Abstract

A batch-operated ZVI (zero valent iron) desalination reactor will be able to partially desalinate water. This water can be stored in an impoundment, reservoir or tank, prior to use for irrigation. Commercial development of this technology requires assurance that the partially-desalinated product water will not resalinate, while it is in storage. This study has used direct ion analyses to confirm that the product water from a gas-pressured ZVI desalination reactor maintains a stable salinity in storage over a period of 1–2.5 years. Two-point-three-litre samples of the feed water (2–10.68 g (Na+ + Cl−)·L−1) and product water (0.1–5.02 g (Na+ + Cl−)·L−1) from 21 trials were placed in storage at ambient (non-isothermal) temperatures (which fluctuated between −10 and 25 °C), for a period of 1–2.5 years. The ion concentrations (Na+ and Cl−) of the stored feed water and product water were then reanalysed. The ion analyses of the stored water samples demonstrated: (i) that the product water salinity (Na+ and Cl−) remains unchanged in storage; and (ii) the Na:Cl molar ratios can be lower in the product water than the feed water. The significance of the results is discussed in terms of the various potential desalination routes. These trial data are supplemented with the results from 122 trials to demonstrate that: (i) reactivity does not decline with successive batches; (ii) the process is catalytic; and (iii) the process involves a number of steps.

Keywords:

desalination; zero valent iron (ZVI; Fe0); irrigation; ion concentration; Na+ ions; Cl− ions 1. Introduction

Desalination associated with zero valent iron (ZVI, Fe0) has been demonstrated in more than 160 batch trials (utilizing 0.2–240 L/batch [1,2,3,4,5]) and by monitoring the salinity of water flowing through granular Fe0 permeable reactive barriers (PRB) [6,7,8,9,10]. These trials have demonstrated that ZVI desalination has potential applications for groundwater management, road runoff water management, agricultural water management, municipal and domestic water, emergency and disaster water requirements, feed and waste water treatment associated with conventional desalination plants, waste water associated with the extractive industries and environmental damage mitigation [1,2,3,4,5,6,7,8,9,10].

The major potential market for ZVI desalination product water is the provision of partially-desalinated water for irrigation [2]. Salinization affects 260–1000 billion m3/a of irrigation water [2,11,12,13,14,15,16].

There is an increasing requirement for desalinated (or partially desalinated) water to sustain agriculture (for wheat, barley, oil palm, cotton, soybean, maize, sugar cane, etc.) as the alternative water sources become salinized [17]. Irrigation with desalinated water (when compared to irrigation with salinated water) may produce a small ($/ha) increase in crop value [2]. The increase in crop value is unlikely to economically sustain the delivery cost of desalinated, or partially desalinated, water of more than $0.1–$0.5/m3 [2].

A reverse osmosis (RO) desalination plant producing 600–500,000 m3/day requires an external energy source, which is in the range of 2.5–9.38 kWh/m3 of product water [18,19]. Similar amounts of external energy are required for each of the alternative desalination technologies (e.g., mechanical vapour compression (MVC), thermal vapour compression (TVC), multistage flash distillation (MSF), multistage vacuum membrane distillation (MSVM), electrolysis desalination (ED), humidification desalination (HDHD) and multi-effect distillation (MED) [18,19].

The product water delivery cost from a large-scale (100,000 m3/day) desalination plant varies internationally. The delivery cost is typically in the range of $2.5–$4/m3, e.g., [2,20,21,22,23]. These delivery costs may increase substantially (e.g., by an order of magnitude) for small-scale plants producing less than 250–1000 m3/day [20,21,22,23]. It is highly unlikely that these small-scale plants will be able to produce desalinated water for a delivery price of $0.1–$0.5/m3.

Green (solar powered) desalination systems based on solar photovoltaic (PV) cells [24] and solar membrane distillation technology [25] are capital intensive and require a large land take. Solar membrane technology producing 0.5–1 m3/day has been demonstrated to have an operating cost within the range of $5–$16/m3 [25].

A new redox chemical route for the partial desalination of water using ZVI was discovered in 2010 [3,26]. Subsequent investigations [1,2,4,5] established that this technology could be used to partially desalinate small water bodies (e.g., 1–10,000 m3). The anticipated delivery cost from a commercial unit is considered to fall within the range of $0.001–$0.5/m3 [2]. A number of different reactor combinations, reactor types, reactor configurations and ZVI combinations have been trialed [1,2,3,4,5,26]. The two principal reactor technologies (based on ZVI diffusion redox chemistry and a ZVI particle size of 44,000–77,000 nm) are:

- Static diffusion technology [1,2];

- Gas-pressured static diffusion technology [2].

Static diffusion ZVI partial desalination reactors operate at atmospheric pressure with a low air saturation in the water [2]. The air saturation of the water is controlled by diffusion across the air-water interface [2]. The gas-pressured static diffusion reactors use a pressured gas body placed above the gas-water contact to pressurize the water [2]. A gas is bubbled through the water to allow high levels of gas saturation to occur [2]. The gas bubbles are used to increase the available diffusion surface area between the gas and the water [2].

1.1. Static Diffusion ZVI Partial Desalination

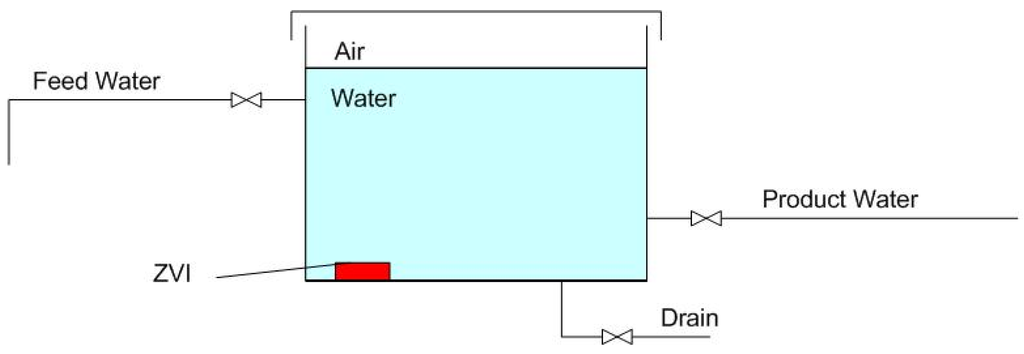

This technology places ZVI-derived products (e.g., pellets, or granules, or powders) [1,2] in a static body of water (e.g., an existing tank (Figure 1), pond or impoundment). The ZVI concentration is within the range of 0.3–90 g·ZVI·L [1,2]. The water in the tank is not stirred, or agitated, and is maintained at ambient atmospheric (or ground) temperatures within the range of −10–55 °C [2]. The water salinity declines gradually (exponentially) over a prolonged time period to a base salinity level (Bs) over a period of 30–250 days [1,2]. The length of time (tBS) taken to achieve the base salinity level varies with the ZVI composition and the manufacturing method used to produce the ZVI-derived product [1,2]. The attainable base salinity level (Bs) has been demonstrated to be between 5% and 50% of the feed water salinity [1,2]. The base salinity level (expressed as a proportion of the feed water salinity) is independent of the feed water salinity [2]. This characteristic of the ZVI desalination process confirms that the desalination follows a pseudo-n-th order process [27]. The ZVI can be reused to partially desalinate at least three batches of water sequentially, where the rate of salinity decline may decrease (and Bs increase) with each succeeding batch of water [1,2]. Desalination removes both Na+ ions and Cl− ions in equal molar proportions [1,2].

Figure 1.

Schematic process flow diagram for a static diffusion ZVI partial desalination reactor.

The salinity of the product water produced using this approach has been demonstrated to remain stable for more than one year [1,2] and is not addressed further in this study.

This technology requires no external energy and can use existing water tanks, ponds, reservoirs and impoundments [2]. It is therefore suitable for application in areas with no energy infrastructure, small agricultural holdings and agricultural units with limited access to capital financing.

The residual ZVI can be reused for water treatment [2] or for gas desulphurization [2]. In some regions, the resale price of the residual ZVI may exceed the purchase cost of the ZVI treatment product [2]. In these circumstances, this desalination technology, when used for irrigation, can still increase the profitability of an agricultural holding, even when no noticeable increase in crop yield occurs [2].

1.2. Gas-Pressured Static Diffusion ZVI Partial Desalination

Many smaller land holdings do not have sufficient water storage (or land that could be used for water storage) to allow the static diffusion ZVI partial desalination to be a practical option.

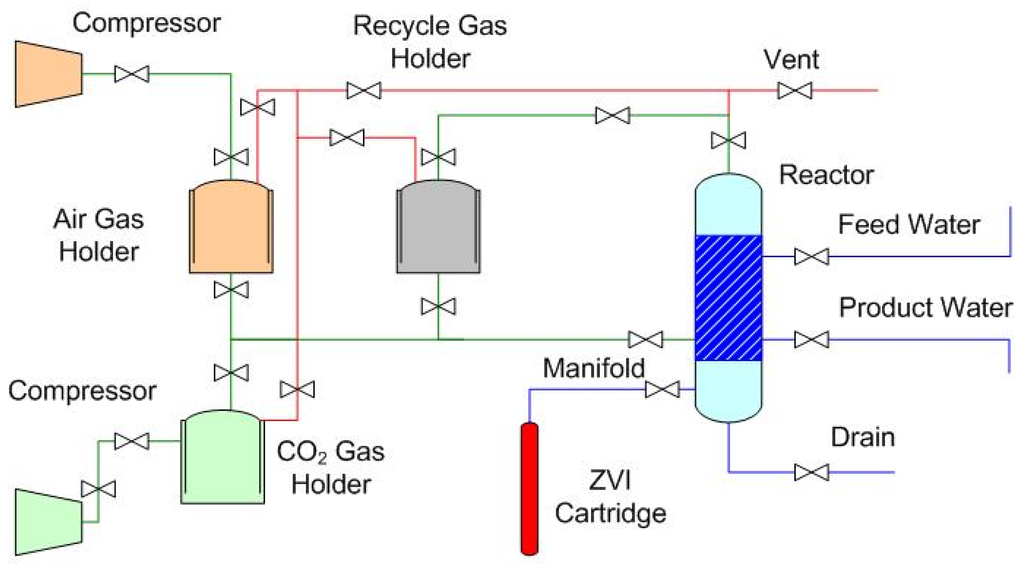

Compact gas-pressured (less than 0.1 MPa) static diffusion reactors (utilizing air or CO2 as the pressurizing agent) operated at ambient temperatures were found to achieve a base salinity level (Bs) within a time frame (tBS) of 2–24 h [2]. These reactors (Figure 2) established that the rate of desalination is a function of the gas saturation of the water and the gas pressure [2]. The desalination rate increases with increased gas saturation and gas/water pressure to an equilibrium salinity level (Bs) [2].

Figure 2.

Schematic process flow diagram for a gas-pressured static diffusion ZVI partial desalination reactor.

The gas-pressured static diffusion reactor trials established [2]:

- A single ZVI (or ZVI product) charge can be reused to partially desalinate multiple batches of water [2]:

- A single ZVI charge can be reused at least 18 times [2];

- The rate of salinity decline is unaffected by:

- reuse of the ZVI [2];

- the salinity of the feed water [2].

- Partial desalination of brackish water (less than 10 g NaCl·L−1) to a base salinity level (Bs) can be undertaken at ambient temperatures (e.g., 0–55 °C) [2]:

- (tBS) is 2–24 h [2];

- (Bs) is between 5% and 90% of the NaCl held in the feed water [2];

- (Bs) is independent of ZVI reuse [2].

- The ZVI:water ratio in the reactor can be in the range of 0.5–30 kg ZVI charge: 1 t water [2]. The ZVI is held in a replaceable cartridge, which is attached to the reactor via a manifold [2].

The trial results [2] have established that a compact gas-pressured reactor containing 10 m3 of water has the potential to produce between 3600 and 29,000 m3 of partially-desalinated water (for irrigation applications) over the course of a year.

1.2.1. Indicative Dimensions and Costs of a Gas-Pressured Reactor with a Batch Capacity of 10 m3.

A batch processing compact reactor (with a capacity of 10 m3/batch) can be constructed as a transportable unit. The reactor can be held within a standard shipping container (2.438 m (8 ft) wide × 2.591 m (8.5 ft) high × 12 m (39.5 ft) long) or standard high cube shipping container (2.438 m (8 ft) wide × 2.896 m (9.5 ft) high × 12 m (39.5 ft) long or 13.556 m (44.33 ft)), or in a skid-mounted structure with similar dimensions.

This structuring allows a number of reactors to be brought to a location to rapidly provide desalination water. For example, a requirement for 100 m3/day of irrigation water for a month could be accommodated using four (temporary) reactor units. Each reactor could be operated with an average 4–10 h batch processing time. The batch processing time required is a function of the chemical complexity of the feed water [2]. The maximum on-site storage requirement for product water in this example is 25 m3. This storage requirement assumes that the product water will be used as irrigation water within 6 h of production. The storage requirement can be accommodated using a bladder tank, an MDPE (medium density polyethylene) tank, a steel tank, an impoundment or a pond.

Each reactor has an expected design life of 20–30 years. The principal consumables are:

- the periodic replacement of ZVI;

- the provision of air and the provision of CO2 [2].

These costs vary with source and location. The trial results [2] indicate that maximum gas supply requirements required for this size of compact gas reactor are five cubic feet/minute air (0.135 m3/min) and 0.8 cubic feet/minute CO2 (0.0229 m3/min). The air can be provided using compressed air tanks, or low cost electric- or petrol-powered compressors. The CO2 is provided as compressed gas, or from the on-site fermentation of waste cellulose (agricultural) material, or from another source. The product gas can be reused in one or more downstream reactors [1] and can be recycled.

The expected delivered cost of partially-desalinated water from a gas-pressured reactor is a function of location, site-specific requirements, commodity prices, water chemistry, regulatory requirements (environmental, health and safety, agricultural, groundwater, planning, fiscal, etc.), insurance requirements, profit requirements, administrative costs, engineering costs, financing costs and the required levels of desalination [2]. An indicative delivery cost in the order of $0.01–$0.4/m3 may be achievable using this technology [2].

