A Novel Set of Analysis Tools Integrated with the Energy Gap Method for Energy Accounting Center Diagnosis in Polymer Production

Abstract

1. Introduction

- Group I—Energy analysis: This includes energy audit methods and tools. These provide tools for investigating and systematically analyzing the company’s energy consumers.

- Group II—Energy assessment methods and tools: These make it possible to establish how energy is consumed within a production process and how this consumption is related to certain aspects of production, such as the technology used, manufacturing parameters, usage patterns, and production planning. In addition, they allow analysis of the effects on energy efficiency and environmental objectives.

- Group III—Energy-saving measures: These include methods and tools to identify and evaluate improvement opportunities to reduce energy consumption and identify appropriate energy-saving actions by collecting relevant data and analyzing correlations between energy-saving opportunities, risks, and cost benefits.

- The introduction of novel analytical tools (PCLD, ABTD, and PCCD) to transform the Energy Gap Method from a theoretical framework into practical diagnostic instruments for polymer processing industries.

- The proposed methodology enables the determination of optimal production batch sizes, minimum productivity requirements, and identification of critical molds for energy performance intervention.

- Case studies demonstrate how energy diagnostic tools can guide production scheduling decisions and accurately allocate energy costs to specific products.

- Integration of energy performance diagnosis with production planning enables manufacturers to optimize both economic and environmental aspects of polymer processing.

- The diagnostic approach provides accessible decision-making tools for SMEs to overcome the “energy efficiency paradox” in polymer manufacturing.

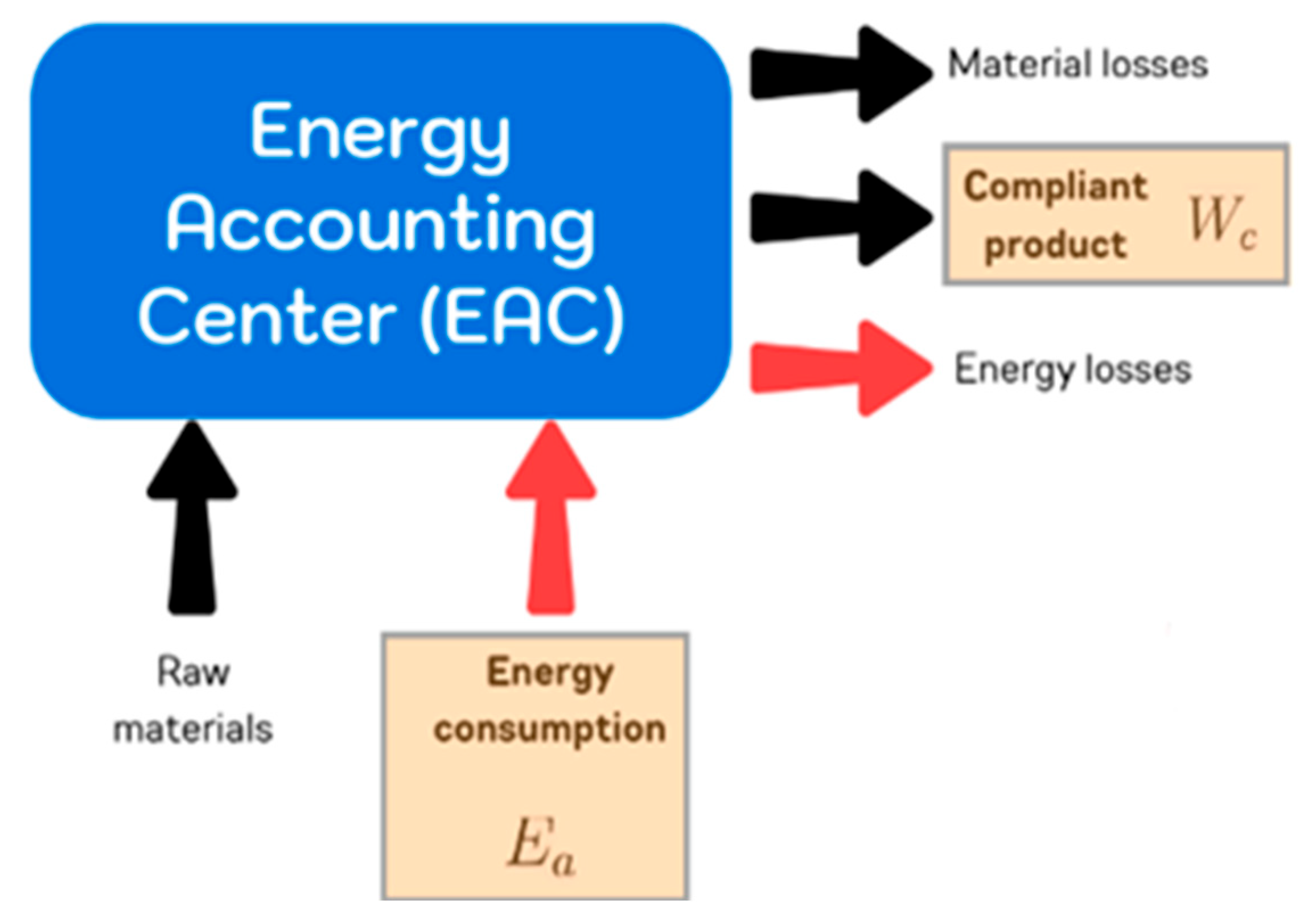

2. Materials and Methods

2.1. Energy Diagnostic Techniques: The Energy Gap Method (EGM)

- The production energy gap (): Represents the magnitude of energy inefficiency due to non-productive time.

- Quality energy gap (): Represents the magnitude of energy inefficiency due to non-compliant product production.

- Process energy gap (): Represents the magnitude of energy inefficiency due to operation under low energy efficient process conditions.

- Technology energy gap (): Represents the magnitude of energy inefficiency due to the use of low energy efficient technology.

- R&D energy gap (): Represents the magnitude of energy inefficiency due to the lack of better technologies.

2.2. The New Analytical Tools of the Energy Gap Method

- Determine the minimum batch size per mold and per reference to optimize the energy performance and efficiency of the EAC.

- Determine the base consumption per mold and per reference to establish opportunities for improvement during changeovers.

- Determine the effective productivity per mold and per reference that is necessary to achieve adequate energy performance and efficiency of the EAC.

- Compare the energy performance and efficiency of the EAC before and after implementing technological improvements to determine the feasibility and optimal conditions for replication.

- Establish criteria for enhancing EAC energy performance and efficiency based on production schedules.

- Accurately allocate energy costs to specific products to ensure that energy-efficient molds and references are not being burdened with the costs of less efficient ones.

2.2.1. Determining the Performance Characteristic Line for Diagnostics (PCLD) and the Activity-Based Target from Diagnostics (ABTD)

- is the slope of the straight line, also known as the variable load, which is typically measured in [kWh/kg].

- is the intercept of the straight line, also known as base load, which is typically measured in [kWh].

