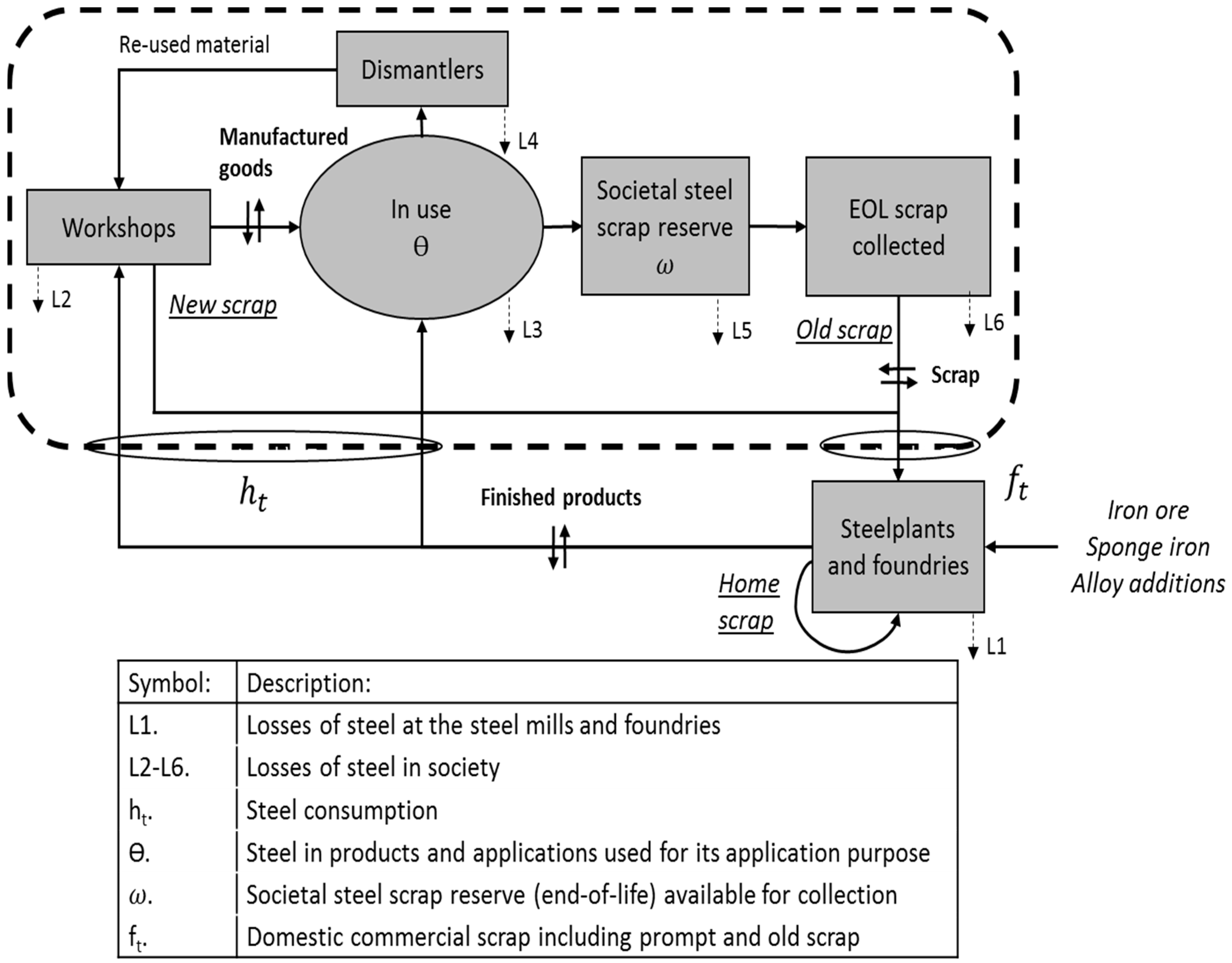

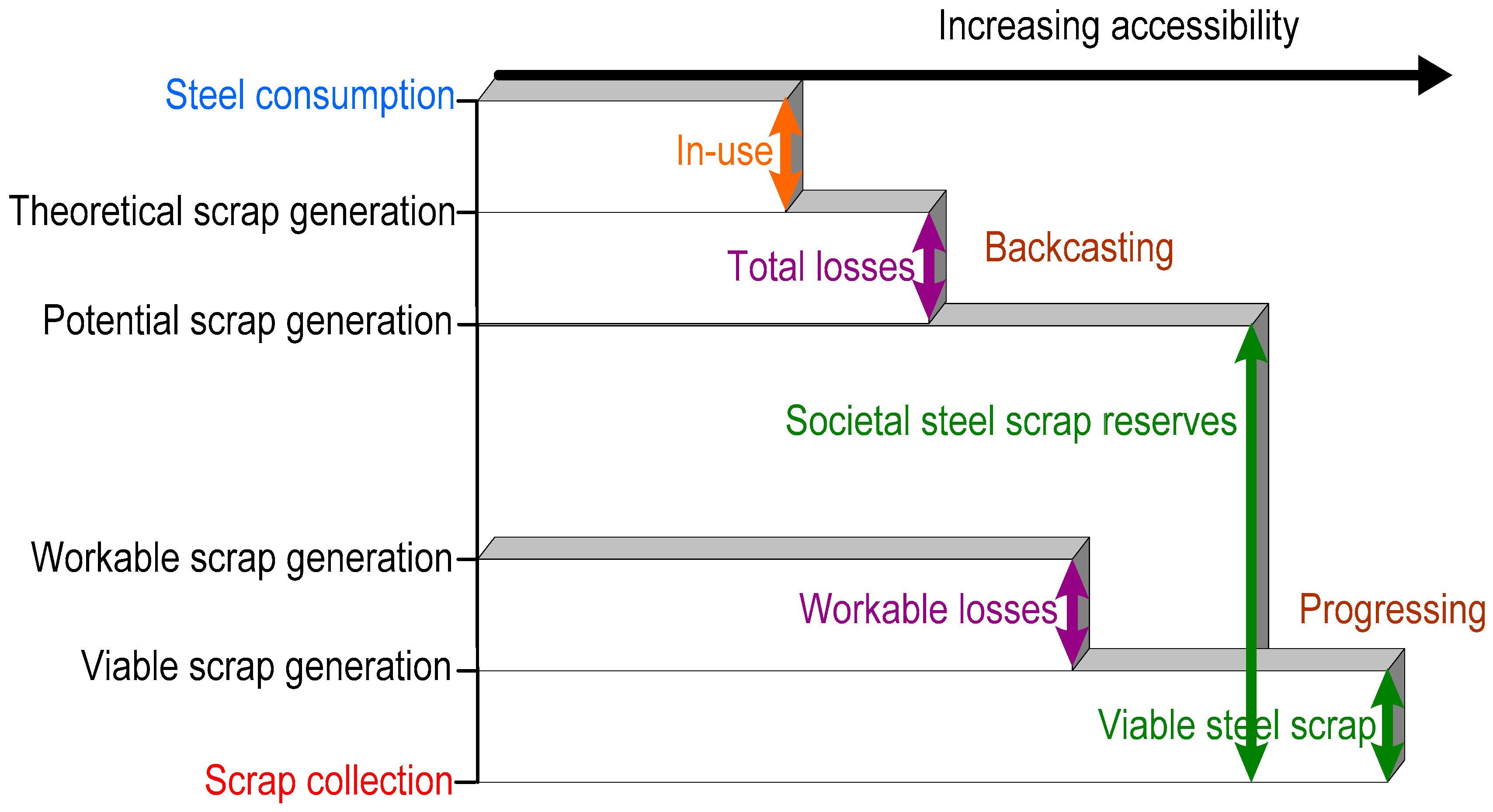

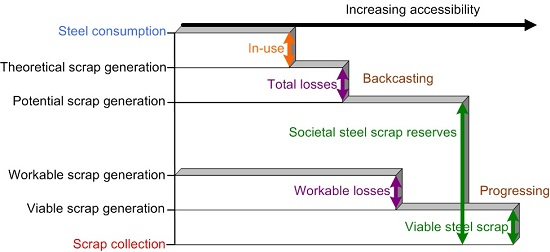

These quantities are given in the order of magnitudes and are referred to as the theoretical scrap generation (TSG), potential scrap generation (PSG), workable scrap generation (WSG), and viable scrap generation (VSG), as seen in

