Abstract

Recycling strategies demonstrate different life cycle environmental performance. In order to assess this performance, a life cycle assessment may be used. In such studies, the recycling should be linked with multifunctionality and allocation. This requires it to be modelled accordingly, especially in terms of environmental burdens and credits. The paper presents a case study of open-loop recycling. A flow of mixed post-consumer multi-material waste was reprocessed into another product with a new application—a fence board made of recycled material (secondary fence board). Although many allocation-related case studies are provided in the literature, no example of a comparison between different substitution scenarios for open-loop recycling has been found. In order to fill the gap, various hypothetical market-mix-based alternatives related to the virgin production and durability of products have been examined. The goal of the study is to assess the potential environmental impact of 1 m2 of secondary fence board modelled in different substitution scenarios. The paper is the second part of a two-part study. In Part 1, life cycle assessment results were presented for a baseline scenario (1A). Part 2 focuses strongly on allocation considerations. In order to ensure a consistency between the results of Part 1 and Part 2, the entire life cycle of the fence board has been taken into account in both calculations. The case study has shown that the results may be highly sensitive to the choice of substitutes and the choice of quality attributes impacting the reference flows (in our example, the durability of products).

1. Introduction

The implementation of the principles of a closed-loop economy means extending the commitment, “from front-runners to the mainstream economic players” [1], which involves the need to popularise practices that are mainly used today by a narrow group of leaders. In the context of waste management, among other things, this translates into the more intensive implementation of the extended producer responsibility system (EPR), and shifting responsibility upstream to the producer and away from municipalities [2]. According to its definition, EPR is, “a set of measures taken by the Member States to ensure that producers of products bear financial responsibility or financial and organisational responsibility for the management of the waste stage of a product’s life cycle” [3]. EPR can go beyond the end of life by including waste prevention and enhancing the reusability and recyclability of products (Directive 2018/851). Changes in the design of products (and services), in their structure, in the way they perform their functions, and in their material structure have a direct impact on the time and manner of use at the end of life stage. In this way, manufacturers take responsibility and shape two important parameters related to the production and material structure of products and their packaging: their recycled content and the recycling rate. These are both closely linked to the “Design for Recycling” strategy [4] and are of key importance for modelling circularity in the life cycle of products. Recycling means, “any recovery operation by which waste materials are reprocessed into products, materials or substances whether for the original or other purposes. It includes the reprocessing of organic material but does not include energy recovery and the re-processing into materials that are to be used as fuels or for backfilling operations” [3]. Technically, two situations can be distinguished:

- Closed-loop recycling, which occurs when a material from a product system is recycled and used in the same product system [5]. In this case, the material is recycled without changes to its inherent properties and is used for its original purposes, e.g., a used aluminium can is recycled into an identical aluminium can.

- Open-loop recycling, which occurs when a material from one product system is recycled into a different product system [5] and may be used for purposes other than the original purposes. Open-loop recycling can be undertaken in two ways:

- ➢

- Without changes to the material’s inherent properties: this happens when recycling in a product system involves contributing to product-independent material pools for recycled glass, steel, aluminium [5], and plastics, e.g., a used post-consumer aluminium can is reused to manufacture another food’s packaging.

- ➢

- With changes to the material’s inherent properties: this occurs when the recycled material, compared with the primary material, has a different structure (e.g., the length of fibres in recycled paper), a higher concentration of impurities, or a different chemical composition [6], e.g., a waste newspaper is reprocessed into toilet paper.

While the use of closed-loop recycling is limited to the specific product system and a certain application, open-loop recycling is not so restricted [7]. Many case studies of closed-loop recycling can be found in the literature. For example, Uekert et al. [8] assessed the technical, economic, and environmental aspects of different examples of closed-loop recycling of the most widely consumed polymers. Myrin et al. [9] evaluated a recycling system where a small manufacturer in Sweden produced and reprocessed multiple-use plastic dining plates in closed-loop reprocessing cycles. Panda et al. [10] proposed a combination of low-temperature ammonium chloride roasting, hydrogen chloride leaching, and cementation as a closed loop recycling strategy for the recovery of metals from waste printed circuit boards. Ha and Kim [11] showed that waste appliances such as refrigerators, washing machines, and air conditioners can be reprocessed with mechanical closed-loop recycling into recycled polypropylene (PP), which can be used for refrigerator plastics. Some examples of open-loop recycling technologies are also provided by different authors. Ha [7] showed that plastics from post-consumer waste polypropylene may be applicable to refrigerator plastics, which have good impact properties at low temperatures. Ha performed analyses (thermal, spectroscopic, morphological, and chromatographic analyses) to show that recycled polypropylene is a balanced plastic, similar in strength and toughness to Impact-PP. Kasmi et al. [12] developed an open-loop chemical recycling process for post-consumer bottles made of polyethylene terephthalate (PET). PET bottle waste was recycled into new mechanically and thermally high-performing materials (value-added polyimines).

The potential environmental consequences of decisions regarding waste management and the circularity of products can be assessed with a method called life cycle assessment (LCA). There are many examples of the use of LCA in the field of waste management [13,14,15,16]. In the LCA methodology, recycling comes with multifunctionality. This results from the fact that multiple circulations of a material make it usable many times for the same (closed-loop) or a different (open-loop) user. This means that the cradle (extraction of primary raw materials) and end of life (disposal and recovery operations by which waste materials are reprocessed into products) processes are common for more than one use and the environmental burdens related to the cradle and to the end of life may be divided (allocated) between the uses. What procedure is used to make that allocation is one of the most substantial issues in life cycle assessment. As Ekvall et al. stated [17], “the choice of method for modelling material recycling can have a decisive impact on the environmental assessment of products that have a high content of recycled material and products that are recycled after use”. Some of the approaches to allocation are recommended for use in the case of open-loop recycling. Examples include simple cut-off [17,18,19], market price-based allocation [6], or the circular footprint formula [20,21]. For example, Tinz et al. [22] used different methods to deal with this allocation in an open-loop recycling process and to calculate the carbon footprint of injection-moulded plastics.

The paper presents a case study of open-loop recycling. A flow of mixed post-consumer multi-material waste (mainly packaging) is reprocessed into another product with a new application—recycled board for fencing. The circular footprint formula [20,21] has been used as an allocation procedure to deal with the element of multifunctionality. The formula includes elements to reflect the consequences of using or supplying recyclable materials. The open-loop recycling means that specific emissions and resources arising from the acquisition and pre-processing of virgin material are different from the specific emissions and resources arising from the acquisition and pre-processing of the virgin material assumed to be substituted for by recyclable materials. Although many allocation-related case studies are provided in the literature, no example of a comparison between different substitution scenarios for such open-loop recycling has been found. In order to fill the gap, various hypothetical market-mix-based alternatives related to the virgin production and durability of products have been examined. The goal of the study is to assess the potential environmental impact of 1 m2 of secondary fence board modelled in different substitution scenarios. The paper is the second part of a two-part study of life cycle assessment. In Part 1, the LCA results for a baseline scenario were presented and the environmental hot spots in the life cycle of the secondary fence board were identified. Part 2 focuses strongly on allocation considerations. In order to ensure a consistency between the results of Part 1 and Part 2, the entire life cycle of the fence board has been taken into account in both calculations.

The following two research questions have been noted in this paper:

- (i)

- Is the choice of virgin production a key driver of the environmental impact in the life cycle of secondary fence board?

