1. Introduction

Expansive clays, particularly black cotton soils, are prevalent across regions such as East Africa, India, and Southeast Asia, exhibiting considerable volumetric fluctuations ranging from 5% to 20%. These soils exhibit substantial swell–shrink behaviour, primarily driven by seasonal fluctuations in matric suction resulting from rainfall. The expansive nature of these soils results in severe geotechnical challenges, including differential settlement of structures, deterioration of pavement smoothness, and shallow slope failures [

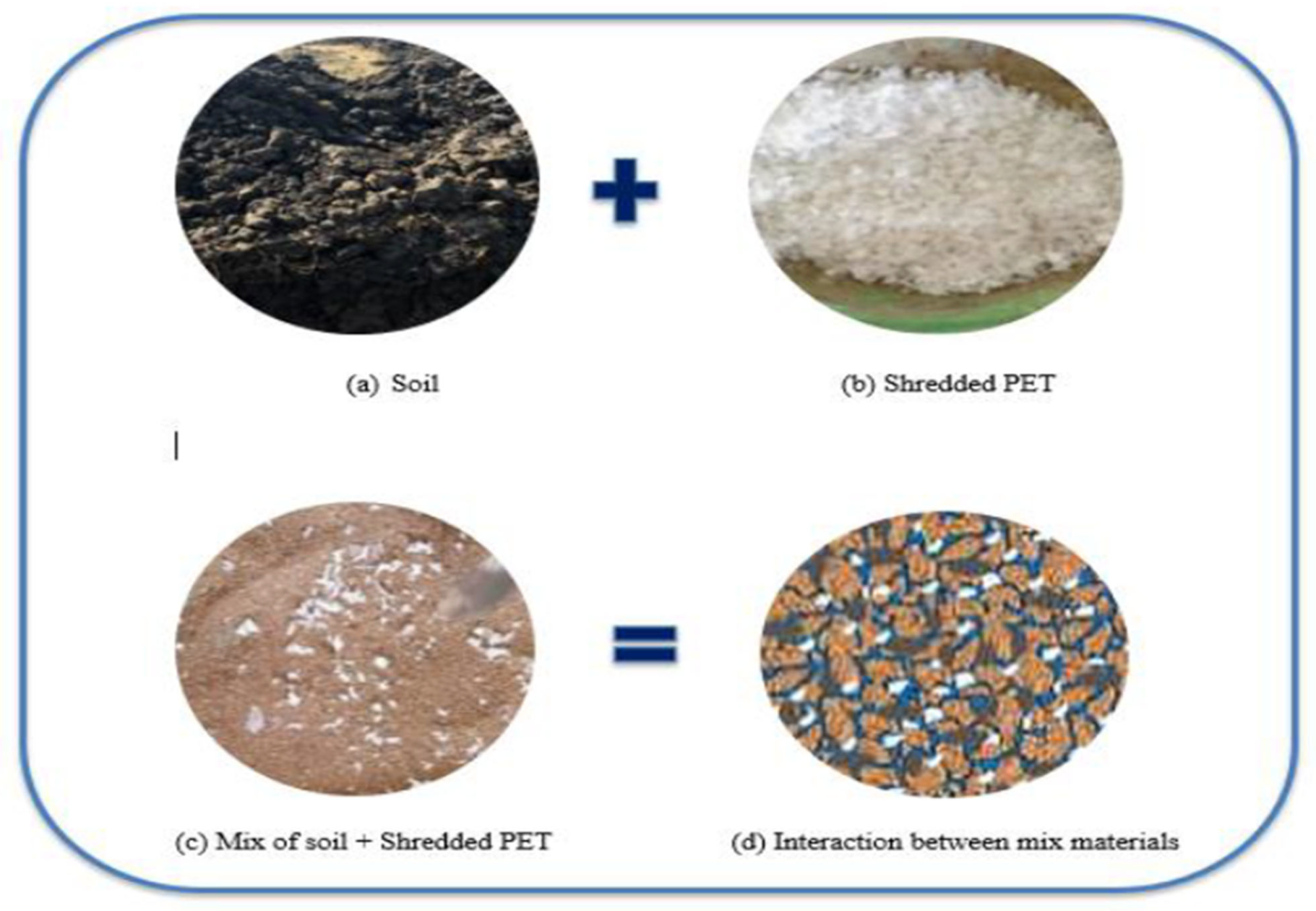

1]. These issues are particularly pressing in rapidly urbanising regions, where expansive soils jeopardise the stability of infrastructure, increase maintenance costs, and heighten public safety risks. Additionally, the adverse effects of climate change, manifested as altered rainfall patterns, further destabilise these soils, amplifying ground movements and increasing infrastructural vulnerability [

2].

Conventional soil stabilisation techniques, such as the use of lime and Ordinary Portland Cement (OPC), have been widely employed to mitigate the adverse effects of expansive soils. While these methods provide effective short-term improvements, they pose notable environmental challenges. The production of Ordinary Portland Cement (OPC) is a major source of global carbon emissions, contributing about 8% of total CO

2 output, with roughly 0.9 tonnes of CO

2 released per tonne of cement produced. The high carbon footprint of cement production remains a critical barrier to meeting international sustainability goals, particularly the emission reduction targets established under the Paris Agreement [

3]. Consequently, there is a critical and urgent need to explore sustainable, low-carbon alternatives to conventional cement-based stabilisation methods—solutions that can mitigate environmental impact while maintaining or improving engineering performance. Advancing such eco-efficient solutions is essential not only to reduce the ecological footprint of geotechnical practices but also to support long-term resilience and compliance with global sustainability frameworks.

Simultaneously, the global plastic waste crisis has escalated, with plastic production expected to exceed 400 million tons annually by 2024. Alarmingly, less than 10% of post-consumer plastic is recycled, and an estimated 4.8–12.7 million tons of plastic waste enter marine ecosystems each year [

4,

5,

6]. Polyethene Terephthalate (PET), particularly in beverage bottles, is a major contributor to this environmental crisis. The global per capita consumption of PET increased sixfold from 2007 to 2022 [

7], underscoring the urgent need for innovative and effective waste management strategies. Using shredded PET as reinforcing fibres for soil stabilisation presents a dual-purpose solution that addresses both plastic waste management and the demand for sustainable soil stabilisation alternatives [

8,

9].

Recent research has highlighted the benefits of incorporating PET fibres into soil. The addition of less than 1% PET fibres by dry soil mass to sands, lateritic soils, and low-plasticity clays has been reported to improve performance, with an increase in Unconfined Compressive Strength (UCS) of 130–300% and California Bearing Ratio (CBR) values of 50–150% [

10,

11]. Specifically, for expansive clays, incorporating 1% PET fibres (with aspect ratios ranging from 5 to 10) resulted in a 70–110% increase in the UCS and a 50% reduction in axial swelling, accompanied by more ductile post-peak stress–strain behaviour [

7,

12]. These enhancements in strength and stability demonstrate not only the mechanical benefits of PET fibres but also their potential to mitigate the expansive behaviour of soils, providing a sustainable solution to soil instability.

Additional performance improvements were observed when PET fibres were used in conjunction with minimal amounts of OPC (≤5%). This combined approach leads to an enhanced resilient modulus, reduced soil compressibility, and a reduction in cement consumption by 30–40%. This dual strategy not only improves the mechanical performance of soils but also offers substantial environmental benefits by reducing reliance on OPC, an energy-intensive material [

13,

14,

15]. The use of PET fibres in soil stabilisation, along with reduced OPC content, represents a promising solution for sustainable infrastructure development.