Figure 2. The graph in

Figure 2 illustrates the relation between the model results and the different phases of steel in society. Note that the quantities and the accessibilities are in order but not scaled. The difference between the steel consumption and the TSG represents the in-use steel. The difference between the TSG and PSG values represents the amount of losses, and the difference between the PSG and the scrap collection represents the societal steel scrap reserves, as seen in

Figure 2. The Progressing model calculates the lower limits on the corresponding quantities called the viable steel scrap and workable losses. The difference between the WSG and VSG values represents the workable losses and the difference between the VSG and the scrap collection represents the viable steel scrap amount. The above mentioned phases of steel are accessible in the same order, which is illustrated in the horizontal axis in

Figure 2. These amounts of steel scrap assets are recoverable based on probability due to the lifetime of steel data used. This indicates that the time duration of the steel consumption in society determines when the steel will become a societal steel scrap reserve, a loss, or a collected steel scrap amount. In comparison to natural resources, these quantities are not economically feasible amounts of commodities, but statistical amounts of metal scrap assets available for collection in society. Statistical refers to the scale parameters and distribution functions used in the models. The steel scrap reserves are thereby a probabilistic amount of steel scrap available for steelmaking at a given point in time.

The societal steel scrap reserves represent the amount of steel that has reached an EOL stage and which therefore is available for collection. The societal steel scrap reserve is the redundant amount of steel saturated in society which is not used for its application purpose but has not yet been collected for recycling purposes. This amount of steel scrap could potentially be recovered by increased scrap prices, capacity expansions of waste management facilities, improved collection systems, etc. The lower part of the societal steel scrap reserve is called the viable steel scrap amount. The viable steel scrap can be interpreted as the economically feasible amount of steel scrap available for collection. This amount of steel scrap can be interpreted as the scrap stock available at waste management companies and collection systems in society. This amount of steel scrap is the part of the societal steel scrap reserve that is more easily accessible for recycling purposes than the redundant steel scrap in products and applications in society.

The amount of losses are the steel consumption that has been redundant for more than a period of a lifetime of steel and that are thereby not recoverable based on time. Specifically, the societal steel scrap reserves that are not recovered over a longer period of time become losses. The amount of losses can be interpreted as the non-recoverable amount of steel which is not economically feasible to collect for recycling purposes. The total losses consist of the sum of the absolute losses and the workable losses. The amount of absolute losses will not be available as a resource for the steel industry. The workable losses represent the reversible amounts of losses. This quantity has been registered as a loss, which could potentially be recoverable in the future based on the implementation of new technologies and increased scrap prices. For example, workable losses could be steel inside landfills, which due to increased scrap prices and more efficient technologies could be economically feasible to recycle in the future. The workable losses are included in the total amount of losses.

