Abstract

Industrial ecology (IE) argues the need for an efficient materials economy based on recycling where environmental degradation associated with inputs of new materials and outputs of waste or pollution is minimal. There is often an assumption that efficiency in the use of materials equates to economic efficiency; however, this is not necessarily the case. Central to this tension between engineering and economic approaches to materials efficiency are different conceptual framings of value. Because a large scale shift towards valuing waste materials as future resources involves changes to existing practices of a great many actors and organizations, ranging from consumers and household disposal practices, through to government agencies and multi-national corporations, it cannot be assumed that all operate with similar conceptions of value. This paper reviews current understandings of value in IE and argues that they need to be expanded to accommodate approaches to valuing used goods and materials that manifest across different spatial scales, from household disposal practices to national policy to global production networks (GPNs). The paper focuses, in particular, on understandings of value relevant to metals recycling in Australia and contrast material flow models from IE with other models of material flows and transformations available in the social sciences, including anthropological analysis of the movement of objects through different regimes of value within society and analysis in economic geography that highlights spatial and structural dimensions influential in commodity chains and networks for used products and materials. It concludes by reflecting on the significance of the dynamic and creative tensions inherent in the production of value for recycled metals from Australia.

1. Introduction

Environmental scenarios developed by industrial ecologists have influenced contemporary concern around the need for greater materials efficiency and more closed loop production systems that use materials obtained from recycled end of life products. They have informed national and international initiatives to promote recycling and product stewardship in the public interest. While Industrial Ecology (IE) often refers to the economic benefits of materials efficiency, the underlying framing of value is different from the framing of value in economics so that the term “materials efficiency” has different meanings in IE and economics [1]. This difference is relevant to a significant critique leveled at IE, that it has failed to develop a sophisticated understanding of the spatial dimensions of capturing economic value that drive global material flows [2,3,4,5]. Evidence of this is provided by the failure of the regionally focused closed loop industrial system models to take off beyond a few exceptional examples.

A further critique is that IE fails to consider the broader societal changes that are required to capture end of life materials for recycling, including social values and norms of practice around disposal of used goods and materials. This aspect also requires a more carefully considered framing of value than that currently drawn on in IE. While various authors do acknowledge that broader social changes are required, there has not yet been any considered engagement with social values and processes of social change that might, for example, affect social practices and norms around the acquisition, use and disposal of goods.

Both these critiques are relevant to initiatives to promote metals recycling in Australia, a country with high levels of per capita consumption of material goods and waste generation. Rather than attempt to address these critiques in full, the paper draws on them to highlight the need for more careful consideration of understandings of value associated with a more efficient or “circular” materials economy, and examine this in relation to metals recycling in Australia. Australia has a small domestic manufacturing industry compared with a significant mining industry largely focused on export markets [6]. While a modest metals recycling industry exists in Australia, it is likely that total quantities of bulk scrap metal exported overseas each year are much greater than those recycled locally. Flows of used metals, whether in used products or in bulk scrap, are likely to follow a similar pattern to flows of virgin metals from Australia’s mines. This trend is consolidating with the closure of major smelters such as the Alcoa aluminum smelter at Port Henry, near Geelong in Victoria. However, a large potential resource exists in products containing metals that are used in households or commercial buildings, distributed across major population centres. The availability of this resource depends on disposal practices of households and businesses and on the presence of appropriate collection systems.

In 2011, the Australian Government introduced National Product Stewardship legislation which provides a range of options for national collection schemes, ranging from fully voluntary industry led schemes, such as the current Mobile Muster program for mobile phones (run by the Australian Mobile Telecommunications Association), through to fully regulated schemes. A voluntary product stewardship scheme for computers and TVs was introduced in 2012, with support from national and state governments and a majority of companies involved in importing, retailing and recycling computers and TVs. While some sorting and reprocessing takes place in Australia, most of the processes involving extraction of rare earth metals for reuse in other manufacturing take place in factories in Singapore or Hong Kong in compliance with specified certification standards [7].

Drawing on the example of used metals originating in Australia, the paper examines the material flow models developed in IE to identify and unpack notions of value that are implied but not explained. It then considers the dynamics of value involved in recycling used metals from Australia, drawing on two quite different conceptual framings from economic geography and anthropology that each offers important insights into the processes involved in the revaluing of waste materials. It concludes with a reflection on the potential of the calculative tools of IE to influence the material flows they describe and considers the kind of information needed to refine these tools to better accommodate the multiple valuing practices that operate at different spatial scales.

2. Understanding Value in Industrial Ecology Flow Models

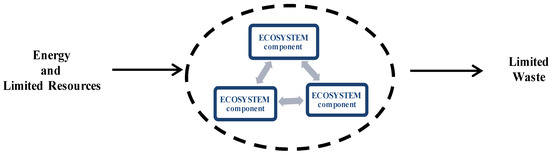

IE provides a systematic way of understanding material flows through society that includes calculations of inputs of environmental resources and outputs of waste (including materials and emissions from energy consumption). The benefit of this type of input-output flow modeling is to make environmental costs, in the form of resource consumption and pollution, both visible and measurable. At the heart of IE is the metaphor of the ecosystem, viewed as a dynamic and evolving complex system involving energy and matter flows [8,9]. Value in IE is measured in terms of environmental costs of material inputs and waste outputs. Figure 1 depicts an inefficient material flow with significant environmental costs associated with its assumptions of unlimited resources available as inputs and no limits on production of waste. The industrial processing and manufacturing stage is represented as a simple ecosystem component.