2.2.2. Determining the Activity-Based Target from Diagnostics (ABTD)

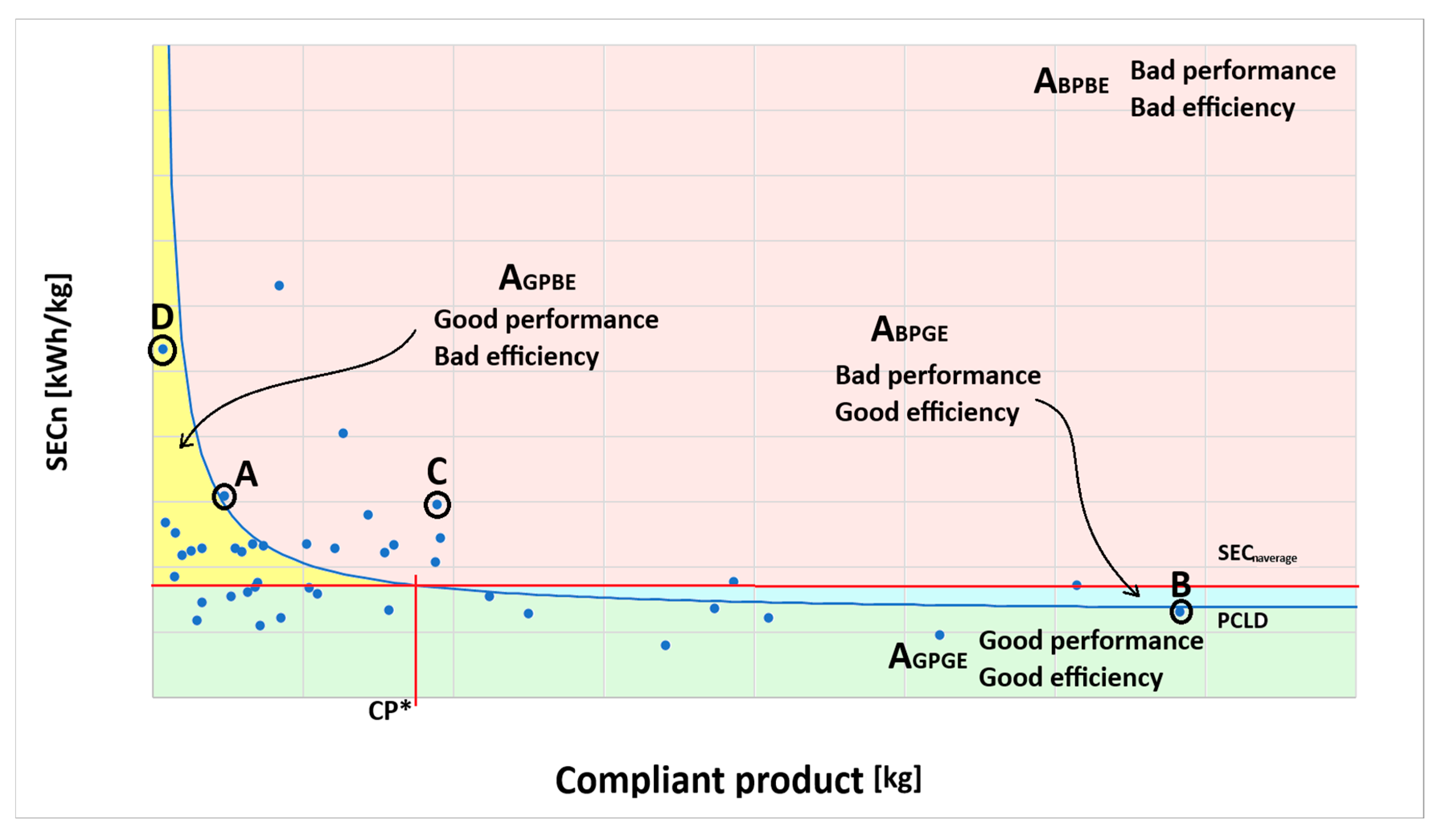

2.3. Determining the Performance Characteristic Curve for Diagnostics (PCCD)

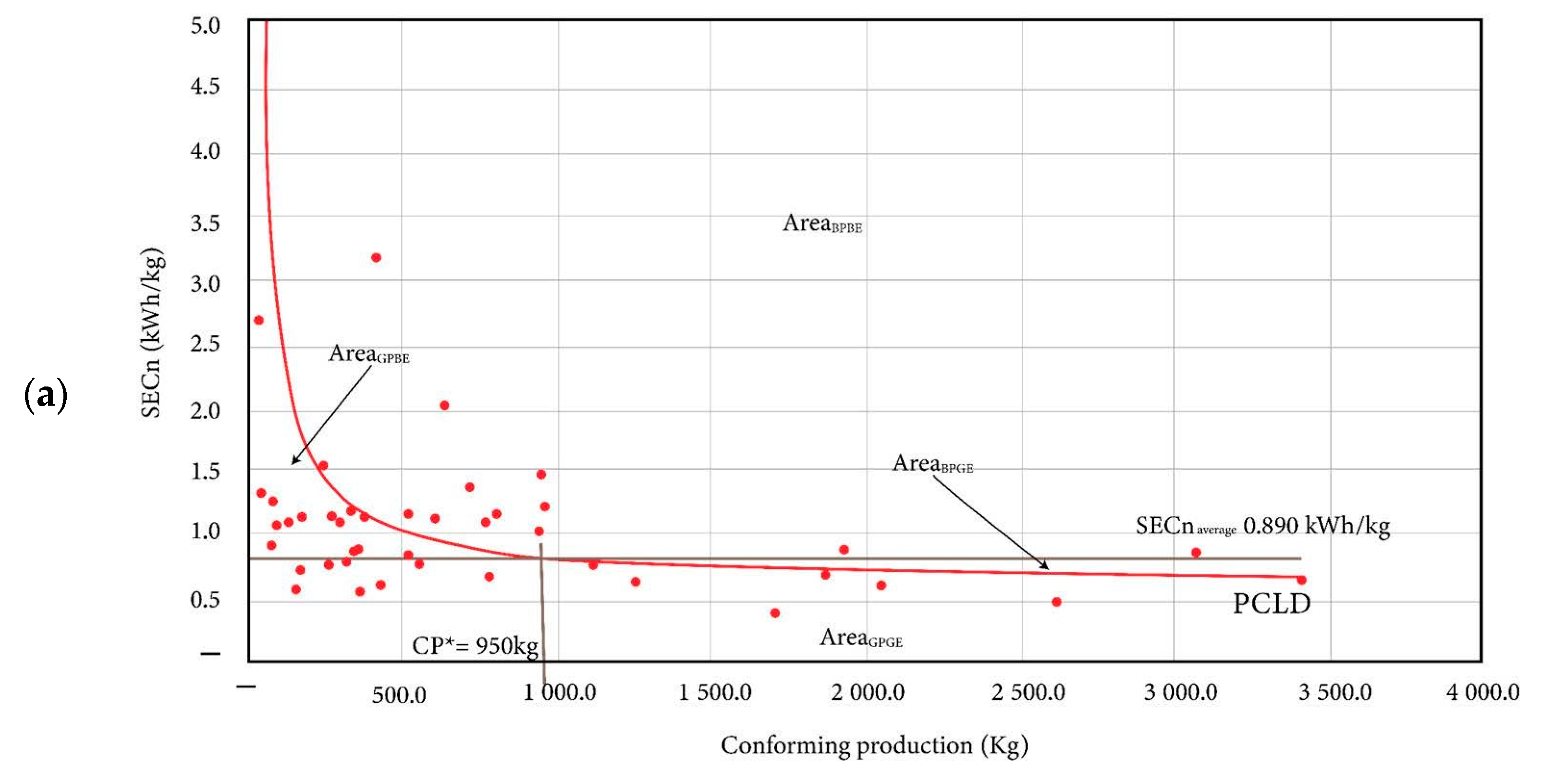

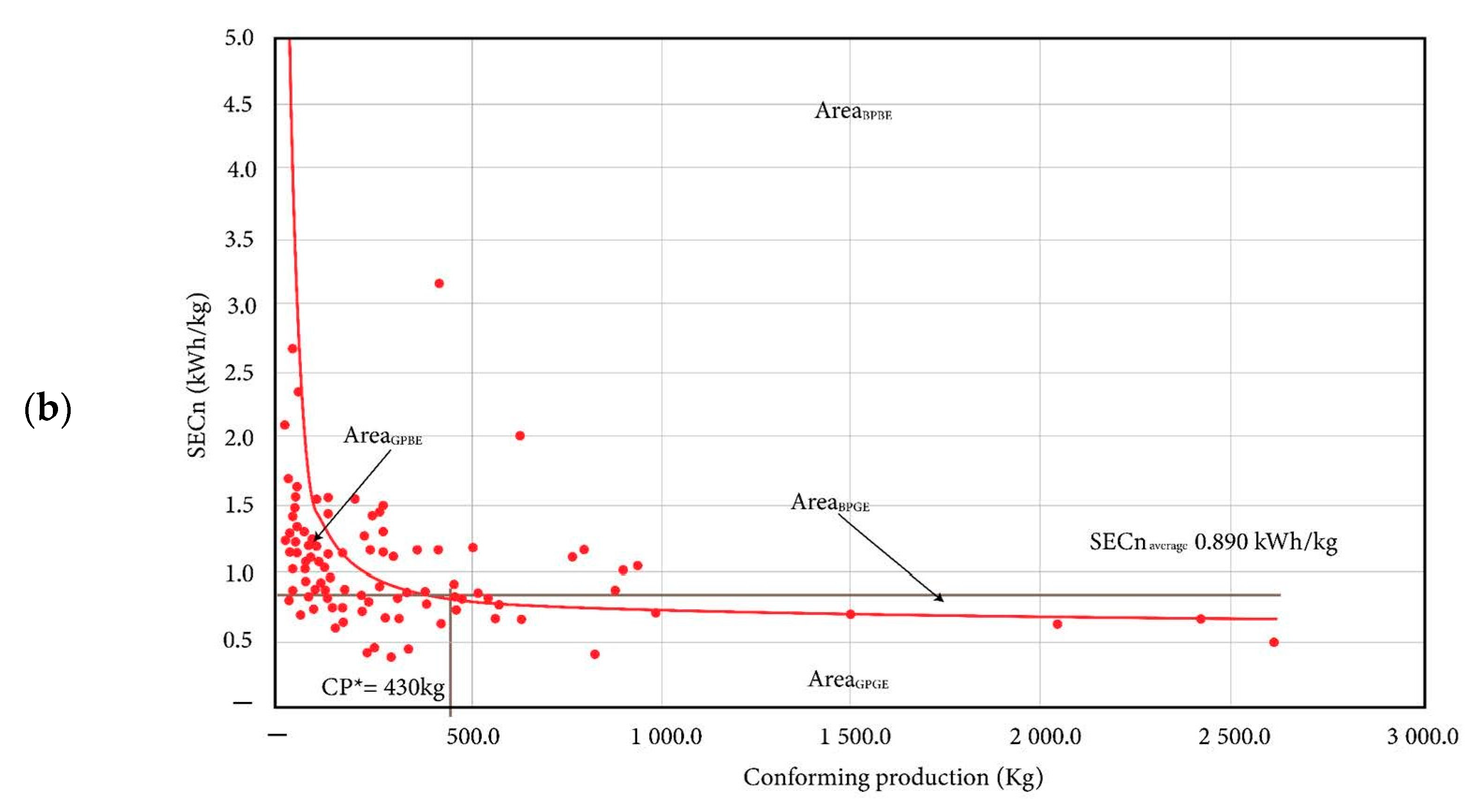

- The red area above the line representing and above the PCCD: This is an area where points exhibit poor energy performance and low energy efficiency and is called ABPBE. These are critical points whose improvement depends on radical engineering or production decisions. Improving them usually has a high associated cost.

- The yellow area above the value and below the PCCD: This area corresponds to points that have good energy performance, but low energy efficiency and the zone is called AGPBE. To improve these points, it is only required to increase the size of the production batches, preferably above CP*.

- The blue area (ABPGE) that is above the PCCD and below the value: The points that are in this area are not a priority, although it is very likely that during continuous improvement, there will come a time when a new diagnosis will make them points that merit intervention.

- The green area below the PCCD and below the value: This area is named AGPGE and has the points of good energy performance and good energy efficiency.

- The points located in the ABPBE area meet the following conditions:

2.4. Determination of SECs Using Diagnostic Tools

3. Case Study: Diagnostics Using PCLD, ABTD, and PCCD Determinations

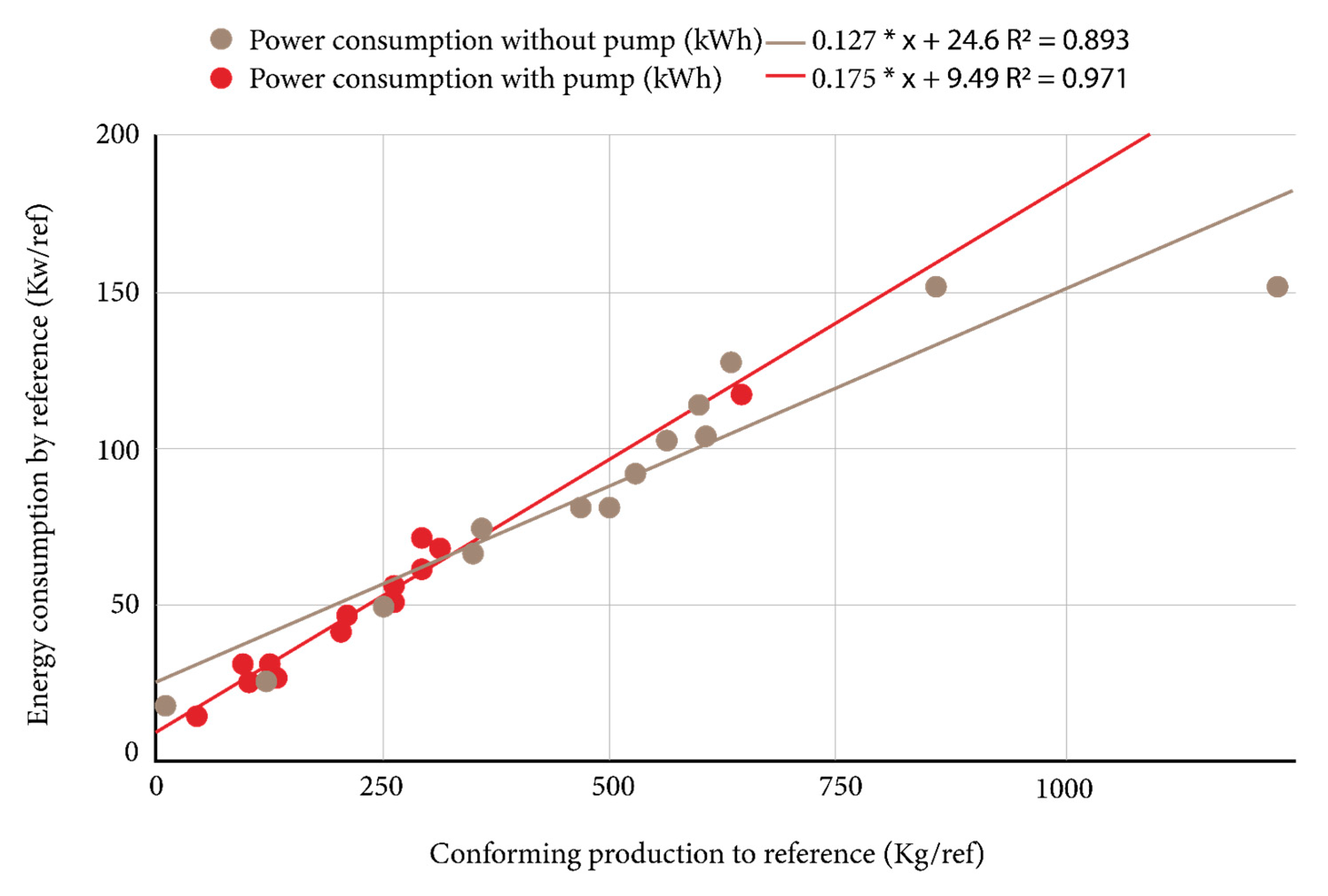

3.1. EAC: EPDM Rubber Profile Extrusion Line

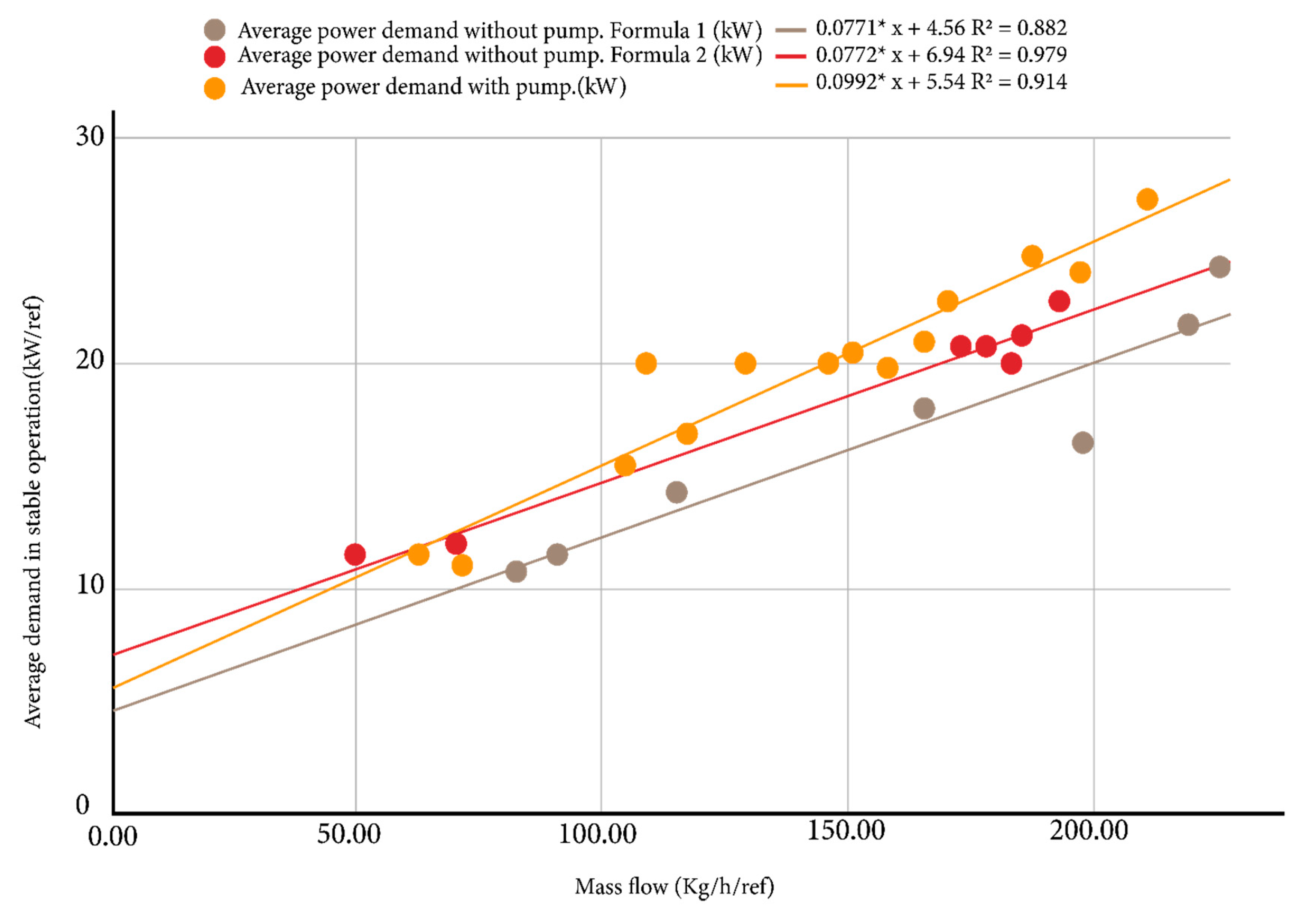

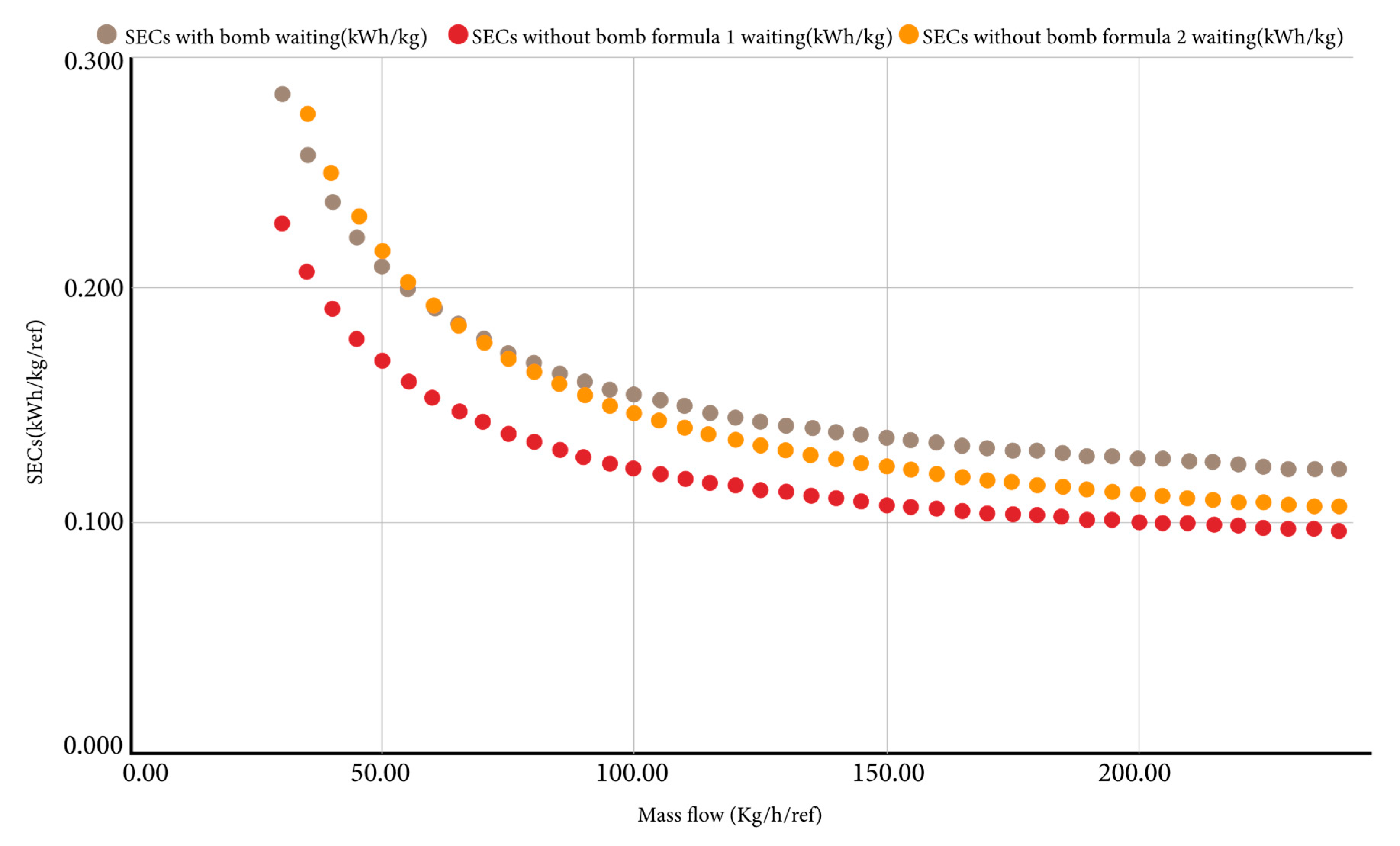

- The economic formula (formula (2)) has a higher specific energy consumption at stable operating conditions () than the technical formula when operated without a melt pump. For example, at a mass flow of 50 kg/h, the difference between formulas is approximately 0.048 kWh/kg. This difference is reduced to 0.001 kWh/kg at a mass flow of 250 kg/h. Both curves are asymptotic at a value of kWh/kg, which is the theoretical minimum value of that is possible to obtain from the technology when .

- In comparison, the energy performance of the extruder with a melt pump at high and low process speeds is lower than that of the extruder without a pump. At 50 kg/h it is 0.042 kWh/kg while at 250 kg/h it is 0.026 kWh/kg. The minimum value of that is possible to have in the vulcanized rubber extruder studied with the melt pump coupling is kWh/kg, which is 0.0221 kWh/kg higher than in the extruder without a melt pump. This is not necessarily detrimental if the melt pump allows for reduced non-compliant product or downtime due to reference change to achieve a lower . Otherwise, its use is not justified.

