Circular Economy: Questions for Responsible Minerals, Additive Manufacturing and Recycling of Metals

Abstract

:1. Introduction

- (1)

- More from less: companies, governments and communities will discover new ways of ensuring quality of life for current and future generations within the natural world’s limited resources;

- (2)

- Going, going, ... gone? Many of the world’s natural habitats, plant species and animal species are in decline or at risk of extinction. This megatrend also captures the issue of climate change;

- (3)

- The silk highway: The powerhouses of the new world economy are China and India and, to a lesser extent, South America and Africa; billions transition from poverty to the middle classes;

- (4)

- Forever young: Overall the ageing population is an asset in skills, knowledge, wisdom—whilst rising healthcare costs and limited retirement savings are a challenge;

- (5)

- Virtually here: We are increasingly moving online to connect, to deliver and access services, to obtain information and to perform transactions such as shopping and working;

- (6)

- Great expectations: This is a consumer, societal, demographic and cultural megatrend noting the rising demand for experiences over products and the rising importance of social relationships.

2. Circular Economy

2.1. The Drivers of a Circular Economy

- Continued and forecast growth in demand for metals, and other materials will be driven, to a large extent, by economic growth in Asia [14];

- Increased generation of waste material—ten years ago, around 0.68 billion t of urban municipal solid waste was generated globally each year. Today, this has increased to around 1.3 billion t and by 2025 it is likely to reach 2.2 billion t per year [17];

- Rising costs of waste disposal—globally, solid waste management costs will increase from $205.4 billion per year today, to about $375.5 billion in 2025. These cost increases will be most severe in low income countries (more than 5-fold increases) and lower-middle income countries (more than 4-fold increases) [17];

- There has been a significant improvement in the evolution of recycling technology for metals [18]—product complexity has been a significant barrier for recycling due to the effort required to separate materials of interest. Coming decades, however, will see the continued advancement of chemical and physical processes for recycling and computer tools to aid the recycling process. This will make recycling more efficient and less costly;

- Demand for more sustainable mining practices - significant pressure remains to reduce energy consumption in order to reduce operational costs as well as stem greenhouse gas emissions. Producing aluminium from recycled sources requires 95% less energy than producing it from virgin materials [19] and copper reclaimed through recycling also requires 75% less energy for low quality scrap [20] through to over 90% less energy than the amount needed to convert copper ores to metal [21,22];

- Consumer demand for responsible products has risen as environmental certification standards have grown and matured, mostly for primary metals, and seeing this also addressed for secondary materials is an important issue [23].

