Abstract

Currently, the recovery of resources from urban wastewater (WW) represents a priority. On this topic, the potential recovery of cellulose for its subsequent reuse in different sectors is gaining interest. In this work, a large-size conventional wastewater treatment plant (WWTP) was selected as a case study. A preliminary mechanical treatment was used, with the aim of separating, quantifying, and characterizing cellulose in WW. The results suggest that the per-capita production of dry primary cellulosic sludge (D-PCS) is equal to 1.46 ± 0.13 kgD-PCS PE−1 y−1, with an average calorific value of 21.04 MJ kg−1DM. Cellulosic fibres have an average length of >100 µm and a thickness of 2–5 µm. The D-PCS was subsequently treated via medium-temperature pyrolysis; a total of 29.5% of the initial D-PCS was converted into pyrolyzed primary cellulosic sludge (P-PCS) and only 26% into pyrolytic gas. More than 44.5% of the dried cellulose can be converted into pyrolytic oil. Moreover, three different scenarios of recovery have been considered, and the impact of cellulose separation in terms of COD fluxes entering the WWTP and potential energy recovery has been studied. The results suggested that, in this case study, the potential separation of the primary cellulosic sludge from the influent water flux would have no significant impact on COD load entering the biological treatments and biogas production in the anaerobic digestion of the secondary sludge.

1. Introduction

The management of wastewater (WW) has undergone changes due to emerging global trends related to resource availability. Wastewater treatment plants (WWTPs) have evolved from being solely purification facilities to also encompassing the reuse of resources derived from WW [1]. In recent years, to address the challenge of reducing energy consumption during the aeration process and minimizing the production of excess sludge, the removal of part of the organic carbon prior to the biological treatment stage has gained importance [2,3].

In this sense, cellulose can play a key role. Its source in urban WW is mainly toilet paper (TP) [4], and the predicted per-capita annual consumption of TP in 2023 is estimated to be almost 5.98 kg, with differences depending on the country [5]. Within WW, cellulose originating from TP in Western European countries constitutes a significant portion of the primary cellulose sludge (PCS), accounting for 60–80% of the total content [6,7]. The remaining components include hair, sands, clay, and inorganic salts [8]. While the installation of technologies for collecting cellulose fibres has been proposed for WWTPs, they have not been very commonly applied to date.

Cellulose is generally an appealing product because it can be reused for green energy production, such as for biogas production in anaerobic reactors, as a bioenergy source in the form of pellets, and for bioethanol production [9,10,11,12]. Additionally, it can be utilized as a raw material to produce biomaterials such as bioplastics, recycled paper, and building materials [13,14,15,16,17]. Cellulose, as an abundant organic compound, possesses substantial energy potential and can also be effectively used to produce biofuels when adequately separated and refined [18]. The specific heat capacity of cellulose in PCS is 1.55 kJ kg−1 °C−1 [8]. Via the hydrothermal carbonization method, the calorific value of row cellulose is estimated to be 16.5 MJ kg−1 on a dry basis [19].

Also, medium-temperature pyrolysis (MTP) is a viable approach for the transformation of materials containing a significant amount of organic matter [20,21]. Pyrolysis is a thermochemical reduction process that converts PCS into three products: (i) a solid carbonaceous product with a high carbon content; (ii) pyrolysis oil (P-oil), which is a mixture of water and oil; and (iii) pyrolysis gas (P-gas) [21,22]. The obtained solid carbonaceous product has various applications, such as its use in agriculture as an additive to improve soil properties, soil fertilization, and water retention in the landscape due to its significant hygroscopic properties [21,23,24]. A key parameter in the MTP of cellulose is the residence time, which can influence the pathways of transformation of cellulose [25]. Detailed designs of installations, technologies, and facilities for the MTP of cellulose from WW are the subjects of ongoing research, as is the definition of the pyrolysis product manufacturing process.

The cellulose extraction methods used in WWTPs are characterized by their simplicity and effectiveness and determine several advantages in the management of WWTPs such as: (i) reduction of chemical consumption; (ii) lower electricity consumption during aeration; (iii) diminished probability of phosphate release; and (iv) lower sludge volumes. Consequently, these advantageous factors contribute to a reduction in the costs of WWTP management [15]. Within the activated sludge tank, a reduction in the load of organic matter fed leads to an augmentation in treatment capacity and a notable decrease in energy consumption for aeration [26,27]. A significant reduction in the volume of excess sludge was also observed [28].

In the literature, several methods have been proposed for cellulose separation from WW, such as rotating bed filters and membranes [27,28]. However, studies on the impact of cellulose removal on the operation of WWTPs mainly focused on the amount of oxygen required for oxidation and the amount of sludge produced [27], but few data are available in terms of impacts on COD fluxes and potential energetic valorisation of sludge.

This work aims to provide results about the recovery of cellulose in a conventional WWTP, used as case study, via a preliminary treatment of mechanical separation. The primary cellulosic sludge was quantified, characterized, and subsequently treated via MTP. Three different scenarios of recovery were taken into account, and the impact of cellulose separation in terms of COD fluxes entering the WWTP, and potential energy recovery have been studied. This work does not aim to focus on cellulose separation methods but on the evaluation of its energy value and valorisation in MTP. This work also aims to analyse and discuss the impact of the whole PSC separation process on the energy and mass balance of the WWTP. These results will be useful for (i) the scientific community, providing important information about cellulose amount and characteristics in WW, and for (ii) water utilities, providing preliminary details about the impact of cellulose separation and recovery in conventional WWTPs.

2. Materials and Methods

This work was divided into three steps: (i) the evaluation of the separation of cellulose; (ii) the recovery as a carbonaceous product after MTP; and (iii) the analysis of the impact of cellulose separation in terms of COD fluxes in the WWTP.

2.1. Cellulose Separation

The WW used in the tests was sampled at the urban WWTP of Brno-Modřice. The plant is a large-size WWTP (530,000 population equivalent—PE) and serves the Brno metropolitan area (Czech Republic) with an average WW inflow of 1.1–4.2 m3 s−1. Influent WW presented a content of organic matter and nutrients typical of urban sewers. The daily average samples were taken on the same days in which the separation of cellulose from WW was performed. The main characteristics of the influent WW and the flowrate are reported in Table 1. The plant presents a conventional scheme with a gravel grit trap, fine screens, an aerated sand grit trap with grease separation, a primary settling tank, and secondary biological treatment as a conventional activated sludge system (CAS) for the removal of organic carbon and nitrogen. Phosphorus was removed via the addition of ferric sulphate when necessary. Details about the WWTP scheme are reported in Figure S1.