3.1. The Swedish Societal Steel Scrap Reserves and Amounts of Losses

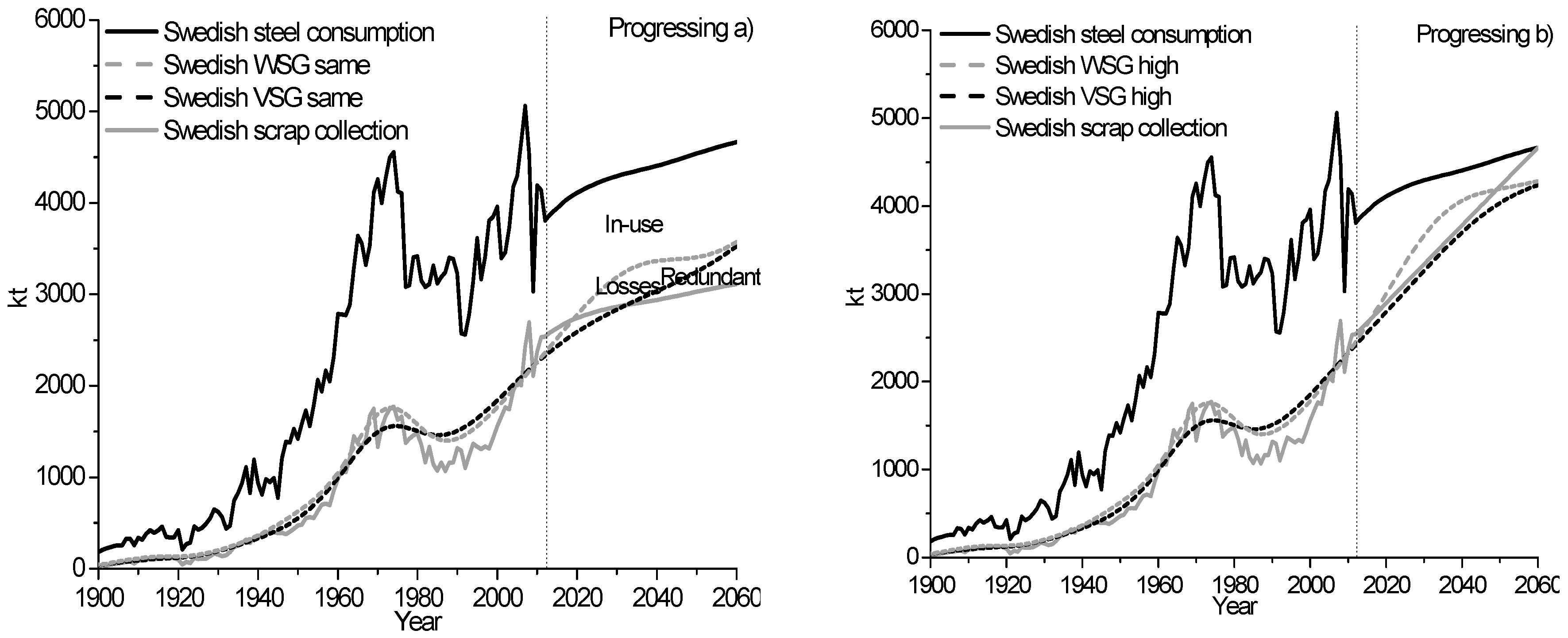

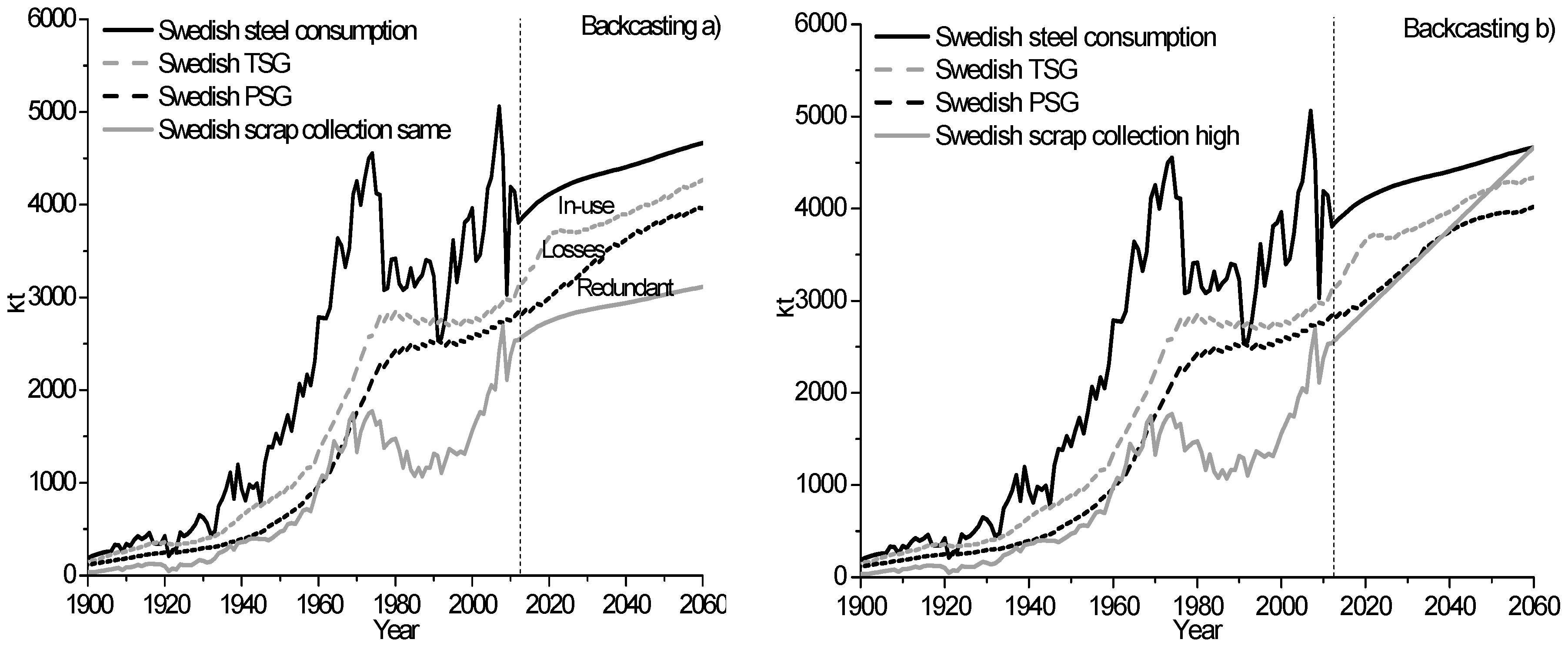

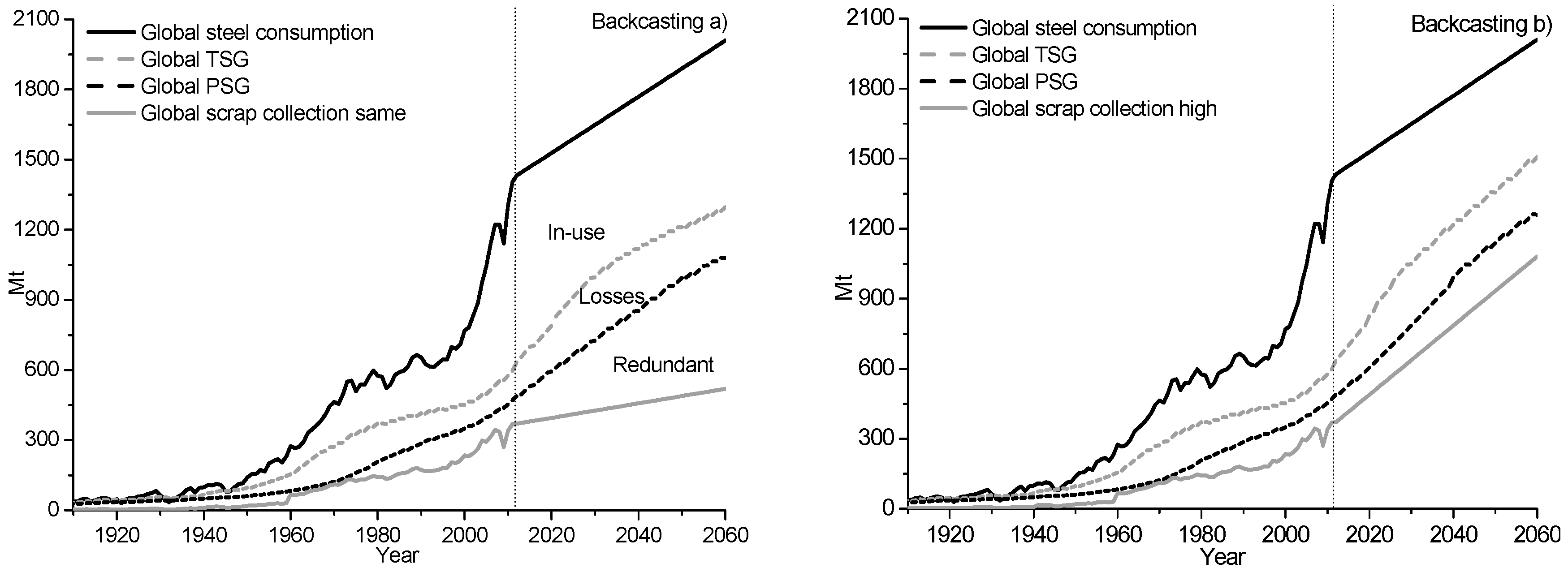

The Progressing and Backcasting model results for the Swedish steel consumption with historical data between 1900 and 2012 and for an outlook between 2013 and 2060 for a target value on the scrap collection rate and the same scrap collection rate as in 2012 are shown in

Figure 3 and

Figure 4. The outlook on the higher scrap collection rate, shown in

Figure 3 and

Figure 4b, are calculated as the steel scrap collection to reach the same level as the steel consumption in 2060. This outlook was used to evaluate if the Backcasting and Progressing models can be used to calculate the steel scrap generation as a function of the collection rate of steel scrap. Thereby, if the models are able to calculate robust forecasts on the available amounts of steel scrap.

The Progressing and Backcasting model results show that the adaptation of the curves between the steel scrap generations and the scrap collection data, trend-wise and area-wise, are highly dependent on the distribution function that is used. This is illustrated in

Figure 3 and

Figure 4. The steel scrap generations calculated with a normal distribution function follow the trend of the curve of the scrap collection, as shown in the graphs in

Figure 3. This is due to the fact that for a high bias distribution function, the probability of the outcome is more intense around the mean lifetime value. Furthermore, this indicates that the lifetime of the steel data calculated based on the volume correlation model is useful in DMFMs. This is due to the fact that the steel scrap generations are well adapted to the curve of the scrap collection by using the annual values on the lifetime of steel calculated based on the volume correlation model [

30]. Furthermore, the model results validate the volume correlation model as a new method for calculating the lifetime of steel on a continuous basis [

30].

The calculated values on the lifetime of steel are internal time-varying parameters. Thus, the Progressing and Backcasting models represent statistical models. These statistical models further contribute to a standardized way of obtaining consistent results. It should also be noted that the volume correlation model can be applied to continuous data series of any consistent stable material flow, e.g., fluid flows, energy units, patients under medication, etc.

The forecasted results based on the Progressing model between 2013 and 2060 show that the WSG and VSG seems to no longer be as well adapted to the curve of the scrap collection for a full lifetime of steel usage from the end data, see

Figure 3. This is due to the fact that the lifetime of steel usage data was put as a constant value, where no data could be calculated [

29]. This effect can be overcome in the future by further forecasting the input data on the steel consumption and scrap collection.

The historical results show that the societal steel scrap reserves and viable steel scrap were significantly higher between 1969 and 2010, as shown in

Figure 3 and

Figure 4. This can be explained by the implementation of an export ban on steel scrap between 1927 and 1993 in Sweden, which contributed to increased societal steel scrap reserves in society [

32]. The model results show that the societal steel scrap reserve was higher than the demand of steel scrap to supply the Swedish steel mills for over more than four decades. During this time period the steel scrap was not utilized and instead its share was replaced by iron ore to produce steel. For the Backcasting model results shown in

Figure 4, the societal steel scrap reserves are forecasted to be generated as losses around the year 2021. Specifically, about 662 kt per annum compared to 276 kt per annum in 2012. This is due to the large stock of steel scrap reserves in society. The results show that export bans to secure domestic supplies of scrap do also damage the internal market, due to increased amounts of losses. This suggests that to optimize recycling in society, export bans should be lifted.

The outlook for the Swedish steel consumption between 2013 and 2060 for two different scenarios with the same scrap collection rate as in 2012 and a higher scrap collection rate, reaching the same level as the steel consumption in 2060, is shown in

Figure 4. The results show that if the demand of steel scrap is kept at the same rate as in 2012, the societal steel scrap reserves and losses will increase significantly over the upcoming years. Thus, to utilize steel scrap, the collection rate of steel scrap has to be increased to compensate for the historical large amount of societal steel scrap reserve in society. Furthermore, the outlook of the high scrap collection rate shows that the forecasted demand of steel scrap exceeds the potential scrap generation in 2039. This shows that it is not possible that the available amounts of steel scrap would reach the same level as the steel consumption in 2060 in Sweden. More specifically, the forecasted high scrap collection value exceeds the limits of what the model considers as a sustainable value. This differs from economic price-driven models that calculate unlimited amounts of metal scrap assets, just if the demand would be high enough. This is due to the fact that they are not limited in availability due to the steel consumption in society. This indicates that for evaluating the metal scarcity, economic models are not sufficient enough. The present model results show that the Backcasting model can be used to evaluate sustainable outlooks on the available amounts of steel scrap. Sustainable outlook refers to optimizing the recycling rate without decreasing the lifetime of steel in society. These robust forecasts of the steel scrap generations can be used to ease future structural plans of steelmaking. Thereby, it is possible to keep the collection rate of steel scrap at a continuous high level.