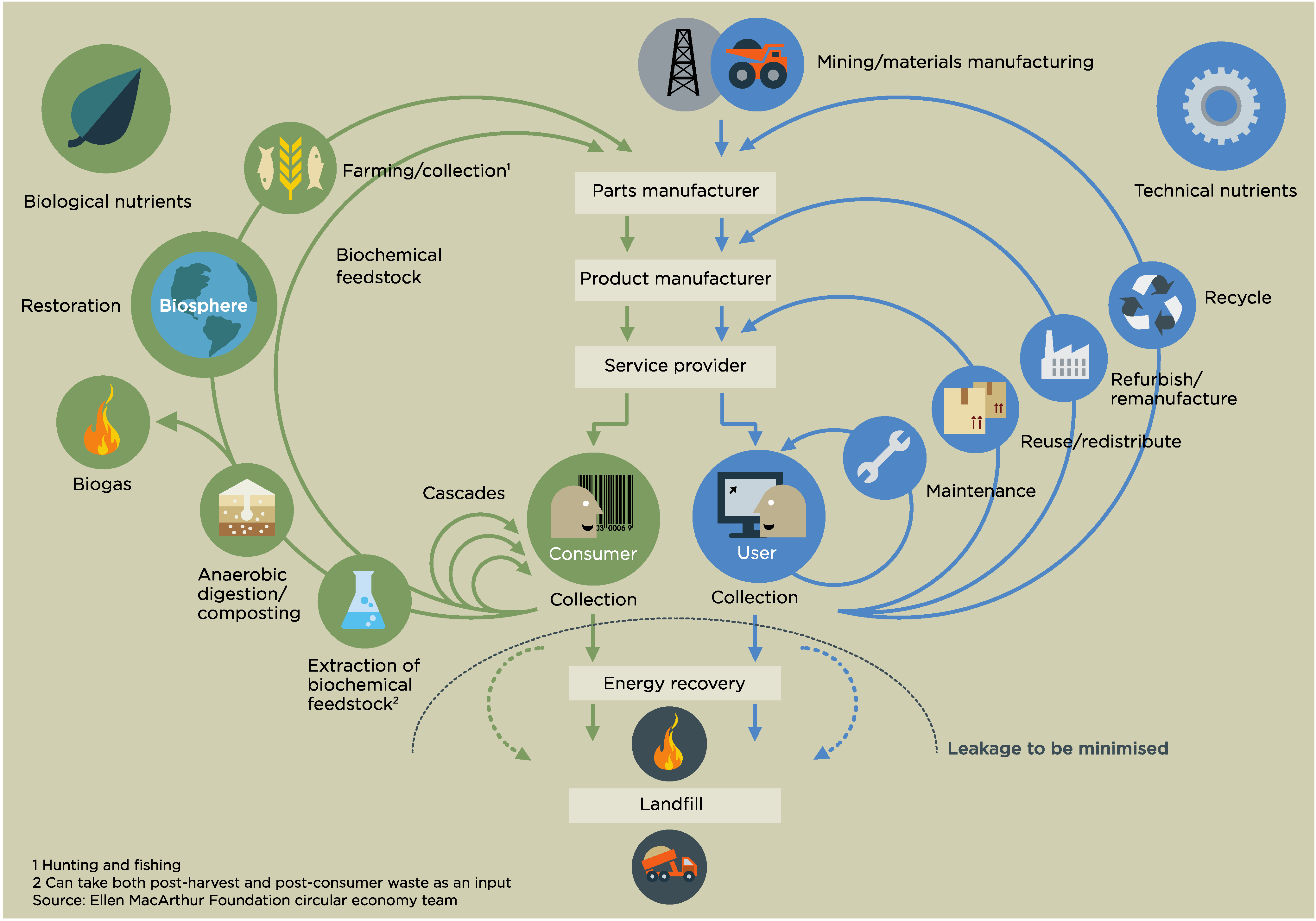

2.2. The Concept of a Circular Economy

- (i)

- The individual firm level using cleaner production;

- (ii)

- Eco-industrial park level with clustered or chained industries/responsible supply chain;

- (iii)

- Between production and consumption systems in regions, between industries and urban environment in an “eco-region” or municipality.

- Inner circles: offering greater substitution of embedded costs for materials, labor, energy;

- Circling longer: through better design to make products last longer, be repairable;

- Cascaded uses: such as old clothing into fiber for furniture;

- Pure, non-toxic inputs, easy to separate designs: this aims to have purer material streams to improve reuse and recycling potential.

