, USA, 2010.

- U.S. Department of Energy. Critical Materials Strategy: 2011; Technical Report; U.S. Department of Energy: Washington, DC, USA, 2011.

- Erdmann, L.; Behrendt, S.; Feil, M. Kritische Rohstoffe für Deuschland: Identifikation aus Sicht Deutscher Unternehmen Wirtschaftlich Bedeutsamer Mineralischer Rohstoffe, Deren Versorgungslage Sich Mittel- bis Langfristig als Kritisch Erweisen könnte; Technical Report; IZT/Adelphi im Auftrag der KfW: Berlin, Germany, 2011. [Google Scholar]

- Duclos, S.J.; Otto, J.P.; Konitzer, D.G. Design in an Era of Constrained Resources. Mech. Eng. 2008, 132, 36–40. [Google Scholar]

- Nassar, N.T.; Barr, R.; Browning, M.; Diao, Z.; Friedlander, E.; Harper, E.M.; Henly, C.; Kavlak, G.; Kwatra, S.; Jun, C.; et al. Methodology of Metal Criticality Determination: Criticality of the Geological Copper Family. Environ. Sci. Technol. 2012, 46, 1071–1078. [Google Scholar] [CrossRef] [PubMed]

- Graedel, T.E.; Nassar, N.T. The criticality of metals: A perspective for geologists. Geol. Soc. Lond. Spec. Publ. 2013. [Google Scholar] [CrossRef]

- Nuss, P.; Harper, E.M.; Nassar, N.T.; Reck, B.K.; Graedel, T.E. Criticality of Iron and Its Principal Alloying Elements. Environ. Sci. Technol. 2014, 48, 4171–4177. [Google Scholar] [CrossRef] [PubMed]

- Harper, E.; Kavlal, G.; Burmeister, M.; Erbis, S.; Espinoza, V.; Nuss, P.; Graedel, T. Criticality of the geological zinc, tin, and lead family. J. Ind. Ecol. 2015, 19, 628–699. [Google Scholar] [CrossRef]

- Nassar, N.T.; Graedel, T.E.; Harper, E.M. By-product metals are technologically essential but have problematic supply. Sci. Adv. 2015, 1, e1400180. [Google Scholar] [CrossRef] [PubMed]

- Harper, E.M.; Diao, Z.; Panousi, S.; Nuss, P.; Eckelman, M.J.; Graedel, T.E. The criticality of four nuclear energy metals. Resour. Conserv. Recycl. 2015, 95, 193–201. [Google Scholar] [CrossRef]

- Panousi, S.; Harper, E.M.; Nuss, P.; Eckelman, M.J.; Hakimian, A.; Graedel, T.E. Criticality of Seven Specialty Metals. J. Ind. Ecol. 2015. [Google Scholar] [CrossRef]

- Hatayama, H.; Tahara, K. Criticality assessment of metals for Japan’s resource strategy. Mater. Trans. 2015, 56, 229–235. [Google Scholar] [CrossRef]

- Hatayama, H.; Tahara, K. Evaluating the sufficiency of Japan’s mineral resource entitlements for supply risk mitigation. Resour. Policy 2015, 44, 72–80. [Google Scholar] [CrossRef]

- Kalvig, P.; Clausen, R.J.; Fold, N.; Hanghøj, K. To what extent is Denmark vulnerable to mineral supply shortage? Geol. Surv. Den. Greenl. Bull. 2014, 2014, 95–98. [Google Scholar]

- Verband der Bayrischen Wirtschaft e.V. (vbw). Rohstoffsituation Bayern: Keine Zukunft ohne Rohstoffe: Strategien und Handlungsoptionen; Technical Report; Verband der Bayrischen Wirtschaft e.V. (vbw): München, Germany, 2009. [Google Scholar]

- Verband der Bayrischen Wirtschaft e.V. (vbw). Rohstoffversrogung Langfristig Sichern: Verband der Bayrischen Wirtschaft e.V.; Technical Report; Verband der Bayrischen Wirtschaft e.V. (vbw): München, Germany, 2012. [Google Scholar]

- Moss, R.L.; Tzimas, E.; Kara, H.; Willis, P.; Kooroshy, J. Critical Metals in Strategic Energy Technologies: Assessing Rare Metals as Supply Chain Bottlenecks in Low-Carbon Energy Technologies; Technical Report; JRC Scientific and Technical Reports; European Commission: Brussels, Belgium, 2011. [Google Scholar]