Table 1.

Basic parameters of the inflow to WWTP Brno-Modřice during the days of tests. u.m.: unit of measure; EC: electrical conductivity; TSS: total suspended solids; TDS: total dissolved solid; AOX: adsorbable organic halides. (number of samples: 4).

The rotary drum screen device SVSLS (Fontana R s.r.o., Brno, Czech Republic) (microsieve size: 0.3 mm) was installed after the sand and grease trap and before the primary settler as a mechanical pretreatment of the plant. The device was operated for approximately 4 h per day for a duration of 4 days.

The WW was pumped onto the screen device (Q = 150 L min−1). The filtered WW (permeate) continued to flow into the water line of the WWTP while the PCS was collected separately. Visual observation revealed that the PCS extracted via the rotary drum screen still contained food waste residues. To remove these impurities, PCS was manually screened for laboratory analysis via a two-stage system (sieve size: 2 mm and 0.4 mm). The treated PCS (T-PCS) was then solar dried to reduce the water content of the matrix (D-PCS). The time required to reach a constant weight of the dried sample was 2 to 4 days, depending on weather conditions.

2.2. Pyrolytic Tests

Before pyrolytic tests, samples of D-PCS were pelletized using the press JGE 230 (Green Energy Machine Product s.r.o., Vlčnov, Czech Republic) up to 6 mm in diameter.

The pyrolysis unit was equipped with a stainless-steel cylindrical reactor with a volume of approximately 10 L, operating at process temperatures ranging up to 600 °C. In each test, 3 kg of D-PCS was loaded. The reactor was conventionally heated via a wire thermocouple connected to a power source. To ensure an inert environment before and after the experiment, the entire unit was connected to a pressure vessel containing inert gas, and the system was flushed prior to the experiment.

During the process, the pyrolytic gases from the reactor were directed through an outlet pipe to a condenser, where they condensed and were captured in the form of pyrolytic oil. The remaining vapours were directed to a laboratory combustion device.

2.3. Analytical Methods

The quality of the influent WW was assessed using Standard Methods for the Examination of Water and Wastewater [29].

In regard to the PCS, the energy efficiency of the samples was measured using a combustion test in laboratory conditions using the semi-automatic device IKA C 200 (IKA-Werke GmbH & Co., Staufen im Breisgau, Germany), in accordance with the standard EN ISO 1716 [30]. The analyses were performed in triplicate, with a maximum allowable deviation of 1%.

Heavy metals (As, Cd, Cr, Cu, Ni, Pb, Hg, V, and Zn) and total phosphorus in T-PCS and D-PCS samples were analysed using to ČSN EN ISO 11885 [31], ČSN EN 13657 [32], and ČSN 46 5735 [33] methods. The dry matter (DM) was determined using to ČSN EN 12879 [34] and ČSN EN 12880 [35] methods, while the pH was measured using ČSN EN 12176 [36] method.

T-PCS samples were analysed using the Eclipse E200 (Nikon, Tokyo, Japan), with a magnification of ×200; colour images were captured using the DS-Fi3 camera (Nikon, Japan).

2.4. Evaluation of the Scenarios

To evaluate the impact of cellulose recovery in the management of the WWTP in terms of COD fluxes and energy recovery, three scenarios were evaluated, depending on the percentage of cellulose supposed to be recovered:

- Scenario 1 (S1): 100% of the cellulose is recovered. Given the application of a multiple-stage mechanical separation system, the cellulose separation from WW flux in this study is assumed to be close to complete.

- Scenario 2 (S2): 75% of the cellulose in the WW is separated and recovered.

- Scenario 3 (S3): Only 50% of the cellulose in the WW is separated and recovered.

In every scenario, the amount of pyrolyzed PCS (P-PCS) is defined based on the results of the tests made with a lab-scale reactor.

3. Results and Discussion

3.1. Cellulose Separation and Characterization

Almost 115.2 m3 of WW was pumped through the rotary drum screen for PCS extraction. Approximately 3 kg of D-PCS was obtained during this period, resulting in the production of almost 0.026 kg m−3 wastewater.

Within the scope of this research, further characterization of PCS and T-PCS was conducted to verify their potential for material and energy utilization. Table 2 shows the results of the characterization performed on PCS and T-PCS.

Table 2.

Characteristics of separated PCS and T-PCS. SD: standard deviation; DM: dry matter; ROI: residue on ignition on 550 °C; LOI: loss on ignition; Total P: total phosphorus, TOC: total organic carbon. n: number of samples; n.e.: not evaluated.

The evaluation showed that the DM in the mechanically extracted samples of PCS was 14.6 ± 1.5%. This parameter is crucial for determining the optimal approach and technology for PCS dewatering [37]. In fact, to reduce the costs and drying time of PCS, achieving the highest possible DM content of PCS is highly suggested. For this reason, samples of T-PCS were then solar dried (S-PCS), reaching 92.5 ± 9.3%. Based on the results, the concentration of organic matter in the form of cellulose does not affect the pH value. These values (7.4 ± 0.2) are similar to those found in the influent of the WWTP (Table 1).

The high values of LOI (94.5 ± 9.5%DM) in PCS are due to the high proportion of organic matter in the samples. Comparing results with T-PCS, a slightly lower value after two-stage sieving was reported (83.2 ± 4.2%DM), probably due to the removal of food residues by the refinement treatment. The concentration of heavy metals (HMs) in PCS is influenced by the presence of HMs in WW [21] and, considering only a mechanical process of separation as performed, no significant differences in HMs concentration in PCS and T-PCS were highlighted. Since the process temperature of pyrolysis does not significantly affect the HMs concentration [21], the HMs in the T-PCS are assumed to reflect the content in the P-PCS.

The average calorific value resulting from the combustion test on the T-PCS was reported as 21.04 MJ kg−1DM. This differs from the value found by Kim et al. [19,38] (16.50 MJ kg−1DM) for the cellulose alone. This could be explained by the fact that T-PCS contains at least 60% cellulose but also other organic matter with high energy value, such as hemicellulose, lignin, and oil [8].