The forecasted model results show different outputs on the TSG, PSG, WSG, and VSG values, dependent on the forecasted scrap collection value that was the same or higher than the value in 2012. This shows that the Backcasting and Progressing models are able to calculate the steel scrap generations as a function of the collection rate of steel scrap. This differs from previous DMFMs that have used adjustable parameters on sector-specific single value data on the lifetime of steel as the basis for the model predictions. Thereby, the forecasted steel scrap generation has reached the same level regardless of the increase in the demand of steel scrap over the years. This is due to an increased scrap collection that has not decreased the lifetime of steel data used in the previous DMFMs. More specifically, in previous models the input data of the lifetime of steel and distribution functions have been projected over the years, while the Progressing and Backcasting models are able to distinguish the interactions between the parameters on the recycling rate, lifetime of steel, and the in-use steel stock. The results show that the new models can be used to calculate robust forecasts on the long-term availability of steel scrap. This information is of importance when planning future installations of scrap consuming steelmaking mills and waste management facilities, for evaluations of future demands of steel to industrialize countries, as well as to calculate resource limitations associated with steelmaking.

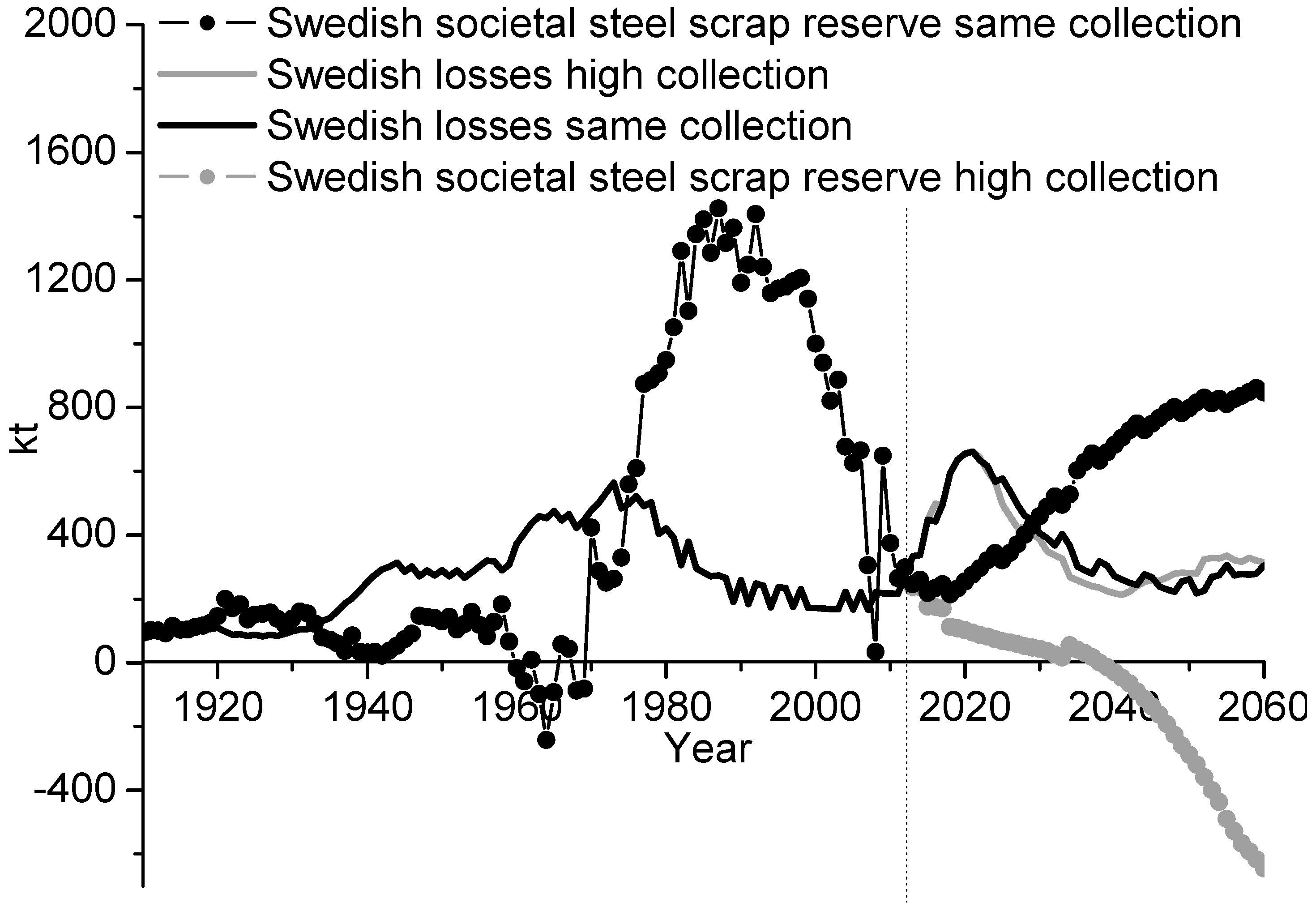

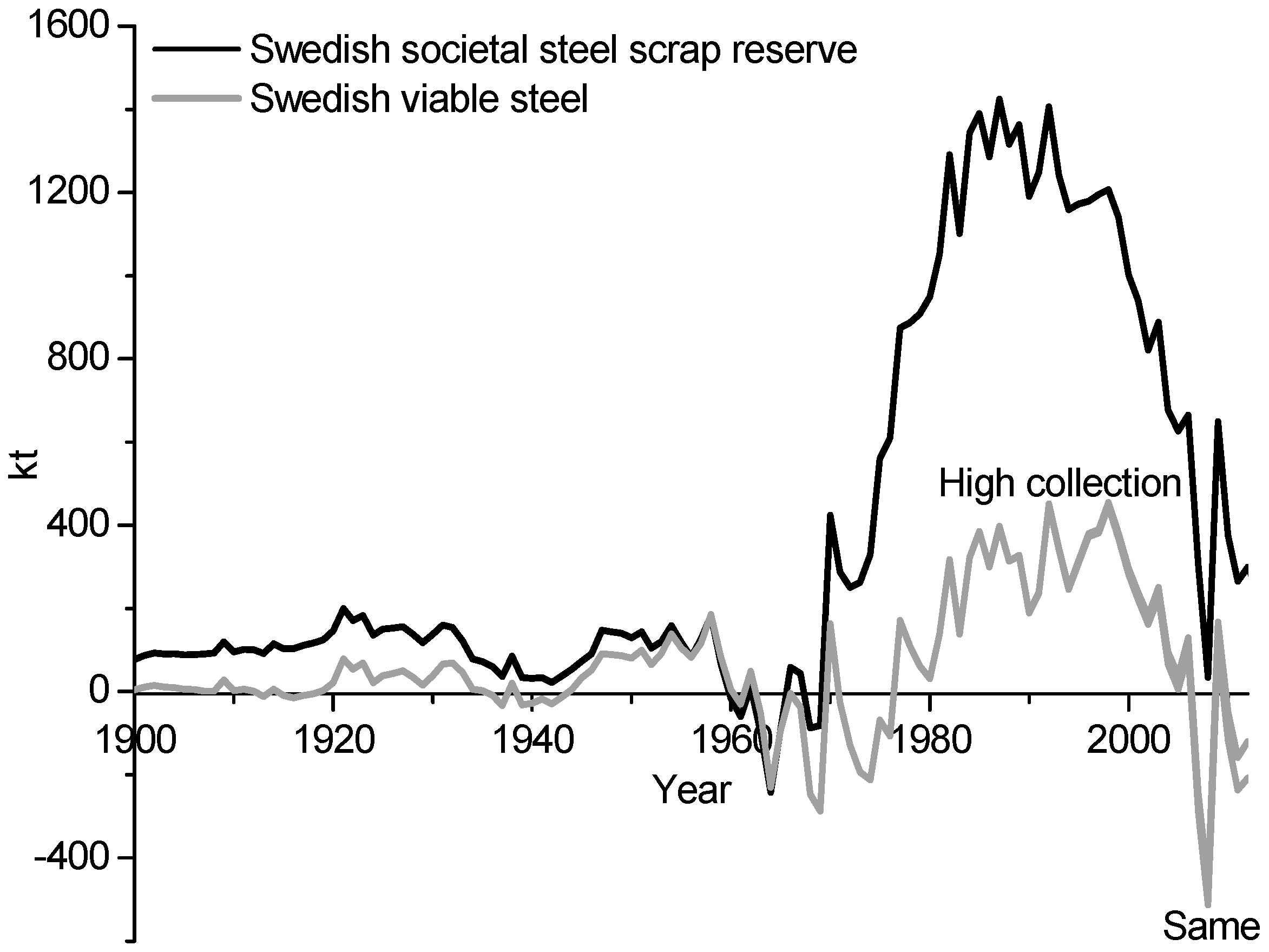

The annual quantities of the Swedish societal steel scrap reserves and amounts of losses are shown in