- Moss, R.L.; Tzimas, E.; Willis, P.; Arendorf, J.; Tercero Espinoza, L. Critical Metals in the Path towards the Decarbonisation of the EU Energy Sector: Assessing Rare Metals as Supply Chain Bottlenecks in Low-Carbon Energy Technologies; Technical Report; JRC Scientific and Technical Reports; European Commission: Brussels, Belgium, 2013. [Google Scholar]

- Knašytė, M.; Kliopova, I.; Staniškis, J.K. Economic Importance, Environmental and Supply Risks on Imported Resources in Lithuanian Industry. Environ. Res. Eng. Manag. 2012, 60. [Google Scholar] [CrossRef]

- AEA Technology. Raw Materials Critical to the Scottish Economy; Technical Report; Scottland and Nothern Ireland Forum for Environmental Research: Edinborough, Schottland, 2011. [Google Scholar]

- British Geological Survey (BGS). Risk List of the British Geological Survey; Technical Report; British Geological Survey: London, UK, 2012.

- Buchholz, P. Angebotskonzentration bei mineralischen Rohstoffen und Zwischenprodukten—potenzielle Preis- und Lieferrisiken: DERA-Rohstoffliste 2012. In DERA Rohstoffinformationen; Deutsche Rohstoffagentur (DERA): Hannover, Germany, 2014; Volume 24. [Google Scholar]

- Helbig, C.; Bradshaw, A.M.; Kolotzek, C.; Thorenz, A.; Tuma, A. Supply risks associated with CdTe and CIGS thin-film photovoltaics. Appl. Energy 2016, 178, 422–433. [Google Scholar] [CrossRef]

- Patiño, D.; Alberto, E. Metallic Mineral Resources in the Twenty-First Century. I. Historical Extraction Trends and Expected Demand. Natl. Resour. Res. 2015, 25, 71–90. [Google Scholar] [CrossRef]

- Mayer, H.; Gleich, B. Measuring Criticality of Raw Materials: An Empirical Approach Assessing the Supply Risk Dimension of Commodity Criticality. Natl. Resour. 2015, 6, 56–78. [Google Scholar] [CrossRef]

- Habib, K.; Wenzel, H. Exploring rare earths supply constraints for the emerging clean energy technologies and the role of recycling. J. Clean. Prod. 2014, 84, 348–359. [Google Scholar] [CrossRef]

- Roelich, K.; Dawson, D.A.; Purnell, P.; Knoeri, C.; Revell, R.; Busch, J.; Steinberger, J.K. Assessing the dynamic material criticality of infrastructure transitions: A case of low carbon electricity. Appl. Energy 2014, 123, 378–386. [Google Scholar] [CrossRef]

- Angerer, G.; Erdmann, L.; Marscheider-Weideman, F.; Scharp, M.; Luellmann, A.; Handke, V.; Marwede, M. Rohstoffe für Zukunftstechnologien: Einfluss des Branchenspezifischen Rohstoffbedarfs in Rohstoffintensiven Zukunftstechnologien auf Die Zukünftige Rohstoffnachfrage; Technical Report; Fraunhofer ISI and IZT, Fraunhofer Verlag Stuttgart: Berlin, Germany, 2009. [Google Scholar]

- Marscheider-Weidemann, F.; Langkau, S.; Hummen, T.; Erdmann, L.; Tercero Espinoza, L.A.; Angerer, G.; Marwede, M.; Benecke, S. Rohstoffe für Zukunftstechnologien 2016: Auftragsstudie. In DERA Rohstoffinformationen; Deutsche Rohstoffagentur (DERA): Hannover, Germany, 2016; Volume 28. [Google Scholar]

- Buchholz, P.; Liedtke, M.; Gernuks, M. Evaluating Supply Risk Patterns and Supply and Demand Trends for Mineral Raw Materials: Assessment of the Zinc Market. In Non-Renewable Resource Issues, International Year of Planet Earth; Sinding-Larsen, R., Wellmer, F.W., Eds.; Springer: Dordrecht, The Netherlands; London, UK, 2010; pp. 157–181. [Google Scholar]

- Buchert, M.; Schüler, D.; Bleher, D.; Neurohr, N.; Hagelüken, L. Critical Metals for Future Sustainable Technologies and Their Recycling Potential: Sustainable Innovation and Technology Transfer Industrial Sector Studies; Technical Report; Öko Institut e.V.: Freiburg, Germany, 2009. [Google Scholar]

- Frondel, M.; Grösche, P.; Huchtemann, D.; Oberheitmann, A.; Peters, J.; Angerer, G.; Sartorius, C.; Buchholz, P.; Röhling, S.; Wagner, M. Trends der Angebots- und Nachfragesituation bei Mineralischen Rohstoffen; Technical Report; RWI, BGR, Fraunhofer ISI: Berlin, Germany, 2006. [Google Scholar]

- US Geological Survey (USGS). Mineral Yearbooks; Technical Report; US Geological Survey: Reston, VA, USA, 2016.