- (ii)

- Is the durability of the substituted products an influential quality indicator in the life cycle of the secondary fence board?

The paper starts with an introduction where the relationship between recycling and allocation is highlighted. The Section 2 includes a description of the LCA method, allocation procedures, goal, and scope of the study, inventory results, and modelling scenarios. In the following section, the results of a life cycle impact assessment for all scenarios are shown. The paper ends with a discussion and formulation of the final conclusions. The intended audience for the paper is composed of scientists and practitioners interested in environmental assessment of open-loop recycling processes. The paper shows that the choice of quality parameters and the definition of market alternatives can be the most influential decisions in the case of open-loop recycling.

2. Materials and Methods

Environmental life cycle assessment (LCA) [23,24,25,26] has been used to assess the potential environmental impact over the life cycle of secondary fence board. LCA is a universally used, normalised, and science-based tool. It is used to compile and evaluate the inputs, outputs, and potential environmental impacts of a product system throughout its life cycle [26]. LCA is structured into four phases: the goal and definition of the scope, the life cycle inventory (LCI), the life cycle impact assessment (LCIA), and the interpretation [26]. In the first phase, the goal of the study, the product system to be studied, its function, the functional unit, system boundaries, and allocation procedures should be defined. The inventory analysis involves data collection and calculation procedures to quantify the relevant inputs and outputs of a product system [26]. The impact assessment phase is aimed at evaluating the significance of potential environmental impacts with reference to the functional unit. The LCIA phase consists of obligatory and voluntary elements. The mandatory ones are the selection of the impact categories, category indicator, and characterisation models, the classification, and the characterisation. The optional elements are the grouping, normalisation, and weighting [26]. Various life cycle impact assessment methods are available [27]. One of the most recent is the Environmental footprint (EF) method developed as part of the Environmental footprint methodology and established with the European Commission Recommendation (EU) 2021/2279 of 15 December 2021 on the use of Environmental footprint methods to measure and communicate the life cycle environmental performance of products and organisations [21]. In the case study presented, the life cycle impact assessment calculations were made using the Environmental footprint EF 3.0 method (adapted) v. 1.0 available in the SimaPro software [28]. With this method, the environmental impact was assessed within 16 impact categories reflecting various environmental problems, e.g., Climate change, Resource use—fossils, Eutrophication—freshwater, Human toxicity, non-cancer effects, Acidification, and Particulate matter. As far as the case study presented is concerned, all the impact categories have been taken into account and no selection has been made prior to the LCIA calculations. It should be noted that the EF method includes weighting as an optional element. This means that the weighting factors are an inherent element of this method [29], and they are used to calculate the weighted results and a single score. A main role of the weighting is to support the identification of the most relevant issues [29]. The weighting factors reflect the importance of the impact categories. With the EF method, Climate change has been rated the highest (with a weighting factor of 21.06) and Human toxicity and non-cancer effects have been rated the lowest (with a weighting factor 1.84). The last phase of LCA is the interpretation, “in which the findings of either the inventory analysis or the impact assessment, or both, are evaluated in relation to the defined goal and scope in order to reach conclusions and recommendations” [26].

In this case study, the interpretation of the results was inspired by a procedure for the identification of the most relevant issues developed by the Joint Research Centre as part of the Environmental footprints methodology and described in Annex I in Section 6.3 of the Commission Recommendation (EU) 2021/2279 [21]. According to the procedure, the most relevant issues (impact categories, life cycle stages, processes, or elementary flows) are those that together contribute at least 80% of the environmental impact. A detailed description of the procedure can be found in Recommendation (EU) 2021/2279 [21]. The LCA calculations have been made using the SimaPro software v. 9.3 and the ecoinvent v. 3.8 database.

The Circular Footprint Formula

Many approaches have been developed to determine the allocation used in LCA calculations. The methods differ in many respects: in the subject of allocation (some of them only include recycling, while others also take primary production into account), in the way that primary production is included (the allocation of the primary production of the material and/or the primary production avoided through recycling), in the consideration of the recyclable material (treated as a waste or as a by-product), in the stages of the life cycle to which the allocation applies (end of life or cradle and end of life or the entire life cycle), and in the recycling situation to be modelled (closed-loop, open-loop). Allacker et al. [30] reviewed eleven different methods, while Ekvall et al. [17] listed and compared twelve approaches to allocation. The easiest is “a simple cut off”, often called the recycled-content approach [17,18,19,31,32] or the 100/0 method [30]. The opposite of the simple cut off is the 0/100 method [30], also called the closed-loop approach [5,32], allocation to material losses [17], or the end-of-life approach [17]. Another example is the 50/50 method recommended by the Nordic Guidelines on LCA [33]. Ekvall [34] suggested a consequential version of the 50/50 method.

The most recent approach is the circular footprint formula developed by the European Commission as a part of the Environmental footprint methodology [20,21,35]. This formula can be applied in open-loop and closed-loop situations, can take downcycling into account and, most importantly, can accommodate different end-of-life scenarios: reuse (modelled as recycling), recycling, energy recovery, and landfill [36]. It is used to model the end of life of products, as well as the recycled content and is a combination of “material + energy + disposal” (Equation (1)). The formula takes into account the share of recycled material (recycled content: R1), the ratio of material recycling at the end of the life cycle (recycling rate: R2), the quality of recycled material entering and leaving the life cycle, and the balance between supply and demand for individual recycled materials (factor A) [17,21]. Factor A can vary between 0.2 and 0.8 [20]. A low value of A indicates a low offer of recyclable materials and a high demand; the formula focuses on recyclability at the end of life. A high value of A indicates a high offer of recyclable materials and a low demand; the formula focuses on recycled content [20]. The CFF takes into account the production of the virgin material and processes outside the life cycle studied. It takes account of the virgin material production avoided through recycling. Open-loop recycling means that the specific emissions and resources arising from the acquisition and pre-processing of virgin material (Ev) are different from the specific emissions and resources arising from the acquisition and pre-processing of the virgin material for which the recyclable materials are assumed to be a substitute (). The concept behind the CFF formula is presented in Equation (1).

Equation (1) is the circular footprint formula [21], where:

A—allocation factor of burdens and credits between the supplier and the user of recycled materials;

B—allocation factor of energy recovery processes;

QSin—quality of the ingoing secondary material, i.e., the quality of the recycled material at the point of substitution;

QSout—quality of the outgoing secondary material, i.e., the quality of the recyclable material at the point of substitution;

Qp—quality of the primary material, i.e., quality of the virgin material;

R1—the proportion of material in the input to the production that has been recycled from a previous system;

R2—the proportion of the material in the product that will be recycled (or reused) in a subsequent system. R2 should include the inefficiencies in the collection and recycling (or reuse) processes (measured at the output of the recycling plant);

R3—the proportion of the material in the product that is used for energy recovery at EoL;

Ev—specific emissions and resources consumed (per functional unit) arising from the acquisition and pre-processing of virgin material;

—specific emissions and resources consumed (per functional unit) arising from the acquisition and pre-processing of virgin material assumed to be substituted by recyclable materials;

Erecycled—specific emissions and resources consumed (per functional unit) arising from the recycling process of the recycled (reused) material, including collection, sorting, and transportation process;

Erecycling_EoL—specific emissions and resources consumed (per functional unit) arising from the recycling process at EoL, including the collection, sorting, and transportation processes;

EER—specific emissions and resources consumed (per functional unit) arising from the energy recovery process (e.g., incineration with energy recovery, landfill with energy recovery, etc.);

ESE_elec ESE_heat—specific emissions and resources consumed (per functional unit) that would have arisen from the specific substituted energy source, heat, and electricity, respectively;

ED—specific emissions and resources consumed (per functional unit) arising from disposal of waste material at the EoL of the product being analysed, without energy recovery;

XER_elec XER_heat—the efficiency of the energy recovery process for both heat and electricity;

LHV—lower heating value of the material in the product that is used for energy recovery (Recommendation 2021/2279/EU).