Although several studies have demonstrated the potential of PET fibres to enhance the mechanical behaviour of soils, most prior research has focused on sands, lateritic soils, or low-plasticity clays, where notable increases in UCS and CBR were reported at fibre contents below 1% by dry soil mass [

1,

2,

3]. For expansive high-plasticity CH clays, however, the literature remains sparse. Previous investigations have typically examined only a limited set of properties (e.g., UCS or CBR), without integrating compaction, bearing capacity, and swell behaviour into a single framework [

4,

5]. Moreover, although some works have reported improvements in strength, the underlying microstructural mechanisms have largely been inferred rather than demonstrated through techniques such as SEM [

6].

Another key gap relates to dosage control. Existing studies have primarily focused on low PET contents (≤1%), giving little attention to the reduced performance that can occur at higher dosages as a result of fibre clustering and void development [

7,

8,

9]. In addition, many studies briefly mention PET reuse but do not explicitly frame it as a low-carbon, cement-saving strategy for sustainable soil stabilisation [

10,

11,

12].

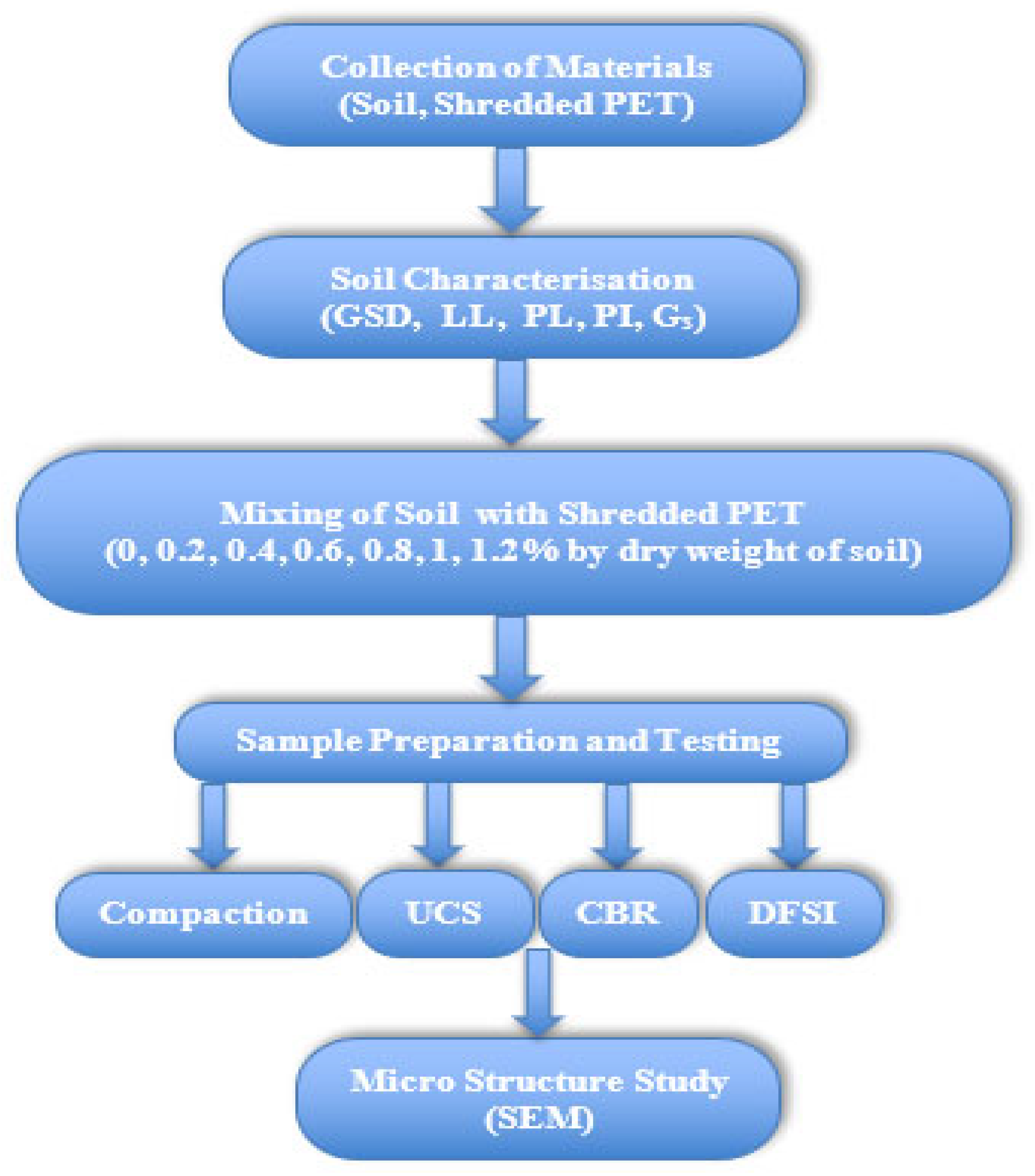

This study addresses these gaps through a multi-scale experimental programme on a high-plasticity CH clay. The PET fibre content was systematically varied between 0% and 1.2%, and its effects on compaction characteristics, UCS, unsoaked CBR, and swelling behaviour (DFSI) were evaluated in accordance with ASTM standards. Microstructural mechanisms—including fibre bridging, pore refinement, and agglomeration effects—were investigated using SEM. The results show that a PET content of about 1.0% provided the highest mechanical performance, while higher contents were associated with a slight decrease in strength. This work presents a comprehensive, multi-scale evaluation, a wider dosage window, and a clear sustainability framework for PET-fibre stabilisation as an alternative to cement-based approaches, as summarised in

Table 1.

This study will aim to:

Integrate mechanical testing with SEM to reveal how PET fibres influence the soil fabric, pore structure, and microcracking, thereby contributing to a deeper understanding of fibre–soil interactions at the microscale and their subsequent macroscopic effects.

The characterisation of the physicochemical interactions between PET fibres and clay particles was performed to elucidate how these interactions enhance soil cohesion, load transfer, and volumetric stability, ultimately leading to improved overall soil performance.

The PET fibre dosage should be selected to achieve effective mechanical performance while maintaining sustainability and practical applicability in soil stabilisation. The aim is to establish guidelines for suitable fibre content that enhance performance and minimise environmental impact, especially in regions dependent on stabilised soils for infrastructure development.

The expected outcomes of this study are anticipated to make a meaningful contribution to advancing sustainable practices in geotechnical engineering. This study directly contributes to global sustainability objectives by validating polyethene terephthalate (PET) fibre reinforcement as a cost-effective, eco-friendly, and scalable solution for stabilising expansive soils. In particular, it offers the dual benefit of reducing the carbon footprint of soil stabilisation processes and diverting large volumes of plastic waste away from landfills and oceans. This approach not only promotes environmental conservation but also enhances the long-term resilience and durability of infrastructure.

Relevance to Resource Sustainability

The present study contributes not only to geotechnical engineering but also to the broader domain of resource sustainability. Issues such as natural resource depletion, waste management, and the circular economy are central to contemporary sustainability discourse, and this research engages them in the following ways:

- (i)

Minimising use of virgin resources:

The stabilisation of expansive soils traditionally requires high volumes of cement or lime, which involves the extraction of minerals (e.g., limestone and clay), considerable water use, and energy-intensive processing. These practices accelerate greenhouse gas emissions and deplete geological reserves. By exploring alternatives, such as recycled PET fibres, this study reduces reliance on virgin, non-renewable resources and promotes more sustainable material practices in infrastructure development.

- (ii)

Valorisation of plastic waste:

Polyethene terephthalate (PET) plastics constitute one of the most persistent global waste streams. Although recycling initiatives exist, global recovery rates remain modest, and large quantities of PET continue to be disposed of in landfills and oceans. By proposing a novel reuse pathway for PET waste in soil stabilisation, this study demonstrates resource valorisation, transforming a problematic waste stream into a functional engineering input.