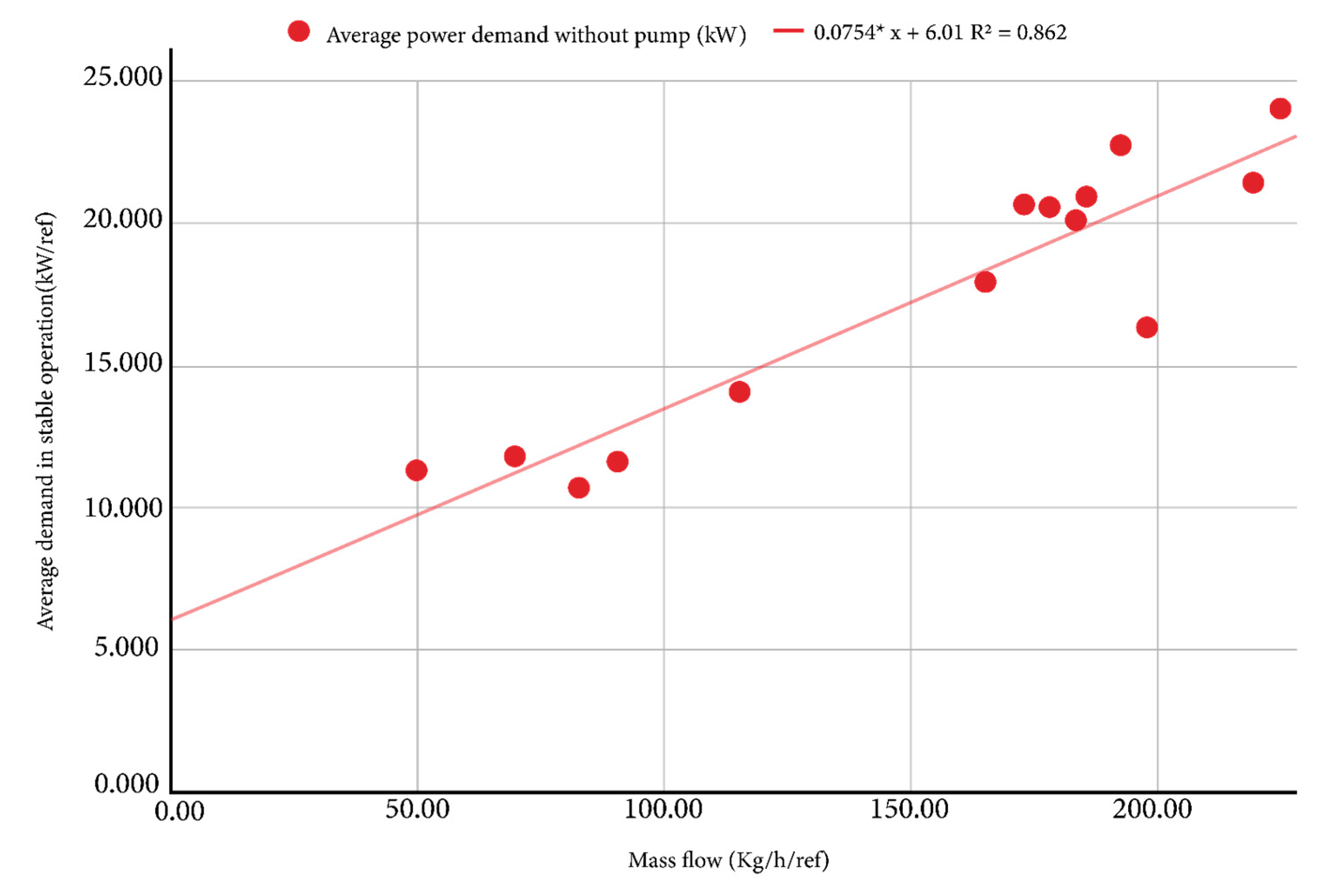

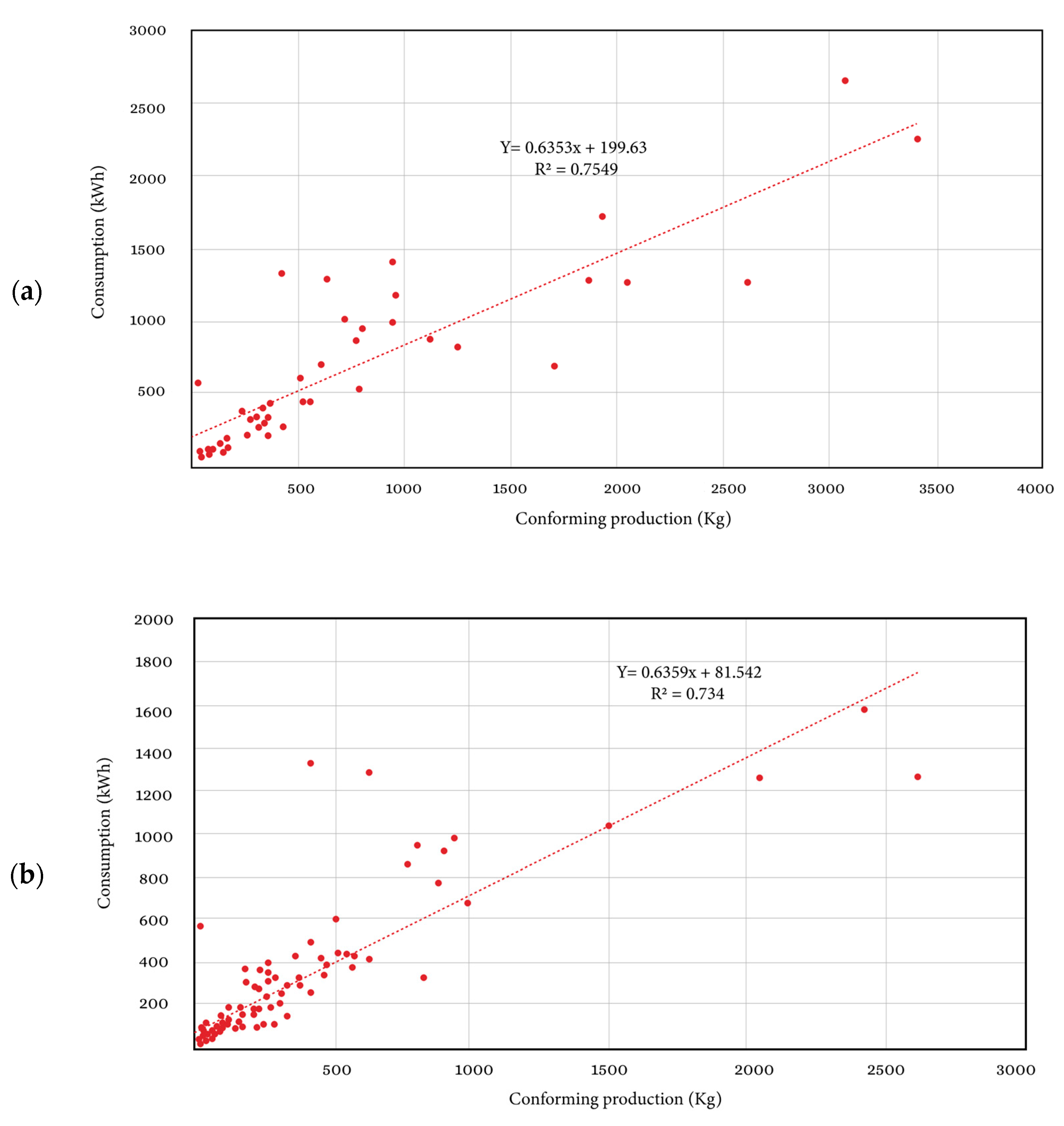

3.2. EAC: Thermoplastic Injection Line

- When a mold is assembled, it should be used for production runs above 950 kg;

- When several references are assembled in the same mold, the production batch size per reference cannot be less than 430 kg;

