Environmental and Closure Costs in Strategic Mine Planning, Models, Regulations, and Policies

Abstract

1. Introduction

2. Inclusion of Environmental Costs in Mine Planning

3. Quantitative Approaches for the Evaluation of Environmental and Mine Closure Costs

3.1. Quantification Methodology for Environmental and Ecological Costs in Mining

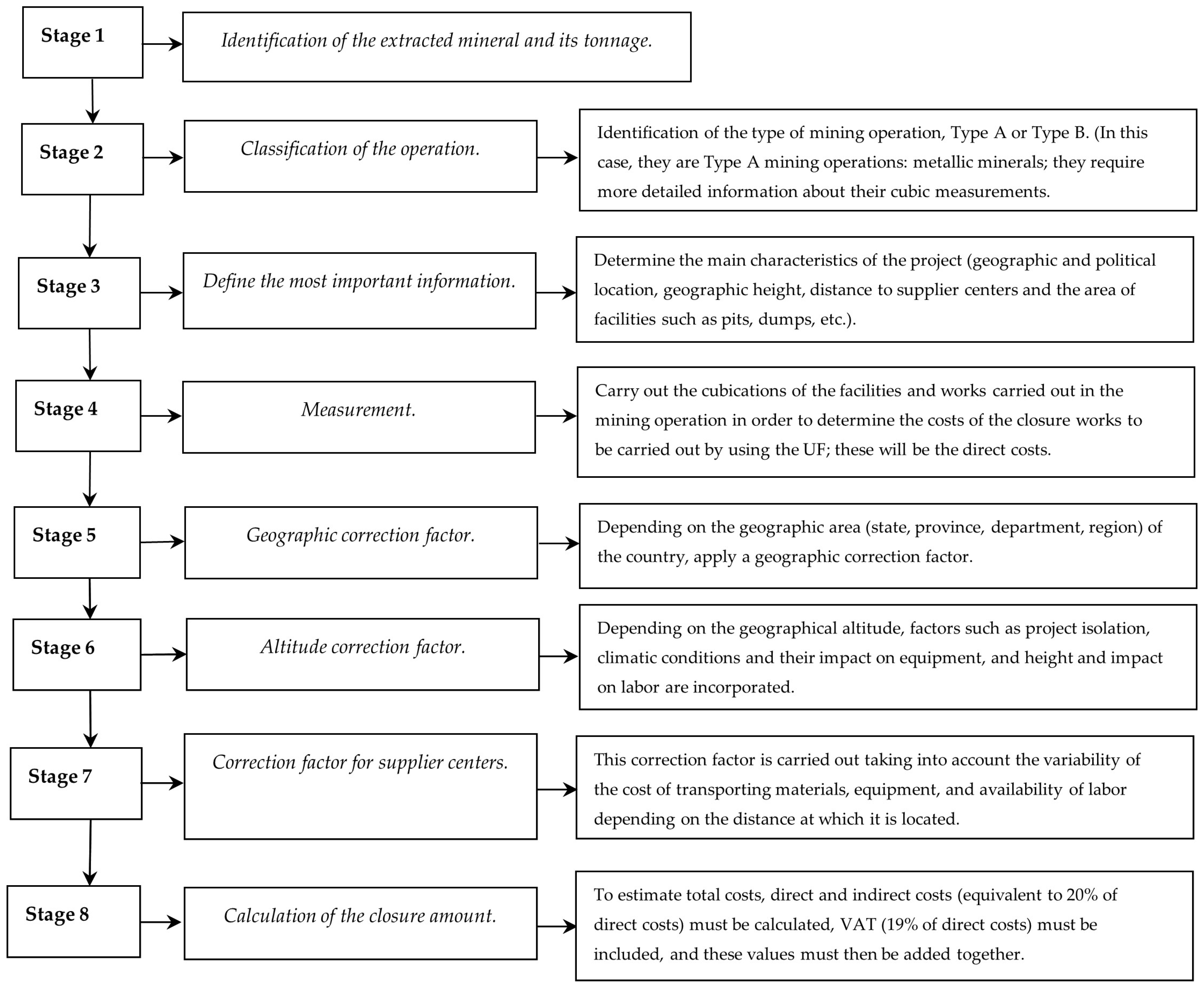

3.2. Methodology for Calculating Mine Closure Costs (Servicio Nacional de Geología y Minería Sernageomin)

3.3. Sustainability Indices in Mining—APH Method

3.3.1. Stage 1

3.3.2. Stage 2

3.3.3. Stage 3

4. Legal Frameworks

4.1. Chile

4.2. Peru

4.3. Colombia

4.4. Bolivia

4.5. Canada

4.6. Spain

4.7. Sweden

4.8. Australia

5. Innovation in Public Policies Adopted by Some Governments

Toward Global Approaches?

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Correction Statement

References

- ONU. Informe de la Conferencia de las Naciones Unidas Sobre el Medio Ambiente y el Desarrollo: Rio de Janeiro, 3 a 14 de Junio de 1992, Organización de las Naciones Unidas; Naciones Unidas: Rio de Janeiro, Brasil, 1993. [Google Scholar]

- ONU. La Agenda 2030 y los Objetivos de Desarrollo Sostenible: Una Oportunidad para América Latina y el Caribe. Organización de las Naciones Unidas. 2018. [En línea]. Available online: https://repositorio.cepal.org/server/api/core/bitstreams/cb30a4de-7d87-4e79-8e7a-ad5279038718/content (accessed on 16 September 2024).

- Oyarzún, J.; Oyarzún, R. Léxico de Geología Económica: Términos de uso Común en España e Iberoamérica, 1.ª ed. La Serena, Chile: GEMM—Aula2puntonet. 2014. [En línea]. Available online: https://www.aulados.net/Libros_Aula2puntonet_GEMM/Libro_Lexico_Geologia_Economica.pdf (accessed on 16 September 2024).

- Tost, M.; Hitch, M.; Chandurkar, V.; Moser, P.; Feiel, S. The state of environmental sustainability considerations in mining. J. Clean. Prod. 2018, 182, 969–977. [Google Scholar] [CrossRef]

- Franco, S.G.; Jaramillo, A.P.; Branch, B.J. Stochastic optimization in mine planning scheduling. Comput. Oper. Res. 2020, 115, 104823. [Google Scholar] [CrossRef]

- Lamghari, A.; Dimitrakopoulos, R. Network-flow based algorithms for scheduling production in multi-processor open-pit mines accounting for metal uncertainty. Eur. J. Oper. Res. 2016, 250, 273–290. [Google Scholar] [CrossRef]

- Eerola, T.; Komnitsas, K. Preliminary Assessment of Social License to Operate (SLO) and Corporate Communication in Four European Lithium Projects. Mater. Proc. 2023, 15, 35. [Google Scholar] [CrossRef]

- Laurence, D. Establishing a sustainable mining operation: An overview. J. Clean. Prod. 2011, 19, 278–284. [Google Scholar] [CrossRef]

- Lyytimäki, J.; Peltonen, L. Mining through controversies: Public perceptions and the legitimacy of a planned gold mine near a tourist destination. Land Use Policy 2016, 54, 479–486. [Google Scholar] [CrossRef]