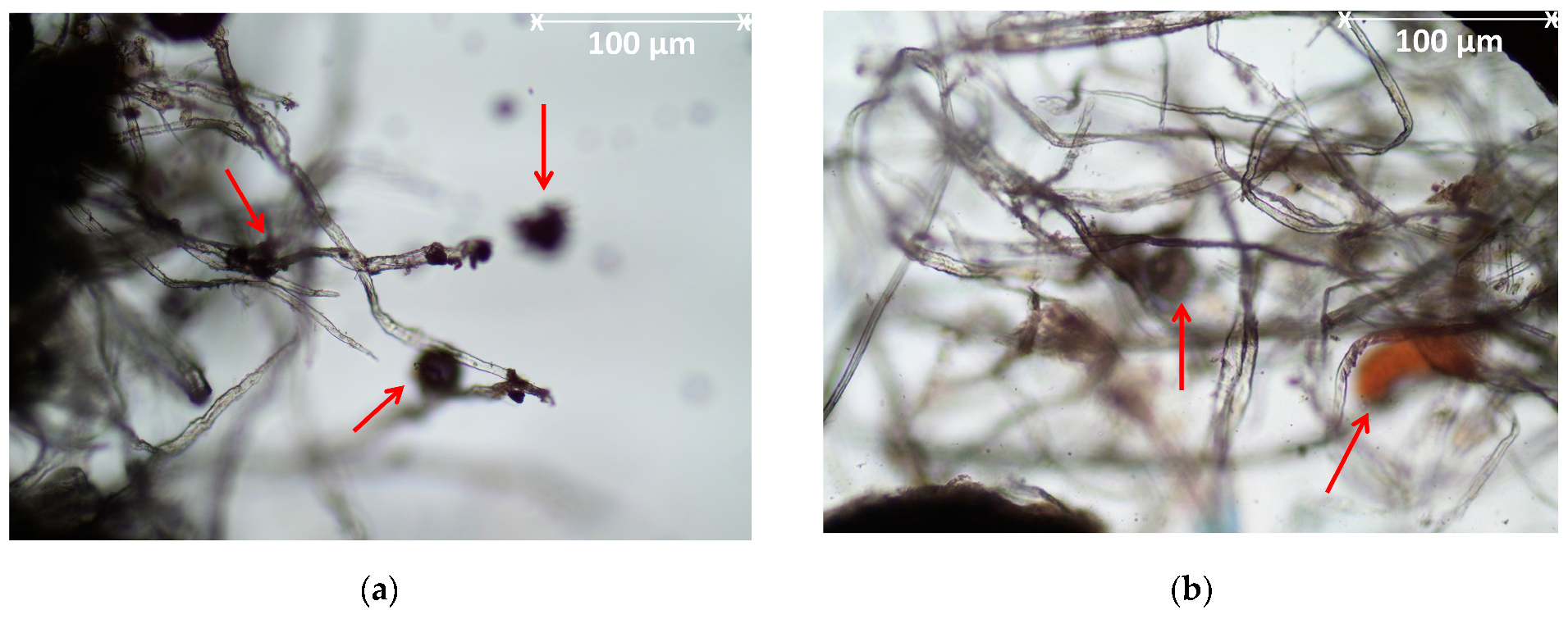

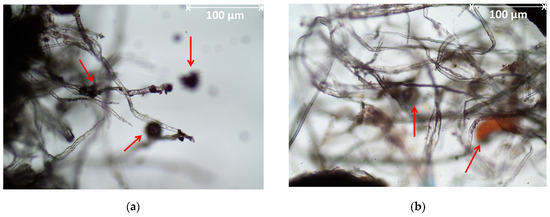

The analysis of D-PCS showed the presence of cellulosic fibres with, on average, a length > 100 µm and a thickness equal to 2–5 µm (Figure 1). These values are not very different from those from Ruiken et al. [28], who reported that the fibres of toilet paper in WW are 1–1.2 mm in length. These values are also similar to those of various types of toilet paper before use, suggesting that the dimension of the fibres remain consistent during transport in the sewer system [28].

Figure 1.

(a,b): Microscope images (200×) of D-PCS. Red arrows indicate some impurities that remain after the manual screening.

Despite the presence of a two-stage system, the analysis suggested the presence of impurities that are not retained by the mesh (sieve size up to 0.4 mm). However, further studies are necessary to completely characterize them.