3. Life Cycle Assessment

3.1. Goal and Scope Definition

The goal of the study is to assess the potential environmental impact of secondary fence board modelled in the context of different substitution scenarios. The fence boards analysed are made up of 100% waste in Recycling process I. In the reference year (2019), they contained six waste materials (mainly packaging plastics): high-density polyethylene (HDPE) = 30%, polypropylene (PP) = 30%, polycarbonate (PC) = 10%, polyamide (PA) = 10%, acrylonitrile butadiene styrene (ABS) = 10%, and aluminium (ALU) = 10%. A single board weighs 70 kg (2.0 m × 1.4 m × 0.02 m). The boards can be used as fence panels in outdoor construction, e.g., in horticulture, agriculture, and so-called small-scale architecture. The functional unit (FU) is defined as the space separation and protection provided by 1 m2 of fencing with a durability of 15 years. The reference flow is 1 m2 of secondary fence board with a mass of 25 kg. The life cycle stages are included in the system boundaries presented in Table 1.

Table 1.

Life cycle stages included in the system boundaries.

3.2. Allocation Scenarios

Different hypothetical scenarios have been modelled. Some general assumptions are common to all of them. In all scenarios, the entire life cycle is taken into account, open-loop recycling processes are under allocation, the virgin production is under substitution, the durability is used as a quality indicator of products, and the recyclable materials are treated as waste, not as by-products (Table 2). Both waste and by-products are production residues defined as, “a material that is not deliberately produced in a production process but may or may not be a waste” [37]. A key difference between them is that a by-product is not considered waste. In the case study presented, the secondary products are reprocessed from post-consumer materials classified as waste.

Table 2.

General assumptions relating to allocation.

In all scenarios, the circular footprint formula is used to deal with multifunctionality. For all packaging plastics, the value of the allocation factor used is A = 0.5, and for aluminium, it is A = 0.2 [38]. This means that 50% of Recycling process I should be allocated to plastic packaging and the other 50% to fence boards (and similarly, 80% to aluminium packaging and 20% to fence boards). For fence boards, on the other hand, A = 0.5 has been adopted, which means that Recycling process II will be divided equally between the life cycles of the fence board and the plant pots.

In all scenarios, the fence boards analysed are made of 100% waste and produced in Recycling process I. After use, they can be treated in different ways. No recycling at the end of life has been assumed for scenarios with option A, while for the other scenarios, their recycling has been included (options B, C, and D). In scenarios with option A, 25.025 kg of packaging waste goes to Recycling process I in order to produce 25 kg of secondary board. The fence board is entirely made up of recycled materials (R1_fence_board = 1). After production, the secondary fence board is transported to the place of installation, installed, used (for 15 years), and finally, disposed of as waste. At the end of its use, 99% of the board goes to landfill and 1% is incinerated (R2_fence_board = 0). The values for landfilling and incineration are assumed in accordance with the country-specific default values included in Annex C to the EF method. The default values of 99% and 1% were provided for Poland [38]. In alternative scenarios (with options B, C, and D), 12.5 kg of used fence board goes to recycling (Recycling process II), 0.125 kg is incinerated, and 12.375 kg is landfilled. From the 12.5 kg of waste board, 12.48 kg of garden pots are produced. This means that R2_fence board is 0.499 (12.48 kg/25 kg = 0.499). Recycling process II links the fence board with the life cycle of the plant pots (subsequent product system). In the former, the materials serve a protective and fencing function, and in the latter, they provide protection and stability for plants and their substrate. The system boundaries are presented in the Supplementary Information in Figures S1 and S2.

The allocation factor A indicates to what extent the specific emissions and resources consumed that arise from the recycling process should be allocated between the supplier and the user of the recycled materials [21]. It allocates the burdens of recycling at the cradle with the following part of the CFF formula R1 × (AErecycled + (1 − A)Ev × QSin/Qp) (Equation (1)). The use of the recycled materials by the user being analysed (producer of the secondary fence board) makes the recycled materials unavailable to other users operating on the market. As a consequence, the other users need to use corresponding (primary) substitutes, and additional primary production is needed to cover the demand of these other users. For this reason, recycling at the cradle should be debited with a portion of increased virgin production Ev × QSin/Qp (Equation (1)). The following question seems to be essential in our case study: “What is the virgin production to be debited?” In fact, this is a question about substitution modelling. In our analysis, various variants of substitution modelling for recycling at the cradle have been assumed.

The packaging market could be the end market for the plastic packaging waste (closed-loop recycling) that is investigated. Using the recycled materials in the packaging industry may be recognised as a “high-value application”, because the properties of the recycled polymers required for packaging are probably stricter than for application in the construction sector [35]. In our case study, packaging waste (originating from the packaging industry) is used to generate the recycled materials forming the final product—the secondary fence board (used in the construction industry). So, this is a case of open-loop recycling at the cradle (different application of the material in the previous and current product system) and a low-value application (lower requirements for recycled materials in the construction sector than in the packaging one). As Schrijvers et al. has pointed out, in some cases, recycling into a high-value application, “could be less profitable than recycling into a low-value application, due to a more rigorous sorting, or the use of more advanced materials or energy-intensive recycling technologies” [35]. In our case study, the waste materials are contaminated and highly mixed, which makes their application in the packaging industry currently challenging and difficult, if not impossible.

Four hypothetical options are assumed for substitution modelling at the cradle, named 1, 2, 3, and 4. Option 1 assumes that the use of the recycled materials for manufacturing the secondary fence board affects the packaging industry (the production of primary packaging materials is to be increased because of the unavailability of recycled materials already used in the secondary fence board production and absorbed by the fencing market). The specific emissions and resources consumed that arise from the recycling of 11.75 kg of packaging waste (Erecycled with Recycling process I) have been allocated to 1 m2 of the secondary fence board. In addition, in option 1 the recycling at the cradle is debited with a virgin production of 10.625 kg of primary packaging materials (30% of primary HDPE, 30% of primary PP, 10% of primary PC, 10% of primary PA, 10% of primary ABS, and 10% of primary aluminium). In option 1, the values of allocation factor A and quality corrections QSin/Qp (Equation (1)) are taken from Annex C to the EF method [38]. For plastics, the allocation factor A equals 0.5 and for aluminium 0.2. The quality-correction factors (QSin/Qp) for all plastics are assumed as 0.9 and for aluminium 1.0.