1.2.2. Stored Product Water

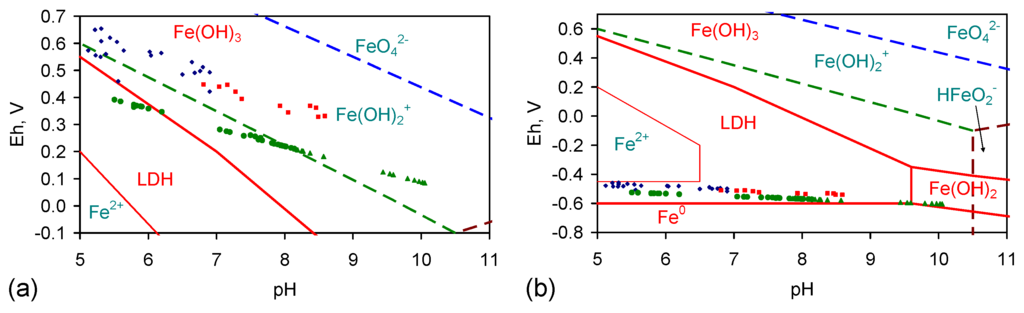

The product water from gas-pressured reactors (CSD1 [2], E143 [2] and E144 [2] series of trials) showed major changes in pH in the first 3–6 weeks of storage [2]. The acid or alkaline product water pH drifted towards a neutral alkalinity (pH = 7) [2]. This change in pH was accompanied by fluctuations in Eh and EC (electrical conductivity) [2]. Eh, V = (2.303RT/F)(−Log(e−)). R = gas constant; T = Temperature, K; F = Faraday Constant; e− = activity of electrons. Eh is measured using an ORP (oxidation reduction potential) probe which has been calibrated to the standard hydrogen electrode using a quinhydrone calibration at pH = 4 and pH = 7. This study establishes (Appendix A, Table A1, Table A2, Table A3, Table A4, Table A5, Table A6, Table A7, Table A8, Table A9, Table A10 and Table A11) that these pH, Eh and EC changes do not alter the Na+ and Cl− ion concentrations in the stored product water. The trial series notation (CSD1a–CSD1d; E143a–E143k; E144a–E144f) used in reference [2] is retained in this study. Further details are provided in reference [2].

The published product water desalination assessment from gas-pressured static diffusion ZVI partial desalination reactor trials [2] is based on changes in EC [2] and changes in UV-visible absorbance spectra [2]. The UV-visible absorbance spectra [2], redox analyses [1,2] and kinetic analyses [1] have established that the desalination reaction is a redox reaction, which involves at least one reaction step [1,2]. Intermediate NaCl degradation products (ClO−, ClO-OCl, NaO−) have been recorded in the nano-particles produced within the reactor during desalination [2].

The NaCl is either removed permanently by precipitation (reaction route Group A (Appendix B)) or is retained in a different form within the product water (reaction route Group B (Appendix C)).

To date, no ion studies (Na+ and Cl− ions) have been published that demonstrate that the partially-desalinated product water from a gas-pressured static diffusion ZVI partial desalination reactor will remain stable while in storage. The end user for the partially-desalinated water will require assurances that the water will not resalinate, when it is placed in storage or used for irrigation.

This study assesses the stability of stored product water from a gas-pressured reactor, after 1–2.5 years of storage.

1.3. Appendices

This study has a number of appendices that provide data (Appendix A), background information (Appendix B and Appendix C) and expand the discussion of specific aspects of the results, provided in Appendix D, Appendix E, Appendix F, Appendix G, Appendix H and Appendix I. The appendices are:

- Appendix A: Ion Analyses;

- Appendix B: Summary of Reaction Route A;

- Appendix C: Summary of Reaction Route B;

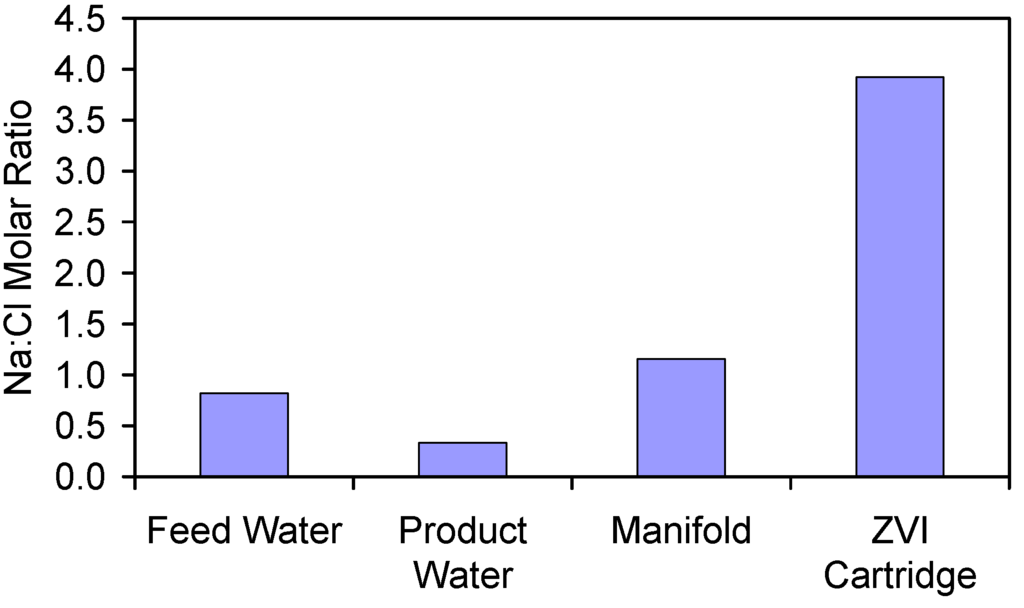

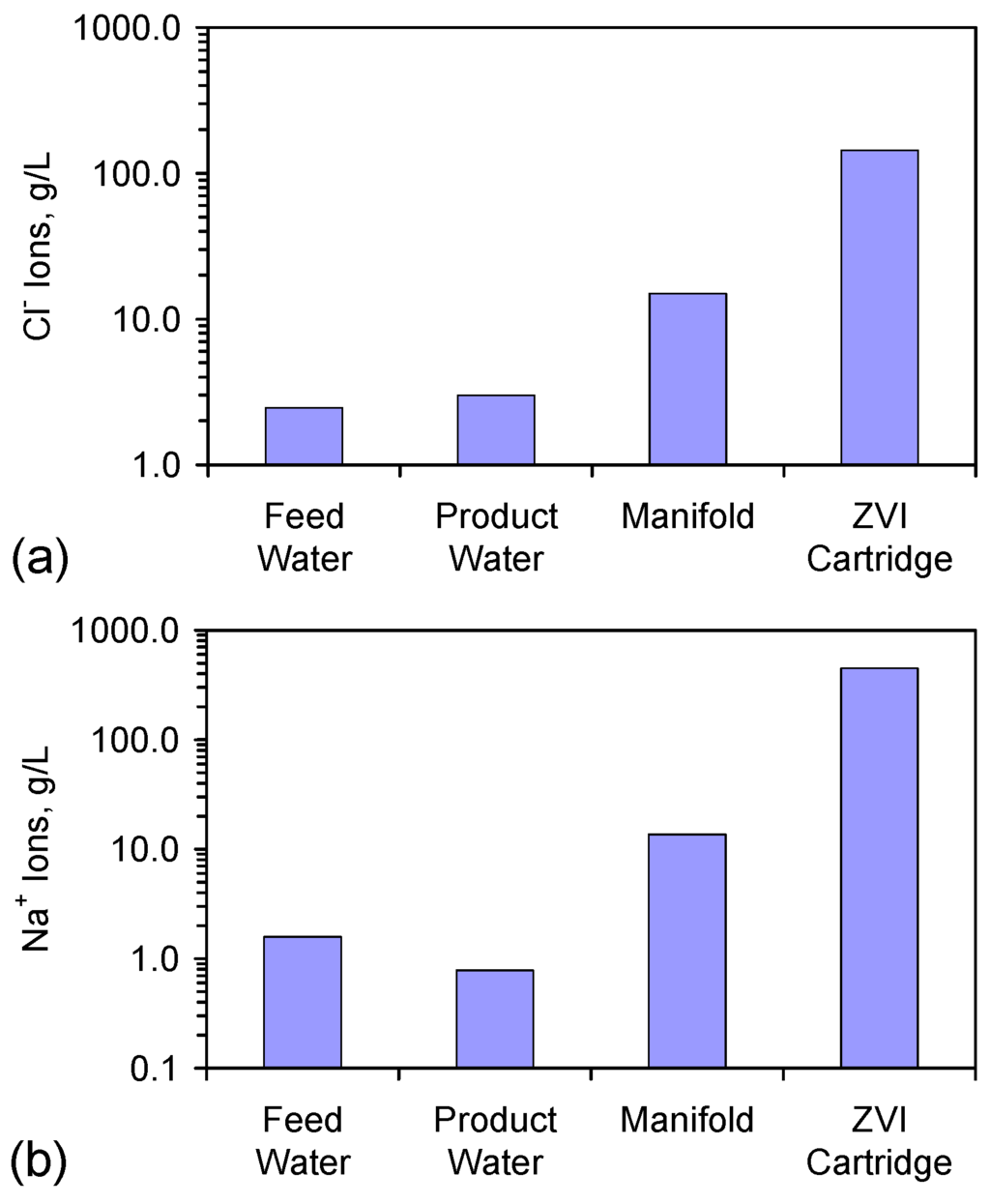

- Appendix D: The Significance of Increased Na+ and Cl− Ion Concentrations in the Manifold and ZVI Cartridge (Figure D1 and Figure D2);

- Appendix H: Desalination Pathway (Figure H1);

2. Methods and Analysis of Stored Product Water

Gas-pressured desalination is associated with declines in product water EC (due to desalination) (CSD1, E143, E144 trial series [2]) when the pH remains stable or decreases within the pH range of 5–7 during desalination [2]. This study analyses the stability of this product water (Table A1, Table A2, Table A3, Table A4, Table A5, Table A6, Table A7, Table A8, Table A9, Table A10 and Table A11).

2.1. Water Samples

Two-point-three-litre samples of the feed water and product water from each of the CSD1, E143 and E144 series of trials [2] (21 trials) were collected and placed in sealed MDPE (medium density polyethylene) containers. The feed water sample was collected when the reactor was loaded. The product water sample was collected from the reactor at the conclusion of the individual trial. The EC, Eh and pH of the water samples at the time of collection are recorded in reference [2]. The containers were then placed in an external, unheated, uninsulated, sheltered environment, where the temperature was allowed to fluctuate with changes in atmospheric temperature, over the range of −10–25 °C over a period of 1–2.5 years.

2.2. ZVI and Trial Details

Details of the reactors, ZVI and operating conditions for each of the 21 trials are provided in reference [2]. Each trial series (CSD1, E143, E144 [2]) used a different ZVI charge [2]. The ZVI charge used in the first trial of a series was reused in each subsequent trial in the same series [2].

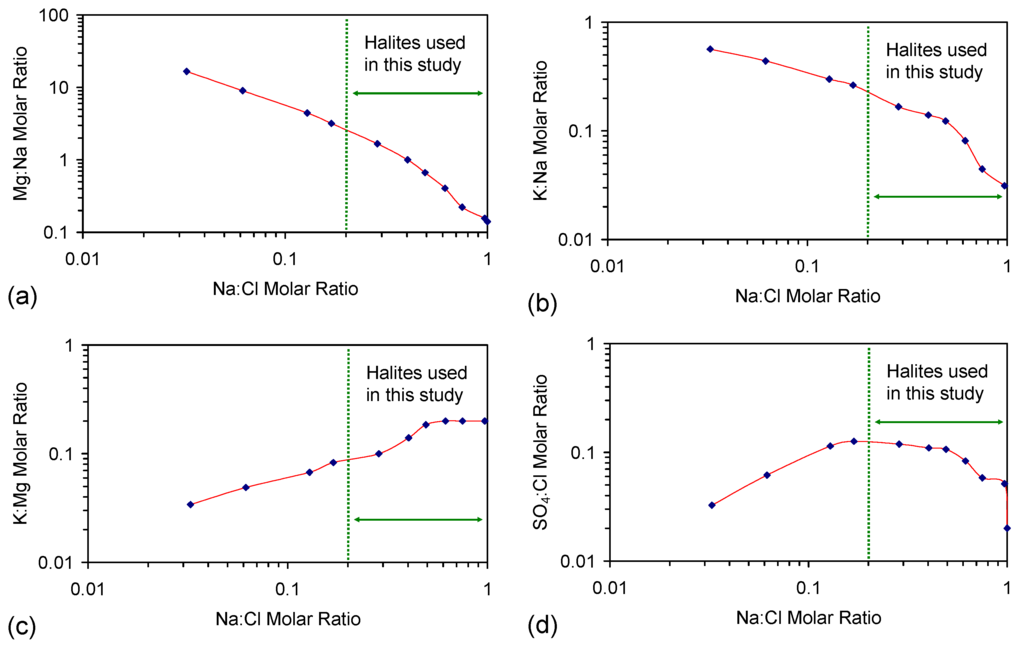

2.3. Saline Water Construction

The CSD1 and E143 trial series (Table 1) used saline water constructed from chemically-pure NaCl and fresh water [2]. The expected Na:Cl molar ratio in the saline feed water is 1.0. Trial series E144 used saline water (Table 1) constructed from road de-icing-grade halite (Zechstein halite from the UK) [28]. Saline water constructed using Zechstein halite is characterized by a Na:Cl molar ratio that is less than 1.0 [29]. The lower Na:Cl molar ratio results from the presence of Ca2+, Mg2+, Fen+ and K+ cations in the halite [29]. The halite can also contain OH−, HO2−, CO32−, HCO3−, SO3− and SO42− anions [29].

The fresh water used to construct the synthetic saline water was natural spring water derived from a private water supply in Dunning, Ochil Hills, Scotland [2]. The groundwater is extracted from a fractured Devonian, Old Red Sandstone volcanic series aquifer (fractured andesites, fractured dacites, fractured pyroclastics, (Dunning, Perthshire, UK). A typical ion composition is [2]: Anions: Cl = 11.67 mg·L−1; N(NO3) = 11.28 mg·L−1; S(SO4) = 4.16 mg·L−1; P(PO4) ≤ 0.10 mg·L−1; F = 0.024 mg/L; N(NO2) = 0.04 mg·L−1; HCO3−/CO32− ≤ 10 mg·L−1; Cations: K = 1.69 mg·L−1; Ca = 32.91 mg·L−1; Na = 6.32 mg·L−1; Al ≤ 150.0 µg·L−1; Fe ≤ 30.0 µg·L−1; Mn = 1.70 µg·L−1; P ≤ 0.005 mg·L−1; S = 4.31 mg·L−1; B = 29.40 µg·L−1; Ba = 135.60 µg·L−1; Cd ≤ 0.2 µg·L−1; Co ≤ 0.2 µg·L−1; Cr ≤ 0.2 µg·L−1; Cu = 77.7 µg·L−1; Ni ≤ 3 µg·L−1; Pb ≤ 10 µg·L−1; Si = 5.21 mg·L−1; Sr = 144.9 µg·L−1; Zn = 37.4 µg·L−1; As ≤ 5 µg·L−1; Mo ≤ 20 µg·L−1; Se ≤ 20 µg·L−1; Sn ≤ 20 µg·L−1; Sb ≤ 10 µg·L−1. This water analysis is reproduced from reference [2].