- (iii)

Enhancing durability and conserving resources:

Infrastructure built on treated expansive soils benefits from its increased durability and reduced maintenance requirements. A longer service life results in lower recurring use of construction materials, such as aggregates, binders, and reinforcement, while also reducing labour, energy, and financial costs over time. Thus, benefits extend beyond immediate performance improvements to long-term resource conservation.

- (iv)

Alignment with global sustainability goals:

The outcomes of this study align with several United Nations Sustainable Development Goals (SDGs), specifically SDG 12 (Responsible Consumption and Production), SDG 11 (Sustainable Cities and Communities), and SDG 13 (Climate Action). This demonstrates that the study not only addresses a technical challenge but also makes a meaningful contribution to global sustainability imperatives.

4. Discussion

The results demonstrate that the inclusion of shredded PET fibres influences the compaction characteristics, mechanical strength, swelling behaviour, and microstructural configuration of expansive clay. Among the tested dosages, the 1.0% PET fibre content showed the highest measured values for Unconfined Compressive Strength (UCS) and California Bearing Ratio (CBR), along with a noticeable reduction in the Differential Free Swell Index (DFSI). At this dosage, the reinforcing effect of PET fibres was most effective, contributing to a denser and more stable soil structure. However, beyond this level—specifically at 1.2%—a slight reduction in performance was observed, which may be attributed to fibre agglomeration and the formation of macro voids that disrupted uniform stress distribution.

The microstructural observations from Scanning Electron Microscopy (SEM) further corroborate these findings. The treated soil exhibited a well-distributed three-dimensional tensile network formed by intersecting PET fibres, which acted as bridging elements across clay clusters. This fibre-induced network enhanced interparticle bonding and reduced microcrack propagation, thereby linking micro-level structural modifications to the observed macro-scale improvements in strength and stability. These findings highlight the importance of maintaining an appropriate fibre dosage to achieve effective reinforcement and indicate a clear relationship between microstructural refinement and improved geotechnical performance. A comprehensive interpretation of these mechanisms is provided in the subsequent sections.

4.1. Compaction Characteristics

With the increase in PET fibre content from 0% to 1.2%, the Optimum Moisture Content (OMC) increased from 17.0% to 18.4%, while the maximum dry unit weight (MDD) decreased from 16.9 kN/m3 to 16.2 kN/m3. The rise in OMC can be attributed to the interaction between the PET fibres and the soil matrix. PET fibres, with a specific gravity (Gs) of approximately 1.3, occupy the void spaces between soil particles and repel water, thereby necessitating additional moisture to facilitate better lubrication of the soil fabric for effective compaction. The decrease in MDD can be attributed to the low unit weight of PET fibres, which disrupts the natural interlock between soil particles and reduces the overall compactness of the soil matrix.

However, the MDD curve shows a nonlinear trend, with the rate of decrease in density accelerating beyond approximately 0.8% PET. This observation aligns with the findings of Zhu et al. (2023) [

18], where the addition of PET fibres at higher dosages resulted in reduced compactness, likely because the fibres introduced additional voids and impeded effective particle interlocking. This suggests that beyond a certain threshold, the benefits of adding PET fibres to the soil matrix begin to diminish, with excessive fibre content potentially compromising the overall packing efficiency of the soil matrix. These findings highlight the importance of selecting an appropriate PET fibre content to balance reinforcement effectiveness and compaction efficiency, which is important for practical soil stabilisation applications.

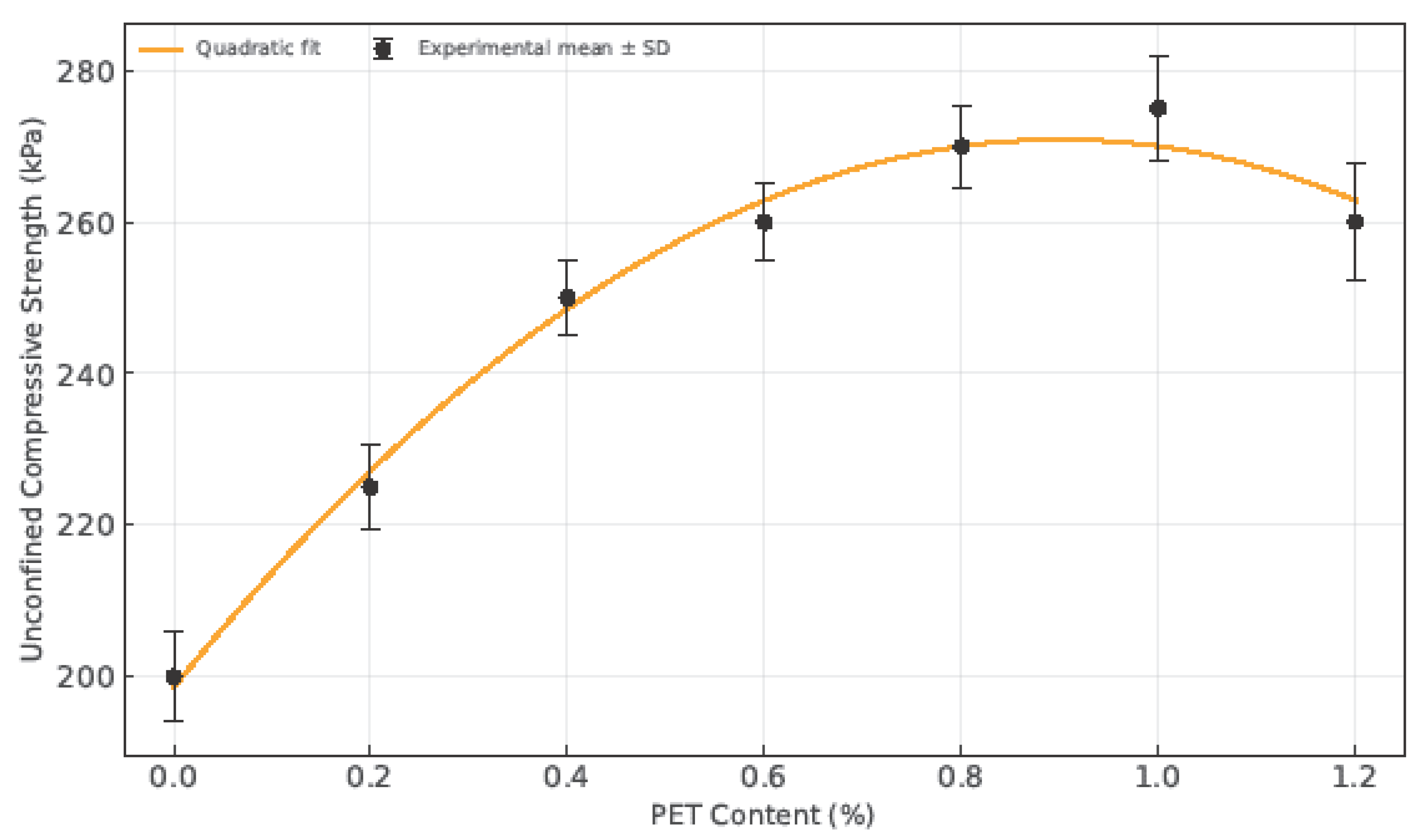

4.2. Unconfined Compressive Strength (UCS)

The Unconfined Compressive Strength (UCS) of soil reinforced with shredded Polyethene Terephthalate (PET) initially started at 200 kPa, gradually increasing to a value of approximately 274 kPa at a fibre dosage of 1.0%, and then decreasing to 260 kPa at a fibre dosage of 1.2%. This can be attributed to the frictional anchorage of the PET fibres within the soil matrix, which enhances the cohesion between soil particles and facilitates better load distribution. The PET fibres, acting as reinforcements, dissipate energy more effectively during loading, contributing to the observed strength gain [

16].