- Bashir, M.A.; Qing, L.; Syed, Q.R.; Barwińska-Małajowicz, A.; Hashmi, S.M. Resources policy from extraction to innovation: The interplay of minerals, geothermal energy, technological advancements, and ecological footprint in high-ecological footprint economies. Resour. Policy 2024, 95, 105182. [Google Scholar] [CrossRef]

- Murguía, D.I.; Bastida, A.E. The elephant in the mine: Why voluntary sustainability standards are insufficient to ensure responsible mining. Extr. Ind. Soc. 2024, 19, 101485. [Google Scholar] [CrossRef]

- Tuulentie, S.; Halseth, G.; Kietäväinen, A.; Ryser, L.; Similä, J. Local community participation in mining in Finnish Lapland and Northern British Columbia, Canada—Practical applications of CSR and SLO. Resour. Policy 2019, 61, 99–107. [Google Scholar] [CrossRef]

- Baba, S.; Mohammad, S.; Young, C. Managing project sustainability in the extractive industries: Towards a reciprocity framework for community engagement: Managing Project Sustainability in the Extractive Industries. Int. J. Proj. Manag. 2021, 39, 887–901. [Google Scholar] [CrossRef]

- Bascompta, M.; Sanmiquel, L.; Vintró, C.; Yousefian, M. Corporate Social Responsibility Index for Mine Sites. Sustainability 2022, 14, 13570. [Google Scholar] [CrossRef]

- Murguía, D.I.; Böhling, K. Sustainability reporting on large-scale mining conflicts: The case of Bajo de la Alumbrera, Argentina. J. Clean. Prod. 2013, 41, 202–209. [Google Scholar] [CrossRef]

- Wagner, M.; Wellmer, F.W. A Hierarchy of Natural Resources with Respect to Sustainable Development—A Basis for a Natural Resources Efficiency Indicator. In Mining, Society, and a Sustainable World; Richards, J., Ed.; Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar] [CrossRef]

- Isacowitz, J.J.; Schmeidl, S.; Tabelin, C. The operationalisation of Corporate Social Responsibility (CSR) in a mining context. Resour. Policy 2022, 79, 103012. [Google Scholar] [CrossRef]

- Garcia-Zavala, C.; Ordens, C.M.; Pagliero, L.; Lèbre, É.; Aitken, D.; Stringer, M. An approach for prioritising environmental, social and governance (ESG) water-related risks for the mining industry: The case of Chile. Extr. Ind. Soc. 2023, 14, 101259. [Google Scholar] [CrossRef]

- Borregaard, N. Valorización económica de los impactos ambientales en la minería Chilena. Ambiente Desarro. 2001, XVII, 50–58. [Google Scholar]

- Moran, R. Aproximaciones al costo económico de impactos ambientales en la minería. Ambiente Desarro. 2001, 17, 59–66. [Google Scholar]

- Juan David, O.; Francisco, C. VALORACIÓN ECONÓMICA DE COSTOS AMBIENTALES: MARCO CONCEPTUAL Y MÉTODOS DE ESTIMACIÓN. Semest. Económico 2004, 7, 159–193. [Google Scholar]

- Ouoba, Y. Gold companies and local economic sustainability: The case of Kalsaka Mining SA in Burkina Faso. J. Environ. Econ. Policy 2023, 12, 79–95. [Google Scholar] [CrossRef]

- Moia, G.C.M.; Matlaba, V.J.; dos Santos, J.F. Evaluation of the impact of mining royalties on socio-environmental indicators in Parauapebas, Pará, the Eastern Amazon. Extr. Ind. Soc. 2024, 19, 101512. [Google Scholar] [CrossRef]

- Andía Valencia, W. Los Estudios de Impacto Ambiental y su Implicancia en las Inversiones de los Proyectos. Prod. Gest. 2012, 15, 17–20. [Google Scholar]

- Galo, D.d.B.; dos Anjos, J.Â.S.A.; Sánchez, L.E. Are mining companies mature for mine closure? An approach for evaluating preparedness. Resour. Policy 2022, 78, 102919. [Google Scholar] [CrossRef]

- Adibi, N.; Ataee-Pour, M.; Rahmanpour, M. Integration of sustainable development concepts in open pit mine design. J. Clean. Prod. 2015, 108, 1037–1049. [Google Scholar] [CrossRef]

- Vymazal, J.; Sklenicka, P. Restoration of areas affected by mining. Ecol. Eng. 2012, 43, 1–4. [Google Scholar] [CrossRef]

- Laurence, D. Optimisation of the mine closure process. J. Clean. Prod. 2006, 14, 285–298. [Google Scholar] [CrossRef]

- Mancini, L.; Sala, S. Social impact assessment in the mining sector: Review and comparison of indicators frameworks. Resour. Policy 2018, 57, 98–111. [Google Scholar] [CrossRef]

- Sheveleva, O.; Slesarenko, E.; Kudrevatykh, N.; Mamzina, T. The unity of the trajectory of sustainable development of the mining region and ensuring its environmental safety. In E3S Web of Conferences; EDP Sciences: Essonne, France, 2019. [Google Scholar] [CrossRef]

- Espinoza, R.D.; Rojo, J. Towards sustainable mining (Part I): Valuing investment opportunities in the mining sector. Resour. Policy 2017, 52, 7–18. [Google Scholar] [CrossRef]

- Upadhyay, S.P.; Askari-Nasab, H. Simulation and optimization approach for uncertainty-based short-term planning in open pit mines. Int. J. Min. Sci. Technol. 2018, 28, 153–166. [Google Scholar] [CrossRef]

- Del Castillo, M.F.; Dimitrakopoulos, R. Dynamically optimizing the strategic plan of mining complexes under supply uncertainty. Resour. Policy 2019, 60, 83–93. [Google Scholar] [CrossRef]

- Armstrong, M.; Lagos, T.; Emery, X.; Homem-de-Mello, T.; Lagos, G.; Sauré, D. Adaptive open-pit mining planning under geological uncertainty. Resour. Policy 2021, 72, 102086. [Google Scholar] [CrossRef]

- Jélvez, E.; Morales, N.; Nancel-Penard, P.; Cornillier, F. A new hybrid heuristic algorithm for the Precedence Constrained Production Scheduling Problem: A mining application. Omega 2020, 94, 102046. [Google Scholar] [CrossRef]

- Gilani, S.-O.; Sattarvand, J.; Hajihassani, M.; Abdullah, S.S. A stochastic particle swarm based model for long term production planning of open pit mines considering the geological uncertainty. Resour. Policy 2020, 68, 101738. [Google Scholar] [CrossRef]

- Morales, N.; Mancilla, D.; Miranda, R.; Vallejos, J. A fast method to develop an optimal operational sublevel stope design. Resour. Policy 2022, 77, 102670. [Google Scholar] [CrossRef]

- Tabesh, M.; Moradi Afrapoli, A.; Askari-Nasab, H. A two-stage simultaneous optimization of NPV and throughput in production planning of open pit mines. Resour. Policy 2023, 80, 103167. [Google Scholar] [CrossRef]