Figure 1.

Linear material flows, after Jelinski et al. [8] (p.793).

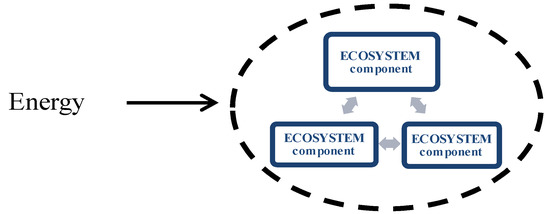

Figure 2 presents a partly cyclical materials flow in which there are recognized limits on material resource inputs but no limits on energy inputs. Because there is some recycling of resources involved, depicted by the interactions among the several ecosystem components, the waste outputs are more limited than in Figure 1. Both inputs and outputs are still negatively valued in environmental terms, but are less negative than in Figure 1.

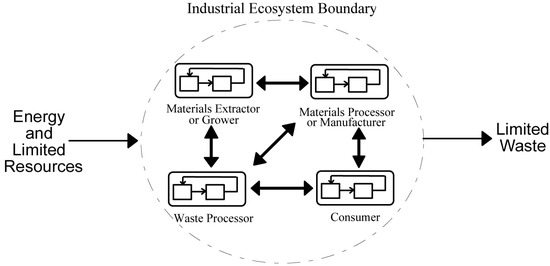

Figure 3 presents a materials efficient system with only energy inputs and no waste outputs as the normative ideal—a materials economy completely comprised of the recycling of existing manufactured goods and materials so that no material inputs are required and no waste output is produced. There are no negative environmental values associated with materials. Current manufacturing systems for durable goods involving metals are probably best depicted as somewhere between Figure 1 and Figure 2.

Figure 2.

Quasi-cyclical material flows, after Jelinski et al. [8] (p.794).

Figure 3.

Cyclical materials flows, after Jelinski et al. [8] (p.794).

In other theoretical work around waste, the impossibility of ever achieving the “zero waste” ideal is itself a focus [10,11,12]. This work recognizes that there will always be some form of material remainder, including from recycling and remanufacturing processes [12] and considers this central to the understanding of material flows in society. Despite these criticisms, modeling from IE does provide a coherent rationale for a new normative model for a materials economy based on the need to avoid environmental degradation and maximize the use value of all materials in the system over time. Importantly, it offers a useful means of quantifying environmental costs in the materials economy that are not currently included in the exchange or market values for either the virgin resources that provide inputs or the waste outputs. In the case of production systems involving metals, Australia currently provides inputs in the form of mineral resources, but manufacturing processes depicted within the circles take place elsewhere. While waste associated with manufacturing occurs elsewhere, waste in the form of end of life products does accumulate in Australia.

Materials efficiency is a central theme in IE, defined as “the provision of material services with less material production and processing” [13] (p. 362). This definition requires an understanding of the different properties of various materials that influence both the environmental impacts of their production and the options available for reuse and recycling. The case for materials efficiency may be based on the need to ensure future resources for manufacturing as well as the need to reduce environmental impacts associated with continued extraction of virgin materials, but various authors observe that the environmental costs of extraction are emerging as the more significant aspect [13]. This is particularly the case for metals production where the environmental costs of mining virgin metals are increasing as rich ore deposits are depleted and larger open cut mines are needed to extract the same quantities of minerals from poorer ore deposits [14]. Despite these trends, however, the price of most bulk metals has actually gone down over time, and both Mudd [14] and Allwood et al. [13] conclude that economic costs of environmental resources, as they currently manifest in prices, are unlikely to precipitate the shift from the linear flows of Figure 1 to the quasi-cyclical flows of Figure 2.

This materials focused definition of efficiency is contested by Söderholm and Tilton [1] who argue that materials efficiency should be defined in economic terms, with environmental costs throughout the commodity chain understood as market failures that distort purchase decisions made by firms, households and individuals. In doing so, they downplay the properties of the materials and their relationship to current recycling technologies and consider environmental impacts should be regarded as one of a number of market failures that prevent the realization of materials efficiency defined in economic terms. Market failures in relation to recycled goods and materials include the failure to internalize environmental costs of virgin material inputs, information asymmetries around recycled products or materials, innovation related failures in which lack of new knowledge around recycling carries an economic cost rather than benefit, and technological externalities that could affect the reuse or recycling of products or materials [1].

Figure 4 provides a more detailed representation of an efficient materials economy that unpacks the black boxes of ecosystem components shown in Figure 3 to expose internal processing and reprocessing elements, including the critical role played by consumers in feeding used materials back into the system.

Figure 4.