The decrease in strength at higher fibre contents can be explained by the tendency of excess fibres to agglomerate and form clusters within the soil matrix. These clusters create localised stress concentrations that disrupt the uniform transfer of load between soil particles, resulting in uneven stress distribution. As the fibres group together, they also increase the void ratio within the soil, further compromising the material’s structural integrity and reducing its load-bearing capacity. This phenomenon aligns with the findings of Miturski et al. (2025) [

15], who observed that a higher fibre content leads to an ineffective distribution of fibres, which negatively impacts soil strength. These results highlight the need to select an appropriate fibre dosage so that PET fibres contribute effectively to soil reinforcement without introducing negative effects at higher contents.

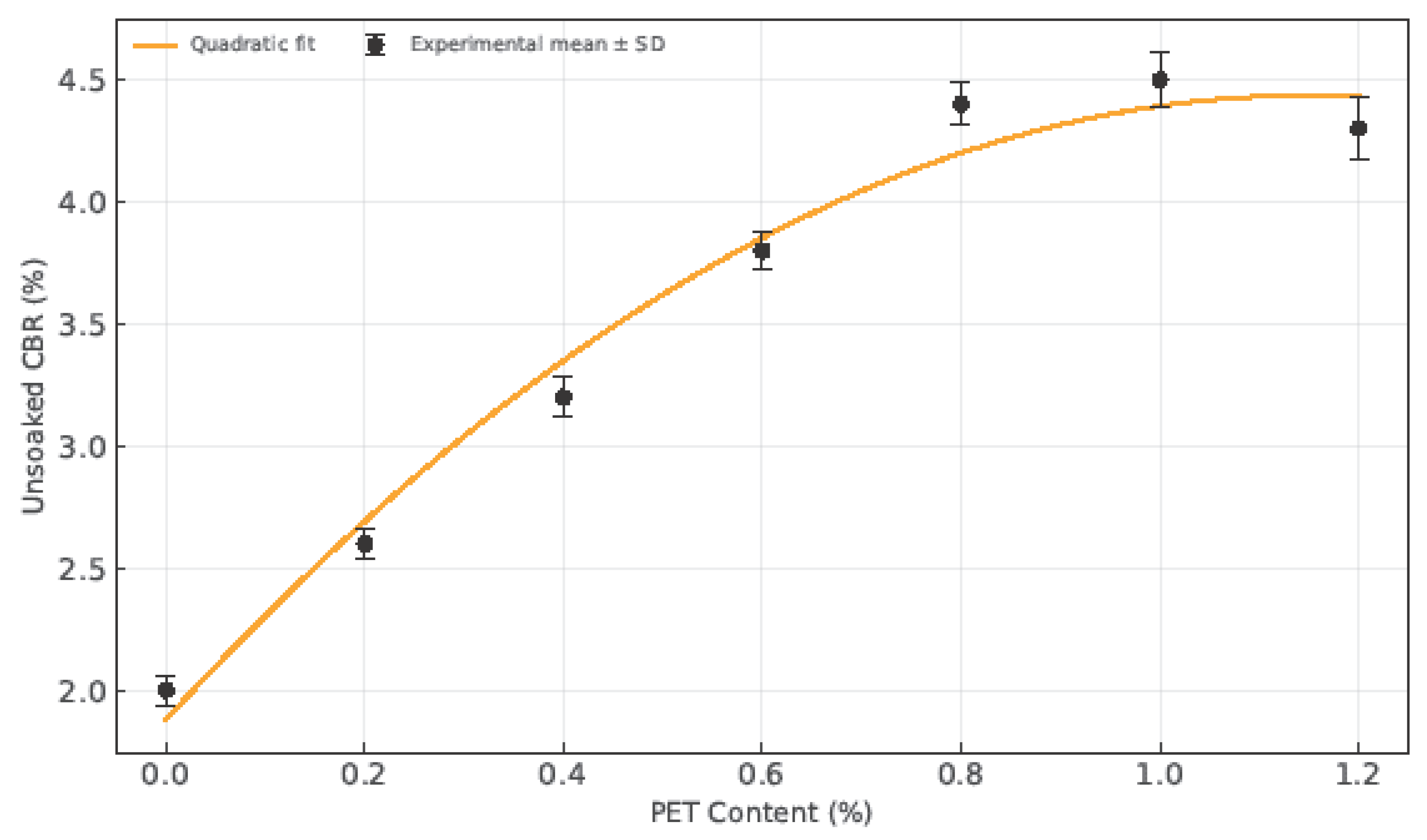

4.3. CBR Behaviour

The unsoaked CBR of virgin soil was 2.0%, increasing to 4.5% at a 1.0% PET content. The value marginally declined to 4.3% at 1.2% PET. This nonlinear response suggests that there is a threshold beyond which further additions of PET fibres do not contribute to, and may even hinder, the improvement of soil performance. The initial increase in CBR can be attributed to the high-aspect-ratio PET strips, which effectively bridged intergranular voids within the soil structure. By doing so, these fibres limit the movement of soil particles during penetration, effectively preventing the formation of microshear planes that would otherwise cause soil deformation under load.

The fibre–soil interaction mechanisms, primarily involving reinforcement and bridging effects, result in an enhanced load distribution beneath the indenter. This improved load transfer capacity directly translates into an increased bearing capacity, as the PET fibres help distribute the applied load more efficiently across the soil matrix. As the PET content increases to 1.0%, these reinforcement mechanisms become dominant, resulting in a near-linear increase in the CBR. This finding is consistent with results from other studies on fibre-reinforced soils, such as those involving polypropylene fibres, where similar CBR improvements of 100–150% were observed at fibre contents ranging from 0.5% to 1.5% [

17]. Furthermore, cyclic loading tests on soils reinforced with shredded PET fibres have demonstrated comparable gains in strength, providing additional evidence of the efficacy of PET fibres in enhancing soil performance under dynamic loading conditions [

13,

14].

However, the slight reduction in CBR observed at 1.2% PET content indicates the onset of diminishing returns, which can be attributed to the clustering of excess fibres within the soil matrix. When the PET content exceeded 1.0%, the fibres tended to agglomerate, forming localised areas within the soil where the reinforcement effect was reduced. These fibre clusters generate localised stress concentrations, disrupting the uniform transfer of load between soil particles. The agglomeration of fibres also increases the void ratio, resulting in a decrease in soil compaction. This increase in voids reduced the effective contact area under the applied load, thereby diminishing the soil’s overall bearing capacity. This clustering effect indicates the importance of maintaining an appropriate fibre dosage to promote a uniform distribution of fibres within the soil matrix. Beyond a specific dosage, excessive PET fibres not only lose their reinforcing effect but may also negatively impact the mechanical performance of the soil, resulting in a reduction in CBR values and undermining the soil stabilisation benefits.