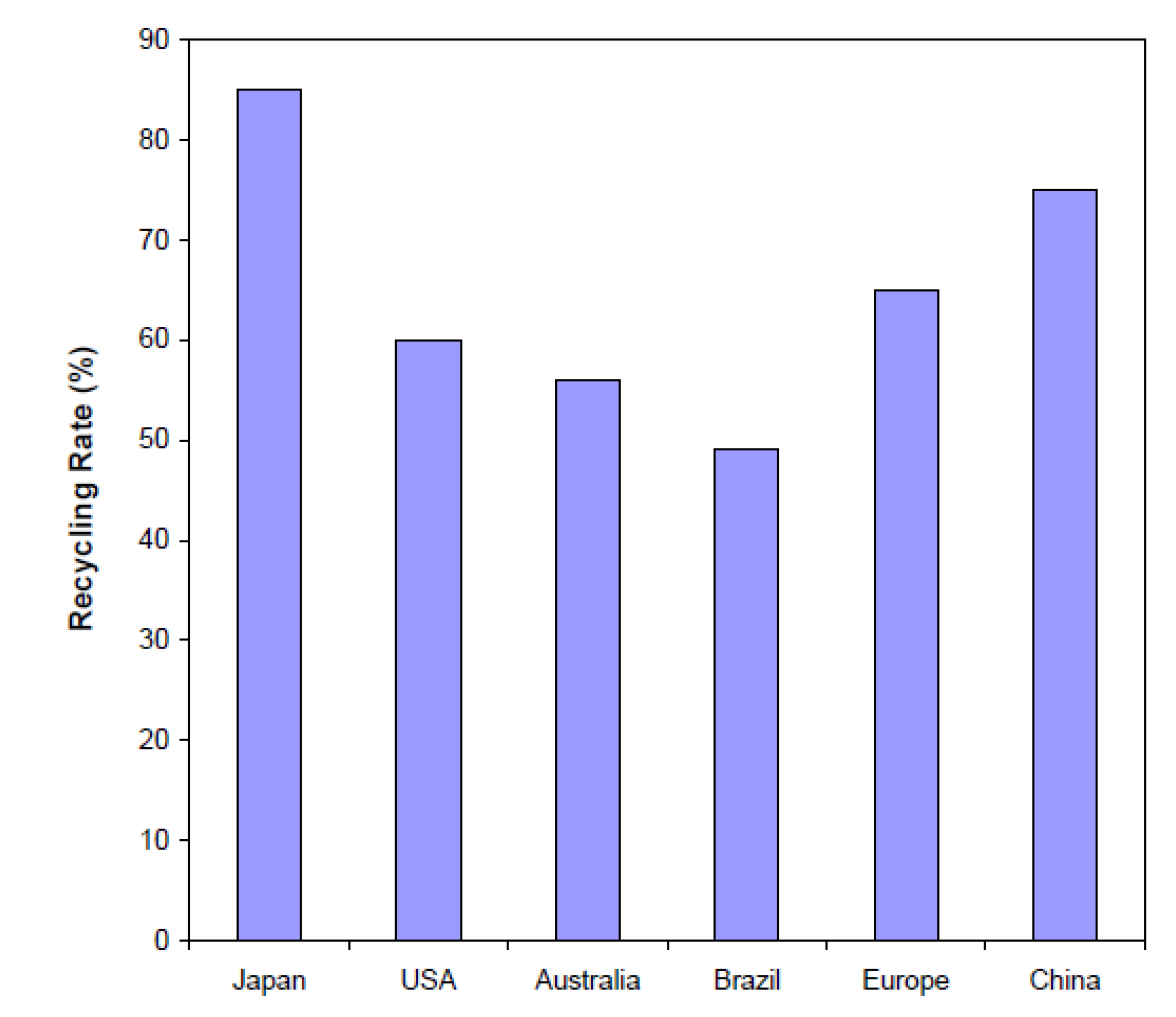

2.3. The Global Significance of the Circular Economy

“We will aim to improve the output efficiency of resource utilization, strengthen planning guidance, support fiscal and monetary policies, perfect the laws and regulations, implement extended producer responsibility and propel all links between production, circulation and consumption. We will speed up the development of the resource recycling industry, comprehensively utilize mineral resources, encourage the recycling of industrial waste, upgrade recycling systems and waste separation and recovery of renewable resources, and advance the industrialization of renewable resource recycling. We will encourage low carbon consumption models and lifestyles among the people and government. Our development model should adopt resource reduction, recycling, remanufacturing, zero emissions and industry links and popularize the classical recycling economic model.”

3. Responsible Supply Chains: Contributions from Primary and Secondary Resources

- (i)

- a mine where the workers are well paid and which utilitises clean energy and processing practices, or;

- (ii)

- whether the metal comes from recycled post-consumer scrap (or even home scrap/recycled production waste).

4. Future Trends in Additive Manufacturing

4.1. Overview of Additive Manufacturing

4.1.1. Extension of Product-Use Lifetimes

4.1.2. Mass Customization, Targeted Production

4.1.3. Consumer Assembly, Design for Disassembly

4.1.4. Induced Production

4.1.5. Enabler of Local Recycling

4.1.6. Materials Complexity

4.2. Design

5. Australian Context for Trends in Mining, Manufacturing, Disposal, Collection and Recycling Including Metals

5.1. Context for Mining

5.2. Context for Manufacturing

5.3. Context for Waste Disposal, Collection and Recycling

5.3.1. Brief history of Metals Recycling

| Year | Revenue ($m) | IVA ($m) | Establishments (Units) | Enterprises (Units) | Employment (Units) | Exports ($m) | Imports ($m) | Wages ($m) | Domestic demand ($m) |

|---|---|---|---|---|---|---|---|---|---|

| 2003–2004 | 2301.3 | 369.6 | 175 | 107 | 3625 | 1011.2 | 78.9 | 204.6 | 1369.0 |

| 2004–2005 | 2496.6 | 386.0 | 180 | 114 | 3720 | 1047.7 | 78.4 | 209.1 | 1527.3 |