Model of the Industrial Ecosystem incorporating cyclical materials flows after Jelinski et al. [8] (p. 794).

The range of actors involved in the internal processes depicted in Figure 4 highlights the need to frame a concept of value that connects with a broad range of interests and concerns including economic concerns influencing relationships among businesses, and the diverse social or cultural values that influence consumers. In their review of barriers and incentives for materials efficiency, Allwood et al. [13] acknowledge that a wider range of values are involved, particularly in their discussion of incentives outlined in terms of business opportunities, government interventions and consumer drivers. The economic paradigm presented by Söderholm and Tilton [1] is only able to account for social values to the extent that they comply with the ideal of rational self-interested decisions by individuals, households and firms. The failure to do so is treated as a “behavioural failure” that might also need to be addressed through policy measures [1].

Neither the engineering nor the economic approach to materials efficiency engages with the significant body of social science research on how social values are invested in goods and materials and on processes of change in socio-technical systems. Literature on consumption studies and material culture shows that consumers operate with very diverse motivations as values ascribed to products and materials are bound up with relationships to other people both formally, through economic systems, and informally through relations of sharing, gifting, etc. [15,16,17]. Paid and unpaid human labor may be involved in their production, purchase, ongoing repair or maintenance and in waste management or recycling [15,17,18,19,20]. With increasing industrialization and urbanization, the scale of resource consumption, waste generation and potential recycling has undergone profound change over time from a locally contained system to a global scale open system, although the character and time frame of this trajectory has varied between countries.

Contemporary environmental concerns around waste and resource consumption can be understood as a new framing of old themes in a globalised materials economy. As with the patriotic imperatives for thrift and recycling during war time [21,22], there is a strong moral injunction to contemporary recycling framed in terms of environmental public good benefits, whether at the scale of national waste policy, e.g., Australia’s national waste policy Less Waste More Resources [23], or at the scale of individual or household practices [24]. The act of putting out the garbage is now governed by new sets of social norms that combine with regulatory structures and infrastructure to promote what might be described as a new regime of waste management that aims to capture waste as a resource and reduce disposal in landfill [24]. This new/old ethic has been internalised by many householders who go beyond the waste management systems provided by governments to implement their own stewardship practices for reusing and recycling goods and materials within homes and neighbourhoods [20,24].

The issue of the appropriate geographical scale for materials efficiency or a circular materials economy is far from resolved and carries similar tensions between efficiency measured in terms of materials conservation versus economic efficiency. The internal processes involved in the type of industrial ecosystem depicted in Figure 4 may include processes that operate at quite different geographical scales, ranging from the scale of consumers within households to the globalised production systems involved in many manufacturing industries. To date, the main approach advanced for implementing such closed loop industrial system models is through the establishment of eco-industrial parks, a form of industrial symbiosis where industrial activities are co-located in order to maximise the potential for use of waste outputs from one industry as inputs into a different industry. While there has been some experimentation with this type of regional industrial development, with several examples from various developed countries repeatedly referred to in the literature [4], it has not proved influential globally [2,3,4]. In some cases, geographical proximity may facilitate the two-way material flows depicted but proximity alone is clearly not enough.

Various scholars have questioned the implicit assumptions that firms or industrial processes manifest at particular spatial scales or that particular scales should be privileged in contemporary commodity trading [3,4,25,26]. Just in terms of the environmental resources consumed, including energy used in transport as well as manufacturing processes, the calculations are quite complex with key variables subject to change over time. Based on a study of global flows of scrap metal originating from the USA, Lyons et al. [4] concluded that, while ideally all scrap would be sorted and aggregated close to the site of generation to minimise transportation and place responsibility for waste materials in the region or country where they were consumed, there was a practical case for continuing to close scrap loops at the international level in the short to medium term because the overall environmental benefits of recycling “are likely to outweigh the environmental costs of transportation and virgin production” [4] (p. 297). They note that an oversupply of scrap in the developed world combined with a lack of supply in the developing world is a significant driver of global flows and ensures a level of recycling that is not currently economically feasible within the US. However, they emphasise the need for more detailed analysis of social impacts of these processes and assessment of the costs, benefits and opportunities that result in particular outcomes in real places.

International concern about the environmental and public health impacts of electronic and other hazardous waste is another driver for geographical containment of recycling processes in the country of origin. These include the Basel Convention on trans-boundary movement of hazardous wastes and various European Commission Directives around end-of-life take back and reprocessing for products ranging from motor vehicles to electrical and electronic waste. While these have so far had only limited success at containing where recycling occurs, they have increased the costs associated with landfilling and made waste management costs in general more visible [27].