However, the assumption that the use of recycled materials in the secondary fence board affects the packaging market can be seen as disputable. In fact, Recycling process I does not provide secondary raw materials with a broad spectrum of potential applications (e.g., in the packaging industry), but it provides a secondary final product ready to fulfil its specific function in the construction sector. For this reason, the other options 2, 3, and 4 in our modelling have been taken into account. In all these options, one assumes that Recycling process I affects the fencing market as the production of primary fencing materials is potentially increased because of the non-availability of the recycled materials already used in the secondary fence board being analysed. In these options, the specific emissions and resources consumed that arise from the recycling of 12. 5 kg of packaging waste (Erecycled with Recycling process I) have been allocated to 1 m2 of the secondary fence board. Additionally, the recycling at the cradle is debited with a virgin production of primary fencing in the following way:

- Option 2: Recycling process I is debited with primary production of 14 kg of plastic and composite panels made of polyvinyl chloride (PVC). The secondary board and the market plastic board have the same durability of 15 years;

- Option 3: Recycling process I is debited with primary production of market fencing materials. The 10-year average market shares for fencing (by materials) have been used as follows: metal fencing 53%, wooden fencing 27%, plastic and composite fencing 15%, and concrete fencing 7% [39]. The secondary board analysed and all the market fence boards have the same durability of 15 years. In option 3, Recycling process I is debited with 46.39 kg of primary production per FU (1 m2);

- Option 4: Recycling process I is debited with a primary production of market fencing materials. The same market shares for fencing (by materials) have been used as presented for option 3. The secondary board analysed and all the market fence boards have different durabilities (steel fencing 40 years, wooden fencing 20 years, plastic and composite fencing 15 years, concrete fencing 40 years). In option 4, Recycling process I is debited with 8.04 kg of primary production, per FU (1 m2 of fencing).

The results of the calculations with the CFF formula are presented in the Supplementary Information in Table S1.

The CFF formula also allocates burdens and benefits resulting from the recycling at the EoL. This is to be performed with the following part of the CFF formula (1 − A)R2 × (ErecyclingEoL − × QSout/Qp) (Equation (1)). Recycling at the end of life provides recycled materials that are potentially available for other users to use in the same or other applications. These other users do not need to look for virgin material, so the portion of virgin production is to be decreased (the recycling at end of life should be credited with the avoided burdens of primary production— × QSout/Qp) (Equation (1)). At this point, the following question may be asked: “What is the virgin production to be credited?” Again, this is a question based on substitution modelling, this time at EoL. In our analysis, various options of substitution modelling have been considered and are presented in Table 2 (as options A, B, C, and D).

Firstly, let us assume that no recycling of the secondary board exists at the EoL (R2 = 0). This is option A. In this option, 99% of the waste fence board is sent to landfill (24.75 kg) and 1% to incineration (0.2475 kg). Now, let us assume that 50% of the waste secondary board (25 kg × 0.5 = 12.5 kg) is sent for recycling at the EoL using Recycling process II. The assumed recycling efficiency is 99.9%, which gives factor R2 = 0.499 ((12.5 kg × 0.999)/25 kg = 0.499). The assumed factor A for the secondary fence board is 0.5. According to the formula (1 − A)R2 × (ErecyclingEoL − × QSout/Qp) (Equation (1)), the specific emissions and resources consumed that arise from the recycling of 12.48 kg of waste board (Erecycling_EoL with Recycling process II) have been allocated to 1 m2 of the board (Supplementary Information, Table S2).

According to the CFF formula, the recycling at EoL should be credited with the primary production avoided. The issue of substitution appears again with the following questions: “What recycled materials could be generated in the recycling process?” “What markets would be affected?”. It seems reasonable to assume that, after 15 years of use in construction applications, the quality of the materials included in the waste in secondary fence board is low and the spectrum of potential applications for these materials is rather limited. Because of the low quality and potential contamination, recycled materials cannot be considered as a source of materials for high-quality applications, e.g., in the packaging industry. For this reason, in our case study, the packaging industry is found to be unaffected by the recycling of waste board and it is not justified to credit the recycling process at EoL with the production of primary packaging polymers.

What about other industries? In theory, the secondary board made from waste could be used to generate secondary materials that are potentially useful for the construction industry. For example, they could be used to produce a next generation of secondary fence boards (closed-loop recycling). These would replace the primary ones, and the fencing market would be affected by a reduction in the production of fencing made of primary materials. In this situation, the recycling at EoL should be credited with the production of the primary fencing materials that is avoided. This is a realistic scenario and theoretically could be taken into account in our analysis. However, instead of that, it was found to be more interesting and less obvious to model the recycling at the end of life as an open-loop recycling process. In the circular economy, open-loop recycling processes that are aimed at reprocessing waste materials into products, materials, or substances for purposes other than their original purposes are more and more common. For this reason, our example assumed that the recycling at the EoL (Recycling process II) hypothetically generates a clearly defined secondary final product—plant pots—with strict application in providing protection and stability for plants. In options B, C, and D, the market affected is the plant pot market, as the use of waste secondary fence board to produce secondary pots (open-loop recycling) potentially results in reducing the production of pots made of primary materials. Recycling at the EoL is credited with the virgin production of primary plant pots in the following way:

- Option B: Recycling process II is credited with a primary production of 2.43 kg of plastic plant pots made of polyethylene (HDPE) with an assumed durability of 5 years;

- Option C: Recycling process II is credited with a primary production of market plant pot materials. The 10-year average market shares for plant pots (by materials) have been used as follows: pots made of refractory materials 47%, polymer pots 31%, metal pots 13%, and wooden pots 9% [40]. The pots have the same durability of 5 years. In option C, Recycling process II is credited with −5.84 kg of primary pot production per FU (1 m2 of fencing);

- Option D: Recycling process II is credited with a primary production of market plant pot materials. The same market shares for pots (by materials) have been used as presented for option C. The market pots have different durabilities (refractory pots 10 years, polymer pots 5 years, metal pots 10 years, wooden pots 8 years). In option D, Recycling process II is credited with −3.31 kg of primary pot production per FU (1 m2 of fencing).

The results of our calculations carried out for each of the options are presented in the Supplementary Information in Table S2.

Various modelling options have been assumed for recycling at the cradle (options 1, 2, 3, 4) and recycling at EoL (options A, B, C, D). Some of the life cycle stages have been modelled in a different way by combining different options and creating 16 scenarios, which are explained and presented in Table 3. Four stages are the same for all scenarios (materials (auxiliary materials), transport, installation, and use, end of life (auxiliary materials)), so they have been omitted in Table 3.

Table 3.

Modelling of the full life cycle of secondary fence board with different options for recycling and substitution modelling (per FU, 1 m2 of fencing).

3.3. Life Cycle Inventory

The inventory results for all life cycle stages are presented in the Supplementary Information in Tables S3–S10. The particular company’s primary data have been used for Recycling process I. Data regarding the use of auxiliary materials and installations have been estimated based on the general instructions taken from the fencing panel installation guide (Installation Guide). The mass of auxiliary materials has been estimated by using information from shops. Data on the durability of market fence panels and pots, the use stages, transport, and the Recycling process II (production of the secondary pots) are non-qualified estimates (our own assumptions or secondary data taken from datasets on similar processes). Market shares of fencing panels and gardening pots (by material) have been taken from market reports and obtained from [39,40].