| 2005–2006 | 2908.2 | 381.8 | 181 | 115 | 3739 | 1319.6 | 76.6 | 211.8 | 1665.2 |

| 2006–2007 | 3233.0 | 379.4 | 201 | 121 | 3759 | 1359.2 | 71.6 | 216.0 | 1945.4 |

| 2007–2008 | 3487.9 | 429.0 | 205 | 123 | 3995 | 1476.9 | 75.0 | 233.6 | 2086.0 |

| 2008–2009 | 3574.9 | 334.9 | 196 | 118 | 3974 | 1620.6 | 77.4 | 233.2 | 2031.7 |

| 2009–2010 | 3073.8 | 326.9 | 195 | 119 | 3855 | 1380.7 | 68.1 | 226.9 | 1761.2 |

| 2010–2011 | 3182.6 | 332.6 | 193 | 118 | 3766 | 1472.7 | 68.3 | 220.6 | 1778.2 |

| 2011–2012 | 3110.1 | 252.0 | 190 | 119 | 3625 | 1447.1 | 64.0 | 215.7 | 1727.0 |

| 2012–2013 | 3064.1 | 293.0 | 188 | 120 | 3592 | 1456.2 | 63.8 | 216.4 | 1671.7 |

5.3.2. Current Waste Policy Landscape

5.3.3. Waste Collection and Resource Recovery

| Waste Stream | Collection Services | Resource Recovery |

|---|---|---|

| Municipal Solid Waste (MSW) | Kerbside landfill and recyclables collection contracted or provided by local or state government. | Mixed recyclables to MRF. General waste may be treated in AWT before landfill disposal. |

| Commercial & Industrial (C&I) | Fragmented—individually negotiated by businesses depending on nature and volume of waste stream. | Mixed recyclables to MRF. Only a fraction of mixed waste treated by AWTs due to variability in content and volume. |

| Construction & Demolition (C&D) | Form of service depends on nature and volume of waste. Small residential jobs typically use skip bins. Large demolition sites serviced directly by a C&D waste processor, or indirectly via a waste collection services provider. | Source separated may be delivered directly to re-processing facility. Otherwise sent to transfer station. |

5.3.4. Recovery Rates

| Jurisdiction | Generation (kg per capita) | Recovered (kg per capita) | Recovery rate (%) |

|---|---|---|---|

| NSW | 252 | 227 | 90 |

| Victoria | 218 | 202 | 93 |

| Queensland | 179 | 156 | 87 |

| South Australia | 212 | 192 | 90 |

| Western Australia | 214 | 168 | 78 |

| Tasmania | 27 | 2 | 9 |

| Australian Capital Territory | 123 | 107 | 87 |

| Northern Territory | 45 | 4 | 8 |

| National | 212 | 188 | 89 |

5.3.5. Reprocessing Infrastructure

6. Concluding Discussion

“The circular economy offers a transformational agenda that aims to redesign global production and consumption systems. Many of the ideas are decades old, but a combination of environmental and resource price pressures, technological advancements and changes in consumer demand is finally building momentum. Both the private sector and governments increasingly recognize that future competitiveness will depend on leadership in resource-related innovation.”

| Theme | Australia (at local sites) | Australia (at sector/economy level) | Implications for Australia as a supplier to global customers |

|---|---|---|---|

| Circular economy | How can existing examples of established industrial ecology precincts (e.g., Gladstone, Kwinana) be used to develop best practices and global leadership? | What awareness raising is required to adequately address the future significance of the circular economy (for example given policy level commitments in China and Japan)? What indicators are appropriate? | What is Australia’s niche in terms of primary and secondary supplier and new business models under a circular economy? |

| Responsible supply chains | How may local supply chains be affected if 3D printing enables distributed manufacturing? | What can be learned from the Steel Stewardship Forum and the Responsible Jewellery Council for new geographies of production and consumption from primary and secondary sources? | Can Australia lead the development of chain of custody standards into China whilst promoting Brand Australia? |

| Steel | What economic diversification options exist for the Australia steel manufacturing sector? How will tagging of steel properties in infrastructure applications affect reuse rates? | What will be the effect of recycling in China on iron ore demand from Australia? | |

| Gold | How will e-waste recovery of gold affect Australian supply (the gold content of electronics can determine the economics of recycling)? | ||