- Yaakoubi, Y.; Dimitrakopoulos, R. Decision-focused neural adaptive search and diving for optimizing mining complexes. Eur. J. Oper. Res. 2024, 320, 699–719. [Google Scholar] [CrossRef]

- Osanloo, M.; Rashidinejad, F.; Rezai, B. Incorporating environmental issues into optimum cut-off grades modeling at porphyry copper deposits. Resour. Policy 2008, 33, 222–229. [Google Scholar] [CrossRef]

- Rimélé, M.A.; Dimitrakopoulos, R.; Gamache, M. A stochastic optimization method with in-pit waste and tailings disposal for open pit life-of-mine production planning. Resour. Policy 2018, 57, 112–121. [Google Scholar] [CrossRef]

- Kumral, M. Optimizing ore-waste discrimination and block sequencing through simulated annealing. Appl. Soft Comput. J. 2013, 13, 3737–3744. [Google Scholar] [CrossRef]

- Seredkin, M.; Zabolotsky, A.; Jeffress, G. In situ recovery, an alternative to conventional methods of mining: Exploration, resource estimation, environmental issues, project evaluation and economics. Ore Geol. Rev. 2016, 79, 500–514. [Google Scholar] [CrossRef]

- Adiansyah, J.S.; Rosano, M.; Vink, S.; Keir, G. A framework for a sustainable approach to mine tailings management: Disposal strategies. J. Clean. Prod. 2015, 108, 1050–1062. [Google Scholar] [CrossRef]

- Canales-Bustos, L.; Santibañez-González, E.; Candia-Véjar, A. A multi-objective optimization model for the design of an effective decarbonized supply chain in mining. Int. J. Prod. Econ. 2017, 193, 449–464. [Google Scholar] [CrossRef]

- Yu, S.; Zheng, S.; Gao, S.; Yang, J. A multi-objective decision model for investment in energy savings and emission reductions in coal mining. Eur. J. Oper. Res. 2017, 260, 335–347. [Google Scholar] [CrossRef]

- Mirzehi, M.; Moradi Afrapoli, A. A novel framework for integrating environmental costs and carbon pricing in open-pit mine plans: Towards sustainable and green mining. J. Clean. Prod. 2024, 468. [Google Scholar] [CrossRef]

- Li, L.; Lei, Y.; Wu, S.; He, C.; Yan, D. Study on the coordinated development of economy, environment and resource in coal-based areas in Shanxi Province in China: Based on the multi-objective optimization model. Resour. Policy 2018, 55, 80–86. [Google Scholar] [CrossRef]

- Rezaie, B.; Anderson, A. Sustainable resolutions for environmental threat of the acid mine drainage. Sci. Total Environ. 2020, 717, 137211. [Google Scholar] [CrossRef]

- Ullah, G.M.W.; Nehring, M.; Kizil, M.; Knights, P. Environmental, Social, and Governance Considerations in Production Scheduling Optimisation for Sublevel Stoping Mining Operations: A Review of Relevant Works and Future Directions. Min. Metall. Explor. 2023, 40, 2167–2182. [Google Scholar] [CrossRef]

- Xu, X.C.; Gu, X.W.; Wang, Q.; Liu, J.P.; Wang, J. Ultimate pit optimization with ecological cost for open pit metal mines. Trans. Nonferrous Met. Soc. China Engl. Ed. 2014, 24, 1531–1537. [Google Scholar] [CrossRef]

- Moradi, G.; Osanloo, M. Prioritizing Sustainable Development Criteria Affecting Open Pit Mine Design: A Mathematical Model. Procedia Earth Planet. Sci. 2015, 15, 813–820. [Google Scholar] [CrossRef]

- Narrei, S.; Osanloo, M. Optimum cut-off grade’s calculation in open pit mines with regard to reducing the undesirable environmental impacts. Int. J. Min. Reclam. Environ. 2015, 29, 226–242. [Google Scholar] [CrossRef]

- Lane, K. Choosing the optimum cut-off grade. In Choosing the Optimum Cut-Off Grade; Colorado School of Mines: Golden, CO, USA, 1964; pp. 5–492. [Google Scholar]

- Rahimi, E.; Ghasemzadeh, H. A new algorithm to determine optimum cut-off grades considering technical, economical, environmental and social aspects. Resour. Policy 2015, 46, 51–63. [Google Scholar] [CrossRef]

- Nehring, M.; Cheng, X. An investigation into the impact of mine closure and its associated cost on life of mine planning and resource recovery. J. Clean. Prod. 2016, 127, 228–239. [Google Scholar] [CrossRef]

- Environmental Protection Authority and Department of Mines and Petroleum (EPA/DMP). Guidelines for Preparing Mine Closure Plans; Government of Western Australia: Perth, Australia, 2011.

- Paricheh, M.; Osanloo, M. A simulation-based framework for estimating probable open-pit mine closure time and cost. J. Clean. Prod. 2017, 167, 337–345. [Google Scholar] [CrossRef]

- Hutchison, I.; Dettore, R. Statistical and probabilistic closure cost estimating. In Proceedings of the 15th International Conference on Tailings and Mine Waste, Vancouver, BC, Canada, 9 November 2011; University of British Columbia Institute of Mining Engineering: Vancouver, BC, Canada, 2011. [Google Scholar]

- Rahmanpour, M.; Osanloo, M. A decision support system for determination of a sustainable pit limit. J. Clean. Prod. 2017, 141, 1249–1258. [Google Scholar] [CrossRef]

- Xu, X.; Guo, X.; Wang, Q.; Liu, J.; Zhu, Q. Production Scheduling of Open Pit Metal Mine with Ecological Cost. Geo-Resour. Environ. Eng. 2017, 2, 59–63. [Google Scholar] [CrossRef][Green Version]

- Xu, X.C.; Cu, X.; Wang, Q.; Gao, X.; Liu, J.; Wang, Z.; Wang, X. Production scheduling optimization considering ecological costs for open pit metal mines. J. Clean. Prod. 2018, 180, 210–221. [Google Scholar] [CrossRef]

- Jafarpour, A.; Khatami, S. Analysis of Environmental Costs’ Effect in Green Mining Strategy Using a System Dynamics Approach: A Case Study. Math. Probl. Eng. 2021, 18. [Google Scholar] [CrossRef]

- Badakhshan, N.; Shahriar, K.; Afraei, S.; Bakhtavar, E. Optimization of transition from open-pit to underground mining considering environmental costs. Resour. Policy 2024, 95, 105178. [Google Scholar] [CrossRef]

- Liu, F.; Yang, K.; Yang, T.; Deng, W.; Li, H.; Yang, L. Open pit limit optimization considering the pumped storage benefit after mine closure: A case study. Geomech. Geophys. Geo-Energy Geo-Resour. 2024, 10, 44. [Google Scholar] [CrossRef]

- Oblasser, A.; Chaparro, E. Estudio comparativo de la gestión de los pasivos ambientales mineros en Bolivia, Chile, Perú y Estados Unidos. Arbor 2008, 17, 3. [Google Scholar] [CrossRef]