4. Results: Life Cycle Impact Assessment (LCIA)

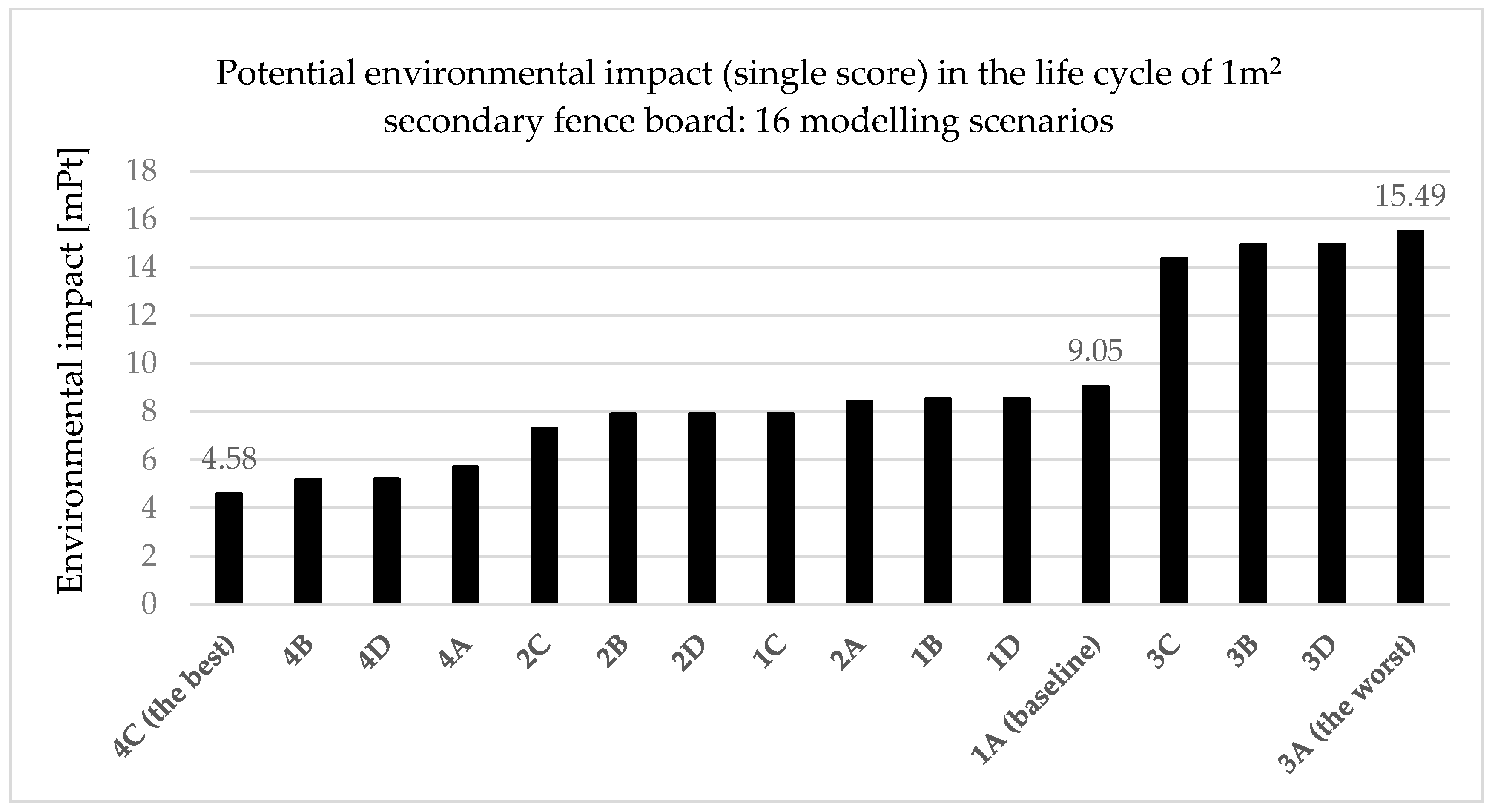

The potential environmental impact during the life cycle of the secondary board in the baseline scenario 1A is presented in Part 1 of the two-part paper. For A1, the single score obtained with the EF 3.0 (adapted) method is 9.05 miliPoints (mPt). The results showed that the debiting of the primary production of packaging materials is one of the two key drivers of the environmental impact. In scenario 1A, there is no recycling at the end of life. However, as presented in the previous sections, there are some arguments for debiting the life cycle of the secondary fence board with the primary production of the market fencing (instead of the packaging materials), and these can be seen as justified. Additionally, recycling of the secondary board at the end of life is possible, so the issue of substitution modelling at EoL arises too. The results of the comparison of the 16 scenarios are presented in Figure 1 and Table 4—as the cumulative environmental impact (a single score) per functional unit. More detailed LCIA results for all scenarios can be found in Tables S9 and S10 in the Supplementary Information. Additionally, the results of a sensitivity analysis are presented in Table 4. Different LCIA methods (single issue (IPCC GWP 2021, AWARE) and multi-issue (midpoint EF method, endpoint IMPACT World+)) were used to calculate the environmental impact of the fence board modelled according to the 16 scenarios. The results with two versions of the ecoinvent database (v. 3.8 and 3.9) are also included.

Figure 1.

The cumulative environmental impact (single score) in the life cycle of 1 m2 of secondary board in different scenarios (EF 3.0 method (adapted), SimaPro).

Table 4.

Environmental impact (single score) in the life cycle of 1 m2 of secondary board and ranking of the scenarios obtained with different LCIA methods.

5. Discussion

As mentioned in the previous sections, in our specific case study, some arguments can be provided for different models that either debit or credit virgin production. For this reason, 16 hypothetical scenarios have been assumed to reflect the differences. A key point of the discussion is the question, “How, if at all, does the choice of substitution modelling impact the LCA results for the secondary fence board analysed?” The results presented in Table 4 and in Tables S9 and S10 (Supplementary Information) show that, in terms of the single score value, the substitution modelling produces significant impacts on the results. The single score is 4.58, 9.05, and 15.48 mPt for the best (4C), baseline (1A), and worst (3A) scenarios, respectively. So, the result for the baseline scenario is very sensitive to the choice of approach for substitution modelling (the single score for the baseline is 49% higher than for the best scenario and 71% lower than for the worst scenario). In Table 4, the scenarios are ordered from the best (the lowest single score) to the worst result (the highest single score). It may be observed that, for calculations with EF 3.0 (adapted) method, all the scenarios with option 4 have the lowest single score. Analogically, all scenarios with option 3 have the highest single score. The results for options 2 and 3 have been classified between the best and worst scenarios. A similar ranking was obtained using the IPCC 2021 GWP 100 and IMPACT World + endpoint methods. This means that, in our case study, the most important driver is the way in which the debit of virgin production is modelled. Not only does the type and amount of the virgin materials matter (virgin packaging materials vs. virgin fencing materials), but also the difference in the quality of the substitutes (reflected by different durabilities) has a significant impact on the results.

It is worth asking why, in our case study, the modelling of the credits (avoided virgin production) at the end of life does not affect the results as visibly as the modelling of the debits at the cradle. There are a few reasons for this, firstly because, in options B, C, and D, only half of the waste secondary board is sent for recycling at the EoL. By contrast, 100% of the board is produced from waste at the cradle. This means that a much higher debit of virgin production is to be calculated at the cradle than the credit of virgin production at the EoL. Secondly, the mass of market fencing as the final product is greater than the mass of market pots. Table S1 in the Supplementary Information shows the differences. Per functional unit, the cradle is debited with the production of 10.625 kg of primary packaging materials (option 1), 14 kg of plastic market fencing (option 2), 46.39 kg of market fencing materials with the same durability (option 3), and 8.04 kg of market fencing materials with different durabilities (option 4). On the other hand, the end of life is credited with the avoided production of 2.43 kg of plastic market pots (option B), 5.84 kg of market pots with the same durability (option C), and 3.31 kg of market pots with different durabilities (option D). It is clear that, in our case study, in all the hypothetical scenarios, a higher quantity of materials is debited than credited. In Table 4, it may be observed that, in the results obtained with the EF 3.0 method, the scenarios are ordered in the same way in terms of EoL modelling: C, B, D, A (4C, 4B, 4D, 4A … 1C, 1B, 1D, 1A). This means that the lowest environmental impact is obtained for option C (R2 = 0.5, and Recycling process II is credited with a mix of primary production of market pots with the same durability) and the highest environmental impact is obtained for option A (R2 = 0, no recycling at EoL, no credits). There are two opposing key drivers of this ordering: primary production credits (the more primary production is credited, the lower is the environmental impact) and aluminium sent to landfill (the more secondary fence board is sent to landfill, the higher is the environmental impact).