ZVI desalination studies have historically either used synthetic saline water constructed using chemically-pure NaCl [1,2,5] or saline water constructed using Zechstein halite [2,3,4]. The use of chemically-pure NaCl creates a simple chemical environment (e.g., H2O + Fe0 + Na+ + Cl−), which allows directional changes to be easily identified (e.g., linkage of salinity decline to measures, such as EC reduction [1,2]). The use of Zechstein halite creates a more complex water, where reductions in salinity can be associated with increases in EC [2,3], and the initial molar ratio of Na:Cl is rarely 1:1 [29]. In complex saline water, desalination is recognized using either UV-visible absorbance spectroscopy [2] or ion analyses [3].

2.4. Salinity Measurement

The ion concentrations in the stored water samples were analysed using Cl− ion and Na+ ion selective electrodes and ion meters manufactured by Bante Instrument Ltd., Shanghai, China (Model 931).

The salinity values associated with the ion selective electrodes were calibrated (in accordance with the manufacturer’s instructions) using a four-point molar calibration (0.001, 0.01, 0.1, 1.0 moles·L−1) for both Cl− and Na+ ions. Calibration and measurements were undertaken at the same temperature.

3. Results

The ion analyses for the stored water are provided in Appendix A as follows: (i) Trials CSD1a–CSD1d: Table A1 and Table A2; storage time: 2–2.5 years; (ii) Trials E143a–E143k, Table A3, Table A4, Table A5, Table A6 and Table A7; storage time: 18–24 months; (iii) Trials E144a–E144f, Table A8, Table A9, Table A10 and Table A11; storage time: 12–18 months.

3.1. Principal Operating Differences between Trial Series CSD1, E143, E144

The Trial Series CSD1 assessed the operation of the desalination process over the temperature range of 20–55 °C. Trial Series E143 repeated the desalination process over the temperature range of 0–25 °C. Trial series E144 repeated the E143 series of trials using chemically-complex saline water (constructed using halite).

3.2. Initial Salinity Calculation Approach in Trial Series CSD1, E143, E144

The feed water and product water salinity for Trial Series CSD1, E143 and E144 was initially calculated from EC [2] using the regression equation [2]:

Salinity, g·L−1 = 0.5401 EC (mS·cm−1) − 0.1

The feed water EC was measured when the water was placed in the reactor [2]. The product water EC was measured when the water was extracted from the reactor [2].

The general regression equation [2]:

is widely used as a measure of salinity assessment [2]. {F} is commonly in the range of 0.5–0.55 for pure NaCl and decreases in pure NaCl:H2O solutions with increasing temperature (as EC increases with temperature) [2]. {F} increases in high salinity chemically-impure saline solutions, e.g., [1], and can fall below 0.5 in some circumstances. A graphical plot of measured EC vs. measured salinity (Na+ + Cl− ions) will show a strong regression relationship [1,2].

(Salinity, g·L−1 = {F} EC (mS·cm−1))

3.3. Observed Stored Water Salinities for Trial Series CSD1, E143, E144

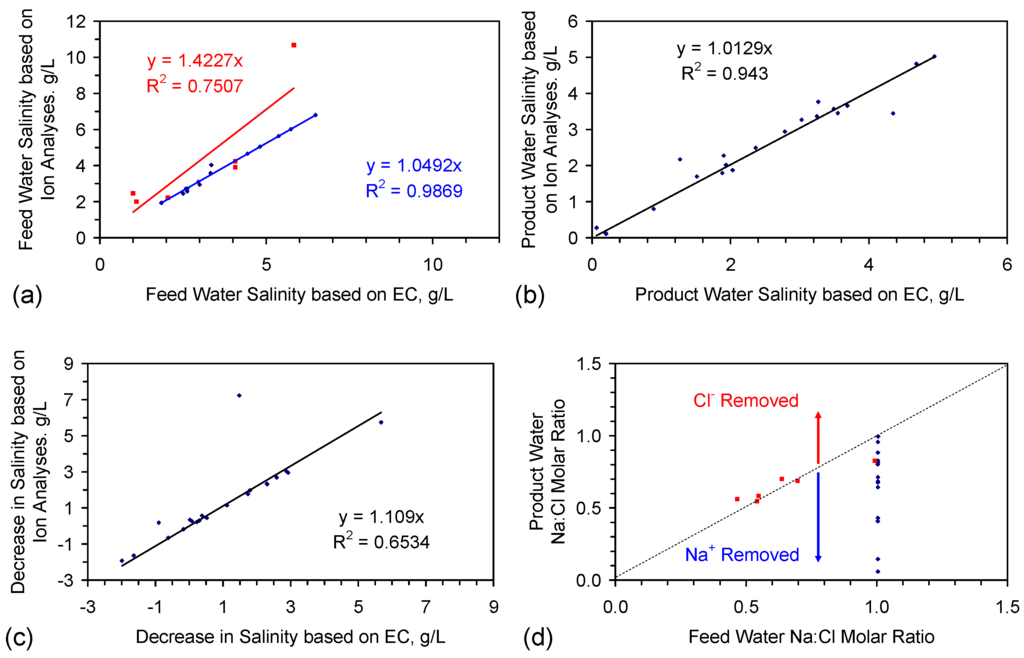

Figure 1 provides the salinity measurements based on EC at the time the water was extracted from the reactor and the salinity measurements based on direct ion analysis following 1–2.5 years of storage. The regression analyses (Figure 3) establish that:

- EC analyses provide a reasonable estimate of feed water salinity when the saline water is constructed from chemically-pure NaCl (Figure 3a), i.e., {F} approximates to 0.54;

- EC analyses can underestimate the salinity of feed water, when the feed water is constructed using halite (E144 Trial Series) (Figure 3a), i.e., {F} is greater than 0.54;

- EC analyses provide a reasonable indication of product water salinity. The regression correlation indicates that the product water salinity has remained unchanged while the samples were held in storage (Figure 3b);

- Decreases in salinity based on EC may underestimate the actual change in salinity by about 10% (Figure 3c);

- The product water molar Na:Cl ratios indicate that preferential removal of Na+ ions (relative to Cl− ions) can occur (and vice versa) during the desalination process (Figure 3d).

Figure 3.

Comparison of trial results made using electrical conductivity (EC) when the water was extracted from the reactor and using direct ion analysis following 1–2.5 years of storage. (a) Feed water. Red markers = E144 trial series. Blue markers = CSD1 and E143 trial series; (b) Product water; (c) Decrease in salinity based on EC when the water was removed from the reactor vs. decrease in salinity based on direct ion analyses of the feed and product water following 1–2.5 years of storage; (d) Na:Cl molar ratio, feed water vs. product water. Red markers = E144 trial series. Blue markers = CSD1 and E143 trial series; arrows indicate where the number of moles of Na+ removed exceeds the number of moles of Cl− removed, and vice versa. Data sources: (i) ion data: Table A1, Table A2, Table A3, Table A4, Table A5, Table A6, Table A7, Table A8, Table A9, Table A10 and Table A11; (ii) EC data: [2]. Further details associated with salinity assessment using EC are provided in reference [2].

4. Discussion

The results (Figure 3, Table A1, Table A2, Table A3, Table A4, Table A5, Table A6, Table A7, Table A8, Table A9, Table A10 and Table A11) demonstrate that the removed Na+ and Cl− ions are irreversibly held on either the ZVI, or on a ZVI corrosion product, or are retained in the reactor in the manifold, or ZVI cartridge. The results are consistent with the NaCl being removed using reaction route A (Appendix B). They do not preclude the presence of intermediate reactions associated with reaction route B (Appendix C). The results establish that NaCl is preferentially removed from the bulk of the water body and is concentrated in the manifold and reactor cartridge (Table A6). This concentration is associated with preferential removal of Na+ ions from the bulk of the water in the reactor. The significance of this observation is discussed further in Appendix D, Appendix E, Appendix F, Appendix G, Appendix H and Appendix I.

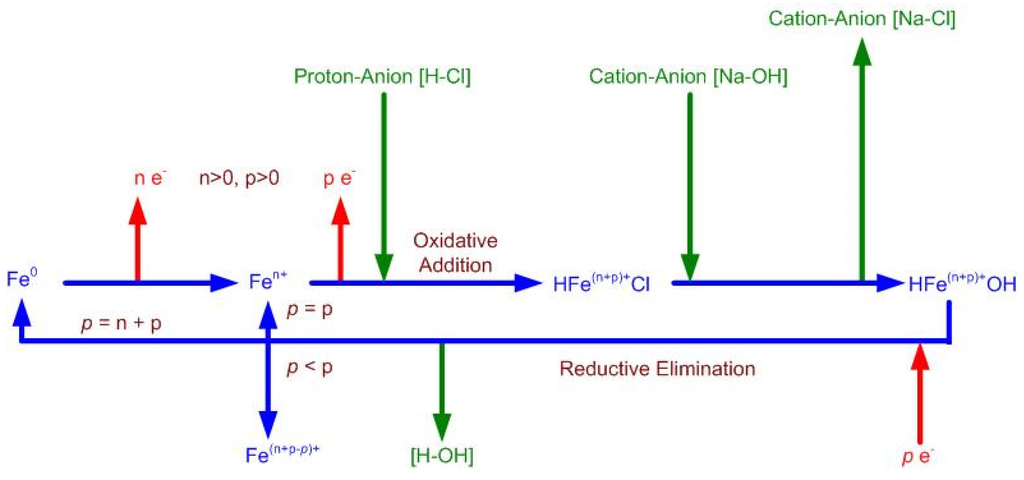

The mechanism for desalination appears to contain elements that are consistent with both reaction group A (Appendix B) and reaction group B (Appendix C). The reaction is not a simple pseudo-first order reaction [1] and appears to contain a number of stages [1]. The reaction is electrochemical [1,2,3,4,5] and is associated with a measurable capacitance in the ZVI [2].

Acid gases (CO, CO2), reducing gases (H2, CH4) and oxidizing gases (O2) have been demonstrated to be effective in ZVI desalination [2]. This study has demonstrated (Table A1, Table A2, Table A3, Table A4, Table A5, Table A6, Table A7, Table A8, Table A9, Table A10 and Table A11) by using two widely-available and low cost gases (CO2 and air) in the desalination process that it is possible to:

- accelerate the rate of ZVI desalination to allow small compact units to be used to produce the product water;

- produce a product water that is stable when placed in storage;

- adjust the Na:Cl molar ratio in the product water to optimize irrigation water quality and maximize crop yields.

The manipulation of temperature, reactor pressure, gas saturation and gas composition is demonstrated to have the potential to create (by utilizing Nernst theory [27]) a commercial reactor unit, which can actively control: (i) the rate of desalination (time taken to achieve tBS); (ii) the base salinity (Bs) of the product water; and (iii) the Na:Cl molar ratio in the product water.

5. Conclusions

This study has used direct ion analyses (Figure 3, Table A1, Table A2, Table A3, Table A4, Table A5, Table A6, Table A7, Table A8, Table A9, Table A10 and Table A11) to confirm that the product water from a gas-pressured ZVI desalination reactor maintains a stable salinity in storage over a period of 1–2.5 years. The demonstration of product water stability is an essential pre-requisite for any commercial development of this desalination technology. The ion analyses have demonstrated Na+ ion removal of up to 99% (e.g., Trial E143a, feed water contained 2.363 g Na+·L−1). This demonstrates that the desalination process will be able to improve the quality of irrigation water.

The ability (Figure 1) of this technology to preferentially remove Na+ ions relative to Cl− ions (and vice versa) has important agricultural implications. It establishes that ZVI desalination could be used to provide irrigation water from saline sources in order to boost the yield of specific crops [2].

The demonstration of higher rates of Na+ removal, relative to Cl− removal, in an oxygenated environment (Figure 1, Table A1, Table A2, Table A3, Table A4, Table A5, Table A6, Table A7, Table A8, Table A9, Table A10 and Table A11) is consistent with a catalytic model (Appendix F), where (during discharge reactions (pH increase)) Na+ ions react with derivatives from the pressurizing gas to effect removal. The galvanic charge-discharge model for ZVI desalination (and corrosion) provides a practical basis for the acceleration of ZVI desalination and the manipulation of the composition of the ZVI desalination product.

The next major stage required in the commercial development of this gas-pressured ZVI desalination technology is the testing (including independent verification and regulatory verification) of a commercial scale (transportable) batch reactor unit with a capacity in the range of 5–30 m3/water batch (producing 500–30,000 m3/a of partially-desalinated water).

Acknowledgments

This study was funded by DCA Consultants Ltd.

Conflicts of Interest

The author declares no conflict of interest.

Appendix A: Tables of Data and Ion Analyses

Table A1.

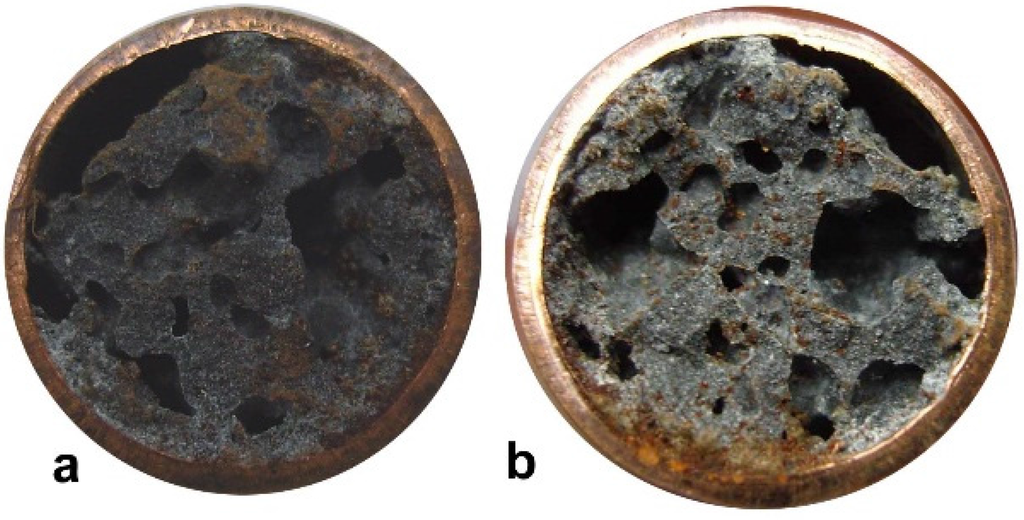

CSD1 trial’s basic data. ZVI = 26.66 g·L−1 [2]. Reactor capacity = 8.4 L. Trials CSD1a–CSD1d were pressurized (<0.1 MPa) with air [2]. Trial CSD1d included pressurization by 20% CO2 + 80% N2 [2]. Batch operation, air flow = 1.3–3.8 L·h−1. CO2 flow = 0.18 L·h−1. Pressure = atmospheric + 0.01 MPa; Non-isothermal temperature = 10–50 °C; reactor capacity = 8.4 L; reactor: Figure 2; feed water constructed using NaCl; CSD ZVI cartridge [2]; cartridge diameter = 20 mm; manifold diameter = 40 mm; energy usage ≤0.18 kW·m−3 (during air flows); further details are provided in reference [2].

| Trial | Maximum Temperature (°C) | Duration (h) |

|---|---|---|

| CSD1a | 50 | 15 |

| CSD1b | 44 | 124 |

| CSD1c | 39 | 30 |

| CSD1d | 36 | 11 |

Table A2.