- Martinez-Alier, J. Mining conflicts, environmental justice, and valuation. J. Hazard. Mater. 2001, 86, 153–170. [Google Scholar] [CrossRef]

- Vela-Almeida, D. Territorial partitions, the production of mining territory and the building of a post-neoliberal and plurinational state in Ecuador. Polit. Geogr. 2018, 62, 126–136. [Google Scholar] [CrossRef]

- Getty, R.; Morrison-Saunders, A. Evaluating the effectiveness of integrating the environmental impact assessment and mine closure planning processes. Environ. Impact Assess. Rev. 2020, 82, 106366. [Google Scholar] [CrossRef]

- Gałaś, S.; Gałaś, A. The qualification process of mining projects in environmental impact assessment: Criteria and thresholds. Resour. Policy 2016, 49, 204–212. [Google Scholar] [CrossRef]

- Lechner, A.M.; Baumgartl, T.; Matthew, P.; Glenn, V. The Impact of Underground Longwall Mining on Prime Agricultural Land: A Review and Research Agenda. Land Degrad. Dev. 2016, 27, 1650–1663. [Google Scholar] [CrossRef]

- McCullough, C.D.; Harvey, B.; Unger, C.J.; Winchester, S.; McCarthy, B.; Coetzee, J. From start to finish—A perspective on improving sustainable development aspects of life-of-mine practices. In From Start to Finish: Life of Mine Perspective, Spectrum 24; AusIMM: Carlton Victoria, Australia, 2018. [Google Scholar]

- Centro de Investigación y Desarrollo—PUCESE. Economic Valuation of the Environmental Assessments of Gold Mining Activity in the North of Ecuador; Ministerio del Ambiente: Esmeraldas, Ecuador, 2011. [Google Scholar] [CrossRef]

- Yupari, A. Pasivos Ambientales Mineros en Sudamérica; Report prepared for the CEPAL; Instituto Federal de Geociencias y Recursos Naturales—BGR and Servicio Nacional de Geología y Minería—SERNAGEOMIN: Santiago de Chile, Chile, 2003. [Google Scholar]

- Arango Aramburo, M. Requerimientos Para el Diseño de una Metodología que Permita Estimar el Valor de Pasivos Ambientales Mineros; Universidad Nacional de Colombia: Bogotá, Colombia, 2011; Available online: https://repositorio.unal.edu.co/bitstream/handle/unal/8766/43869159.2011.pdf?sequence=1&isAllowed=y (accessed on 9 October 2024).

- Liao, X.; Li, W.; Hou, J. Application of GIS Based Ecological Vulnerability Evaluation in Environmental Impact Assessment of Master Plan of Coal Mining Area. Procedia Environ. Sci. 2013, 18, 271–276. [Google Scholar] [CrossRef]

- Wu, Z.; Lei, S.; Lu, Q.; Bian, Z.; Ge, S. Spatial distribution of the impact of surface mining on the landscape ecological health of semi-arid grasslands. Ecol. Indic. 2020, 111, 105996. [Google Scholar] [CrossRef]

- Glaister, B.J.; Mudd, G.M. The environmental costs of platinum-PGM mining and sustainability: Is the glass half-full or half-empty? Miner. Eng. 2010, 23, 438–450. [Google Scholar] [CrossRef]

- Pietrzyk-Sokulska, E.; Uberman, R.; Kulczycka, J. Minería e impactos ambientales en Polonia. Gospod. Surowcami Miner. Miner. Resour. Manag. 2015, 31, 45–64. [Google Scholar] [CrossRef]

- Lechner, A.M.; Kassulke, O.; Unger, C. Spatial assessment of open cut coal mining progressive rehabilitation to support the monitoring of rehabilitation liabilities. Resour. Policy 2016, 50, 234–243. [Google Scholar] [CrossRef]

- Kasztelewicz, Z.; Szwed, L. Directions of Reclamation in Polish Lignite Mines on Selected Examples. Min. Geoengin. 2010, 66, 86–102. [Google Scholar]

- Feng, Z.; Hu, Z.; Li, G.; Zhang, Y.; Zhang, X.; Zhang, H. Improving mine reclamation efficiency for farmland sustainable use: Insights from optimizing mining scheme. J. Clean. Prod. 2022, 379, 134615. [Google Scholar] [CrossRef]

- Kosinskiy, P.; Merkuriev, V.; Medvedev, A. Approaches to evaluation of environmental and economic damage to the Kuzbass agglomeration caused by coal mining industry development. E3S Web Conf. 2019, 134, 03009. [Google Scholar] [CrossRef]

- Delgado, A.; Romero, I. Environmental conflict analysis using an integrated grey clustering and entropy-weight method: A case study of a mining project in Peru. Environ. Model. Softw. 2016, 77, 108–121. [Google Scholar] [CrossRef]

- Gulley, A.L. Valuing environmental impacts of mercury emissions from gold mining: Dollar per troy ounce estimates for twelve open-pit, small-scale, and artisanal mining sites. Resour. Policy 2017, 52, 266–272. [Google Scholar] [CrossRef]

- Narrei, S.; Ataee-pour, M. Estimations of utility function and values of sustainable mining via the choice experiment method. J. Clean. Prod. 2020, 267, 121938. [Google Scholar] [CrossRef]

- Vergara Tamayo, C.; González Quesada, A.; González Coronado, C. Evaluación de impacto ambiental y estudios previos a una valoración contingente. Caso La Colosa, Cajamarca, Tolima, Colombia. Ens. Econ. 2013, 23, 191–222. [Google Scholar]

- Kitula, A.G.N. The environmental and socio-economic impacts of mining on local livelihoods in Tanzania: A case study of Geita District. J. Clean. Prod. 2006, 14, 405–414. [Google Scholar] [CrossRef]

- Willis, K.G.; Garrod, G.D. Valuing landscape: A contingent valuation approach. J. Environ. Manag. 1993, 37, 1–22. [Google Scholar] [CrossRef]

- Rodríguez-Zapata, M.A.; Ruíz-Agudelo, C.A.; Ahrens, M.J. Analysis of social perception and field verification as a route to evaluation of environmental liabilities in Colombia: Case study Cesar (Colombia). World Dev. Sustain. 2024, 4, 100133. [Google Scholar] [CrossRef]

- Gu, X.W.; Xu, X.C.; Wang, Q.; Wang, R. Ecological Cost of Mining. J. Northeast. Univ. Nat. Sci. 2013, 34, 594–597. [Google Scholar]

- Servicio Nacional de Geología y Minería (SERNAGEOMIN). Guía Metodológica para la Presentación de Planes de Cierre Sometidos al Procedimiento de Aplicación General; Ministerio de Minería, Gobierno de Chile: Santiago, Chile, 2014. [Google Scholar]

- Valdebenito, L.M. Estimación de Costos de Cierre de Pasivos Ambientales Mineros Identificados en Chile de Acuerdo a los Requerimientos de la Ley 20.551; Universidad de Chile: Santiago, Chile, 2015. [Google Scholar]

- Dialga, I. A mining industry sustainability index: Experiences from gold and uranium sectors. In Environmental Footprints and Eco-Design of Products and Processes; Springer: Berlin/Heidelberg, Germany, 2019; pp. 27–63. [Google Scholar] [CrossRef]

- Global Reporting Initiative. GRI 14: Mining Sector 2024; GRI: Amsterdam, The Netherlands, 2024; Available online: https://www.globalreporting.org/ (accessed on 19 February 2025).