Figure 5. These quantities are calculated based on the Backcasting model and are taken from

Figure 4. The results show that the new model is able to segregate the non-recirculated amount of steel into the societal steel scrap reserves available for future collection and the amount of losses. This differs from previous material flow models that have not been able to distinguish the quantities apart based on statistics. Statistics refer to the scale parameters and distribution functions used in DMFMs. This is due to previous models that have used sector-specific single-value data on the lifetime of steel. Based on the model results, it is thereby possible to evaluate the potential of increasing the recycling of steel scrap in society. The figure shows that the most fluctuating quantity of the non-recovered amount of steel is the size of the societal steel scrap reserves. The results also show that the amount of losses are never below zero. The positive amount of losses indicates that the model follows the second law of thermodynamics. Specifically, the historical results show that the losses of steel reached the highest value of around 500 kt in 1975 and that they thereafter have decreased gradually to 277 kt in 2012. The decreased quantity of losses can be explained by increased installations of scrap consuming steelmaking facilities and the introduction of the continuous casting technique. These changes increased the demand of purchased steel scrap in the steelmaking mills. Furthermore, it can be explained by improved sorting techniques e.g., fragmentation facilities, that have increased the capacity of scrap production at the waste management companies.

The historical results also show that the societal steel scrap reserves had the highest value of around 1424 kt in 1987. Thereafter, the societal steel scrap reserves and losses have significantly decreased. This is due to the lifting of the export ban of steel scrap in 1993 in Sweden. Also, the model results show that the large amounts of societal steel scrap reserves will be generated as losses around year 2021. This is regardless if the forecasted scrap collection rate is the same or higher than it was in 2012. The model results demonstrate that the collection rate of steel scrap should be continuously high to decrease the amount of losses in society.