The substitution modelling has a strong impact on the value of the single score, but this leaves the question of the identification of the most relevant issues. The results presented in the Supplementary Information (Tables S11 and S12) show that the most relevant impact categories identified for all the study scenarios are more or less similar. Four impact categories always contribute the most: Climate change, Resource use—fossil fuels, Ecotoxicity—freshwater, and Eutrophication—freshwater (but ranked differently depending on the scenario). Some differences are observed in relation to Acidification, Resource use—minerals, and metals, and Human toxicity—cancer. The differences, and especially the significant contribution of Human toxicity—cancer, are a result of the environmental impact of primary steel. In all the scenarios with option 3, 41.04 kg of primary steel is debited, and the emissions of pollutants in the supply chain of the steel make the contribution of Human toxicity—cancer very relevant. In terms of identifying the most relevant life cycle stages, the results for all scenarios are similar. In all cases, the first life cycle stage, Materials & production—secondary board, is the clear hot spot. Table 4 shows that, when the single-issue AWARE method is used, the ranking obtained is different. In this case, scenarios with option 2 (2B, 2C, 2A, and 2D) are the best and scenarios with option 1 (1B, 1C, 1A, and 1D) are the worst. This has a direct connection with the most relevant impact categories mentioned above. Most of these are related to the extraction and combustion of fossil fuels. Methods like EF 3.0 and IMPACT World+ endpoint include over a dozen different impact categories. By contrast, the AWARE method only takes into account exchanges of water, and other elementary flows are not included in the analysis, so the ranking obtained with this method is based on the water flows alone. If the EF 3.0 and IMPACT World+ endpoint methods are used, no water-related impact category has been identified as significant (the share in the single score of Water use is below 3%). This means that the water-related hot spots are different from the fossil fuel-related ones, and they are mostly significant in scenarios with option 1 (1B, 1C, 1A, and 1D). From the point of view of the water footprint, the debit in the production of primary polyamide (nylon) is the most-relevant process. It accounts for about 40% of the environmental impact. In the scenarios with option 1, the substitution is based on the primary production of packaging materials, including polyamide (nylon). No debit in the production of polyamide occurs in other options.

The general key drivers are also similar—the electricity consumption, the debit of the production of primary materials (depending on the scenario: virgin packaging materials, virgin fencing materials, or virgin pot materials), and the landfilling of secondary fence board. The lower the quantity of materials needed per functional unit that are debited, the lower the environmental impact is. By contrast, the lower the quantity of materials needed per functional unit that is credited, the higher the environmental impact is. This works also for the durability of materials. The higher the durability, the lower the reference flow is. The greater durability of materials debited at the cradle stage reduces the environmental impact (as fewer materials are added). The greater durability of materials credited at the EoL increases the environmental impact (as fewer materials are avoided). The most relevant processes identified for the best and the worst scenarios either concern the life cycle of electricity (activity of hard coal and lignite mines and coal power plants) or about the life cycle of the primary fencing materials (extraction of raw materials and the production of pig iron, iron sinter, ferrochromium, ethylene, copper, etc.). General recommendations for further environmental development of the secondary fence board are to improve the energy efficiency of Recycling process I and to increase the recycling rate of the secondary fence board (to avoid landfilling). The first could be achieved by the recycling company reducing its electricity consumption and/or using renewable power and the second by developing recycling technologies.

A strong influence of the allocation method on the results of LCA has been revealed by different authors. Tinz et al. [22] made a comparative assessment of the carbon footprint for open-loop recycling across a cascade of three products (A, B, C) made of various plastics. Four life cycle stages were included in the system boundaries: raw material production, product manufacturing, use phase, and disposal. Three procedures are used to make the allocation: cut-off, 50:50, and end of life. A quality correction based on the physical value of tensile strength was used. As in our example, the raw production was identified by Tinz et al. as the most relevant life cycle stage. In a similar manner to this example, their study also highlighted that the magnitude of the environmental impact can change significantly (up to 44%) as a result of the accounting of credits and burdens, which depend on the allocation method selected [22]. Civancik-Uslu et al. [41] also investigated the effect of end-of-life (EoL) allocation and crediting strategies on LCA results. They studied the replacement of the sheets of eucalyptus wood used to separate loaded pallets with plastic alternatives composed of virgin polypropylene, recycled polypropylene, and mineral fillers. In their case study, the methodologies for crediting the system of plastic compound sheets did not change the results, since the loss of quality when recycling was low. Among the methodologies investigated by Civancik-Uslu et al. [41], an approach with open-loop recycling and market-mix substitution gave the highest environmental impact. This occurred because this approach considers both the use of the quality factor and the market share of recycled polypropylene. The study presented in this paper is specific because the scenarios investigated differ not only in the quality of the materials/products (durability), but also in understanding what is the material that is substituted. No similar case study has been found in the literature.

6. Conclusions

Many approaches for recycling and substitution modelling are described in the literature and used in LCA practice. One of the most recent proposals is the circular footprint formula developed by the European Commission as part of the Environmental Footprint Initiative [21]. Using the formula for closed-loop recycling seems clear and more transparent, while the application of open-loop recycling may be found to be more difficult and uncertain. The aim of this paper was to use the formula in a more complex situation—in which both recycling processes (at the cradle and at the end of life) are modelled as open-loop and provide secondary final products with various applications. This situation is likely to appear in practice, especially in the era of a circular economy. The calculations are based partially on real data taken from an existing recycling plant, partially on our own assumptions, and also, on secondary data for similar processes. The unique feature was that the scenarios analysed differed not only in the quality of the materials/products, but also in defining what is the substituted material (market-mix-based alternatives). The debiting and crediting of the product system investigated with market functional substitutes has been found as a key driver of the environmental impact in the life cycle of secondary fence board. Not only durability, but also the type of materials selected for market mix substitution strongly impacted the results. The debits at the cradle impacted the results more than the credits at end of life. This study is another example showing just how difficult the allocation process is. The existence of many different approaches to allocation makes it more difficult to deal with this problem in practice.