- Taoufikallah, A. Capítulo 5. Aplicación de la Metodología AHP; Escuela Técnica Superior de Ingenieros de Sevilla, Universidad de Sevilla: Sevilla, Spain, 2010; Available online: https://biblus.us.es/bibing/proyectos/abreproy/70496/fichero/Capitulo+5+Aplicaci%C3%B3n+de+la+metodologia+AHP.pdf (accessed on 23 March 2024).

- Hwang, C.-L. Multiple Attribute Decision Making: An Introduction; Sage Publications: Thousand Oaks, CA, USA, 1995; Volume 104. [Google Scholar]

- Saaty, T.L. The Analytic Hierarchy Process: Planning, Priority Setting, Resource Allocation, 2nd ed.; McGraw-Hill International Book Company: New York, NY, USA, 1980. [Google Scholar]

- Jiskani, I.M.; Cai, Q.; Zhou, W.; Ali Shah, S.A. Green and climate-smart mining: A framework to analyze open-pit mines for cleaner mineral production. Resour. Policy 2021, 71, 102007. [Google Scholar] [CrossRef]

- Varouchakis, E.A.; Perez, G.A.C.; Loaiza, M.A.D.; Spanoudaki, K. Sustainability of mining activities in the European Mediterranean region in terms of a spatial groundwater stress index. Spat. Stat. 2022, 50, 100625. [Google Scholar] [CrossRef]

- Hosseinpour, M.; Osanloo, M.; Azimi, Y. Evaluation of positive and negative impacts of mining on sustainable development by a semi-quantitative method. J. Clean. Prod. 2022, 366, 132955. [Google Scholar] [CrossRef]

- Li, Y.; Barrueta Pinto, M.C.; Kumar, D.T. Analyzing sustainability indicator for the Chinese mining sector. Resources. Policy 2023, 80, 103275. [Google Scholar] [CrossRef]

- Gabus, A.; Fontela, E. World Problems, an Invitation to Further Thought within the Framework of DEMATEL, 1st ed.; Battelle Geneva Research Center: Geneva, Switzerland, 1972. [Google Scholar]

- Wu, Y.; Wu, C.; Zhou, J.; Zhang, B.; Xu, C.; Yan, Y.; Liu, F. A DEMATEL-TODIM based decision framework for PV power generation project in expressway service area under an intuitionistic fuzzy environment. J. Clean. Prod. 2020, 247, 119099. [Google Scholar] [CrossRef]

- Yousefian, M.; Bascompta, M.; Sanmiquel, L.; Vintró, C. Corporate social responsibility and economic growth in the mining industry. Extr. Ind. Soc. 2023, 13, 101226. [Google Scholar] [CrossRef]

- Heydari, M.; Osanloo, M. Untangling the complex web of environmental, social, and economic impacts in deep and large-scale open-pit mining projects using a dynamic modeling framework. Resour. Policy 2024, 90, 104690. [Google Scholar] [CrossRef]

- Leopold, L.B.; Clarke, F.E.; Hanshaw, B.B.; Balsley, J.R. A Procedure for Evaluating Environmental Impact; US Geological Survey: Washington, DC, USA, 1977.

- Conesa Fernández, V. Guía Metodológica para la Evaluación del Impacto Ambiental, 4th ed.; Ediciones Mundi-Prensa: Madrid, Spain, 2011. [Google Scholar]

- Mendoza, A.; Solano, C.; Palencia, D.; Garcia, D. Aplicación del proceso de jerarquía analítica (AHP) para la toma de decisión con juicios de expertos. Ingeniare Rev. Chil. Ing. 2019, 27, 348–360. [Google Scholar] [CrossRef]

- Bainton, N.; Holcombe, S. A critical review of the social aspects of mine closure. Resour. Policy 2018, 59, 468–478. [Google Scholar] [CrossRef]

- Akhmaddhian, S.; Budiman, H.; Bhandari, R. The Strengthening Government Policies on Mineral and Coal Mining to Achieve Environmental Sustainability in Indonesia, Africa and Germany. Bestuur 2023, 11, 95–120. [Google Scholar] [CrossRef]

- APEC. Mine Closure Checklist for Governments; Asia-Pacific Economic Cooperation: Singapore, 2018. [Google Scholar]

- Porter, M.E.; Linde, C.V.D. Toward a New Conception of the Environment-Competitiveness Relationship. J. Econ. Perspect. 1995, 9, 97–118. [Google Scholar] [CrossRef]

- Brännlund, R.; Lundgren, T. Environmental Policy Without Costs? A Review of the Porter Hypothesis 1; School of Business, Umeå University: Umeå, Sweden, 2009. [Google Scholar]

- ISO 21795-2; Mine Closure and Reclamation Planning. International Organization for Standardization. ISO: Geneva, Switzerland, 2021. Available online: https://www.iso.org/es/contents/data/standard/08/04/80425.html (accessed on 19 February 2025).

- Jonek-Kowalska, I. Environmental Costs of Mining Production in the Perspective of the Mine Lifecycle. In Business & Economics—BE-ci 2017, Vol 1. European Proceedings of Multidisciplinary Sciences; Bekirogullari, Z., Minas, M.Y., Thambusamy, R.X., Eds.; Future Academy: Brno, Czech Republic, 2017; pp. 80–90. [Google Scholar] [CrossRef]

- Zhang, A.; Moffat, K.; Lacey, J.; Wang, J. Understanding the social licence to operate of mining at the national scale: A comparative study of Australia, China and Chile. J. Clean. Prod. 2015, 108, 1063–1072. [Google Scholar] [CrossRef]

- Debrah, A.A.; Mtegha, H.; Cawood, F. Social licence to operate and the granting of mineral rights in sub-Saharan Africa: Exploring tensions between communities, governments and multi-national mining companies. Resour. Policy 2018, 56, 95–103. [Google Scholar] [CrossRef]

- United Nations Development Programme (UNDP). Guidance Note—Application of the Sustainable Livelihoods Framework in Development Projects; UNDP GCP: Panama City, Panama, 2017. [Google Scholar]

- Lima, A.T.; Mitchell, K.; O’Connell, D.W.; Verhoeven, J.; Van Cappellen, P. The legacy of surface mining: Remediation, restoration, reclamation and rehabilitation. Environ. Sci. Policy 2016, 66, 227–233. [Google Scholar] [CrossRef]

- Makhmudova, G.; Matsui, K. The remediation policy after mining works in the Kyrgyz Republic. Resour. Policy 2019, 61, 304–310. [Google Scholar] [CrossRef]

- Qi, R.; Liu, T.; Jia, Q.; Sun, L.; Liu, J. Simulating the sustainable effect of green mining construction policies on coal mining industry of China. J. Clean. Prod. 2019, 226, 392–406. [Google Scholar] [CrossRef]

- Li, H.L.; Zhu, X.H.; Chen, J.Y.; Jiang, F.T. Environmental regulations, environmental governance efficiency and the green transformation of China’s iron and steel enterprises. Ecol. Econ. 2019, 165, 106397. [Google Scholar] [CrossRef]

- Irarrazaval, F. Social protest at mining territories: Examining contentious politics at mining districts in Chile. Resour. Policy 2022, 78, 102787. [Google Scholar] [CrossRef]

- Ministerio de Hacienda de Chile. Ley No 21.591—Ley Sobre Royalty a la Minería; República de Chile: Santiago de Chile, Chile, 2024; Available online: https://faolex.fao.org/docs/pdf/chi218930.pdf (accessed on 26 October 2024).