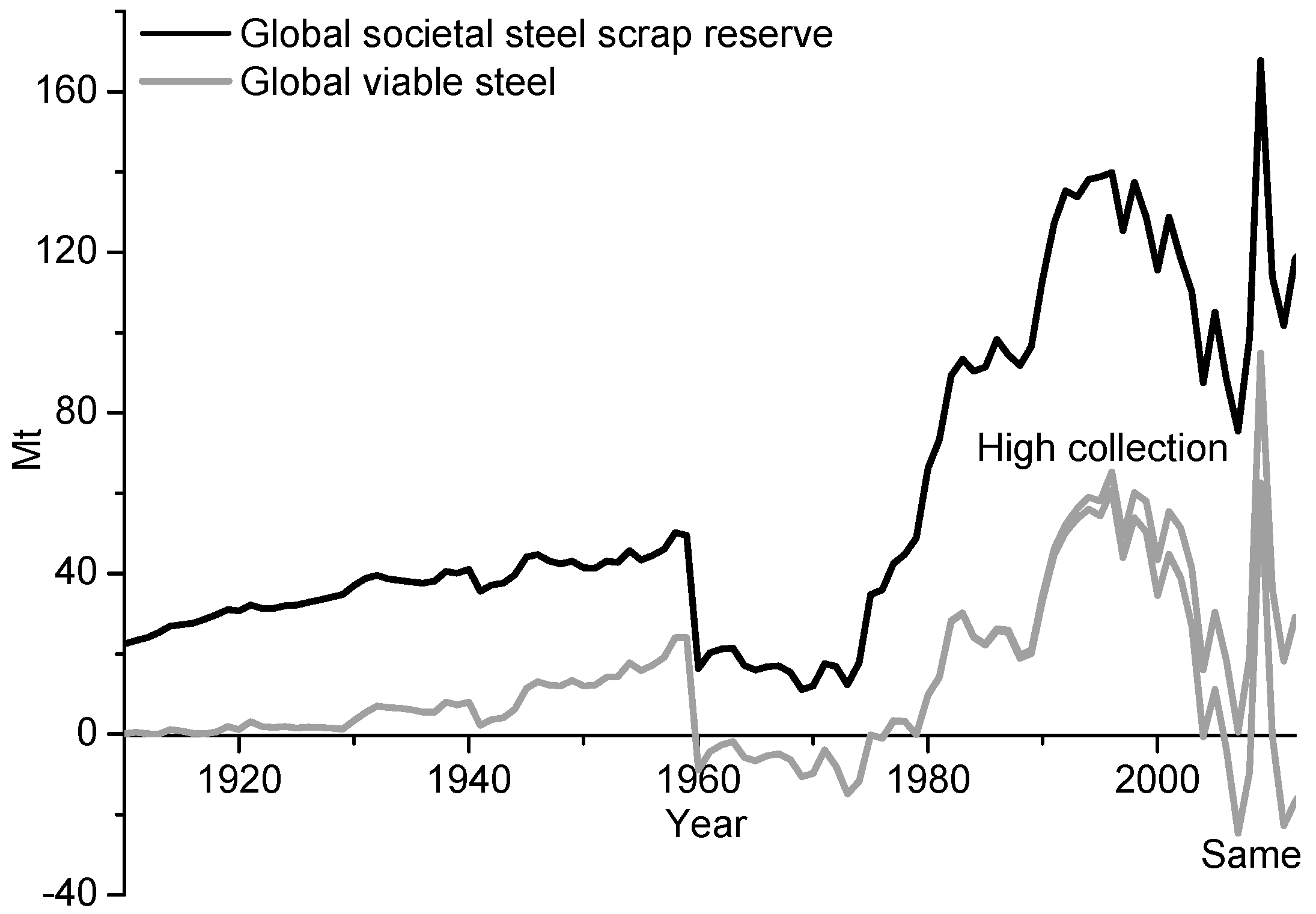

3.2. The Global Societal Steel Scrap Reserves and Amount of Losses

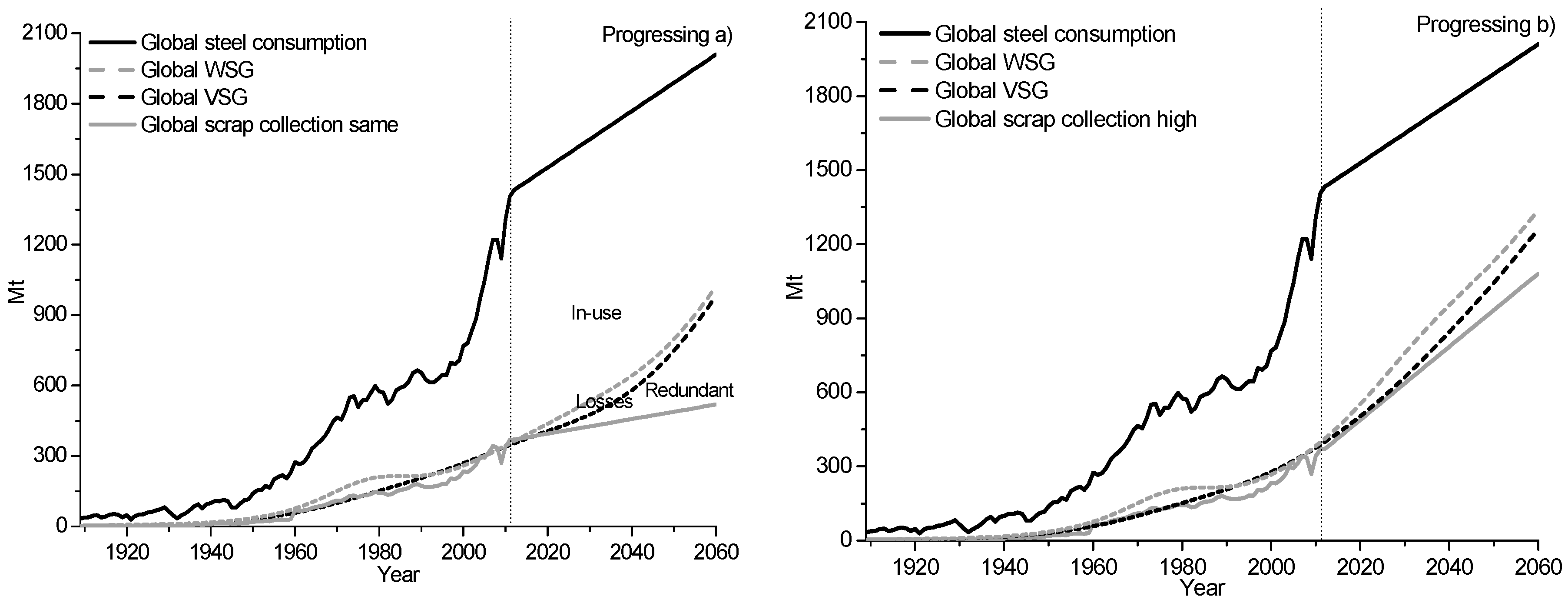

The model results on the global steel consumption for historical data between 1910 and 2012 as well as the outlook between 2013 and 2060 for both a high scrap collection rate and the same scrap collection rate as in 2012 are shown in

Figure 6 and

Figure 7. The Progressing model results on the upper limit of in-use steel stock, workable losses, and viable steel scrap are shown in

Figure 6. The Backcasting model results on the in-use steel, societal steel scrap reserves, and amount of losses are shown in

Figure 7.

The results show that for a whole century between 1910 and 2012, the TSG and PSG values have been higher than the scrap collection values, as is shown in

Figure 7. Between 1910 and 1987 the amount of losses has also been higher than the collected amount of steel scrap. In addition, the societal steel scrap reserves have increased during the last four decades. Overall, the model results show that the societal steel scrap reserves and amount of losses are high in the world. This indicates that there is a need for a drastic increase as well as a better utilization of steel scrap on a country basis. This can be achieved by increased installations of the EAF route of steelmaking, by improved collection systems, and by increased installations of waste management facilities. Thus, it is of great importance to locate the societal steel scrap reserves on a country basis.

Due to economic benefits and decreased environmental impacts for the steel producers with the implementation of and increased recycling of steel scrap, scrap collection should be relatively high in the world. Despite incentives, the model results show that a large difference still exists between the collected steel scrap and the societal steel scrap reserves which are available in society.

However, the societal steel scrap reserves are accessible to different extents and amounts, dependent on how profitable it is to recycle the steel. It is thereby of great importance to evaluate where the societal steel scrap reserves are saturated in society. This can be done by calculating the steel scrap reserves by specific industrial sectors in society.

The lower limit on the steel scrap generation calculated based on the Progressing model can be interpreted as the most commonly available steel scrap assets in society. The information on the economically feasible amounts of steel scrap available for collection can be used to optimize the recovery, without improving the existing collection system in society or by increasing the installed capacity of waste management facilities. Thereby, it is possible to avoid supply bottlenecks. This could potentially further aid to stabilize the volatility effect of the raw materials used for steelmaking. The Progressing model results shows that the viable steel scrap started to be generated in larger quantities between 1977 and 2007, as seen in

Figure 6. In addition the viable steel scrap peaked in 2009 due to the economic crisis.

Based on the Progressing and Backcasting models, the forecasted steel demand was calculated to reach a level of 2010 Mt in 2060. This shows that the world will consume double the amount of steel up to the year 2060 compared to the total historical consumption until today. Furthermore, depending on what production process the steel will be produced by, it will have a huge impact on the environment. The recycling rate of steel is directly related to the global installed capacity of scrap consuming steelmaking mills. Considering that, the global environmental issue regarding CO2 emissions and energy usages can to a large extent be solved by an increased recycling of metal, but this requires among other actions robust models to be able to calculate the societal scrap reserves. Furthermore, by mapping the steel scrap reserves, it is possible to ease the trade of steel scrap across country borders. Hence, it is possible to optimize the global supply of steel scrap for steelmaking. This would further enable an optimized usage of recyclable metals as sustainable resources for the industry.

The forecasted steel demand can also be calculated based on mathematical functions such as the Box-Jenkins function, exponential smoothing, and regression analysis [

33]. These calculations are mainly based on the data on scrap collection from the past as well as present data. Furthermore, on their historical trends, on assumptions based on experience, industrial knowledge, and financial indicators [

34]. However, the projections are also time dependent, whereby the potential of increasing the recycling rate of steel also needs to be considered when evaluating the amounts of steel that will be consumed in the future. The Backcasting and Progressing models are able to distinguish the relationship between the dynamic behaviors of the lifetime of steel, recycling rate, and in-use steel stock. The use of the new models improves the forecasting of the available amounts of steel scrap as well as the demand of steel to industrialize countries.

The outlook on the global steel consumption between 2013 and 2060 for two scenarios, using the same scrap collection rate as in 2012 and a high scrap collection rate, are shown in

Figure 6 and

Figure 7. The results show that if the scrap collection rate is the same as in 2012, the societal steel scrap reserves will significantly increase in the upcoming years. Finally, the societal steel scrap reserves will surpass the amounts of scrap collected in the year 2048, as seen in

Figure 7. The results also show that despite a higher scrap collection rate, the amount of losses will still be high in the future. This can be explained by the fact that the societal steel scrap reserves have continuously been high in the world. Also, the large amounts of losses are shown as the large difference between the TSG and PSG values in 2060, as seen in

Figure 7. To maintain a global high collection rate of steel scrap, the steel scrap collection should follow the forecasted PSG value. Based on the information on the potential scrap generation, it is possible to ease future structural plans of scrap based steelmaking mills and waste management facilities. Thereby, it is possible to keep the collection rate of steel scrap at a continuously high level. This would further aid to delay as well as to minimize the usage of natural resources for steelmaking in the future.

Both the model calculations for the Swedish steel consumption and global steel consumption show that the forecasted model results are different for the TSG, PSG, WSG, and VSG, dependent on the forecasted demand of steel scrap. Thereby, the Backcasting and Progressing models are able to calculate the steel scrap generations as a function of the collection rate of steel scrap. This is based on time-varying internal parameters on the lifetime of steel data. Furthermore, the models use no additional external parameters. These statistical models enable the possibility to evaluate the relation between the recycling rates of steel against the in-use steel, the societal steel scrap reserves, and the amounts of losses over time. This is due to the fact that these quantities influence each other. Based on the information of the potential scrap generation and based on the assumption of a maximized EAF capacity, it is possible to calculate the future demand of iron ore to produce steel.

In a previous DMFM study by J. Oda et al., the old scrap consumption value was calculated to be 859 Mt and the prompt scrap consumption value was forecasted to be 209 Mt in 2060 [

26]. This is a total value of 1068 Mt of commercial steel scrap that is forecasted to be consumed in the iron and steel mills. In this study, the scrap collection (old and prompt) was calculated to reach a target value of 1081 Mt in 2060. This value is very similar to the results found in the previous study by J. Oda et al [

26]. However, the model results from this study also show that there exists an even greater potential of increasing the scrap collection to a value of 1261 Mt in 2060. This is shown as the potential scrap generation value in 2060 in

Figure 7b. In another DMFM study by S. Pauliuk et al., the old and prompt scrap supply was calculated to be approximately 1470 Mt in 2060 [

27]. This is higher than the results calculated based on the Backcasting model; specifically, 400 Mt higher than the potential scrap generation in 2060. The difference can be explained because the study by S. Pauliuk et al. assumed a target value of the End-of-life recycling rate to be 90% in 2050 [

27]. This is 13% higher than the recycling rate calculated based on the Backcasting model and 37% higher than the EOL-RR calculated by J. Oda et al. for the same year [

26,

28].