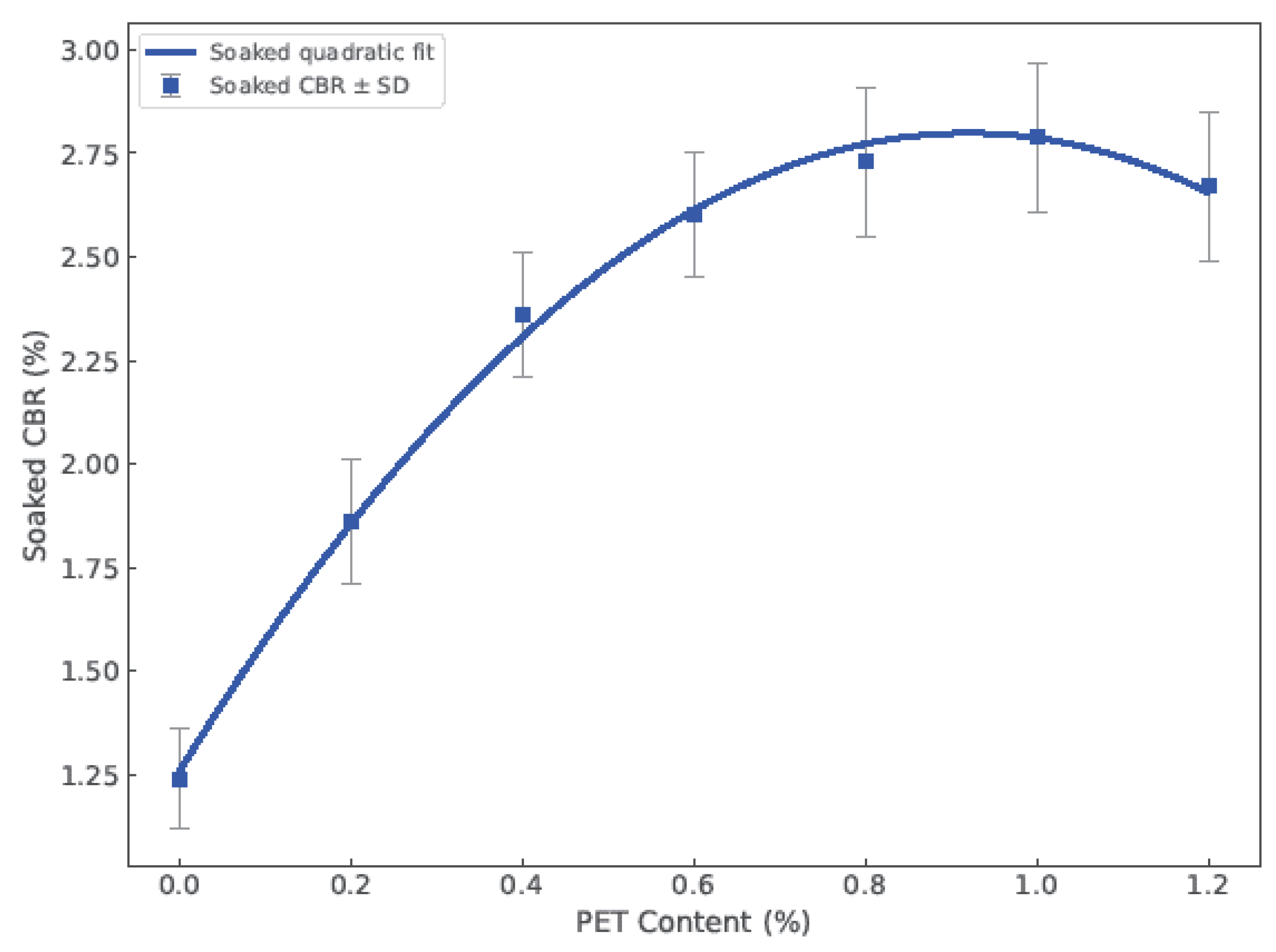

4.4. Implications of Soaked CBR

In addition to unsaturated conditions, the performance of PET-fibre-reinforced expansive soil was also examined under saturated conditions to simulate better field scenarios where subgrades are frequently exposed to moisture. Expansive clays are highly sensitive to moisture variations, and soaking typically results in a reduction in bearing capacity due to softening of the clay structure and weakening of interparticle bonds. In the present study, the soaked CBR values exhibited a similar parabolic response to PET content as observed under unsoaked conditions, but with lower absolute magnitudes. The soaked CBR of the untreated soil was recorded at approximately 1.2%, indicating a severe loss of strength due to moisture ingress. With PET fibre reinforcement, the soaked CBR progressively increased, reaching maximum at 2.8% for a 1.0% PET content, representing more than a twofold improvement compared to the untreated condition. This enhancement can be attributed to the tensile bridging action of PET fibres, which resists penetration even under reduced matric suction, thereby maintaining structural integrity.

Beyond 1.0% PET, the soaked CBR slightly declined, which is consistent with the fibre agglomeration effect observed in the unsoaked condition, indicating that excessive fibre content can increase the void ratio and reduce compaction efficiency. These findings align with earlier studies on fibre-reinforced expansive soils, where soaked CBR typically ranged from 60% to 70% of the unsoaked values, with reinforcement helping to narrow the moisture sensitivity gap [

14]. The soaked CBR curve (

Figure 9) further substantiates the reinforcing efficiency of PET fibres under realistic field moisture conditions, indicating that 1.0% PET performed most effectively for subgrade stabilisation in areas subject to seasonal moisture variations.

These results underscore the importance of selecting an appropriate PET fibre dosage for achieving effective soil stabilisation. The CBR values exhibit a clear improvement in load-bearing capacity with an increasing PET content up to 1.0%, after which a slight decrease is observed. This maximum value corresponds to the highest performance observed experimentally, which may be attributed to improved fibre–soil interaction at moderate dosages and fibre agglomeration at higher contents. Achieving this balance between reinforcement and compaction is crucial for the practical application of PET-reinforced soils in road construction and pavement projects. The observed improvement at 1.0% PET also aligns with global trends that promote the use of recycled PET fibres to enhance soil properties, thereby supporting sustainable construction practices.