- Congreso de la República de Perú. Ley N° 28090—Ley que Regula el Cierre de Minas; Congreso de la República de Perú: Lima, Perú, 2003. [Google Scholar]

- EY Building a Better Working World. Análisis Comparado de Carga Tributaria en Algunos Países Mineros; EY Building a better Working World: Santiago, Chile, 2020. [Google Scholar]

- Instituto Peruano de Economía. 2019-08-28-Minería-Tiene-Alta-Carga-Tributaria-El-Comercio. Perú, 2019. Available online: https://www.ipe.org.pe/portal/wp-content/uploads/2019/08/2019-08-28-Miner%C3%ADa-tiene-alta-carga-tributaria-El-Comercio.pdf (accessed on 2 November 2024).

- República de Colombia, Ley 685 del 2001, Código de Minas. Bogotá, Colombia. 2001. Available online: https://www.funcionpublica.gov.co/eva/gestornormativo/norma.php?i=9202 (accessed on 7 November 2024).

- Marmolejo Cervantes, M.Á.; Garduño-Rivera, R. Mining-energy public policy of lithium in Mexico: Tension between nationalism and globalism. Resour. Policy 2022, 77, 102686. [Google Scholar] [CrossRef]

- República de Bolivia. Ley de Minería y Metalurgia. 2014. Available online: https://www.lexivox.org/norms/BO-L-N535.html (accessed on 8 November 2024).

- República de Bolivia. Reglamento Ambiental para Actividades Mineras. 1997. Available online: https://www.lexivox.org/norms/BO-RE-DS24782.html (accessed on 8 November 2024).

- Valeriano Rodríguez, Z. Análisis comparativo de políticas de cierre de minas y reparación de pasivos ambientales en el Estado Plurinacional de Bolivia. Cienc. Lat. Rev. Científica Multidiscip. 2023, 7, 4483–4508. [Google Scholar] [CrossRef]

- European Commission—Environment. European Commission. 2020. Available online: https://environment.ec.europa.eu/topics/waste-and-recycling/mining-waste_en (accessed on 25 June 2020).

- Ministerio de Industria y Energía. Real Decreto 2857/1978 Reglamento General para el Régimen de la Minería; Agencia Estatal Boletín Oficial del Estado (BOE): Madrid, Spain, 1978. [Google Scholar]

- Generalitat de Catalunya. Decret 202/1994; Agencia Estatal Boletín Oficial del Estado (BOE): Barcelona, Catalunya, 1994; Available online: https://portaljuridic.gencat.cat/ca/document-del-pjur/?documentId=100010 (accessed on 12 November 2024).

- Generalitat de Catalunya. Decret Legislatiu 14/1994; Agencia Estatal Boletín Oficial del Estado (BOE): Barcelona, Catalunya, 1994; Available online: https://portaljuridic.gencat.cat/ca/document-del-pjur/?documentId=103865 (accessed on 12 November 2024).

- Fernández Gómez del Castillo, A.M. Régimen Fiscal de la Minería Propuestas para una Actividad Sostenible; Tesis Doctoral, Universidad de Sevilla: Sevilla, España, 2015; Available online: https://idus.us.es/items/2e12ab83-002a-47c9-be78-6bf3e502e487 (accessed on 14 November 2024).

- Geological Survey of Sweden. Minerals Ordinance (1992:285). Geological Survey of Sweden. 1992. Available online: https://www.sgu.se/en/mining-inspectorate/legislation/minerals-ordinance-1992285/ (accessed on 15 November 2024).

- OECD. Revenue Statistics Sweden; Centre of Tax Policy and Administration: 2020. Available online: https://www.oecd.org/tax/revenue-statistics-sweden.pdf (accessed on 16 November 2024).

- Tarras-Wahlberg, H. Mining and taxation in Sweden. Miner. Econ. 2023, 36, 291–299. [Google Scholar] [CrossRef]

- Western Australia Government. Mining Rehabilitation Fund Regulations 2013; Western Australia Government: Perth, Australia, 2013.

- Queensland Government. User Guide: Estimated Rehabilitation Cost Calculator for Mining; Environmental Services and Regulation, Department of Environment, Science and Innovation: Brisbane, Australia, 2022.

- Avcı, D. Mining conflicts and transformative politics: A comparison of Intag (Ecuador) and Mount Ida (Turkey) environmental struggles. Geoforum 2017, 84, 316–325. [Google Scholar] [CrossRef]

- Hilson, G.; Maconachie, R. For the environment: An assessment of recent military intervention in informal gold mining communities in Ghana. Land Use Policy 2020, 96, 104706. [Google Scholar] [CrossRef]

- Amoako, K.O.; Lord, B.R.; Dixon, K. Narrative accounting for mining in Ghana: An old defence against a new threat? Resour. Policy 2021, 74, 102439. [Google Scholar] [CrossRef]

- Pokhrel, L.R.; Dubey, B. Global scenarios of metal mining, environmental repercussions, public policies, and sustainability: A review. Crit. Rev. Environ. Sci. Technol. 2013, 43, 2352–2388. [Google Scholar] [CrossRef]

- Jie, Y.; Rasool, Z.; Nassani, A.A.; Mattayaphutron, S.; Murad, M. Sustainable Central Asia: Impact of fintech, natural resources, renewable energy, and financial inclusion to combat environmental degradation and achieving sustainable development goals. Resour. Policy 2024, 95, 105138. [Google Scholar] [CrossRef]

- Blondeel, M.; Van de Graaf, T. Toward a global coal mining moratorium? A comparative analysis of coal mining policies in the USA, China, India and Australia. Clim. Chang. 2018, 150, 89–101. [Google Scholar] [CrossRef]

- Pane, E.; Yanis, A.M. Reconstruction of Mining Policies on Justice in Lampung Province. J. Best. 2020, 8, 139–151. [Google Scholar] [CrossRef]

- Hota, P.; Behera, B. Extraction of mineral resources and regional development outcomes: Empirical evidence from Odisha, India. Extr. Ind. Soc. 2019, 6, 267–278. [Google Scholar] [CrossRef]