Ion measurements for the CSD1 trials. NaCl = Na+ + Cl−.

| Trial | Feed Water (g·L−1) | Product Water (g·L−1) | ||||

|---|---|---|---|---|---|---|

| Na+ | Cl− | NaCl | Na+ | Cl− | NaCl | |

| CSD1a | 0.962 | 1.489 | 2.452 | 0.005 | 0.131 | 0.136 |

| CSD1b | 0.962 | 1.489 | 2.452 | 0.004 | 0.104 | 0.108 |

| CSD1c | 1.009 | 1.562 | 2.570 | 0.173 | 0.625 | 0.799 |

| CSD1d | 1.155 | 1.788 | 2.943 | 0.545 | 1.251 | 1.796 |

Table A3.

E143 series trials. Data source: [2]. Batch operation, air flow = 13.2 L·h−1. CO2 flow = 3.3 L·h−1. Pressure = atmospheric + 0.01 MPa; non-isothermal temperature = 5–12 °C; reactor capacity = 5.8 L; reactor: Figure 2; feed water constructed using NaCl; E143 ZVI cartridge [2]; cartridge diameter = 20 mm; manifold diameter = 40 mm; energy usage ≤0.18 kW·m−3 (during air flows); further details are provided in reference [2].

| Trial | Feed Water Volume (L) | Product Water Volume (L) | Duration (h) | Air Flow Duration (%) |

|---|---|---|---|---|

| E143a | 5.8 | 5.0 | 9.00 | 100.0% |

| E143b | 5.8 | 5.0 | 8.33 | 60.6% |

| E143c | 5.8 | 5.1 | 4.37 | 58.6% |

| E143d | 5.8 | 5.1 | 4.02 | 43.8% |

| E143e | 5.8 | 5.1 | 3.87 | 44.2% |

| E143f | 5.8 | 5.2 | 2.70 | 100.0% |

| E143g | 5.8 | 5.0 | 3.08 | 100.0% |

| E143h | 5.8 | 4.3 | 14.30 | 100.0% |

| E143i | 5.8 | 4.4 | 8.90 | 50.6% |

| E143j | 5.8 | 4.3 | 7.50 | 29.3% |

| E143k | 5.8 | 4.3 | 3.58 | 72.1% |

Table A4.

Ion measurements for the E143 trial series. NaCl = Na+ + Cl−.

| Trial | Feed Water (g·L−1) | Product Water (g·L−1) | ||||

|---|---|---|---|---|---|---|

| Na+ | Cl− | NaCl | Na+ | Cl− | NaCl | |

| E143a | 2.363 | 3.658 | 6.021 | 0.024 | 0.255 | 0.279 |

| E143b | 1.829 | 2.831 | 4.660 | 0.497 | 1.201 | 1.698 |

| E143c | 1.982 | 3.067 | 5.049 | 0.617 | 1.403 | 2.020 |

| E143d | 2.210 | 3.422 | 5.632 | 1.001 | 1.940 | 2.942 |

| E143e | 2.668 | 4.130 | 6.799 | 1.837 | 2.985 | 4.821 |

| E143f | 0.761 | 1.178 | 1.939 | 1.294 | 2.277 | 3.570 |

| E143g | 1.068 | 1.653 | 2.722 | 0.784 | 1.709 | 2.494 |

| E143h | 1.068 | 1.653 | 2.722 | 1.171 | 2.199 | 3.370 |

| E143i | 1.219 | 1.886 | 3.105 | 1.961 | 3.064 | 5.026 |

| E143j | 1.405 | 2.175 | 3.580 | 1.123 | 2.147 | 3.270 |

| E143k | 1.585 | 2.454 | 4.039 | 0.784 | 2.985 | 3.769 |

Table A5.

Product water ion measurements adjusted for water loss/consumption for the E143 trial series. NaCl = Na+ + Cl−.

| Trial | Product Water (Adjusted for Water Loss) (g·L−1) | Net Ion Removal (g·L−1) | ||||

|---|---|---|---|---|---|---|

| Na+ | Cl− | NaCl | Na+ | Cl− | NaCl | |

| E143a | 0.0207 | 0.2198 | 0.2405 | 2.342 | 3.438 | 5.780 |

| E143b | 0.4284 | 1.0353 | 1.4638 | 1.401 | 1.796 | 3.196 |

| E143c | 0.5425 | 1.2337 | 1.7762 | 1.439 | 1.833 | 3.273 |

| E143d | 0.8802 | 1.7059 | 2.5869 | 1.330 | 1.716 | 3.045 |

| E143e | 1.6153 | 2.6247 | 4.2392 | 1.053 | 1.505 | 2.560 |

| E143f | 1.1490 | 2.0218 | 3.1699 | −0.388 | −0.844 | −1.231 |

| E143g | 0.6759 | 1.4733 | 2.1500 | 0.392 | 0.180 | 0.572 |

| E143h | 0.8682 | 1.6303 | 2.4984 | 0.200 | 0.023 | 0.224 |

| E143i | 1.4877 | 2.3244 | 3.8128 | −0.269 | −0.438 | −0.708 |

| E143j | 0.8326 | 1.5917 | 2.4243 | 0.572 | 0.583 | 1.156 |

| E143k | 0.5812 | 2.2130 | 2.7943 | 1.004 | 0.241 | 1.245 |

Table A6.

Trial E143k: ion concentrations. The manifold water (0.3 L) and ZVM cartridge water (0.1 L) are described further in reference [2].

| Item | Na (g·L−1) | Cl (g·L−1) | NaCl (g·L−1) | Na:Cl Molar Ratio |

|---|---|---|---|---|

| Feed Water | 1.585 | 2.454 | 4.039 | 1.000 |

| Product Water | 0.784 | 2.985 | 3.769 | 0.407 |

| Manifold Water | 13.653 | 14.966 | 28.620 | 0.912 |

| ZVI Cartridge Water | 446.678 | 144.185 | 590.862 * | 3.098 |

Note: * includes NaOH and related species.

| Trial | Analyses Based on EC | Direct Ion Analyses | NaCl Removed (g·L−1) | NaCl Removed * (g·L−1) | ||||

|---|---|---|---|---|---|---|---|---|

| Feed Water (g·L−1) | Product Water (g·L−1) | Feed Water (g·L−1) | Product Water (g·L−1) | EC Analyses | Ion Analyses | EC Analyses | Ion Analyses | |

| E143a | 5.74 | 0.06 | 6.02 | 0.28 | 5.68 | 5.74 | 5.688 | 5.780 |

| E143b | 4.44 | 1.51 | 4.66 | 1.70 | 2.93 | 2.96 | 3.138 | 3.196 |

| E143c | 4.81 | 1.93 | 5.05 | 2.02 | 2.88 | 3.03 | 3.113 | 3.273 |

| E143d | 5.37 | 2.79 | 5.63 | 2.94 | 2.58 | 2.69 | 2.917 | 3.045 |

| E143e | 6.48 | 4.69 | 6.8 | 4.82 | 1.79 | 1.98 | 2.356 | 2.560 |

| E143f | 1.85 | 3.49 | 1.94 | 3.57 | −1.64 | −1.63 | −1.249 | −1.231 |

| E143g | 2.59 | 2.36 | 2.72 | 2.49 | 0.23 | 0.23 | 0.556 | 0.572 |

| E143h | 2.63 | 3.25 | 2.72 | 3.37 | −0.62 | −0.65 | 0.221 | 0.224 |

| E143i | 2.96 | 4.95 | 3.11 | 5.03 | −1.99 | −1.92 | −0.795 | −0.708 |

| E143j | 3.33 | 3.03 | 3.58 | 3.27 | 0.30 | 0.31 | 1.084 | 1.156 |

| E143k | 3.35 | 3.27 | 4.04 | 3.77 | 0.08 | 0.27 | 0.926 | 1.245 |

Note: * NaCl removed calculations adjust the amount of NaCl removed for water consumption (Table A3).

Table A8.

E144 series trials. Details of each reactor and ZVI are provided in reference [2]. The difference in water volume between the feed water and product water volumes is primarily a result of the reaction of the ZVI with the water, but may include some water removed by the pressurizing gas (air, or 20% CO2 + 80% N2) [2]. Batch operation, air flow = 13.2 L·h−1. CO2 flow = 3.3 L·h−1. Pressure = atmospheric + 0.01 MPa; non-isothermal temperature = 5–19 °C; reactor capacity = 5.8 L; reactor: Figure 2; feed water constructed using Zechstein Halite; E144 ZVI cartridge [2]; cartridge diameter = 20 mm; manifold diameter = 40 mm; energy usage ≤0.18 kW·m−3 (during air flows); further details are provided in reference [2].

| Trial | Feed Water Volume (L) | Product Water Volume (L) | Duration (h) | Air Flow Duration (%) |

|---|---|---|---|---|

| E144a | 5.8 | 4.4 | 6.48 | 58.64% |

| E144b | 5.8 | 4.4 | 104.30 | 67.59% |

| E144c | 5.8 | 4.9 | 690.00 | 0.00% |

| E144d | 5.8 | 4.6 | 291.00 | 0.00% |

| E144e | 5.8 | 4.4 | 537.00 | 0.00% |

| E144f | 5.8 | 3.9 | 1295.00 | 0.00% |

Table A9.

Ion measurements for the E144 trial series. NaCl = Na+ + Cl−.

| Trial | Feed Water (g·L−1) | Product Water (g·L−1) | ||||

|---|---|---|---|---|---|---|

| Na+ | Cl− | NaCl | Na+ | Cl− | NaCl | |

| E144a | 1.134 | 2.770 | 3.904 | 1.074 | 2.381 | 3.455 |

| E144b | 1.312 | 2.925 | 4.237 | 1.123 | 2.537 | 3.660 |

| E144c | 0.636 | 1.826 | 2.462 | 0.593 | 1.684 | 2.276 |

| E144d | 0.522 | 1.480 | 2.002 | 0.593 | 1.582 | 2.174 |

| E144e | 0.512 | 1.707 | 2.219 | 0.497 | 1.378 | 1.875 |

| E144f | 4.161 | 6.519 | 10.680 | 1.196 | 2.251 | 3.446 |

Table A10.

Product water ion measurements adjusted for water loss/consumption for the E144 trial series.

| Trial | Product Water (Adjusted for Water Loss) (g·L−1) | Net Ion Removal (g·L−1) | ||||

|---|---|---|---|---|---|---|

| Na+ | Cl− | NaCl | Na+ | Cl− | NaCl | |

| E144a | 0.8148 | 1.8063 | 2.6210 | 0.319 | 0.964 | 1.283 |

| E144b | 0.8519 | 1.9246 | 2.7766 | 0.460 | 1.000 | 1.460 |

| E144c | 0.5010 | 1.4227 | 1.9228 | 0.135 | 0.403 | 0.539 |

| E144d | 0.4652 | 1.2411 | 1.7055 | 0.057 | 0.239 | 0.297 |

| E144e | 0.3770 | 1.0454 | 1.4224 | 0.135 | 0.662 | 0.797 |

| E144f | 0.8042 | 1.5136 | 2.3171 | 3.357 | 5.005 | 8.363 |

Table A11.

Trial E144 series: comparison of trial analyses. Data source for EC analyses: [2].

| Trial | Trial Analyses Based on EC | Direct Ion Analyses | NaCl Removed (g·L−1) | |||

|---|---|---|---|---|---|---|

| Feed Water (g·L−1) | Product Water (g·L−1) | Feed Water (g·L−1) | Product Water (g·L−1) | EC Analyses | Ion Analyses | |

| E144a | 4.07 | 3.55 | 3.904 | 3.455 | 0.52 | 0.449 |

| E144b | 4.07 | 3.69 | 4.237 | 3.66 | 0.38 | 0.577 |

| E144c | 1 | 1.9 | 2.462 | 2.276 | −0.9 | 0.186 |

| E144d | 1.1 | 1.27 | 2.002 | 2.174 | −0.17 | −0.172 |

| E144e | 2.05 | 2.03 | 2.219 | 1.875 | 0.02 | 0.344 |

| E144f | 5.83 | 4.35 | 10.68 | 3.446 | 1.48 | 7.234 |

Appendix B: Reaction Route Group A

ZVI redox remediation reactions, which result in the permanent removal of Na+ and Cl− ions, fall into a number of distinct groups:

- direct reaction with ZVI to produce a product;

- catalysed reaction involving ZVI;

- removal in hydration shells;

- adsorption by ZVI.

B.1. Direct Reaction with ZVI

Examples of direct reaction with the ZVI to produce a precipitated product containing Fe and one or more of Na+ and Cl− include:

- β-FeOOH (akaganeite), e.g., [30,31,32,33,34,35,36,37,38,39,40,41,42,43,44,45,46,47,48,49,50,51,52,53], where the Na+ and Cl− ions are concentrated in tunnels within the structure and in its hydrated ionic shell [30,31,32,33,34,35,36,37,38,39,40,41,42,43,44,45,46,47,48,49,50,51,52,53]. β-FeOOH is the dominant FeOOH corrosion species when the water contains significant concentrations of Cl− ions [30,31,32,33,34,35,36,37,38,39,40,41,42,43,44,45,46,47,48,49,50,51,52,53], i.e., Log(Cl−/OH−) is greater than 1.16 and preferably greater than eight [2,30,31,32,33,34,35,36,37,38,39,40,41,42,43,44,45,46,47,48,49,50,51,52,53]. The general ZVI corrosion route is [2,30,31,32,33,34,35,36,37,38,39,40,41,42,43,44,45,46,47,48,49,50,51,52,53]:Fe0 → Fe(OH)2→ GR1(Cl−)→β-FeOOH (akaganeite)—medium Eh route [2]

Fe0→Fe(OH)2→Fe(OH)3→β-FeOOH—high Eh route [2]

Fe0→FeII→FeII + FeIII→FeIII [2] - Green Rust 1 (chloride) ((NaI(a = 1 – c − b)FeII(b = 1 − c − a)FeIIIc(OH)g]x−·[(x/n)Cln−·mH2O]x+))[2] (GR1(Cl−)), ferrous hydroxychloride, e.g., [54,55,56,57,58,59,60,61]. The Na+ and Cl− ions are concentrated within the layered molecular structure [54,55,56,57,58,59,60,61]. The general ZVI corrosion route is [2,54,55,56,57,58,59,60,61]:Fe0→Fe(OH)2→GR1(Cl−)—low Eh route [2]

Fe0→Fe(OH)2→GR1(HCO3−)→GR1(Cl−)—low Eh route coupled with decreasing pH [2]

Fe0→Fe(OH)2→GR1(HCO3−)→GR1(Cl−)→GR1(SO3−)→GR2(SO4−) [2]

Fe0→FeII→FeII + FeIII [2]

GR1 and GR2 are different layered structural arrangements for ferrous hydroxyl species [54,55,56,57,58,59,60,61]. The structural arrangement of the layered double hydroxide (LDH) varies with the dominant anion species and the relative proportion of the different anion species (e.g., OH−, HO2−, NO3−, HCO3−, CO32−, Cl−, F−, SO3−, SO42−, etc.) contained within the structure [54,55,56,57,58,59,60,61].