3. Generating Value in Recycling

The availability of metals for recycling usually coincides with the end of life of a specific product that contains metals, whether a building that is demolished making metal infrastructure available or a durable product that is disposed of. As the capacity for materials to be first devalued and then revalued is integral to recycling, the paper now turns attention to the dynamic character of value in recycled materials, reviewing the contribution of two very different traditions of scholarship, the first from anthropological work on material culture and the second from economic geography. The work of anthropologists on regimes of value is concerned with the role of materials in social and cultural change. It follows the pathway taken by an object through different regimes of value, highlighting the dynamic character of these pathways and the significance of the interface between different regimes of value. This is particularly useful for understanding processes that bring about a blurring and reframing of categories of objects from that of waste to that of resource. Scholarship on Global Value Chains (GVCs) and Global Production Networks (GPNs) provides insights into the market logic that propels current globalised commodity chains for used products and materials, highlighting the influence of regulatory regimes in different countries and of transport logistics. It emphasizes the importance of knowledge held by the various actors and organizations along the commodity chain in influencing the pathway that specific products and materials will take.

3.1. Following Things through Regimes of Value

In the trajectory of used products and materials from waste to potential economic resource, items may usefully be understood to move through successive regimes of value [28], not all of which involve economic value as a commodity. Anthropologist, Igor Kopytoff [29] proposed a processual model for understanding how objects or materials move in and out of the state where they are valued as commodities (defined as any items with real or potential exchange value). It draws to some extent on Marx’s concern with processes of commodification that move things between use value and commodity (exchange) value—specifically the role of human labor—but also includes incidents where objects are attributed more singular value due to specific social or cultural attributes and removed from both use and commodity value only to return to a regime of commodity value at a later date.

The utility of this model is in its recognition of the social and cultural dimensions that are bound up with how an object is valued as well as the capture of economic surplus from the labor congealed in the object. Further, it describes a process by which objects may take an alternative pathway to the more common ones that lead to deposition in land fill or to some form of reprocessing in another country, towards new pathways where they are accumulated for further processing and commoditization. Endurance of these new pathways however may require policy interventions to foster the demand for recycled metals of various kinds. A simple way of depicting the movement of waste products or materials through to a new regime of value as a resource might be as follows: Use value (with first owner/user) > negative value as waste and surrender of property rights > collection stage where value is usually bound up in a contract for waste collection services and where new property rights emerge > sorting stage sending items in one of several directions, i.e. resale, refurbishing or repair, materials recycling, remanufacturing, etc. as new commodity forms.

In this model, the value of used goods and materials is “an effect of the circulation of objects between regimes of value” [16] (p. 36). In other words, value is never a pre-given attribute of materials or objects but derived from the relationship between the different and often competing regimes of value that it moves through. Throughout the trajectory of an object, forms of value can be lost as well as gained, which is important for understanding how products come to enter the waste stream in the first case. The material flow pathways of second hand goods and materials are characterized by the intersection of different regimes of value which is itself generative of new forms of value. The geographical scale at which goods and materials circulate adds further complexity as different processes and politics are associated with change at the macro-scale of national policy regimes and at the micro-scale of consumer practices [30].

Power and knowledge are important in influencing the trajectory taken by specific products or materials. For example, powerful players in society and industry may contest the value of discarded products or materials by developing calculated diversions that could potentially lead to new paths of commodity flow but these will be contested by other players who benefit from existing commodity pathways [28]. However, the contestation in itself can bring about a loosening of social norms about what categories of objects or materials are seen to have potential exchange value, thereby blurring the line between the category of waste and that of resource. Research applying a regime of value analysis to waste and recycling has highlighted the significance of the surrender of property in unwanted goods in facilitating their movement into new regimes of recycled materials [20,24,31,32]. As Graeber [32] explains:

“The idea of recycling is entirely dependent on the logic of property. It is property arrangements, after all, which allow the transfer of rights to objects through commercial transactions, and therefore allow the ‘circulation’ of objects from the sphere of production to the sphere of consumption in the first place”.[32] (p. 287)

Knowledge both influences commodity flows and shapes demand for new types of commodities [28]. The locus of technical production knowledge is usually at the site of manufacture and this is more likely to be standardized for primary commodities such as metals than for secondary commodities such as the manufactured goods that use metals. Knowledge of markets, consumers and destinations are also important aspects of production knowledge. However, both these areas of knowledge require some understanding of the spatial and logistical dimensions of commodity chains for recycled products and materials.

A general criticism of material culture studies in anthropology is that they tend to focus on relationships involved in consumption of goods rather than those involved in production [33]. This results in an undue emphasis on objects or products as having material integrity, which distracts attention from the component materials and their qualities, some of which are central to their capacity to be recycled and used in secondary manufacturing [34]. It also deflects attention from the other kinds of environmental resources that are consumed in the context of manufacturing or circulation of products, the very concerns of IE which argues the need to consider all resources, including energy as well as materials, consumed as inputs or released as outputs in the circulation of materials through society.

3.2. Value chains and Networks for Recycled Resources

Spatialised understandings of value chains and networks developed by economic geographers focus on how economic value is captured and generated in production processes and associated logistics focusing on the macro-scale of GPNs or GVCs [35]. While initially developed to understand the structural characteristics of globalised commodity chains for the production of new products and materials, these analytical approaches potentially apply equally to what may be called “reverse logistics”—commodity chains or networks for used products and materials. In the production of new goods, a structural distinction has been identified between producer-driven commodity chains that are characteristically controlled by manufacturing firms and have high levels of capital investment and a skilled labor force, and buyer-driven commodity chains that are controlled by large retail companies and involve unskilled low waged labor and avoid capital investment in technology [36]. The type of commodity chain for metals recycling within Australia best fits the producer-driven model in that it involves skilled labor and considerable capital investment in technology. It is typical of recycling industries in the developed world [5].