- Broad, R.; Fischer-Mackey, J. From extractivism towards buen vivir: Mining policy as an indicator of a new development paradigm prioritising the environment. Third World Q. 2017, 38, 1327–1349. [Google Scholar] [CrossRef]

- Ruokonen, E. Preconditions for successful implementation of the Finnish standard for sustainable mining. Extr. Ind. Soc. 2020, 7, 611–620. [Google Scholar] [CrossRef]

- Ştefănescu, L.; Alexandrescu, F. Environmental protection or subversion in mining? Planning challenges, perspectives and actors at the largest gold deposit in Europe. Land Use Policy 2020, 95, 103649. [Google Scholar] [CrossRef]

- Helwege, A. Challenges with resolving mining conflicts in Latin America. Extr. Ind. Soc. 2015, 2, 73–84. [Google Scholar] [CrossRef]

- Krzysztofik, R.; Dulias, R.; Kantor-Pietraga, I.; Spórna, T.; Dragan, W. Paths of urban planning in a post-mining area. A case study of a former sandpit in southern Poland. Land Use Policy 2020, 99, 104801. [Google Scholar] [CrossRef]

- Suopajärvi, L.; Kantola, A. The social impact management plan as a tool for local planning: Case study: Mining in Northern Finland. Land Use Policy 2020, 93, 104046. [Google Scholar] [CrossRef]

- Segerstedt, E.; Abrahamsson, L. Diversity of livelihoods and social sustainability in established mining communities. Extr. Ind. Soc. 2019, 6, 610–619. [Google Scholar] [CrossRef]

- Okombi, I.F.; Mampieme, V.B. Cyclicality of public debt in developing countries: Does dependence on natural resources matter? Resour. Policy 2024, 96, 105231. [Google Scholar] [CrossRef]

- Tanda, P.A.; Genc, B. Zimbabwe’s mining policy impact on revenue leakages. Resour. Policy 2024, 91, 104884. [Google Scholar] [CrossRef]

- Zhou, Z.; Liu, J.; Zhang, H. Does the reform of China’s mineral royalty policies exert economic pressure on mining companies? Extr. Ind. Soc. 2023, 15, 101325. [Google Scholar] [CrossRef]

- Jiang, W.; Hou, X.; Du, L. Has soil regulation policy reduced environmental violations by mining firms? Resour. Policy 2024, 96, 105223. [Google Scholar] [CrossRef]

- Pepper, M.; Hughes, M.; Haigh, Y. Loophole or lifeline? The policy challenges of mines in care and maintenance. Extr. Ind. Soc. 2021, 8, 100879. [Google Scholar] [CrossRef]

- IGF. Restitución de Sitios de Minas Cerradas: Pasos para Creación de Políticas para los Gobiernos; The Intergovernmental Forum on Mining, Minerals, Metals and Sustainable Development: Ontario, Canada, 2023; Available online: https://www.igfmining.org/es/ (accessed on 15 November 2024).

- Indrayanti, K.W. Law enforcement of reclamation and post coal mining policy in East Kalimantan Province, Indonesia. Int. J. Soc. Sci. Res. Rev. 2023, 6, 10–20. [Google Scholar] [CrossRef]

- Zhironkin, S.; Szurgacz, D. Mining Technologies Innovative Development: Economic and Sustainable Outlook. Energies 2021, 14, 8590. [Google Scholar] [CrossRef]

- García-Estévez, J.; Vargas-Prieto, A.; Ariza, J. Mining-energy boom and local institutional capacities—The case of Colombia. Extr. Ind. Soc. 2024, 17, 101387. [Google Scholar] [CrossRef]

- Orihuela, J.C.; Mendieta, A.; Pérez, C.; Ramírez, T. From paper institutions to bureaucratic autonomy: Institutional change as a resource curse remedy. World Dev. 2021, 143, 105463. [Google Scholar] [CrossRef]

- Zhang, S.; Li, Y.; Xu, C.; Xiong, Z. Does fiscal decentralization reduce environmental degradation through mitigating resource mismatch and digital transformation? Evidence from China’s resource-based cities. Resour. Policy 2024, 95, 105155. [Google Scholar] [CrossRef]

- Mwangi, J.; Naituli, G.; Kilika, J.; Muna, W. Fiscal decentralisation and public service delivery: Evidence and lessons from sub-national governments in Kenya. Commonw. J. Local Gov. 2023, 28, 5–23. [Google Scholar] [CrossRef]

- Ahmad, M.; Satrovic, E. Relating fiscal decentralization and financial inclusion to environmental sustainability: Criticality of natural resources. J. Environ. Manage. 2023, 325, 116633. [Google Scholar] [CrossRef]

- Shao, S.; Razzaq, A. Does composite fiscal decentralization reduce trade-adjusted resource consumption through institutional governance, human capital, and infrastructure development? Resour. Policy 2022, 79, 103034. [Google Scholar] [CrossRef]

- Onofrei, M.; Oprea, F.; Iaţu, C.; Cojocariu, L.; Anton, S.G. Fiscal Decentralization, Good Governance and Regional Development—Empirical Evidence in the European Context. Sustainability 2022, 14, 7093. [Google Scholar] [CrossRef]

- Lin, B.; Zhou, Y. Does fiscal decentralization improve energy and environmental performance? New perspective on vertical fiscal imbalance. Appl. Energy 2021, 302, 117495. [Google Scholar] [CrossRef]

- Wu, H.; Li, Y.; Hao, Y.; Ren, S.; Zhang, P. Environmental decentralization, local government competition, and regional green development: Evidence from China. Sci. Total Environ. 2020, 708, 135085. [Google Scholar] [CrossRef] [PubMed]

- Zhang, K.; Zhang, Z.-Y.; Liang, Q.-M. An empirical analysis of the green paradox in China: From the perspective of fiscal decentralization. Energy Policy 2017, 103, 203–211. [Google Scholar] [CrossRef]

- He, Q. Fiscal decentralization and environmental pollution: Evidence from Chinese panel data. China Econ. Rev. 2015, 36, 86–100. [Google Scholar] [CrossRef]

- Dexu, H.; Wenlong, M. Fiscal Decentralization, Financial Decentralization and Macroeconomic Governance. China Econ. 2022, 17, 84–105. Available online: https://www.proquest.com/scholarly-journals/fiscal-decentralization-financial-macroeconomic/docview/2624700504/se-2 (accessed on 1 December 2024).