- 3.

- Formation of sodium ferrates (FeIV species, Na2FeO4), e.g., [62,63]:Fe0→FeII→FeII + FeIII→FeIII→FeIV [2]

2Na+ + FeO42− = Na2FeO4 (purple colour)

HFeO2− + 2H2O = FeO42− + 5H+ + 4e−

Fe3+ + 4H2O = FeO42− + 8H+ + 3e−

FeOH2+ + 3H2O = FeO42− + 7H+ + 3e−

The Eh and pH of the product water associated with gas-pressured ZVI desalination [1,2] are consistent with the removal of NaCl in association with β-FeOOH and ferrous hydroxychloride [1,2].

B.2. Direct Catalytic Reaction with ZVI

Cl− ions act as a catalyst and phase distributor for iron corrosion (rust formation) [63,64,65,66,67,68,69]. The redox (Eh, pH) relationships for Cl, Fe and Na species (ions and precipitants) are provided in [63]. Two roles have been proposed for Cl− during iron corrosion, they are:

- A role as a catalyser [65]:Fe0 + nCl− = Fen+nCl− + ne− (production of intermediate)

Fen+nCl− = Fen+ + nCl− (ionisation of Fe)

Fe0→FeII→FeII + FeIII→FeIII→FeIV

The catalyser role releases electrons (e−) and Fen+ ions into the environment [65,70]. The released electrons catalyse a variety of remediation reactions within the water [70,71].

- 2.

- A role as phase distributor [65]: The end corrosion product (rust) at the water ZVI interface is FeOOH (Equation (B1)). The formation of the surface rust (FeOOH) species results in the initial corrosion (-OH) terminal groups at the rust-water interface changing to (-OH2)+ groups [65]. This change both attracts Cl− ions and allows Cl− ions to migrate through the rust to the metal surface [65] (e.g., Appendix E).

B.3. Removal in Hydration Shells

The significance and structure of the hydration shells associated with the formation of Fe corrosion species is poorly understood. Two types of terminal surface occur [2,72,73,74,75,76]. They are:

- Negatively-charged terminal surface: which can be defined as FeOH0.5− and takes the general structure: (OH)-(OH)-Fe-O-O-Fe-R (where R = a repeat of the stoichiometric atomic layer sequence or tethering surface. R can include hydrated layers) [2]. A double hydrated terminal surface takes the form: (H2O)-(H2O)-(OH)-(OH)-Fe-O-O-Fe-R [2]. This surface type has a negative charge and can be expected to remove Na+ ions from the water [2].

- Positively-charged interface terminal surface: which can be defined as FeOH20.5+ and takes the general structure: (OH2)-(OH)-Fe-O-O-Fe-R [2]. A double hydrated interface terminal surface takes the form: (H2O)-(H2O)-(OH2)-(OH)-Fe-O-O-Fe-R [2]. This surface type has a positive charge and can be expected to remove Cl− ions from the water [2].

B.4. Adsorption

The ZVI corrosion surface is covered with surface hydroxyl groups (≡Fe-OH). These groups are ampholytes and are able to react to produce positively- and negatively-charged surfaces [77]:

≡Fe-OH + H+ = ≡Fe-OH2+

≡Fe-OH = ≡Fe-O− + H+

≡Fe-OH = ≡Fe-O− + H+

Cation (Me+) and anion (ligand, L) adsorption is explained by Lewis base relationships [77]. Cation adsorption (e.g., Na+) is characterised by the release of hydrogen ions, while anion adsorption is characterised by the release of hydroxyl groups [77]:

≡Fe-OH + Men+ (e.g., Na+) = ≡Fe-OMen+ (e.g., ≡Fe-ONa+ ) + H+

≡Fe-OH + L− (e.g., Cl−) = ≡Fe-L (e.g., Fe-Cl) + OH−

≡Fe-OH + L− (e.g., Cl−) = ≡Fe-L (e.g., Fe-Cl) + OH−

The initial theories for the mechanism of ZVI desalination are by: (i) ion exchange in double layered hydroxides [26]; and (ii) by direct adsorption onto corroding ZVI surfaces [1,2,3,4,5]. Both theories assume that the Na+ and Cl− ions are permanently removed from the water and are retained with the ZVI bed and any Fe corrosion product precipitates, which are entrained in the product water.

Appendix C: Reaction Route Group B

Redox reactions include reactions where the dominant ion adduct, or ions, are controlled by the Eh and pH of the water [63,70,71]. Both reactants and products associated with this type of reaction are soluble in water [63,70,71]. This type of ion remediation is a characteristic of ZVI redox remediation for organo-halides, nitrates, oxides, hydroxides and sulphur species [26,63,70,71]. Typical ZVI nitrate removal reactions include [63,71]:

NO3− + H3O+[H2O]2 = NH4+ + 3HO2−

NO3− + H3O+[H2O]2 = NH4+ + 3HO− + 1.5O2 (g,aq)

2NO3− + 12H+ + 10e− = N2 (g, aq) + 6H2O

NO3− + 2H+ = NO2− + H2O

NO3− + H3O+[H2O]2 = NH4+ + 3HO− + 1.5O2 (g,aq)

2NO3− + 12H+ + 10e− = N2 (g, aq) + 6H2O

NO3− + 2H+ = NO2− + H2O

ZVI-induced organo-chloride removal reactions fall into three free electron catalysed groups [71]. The appropriate reactions for organo-halides or organo-halides formed on catalytic sites within the ZVI include ZVI surface-based reactions [71].

C.1. n-Fe Surface-Based Reaction or Aqueous ZVM Ion-Based Reaction [71]

Initial ZVI nano-scale reaction − xCs(+/−) + zH+ + yCl− = HzCxCly (corrosion product)

HzCxCly (corrosion product or pollutant) + e− = HzCxCly−

HzCxCly− + Fen+ = [HzCxCly-Fe](n−1)+

[HzCxCly- Fe](n−1)+ + H2O = [Hz+1CxCly-1] + Fe-Cl(n−1)+ (ion adduct) + OH + e−

xCs(+/−) sites form in the corroding iron when the iron contains carbon [2].

HzCxCly (corrosion product or pollutant) + e− = HzCxCly−

HzCxCly− + Fen+ = [HzCxCly-Fe](n−1)+

[HzCxCly- Fe](n−1)+ + H2O = [Hz+1CxCly-1] + Fe-Cl(n−1)+ (ion adduct) + OH + e−

xCs(+/−) sites form in the corroding iron when the iron contains carbon [2].

C.2. n-Fe-Hydroxide/Peroxide Surface-Based Reaction or Aqueous Fe-Hydroxide/Peroxide Ion-Based Reaction [71]

Initial ZVI nano-scale reaction − xCs(+/−) + zH+ + yCl− = HzCxCly (corrosion product)

FejOkHdn+ + HzCxCly (corrosion product or pollutant) + e− = [HzCxCly-FejOkHd](n−1)+

[HzCxCly-FejOkHd](n−1)+ + H2O = [Hz+1CxCly-1] + FejOk+1Hd+1(n−2)+ + Cl + e−

FejOkHdn+ + HzCxCly (corrosion product or pollutant) + e− = [HzCxCly-FejOkHd](n−1)+

[HzCxCly-FejOkHd](n−1)+ + H2O = [Hz+1CxCly-1] + FejOk+1Hd+1(n−2)+ + Cl + e−

C.3. n-Fe Surface-Based Reaction or Aqueous ZVM Ion-Based Reaction [71]

HzCxN3Cly + e− = HzCx N3Cly−

HzCx N3Cly− + Fen+ = [HzCx N3Cly-Fe](n−1)+

[HzCx N3Cly-Fe](n−1)+ + H2O = [Hz+1Cx N3Cly-1] + FeCl(n−1)+ + OH + e−

HzCx N3Cly− + Fen+ = [HzCx N3Cly-Fe](n−1)+

[HzCx N3Cly-Fe](n−1)+ + H2O = [Hz+1Cx N3Cly-1] + FeCl(n−1)+ + OH + e−

C.4. Implications of Surface-Based Reactions

These reaction series (Equations (C2)–(C4)) demonstrate that e− may act as a catalyst [70,71]. They create the possibility that in a gas-pressured reactor, the initial stages in the removal of NaCl may involve radicals associated with the pressurizing gases, O2 and CO2. This would allow:

- the Na+ and Cl− ion concentrations measured in the product water within the reactor to decline as the concentration of radical products increased;

- the desalination reactions to be reversed in the stored water, as the pH changes;

- the relative molar proportion of Na:Cl ions in the product water to be adjusted during reactor operation.

C.5. Pressurization by CO2

When the water is pressured by CO2, the generic pH sensitive reaction sequence is [63]:

H2O + CO2 = H2CO3 = HCO3− + H+= CO32− + 2H+

This reaction is characterized by an initial pH drop as H2CO3 is formed [63] (e.g., CSD, E143, E144 trial series). When CO2 gas charging ceases, the pH gradually rises as the proportion of, first, HCO3− and, then, CO32− increases [2,63].

C.6. Pressurization by O2

When the water is pressured by O2 (air), the generic pH sensitive reaction sequence is [63]:

H2O + 0.5O2 + 2e− = 2OH−

This reaction is characterized by an initial increase in pH to a stable level [2,63] (e.g., E146 trial series). Cessation of O2 gas charging may partially reverse the reaction and may be associated with a pH reduction and/or Eh change [2,63,70].

C.7. Generic ZVI Reactions Associated with CO2 and O2 Gas Charging

During CO2 charging [2,63,70,71]:

Fe(s) + 2H+ (aq) = Fe2+ (aq) + H2 (g,aq)

H2(g, aq) = 2H+ + 2e−

Fe(s) + 2H+ (aq) = Fe2+ (aq) + aH2 (g,aq) + b(2H+) + b(2e−)

H2(g, aq) = 2H+ + 2e−

Fe(s) + 2H+ (aq) = Fe2+ (aq) + aH2 (g,aq) + b(2H+) + b(2e−)

During O2 charging [2,63,70,71]:

Fe2+ (aq) + 2OH− (aq) = Fe(OH)2 (s)

Fe(OH)2 + 0.5O2 + e− = FeOOH + OH−

Fe2+ (aq) + 2OH− (aq) + 0.5O2 + e− = FeOOH + OH−

Fe(OH)2 + 0.5O2 + e− = FeOOH + OH−

Fe2+ (aq) + 2OH− (aq) + 0.5O2 + e− = FeOOH + OH−

C.8. Na Removal Associated with Fe Valency Changes

If a generic anodic Fe oxyhydroxide ion site takes the form [(Fe2(OH)6(OH2)3]2−, then the corresponding generic cathodic site may take the form [Fe2O3(OH)3(OH2)3]3− [78,79,80]. This allows the Na+ removal (adsorption) reaction to occur when the Fe valency increases from 2 to 3:

[(FeII)2(OH)6(OH2)3]2− + 3Na+ + 3OH− = [(FeIII)2O3(OH)3(OH2)3]3−·3Na+ + 3H2O + 2e−

In this example, the generic Fe oxyhydroxide ion pair takes the form [(Fem(OH)x(OH2)y]n− and [FemOp(OH)a(OH2)b]k− [78,79,80]. The control on the amount of Na+ that can be adsorbed is a function of the availability of OH− ions (i.e., an increase in pH). An increase in Na+ adsorption will result in an increase in the availability of e−. Equation (C9) implies that if: (i) the pH of water is raised by O2 charging (producing OH− ions); and (ii) the gas charging is then removed; then (iii) the pH (and Na+ ion concentration) will decline during the subsequent time period e.g., CSD1 and E143 trial series [2]. The generic reaction takes the simplified form [78,79,80]:

[(OH)6(OH2)3]6− + 6Na+ = [(OH)6(OH2)3]6−·6Na+

(≡[(OH)6(OH2)3](6 − n)−) + (6-n)Na+ = (≡[(OH)6(OH2)3](6−n)−·(6 − n)Na+)

(≡) = site with a charge of n(+), e.g., ≡(OH2)+

(≡[(OH)6(OH2)3](6 − n)−) can be (≡[(OH)m(OH2)y]·z(OH2)+) (m − n − z)−

In the presence of CO2 the adsorption site may potentially take the form:

(≡[(OH)m(CO2)d(HCO3)e(CO3)f (OH2)y] z(OH2)+) (m + e + 2f − n − z)−

(≡[(OH)6(OH2)3](6 − n)−) + (6-n)Na+ = (≡[(OH)6(OH2)3](6−n)−·(6 − n)Na+)

(≡) = site with a charge of n(+), e.g., ≡(OH2)+

(≡[(OH)6(OH2)3](6 − n)−) can be (≡[(OH)m(OH2)y]·z(OH2)+) (m − n − z)−

In the presence of CO2 the adsorption site may potentially take the form:

(≡[(OH)m(CO2)d(HCO3)e(CO3)f (OH2)y] z(OH2)+) (m + e + 2f − n − z)−

The hydrated hydroxide ion may be replaced or supplemented with an alternative hydrated anion (e.g., HCO3−, CO32−, etc.). In these examples, the Na+ ion concentration will show a decrease using an ion analyser, but the total amount of Na in the water will remain constant (unless the hydrated hydroxide ion adduct is attached to a precipitated particle, which can be removed by filtration prior to analysis). The reduction in Na+ ion concentration will signify a decrease in salinity.

C.9. Catalysed Cl Removal Associated with Fe

The catalysed Cl− removal reaction may take the form [71,81]:

0.5Cl2 + e− + [FejOk + 1Hd + 1](n − 2)+ + [Hz + 1CxCly − 1] = H2O + [HzCxCly-FejOkHd](n − 1)+

HzCxCly-FejOkHd](n − 1)+ = HzCxCly + [FejOkHd]n+ + e−

HzCxCly-FejOkHd](n − 1)+ = HzCxCly + [FejOkHd]n+ + e−

The catalysed reaction route is complicated further in the presence of bicarbonate species as [65,70,71,81,82,83]:

0.5Cl2 + e− + [FejOk + 1Hd + 1](n−2)+ + [Hz + 1CxOnCly - 1] = H2O + [HzCxOnCly-FejOkHd](n − 1)+

HzCxOnCly-FejOkHd](n−1)+ = HzCxOnCly + [FejOkHd]n+ + e−

HzCxOnCly-FejOkHd](n−1)+ = HzCxOnCly + [FejOkHd]n+ + e−

Bicarbonate/carbonate ions and chloride actively facilitate and encourage Fe0 to act as a catalyst in the aqueous environment in the presence of COx gas species [81,82].