4.5. Performance at Higher Fibre Contents

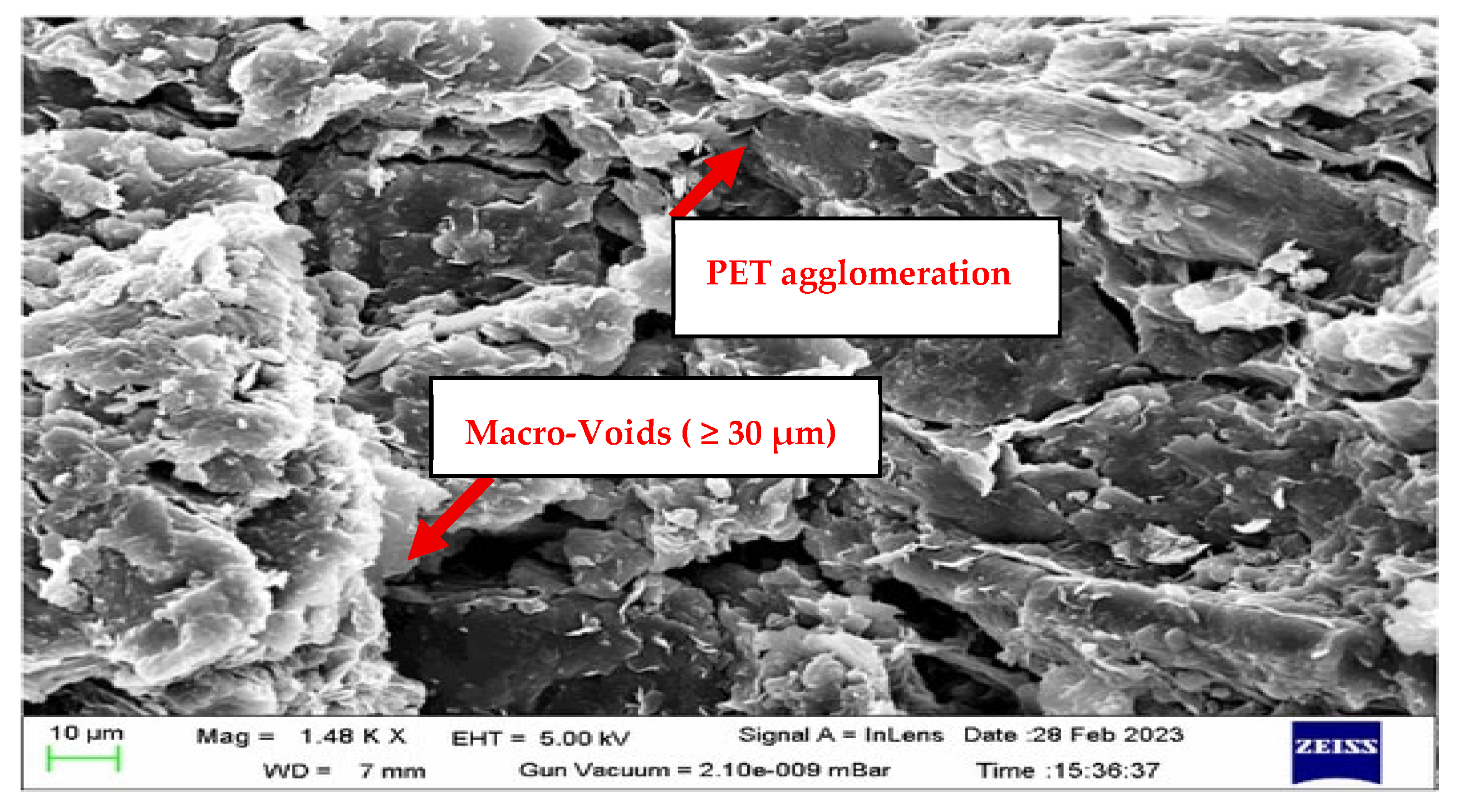

The slight reduction in performance observed at a 1.2% PET fibre content can be attributed to fibre agglomeration and inadequate dispersion within the soil matrix. At low to moderate PET dosages, individual fibres distribute uniformly and act as discrete reinforcement elements, bridging microcracks and refining the pore structure. However, as the fibre volume fraction increases beyond a critical threshold, the specific surface area and inter-fibre friction also increase, making it more challenging to achieve homogeneous mixing [

28]. This results in the clumping or entanglement of fibres, forming localised fibre balls and macrovoids, as also visible in the SEM micrographs.

These agglomerated zones reduce the effective contact area between fibres and soil particles, interrupting the load-transfer mechanisms and creating stress concentration points that weaken the matrix instead of strengthening it. Moreover, excessive PET fibres can reduce workability and compaction efficiency, lowering the overall dry density and increasing the likelihood of interconnected pore networks [

29]. This explains why the UCS and CBR values are maximum at 1.0% PET and then slightly declined at 1.2%, despite the higher fibre content. Comparable trends have been observed in polypropylene and coir fibre systems, where higher fibre contents tend to cause fibre entanglement and weaker bonding with the soil matrix [

14,

28,

29].

The mechanical performance of PET-fibre-reinforced soils observed in this study is comparable to or slightly better than that of other commonly used fibre types, such as polypropylene and coir fibres, at similar dosage ranges. For example, polypropylene fibre reinforcement in clayey soils has been reported to improve the UCS by 35–50% and the CBR by up to 150% at fibre contents between 0.5% and 1.5% [

30]. In this study, PET fibres achieved an approximately 37% improvement in UCS and a 125% increase in CBR at a dosage of 1.0%, which falls within the same performance envelope. Unlike virgin polypropylene fibres, PET fibres are sourced from post-consumer waste, making them more cost-effective and environmentally friendly.

When compared to traditional stabilisers such as cement and lime, PET fibre reinforcement offers distinct advantages. Cement- and lime-treated soils can yield higher compressive strengths, but often exhibit brittle failure modes, higher shrinkage cracking potential, and higher embodied carbon [

31]. PET fibres, in contrast, enhance ductility, control swell–shrink behaviour, and improve residual strength without introducing chemical reactivity into the soil matrix [

32]. This provides an effective, low-carbon stabilisation pathway aligned with sustainable infrastructure goals

4.6. Differential Free Swell Behaviour

The soil exhibited a high DFSI of 55%, which was reduced to 46.9% (~15% reduction) at a PET content of 0.8–1.0%, demonstrating effective swell mitigation. However, at 1.2% PET, the DFSI increased slightly to 48%, suggesting that the improvement in swelling control became less pronounced at higher fibre contents. At low dosages, the high-aspect-ratio PET strips interlock with the clay fabric, exerting tensile confinement on clay platelets during hydration. This physical “bridging” effect plays a crucial role in restricting the vertical expansion by impeding the osmotic swelling mechanism.

The inclusion of PET fibres physically restricts swelling by impeding water movement and reducing void connectivity, which indirectly limits the development of moisture-induced expansion in the clay matrix [

16]. Similar reductions in free-swell potential, ranging from 10% to 20%, have been observed in polypropylene-fibre-reinforced expansive soils with fibre contents between 0.5% and 1.5%, which are attributed to fibre–water interactions and steric hindrance of clay interlayers [

33,

34]. Although the reduction in swelling may be partly associated with changes in the soil’s electrochemical environment (e.g., reduced diffuse double layer expansion), such effects were not directly measured in this study. They should be explored in future work using methods such as zeta potential or pore-water chemistry analysis.

However, the slight increase in DFSI at 1.2% PET indicated the onset of fibre agglomeration, which led to the formation of macrovoids within the soil matrix. These macrovoids allow localised water ingress, which can lead to swelling in specific areas of the soil. The fibre agglomerates disrupt the uniform distribution of PET throughout the soil, thereby diminishing its effectiveness in reducing swelling and creating pockets of excess moisture that contribute to localised expansion. This observation emphasises the importance of maintaining an appropriate PET dosage to balance fibre reinforcement with effective swelling control, ensuring that the fibre content remains within the range where beneficial effects dominate and excessive fibres do not adversely affect soil performance.