GPNs are inherently dynamic in nature, both in terms of organization and geography, and the term “network” is used in preference to “chain” in order to capture this character [37]. They are constantly contested by the various actors involved who seek to influence aspects of the institutional context in their own interest. The institutional context affects not only how economic value is generated and captured but also the pathways taken by materials and products around the world. It may be defined in terms of formal and informal frameworks. Formal frameworks include rules and regulations, taxation policy, trade policy, government incentives schemes and health and safety and environmental regulations. National governments are particularly important to this but so too are global institutions such as the World Trade Organisation and the International Monetary Fund that shape the rules of the game for global trade [4]. Informal frameworks include the entrepreneurial and political cultures of particular places that establish informal rules around how business is transacted, and knowledge of the sources of supply of materials and of potential buyers of recycled products and materials. Technical knowledge associated with reprocessing and remanufacturing is also critical.

Value in the GPN approach is primarily understood along political economy lines as the creation and capture of economic or market value through rents or through the appropriation of surplus value from labor in production through cost structures [26]. It emphasizes the inherently political and contested character of GPNs, which can also be represented as struggles between different actors for control or influence over the relationships, governance structures, and institutional rules and norms of conduct. The main types of actors involved in this struggle include transnational corporations, nation states, civil society organizations (e.g., environmental Non Government Organisations (NGOs)), labor organizations (e.g., the International Labour Organisation (ILO)), and consumer organizations. A further observation is that while GPNs are increasingly dispersed at a global scale, they are characterized by concentration of economic activity at specific geographical scales, especially at the scale of the city and at even more localized clusters within cities. There are clearly synergies involved in the co-location of related industrial activities. While inter-firm relationships are depicted as networks in which there may be two-way flows of information, conceptualization of value in GPN and GPC frameworks reflects a more linear process in that value is seen to increase along each pathway in the production network.

As with IE models, the GPN framework depicts the materials economy in terms of inputs and outputs but provides a more sophisticated framing of inputs that includes technology inputs (e.g., research, design, process technologies, etc.), service inputs (e.g., procurement processes, human resources, marketing, etc.) and logistical inputs (e.g., movement of materials, products, people and information) [38]. Figure 5 shows how inputs of various kinds are transformed into products that are distributed and consumed. In this conceptualization, materials and products, depicted by the solid arrow in Figure 5, flow in one direction and information, including customer orders, flows in the opposite direction, depicted by the transparent arrow. Unlike the IE framing of the materials economy, material and product flows that end with consumption and waste outputs are not depicted. Importantly, the whole production network is understood as operating within a financial system (now global in reach) which is subject to various forms of regulation, coordination and control that may operate at the scale of countries, regional trade blocs or be specific to major industries. Currently, the most powerful actors in GPNs are the providers of financial services and their investment decisions exert significant influence on all aspects of the production circuit.

A small but growing body of work applies the GPN and GVC frameworks to commodity chains and networks for used products and materials ranging from end of life ships [5,26], to electronic waste [39], clothing [5] and cars [40]. Material flows of used or recycled goods and materials appear to be more complex and multidirectional in contrast with those for new products and materials shown in Figure 5. They are more likely to be brokered by multiple actors rather than dominated by large transnational firms and they appear to be much more volatile [26]. Currently, the dominant flows of used products and materials originating in developed countries are transnational with significant industrial reprocessing hubs in developing countries in Asia [4,26,39]. This is somewhat contrary to the notion of industrial symbiosis promoted in IE which involves in-country co-located manufacturing industries where waste products from one are used as production inputs by another [3,4]. The GPN and GVC frameworks help to understand how profits are made from recycling metals in Australia and why it is currently more profitable for most processing to be undertaken offshore. The focus on institutions, waged labor, technology and knowledge provides some pointers as to what elements would need to change in order to favor a local recycling industry over either exports for offshore reprocessing, or dumping in landfill. The volatile and dynamic character of current international material flows indicates that potential for change exists.

Figure 5.

The basic components of a production circuit, after Dicken [38] (p. 57).

While the regimes of value analysis suggested how new alternative pathways might emerge in the trajectory of products and materials through initial use and disposal into being re-assigned valued as commodities again, the GPN and GVC frameworks help to understand how specific production processes become entrenched and highlight political and structural dimensions that need to be engaged with for significant change to occur. The spatial character of economic value capture signals particular challenges for the development of metals recycling in Australia, an island nation with high environmental and labor standards compared with its near neighbors in the Asian region.