C.10. UV Absorption Peaks which May Be Associated with Catalysed Cl Removal

The generic reactions (Equations (C9)–(C12)) imply that UV-visible absorbance spectra of nano-particles forming within a gas charged reactor should show evidence of HzCxOnCly species (230–250 nm) [83,84,85], HCO3− species (275 nm)[2] and (≡[(OH)6(OH2)3](6 − n)−·a(6 − n)Na+)(−(6 − n) + a(6 − n)) species (262/8 nm, 275/6 nm, 301 nm, 324/8 nm, 337 nm, 351 nm, 365 nm, 395 nm) [2].

C.10.1. UV-Visible Absorbance Peaks Associated with Cl Species

The specific adsorption (peak) wavelengths of potential Cl− products include: Cl2 = 250 nm, 330 nm [83,84]; ClO = 270 nm [83]; ClO− = 290 nm [2]; Cl2O = 250–260 nm [83]; ClO2 = 292 nm [2]; ClClO2 = 230 nm [83]; Cl2O4 = 230-235 nm [83]; Cl2O6 = 215 nm [83]; OClO = 340–360 nm [83]; ClO-OCl = 240–250 nm [83]; HOCl = 240 nm [83]; CH2ClO = 230 nm [85]; CH3OCl = 235–240 nm [83]; COHCl = 245–260 nm [83]; CH2ClCHO = 290–310 nm [83]; CHCl2CHO = 295–300 nm [83]; CCl3CHO = 290–295 nm [83]; CH3C(O)Cl = 235–245 nm [83]; CH2ClCOCl = 240–250 nm [83]; CHCl2C(O)Cl = 250–260 nm [83]; CCl3C(O)Cl = 245–265 nm [83]; CH3C(O)CH2Cl = 220–235 nm [83]. This list is not definitive, and other HzCxOnCly species exist.

C.10.2. UV-Visible Absorbance Peaks Associated with Nano-Particles Produced during Desalinations

The published UV-visible absorbance spectra for nano-particles produced by an active gas-charged ZVI desalination reactor have been interpreted [2] as being a result of the formation of Fe ion species, OxHy radicals, O2−, NaO−, ClO-OCl, ClO2 and ClO−.

Appendix D: Significance of Higher Residual Salinities in the Manifold and ZVI Cartridge

Higher residual salinity levels (based on EC) have been recorded in the manifold (50.17 mS·cm−1) and ZVI cartridge (350.37 mS·cm−1) associated with the E143 trial series [2]. The ion analyses in Table A6 confirm these elevated salinities: (i) manifold (28.62 g·L−1); and (ii) ZVI cartridge (446.678 g Na+·L−1 + 144.185 g Cl−·L−1). Desorption of NaCl from the ZVI (within the reactor) may account for the occasional increases in product water salinity observed in the E143 series trials (Table A3, Table A4, Table A5, Table A6 and Table A7).

Analysis of the Na:Cl molar ratio in the water associated with the E143k trial (Figure D1) establishes that the product water is depleted of Na+ ions, while the relative concentration of Na+ ions progressively increases through the manifold and into the attached ZVI cartridge.

Figure D1.

Comparison of molar Na:Cl ratios from the feed water, product water; manifold water and ZVI cartridge water associated with Trial E143k. Data Source: Table A6.

D.1. Salinity Concentration Associated with ZVI Corrosion Products

Sediment located 0.1–0.4 m below the seawater-seabed interface has been demonstrated to concentrate Cl− ions from 18.986 g Cl−·L−1 in the seawater to 20–24 g Cl−·L−1 when akaganeite has formed as a digenetic product [86]. The observations in Figure D1 are therefore consistent with observations made in the natural environment.

Akaganeite concentrates Na+ and Cl− ions in its hydrated shell [49] and concentrates Cl− ions within molecular tunnels inside its crystallites [49]. The observations in Figure D1 are consistent with ZVI corrosion products preferentially attracting Na+ and Cl− ions from the water and preferentially binding the Cl− ions into pores within the ZVI corrosion products. The high Na:Cl ratio in the ZVI implies that a substantial part of the Na+ ions is held as NaOH, NaO−, (≡[(OH)6(OH2)3](6 − n)−·a(6 − n)Na+)(−(6 − n) + a(6 − n)) species in the pore waters. The Na+ ions may be bound to the ZVI through sites of the type: ≡Fe-ONa+; FeOH0.5−, ((OH)-(OH)-Fe-O-O-Fe-R)n−; or through tethered anodic groups (electrochemical redox switchable moieties), which are attached to the ZVI or ZVI corrosion products [1,87,88,89].

D.2. Recovery of NaCl Held in ZVI Corrosion Products

Mineralogical studies [40,41] and museum conservation studies [30,31,32,33,34,35,36] have established that both Na+ and Cl− ions can be removed from the ZVI corrosion products by washing. Displacement of Na+ and Cl− ions concentrated in the ZVI may occur when a batch of product water is replaced by a new batch of feed water [28,29,30,31,32,33,34,38,39]. This can potentially result in concentrations of Na+ ions and/or Cl− ions being higher in the resulting product water than in the feed water. Examples of this situation are provided by Trials E143f and E143i (Table A5).

This situation was observed in less than 10% of the trials considered in this study and does not occur if the ZVI cartridge is fully drained (and rinsed) at the conclusion of each trial.

D.3. Significance of Water Volume Reduction

Product water associated with conventional desalination plants (e.g., reverse osmosis, etc.) is typically within the range of 20%–50% of the feed water [18,19,20,21,22,23]. The residual enhanced salinity waste water (reject brine) is discharged into the environment [18,19,20,21,22,23]. The discharged waste water volume is in the order of 50%–80% of the feed water volume [18,19,20,21,22,23].

D.3.1. Observed Water Volume Reduction

Unlike conventional desalination processes, the gas-pressured static diffusion desalination process produces no waste water [1,2,3,4,5]. The product water volume can decline with increasing time in the reaction environment [2]. The water volume losses recorded in Table A1, Table A2, Table A3, Table A4, Table A5, Table A6, Table A7, Table A8, Table A9, Table A10 and Table A11 are between 10% and 40%. Water volume losses occur as a result of the following chemical processes:

The bulk of the water losses are associated with physical processes:

- Water losses associated with evaporation at the gas: water contact;

- Water losses associated with humidification as a dry gas is bubbled through the water.

The principal water loss in trials CSD1, E143 and E144 results from humidification. In these trials, the waste gas was vented into the atmosphere. In commercial unit humidification (and evaporation), losses are reduced by capturing and recycling the bulk of the discharging gas.

Water losses associated with humidification have been demonstrated to be negligible when the gas is humidified prior to use (e.g., E146 trial series [2]).

A suitably-designed commercial gas-pressured static diffusion desalination reactor can be expected to operate with water losses of less than 5%. This compares to water losses of 50%–80%, which are associated with conventional desalination plants [18,19,20,21,22,23].

D.3.2. Impact of High Water Losses Due to Suboptimal Reactor Design on Desalination Assessment

An earlier study established [1] that the humidified gas does not remove Na+ ions and Cl− ions from the water body. Water volume reductions associated with humidification will increase the product water salinity, due to the concentration of the residual NaCl [2].

An increase in NaCl concentration in the product water in these circumstances can mask a net removal of NaCl [2], i.e., with the placement of 1 g NaCl/L in the reactor, with a 50% reduction in product water volume, one would expect to recover water with a salinity of 2 g NaCl/L [2]. If the product water has a salinity of less than 2 g NaCl/L, then part of the excess salinity will have been removed by the ZVI [2].

No attempt was made in the design and construction of the trial reactors used in the trials (Table A1, Table A2, Table A3, Table A4, Table A5, Table A6, Table A7, Table A8, Table A9, Table A10 and Table A11) to minimize water losses due to humidification [2]. This was a deliberate design decision for the trials. The trial design was used to establish whether a gas process (recycle) loop (Figure 2) would be required in a commercial unit to minimize humidification losses.

Trial examples, E143f–E143i (Table A4), demonstrate increased raw product water salinities. Mass balance analyses, which adjust the salinities for water consumption (e.g., Table A5) are required to establish if the increased salinity results from:

- no desalination occurring [2];

- a real increase in salinity due to displacement of previously-removed NaCl from the ZVI into the product water;

- desalination occurring at a slower rate than the rate of water removal [2].

The mass balance analysis (Table A5) establishes that (with the exception of Trials E143f and E143i) there has been a net removal of Na+ ions and Cl− ions in these trials.

D.4. Different Na+ and Cl− Ion Concentrations in Different Parts of the Reactor

The ion concentrations for Trial E143k (Figure D2, Table A6) demonstrate that the Cl− ion concentration in the raw product water is greater than the Cl− ion concentration in the feed water. The Na+ ion concentration (and total salinity) is lower in the product water (Figure D2, Table A6). The mass balance analysis establishes (Table A5) that both Na+ and Cl− ions have been removed from the product water. In this example (Trial E143k), the rate of Cl− removal is less than the rate of water removal, while the rate of Na+ removal is greater than the rate of water removal.

The concentration of Na+ ions and Cl− ions increases into the manifold and ZVI cartridge (Figure D2, Table A6). This increase is accompanied by preferential Na+ ion concentration into the manifold and ZVI cartridge (Figure D2). This example demonstrates that some of the Na+ and Cl− ions, which are removed from the product water (during the desalination process), prior to placement in storage, are retained in the reactor in both the manifold and ZVI cartridge.

Figure D2.

Comparison of ion concentrations from the feed water, product water; manifold water and ZVI cartridge water associated with Trial E143k. (a) Cl− ions; (b) Na+ ions. Data source: Table A6.

Appendix E: Location of the Desalination Sites

The trial results (Figure 1, Appendix A) have established that ZVI desalination results in a permanent removal of Na+ and Cl− ions. The ions are removed separately, resulting in a change in the molar Na:Cl ratio in the product water when compared to the feed water (Figure 3d).

E.1. Basic Desalination Model: Observations

Placement of NaCl in water will result in the equilibrium reaction:

NaCl (aq) = Na+ (aq) + Cl− (aq)

The Gibbs free energy, enthalpy and entropy of each ion is provided in [90]. In a gas-pressured reactor, the following adsorption reactions may occur:

- During periods of CO2 charging [2,63]:H2O + CO2 = H2CO3 = HCO3− + H+

Cl− + Fe–O–O–(OH)–(OH) + H+ = Fe–O–O–(OH)–(OH2)+·Cl− - During periods of O2 (air) charging [2,63]:2H2O + O2 = H2O2 = 2OH· + 2e− = 2OH−