The model results demonstrate that it is possible to assess the steel scrap generation in society based on the statistical DMFMs. Also, based on the newly developed Progressing and Backcasting models, it is possible to calculate robust forecasts on the long term availability of steel scrap.

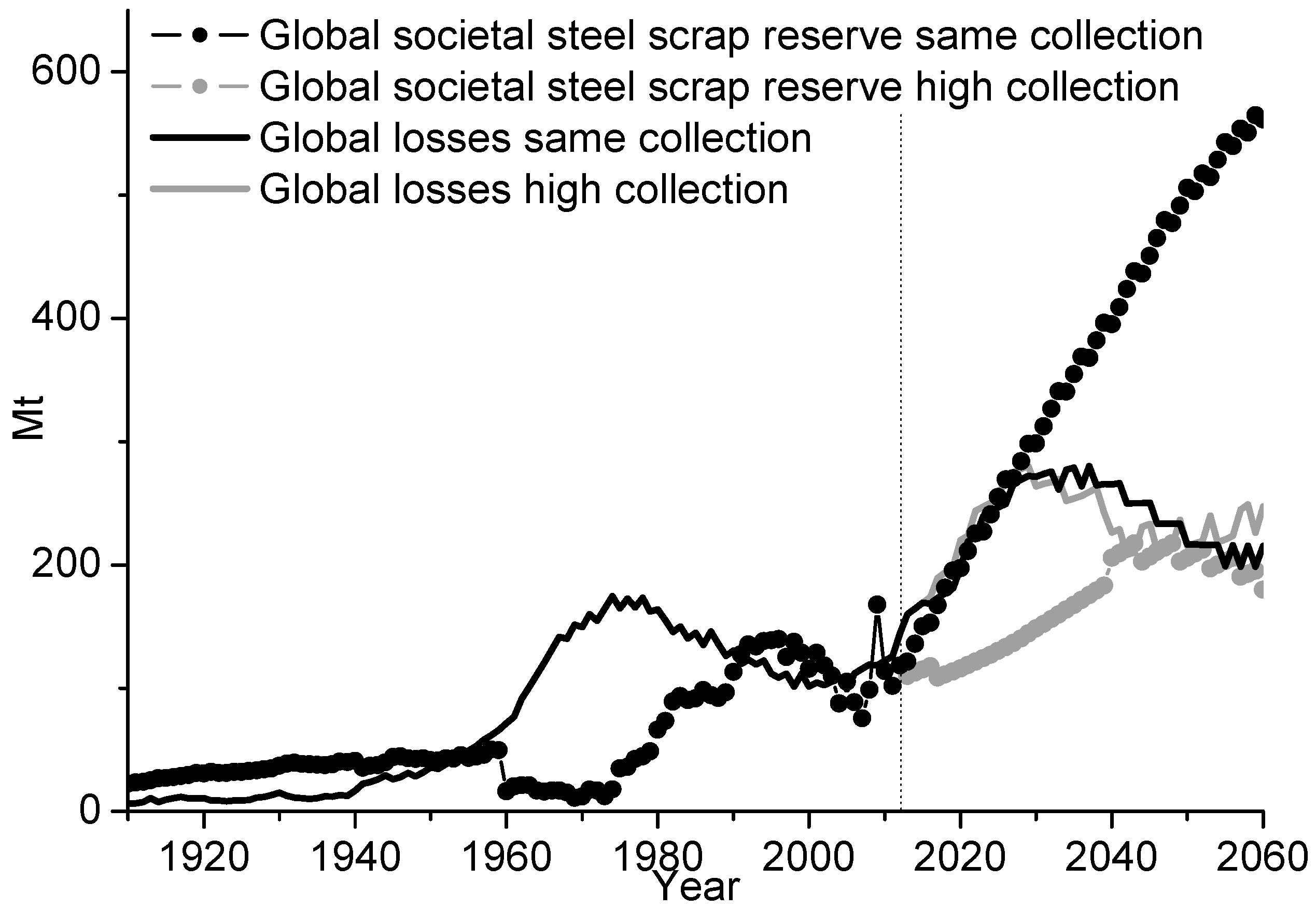

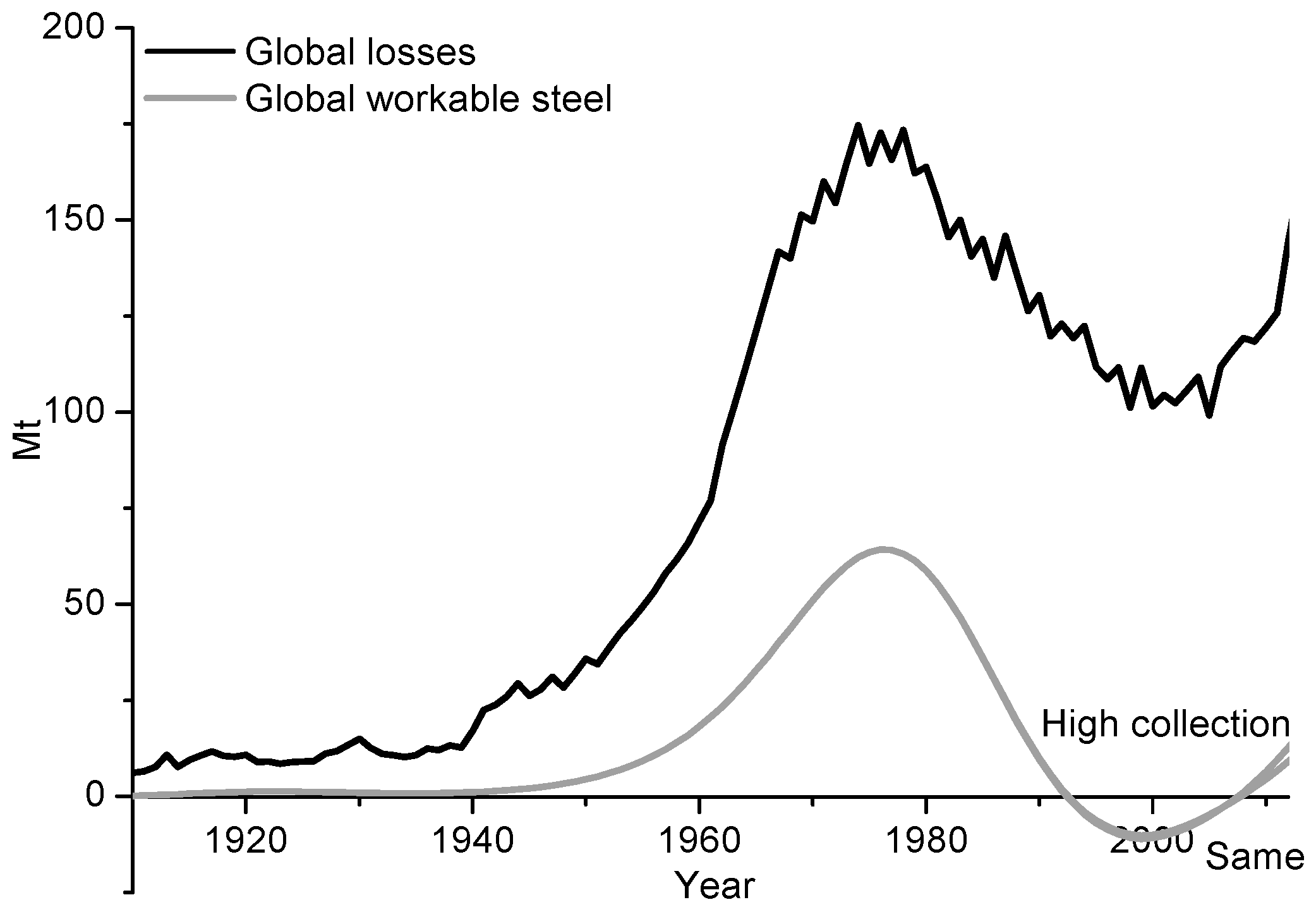

The annual quantities of the global societal steel scrap reserves and amounts of losses are shown in

Figure 8. These quantities are calculated based on the Backcasting model and are taken from

Figure 7. The historical data show that the cumulative amounts of the societal steel scrap reserves have been higher than the losses until 1968, after which the amounts of losses have been higher than the societal steel scrap reserves. In addition, the results also show that the amounts of losses will significantly increase in the future and that they will be around 280 Mt in 2029 and thereafter will decrease to a value between 215 and 247 Mt in 2060. This result is true regardless if a higher or the same scrap collection rate as in 2012 is assumed. However, according to the model calculations, it is necessary to keep the collection rate at a continuously high level, to reduce the amounts of losses. This can be achieved by assessing the available amounts of steel scrap in society. Furthermore, the forecast shows that there exists a great potential to decrease the amount of the societal steel scrap reserves to a level below the amounts of the losses in 2060.