3.2. Production of Carbon-Based Material from Medium-Temperature Pyrolysis

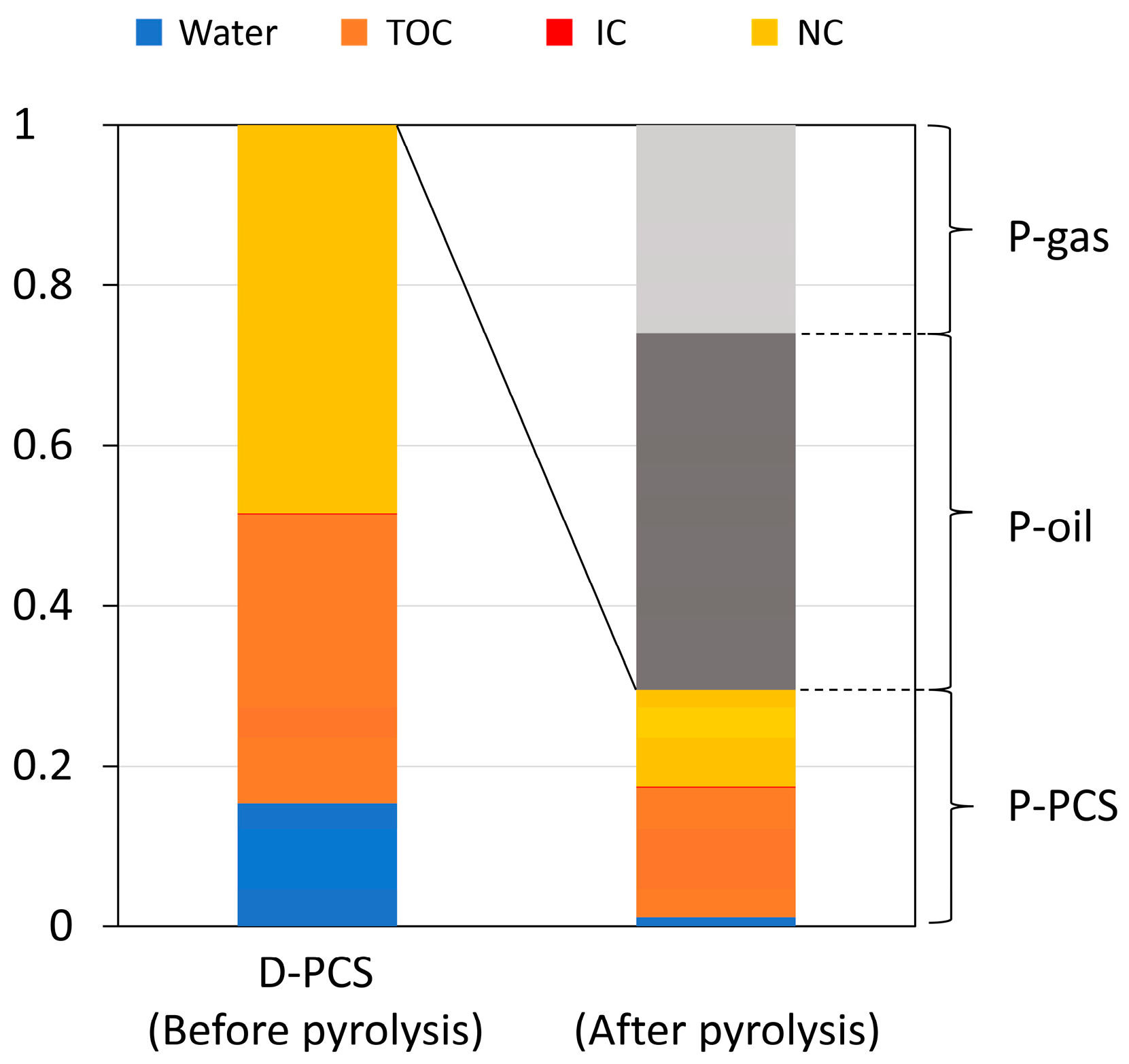

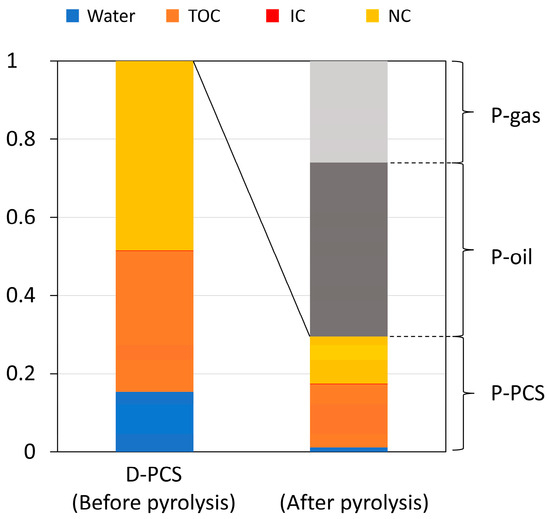

The D-PCS was subjected to a medium temperature pyrolysis process to obtain P-PCS (Figure 2).

Figure 2.

(a) D-PCS and (b) P-PCS (before and after the pyrolytic process, respectively).

Almost 50% of the total weight (more than 60% of the DM) is composed of non-organic content. A total of 99.6% of the total carbon (TC) in the D-PCS is of organic origin (TOC).

Looking at the mass fluxes (Figure 3), 29.5% of the initial D-PCS was converted to P-PCS, but only 26% into pyrolytic gas. More than 44.5% of the dried cellulose was converted into pyrolytic oil. In this study, the characteristics of pyrolytic oil and gas (P-oil and P-gas, respectively) have not been analysed because this was outside of the scope of our research. Regarding the properties of the P-PCS, it can be assumed that the contents of HMs and inorganic matter remain the same as those of the D-PCS, considering pyrolysis is generally not able to convert these forms [21].

Figure 3.

Composition of the PCS before and after pyrolysis and percentage of P-oil and P-gas with respect to the initial mass. Light and dark grey represent P-gas and P-oil, respectively. TOC: total organic carbon; IC: inorganic carbon; NC: non-carbonic matter; P-oil: pyrolysis oil; P-gas: pyrolysis gas.

3.3. Production of D-PCS and P-PCS: Estimation in the Case Study

Considering the specific D-PCS production (according to the experimental tests, almost 0.026 kg m−3) and taking into account that the daily inflow of the WWTP during the period of monitoring was 81,688 ± 7203 m3 d−1, the amount of D-PCS that can be extracted is 2.13 ± 0.19 tD-PCS d−1. The per-capita production is therefore equal to almost 1.46 ± 0.13 kgD-PCS PE−1 y−1.