| Aluminium | How might container deposit and other extended producer legislation for aluminium or e-waste foster drop off centres, change recycling economics and support city-based mini-recycling plants? | How may the relative export demand for Australian bauxite shift as the geography of aluminium smelting shifts to lower carbon intensity and lower cost electricity jurisdictions? How might investment in clean energy in place of coal based power affect the economics of aluminium production in Australia, in light of recent closure of local aluminium smelting capacity? | |

| Manufacturing and design | How could distributed design and additive manufacturing reshape both manufacturing and recycling in Australia for improved social and environmental outcomes? | What is Australia’s competitive advantage in new global markets for manufacturing and design such as leasing ‘responsibly sourced (or recycled) metals’ to additive manufacturers? What is required to ensure additive manufacturing is resource efficient? | |

| Waste and recycling context | How can Australia strengthen waste capture rates and promotion of an industry culture compatible with the circular economy? | ||

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Erten, B.; Ocampo, J.A. Super Cycles of Commodity Prices Since the Mid-Nineteenth Century. In Initiative for Policy Dialogue Working Paper Series; Initiative for Policy Dialogue: New York, NY, USA, 2012. [Google Scholar]

- Jacks, D.S. From Boom to Bust: A Typology of Real Commodity Prices in the Long Run; National Bureau of Economic Research: Cambridge, MA, USA, 2013. [Google Scholar]

- Hajkowicz, S.; Cook, H.; Littleboy, A. Our Future World:Global Megatrends that will Change the Way We Live. The 2012 Revision; Commonwealth Scientific Industrial Research Organisation (CSIRO): Brisbane, Australia, 2012. [Google Scholar]

- Giurco, D.; McLellan, B.; Franks, D.; Nansai, K.; Prior, T. Responsible mineral and energy futures: Global perspectives. J. Clean. Prod. 2014. Submitted. [Google Scholar]

- Graedel, T.E.; Harper, E.M.; Nassar, N.T.; Reck, B.K. On the materials basis of modern society. Proc. Natl. Acad. Sci. USA 2013, 2013. [Google Scholar] [CrossRef]

- Valero, A.; Valero, A.; Martínez, A. Inventory of the exergy resources on earth including its mineral capital. Energy 2010, 35, 989–995. [Google Scholar] [CrossRef]

- Mason, L.; Prior, T.; Mudd, G.; Giurco, D. Availability, addiction and alternatives: three criteria for assessing the impact of peak minerals on society. J. Clean. Prod. 2011, 19, 958–966. [Google Scholar] [CrossRef]

- Mathews, J.A.; Tan, H. Progress toward a circular economy in China. J. Ind. Ecol. 2011, 15, 435–457. [Google Scholar] [CrossRef]

- Yuan, Z.; Bi, J.; Moriguichi, Y. The circular economy: A new development strategy in China. J. Ind. Ecol. 2006, 10, 4–8. [Google Scholar] [CrossRef]

- Su, B.; Heshmati, A.; Geng, Y.; Yu, X. A review of the circular economy in China: Moving from rhetoric to implementation. J. Clean. Prod. 2013, 42, 215–217. [Google Scholar] [CrossRef]

- Ma, S.-H.; Wen, Z.-G.; Chen, J.-N.; Wen, Z.-C. Mode of circular economy in China’s iron and steel industry: A case study in Wu’an city. J. Clean. Prod. 2013, 64, 505–512. [Google Scholar]

- Pearce, D.W.; Turner, R.K. Economics of Natural Resources and the Environment; Johns Hopkins University Press: Baltimore, MA, USA, 1990. [Google Scholar]

- Towards the Circular Economy; Ellen Macarthur Foundation: Isle of Wight, UK, 2012; Volume 1.

- West, J.; Schandl, H.; Heyenga, S.; Chen, S. Resource Efficiency: Economics and Outlook for China; United Nations Environment Programme (UNEP): Bangkok, Thailand, 2013. [Google Scholar]

- Mudd, G.M. The environmental sustainability of mining in Australia: Key mega-trends and looming constraints. Resour. Policy 2010, 35, 98–115. [Google Scholar] [CrossRef]

- Prior, T.; Giurco, D.; Mudd, G.; Mason, L.; Behrisch, J. Resource depletion, peak minerals and the implications for sustainable resource management. Glob. Environ. Change 2012, 22, 577–587. [Google Scholar] [CrossRef]

- Hoornweg, D.; Bhada-Tata, P. What a Waste: A Global Review of Solid Waste Management; The World Bank: Washington, WA, USA, 2012. [Google Scholar]