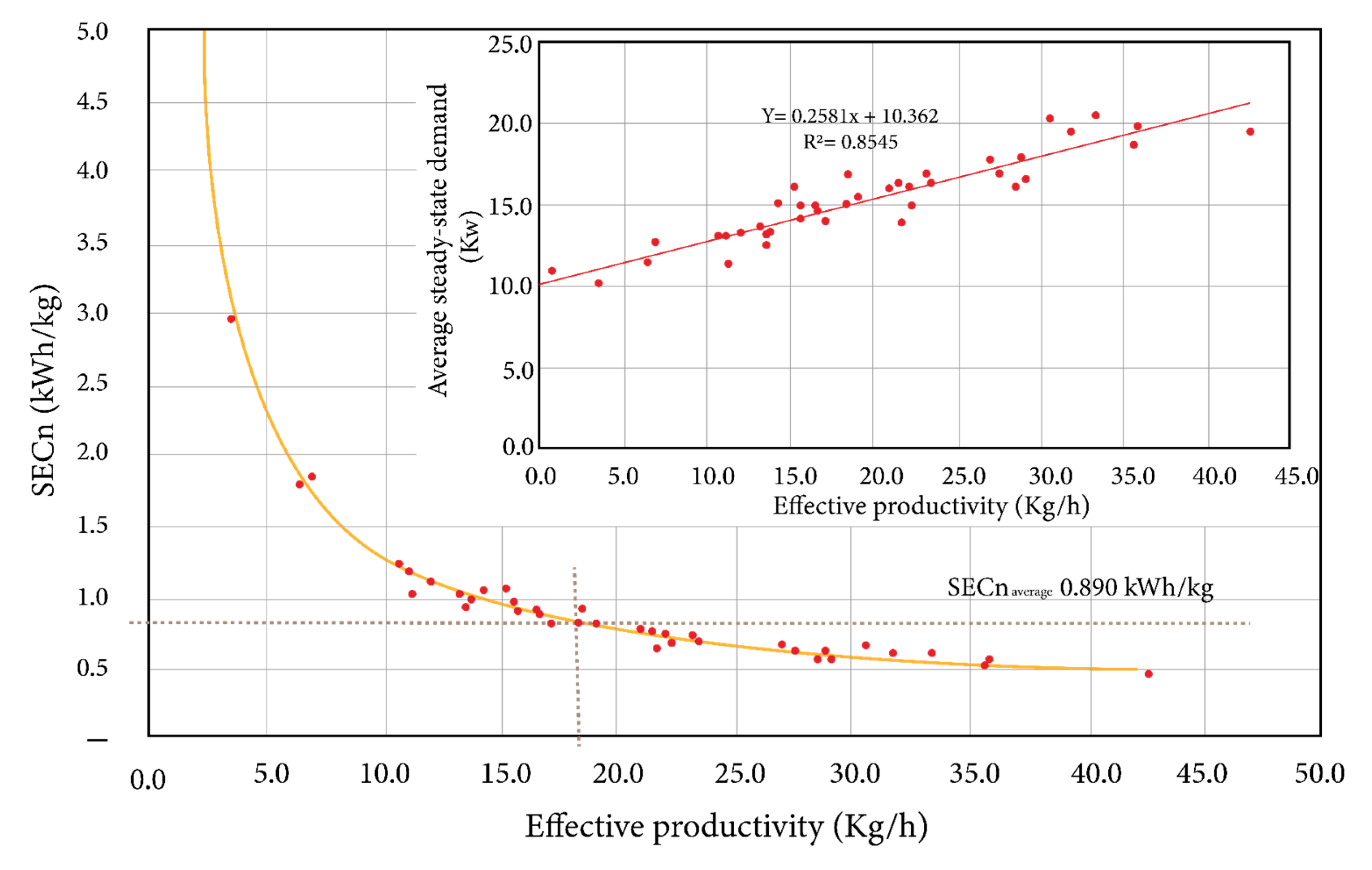

- Molds that cannot run at an effective productivity of more than 18 kg/h should not be mounted.

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nicholson, S.R.; Rorrer, N.A.; Carpenter, A.C.; Beckham, G.T. Manufacturing Energy and Greenhouse Gas Emissions Associated with Plastics Consumption. Joule 2021, 5, 673–686. [Google Scholar] [CrossRef]

- May, G.; Psarommatis, F. Maximizing Energy Efficiency in Additive Manufacturing: A Review and Framework for Future Research. Energies 2023, 16, 4179. [Google Scholar] [CrossRef]

- International Energy Agency Energy Efficiency 2023—Analysis. Available online: https://www.iea.org/reports/energy-efficiency-2023 (accessed on 2 December 2024).

- Kamal, A.; Al-Ghamdi, S.G.; Koc, M. Revaluing the Costs and Benefits of Energy Efficiency: A Systematic Review. Energy Res. Soc. Sci. 2019, 54, 68–84. [Google Scholar] [CrossRef]

- Kent, R. Chapter 1-Cost Management. In Cost Management in Plastics Processing, 4th ed.; Kent, R., Ed.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 3–44. ISBN 978-0-08-102269-6. [Google Scholar]

- Thollander, P.; Palm, J. Improving Energy Efficiency in Industrial Energy Systems: An Interdisciplinary Perspective on Barriers, Energy Audits, Energy Management, Policies, and Programs; Springer: London, UK, 2013; ISBN 978-1-4471-4161-7. [Google Scholar]

- Cai, W.; Wang, L.; Li, L.; Xie, J.; Jia, S.; Zhang, X.; Jiang, Z.; Lai, K. A Review on Methods of Energy Performance Improvement towards Sustainable Manufacturing from Perspectives of Energy Monitoring, Evaluation, Optimization and Benchmarking. Renew. Sustain. Energy Rev. 2022, 159, 112227. [Google Scholar] [CrossRef]

- Kazmer, D.; Peterson, A.M.; Masato, D.; Colon, A.R.; Krantz, J. Strategic Cost and Sustainability Analyses of Injection Molding and Material Extrusion Additive Manufacturing. Polym. Eng. Sci. 2023, 63, 943–958. [Google Scholar] [CrossRef]

- Keränen, T.; Enwald, H. Everyday Energy Information Literacy and Attitudes towards Energy-Related Decisions: Gender Differences among Finns. Resources 2023, 12, 70. [Google Scholar] [CrossRef]

- Koetse, M.J.; Groot, H.L.F.D.; Nijkamp, P. Barriers to Investment in Energy-Saving Technologies of Small Firms: The Energy-Efficiency Paradox Revisited. Stud. Reg. Sci. 2008, 38, 1–15. [Google Scholar] [CrossRef][Green Version]

- Fresner, J.; Morea, F.; Krenn, C.; Aranda Uson, J.; Tomasi, F. Energy Efficiency in Small and Medium Enterprises: Lessons Learned from 280 Energy Audits across Europe. J. Clean. Prod. 2017, 142, 1650–1660. [Google Scholar] [CrossRef]

- Bunse, K.; Vodicka, M.; Schönsleben, P.; Brülhart, M.; Ernst, F.O. Integrating Energy Efficiency Performance in Production Management—Gap Analysis between Industrial Needs and Scientific Literature. J. Clean. Prod. 2011, 19, 667–679. [Google Scholar] [CrossRef]

- Kent, R. Chapter 1-Introduction to Energy Management. In Energy Management in Plastics Processing, 3rd ed.; Kent, R., Ed.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 3–32. ISBN 978-0-08-102507-9. [Google Scholar]

- Diaz, C.J.L.; Ocampo-Martinez, C. Energy Efficiency in Discrete-Manufacturing Systems: Insights, Trends, and Control Strategies. J. Manuf. Syst. 2019, 52, 131–145. [Google Scholar] [CrossRef]

- Ma, S.; Huang, Y.; Cai, W.; Leng, J.; Xu, J. Integrated Sustainable Benchmark Based on Edge-Cloud Cooperation and Big Data Analytics for Energy-Intensive Manufacturing Industries. J. Manuf. Syst. 2024, 74, 1037–1056. [Google Scholar] [CrossRef]

- ElMaraghy, H.A.; Youssef, A.M.A.; Marzouk, A.M.; ElMaraghy, W.H. Energy Use Analysis and Local Benchmarking of Manufacturing Lines. J. Clean. Prod. 2017, 163, 36–48. [Google Scholar] [CrossRef]

- Wójcicki, K.; Biegańska, M.; Paliwoda, B.; Górna, J. Internet of Things in Industry: Research Profiling, Application, Challenges and Opportunities—A Review. Energies 2022, 15, 1806. [Google Scholar] [CrossRef]

- ISO 50001:2018; Sistemas de Gestión de La Energía—Requisitos Con Orientación Para Su Uso. International Organization for Standardization: Geneva, Switzerland, 2018.