OH− + H2O = H2O2 + H+ + 2e−

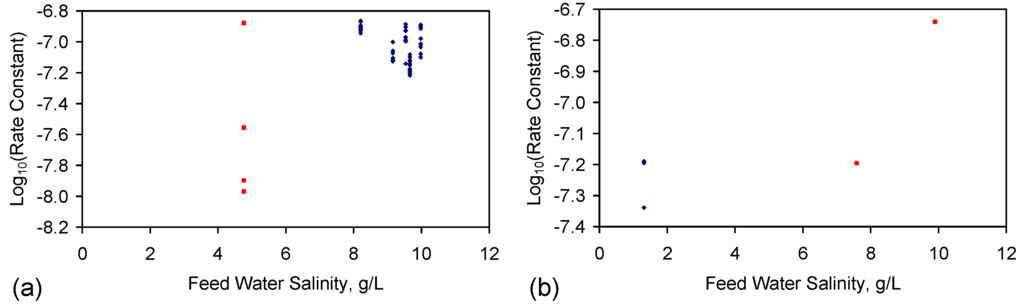

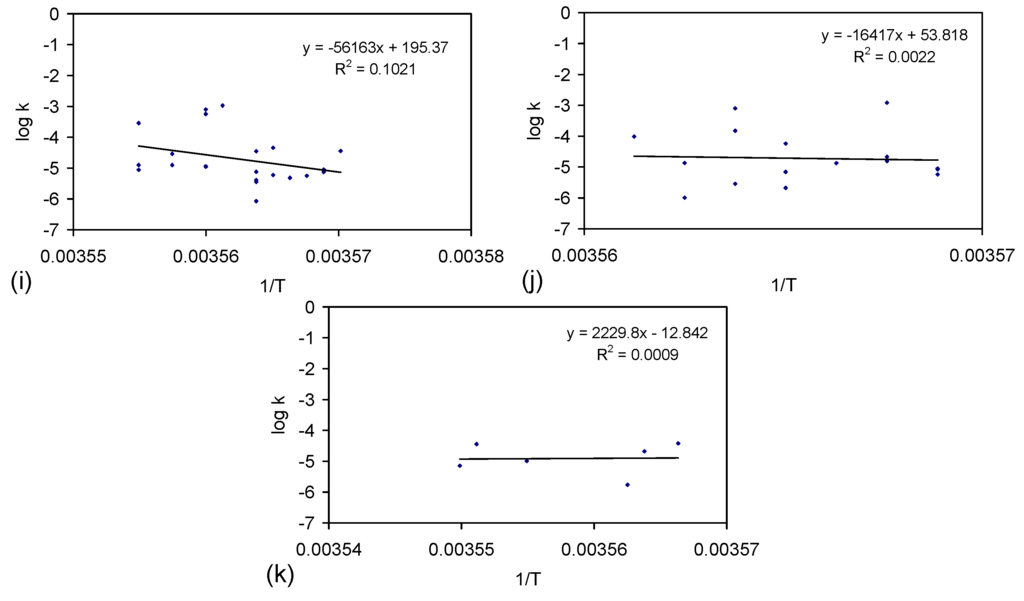

Na+ + Fe–O–O–(OH)–(OH) + e− = Fe–O–O–(OH)–(OH)−·Na+

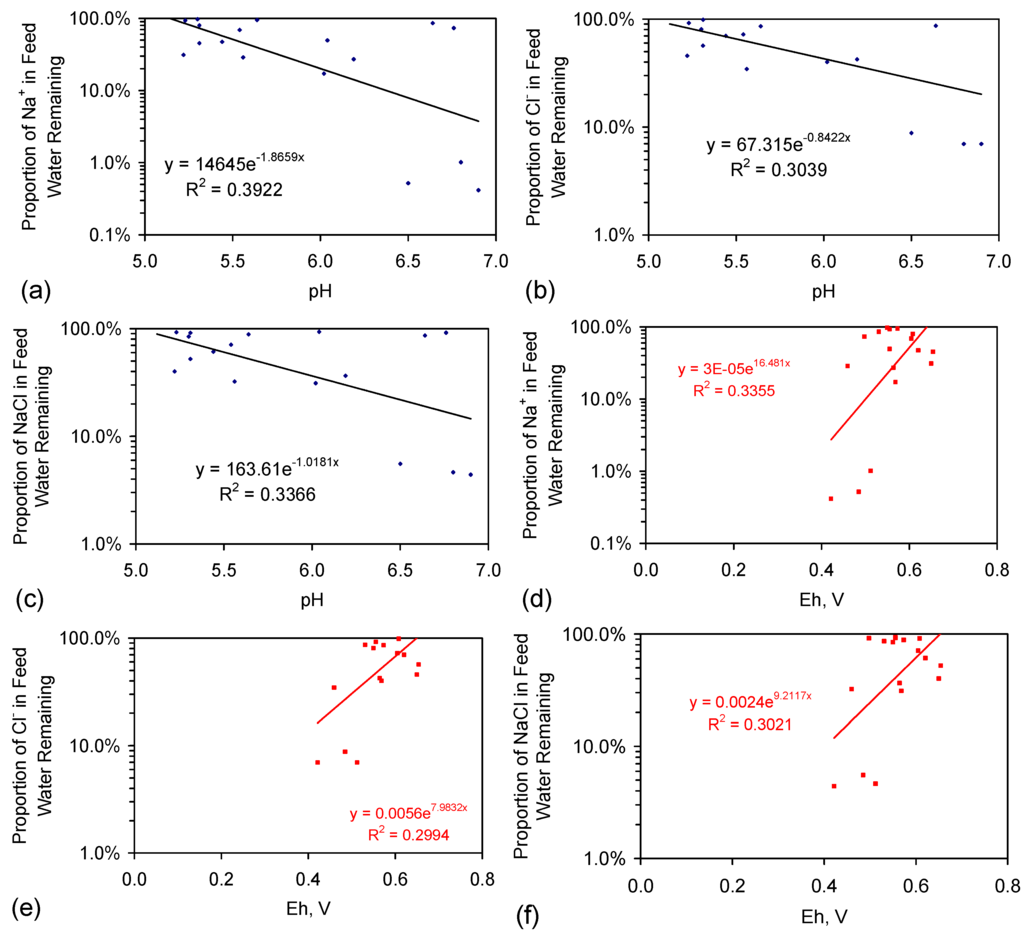

This model suggests that: (i) Cl− removal is a function of the proton (H+) availability and will be favoured by acidic conditions; (ii) Na+ removal is a function of the electron (e−) availability and will be favoured by alkaline conditions or conditions containing an excess of e−. The relationship between pH, Eh and ion removal in Figure E1 indicates that Na+ and Cl− removal occur in mildly acidic reaction conditions. Their removal increases as the pH increases between five and seven. This change is associated with a decrease in Eh (indicating electron removal) [63]. Increasing pH from pH 5 towards pH 7 decreases the equilibrium H2CO3:HCO3− ratio and increases the availability of H+ ions [63]. A strategy that moves the water pH from a lower value to a higher value will increase the availability of OH− ions, OH· radicals and electrons in the water. These observations are consistent with the desalination reaction involving both protons and electrons.

Figure E1.

Trial groups: CSD, E143, E144. (a) Proportion of Na+ in the feed water remaining in the product water vs. pH of the product water on removal from the reactor; (b) Proportion of Cl− in the feed water remaining in the product water vs. pH of the product water on removal from the reactor; (c) Proportion of NaCl in the feed water remaining in the product water vs. pH of the product water on removal from the reactor; (d) Proportion of Na+ in the feed water remaining in the product water vs. Eh of the product water on removal from the reactor; (e) Proportion of Cl− in the feed water remaining in the product water vs. Eh of the product water on removal from the reactor; (f) Proportion of NaCl in the feed water remaining in the product water vs. Eh of the product water on removal from the reactor. Source data in Table A1, Table A2, Table A3, Table A4, Table A5, Table A6, Table A7, Table A8, Table A9, Table A10 and Table A11 are supplemented with redox data from [2]. Eh analyses are based on a quinhydrone Eh calibration at pH = 4 and pH = 7; Eh, mV = (−65.667 pH + 744.67 + ORP (mV)): ORP = oxidation reduction potential, measured with ORP and pH meters manufactured or branded by Hanna Instruments Ltd., Leighton Buzzard, England, UK, and HM Digital Inc., Culver City, CA, USA.

E.2. Mass Balance Considerations

The basic adsorption reaction equations (E2,E3) indicate that 2 M of Fe° are required to remove 1 M NaCl. The ZVI cartridge was reused in each sequential trial within a trial group. The ZVI was constructed as follows [2]: CSD trials: 8.4 L water + ZVI (224 g Fe0 + 35 g Al0); maximum NaCl removal potential = 0.227 M NaCl·L−1 (13.31 g NaCl·L−1) ; E143 trials: 5.8 L water + ZVI (135 g Fe0 + 97 g K-feldspar); maximum NaCl removal potential = 0.208 M NaCl·L−1 (12.17 g NaCl·L−1); E144 trials: 5.8 L water + ZVI (51 g Fe0 + 90 g K-feldspar); maximum NaCl removal potential = 0.0787 M NaCl·L−1 (4.60 g NaCl·L−1). Particle size = 44,000–77,000 nm; ZVI = standard automotive metallic paint (and fiberglass) grade powdered (milled) carbon steel; ZVI surface area = 0.00289–0.01732 m2·g−1. Suppliers: K-Feldspar = Mistral Industrial Chemicals, Antrim, Northern Ireland; Fe0 = ABL (Stevens) Resin & Glass, Sandbach, Cheshire, England; Al0 = ABL (Stevens) Resin & Glass, Sandbach, Cheshire, England. This information was originally provided in reference [2] and has been reproduced above.

E.2.1. Mass Balance Calculation

The mass balance takes the form:

Na+ (feed water) (g·L−1) = Na+ (product water) + Na+ (adsorbed) + Na+ (manifold + cartridge)

Cl− (feed water), g·L−1 = Cl− (product water) + Cl− (adsorbed) + Cl− (manifold + cartridge)

Cl− (feed water), g·L−1 = Cl− (product water) + Cl− (adsorbed) + Cl− (manifold + cartridge)

At the end of each of the CSD and E144 groups of trials, the reactor was completely drained (Figure 2). In the E143 group of trials, some water was retained in the manifold and ZVI cartridge following removal of the product water at the end of each trial.

The observed mass balances were:

- CSD trial group: total (g) removed: Na+ = 28.23; Cl− = 35.42; NaCl removed = 54.5% of ZVI adsorption potential.

- E143 trial group: total (g) removed: Na+ = 2.52; Cl− = 37.77; NaCl removed = 57.3% of ZVI adsorption potential; total (g) removed from the product water: Na+ = 49.92; Cl− = 55.18;

- E144 trial group: total (g) removed: Na+ = 25.88; Cl− = 47.98; NaCl removed = 277% of ZVI adsorption potential.

The operating strategy of leaving residual water in the manifold and ZVI cartridge at the conclusion of each batch trial (E144 series) can result in enhanced concentrations of Na+ and Cl− ions in the water within the manifold and ZVI cartridge (Table A6; Figure D1 and Figure D2).

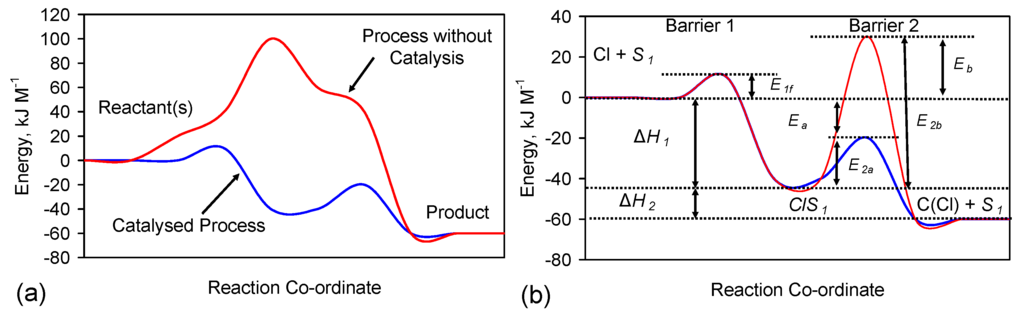

If the adsorption model in Equations (E2) and (E3) is correct, then the mass balance analysis for Trial Group E144 can be interpreted as indicating that the initial stage of the desalination process may be adsorption followed by desorption: i.e.,

Na+ + S1↔NaS1→B(Na) + S1

Cl− + S2↔ClS2→C(Cl) + S2

NaO− + S2↔NaOS2→C(NaO) + S2

ClO− + S2↔ClOS2→C(ClO) + S2

HzCxOnCly−+ S2↔HzCxOnCly S2→C(HzCxOnCly) + S2

Initial State↔Adsorbed State (via Step 1)→Product (via Step 2)

Cl− + S2↔ClS2→C(Cl) + S2

NaO− + S2↔NaOS2→C(NaO) + S2

ClO− + S2↔ClOS2→C(ClO) + S2

HzCxOnCly−+ S2↔HzCxOnCly S2→C(HzCxOnCly) + S2

Initial State↔Adsorbed State (via Step 1)→Product (via Step 2)

S1 = site (Equation (E3)); S2 = site (Equation (E2)); B and C are desorbed products, which permanently remove the ions. The overall adsorption-desorption reaction is complex, and as demonstrated by Equation (E5), specific sites may adsorb, or desorb, both Na+ and Cl− ions.

All of the ZVI batches, which have demonstrated partial desalination of water, have either been coated with carbon [5], or incorporate one or more carbon species [1,2,3,4], or are derived from carbon steel [2], or have been pre-treated with a carbon species (e.g., CH4,CO, CO2 [2]). Fe is known to form catalytic (adsorption-desorption) sites (in the presence of carbon) of the form Fe-CCly(CHn)x, Fe-(CHn)x, Fe-C(CHn)x, Fe-O-(CHn)x, Fe-O-C(CHn)x, Fe-O-O-C(CHn)x, where (CHn)x, is an adsorbed group, prior to desorption [81]. The reaction environment in the three groups of trials may have created catalytic sites of the form Fe-CCly, Fe-C, Fe-O, Fe-O-O-C.

E.3. pH Considerations

Placement of ZVI in water will result in an initial gradual increase in the pH of the water with time to a maximum level (e.g., 30–300 days [1,2,26,70,91,92]). The maximum pH level increases as the ZVI:water ratio in the reactor increases [1,2,26,70,91,92]. In an open (e.g., Figure 1) or semi-closed (e.g., Figure 2) diffusion reaction environment, the pH will subsequently decline to a lower level and approach the initial feed water pH [1,2,26,70,91,92]. The rapidity and magnitude of the pH rise is a function of ZVI composition [91] and increases as the ZVI concentration (g·L−1) increases (e.g., [2]). Comparison of pH changes with time associated with ZVI trials for a 50 nm particle size [1] and a 44,000–77,000 nm particle size [1,91] indicates that the actual ZVI surface area, which is in contact with the water, is not a primary driver of pH increase. In the CSD, E143 and E144 group trials, the ZVI-water contact surface area was maintained at 0.000314 m2 (CSD group trials = 3.74 × 10−5 m2·L−1; E143, E144 group trials = 5.42 × 10−5 m2·L−1).

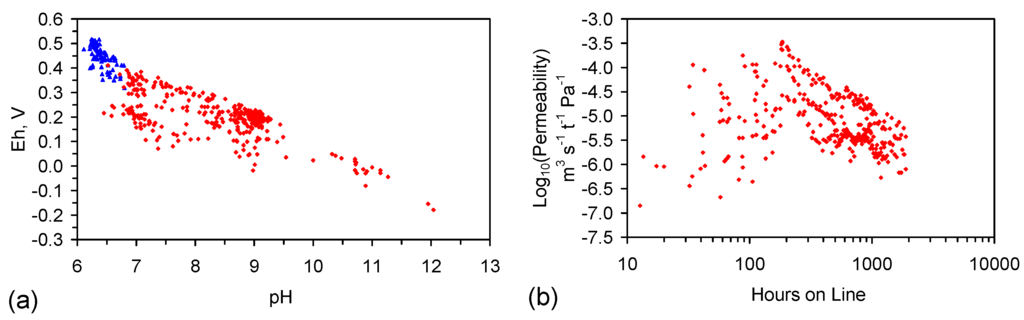

E.4. Loss of Reactivity with Time

Zero valent iron (Fe0, ZVI) has been placed in permeable reactive barriers (PRB’s) and injected into aquifers in order to effect aquifer remediation since the 1970s (e.g., [6,7,8,9,10,70,71,93,94,95,96,97,98]). The principle historical remediation focus has been on the removal of organo-chlorides, organo-nitrates, phosphates, nitrates, arsenic and heavy metals (e.g., [26,70,71,93,94,99,100,101,102]). An extensive list of the chemicals and microbiota that can be removed by ZVI is documented elsewhere (e.g., [70,71,94,95,96]).

ZVI corrodes when it is placed in water to produce ferrous (and ferric) oxyhydroxides and ions (e.g., [1,2,63,64,70,71,93,94,95,96,103]). The corrosion of Fe0 (with time) is catalysed (and accelerated) by the presence of Cl− ions in the water [65,104]. Plugging of porosity (and an associated loss of permeability (e.g., [26])) can result from the ZVI-catalysed (or induced [63]) precipitation of minerals (hydroxides and carbonates) in the ZVI porosity and the development of a hydrogen film on the Fe0 grain surfaces [105].

The precipitated diagenetic products (Fe(OH)x, FeOOH) are hydrated and are more voluminous than the Fe0 [106,107]. This volume increase results in a continuous destruction of porosity, deterioration of permeability (kp) and clogging of Fe0 (PRB’s) [93,99,100] and may be accompanied by a loss of reactivity [93].

E.4.1. Porosity Reduction

Some PRB designers have attempted to overcome the adverse effect of permeability destruction by creating a PRB with a higher initial permeability than the surrounding aquifer [108]. Porosity, ϕ, reduction in a ZVI PRB can be modelled by assuming a pseudo-first order corrosion reaction and by using hydraulic conductivity (Kc) to represent permeability (kp) where [109]:

Kc (t = n) = Kc (t = 0) (ϕ(t = 0) − ϕ(t = n))3/((1 − (ϕ(t = 0) + ϕ(t = n) )/(1 − (ϕ(t = 0)))2

Analysis of ZVI PRBs after one year of operation has established that the bulk of the permeability loss is associated with the upstream entrance face of the PRB, and the reduction in permeability decreases towards the downstream exit face [109]. This progressive reduction in permeability/porosity through the ZVI bed with time has been used to model reactivity, where it is assumed that this change is associated with a loss of reactivity (e.g., [110]).