The contribution of labor to the generation of value in recycling is critical. While the GPN and GVC analyses emphasize inputs of waged labor in large scale industrial systems involved in reprocessing, unpaid labor of consumers is also relevant at the more localized spatial scales of end of life take back schemes such as Australia’s Mobile Muster scheme for mobile phones and the new national product stewardship scheme for computers and TVs. While GPN and GVC analyses assume that economic value is primarily extracted through the creation of goods, anthropological approaches are better able to recognize the role of informal or unpaid labor throughout product life spans. For example, Graeber [32] argues that more labor is invested in “adjusting, refashioning, repairing, maintaining, cleaning, rearranging or transporting things, than in their original creation” (p.288). While political economists, Herod et al. [41] highlight the need for more research attention on how surplus value is captured from labor involved in what they term “Global Destruction Networks”, the pathways of used goods and materials into processes of reuse and recycling relies on the interface between different regimes of value operating at many different spatial scales. Identifying and understanding these critical interfaces requires a conception of value that is broader than this Marxian idea of congealed labor. Rather than attempt to resolve the ‘problem’ of value as it has been presented in political economy debates, it seems more useful to consider value in recycled goods and materials as both a process and a productive tension generative of new conceptual framings, particularly of material aspects of society [42].

4. Conclusions

If value in goods and materials is understood in terms of valuing practices and processes within socio-technical systems, how might IE exert influence on these practices and processes in line with the promotion of a circular materials economy? A key focus of IE has been the development of calculative tools for assessing environmental impacts of products and materials through Life Cycle Assessments and scenario modeling. These are used to compare environmental impacts of continued reliance on virgin metals versus recycled material and have the potential to influence economic modelling for resource futures. Çalışkan and Callon [43] have argued that the calculative tools of economists used to predict prices of products and commodities in markets and model their performance in future scenarios can be regarded as sociotechnical arrangements or mechanisms that exercise agency themselves so that the worlds that correspond to these models end up existing and producing recurrent events. In other words, they perform by prescription. Perhaps, the material flows models of IE can similarly be regarded as a sociotechnical arrangement in Çalışkan and Callon’s [43] terms in that they produce statements about the material world and the phenomenological qualities of materials that can be understood to be co-evolving as knowledge of materials and technologies develops and conditions in the material world change. However, to have any traction among the key actors and agencies influential in current material flows, they must influence other kinds of valuing practices, particularly the public good assessments that influence government policy and the economic assessments that influence commercial strategies. This suggests a useful direction for future research.

The relative economic costs and benefits of reliance on virgin versus recycled metals are strongly influenced by national and international regulatory regimes that govern international trade, corporate taxation regimes and environmental and labor standards standards [44]. Changes in these regulatory regimes can also affect the spatial dynamics of value capture in different types of industry. Without change, economic value capture in metals recycling will continue to take place primarily offshore, may not occur at all or for some products and materials, or will emerge too slowly to position Australian industry strategically. Environmental economists justify interventions of this kind by putting a dollar value on environmental degradation and release of pollutants into the environment. For example, as many countries now assign a dollar value to carbon emissions, the economics of carbon intensive industries is beginning to change. Interventions at the national scale might be justified in terms of the social benefits of promoting local industries around urban mining that divert current material flows to landfill towards new forms of manufacturing that provide local employment opportunities. These could involve further regulatory change or new forms of product stewardship or certification schemes that go beyond conventional end of life take-back schemes to include the whole commodity chain, including the production stage.

Transformation of existing waste disposal practices, from the household scale through to the scale of business practice and whole industry sectors, requires broad based changes to social norms and assumptions about responsibility. This has a recursive aspect as public support for materials recycling can increase government willingness to invest in the more advanced waste collection and sorting facilities needed to support the development of advanced metals recycling capacity (the Australian Government’s decision to support a national product stewardship scheme for recycling computers and TVs was informed by an assessment of public support for this initiative [7]). The charity sector has a long history of involvement in recycling of used goods and already taps existing social values about the benefits of extending product lifespans by donating unwanted goods to the needy [45,46]. Voluntary product stewardship programs, such as Australia’s Mobile Muster take back scheme for mobile phones, rely on understandings of responsibility at the household scale and among the producers and retailers who sign on to the scheme (It should be noted that some manufacturers (e.g., Apple Inc., Cupertino, CA, USA) prefer to maintain their own corporate social responsibility take back schemes that are implemented globally rather than sign up to nationally focused schemes).

At present, key elements required for creating and consolidating alternative pathways for metals recycling in Australia are missing. The most obvious is the current lack of manufacturing expertise and infrastructure for reprocessing used products and materials. However, greater knowledge of the resource is also needed. The current and potential supply of recyclable products and materials is characterized by its spatial distribution across domestic residences and commercial buildings in Australian cities [47]. More detailed knowledge is required, not only about the size and characteristics of the potential resource, but also about the actors and organizations that accumulate these materials and their current practices around disposal. Information is needed about existing collection systems, their logistical elements, how economic value is currently captured in collection of used goods and materials, and the formal and informal institutional frameworks that influence current arrangements. Also required is a better understanding of the informal frameworks of social values, norms and knowledge that influence current disposal practices. These are likely to differ significantly for different products and material types, depending on the types of actors and organizations involved. The inherently interdisciplinary research outlined here will be greatly facilitated by regarding value as a dynamic concept that manifests differently in process and practices at different spatial scales.