- Reuter, M.A.; van Schaik, A.; Heiskanen, K.; Meskers, C.; Hagelüken, C. Metal Recycling: Opportunities, Limits, Infrastructure; UNEP: New York, NY, USA, 2013. [Google Scholar]

- Green, J.A. Aluminum Recycling and Processing for Energy Conservation and Sustainability; ASM International: Materials Park, OH, USA, 2007. [Google Scholar]

- Giurco, D.; Stewart, M.; Suljada, T.; Petrie, J. Copper Recycling Alternatives: An Environmental Analysis. In Proceedings of the 5th Annual Environmental Engineering Research Event, Noosa, Australia, 20–23 October 2006.

- Davenport, W.G.L.; King, M.; Schlesinger, M.; Biswas, A.K. Extractive Metallurgy of Copper; Elsevier: Oxford, UK, 2002. [Google Scholar]

- Giurco, D. Towards Sustainable Metal Cycles: The Case of Copper. Ph.D. Thesis, University of Sydney, Sydney, Australia, 2005. [Google Scholar]

- Schluep, M. Overview Sustainable Recycling. Industries (SRI). In Sustainable Recycling Industries: Advance Raw Materials Stewardship in Developing Countries; EMPA: ETH Zurich, Swezerland, 2013. [Google Scholar]

- Clapp, J. Toxic Exports: The Transfer of Hazardous Wastes from Rich to Poor Countries; Cornell University Press: Ithica, NY, USA, 2001. [Google Scholar]

- Ogushi, Y.; Kandlikar, M. Assessing extended producer responsibility laws in Japan. Environ. Sci. Technol. 2007, 41, 4502–4508. [Google Scholar] [CrossRef]

- Geng, Y.; Fu, J.; Sarkis, J.; Xue, B. Towards a national circular economy indicator system in China: An evaluation and critical analysis. J. Clean. Prod. 2012, 23, 216–224. [Google Scholar] [CrossRef]

- China’s Twelfth Five Year Plan (2011–2015)—The Full English Version. Available online: http://www.britishchamber.cn/content/chinas-twelfth-five-year-plan-2011-2015-full-english-version (accessed on 3 February 2014).

- Department of Foreign Affairs and Trade Australia’s trade with the world graph—Trade Matters. Available online: http://www.dfat.gov.au/tradematters/aus-graph.html (accessed on 12 November 2013).

- Northey, S.; Mohr, S.; Mudd, G.M.; Weng, Z.; Giurco, D. Modelling future copper ore grade decline based on a detailed assessment of copper resources and mining. Resour. Conserv. Recycl. 2013, 83, 190–201. [Google Scholar]

- Laurance, W.F.; Koh, L.P.; Butler, R.; Sodhi, N.S.; Bradshaw, C.J.; Neidel, J.D.; Consunji, H.; Mateo Vega, J. Improving the performance of the roundtable on sustainable palm oil for nature conservation. Conserv. Biol. 2010, 24, 377–381. [Google Scholar] [CrossRef]

- FSC Principles and Criteria for Forest Stewardship; Forest Stewardship Council: Bonn, Germany, 2004.

- Sarin, R. No dirty gold: Consumer education and action for mining reform. J. Clean. Prod. 2006, 14, 305–306. [Google Scholar] [CrossRef]

- Responsible Jewellery Council. Available online: http://www.responsiblejewellery.com/ (accessed on 1 December 2013).

- Steel Stewardship Forum. Available online: http://www.steelstewardship.com (accessed on 1 December 2013).

- Berkhout, P.H.G.; Muskens, J.C.; Velthuijsen, J.W. Defining the rebound effect. Energy Policy 2000, 28, 425–432. [Google Scholar] [CrossRef]

- Cooper, C.; Giurco, D. Mineral resources landscape: Reconciling complexity, sustainability and technology. Int. J. Technol. Intell. Plan. 2011, 7, 1–18. [Google Scholar]

- Zhang, K.; Schnoor, J.L.; Zeng, E.Y. E-waste recycling: Where does it go from here? Environ. Sci. Technol. 2012, 46, 10861–10867. [Google Scholar] [CrossRef]

- Schluep, M. Recycling: From E-Waste to Resources; UNEP and United Nations University: Tokyo, Japan, 2009. [Google Scholar]

- Jolly, J. 2013 Technical Report—The US Copper-Base Scrap Industry and Its By-Products. 2013. Available online: http://www.copper.org/publications/pub_list/pdf/scrap_report.pdf (accessed on 1 December 2103).