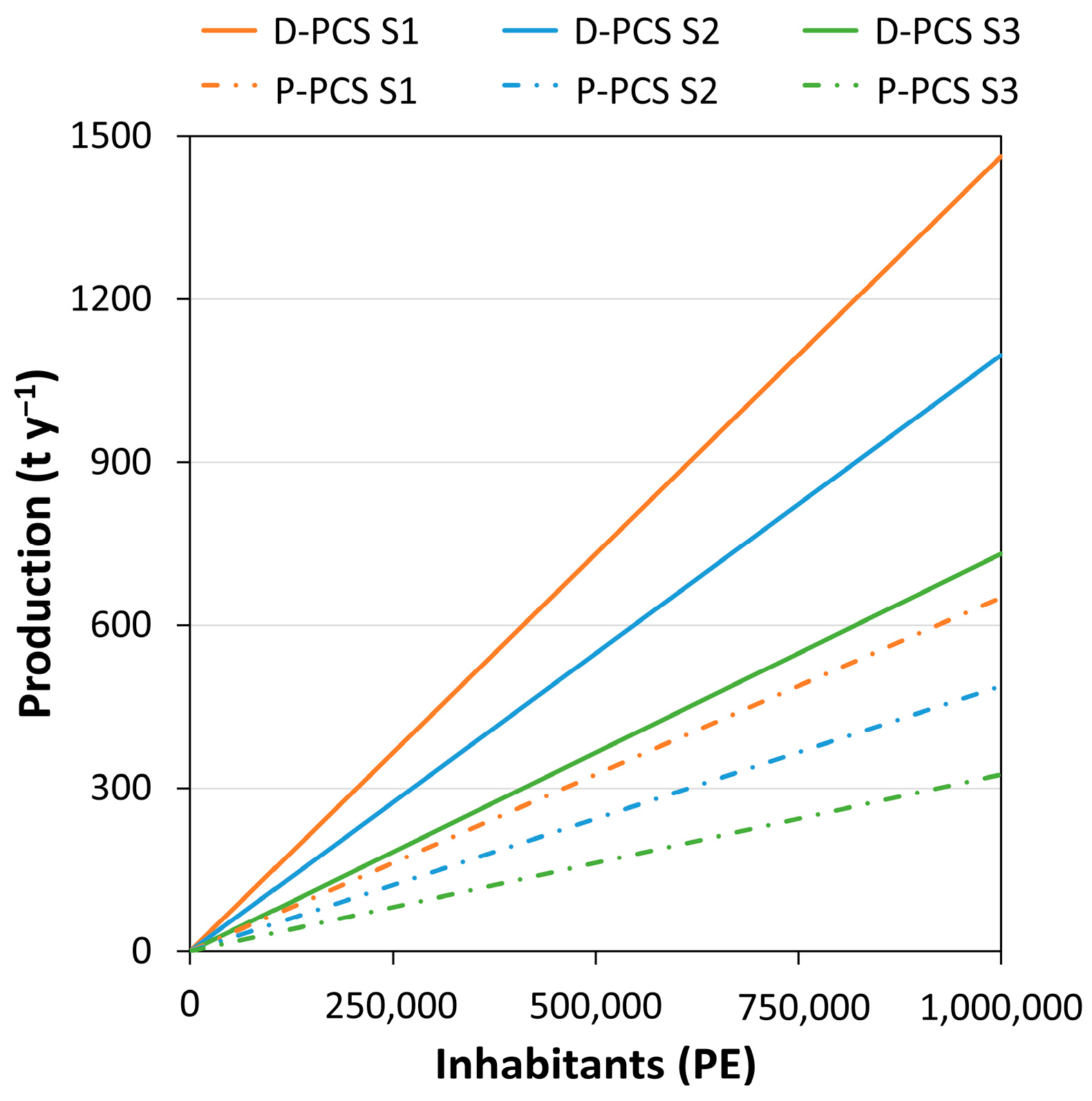

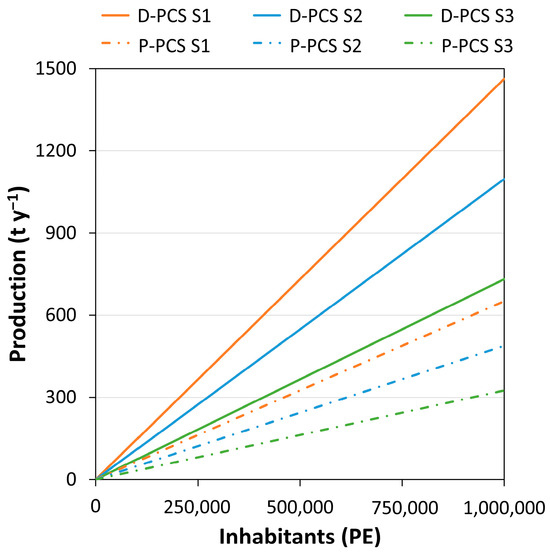

In Figure 4, the production of D-PCS and P-PCS is presented as a function of the PE served, in scenarios S1, S2, and S3. The difference between the diverse scenarios is represented by the amount of cellulose that can be potentially recovered.

Figure 4.

Production of D-PCS and P-PCS as a function of the inhabitants served in scenario 1 (S1), scenario 2 (S2), and scenario 3 (S3).

The amount of material can be very significant, especially in the case of medium- or large-size WWTP. As can be seen, also considering a partial separation of the cellulose (S2—75%) and a medium-size WWTP (500,000), almost 600 tD-PCS y−1 can be separated and more than 200 tP-PCS y−1 can be produced, if D-PCS is subjected to MTP.