- Helbig, C.; Wietschel, L.; Thorenz, A.; Tuma, A. How to evaluate raw material vulnerability—An overview. Resour. Policy 2016, 48, 13–24. [Google Scholar] [CrossRef]

- Habib, K.; Hamelin, L.; Wenzel, H. A dynamic perspective of the geopolitical supply risk of metals. J. Clean. Prod. 2016, 133, 850–858. [Google Scholar] [CrossRef]

- Grupp, H. Messung und Erklärung des Technischen Wandels: Grundzüge einer Empirischen Innovationsökonomik; Springer: Berlin/Heidelberg, Germany, 1997. [Google Scholar]

- Bowen, H.P. On the theoretical interpretation of indices of trade intensity and revealed comparative advantage. Weltwirtschaftliches Arch. 1983, 119, 464–472. [Google Scholar] [CrossRef]

- Walz, R.; Marscheider-Weidemann, F. Technology-specific absorptive capacities for green technologies in Newly Industrialising Countries. Int. J. Technol. Glob. 2011, 5, 212–229. [Google Scholar] [CrossRef]

- Ostertag, K.; Sartorius, C.; Tercero Espinoza, L. Innovationsdynamik in rohstoffintensiven Produktionsprozessen. Chem. Ing. Tech. 2010, 82, 1893–1901. [Google Scholar] [CrossRef]

- Haglund, D.G. The new geopolitics of minerals. Political Geogr. Q. 1986, 5, 221–240. [Google Scholar] [CrossRef]

- Anderson, E.W.; Anderson, L.D. Strategic Minerals: Resource Geopolitics and Global Geo-Economics; Wiley: Chichester, West Sussex, UK; New York, NY, USA, 1998. [Google Scholar]

- National Science and Technology Council (NSTC). Assessment of Critical Minerals: Screening, Methodology and Initial Application; Technical Report; Subcommittee on Critical and Strategic Mineral Supply Chains of the Committee on Environment, Natural Resources, and Sustainability: Washington, DC, USA, 2016.

- Gemechu, E.D.; Helbig, C.; Sonnemann, G.; Thorenz, A.; Tuma, A. Import-based Indicator for the Geopolitical Supply Risk of Raw Materials in Life Cycle Sustainability Assessments. J. Ind. Ecol. 2016, 20, 154–165. [Google Scholar] [CrossRef]

- Müller, E.; Hilty, L.M.; Widmer, R.; Schluep, M.; Faulstich, M. Modeling Metal Stocks and Flows: A Review of Dynamic Material Flow Analysis Methods. Environ. Sci. Technol. 2014, 48, 2102–2113. [Google Scholar] [CrossRef] [PubMed]

- Glöser-Chahoud, S.; Pfaff, M.; Soulier, M. Modeling material flows, cumulative material demand and market dynamics of industrial metals within a system dynamics framework: An overview of concepts and exemplary models. In Proceedings of the 34th International Conference of the System Dynamics Society, Delft, The Netherlands, 17–21 July 2016; pp. 1–20.

| Method | Title (Year) | Commissioner and Reference |

|---|---|---|

| Concept of the criticality matrix | “Critical raw materials for the EU” (2010, 2014) | European Commission [13,14] |

| “Critical Materials Strategy” (2010, 2011) | U.S. Department of Energy [23,24] | |

| “Critcal raw materials for Germany” (2011) | KfW bank group [25] | |

| “Minerals, Critical Minerals, And the U.S. Economy” (2008) | National Research Council [7] | |

| “Design in an Era of Constrained Resources” (2008) | General Electric [26] | |

| “Criticality space” (Criticality matrix enhanced by the third dimension of “Environmental Impact”) | ||

| “Criticality of the Geological Copper Family / Iron and its Principal Alloying Elements / Geological Zinc, Tin and Lead Family / Criticality of the Rare Earth Elements / The criticality of four nuclear energy metals” (2012–2015) | Graedel et al., Yale University [27,28,29,30,31,32,33] | |

| Single risk index based on multi indicator aggregation | “Criticality Assessment of Metals for Japan’s Resource Strategy” (2015) | National Institute of Advanced Industrial Science and Technology, Japan [34] |