Acknowledgments

The author would like to acknowledge the support of the Wealth from Waste Research Cluster, a collaborative program between the Australian CSIRO (Commonwealth Scientific Industrial Research Organisation); University of Technology, Sydney; The University of Queensland, Swinburne University of Technology, Monash University and Yale. The authors gratefully acknowledge the contribution each partner and the CSIRO Flagship Collaboration Fund. The author would specificially like to acknowledge the input from Leah Mason, University of Technology Sydney, and Justine Lacey, CSIRO.

Conflicts of Interest

The author declares no conflict of interest.

References

- Söderholm, P.; Tilton, J.E. Material efficiency: An economic perspective. Resour. Conserv. Recycl. 2012, 61, 75–82. [Google Scholar] [CrossRef]

- Gibbs, D.; Deutz, P. Reflections on implementing industrial ecology through eco-industrial park development. J. Clean. Prod. 2007, 15, 1683–1695. [Google Scholar] [CrossRef]

- Randles, S. Multiscalar landscapes: Transnational corporations, business ethics and industrial ecology. Progr. Ind. Ecol. Int. J. 2007, 4, 164–183. [Google Scholar] [CrossRef]

- Lyons, D.; Rice, M.; Wachal, R. Circuits of scrap: Closed loop industrial ecosystems and the geography of us international recyclable material flows 1995–2005. Geogr. J. 2009, 175, 286–300. [Google Scholar] [CrossRef]

- Gregson, N.; Crang, M.; Ahamed, F.U.; Akter, N.; Ferdous, R.; Foisal, S.; Hudson, R. Territorial agglomeration and industrial symbiosis: Sitakunda-Bhatiary, Bangladesh, as a secondary processing complex. Econ. Geogr. 2012, 88, 37–58. [Google Scholar] [CrossRef]

- Schandl, H.; Turner, G.M. The dematerialization potential of the Australian economy. J. Ind. Ecol. 2009, 13, 863–880. [Google Scholar] [CrossRef]

- Wright Corporate Strategy Pty Limited; Rawtec Pty Limited. A Study of Australia’s Current and Future E-waste Recycling Infrastructure Capacity and Needs; Department of the Environment, Water, Heritage and the Arts (DEWHA): Canberra, Australia, 2010.

- Jelinski, L.W.; Graedel, T.E.; Laudise, R.A.; McCall, D.W.; Patel, C.K. Industrial ecology: Concepts and approaches. Proc. Natl. Acad. Sci. USA 1992, 89, 793–797. [Google Scholar] [CrossRef]

- Boons, F.; Spekkink, W.; Mouzakitis, Y. The dynamics of industrial symbiosis: A proposal for a conceptual framework based upon a comprehensive literature review. J. Clean. Prod. 2011, 19, 905–911. [Google Scholar] [CrossRef]

- Thompson, M. Rubbish Theory: The Creation and Destruction of Value; Oxford University Press: Oxford, UK, 1979. [Google Scholar]

- Hawkins, G.; Meucke, S. Culture and Waste: The Creation and Destruction of Value; Rowman & Littlefield: Lanham, MD, USA, 2003. [Google Scholar]

- O’Brien, M. A Crisis of Waste? Understanding the Rubbish Society; Routledge: Oxon, UK, 2008. [Google Scholar]

- Allwood, J.M.; Ashby, M.F.; Gutowski, T.G.; Worrell, E. Material efficiency: A white paper. Resour. Conserv. Recycl. 2011, 55, 362–381. [Google Scholar] [CrossRef]

- Mudd, G.M. The environmental sustainability of mining in Australia: Key mega-trends and looming constraints. Resour. Policy 2010, 35, 98–115. [Google Scholar] [CrossRef]

- Miller, D. A Theory of Shopping; Polity Press: Cambridge, UK, 1998. [Google Scholar]

- Frow, J. Invidious Distinction: Waste, Difference, and Classy Stuff. In Culture and Waste: The Creation and Destruction of Value; Hawkins, G., Muecke, S., Eds.; Rowman & Littlefield Publishers Inc: Oxford, UK, 2003; pp. 25–38. [Google Scholar]

- Hawkins, G. The Ethics of Waste: How We Relate to Rubbish; University of New South Wales Press: Sydney, Australia, 2006. [Google Scholar]

- Gregson, N. Living with Things: Ridding, Accommodation, Dwelling; Sean Kingston Publishing: Wantage, UK, 2007. [Google Scholar]

- Graham, S.; Thrift, N. Out of order: Understanding repair and maintenance. Theory Cult. Soc. 2007, 24, 1–25. [Google Scholar] [CrossRef]

- Lane, R.; Watson, M. Stewardship of things: The radical potential of product stewardship for re-framing responsibilities and relationships to products and materials. Geoforum 2012, 43, 1254–1265. [Google Scholar] [CrossRef]

- Strasser, S. Waste and Want: A Social History of Trash; Henry Holt & Co.: New York, NY, USA, 1999. [Google Scholar]

- Cooper, T. Challenging the ‘refuse revolution’: War, waste and the rediscovery of recycling, 1900–50*. Hist. Res. 2008, 81, 710–731. [Google Scholar]

- Department of the Environment Water Heritage and the Arts. National Waste Policy: Less Waste, More Resources; Australian Government: Canberra, Australia, 2009.