- Fitzgerald, P.; Therkelsen, P.; Sheaffer, P.; Rao, P. Deeper and Persistent Energy Savings and Carbon Dioxide Reductions Achieved through ISO 50001 in the Manufacturing Sector. Sustain. Energy Technol. Assess. 2023, 57, 103280. [Google Scholar] [CrossRef]

- Costantini, V.; D’Angeli, M.; Mancini, M.; Martini, C.; Paglialunga, E. An Econometric Analysis of the Energy-Saving Performance of the Italian Plastic Manufacturing Sector. Energies 2024, 17, 811. [Google Scholar] [CrossRef]

- Estrada, O.; López, I.D.; Hernández, A.; Ortíz, J.C. Energy Gap Method (EGM) to Increase Energy Efficiency in Industrial Processes: Successful Cases in Polymer Processing. J. Clean. Prod. 2018, 176, 7–25. [Google Scholar] [CrossRef]

- Estrada Ramírez, O.A. Estudio de La Influencia Del Proceso de Plastificación En La Eficiencia Energética Del Proceso de Extrusión Monohusillo. Ph.D. Thesis, Universidad Nacional de Colombia, Bogota, Colombia, 2021. [Google Scholar]

- May, G.; Stahl, B.; Taisch, M.; Kiritsis, D. Energy Management in Manufacturing: From Literature Review to a Conceptual Framework. J. Clean. Prod. 2017, 167, 1464–1489. [Google Scholar] [CrossRef]

- Jallal, M.A.; González-Vidal, A.; Skarmeta, A.F.; Chabaa, S.; Zeroual, A. A Hybrid Neuro-Fuzzy Inference System-Based Algorithm for Time Series Forecasting Applied to Energy Consumption Prediction. Appl. Energy 2020, 268, 114977. [Google Scholar] [CrossRef]

- Wu, Q.; Ren, H.; Shi, S.; Fang, C.; Wan, S.; Li, Q. Analysis and Prediction of Industrial Energy Consumption Behavior Based on Big Data and Artificial Intelligence. Energy Rep. 2023, 9, 395–402. [Google Scholar] [CrossRef]

- Đaković, D.; Kljajić, M.; Milivojević, N.; Doder, Đ.; Anđelković, A.S. Review of Energy-Related Machine Learning Applications in Drying Processes. Energies 2023, 17, 224. [Google Scholar] [CrossRef]

- Siitonen, S.; Tuomaala, M.; Ahtila, P. Variables Affecting Energy Efficiency and CO2 Emissions in the Steel Industry. Energy Policy 2010, 38, 2477–2485. [Google Scholar] [CrossRef]

- Abeykoon, C.; Pérez, P.; Kelly, A.L. The Effect of Materials’ Rheology on Process Energy Consumption and Melt Thermal Quality in Polymer Extrusion. Polym. Eng. Sci. 2020, 60, 1244–1265. [Google Scholar] [CrossRef]

- Marchi, B.; Zanoni, S. Investments in Energy Efficiency with Variable Demand: SEC’s Shifting or Flattening? In Advances in Production Management Systems: Innovative Production Management Towards Sustainable Growth; Umeda, S., Nakano, M., Mizuyama, H., Hibino, N., Kiritsis, D., Von Cieminski, G., Eds.; IFIP Advances in Information and Communication Technology; Springer International Publishing: Cham, Switzerland, 2015; Volume 459, pp. 705–714. ISBN 978-3-319-22755-9. [Google Scholar]

- Zhou, L.; Li, J.; Li, F.; Meng, Q.; Li, J.; Xu, X. Energy Consumption Model and Energy Efficiency of Machine Tools: A Comprehensive Literature Review. J. Clean. Prod. 2016, 112, 3721–3734. [Google Scholar] [CrossRef]

- Kara, S.; Li, W. Unit Process Energy Consumption Models for Material Removal Processes. CIRP Ann. 2011, 60, 37–40. [Google Scholar] [CrossRef]

- Kent, R. Chapter 2-Energy Benchmarking. In Energy Management in Plastics Processing, 3rd ed.; Kent, R., Ed.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 33–78. ISBN 978-0-08-102507-9. [Google Scholar]

- Lawrence, A.; Thollander, P.; Andrei, M.; Karlsson, M. Specific Energy Consumption/Use (SEC) in Energy Management for Improving Energy Efficiency in Industry: Meaning, Usage and Differences. Energies 2019, 12, 247. [Google Scholar] [CrossRef]

- Estrada, O.; Ortiz, J.C.; Hernández, A.; López, I.; Chejne, F.; del Pilar Noriega, M. Experimental Study of Energy Performance of Grooved Feed and Grooved Plasticating Single Screw Extrusion Processes in Terms of SEC, Theoretical Maximum Energy Efficiency and Relative Energy Efficiency. Energy 2020, 194, 116879. [Google Scholar] [CrossRef]

- Mahamud, R.; Li, W.; Kara, S. Energy Characterisation and Benchmarking of Factories. CIRP Ann. 2017, 66, 457–460. [Google Scholar] [CrossRef]

- Menghi, R.; Papetti, A.; Germani, M.; Marconi, M. Energy Efficiency of Manufacturing Systems: A Review of Energy Assessment Methods and Tools. J. Clean. Prod. 2019, 240, 118276. [Google Scholar] [CrossRef]

- Arabeyyat, O.S.; Ragha, L.A. The Use of Energy Management ISO 50001 to Increase the Effectiveness of Water Treatment Plants: An Application Study on the Zai Water Treatment Plant. MethodsX 2024, 12, 102661. [Google Scholar] [CrossRef]

- ISO 50006:2023; Energy Management Systems—Evaluating Energy Performance Using Energy Performance Indicators and Energy Baselines. International Organization for Standardization: Geneva, Switzerland, 2023.

- Cosgrove, J.; Doyle, F.; Littlewood, J.; Wilgeroth, P. A Methodology for Electricity Monitoring and Targeting (M&T) in an Irish Precision Engineering SME. Int. J. Sustain. Eng. 2017, 10, 233–240. [Google Scholar] [CrossRef]

- Roberts, J.G.; Hazel, B.G. Energy Monitoring and Targeting. J. Soc. Dye. Colour. 1985, 101, 180–183. [Google Scholar] [CrossRef]

- Afkhami, B.; Akbarian, B.; Beheshti, A.N.; Kakaee, A.H.; Shabani, B. Energy Consumption Assessment in a Cement Production Plant. Sustain. Energy Technol. Assess. 2015, 10, 84–89. [Google Scholar] [CrossRef]

- Gutowski, T.G.; Dahmus, J.B.; Thiriez, A. Electrical Energy Requirements for Manufacturing Processes. In Proceedings of the Proceedings of LCE, Leuven, Belgium, 31 May–2 June 2006; pp. 623–628. [Google Scholar]

- Prias Caicedo, O.F.; Campos Avell, J.C.; Rojas Rodríguez, D.B.; Palencia Salas, A. Implementación de un Sistema de Gestión de la Energía: Guía con Base en la Norma ISO 50001, 2nd ed.; RED COLOMBIANA DE CONOCIMIENTO EN EFICIENCIA ENERGÉTICA-RECIEE: Bogotá, Colombia, 2019; ISBN 978-958-761-597-5. [Google Scholar]

- Benedetti, M.; Cesarotti, V.; Introna, V. From Energy Targets Setting to Energy-Aware Operations Control and Back: An Advanced Methodology for Energy Efficient Manufacturing. J. Clean. Prod. 2017, 167, 1518–1533. [Google Scholar] [CrossRef]