3.4. Impact of Cellulose Separation on the Operation of the WWTP

3.4.1. COD Fluxes

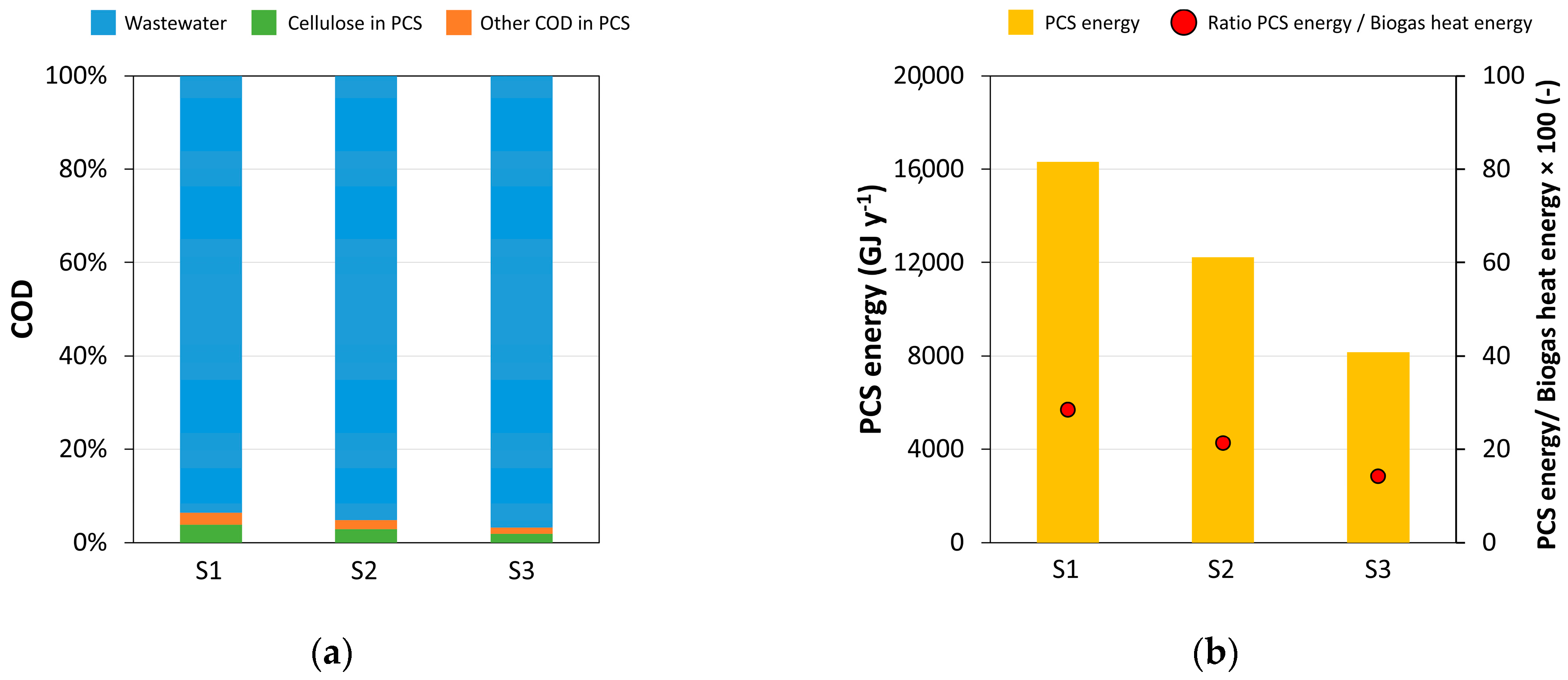

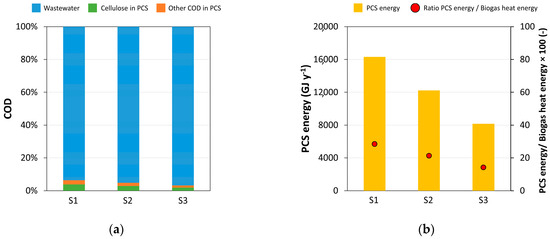

The fluxes of COD were studied in the case of the mechanical separation of the cellulose (Figure 5a). The evaluations were performed assuming the following: (i) the theoretical relation of 1.15 gCOD g−1toilet paper (in this case, D-PCS represents the toilet paper) [6,39] and (ii) only 60% of the PCS consists of TP [8].

Figure 5.

(a) Fluxes of the COD after mechanical separation of cellulose from wastewater in S1, S2, and S3. (b) Energy of the PCS in S1, S2, and S3 and ratio with the heat energy currently produced from biogas.

In all scenarios, the percentage of COD in PCS remained significantly lower than the remaining COD in WW. The COD separated from WW was 6%, 5%, and 3% in S1, S2, and S3, respectively. Assuming that almost all the cellulose was separated (S1), almost 94% of the COD remained in the WW directed to the subsequent treatments in the water line. This value is higher compared to the range reported in the literature, which indicates that cellulose separation removes 25–30% of the COD entering the WWTP [28]. Given that a multiple-stage system with mesh size up to 0.3 mm was used for cellulose separation, it seems quite unlikely that this difference could be attributed to an inefficient phase mechanical separation. However, further study is suggested in order to elucidate the reason for this difference.

3.4.2. Energy Content

In this case study, the biogas produced from the anaerobic digestion of sewage sludge is almost 4.88 Mm3 y−1 which allows to the production of 6738 MWh y−1 of electrical energy and 57,333 GJ y−1 of heat energy [40]. Considering the annual production of PCS and its calorific value, the annual energy value from PCS is expected to be up to 16,310 GJ y−1 in the best scenario for cellulose separation (S1) (Figure 5b). The energy recovered from PCS results in 14.2–28.4% of the current annual heat production from biogas, depending on the scenario.

From a different perspective, the D-PCS can generate a maximum of 0.34 m3CH4 kg−1COD according to Crutchik et al. [7]. Focusing on this case study, COD related with annual production of D-PCS is up to almost 1500 t y−1, which means a potential production of CH4 of 0.25 Mm3 y−1 and 0.51 Mm3 y−1 in S3 and S1, respectively (Table 3).

Table 3.

Potential CODD-PCS, production of CH4, and biogas from D-PCS in different scenarios and comparison with the current situation.

Assuming a biogas composition with 70% of CH4 indicates that the hypothetical production of biogas from D-PCS can reach approximately 7.4–14.8% of the total biogas production at the WWTP of Brno-Modřice. This suggests that the separation of PCS from WW did not negatively impact the energy recovery in the sludge line through anaerobic digestion.

3.5. Limitations of the Study and “Open Questions”

The results of the study demonstrate the technical sustainability of the removal of cellulose from wastewater and its valorisation through pyrolysis. However, the question of whether this approach is also sustainable from an environmental and economic point of view has not yet been evaluated (because it was not within the scope of this work). For this reason, the development of a lifecycle assessment (LCA) and a lifecycle costing (LCC) analysis would be necessary before an upgrade of this approach to full scale.

These types of analyses will also allow the comparison of different approaches for cellulose separation and valorisation in order to solve the following question: is the proposed solution more environmentally and economically “friendly” than the other current approaches?

Another aspect that was not evaluated in this study is the impact of the presence of impurities in the extracted cellulose. Can it influence subsequent valorisation through pyrolysis? Is it convenient, from an environmental and economic point of view, to remove these impurities? Subsequent studies should delve deeper into these aspects not studied in this work.

4. Conclusions

According to the results, the per-capita production of D-PCS was equal to 1.46 ± 0.13 kgD-PCS PE−1 y−1 with an average calorific value of 21.04 MJ kg−1DM. Cellulosic fibres had, on average, a length of >100 µm and a thickness of 2–5 µm. Further studies are required to completely characterize the impurities highlighted by the microscope analysis, despite the presence of a two-stage separation system. Subsequent treatment via MTP allowed the conversion of 29.5% of the initial D-PCS into P-PCS, while more than 44.5% was converted into pyrolytic oil and 26% into pyrolytic gas. DM increased from 21.7 ± 1.3% in T-PCS to 92.5 ± 9.3% in D-PCS. The results also suggested that the potential separation of the PCS from the influent water flux would have no significant impact on the COD load entering the biological treatments (−3–6%). This low value could be attributed to a lower presence of cellulose in the WW in this specific case study, rather than to an inefficient mechanical separation, considering that a multiple-stage system was used. The hypothetical production of biogas from D-PCS can reach approximately 7.4–14.8% of the total biogas production in the selected case study. This suggests that, in this specific case study, the separation of the PCS from the water flux has no significant impact on biogas production. Future studies should focus on the development of a LCA and a LCC to define whether this approach for the removal of cellulose from wastewater and its recovery is sustainable, not only from a technical point of view, but also from environmental and economic perspectives.