Supplementary Materials

The following Supporting Information can be downloaded at: https://www.mdpi.com/article/10.3390/resources13040052/s1, Figure S1: System boundaries in scenarios 1A (baseline), 2A, 3A, and 4A. Figure S2: System boundaries in scenarios with options B, C, and D. Table S1: Recycling at the cradle (Erecycled) and substitution modelling options for primary production (Ev), results per functional unit (1 m2 of secondary fence board). Table S2: Recycling at the EoL (Erecycling_EoL) and substitution modelling options for credited primary production (E*v), results per functional unit (1 m2 of secondary fence board). Table S3: Inventory results for production of secondary fence board (Recycling process I), results per FU, 1 m2 of fence board. Table S4: Inventory results for production of secondary garden pots (Recycling process II)—results per FU, 1 m2 of fence board. Table S5: Inventory results for life cycle stage materials and production, secondary fence board for options 1, 2, 3, and 4, results per FU, 1 m2 of fence board. Table S6: Inventory results for life cycle stage materials, auxiliary materials, results per FU, 1 m2 of fence board. Table S7: Inventory results for life cycle stage transport to the installation place, results per FU, 1 m2 of fence board. Table S8: Inventory results for life cycle stage installation and maintenance (15 years of lifetime), results per FU, 1 m2 of fence board. Table S9: Inventory results for life cycle stage end of life, auxiliary materials, results per FU, 1 m2 of fence board. Table S10: Inventory results for life cycle stage end of life, secondary fence board, results per FU, 1 m2 of fence board. Table S11: The environmental impact (single score) and results of the identification of the most relevant impact categories and life cycle stages, scenarios 4C (the best), 4B, 4D, 4A, 2C, 2B, 2D, and 1C. Table S12: The environmental impact (single score) and results of identification of the most relevant impact categories and life cycle stages, scenarios 2A, 1B, 1D, and 1A (baseline) and 3C, 3B, 3D, and 3A (the worst).

Author Contributions

Conceptualization, A.L., K.J.-L., P.K. and J.K.; methodology, A.L. and K.J.-L.; software, A.L.; validation, A.L. and J.K.; formal analysis, A.L.; investigation, A.L.; resources, A.L. and K.J.-L.; data curation, A.L.; writing—original draft preparation, A.L.; writing—review and editing, A.L., K.J.-L., P.K. and J.K.; visualization, A.L.; supervision, P.K.; project administration, P.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The specific company’s primary data for Recycling process I have been gathered from the analysed company and presented in Table 1. Data regarding the use of auxiliary materials and installation have been estimated based on the general instructions taken from the fencing panel installation guide (https://jagram.com.pl/blog/instrukcja-ogrodzenia-panelowego-na-twardej-powierzchni1 (accessed on 5 December 2023)). The mass of auxiliary materials has been estimated by using information from shops. Background processes have been modelled with secondary data taken from the ecoinvent v. 3.8 database available in SimaPro software. Market data for fencing panels and gardening pots accessed from grandviewresearch.

Acknowledgments

Some of the presented research related to Recycling process I was conducted as a part of the CIRCE2020 Project, financed by the INTERREG CENTRAL EUROPE program. This project was implemented by an international consortium. AM Trans Progres sp.z o.o. was the Polish partner.

Conflicts of Interest

The authors declare no conflicts of interest. The company AM Trans Progres sp. z o.o. was not involved in the study design, collection, analysis, interpretation of the data, the writing of this article, nor the decision to submit it for publication.

References

- COM(2020) 98 Final Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. A New Circular Economy Action Plan for a Cleaner and More Competitive Europe. Brussels, Belgium. Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:9903b325-6388-11ea-b735-01aa75ed71a1.0017.02/DOC_1&format=PDF (accessed on 5 December 2023).

- Pouikli, K. Concretising the role of extended producer responsibility in European Union waste law and policy through the lens of the circular economy. ERA Forum. 2020, 20, 491–508. [Google Scholar] [CrossRef]

- Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:02008L0098-20180705 (accessed on 8 December 2023).

- Dostatni, E. Recycling-Oriented Eco-Design Methodology Based on Decentralised Artificial Intelligence. Manag. Prod. Eng. Rev. 2018, 9, 79–89. [Google Scholar] [CrossRef]

- ISO/TR 14049; Environmental Management—Life Cycle Assessment—Illustrative Examples on How to Apply ISO 14044 to Goal and Scope Definition and Inventory Analysis. The International Organisation for Standardization: Brussels, Belgium, 2012.

- ISO 14067; Greenhouse Gases—Carbon Footprint of Products—Requirements and Guidelines for Quantification. The International Organisation for Standardization: Brussels, Belgium, 2018.

- Ha, K.H. Open-loop recycling to apply refrigerator plastics from post-consumer waste polypropylene. Mater. Des. 2012, 35, 310–317. [Google Scholar] [CrossRef]

- Uekert, T.; Singh, A.; DesVeaux, J.S.; Ghosh, T.; Bhatt, A.; Yadav, G.; Afzal, S.; Walzberg, J.; Knauer, K.M.; Nicholson, S.; et al. Technical, Economic, and Environmental Comparison of Closed-Loop Recycling Technologies for Common Plastic. ACS Sustain. Chem. Eng. 2023, 11, 965–978. [Google Scholar] [CrossRef]

- Myrin, E.S.; Börjesson, P.; Ericsson, K. A case study on closed-loop recycling of co-polyester plates—Assessment of material quality and life-cycle energy and greenhouse gas performance. Clean. Environ. Syst. 2022, 6, 100091. [Google Scholar] [CrossRef]

- Panda, R.; Mishra, S.; Pant, K.K.; Bhaskar, T.; Naik, S.N. A closed loop recycling strategy for sustainable recovery of group 11 metals (Cu, Au, and Ag) from waste PCBs: An amalgamation of low-temperature NH4Cl roasting, HCl leaching and cementation. Sustain. Mater. Techno. 2023, 37, e00652. [Google Scholar] [CrossRef]

- Ha, K.H.; Kim, M.S. Application to refrigerator plastics by mechanical recycling from polypropylene in waste-appliances. Mater. Des. 2012, 34, 252–257. [Google Scholar] [CrossRef]

- Kasmi, N.; Backström, E.; Hakkarainen, M. Open-loop recycling of post-consumer PET to closed-loop chemically recyclable high-performance polyimines. Resour. Conserv. Recycl. 2023, 193, 106974. [Google Scholar] [CrossRef]

- Khoshnevisan, B.; Rafiee, S.; Tabatabaei, M. Waste Management Strategies: Life Cycle Assessment (LCA) Approach. In Biogas Fundamentals, Process, and Operation, 1st ed.; Tabatabaei, M., Ghanavati, H., Eds.; Springer International Publishing AG: Cham, Switzerland, 2018; pp. 305–332. [Google Scholar]

- Koci, V.; Trecakova, T. Mixed municipal waste management in the Czech Republic from the point of view of the LCA method. Int. J. Life Cycle Assess 2011, 16, 113–124. [Google Scholar] [CrossRef]

- den Boer, J.; Obersteiner, G.; Gollnow, S.; den Boer, E.; Bodnárné Sándor, R. Enhancement of Food Waste Management and Its Environmental Consequences. Energies 2021, 14, 1790. [Google Scholar] [CrossRef]

- Manfredi, S.; Pant, R. Improving the environmental performance of bio-waste management with life cycle thinking (LCT) and life cycle assessment (LCA). Int. J. Life Cycle Assess 2013, 18, 285–291. [Google Scholar] [CrossRef]

- Ekvall, T.; Björklund, A.; Sandin, G.; Jelse, K. Modeling Recycling in Life Cycle Assessment; Report Number: 2020:05; Swedish Life Cycle Centre: 2020, p. 138. Available online: https://www.lifecyclecenter.se/wp-content/uploads/2020_05_Modeling-recyling-in-life-cycle-assessment-1.pdf (accessed on 6 December 2023).