4.7. Microstructural Behaviour

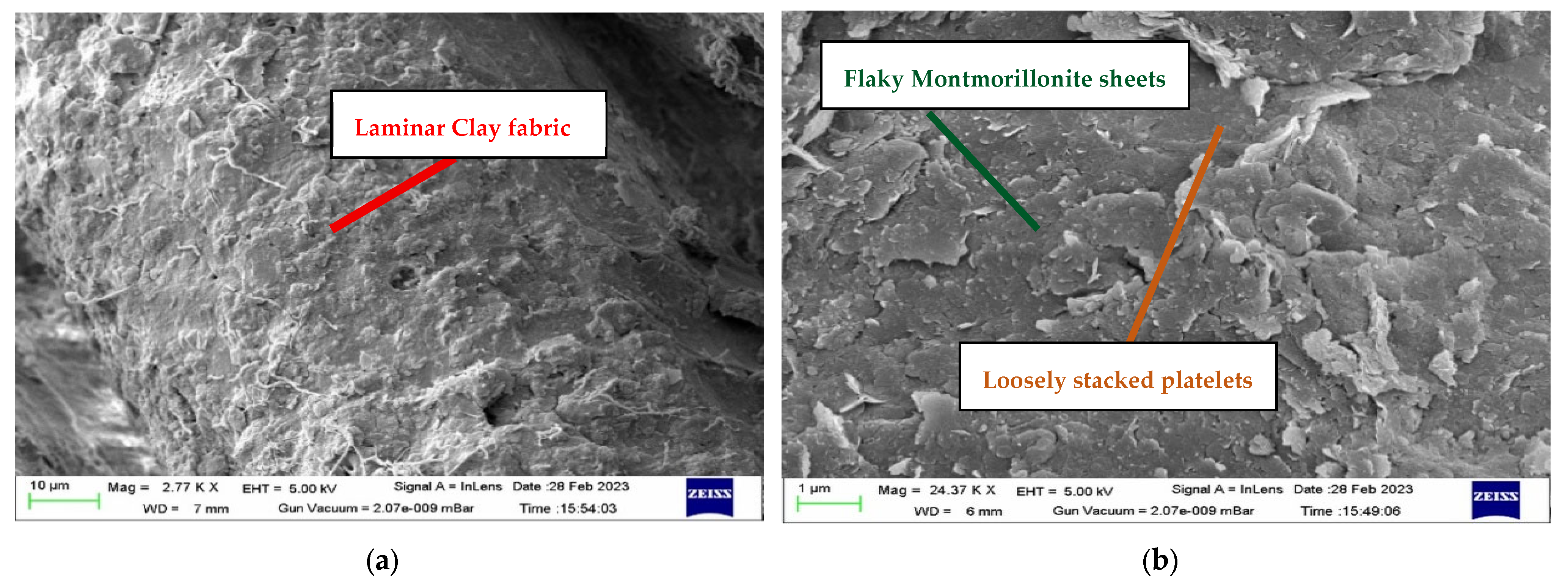

The SEM examination of the untreated soil (

Figure 10) revealed a laminar clay fabric with loosely arranged montmorillonite platelets. The presence of mesovoids measuring 2–5 µm provides microstructural evidence of the expansive nature of the soil. The presence of these voids allows water to be absorbed more easily, leading to swelling that corresponds to the high differential free-swell index (DFSI) of the soil (approximately 55%). The structural arrangement of these clay platelets, along with the mesovoids, contributes to the low Unconfined Compressive Strength (UCS) of the soil, which was found to be approximately 200 kPa. The loose arrangement and high porosity within the soil matrix resulted in reduced resistance to compressive loads, leading to the observed low UCS values. These microstructural features are key to the expansive behaviour of the soil, as they facilitate the uptake of water and subsequent volumetric changes, making it susceptible to swelling in response to variations in moisture.

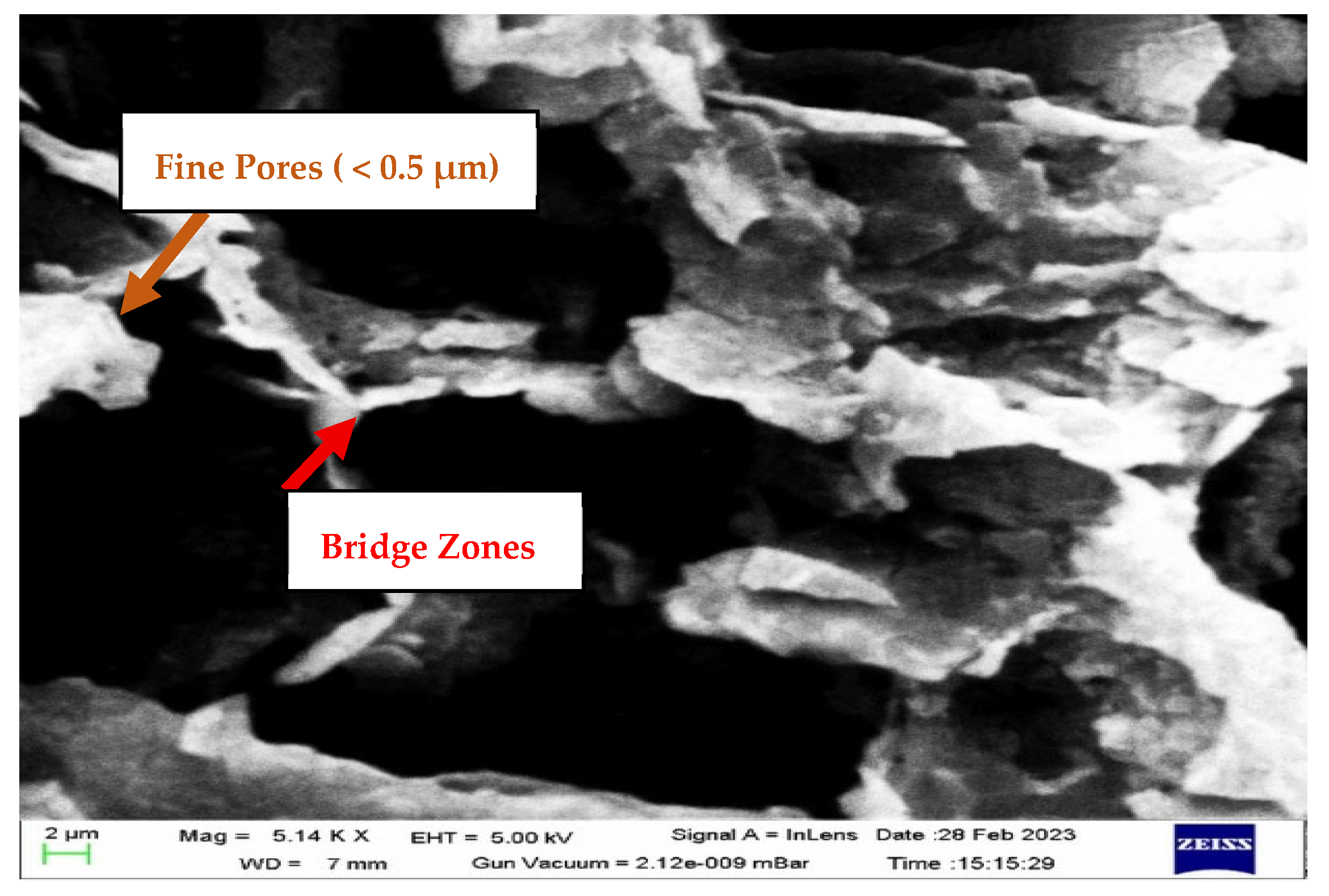

SEM of the soil treated with 1% PET fibres (

Figure 11) revealed a three-dimensional tensile skeleton with bridge zones, where the fibres effectively anchored clay clusters. This network enhanced stress transfer, suppressed microcrack initiation, and improved overall structural integrity. The PET fibres also contribute to the refinement of the soil microstructure by reducing the size of intra-aggregate pores, particularly those smaller than 0.5 µm. This results in a denser and more compact soil matrix, which is reflected in the enhanced geotechnical properties observed. The increased density, facilitated by the improved fibre–soil interaction, aligns with the maximum values of CBR (4.5%) and UCS (275 kPa) achieved at a 1% fibre dosage. These improvements in strength and load-bearing capacity demonstrate the reinforcing effect of PET fibres, which act as both physical and mechanical reinforcements, enhancing the soil’s ability to withstand external loads while mitigating its expansive behaviour.

SEM of the soil with 1.2% PET (

Figure 12) revealed fibre agglomeration and macrovoids exceeding 30 µm, which disrupted the uniform distribution. The presence of these macrovoids effectively offsets the additional bridging mechanisms observed at lower fibre dosages, as the fibres are unable to form continuous connections throughout the soil matrix. As a result, the strength of the soil, as indicated by both the Unconfined Compressive Strength (UCS) and CBR, decreases, and the Differential Free-Swell Index (DFSI) rebounds slightly, suggesting a reduction in the capacity of the fibres to mitigate swelling. This behaviour indicates that when the PET fibre content exceeds about 1.0%, additional fibres provide limited improvement, as fibre agglomeration and void formation reduce the overall stabilisation benefits. Maintaining an appropriate fibre dosage is therefore important for achieving consistent reinforcement.

The SEM observations provide strong microstructural evidence to support and explain the macroscopic mechanical behaviour of PET-fibre-reinforced expansive clay. In the unreinforced soil, the laminar clay fabric exhibits loosely packed montmorillonite platelets and interconnected mesovoids (2–5 µm), which facilitate water ingress, increase swelling susceptibility, and limit load transfer capacity—consistent with the lower UCS (200 kPa) and higher DFSI measured in the control mix [

14].

At the 1.0% PET content, the SEM images reveal a three-dimensional tensile bridging network formed by well-distributed fibres. These fibres effectively interlock with clay aggregates, fill intra-aggregate voids, and refine the pore structure (dominant pore size < 0.5 µm). This pore densification and fibre–matrix bonding result in enhanced stress transfer efficiency, explaining the 37% increase in UCS and 125% increase in CBR, as well as the notable reduction in DFSI [

17].