- Zhang, C.; Xiang, X. Fiscal decentralization, environmental policy stringency, and resource sustainability: Panacea or Pandora’s box in high resource consuming countries. Resour. Policy 2023, 83, 103544. [Google Scholar] [CrossRef]

- Ma, S.; Wang, C.; Liu, J.; Zhu, L.; Jhonson, A. Towards green extraction: Assessing the social and economic progress and challenges of green mining in China for policy formulation. Resour. Policy 2024, 96, 105233. [Google Scholar] [CrossRef]

- Ramiò Matas, C. Interview: Investigación en Propuestas de Reformas en Estructuras Organizativas en Entidades Públicas; Universitat Pompeu Fabra: Barcelona, Spain, 2022. [Google Scholar]

- Ofosu, G.; Sarpong, D. Mineral exhaustion, livelihoods and persistence of vulnerabilities in ASM settings. J. Rural Stud. 2022, 92, 154–163. [Google Scholar] [CrossRef]

- Chambers, D.M. Net Present Value Calculations for Mining Post-Closure Financial Assurance. Mine Water Environ. 2024, 43, 511–515. [Google Scholar] [CrossRef]

- Furnaro, A.; Herpich, P.; Brauers, H.; Oei, P.-Y.; Kemfert, C.; Look, W. German Just Transition: A Review of Public Policies to Assist German Coal Communities in Transitio; Environmental Defense Fund (EDF); Resources for the Future (RFF): Washington, DC, USA, 2021. [Google Scholar]

- Wambwa, D.; Mundike, J.; Chirambo, B. Balancing economic development, social responsibility, and environmental conservation through financial assurance programs in sub-Saharan Africa’s mining industry. Environ. Dev. Sustain. 2023. [Google Scholar] [CrossRef]

- Hilson, G.; Hu, Y. Changing priorities, shifting narratives: Remapping rural livelihoods in Africa’s artisanal and small-scale mining sector. J. Rural Stud. 2022, 92, 93–108. [Google Scholar] [CrossRef]

- Owen, J.R.; Vivoda, V.; Kemp, D. Country-level governance frameworks for mining-induced resettlement. Environ. Dev. Sustain. 2020, 22, 4907–4928. [Google Scholar] [CrossRef]

- Akong, C. Reframing matter: Towards a material-discursive framework for Africa’s minerals. Extr. Ind. Soc. 2020, 7, 461–469. [Google Scholar] [CrossRef]

- Ofosu, G.; Sarpong, D. Defying the gloom: In search of the ‘golden’ practices of small-scale mining operations. Environ. Sci. Policy 2023, 139, 62–70. [Google Scholar] [CrossRef]

- Chen, L.; Yang, J.; Liu, W. Global mining governance evaluation methods. Miner. Econ. 2015, 28, 123–127. [Google Scholar] [CrossRef]

- Franken, G.; Schütte, P. Current trends in addressing environmental and social risks in mining and mineral supply chains by regulatory and voluntary approaches. Miner. Econ. 2022, 35, 653–671. [Google Scholar] [CrossRef]

- Hilson, G.; Bartels, E.; Hu, Y. Brick by brick, block by block: Building a sustainable formalization strategy for small-scale gold mining in Ghana. Environ. Sci. Policy 2022, 135, 207–225. [Google Scholar] [CrossRef]

- EJatlas. Mineral Ore Exploration and/or Extraction. In Atlas of Environmental Justice; Universitat Autònoma de Barcelona (UAB): Barcelona, Spain, 2025; Available online: http://ejatlas.org/conflict/ (accessed on 13 February 2025).

| Reference | Year | Minerals | Partial or Total Inclusion of Variables | Parameters Included | Application | ||

|---|---|---|---|---|---|---|---|

| Environmental Costs | Closure Costs | Open-Pit Project | Underground Project | ||||

| [40] | 2008 | Copper | Partial (acid drainage) | ✓ | ✓ | ||

| [42] | 2013 | Gold | Partial (tailings) | ✓ | ✓ | ||

| [44] | 2014 | Polymetallic | Partial (tailings) | ✓ | ✓ | ||

| [45] | 2014 | Coal | Partial (CO2) | ✓ | ✓ | ||

| [51] | 2014 | Polymetallic | Total | ✓ | ✓ | ✓ | |

| [26] | 2015 | Copper | Total | ✓ | ✓ | ||

| [52] | 2015 | - | Total | ✓ | ✓ | ||

| [53] | 2015 | Iron | Partial (tailings) | ✓ | ✓ | ||

| [55] | 2015 | Copper | Total | ✓ | ✓ | ||

| [43] | 2016 | Uranium | Partial (process) | ✓ | ✓ | ||

| [56] | 2016 | Copper | Total | ✓ | ✓ | ||

| [46] | 2016 | Coal | Partial (CO2) | ✓ | ✓ | ||

| [58] | 2017 | Copper | Total | ✓ | ✓ | ||

| [60] | 2017 | Copper | Total | ✓ | ✓ | ||

| [61] | 2017 | Not specified | Total | ✓ | ✓ | ||

| [41] | 2018 | Not specified | Partial (waste) | ✓ | ✓ | ||

| [62] | 2018 | Polymetallic | Total | ✓ | ✓ | ✓ | |

| [49] | 2020 | Polymetallic | Partial (acid drainage) | ✓ | ✓ | ||

| [63] | 2021 | Copper | Partial | ✓ | ✓ | ✓ | |

| [50] | 2023 | Copper | Partial (ESG) | ✓ | ✓ | ||

| [64] | 2024 | Copper | Total | ✓ | ✓ | ✓ | |

| [65] | 2024 | Iron | Total | ✓ | ✓ | ✓ | |

| [47] | 2024 | Coal | Partial (CO2) | ✓ | ✓ | ||

| Country | Law | Methodology for Calculating Closure Costs | Maximum Tax Burden | Royalties Payment | Management Level |

|---|---|---|---|---|---|

| Chile | Ley 20.551, 2014 | ✓ | 47% | ✓ | Central |

| Peru | Ley N°28090, 2003 | ✘ | 35% | ✓ | Central |

| Colombia | Ley 685, 2001 | ✘ | 70% | ✓ | Central |

| Bolivia | Ley Minería y Metalurgia, 2014 | ✘ | 43% | ✓ | Central |

| Canada (BC) * | RSBC, 1996 | ✘ | 23% | ✘ | Federal |

| Spain (Cat) * | Decret Legislatiu 14/1994 | ✘ | 48% | ✘ | Autonomous ** |

| Sweden | Mineral Ordinance, 1992 | ✘ | 29% | ✘ | State domain |

| Australia (WA) * | Mining Act, 978 | ✓ | 52% | ✓ | State domain |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oliveros-Sepúlveda, D.; Bascompta-Massanés, M.; Franco-Sepúlveda, G. Environmental and Closure Costs in Strategic Mine Planning, Models, Regulations, and Policies. Resources 2025, 14, 41. https://doi.org/10.3390/resources14030041

Oliveros-Sepúlveda D, Bascompta-Massanés M, Franco-Sepúlveda G. Environmental and Closure Costs in Strategic Mine Planning, Models, Regulations, and Policies. Resources. 2025; 14(3):41. https://doi.org/10.3390/resources14030041

Chicago/Turabian StyleOliveros-Sepúlveda, David, Marc Bascompta-Massanés, and Giovanni Franco-Sepúlveda. 2025. "Environmental and Closure Costs in Strategic Mine Planning, Models, Regulations, and Policies" Resources 14, no. 3: 41. https://doi.org/10.3390/resources14030041

APA StyleOliveros-Sepúlveda, D., Bascompta-Massanés, M., & Franco-Sepúlveda, G. (2025). Environmental and Closure Costs in Strategic Mine Planning, Models, Regulations, and Policies. Resources, 14(3), 41. https://doi.org/10.3390/resources14030041