| “Evaluating the sufficiency of Japan’s mineral resource entitlements for supply risk mitigation” (2015) | National Institute of Advanced Industrial Science and Technology, Japan [35] | |

| “To what extent is Denmark vulnerable to mineral supply shortage?” (2014) | Geological Survey of Denmark and Greenland (GEUS) [36] | |

| “Raw material supply in Bavaria” (2009, 2012) | Bavarian industry association (vbw) [37,38] | |

| “Ensuring resource availability for the UK economy” (2008) | UK Environment Agency and BERR [6] | |

| “Critical Metals in Strategic Energy Technologies” (2011, 2013) | JRC European Commission [39,40] | |

| “Economic Importance, Environmental and Supply Risks on Imported Resources in Lithuanian Industry” (2012) | Kaunas University of Technology [41] | |

| “Raw materials critical to the Scottish economy” (2011) | Scottish Environment Protection Agency [42] | |

| “Risk list of the British Geological Survey (BGS)” (2012) | British Geological Survey (BGS) [43] | |

| “Raw materials list for Germany” (2012) | German Geological Survey (DERA) [44] | |

| Raw material or technology specific dynamic assessments based on scenario or econometric analyses | “Supply risks associated with CdTe and CIGS thin-film photovoltaics” (2016) | Augsburg University [45] |

| “Metallic Mineral Resources in the Twenty-First Century. Historical Extraction Trends and Expected Demand” (2015) | University of Georgia [46] | |

| “Measuring criticality of raw materials: an empirical approach assessing the supply risk dimension of commodity criticality” (2015) | Augsburg University [47] | |

| “Exploring rare earths supply constraints for the emerging clean energy technologies and the role of recycling” (2014) “Reviewing resource criticality assessment from a dynamic and technology specific perspective —using the case of direct-drive wind turbines” (2015) | University of Southern Denmark [10,48] | |

| “Assessing the dynamic material criticality of infrastructure transitions: A case of low carbon electricity” (2014) | University of Leeds [49] | |

| “Raw Materials for Future Technologies” (2009, 2016) | BMWI, BGR, DERA [50,51] | |

| “Assessing the long-term supply risks for mineral raw materials” (2009) “Evaluating supply risk patterns and supply and demand trends” (2012) | Volkswagen AG/BGR [4,52] | |

| “Critical Metals for Future Sustainable Technologies and their Recycling Potential” (2009) | UNEP [53] | |

| “Trends in supply and demand of mineral raw materials” (2008) | BMWI, BGR [54] | |

| RXA for country and technology :

| The RXA (Relative Export Activity) is an indicator that evaluates the degree of concentration of exports of a country regarding specific technologies or commodities, respectively. This indicator quantifies the share of exports of specific commodities regarding total exports of a country and compares this value to the share of the commodities in focus on total global trade:

|

| RCA for country and technology :

| The RCA (Revealed Competitive Advantage) additionally takes into account the export–import relations when analyzing the level of specialization in trade. Hence, this indicator further takes into account how well the domestic industry stands its ground when confronting the competition from international imports. The RCA is calculated from the country’s export/import ratio regarding a specific technology and the export/import ratio of all commodities in that country:

|

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Glöser-Chahoud, S.; Tercero Espinoza, L.; Walz, R.; Faulstich, M. Taking the Step towards a More Dynamic View on Raw Material Criticality: An Indicator Based Analysis for Germany and Japan. Resources 2016, 5, 45. https://doi.org/10.3390/resources5040045

Glöser-Chahoud S, Tercero Espinoza L, Walz R, Faulstich M. Taking the Step towards a More Dynamic View on Raw Material Criticality: An Indicator Based Analysis for Germany and Japan. Resources. 2016; 5(4):45. https://doi.org/10.3390/resources5040045

Chicago/Turabian StyleGlöser-Chahoud, Simon, Luis Tercero Espinoza, Rainer Walz, and Martin Faulstich. 2016. "Taking the Step towards a More Dynamic View on Raw Material Criticality: An Indicator Based Analysis for Germany and Japan" Resources 5, no. 4: 45. https://doi.org/10.3390/resources5040045

APA StyleGlöser-Chahoud, S., Tercero Espinoza, L., Walz, R., & Faulstich, M. (2016). Taking the Step towards a More Dynamic View on Raw Material Criticality: An Indicator Based Analysis for Germany and Japan. Resources, 5(4), 45. https://doi.org/10.3390/resources5040045