- Lane, R. The waste commons in an emerging resource recovery waste regime: Contesting property and value in Melbourne’s hard rubbish collections. Geogr. Res. 2011, 49, 395–407. [Google Scholar] [CrossRef]

- Dicken, P.; Malmberg, A. Firms in territories: A relational perspective*. Econ. Geogr. 2001, 77, 345–363. [Google Scholar] [CrossRef]

- Crang, M.; Hughes, A.; Gregson, N.; Norris, L.; Ahamed, F. Rethinking governance and value in commodity chains through global recycling networks. Trans. Inst. Br. Geogr. 2012, 38, 12–24. [Google Scholar]

- Gregson, N.; Watkins, H.; Calestani, M. Political markets: Recycling, economization and marketization. Econ. Soc. 2012, 42, 1–25. [Google Scholar] [CrossRef]

- Appadurai, A. The Social Life of Things: Commodities in Cultural Perspective; Cambridge University Press: Cambridge, UK, 1986. [Google Scholar]

- Kopytoff, I. The Cultural Biography of Things: Commoditization as Process. In The Social Life of Things; Appadurai, A., Ed.; Cambridge University Press: Cambridge, UK, 1986; pp. 64–95. [Google Scholar]

- Gille, Z. Actor networks, modes of production, and waste regimes: Reassembling the macro-social. Environ. Plan. A 2010, 42, 1049–1064. [Google Scholar] [CrossRef]

- Reno, J. Your trash is someone’s treasure: The politics of value at a Michigan landfill. J. Mater. Cult. 2009, 14, 29–46. [Google Scholar] [CrossRef]

- Graeber, D. Afterword: The Apocalypse of Objects—Degradation, Redemption and Transcendence in the World of Consumer Goods. In Economies of Recycling: The Global Transformation of Materials, Values and Social Relations; Alexander, C., Reno, J., Eds.; Zed Books: London, UK; New York, NY, USA, 2012; pp. 277–290. [Google Scholar]

- Ingold, T. Materials against materiality. Archaeol. Dialogues 2007, 14, 1–16. [Google Scholar] [CrossRef]

- Gregson, N.; Crang, M. Materiality and waste: Inorganic vitality in a networked world. Environ. Plan. A 2010, 42, 1026–1032. [Google Scholar]

- Bair, J. Global Commodity Chains: Genealogy and Review. In Frontiers of Commodity Chain Research; Bair, J., Ed.; Stanford University Press: Stanford, CA, USA, 2009; pp. 1–34. [Google Scholar]

- Gereffi, G.; Humphrey, J.; Sturgeon, T. The governance of global value chains. Rev. Int. Polit. Econ. 2005, 12, 78–104. [Google Scholar] [CrossRef]

- Coe, N.M.; Dicken, P.; Hess, M. Global production networks: Realizing the potential. J. Econ. Geogr. 2008, 8, 271–295. [Google Scholar] [CrossRef]

- Dicken, P. Global Shift: Mapping the Changing Contours of the World Economy, 6th ed.; Sage: Los Angeles, CA, USA, 2011. [Google Scholar]

- Lepawsky, J.; Billah, M. Making chains that (un)make things: Waste–value relations and the Bangladeshi rubbish electronics industry. Geogr. Ann. Ser. B Hum. Geogr. 2011, 93, 121–139. [Google Scholar] [CrossRef]

- Brooks, A. Networks of power and corruption: The trade of Japanese used cars to Mozambique. Geogr. J. 2012, 178, 80–92. [Google Scholar] [CrossRef]

- Herod, A.; Pickren, G.; Rainnie, A.; McGrath Champ, S. Global destruction networks, labour and waste. J. Econ. Geogr. 2013, 2013. [Google Scholar] [CrossRef]

- Henderson, G. Value in Marx: The Persistence of Value in a More-Than-Capitalist World; University of Minnesota Press: MMinneapolis, MI, USA; London, UK, 2013. [Google Scholar]

- alışkan, K.; Callon, M. Economization, Part 2: A research programme for the study of markets. Econ. Soc. 2010, 39, 1–32. [Google Scholar]

- Gumley, W. An analysis of regulatory strategies for recycling and re-use of metals in Australia. Resources 2014, 3, 395–415. [Google Scholar]

- Williams, C.C. Why do people use alternative retail channels? Some case-study evidence from two English cities. Urban Stud. 2002, 39, 1897–1910. [Google Scholar] [CrossRef]

- Watson, M.; Lane, R. Mapping Geographies of Reuse in Sheffield and Melbourne. In Material Geographies of Household Sustainability; Lane, R., Gorman-Murray, A., Eds.; Ashgate Publishing: Farnham, UK, 2011; pp. 133–155. [Google Scholar]

- Zhu, X. GIS and urban mining. Resources 2014, 3, 235–247. [Google Scholar] [CrossRef]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).