- Taner, T.; Sivrioğlu, M.; Topal, H.; Dalkılıç, A.S.; Wongwises, S. A Model of Energy Management Analysis, Case Study of a Sugar Factory in Turkey. Sādhanā 2018, 43, 42. [Google Scholar] [CrossRef]

- Kent, R.J. Energy Management in Plastics Processing: Strategies, Targets, Techniques, and Tools, 4th ed.; British Plastics Federation: London, UK, 2024; ISBN 978-1-399-98641-0. [Google Scholar]

- Asuero, A.G.; Sayago, A.; González, A.G. The Correlation Coefficient: An Overview. Crit. Rev. Anal. Chem. 2006, 36, 41–59. [Google Scholar] [CrossRef]

| Article | Classification | Strategies & Tools | Indicator |

|---|---|---|---|

| [45] | Energy analysis | CUSUM, M&T | - |

| [35] | Energy analysis | Regression analysis | SEC |

| [44] | Energy assessment | ISO 50006, M&T | Energy performance indicator (EnPI) |

| [39] | Energy assessment | ISO 50001, M&T | Key performance indicator (KPI) |

| [21] | Energy assessment | Energy Gap Method | SEC |

| Parameter | Value | Units |

|---|---|---|

| Number of production orders analyzed | 299 | None |

| Start date of analysis | 8 August 2023 23:22 | Date and time |

| End date of analysis | 24 January 2024 14:00 | Date and time |

| Consumption for the period | 36,217.7 | kWh |

| Total production for the period | 41,824.89 | kg |

| Compliant production for the period | 40,689.47 | kg |

| Non-compliant production for the period | 1135.42 | kg |

| Total production time for the period | 3738.13 | h |

| Total downtime for the period | 817.25 | h |

| Effective production time of the period | 2920.88 | h |

| Average actual productivity of the period | 10.88 | kg/h |

| Average effective productivity of the period | 14.32 | kg/h |

| SECn for the period | 0.890 | kWh/kg |

| Mold | SECn [kWh/kg] | SECn Average [kWh/kg] | Compliant Production [kg] | SECn PCCD [kWh/kg] | SECn-SECn PCCD [kWh/kg] | SECn-SECn Average [kWh/kg] |

|---|---|---|---|---|---|---|

| MOL13739 | 2.6730 | 0.89 | 34.0 | 6.5028 | −3.8298 | 1.7830 |

| MOL8081 | 1.3419 | 0.89 | 41.6 | 5.4286 | −4.0867 | 0.4519 |

| MOL706 | 1.2637 | 0.89 | 75.4 | 3.2831 | −2.0194 | 0.3737 |

| MOL14087 | 1.1808 | 0.89 | 330.9 | 1.2386 | −0.0578 | 0.2908 |

| MOL14082 | 1.1645 | 0.89 | 365.9 | 1.1809 | −0.0165 | 0.2745 |

| MOL6883 | 1.1477 | 0.89 | 272.9 | 1.3668 | −0.2191 | 0.2577 |

| MOL8968 | 1.1449 | 0.89 | 163.6 | 1.8558 | −0.7110 | 0.2549 |

| MOL14319 | 1.1279 | 0.89 | 126.0 | 2.2193 | −1.0914 | 0.2379 |

| MOL14037 | 1.1208 | 0.89 | 293.9 | 1.3145 | −0.1937 | 0.2308 |

| MOL6446 | 1.0949 | 0.89 | 95.3 | 2.7311 | −1.6362 | 0.2049 |

| MOL8322 | 0.9289 | 0.89 | 71.1 | 3.4430 | −2.5141 | 0.0389 |

| MOL13739 | 2.6730 | 0.89 | 34.0 | 6.5028 | −3.8298 | 1.7830 |

| Mold | SECn [kWh/kg] | SECn Average [kWh/kg] | Compliant Production [kg] | SECn PCCD [kWh/kg] | SECn-SECn PCCD [kWh/kg] | SECn-SECn Average [kWh/kg] |

|---|---|---|---|---|---|---|

| MOL8481 | 21.2797 | 0.89 | 26.7 | 8.1119 | 13.1678 | 20.3897 |

| MOL14575 | 3.1616 | 0.89 | 419.0 | 1.1117 | 2.0499 | 2.2716 |

| MOL7861 | 2.0254 | 0.89 | 632.4 | 0.9510 | 1.0744 | 1.1354 |

| MOL4341 | 1.5482 | 0.89 | 236.7 | 1.4788 | 0.0694 | 0.6582 |

| MOL15202 | 1.4817 | 0.89 | 945.3 | 0.8465 | 0.6352 | 0.5917 |

| MOL15282 | 1.4027 | 0.89 | 715.2 | 0.9144 | 0.4883 | 0.5127 |

| MOL15203 | 1.2290 | 0.89 | 955.5 | 0.8442 | 0.3847 | 0.3390 |

| MOL15229 | 1.1820 | 0.89 | 510.2 | 1.0265 | 0.1555 | 0.2920 |

| MOL15216 | 1.1718 | 0.89 | 801.0 | 0.8845 | 0.2873 | 0.2818 |

| MOL6864 | 1.1504 | 0.89 | 604.3 | 0.9656 | 0.1847 | 0.2604 |

| MOL15207 | 1.1153 | 0.89 | 771.5 | 0.8941 | 0.2212 | 0.2253 |

| MOL8964 | 1.0432 | 0.89 | 938.6 | 0.8480 | 0.1952 | 0.1532 |

| MOL3979 | 0.8915 | 0.89 | 1929.8 | 0.7387 | 0.1528 | 0.0015 |

| M&T | EGM with Proposed Tools |

|---|---|

| It is a control methodology. | Diagnostic method |

| Analyses are performed for selected energy cost centers. | Analyses are performed for selected energy cost centers. |

| It uses the determination of the Performance Characteristic Line, the determination of the objective based on the activity, the Performance Characteristic Curve, and the CUSUM diagrams as tools to establish the consumption behavior. | It employs Monitoring and Targeting tools such as the PCLD, ABTD, and PCCD, which are used in diverse ways to determine energy gaps and detect production elements that require specific actions. |

| The analysis is performed over given periods of time, and information about consumption and compliant production is obtained at regular time intervals, which can be days, weeks, or months. | The analysis is conducted using criteria such as products, molds, references, materials, heads, and machines, so the analysis periods are not regular. |

| The tools are used at regular time intervals to perform continuous and comparative consumption analysis, allowing early decisions to be made and ensuring compliance with the goals. | The tools are used when necessary to determine the causes of a specific performance or observed efficiency of the EAC, define actions, and ensure compliance with the goals. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Estrada-Ramírez, O.A.; Muñoz-Realpe, N.A.; Patiño-Murillo, J.A.; Chejne, F. A Novel Set of Analysis Tools Integrated with the Energy Gap Method for Energy Accounting Center Diagnosis in Polymer Production. Resources 2025, 14, 60. https://doi.org/10.3390/resources14040060

Estrada-Ramírez OA, Muñoz-Realpe NA, Patiño-Murillo JA, Chejne F. A Novel Set of Analysis Tools Integrated with the Energy Gap Method for Energy Accounting Center Diagnosis in Polymer Production. Resources. 2025; 14(4):60. https://doi.org/10.3390/resources14040060

Chicago/Turabian StyleEstrada-Ramírez, Omar Augusto, Nicolás Andrés Muñoz-Realpe, Julián Alberto Patiño-Murillo, and Farid Chejne. 2025. "A Novel Set of Analysis Tools Integrated with the Energy Gap Method for Energy Accounting Center Diagnosis in Polymer Production" Resources 14, no. 4: 60. https://doi.org/10.3390/resources14040060

APA StyleEstrada-Ramírez, O. A., Muñoz-Realpe, N. A., Patiño-Murillo, J. A., & Chejne, F. (2025). A Novel Set of Analysis Tools Integrated with the Energy Gap Method for Energy Accounting Center Diagnosis in Polymer Production. Resources, 14(4), 60. https://doi.org/10.3390/resources14040060