- The Guide to PAS 2050:2011 How to Carbon Footprint Your Products, Identify Hotspots and Reduce Emissions in Your Supply Chain; British Standards Institution: London, UK, 2011; p. 79. Available online: https://www.wkcgroup.com/wp-content/uploads/2023/02/PAS-2050-Assessment-of-the-life-cycle-greenhouse-gas-emissions-of-goods-and-services.pdf (accessed on 12 February 2024).

- Greenhouse Gas Protocol Technical Guidance for Calculating Scope 3 Emissions Supplement to the Corporate Value Chain (Scope 3) Accounting & Reporting Standard. World Resources Institute & World Business Council for Sustainable Development: Geneva, Switzerland, 2013; p. 182. Available online: https://ghgprotocol.org/sites/default/files/2023-03/Scope3_Calculation_Guidance_0%5B1%5D.pdf (accessed on 12 February 2024).

- Zampori, L.; Pant, R. Suggestions for Updating the Product Environmental Footprint (PEF) Method; Publications Office of the European Union: Luxemburg, 2019; p. 248. Available online: https://eplca.jrc.ec.europa.eu/permalink/PEF_method.pdf (accessed on 12 February 2024).

- Recommendation 2021/2279/EU Commission Recommendation (EU) of 15 December 2021 on the Use of the Environmental Footprint Methods to Measure and Communicate the Life Cycle Environmental Performance of Products and Organisations. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32021H2279 (accessed on 5 December 2023).

- Tinz, J.; de Ancos, T.; Volker, F.; Rohn, H. Application of allocation methods in open-loop recycling systems: The carbon footprint of injection molded products based on ABS, PA66GF30, PC and POM. Resour. Conserv. Recycl. 2023, 19, 200176. [Google Scholar] [CrossRef]

- Klöpffer, W.; Grahl, B. Life Cycle Assessment (LCA): A Guide to Best Practice, 1st ed.; Wiley-VCH: Weinheim, Germany, 2000; pp. 1–440. [Google Scholar]

- Guinée, J.B.; Gorrée, M.; Heijungs, R.; Huppes, G.; Kleijn, R.; Koning, A.; de Oers, L.; van Wegener Sleeswijk, A.; Suh, S.; Udo de Haes, H.A.; et al. Handbook on Life Cycle Assessment. Operational Guide to the ISO Standards. III: Scientific Background, 1st ed.; Kluwer Academic Publishers: Dordrech, The Netherlands, 2002; pp. 1–314. [Google Scholar]

- European Commission; Joint Research Centre; Institute for Environment and Sustainability. ILCD International Reference Life Cycle Data System (ILCD) Handbook—General guide for Life Cycle Assessment—Detailed Guidance, 1st ed.; Office of the European Union: Luxembourg, 2010; pp. 1–417. Available online: https://eplca.jrc.ec.europa.eu/uploads/ILCD-Handbook-General-guide-for-LCA-DETAILED-GUIDANCE-12March2010-ISBN-fin-v1.0-EN.pdf (accessed on 5 December 2023).

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. The International Organisation for Standardization: Brussels, Belgium, 2006.

- ILCD Handbook: Recommendations for Life Cycle Impact Assessment in the European Context; Publication office of the European Commission: Luxemburg. 2011, p. 230. Available online: https://eplca.jrc.ec.europa.eu/uploads/ILCD-Handbook-Recommendations-for-Life-Cycle-Impact-Assessment-in-the-European-context.pdf (accessed on 12 February 2024).

- SimaPro Database Manual. Methods Library. Available online: https://simapro.com/wp-content/uploads/2022/07/DatabaseManualMethods.pdf (accessed on 8 December 2023).

- Sala, S.; Cerutti, A.K.; Pant, R. Development of a Weighting Approach for the Environmental Footprint; JRC Technical Report; Publication office of the European Commission: Luxemburg, 2018; p. 146. Available online: https://op.europa.eu/en/publication-detail/-/publication/6c24e876-4833-11e8-be1d-01aa75ed71a1/language-en (accessed on 12 February 2024).

- Allacker, K.; Mathieux, F.; Pennington, D.; Pant, R. The search for an appropriate end-of-life formula for the purpose of the European Commission Environmental Footprint initiative. Int. J. Life Cycle Assess 2017, 22, 1441–1458. [Google Scholar] [CrossRef]

- PAS 2050—Specification for the Assessment of the Life Cycle Greenhouse Gas Emissions of Goods and Services; The British Standards Institution: London, UK, 2008; pp. 1–43. Available online: http://www.carbonconstruct.com/pdf/pas_2050.pdf (accessed on 5 December 2023).

- Product Life Cycle Accounting and Reporting Standard; World Resources Institute and World Business Council for Sustainable Development: Washington, DC, USA, 2011; p. 148. Available online: https://ghgprotocol.org/sites/default/files/standards/Product-Life-Cycle-Accounting-Reporting-Standard_041613.pdf (accessed on 12 February 2024).

- Lindfors, L.G.; Christiansen, K.; Hoffman, L.; Virtanen, Y.; Juntilla, V.; Hanssen, O.J.; Rønning, A.; Ekvall, T.; Finnveden, G. Nordic Guidelines on Life-Cycle Assessment; Nord 1995:20; Nordic Council of Ministers: Copenhagen, Denmark, 1995; p. 226. ISBN 92 9120 692 X. [Google Scholar]

- Ekvall, T. A market-based approach to allocation at open-loop recycling. Resour. Conserv. Recycl. 2000, 29, 91–109. [Google Scholar] [CrossRef]

- Schrijvers, D.L.; Loubet, F.; Weidema, B.P. To what extent is the Circular Footprint Formula of the Product Environmental Footprint Guide consequential? J. Clean Prod. 2021, 320, 128800. [Google Scholar] [CrossRef]

- Mengarelli, M.; Neugebauer, S.; Finkbeiner, M.; Germani, M.; Buttol, P.; Reale, F. End-of-life modelling in life cycle assessment—Material or product-centred perspective? Int. J. Life Cycle Assess 2017, 22, 1288–1301. [Google Scholar] [CrossRef]

- COM(2007) 59 final Communication from the Commission to the Council and the European Parliament on the Interpretative Communication on Waste and By-Products. Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=COM:2007:0059:FIN:EN:PDF (accessed on 12 February 2024).

- Environmental Footprint Reference Packages. Annex C Transition Phase. Available online: https://view.officeapps.live.com/op/view.aspx?src=https%3A%2F%2Feplca.jrc.ec.europa.eu%2Fpermalink%2FAnnex_C_V2.1_May2020.xlsx&wdOrigin=BROWSELINK (accessed on 12 February 2024).

- Grandviewresearch Fencing Market Size, Share & Trends Analysis Report By Material, Grandviewresearch Report ID: 978-1-68038-526-7. Available online: https://www.grandviewresearch.com/industry-analysis/fencing-market (accessed on 19 November 2020).

- Grandviewresearch Gardening Pots Market Size, Share & Trends Analysis Report By Product (Refractory Material, Polymer), Grandviewresearch Report ID: GVR-3-68038-552-6. Available online: https://www.grandviewresearch.com/industry-analysis/gardening-pots-market (accessed on 19 November 2020).

- Civancik-Uslu, D.; Puig, R.; Ferrer, L.; Fullana-i-Palmer, P. Influence of end-of-life allocation, credits and other methodological issues in LCA of compounds: An in-company circular economy case study on packaging. J. Clean Prod. 2019, 212, 925–940. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).