E.4.2. Impact of ZVI Ageing on Reactivity

Laboratory experiments have demonstrated [102] that a seven-year-old ZVI PRB, while containing corrosion precipitates, was as effective at remediation as fresh ZVI. The observed reduction in ZVI reactivity with time, associated with PRBs, has been attributed to clogging of the pore space by precipitates, or gas discharge from the ZVI, or blocking of the reactive iron surface by precipitates, (e.g., [111,112]). Passivation of the Fe surface by FeIII (oxy)hydroxide coatings has been interpreted as the cause of a loss of reactivity (e.g., [113]). Others have demonstrated that the presence of these coatings is an essential component of ZVI operation (e.g., [1,2,70,71,114,115,116,117]). Numerous strategies have been trialed that are designed to mitigate the adverse impact of the progressive destruction of PRB permeability with time (e.g., [96,118]).

E.4.3. Impact of ZVI Particle Aggregation on Permeability

n-Fe0 studies have demonstrated [119] that the corroding Fe0 particles both aggregate and grow in size (with accreting hydrated (oxy)hydroxides) with time to a stable or equilibrium size. Any increase in particle diameter, d, must reduce ϕ, increase pore tortuosity, τ, and increase the complexity of the pore shape, σ [70]. The Hagen-Poiseuille model (e.g., [120,121,122,123]) defines the relationship between intrinsic permeability, k, and porosity, ϕ, as:

where r = pore throat radii, ɳ = viscosity of water. The flow between two pores is controlled by the size of the smaller pore [124,125,126].

k= ϕ r2/ɳτσ

E.4.4. Interpretation of the Relationship between Permeability Decline and Reactivity

Declines in permeability will reduce the amount of water that can flow through the ZVI (in the inter-particle porosity by viscous flow) and must, therefore, reduce the amount of water that can be treated per unit time [120,126]. The initial ZVI corrosion products are dominantly-hydrated layered double hydroxides (LDH) (Appendix B). These products contain a high intra-particle porosity (between the LDH cationic layers (Appendix B)), which allows movement of fluids through the particles by Fickian diffusion. Fickian (and non-Fickian) molecular diffusion through the intra-particle porosity of the ZVI corrosion products may account for why some researchers have indicated that the presence of the corrosion coatings is an essential component of ZVI operation (e.g., [1,2,70,71,114,115,116,117]). The implication is that some ZVI remediation processes are instigated in the inter-particle porosity, while others are instigated in the intra-particle porosity.

This hypothesis indicates that remediation processes, which are dependent on ZVI-water contacts in the inter-particle porosity, are associated with viscous water flow. These processes must show a decline in reactivity, which is related to a decrease in porosity. This is associated with decreases in pore throat radii, increases in pore tortuosity and decreases in permeability (Equation (E7)).

Conversely, remediation processes, which are dependent on intra-particle porosity, will be characterized by Fickian (and non-Fickian) molecular diffusion through the intra-particle porosity. These processes will be largely unaffected by changes in the inter-particle porosity (and viscous flow permeability) of the ZVI.

E.4.5. The Rate Constant, k

A simple test of whether ZVI desalination occurs in the inter-particle porosity or intra-particle porosity is to define the reactivity of the ZVI using the rate constant [27]. The rate constant, k, is defined as [27]:

kNaCl = ln( NaClt = 0/NaClt = n)/t

kCl = ln(Cl−t = 0/Cl−t = n)/t

kNa = ln(Na−t = 0/Na−t = n)/t

kCl = ln(Cl−t = 0/Cl−t = n)/t

kNa = ln(Na−t = 0/Na−t = n)/t

t = time, seconds, where t = 0 is the onset of the trial and t = n is the conclusion of the trial; NaCl = concentration of NaCl (M·L−1, M·L−1); Cl− = concentration of Cl− (M·L−1, M·L−1); Na+ = concentration of Na+ (M·L−1, M·L−1).

Increases in k indicate an increase in reactivity, while decreases in k indicate a decrease in reactivity [27].

If the ZVI desalination reaction is confined to the inter-particle porosity, then k will reduce with successive batches of water. If, however, the ZVI desalination reaction is confined to the intra-particle porosity, then k will remain constant (or fluctuate) with successive batches of water.

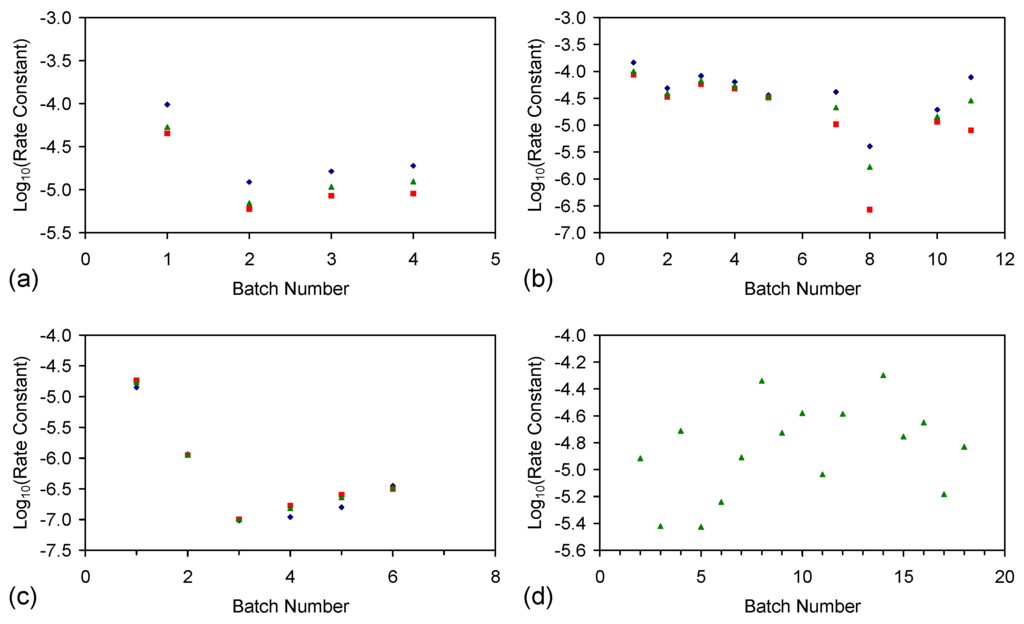

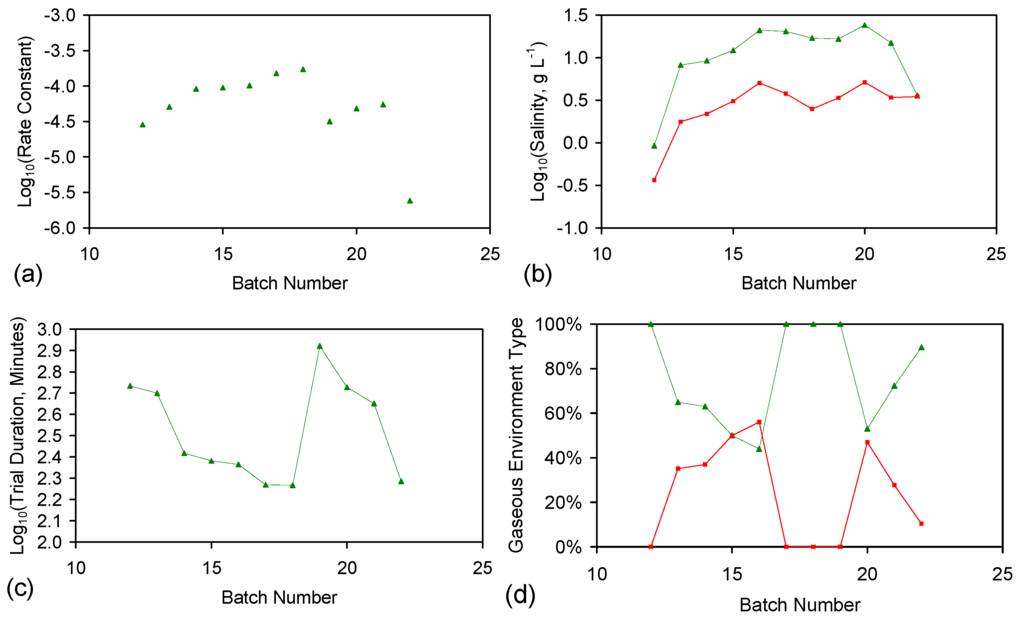

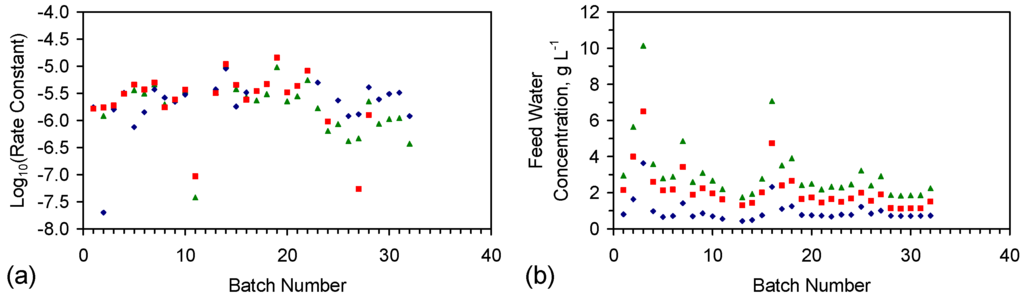

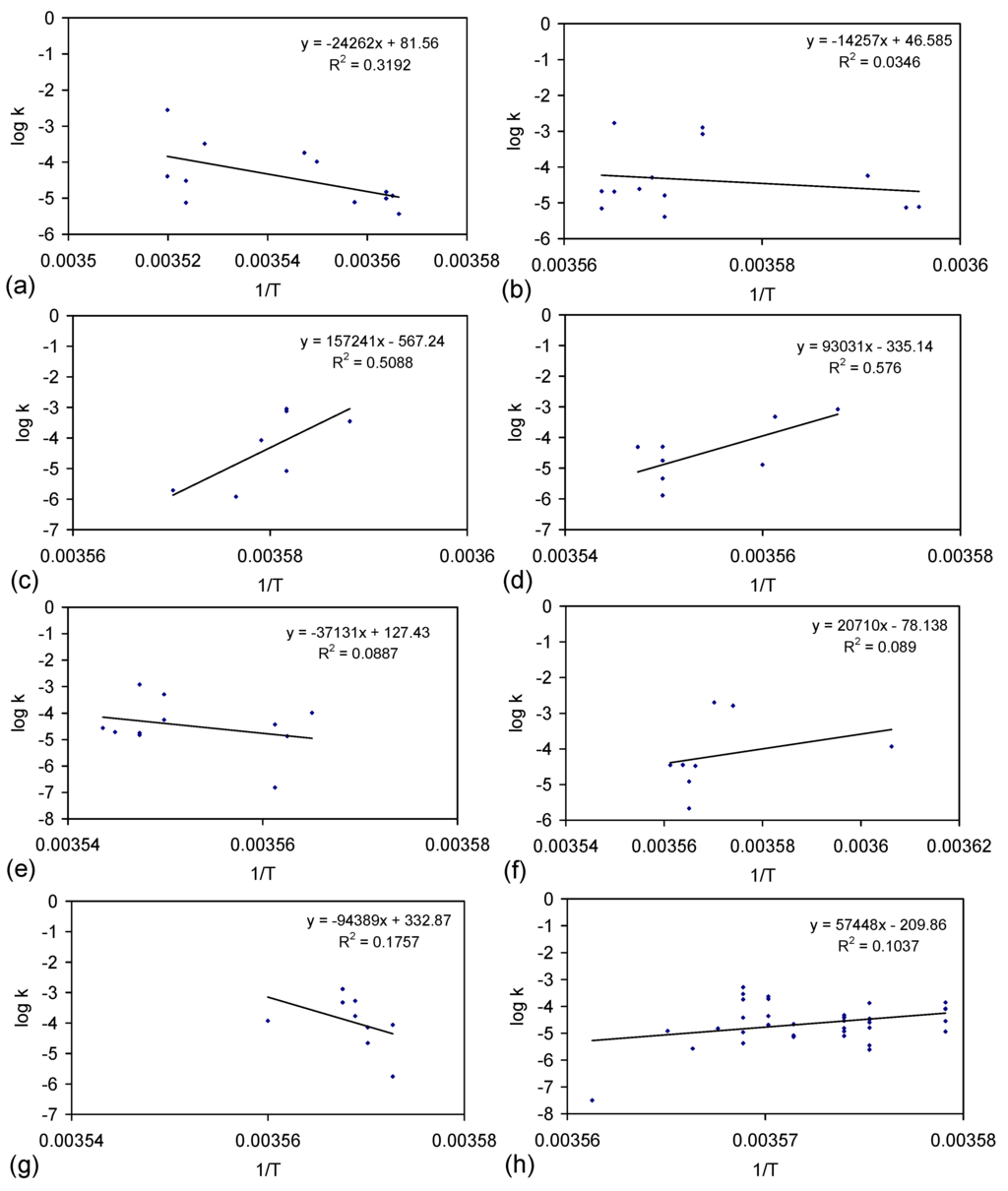

The rate constant was calculated for each trial grouping (Figure E2). Trial Groups CSD and E144 demonstrated an initial drop in reactivity, which was followed by stabilization and a rise in reactivity with increasing batch number (Figure E2). Trial Group E143 demonstrated a minor decrease in reactivity with increasing batch number (Figure E2b). Trial Groups E143 and E144 also demonstrate that increasing the amount of ZVI in the ZVI cartridge (Figure 2) may increase reactivity (Figure E2).

Reducing the water pressure from 0.01 MPa, above atmospheric pressure (CSD, E143, E144) to atmospheric pressure and replacing the gas with air (120 L/h), while increasing the reactor size to 240 L (ZVI = 124 g Fe0 + 276 g K-Feldspar) (E146 Trial Group [2]), shows no effective reduction in reactivity with increasing batch number (Figure E2d).

Figure E2.

Rate constants. (a) Trial group: CSD; (b) trial group: E143; (c) trial group: E144; (d) trial group: E146 (data source: reference [2]). ♦ = Na−; ■ = Cl−; ▲ = NaCl. E146 Trial Group [2]: batch operation, air flow = 120 L·h−1. Pressure = atmospheric; non-isothermal temperature ≤25 °C; reactor capacity = 240 L; reactor: Figure 2; feed water constructed using halite; E146 ZVI cartridge [2]; cartridge diameter = 20 mm; manifold diameter = 110 mm; energy usage ≤0.18 kW·m−3 (during air flows). Further details (including feed salinities, product water salinities, Eh, pH, EC, air flow rates, duration, temperature, product and feed water UV-visible absorbance profiles ) are provided in reference [2].

E.4.6. Control Analysis of the Rate of ZVI Permeability Decline with Time

The viscous flow, inter-particle permeability, kp, of the ZVI (44,000–77,000-nm particle size (asi)) has been measured as a function of time [26] using a vertical (z direction) fixed bed reactor and a constant head (or potential, Φ) using the basic flux (Darcy) Equation [120]:

Qflow rate = δ/δz(kp (δΦ /δz))

kp = Qflow rate/Φ