- Graedel, T.; Allwood, J.; Birat, J.-P.; Buchert, M.; Hagelüken, C.; Reck, B.K.; Sibley, S.F.; Sonnemann, G. Recycling Rates of Metals: A Status Report; UNEP: Paris, France, 2011. [Google Scholar]

- Schandl, H.; West, J. Resource use and resource efficiency in the Asia—Pacific region. Glob. Environ. Chang. 2010, 20, 636–647. [Google Scholar] [CrossRef]

- Mironov, V.; Boland, T.; Trusk, T.; Forgacs, G.; Markwald, R.R. Organ printing: Computer-aided jet-based 3D tissue engineering. TRENDS Biotechnol. 2003, 21, 157–161. [Google Scholar] [CrossRef]

- National Aeronautics and Space Administration (NASA). NASA Tests Limits of 3-D Printing with Powerful Rocket Engine Check. Available online: http://www.nasa.gov/exploration/systems/sls/3d-printed-rocket-injector.html (accessed on 1 December 2013).

- Rosen, D.; Weiss, L. Layered manufacturing: Current status and future trends. J. Comput. Inf. Sci. Eng. 2001, 1, 60–71. [Google Scholar]

- Bak, D. Rapid prototyping or rapid production? 3D printing processes move industry towards the latter. Assem. Autom. 2003, 23, 340–345. [Google Scholar]

- Markets and Markets Global Additive Manufacturing Market worth $3.5 Billion by 2017. Available online: http://www.marketsandmarkets.com/PressReleases/additive-manufacturing.asp (accessed on 1 November 2013).

- Wholers Associates. Wholers Report 2013; Wohlers Associates, Inc: Fort Collins, CO, USA, 2013. Available online: http://wohlersassociates.com/2013report.htm (accessed on 1 November 2013).

- Wohlers Associates. Additive Manufacturing Technology for Australia; CSIRO and Enterprise Connect: Fort Collins, CO, USA, 2011. [Google Scholar]

- Kaur, S. Pushing frontiers with the first lady of emerging technologies—How is “Internet of the 3D printed products” going to affect our lives? IETE Tech. Rev. 2012, 29, 360–364. [Google Scholar] [CrossRef]

- Why You Won’t Have an AM Machine in Your Garage: MTAdditive. Available online: http://www.mtadditive.com/articles/why-you-wont-have-an-am-machine-in-your-garage (accessed on 1 November 2013).

- Wohlers Talk Why Most Adults Will Never Use a 3D Printer. Available online: http://wohlersassociates.com/blog/2012/07/why-most-adults-will-never-use-a-3d-printer/ (accessed on 8 April 2014.).

- Bilton, R. Microsoft’s Brilliantly Simple 3D Printing Mission: Make It just Like 2D Printing. Available online: http://venturebeat.com/2013/08/23/microsofts-briliantly-simple-3d-printing-mission-make-it-just-like-2d-printing/ (1 November 2013).

- Shapeways Make, Buy, and Sell Products with 3D Printing. Available online: http://www.shapeways.com/ (1 November 2013).

- Bourell, D.; Beaman, J.; Leu, M.; Rosen, D. A Brief History of Additive Manufacturing and the 2009 Roadmap for Additive Manufacturing: Looking back and Looking ahead. In Proceedings of the US-Turkey Workshop on Rapid Technologies, Istanbul, Turkey, 24–25 September 2009.

- Department of Foreign Affairs and Trade Australia’s Trade in Goods and Services 2012–2013. Available online: http://dfat.gov.au/publications/tgs/index.html (accessed on 8 April 2014).

- Australian Bureau of Statistics. 1301.0-Year Book of Australia, 2012. Available online: http://www.abs.gov.au/ausstats/abs@.nsf/Lookup/by%20Subject/1301.0~2012~Main%20Features~Mining%20Industry~150 (accessed on 8 April 2014).