Supplementary Materials

The following supporting information can be downloaded at https://www.mdpi.com/article/10.3390/resources13040051/s1, Figure S1: Linear diagram of the WWTP and point in which the PCS was extracted from WW.

Author Contributions

Conceptualization, D.D., M.C.M., J.R., T.C., P.H. and Z.V.; methodology, D.D., M.C.M., J.R., T.C., P.H. and Z.V.; validation, J.R. and P.H.; formal analysis, D.D.; investigation, D.D.; resources, P.H.; data curation, D.D. and M.C.M.; writing—original draft preparation, D.D.; writing—review and editing, M.C.M., J.R., T.C., P.H. and Z.V.; visualization, D.D. and M.C.M.; supervision, P.H.; funding acquisition, P.H. All authors have read and agreed to the published version of the manuscript.

Funding

This article was created with the co-financing by the Governments of Czechia, Hungary, Poland and Slovakia through Visegrad+ Grants from International Visegrad Fund, project ID: 22220131.

Data Availability Statement

All data generated or analysed during this study are included in this published article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Fernández-Arévalo, T.; Lizarralde, I.; Fdz-Polanco, F.; Pérez-Elvira, S.I.; Garrido, J.M.; Puig, S.; Poch, M.; Grau, P.; Ayesa, E. Quantitative Assessment of Energy and Resource Recovery in Wastewater Treatment Plants Based on Plant-Wide Simulations. Water Res. 2017, 118, 272–288. [Google Scholar] [CrossRef] [PubMed]

- Maktabifard, M.; Zaborowska, E.; Makinia, J. Achieving Energy Neutrality in Wastewater Treatment Plants through Energy Savings and Enhancing Renewable Energy Production. Rev. Environ. Sci. Biotechnol. 2018, 17, 655–689. [Google Scholar] [CrossRef]

- Awe, O.W.; Liu, R.; Zhao, Y. Analysis of Energy Consumption and Saving in Wastewater Treatment Plant: Case Study from Ireland. J. Water Sustain. 2016, 6, 63–76. [Google Scholar] [CrossRef]

- Djordjevićová, D.; Carnevale Miino, M.; Raček, J.; Hlavínek, P.; Chorazy, T.; Rajaković-Ognjanović, V.; Cvijetić, N. Influence of Cellulose on the Anoxic Treatment of Domestic Wastewater in Septic Tanks: Statistical Analysis of the Chemical and Physico-Chemical Parameters. Sustainability 2023, 15, 7990. [Google Scholar] [CrossRef]

- Statista Toilet Paper—Worldwide. Available online: https://www.statista.com/outlook/cmo/tissue-hygiene-paper/toilet-paper/worldwide?currency=usd (accessed on 7 July 2023).

- Chen, R.; Nie, Y.; Kato, H.; Wu, J.; Utashiro, T.; Lu, J.; Yue, S.; Jiang, H.; Zhang, L.; Li, Y.-Y. Methanogenic Degradation of Toilet-Paper Cellulose upon Sewage Treatment in an Anaerobic Membrane Bioreactor at Room Temperature. Bioresour. Technol. 2017, 228, 69–76. [Google Scholar] [CrossRef] [PubMed]

- Crutchik, D.; Frison, N.; Eusebi, A.L.; Fatone, F. Biorefinery of Cellulosic Primary Sludge towards Targeted Short Chain Fatty Acids, Phosphorus and Methane Recovery. Water Res. 2018, 136, 112–119. [Google Scholar] [CrossRef]

- Ghasimi, D. Bio-Methanation of Fine Sieved Fraction Sequestered from Raw Municipal Sewage; Technische Universiteit Delft: Delft, The Netherlands, 2016. [Google Scholar]

- Tsavkelova, E.A.; Netrusov, A.I. Biogas Production from Cellulose-Containing Substrates: A Review. Appl. Biochem. Microbiol. 2012, 48, 421–433. [Google Scholar] [CrossRef]

- Balat, M.; Balat, H.; Öz, C. Progress in Bioethanol Processing. Prog. Energy Combust. Sci. 2008, 34, 551–573. [Google Scholar] [CrossRef]

- Pirraglia, A.; Gonzalez, R.; Saloni, D.; Denig, J. Technical and Economic Assessment for the Production of Torrefied Ligno-Cellulosic Biomass Pellets in the US. Energy Convers. Manag. 2013, 66, 153–164. [Google Scholar] [CrossRef]

- Si, Y.; Hu, J.; Wang, X.; Yang, H.; Chen, Y.; Shao, J.; Chen, H. Effect of Carboxymethyl Cellulose Binder on the Quality of Biomass Pellets. Energy Fuels 2016, 30, 5799–5808. [Google Scholar] [CrossRef]

- Cipolletta, G.; Eusebi, A.L.; Palmieri, S.; Giosuè, C.; Tittarelli, F.; Frison, N.; Pastore, C.; Foglia, A.; Fatone, F. Toilet Paper Recovery from Municipal Wastewater and Application in Building Sector. IOP Conf. Ser. Earth Environ. Sci. 2019, 296, 012024. [Google Scholar] [CrossRef]

- Akyol, Ç.; Eusebi, A.L.; Cipolletta, G.; Bruni, C.; Foglia, A.; Giosuè, C.; Frison, N.; Tittarelli, F.; Canestrari, F.; Fatone, F. Cellulosic Materials Recovery from Municipal Wastewater: From Treatment Plants to the Market. In Clean Energy and Resource Recovery; Elsevier: Amsterdam, The Netherlands, 2022; pp. 125–136. [Google Scholar]

- Akyol, Ç.; Foglia, A.; Ozbayram, E.G.; Frison, N.; Katsou, E.; Eusebi, A.L.; Fatone, F. Validated Innovative Approaches for Energy-Efficient Resource Recovery and Re-Use from Municipal Wastewater: From Anaerobic Treatment Systems to a Biorefinery Concept. Crit. Rev. Environ. Sci. Technol. 2020, 50, 869–902. [Google Scholar] [CrossRef]

- Thakur, V.K. (Ed.) Lignocellulosic Polymer Composites; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2014; ISBN 9781118773949. [Google Scholar]