The model results for the Swedish and global data between 1900 and 2012 also show that the societal steel scrap reserves and amounts of losses are counterbalancing each other, as seen in

Figure 5 and

Figure 8. This is because the amount of losses is a function of the societal steel scrap reserves. The losses represent the amounts of the end of life steel that have been redundant for more than a lifetime of steel and that then have become part of the losses in society. Specifically, the losses represent the quantity of steel that is statistically outside the range of being collected for recycling purposes.

Due to the fact that steel scrap is a scarce resource, supply bottlenecks can occur. This can further cause sudden changes of the prices of raw materials used for steelmaking. The collection rate of steel scrap in countries have previously not hit the ceiling of its limitation of available reserves. This excludes temporarily and local situations, when countries have implemented export bans on steel scrap to secure their domestic scrap market. With a better mapping of the steel scrap reserves, it is possible to evaluate how much steel scrap can be purchased before scrap prices would peak due to supply bottlenecks. It is thereby of great importance to assess the amounts of available steel scrap reserves in society. This in turn would help to obtain a sustainable industrial development and a circular economy.

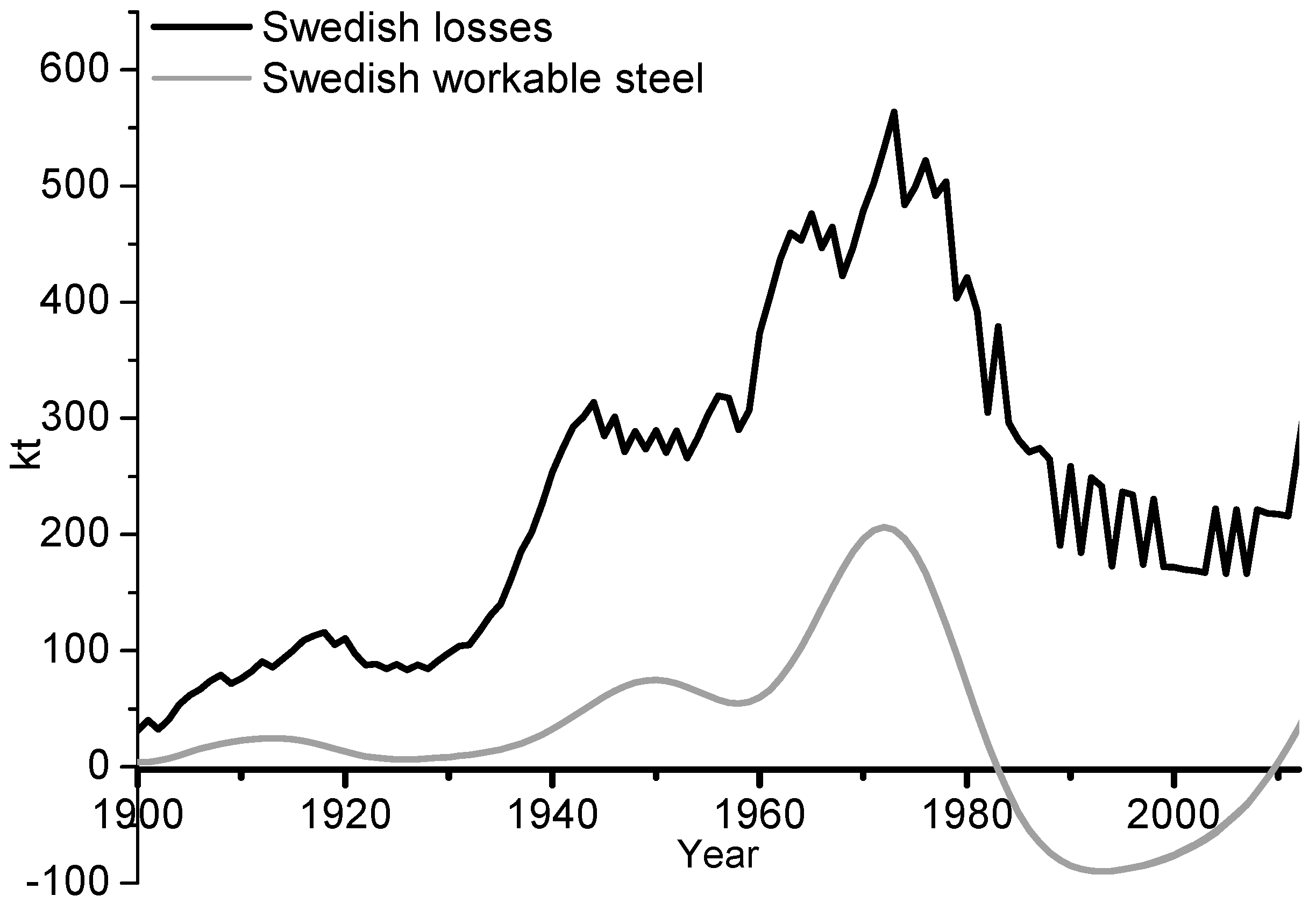

3.3. The Lower and Upper Limit of the Societal Steel Scrap Reserves and Amounts of Losses

The societal steel scrap reserves are accessible for collection to different extents and amounts depending on how economically viable it is to recycle the steel. Therefore, it is important to quantify the lower and upper limits of the societal reserves of steel scrap and losses. The model results on the amounts of the societal steel scrap reserves, viable steel scrap, amounts of losses, and workable losses for the Swedish steel consumption and global steel consumption between 1900 and 2012 are shown in

Figure 9,

Figure 10,

Figure 11 and

Figure 12, respectively. These quantities are taken from the model results shown in

Figure 3,

Figure 4,

Figure 6 and

Figure 7.

The model results show that the societal steel scrap reserves and the viable steel scrap follow each other’s trends to a lower and upper magnitude, respectively. This is shown for both the Swedish steel consumption and the global steel consumption data. The results show that the Backcasting and Progressing models are complementary. Furthermore, the models are able to calculate the range of the statistical outcome of the available steel scrap assets in society. The combined use of the models thereby represents a sensitivity analysis on the possible outcomes of the steel scrap generations based on the lifetime of steel data and the distribution functions being used. The results show that the amounts of the societal steel scrap reserves and viable steel scrap converge and diverge over the century. However, the difference between the amounts of losses and workable losses are more continuous over time. According to the model calculations, there exists a greater potential to recover the societal steel scrap reserves and viable steel scrap assets in society compared to the amounts of losses and workable losses.

The results show that the cumulative societal steel scrap reserves are larger than the cumulative amounts of losses in Sweden in 2012, while the global cumulative losses are larger than the cumulative societal steel scrap reserves in 2012. The global results show that the cumulative losses surpassed the cumulative steel scrap reserve in 1968, as seen in

Figure 11 and

Figure 12. Thereafter, the global losses have been higher than the societal steel scrap reserves. Furthermore, the results show that there exists a great potential to increase the collection of the available scrap reserves in the world. An implemented scrap utilization would decrease the energy usage as well as the CO

2 emissions associated with steelmaking.

In

Figure 10 and

Figure 12 it is shown that the Swedish workable losses and global workable losses have been negative between 1984 and 2008 and between 1998 and 2012, respectively. This indicates that new technologies to handle the amounts of workable losses had been introduced and installed. These new technologies could be installations of the fragmentation facilities, which have further increased the production of steel scrap. The workable losses could be e.g., steel in narrow components, which have been difficult and costly to process into scrap that can be recycled. However, due to increased scrap prices and newly developed technologies it is now economical to recover these sources for recycling purposes.