- Giurco, D.; Evans, G.; Cooper, C.; Mason, L.; Franks, D. Mineral Futures Discussion Paper: Sustainability Issues, Challenges and Opportunities; Institute for Sustainable Futures, UTS and Sustainable Minerals Institute; Univeristy of Queensland: Sydney, Australia, 2009. [Google Scholar]

- Giurco, D.; Prior, T.; Mudd, G.; Mason, L.; Behrisch, J. Peak Minerals in Australia: A Review of Changing Impacts and Benefits; Institute for Sustainable Futures, University of Technology, Sydney (UTS): Sydney, Australia, 2010. [Google Scholar]

- Oke, M.; Allan, P.; Goldsworthy, K; Pickin, J. Waste and Recycling in Australia Report No 1; Hyder for Department of Environment Water Heritage and the Arts: Canberra, Australia, 2008. [Google Scholar]

- Smith, K.; O’Farrell, K.; Brindley, F. Waste and Recycling in Australia; 2011; Hyder for Department of Environment Water Heritage and the Arts: Canberra, Australia, 2012. [Google Scholar]

- Australian Government. National Waste Report 2010; Environment Protection and Heritage Council (EPHC) and Department of Environment Water Heritage and the Arts: Canberra, Australia, 2010.

- van Beers, D.; Corder, G.D.; Bossilkov, A.; van Berkel, R. Regional synergies in the Australian minerals industry: Case-studies and enabling tools. Miner. Eng. 2007, 20, 830–841. [Google Scholar] [CrossRef]

- Giurco, D.; Cohen, B.; Langham, E.; Warnken, M. Backcasting energy futures using industrial ecology. Technol. Forcasting Soc. Change 2011, 78, 797–818. [Google Scholar] [CrossRef]

- Golev, A.; Corder, G.D.; Giurco, D.P. Industrial symbiosis in Gladstone: A decade of progress and future development. J. Clean. Prod. 2014. [Google Scholar] [CrossRef]

- Corder, G.; Golev, A.; King, S.; Fyfe, J. Barriers and enablers to industrial ecology in Australia. Resources 2014, 3, 340–361. [Google Scholar] [CrossRef]

- Scrap Metal Recycling Industry in Australia Report OD4044; IBISWorld: Melbourne, Australia, 2013.

- A Study into Commercial and Industrial (C&I) Waste and Recycling by Industry Division; Sustainable Resource Use Pty Ltd: North Melbourne, Austrilia, 2012.

- Davey, C. National Steel Can Recycling Survey 2006–2007 and 2007–2008; Hyder for the Australian Food and Grocery Council and the National Packaging Covenant Council: Canberra, Australia, 2008. [Google Scholar]

- SITA. The Facts about Steel and Aluminium. Available online: http://www.sita.com.au/media/fact_sheets/AL_Facts_24.1.12.pdf (accessed on 1 December 2013).

- Yellishetty, M.; Mudd, G.; Ranjith, P.G.; Tharumarajah, A. Environmental life-cycle comparisons of steel production and recycling: Sustainability issues, problems and prospects. Environ. Sci. Policy 2011, 14, 650–663. [Google Scholar] [CrossRef]

- Steel Recycling Institute. Available online: http://www.recycle-steel.org/ (accessed on 8 April 2014).

- Preston, F. A Global Redesign? Shaping the Circular Economy; Chatham House: London, UK, 2012. Available online: http://www.chathamhouse.org/sites/default/files/public/Research/ Energy,%20Environment%20and%20Development/bp0312_preston.pdf (accessed on 8 April 2014).

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Giurco, D.; Littleboy, A.; Boyle, T.; Fyfe, J.; White, S. Circular Economy: Questions for Responsible Minerals, Additive Manufacturing and Recycling of Metals. Resources 2014, 3, 432-453. https://doi.org/10.3390/resources3020432

Giurco D, Littleboy A, Boyle T, Fyfe J, White S. Circular Economy: Questions for Responsible Minerals, Additive Manufacturing and Recycling of Metals. Resources. 2014; 3(2):432-453. https://doi.org/10.3390/resources3020432

Chicago/Turabian StyleGiurco, Damien, Anna Littleboy, Thomas Boyle, Julian Fyfe, and Stuart White. 2014. "Circular Economy: Questions for Responsible Minerals, Additive Manufacturing and Recycling of Metals" Resources 3, no. 2: 432-453. https://doi.org/10.3390/resources3020432

APA StyleGiurco, D., Littleboy, A., Boyle, T., Fyfe, J., & White, S. (2014). Circular Economy: Questions for Responsible Minerals, Additive Manufacturing and Recycling of Metals. Resources, 3(2), 432-453. https://doi.org/10.3390/resources3020432