- Hu, F.; Zeng, J.; Cheng, Z.; Wang, X.; Wang, B.; Zeng, Z.; Chen, K. Cellulose Nanofibrils (CNFs) Produced by Different Mechanical Methods to Improve Mechanical Properties of Recycled Paper. Carbohydr. Polym. 2021, 254, 117474. [Google Scholar] [CrossRef] [PubMed]

- Chen, H. Biotechnology of Lignocellulose; Springer: Dordrecht, The Netherlands, 2014; ISBN 978-94-007-6897-0. [Google Scholar]

- Kim, D.; Park, K.Y.; Yoshikawa, K. Conversion of Municipal Solid Wastes into Biochar through Hydrothermal Carbonization. In Engineering Applications of Biochar; IntechOpen: Rijeka, Croatia, 2017. [Google Scholar]

- Zhang, C.; Chao, L.; Zhang, Z.; Zhang, L.; Li, Q.; Fan, H.; Zhang, S.; Liu, Q.; Qiao, Y.; Tian, Y.; et al. Pyrolysis of Cellulose: Evolution of Functionalities and Structure of Bio-Char versus Temperature. Renew. Sustain. Energy Rev. 2021, 135, 110416. [Google Scholar] [CrossRef]

- Raček, J.; Sevcik, J.; Chorazy, T.; Kucerik, J.; Hlavínek, P. Biochar—Recovery Material from Pyrolysis of Sewage Sludge: A Review. Waste Biomass Valorization 2020, 11, 3677–3709. [Google Scholar] [CrossRef]

- Capodaglio, A.G.; Callegari, A. Feedstock and Process Influence on Biodiesel Produced from Waste Sewage Sludge. J. Environ. Manag. 2018, 216, 176–182. [Google Scholar] [CrossRef]

- Novotný, M.; Marković, M.; Raček, J.; Šipka, M.; Chorazy, T.; Tošić, I.; Hlavínek, P. The Use of Biochar Made from Biomass and Biosolids as a Substrate for Green Infrastructure: A Review. Sustain. Chem. Pharm. 2023, 32, 100999. [Google Scholar] [CrossRef]

- Petreje, M.; Sněhota, M.; Chorazy, T.; Novotný, M.; Rybová, B.; Hečková, P. Performance Study of an Innovative Concept of Hybrid Constructed Wetland-Extensive Green Roof with Growing Media Amended with Recycled Materials. J. Environ. Manag. 2023, 331, 117151. [Google Scholar] [CrossRef]

- Chen, L.; Liao, Y.; Guo, Z.; Cao, Y.; Ma, X. Products Distribution and Generation Pathway of Cellulose Pyrolysis. J. Clean. Prod. 2019, 232, 1309–1320. [Google Scholar] [CrossRef]

- Ahmed, A.S.; Khalil, A.; Ito, Y.; van Loosdrecht, M.C.M.; Santoro, D.; Rosso, D.; Nakhla, G. Dynamic Impact of Cellulose and Readily Biodegradable Substrate on Oxygen Transfer Efficiency in Sequencing Batch Reactors. Water Res. 2021, 190, 116724. [Google Scholar] [CrossRef]

- Liu, R.; Li, Y.; Zhang, M.; Hao, X.; Liu, J. Review on the Fate and Recovery of Cellulose in Wastewater Treatment. Resour. Conserv. Recycl. 2022, 184, 106354. [Google Scholar] [CrossRef]

- Ruiken, C.J.; Breuer, G.; Klaversma, E.; Santiago, T.; van Loosdrecht, M.C.M. Sieving Wastewater—Cellulose Recovery, Economic and Energy Evaluation. Water Res. 2013, 47, 43–48. [Google Scholar] [CrossRef] [PubMed]

- American Public Health Association. APHA Standard Methods for the Examination of Water and Wastewater; American Public Health Association (APHA): Washington, DC, USA, 2012; Volume 10. [Google Scholar]

- ČSN ČSN EN ISO 1716 (730883); Testing the Reaction of Products to Fire—Determination of Heat of Combustion (Caloric Values). Czech Standardization Agency (ČSN): Prague, Czech Republic, 1999. Available online: https://www.technicke-normy-csn.cz/csn-en-iso-1716-730883-222197.html (accessed on 19 May 2023). (In Czech)

- ČSN EN ISO 11885 (757387); Water Quality—Determination of 33 Elements by Inductively Coupled Plasma Atomic Emission Spectroscopy (ICP AES). Czech Standardization Agency (ČSN): Prague, Czech Republic, 1999. (In Czech)

- ČSN EN 13657 (838015); Characterization of Waste—Digestion for Subsequent Determination of Aqua Regia Soluble Portion of Elements. Czech Standardization Agency (ČSN): Prague, Czech Republic, 2003. (In Czech)

- ČSN 46 5735 (465735); Industrial Composts. Czech Standardization Agency (ČSN): Prague, Czech Republic, 1991. (In Czech)

- ČSN EN 12879 (758005); Characterization of Sludges—Determination of the Loss on Ignition of Dry Mass. Czech Standardization Agency (ČSN): Prague, Czech Republic, 2001. (In Czech)

- ČSN EN 12880 (758006); Characterization of Sludges—Determination of Dry Residue and Water Content. Czech Standardization Agency (ČSN): Prague, Czech Republic, 2001. (In Czech)

- ČSN EN 12176 (758010); Characterization of Sludge—Determination of PH-Value. Czech Standardization Agency (ČSN): Prague, Czech Republic, 1999. (In Czech)

- Raček, J.; Doskočil, B.; Ševčík, J.; Chorazy, T.; Hlavínek, P. Drying Sewage Sludge for the Conditions of the Czech Republic. Vodovod Info 2018, 2018, 14. (In Czech) [Google Scholar]

- Kim, D.; Yoshikawa, K.; Park, K. Characteristics of Biochar Obtained by Hydrothermal Carbonization of Cellulose for Renewable Energy. Energies 2015, 8, 14040–14048. [Google Scholar] [CrossRef]

- Chen, R.; Nie, Y.; Tanaka, N.; Niu, Q.; Li, Q.; Li, Y.-Y. Enhanced Methanogenic Degradation of Cellulose-Containing Sewage via Fungi-Methanogens Syntrophic Association in an Anaerobic Membrane Bioreactor. Bioresour. Technol. 2017, 245, 810–818. [Google Scholar] [CrossRef]

- BVK Annual Report 2020; Brněnské vodárny a kanalizace: Brno, Czech Republic, 2020. (In Czech)

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).