At higher PET contents (1.2%), SEM micrographs reveal fibre agglomeration and the presence of macrovoids (>30 µm), which disrupt the uniform load-bearing skeleton and reduce interfacial bonding efficiency. This corresponds to a decline in strength from 274 kPa to 260 kPa, accompanied by a slight rebound in swelling, as observed macroscopically. These results align with previous studies that report reduced reinforcement efficiency at high PET fibre dosages due to poor dispersion and void development [

18].

Overall, the SEM observations indicate a micro–macro relationship in which (i) the formation of a fibre-bridged tensile network and pore refinement at moderate dosages correspond to improvements in strength and durability, while (ii) fibre agglomeration and macrovoid formation at higher dosages are associated with a reduction in mechanical performance. This relationship between microstructural features and overall behaviour is consistent with previous studies on fibre-reinforced expansive soils [

31].

4.8. Resource Implications

In addition to improvements in mechanical and microstructural performance, the findings of this study contribute to sustainable resource utilisation and support the transition toward a circular materials economy. The following discussion elaborates on the environmental, lifecycle, and policy-oriented implications, fulfilling both engineering and sustainability perspectives.

4.8.1. Environmental Burden of Cement-Based Stabilisation

Cement production remains among the highest carbon-emitting industrial activities, contributing approximately 8% of global anthropogenic CO

2 emissions [

3]. The manufacture of one ton of Ordinary Portland Cement (OPC) results in nearly 0.9 tons of CO

2 emissions due to the calcination of limestone and combustion of fossil fuels [

35]. This is particularly concerning in large-scale infrastructure development over expansive soils, where cement demand is high. Traditional soil stabilisation methods, relying on OPC or lime, further intensify this environmental burden due to the depletion of non-renewable mineral resources and the energy-intensive processing required. The incorporation of shredded Polyethene Terephthalate (PET) fibres as an alternative stabiliser presents a technically feasible, low-carbon solution. By reducing reliance on cementitious binders, PET fibre reinforcement contributes to lowering the carbon footprint of stabilisation works and supports the transition toward more sustainable and resource-efficient ground improvement methods.

4.8.2. Transition to Sustainable Resource Utilisation

Shifting from virgin mineral-based stabilisers to recycled PET waste represents a paradigmatic shift in resource utilisation, aligning with the principles of the circular economy. PET is globally abundant but underutilised, particularly in countries where recycling infrastructure is insufficient [

7]. Landfilling and incineration of PET waste not only strain waste management systems but also result in long-term ecological harm. The integration of PET fibres into expansive clay soil introduces a high-value reuse pathway, mitigating the need for resource-intensive binders while simultaneously reducing the volume of plastic waste that enters the environment. This strategy conserves finite natural resources and addresses two critical challenges simultaneously: sustainable construction and plastic pollution mitigation.

4.8.3. Valorisation of Post-Consumer PET in Engineering Applications

PET is one of the most widely consumed thermoplastics, with global production exceeding 400 million metric tons annually [

4]. Despite its vast production scale, the effective recycling rate of PET remains below 10% in many regions [

8]. The current study proposes a novel valorisation pathway that utilises shredded PET fibres directly in soil stabilisation, thereby preserving the mechanical strength of the material and eliminating the need for energy-intensive reprocessing. This functional reuse represents an advanced form of upcycling, where waste is not merely disposed of or downcycled, but rather reintegrated into infrastructure systems. Such valorisation of plastic waste exemplifies sustainable engineering practices and reinforces the connection between waste management and civil infrastructure.

4.8.4. Lifecycle Efficiency and Long-Term Resource Conservation

PET fibre stabilisation can reduce the frequency of infrastructure maintenance, particularly for roads, pavements, and shallow foundations constructed on expansive soils. Improved durability and reduced susceptibility to moisture-driven deformation decrease the frequency and scale of repair interventions. This reduction lowers the cumulative demand for aggregates, bitumen, water, fuel, and labour resources over the infrastructure’s lifespan. In low- and middle-income regions with limited economic and material resources, such lifecycle efficiency enhances the viability of sustainable infrastructure systems, contributing to long-term cost savings and resilience.

4.8.5. Alignment with Global Sustainability Goals and Policy Frameworks

This research aligns with several global policy frameworks and environmental targets. The reduction in OPC consumption directly supports Sustainable Development Goal (SDG) 13: Climate Action, while the reuse of PET waste aligns with SDG 12: Responsible Consumption and Production. By enhancing the resilience and longevity of infrastructure, especially in rapidly urbanising areas with challenging soil conditions, the findings also support SDG 11: Sustainable Cities and Communities [

3]. The alignment of technical feasibility with policy direction ensures that the proposed method is not only scientifically robust but also institutionally implementable.

4.8.6. Global Replicability and Scalability of the Approach

The methodology demonstrated in this study—comprising mechanical shredding and uniform mixing of PET fibres into the soil—requires neither high-end laboratory facilities nor specialised equipment. This simplicity allows for easy adoption in resource-constrained regions where expansive soils are prevalent and waste accumulation is severe. The accessibility and cost-effectiveness of the approach make it ideal for sustainable development initiatives in both urban and rural contexts. The results presented here provide a blueprint for integrating waste reuse into mainstream engineering practice, thereby democratising access to sustainable materials technology and promoting scalable implementation.

5. Conclusions

This study systematically investigated the potential of shredded polyethene terephthalate (PET) fibres as a sustainable reinforcement material for stabilising expansive clay soils. The geotechnical and microstructural results indicated that the inclusion of PET fibres enhanced soil performance up to a dosage of 1.0% by dry weight.

Key findings are summarised as follows:

The addition of PET fibres increased the OMC from 17.0% to 18.4% and reduced the MDD from 16.9 to 16.2 kN/m3, reflecting the influence of low-specific-gravity fibres on compaction behaviour.

Mechanical strength parameters exhibited notable improvement at 1.0% PET fibre content: UCS increased by 37% (from 200 kPa to 274 kPa), unsoaked CBR improved by 125% (from 2.0% to 4.5%), and soaked CBR increased from 1.2% to 2.8%, representing more than a twofold gain in bearing capacity under saturated conditions. These enhancements are attributed to the tensile bridging network formed by the PET fibres, which improves soil cohesion, restricts deformation, and promotes more efficient load transfer.

The DFSI decreased by about 15%, indicating a noticeable reduction in swelling potential. SEM analysis showed a refined pore structure, improved fibre–soil interlocking, and reduced microcrack formation at the 1.0% PET content.

Beyond 1.0% PET, performance showed a slight decline, likely due to fibre agglomeration and the formation of macrovoids, indicating the importance of maintaining an appropriate fibre dosage to prevent reduced effectiveness.

Microstructural analysis validated the mechanical trends by confirming the formation of a well-distributed three-dimensional tensile matrix at 1.0% PET, and a disrupted fabric at 1.2% PET.

Importantly, this research highlights critical implications for resource sustainability. The use of recycled PET not only diverts plastic waste from landfills and oceans but also reduces dependence on carbon-intensive stabilisers, such as Ordinary Portland Cement. The proposed method advances both waste valorisation and material circularity, providing a dual environmental benefit. Furthermore, the extended durability and reduced swelling potential of the stabilised soil can lower long-term maintenance needs, resulting in substantial material, energy, and cost savings throughout the infrastructure lifecycle.

In conclusion, shredded PET fibre reinforcement represents a low-carbon, scalable, and eco-efficient alternative for stabilising expansive soils. The findings contribute directly to achieving United Nations Sustainable Development Goals (SDGs), especially SDG 11 (Sustainable Cities and Communities), SDG 12 (Responsible Consumption and Production), and SDG 13 (Climate Action). Future studies should investigate the long-term durability of PET-reinforced soils under varying environmental conditions and employ advanced imaging techniques, such as X-ray micro-CT, to further examine fibre orientation and pore network dynamics.