Continuous Assessment of the Environmental Impact and Economic Viability of Decarbonization Improvements in Cement Production

Abstract

1. Introduction

2. Materials and Methods

2.1. Life Cycle Assessment (LCA)

- Goal and scope definition (including functional unit and system boundaries);

- Life Cycle Inventory (LCI);

- Life Cycle Impact Assessment (LCIA);

- Interpretation.

| Life cycle stage | Cement | Cement | Clinker | Clinker | Concrete | Concrete | |

| Goal and scope definition | Functional unit | 1 ton Portland cement | 1 ton of ordinary Portland cement and 1 ton of clinker | 1 ton of clinker | 1 kg of clinker | Varied specific measures of concrete | 1 m3 of concrete |

| System boundaries | Raw materials and fuels extraction, transportation, electricity usage, and emissions | Life cycle inventory analysis | Cradle-to-gate LCA model. Clinker production in cement kiln, excluding blending and grinding | Cradle-to-gate LCA for old and new cement production lines. Clinker production, excluding blending and grinding | Modified cradle-to-gate. Comparison of traditional and ‘green’ concrete | Cradle-to-gate LCA of graphene production and use in concrete | |

| Country | Brazil | China | Switzerland | Spain | UK | ||

| Life cycle Inventory (LCI) | Inputs and outputs | In—sand, limestone, clinker, chemical additives, and transportation Out—NOx, CO2, HCl, HF, Hg, Pb, Cd, Ta, and Dioxins | In—limestone, sandstone, ferrous tailings and gypsums, energy from coal and electricity, admixtures (fly ash and furnace slag, freshwater) Out—GHG, primary pollution, hazardous air pollutants, noise, heavy metal emissions | In—alternative fuel and raw materials (tires, prepared industrial waste, dried sewage sludge, blast furnace slag) Out—carbon, nitrogen, chloride, fluoride compounds, clinker, raw meal, cement, and kiln dust | In—limestone, sand, iron ore, clay, electricity generation, and heat Out—CO2, NOx, SO2 particulates | In—minerals and fossil fuels, land use Out—NOx, SOx, NH3, pesticides, heavy metals, CO2, hydrochlorofluorocarbons (HCFC), nuclides, polycyclic aromatic hydrocarbons (PAHs), volatile organic compounds, and suspended particulate matter (SPM) | In—Portland cement, ground granulated blast-furnace slag, limestone, sand, water, superplasticizer, graphene nanoplatelets paste, and input energy |

| Data source | Plant, national statistics, and Ecoinvent database | On-site, 18 cement plants with 30 production lines from 2004 to 2007 | On-site, Ecoinvent database | On-site plant data. SimaPro 7.2 software. Ecoinvent 3.0 | LCA-related journals | Commercial companies and the scientific literature. SimaPro software | |

| Life cycle Impact Assessment | LCIA method | ISO Environmental Management—Life Cycle Assessment | Cumulative exergy demand (CExD) [30], eco-indicator | Cumulative exergy demand (CExD) [30] | IPCC 2007 Global Warming Potential (GWP) impact method | Impact 2002 + methodology [31] | |

| Impact analyzed | Ozone depletion, photochemical oxidant formation, terrestrial acidification, freshwater and marine eutrophication, and metal and fossil depletion | Freshwater consumption, noise emissions, heavy metal and hazardous pollution emissions, and indirect consumption of oil and coal | Gas emissions | Global warming, acidification, eutrophication, abiotic depletion, ozone layer depletion, freshwater aquatic ecotoxicity, and photochemical oxidation | Acidification, eutrophication, ecotoxicity, climate change, ozone layer depletion, ionizing radiation, respiratory effects, and carcinogenic | Carcinogens and non-carcinogens, respiratory inorganics, aquatic and terrestrial ecotoxicity, global warming, non-renewable energy, and mineral extraction | |

| Literature reference | [20] | [21] | [30] | [19] | [32] | [33] |

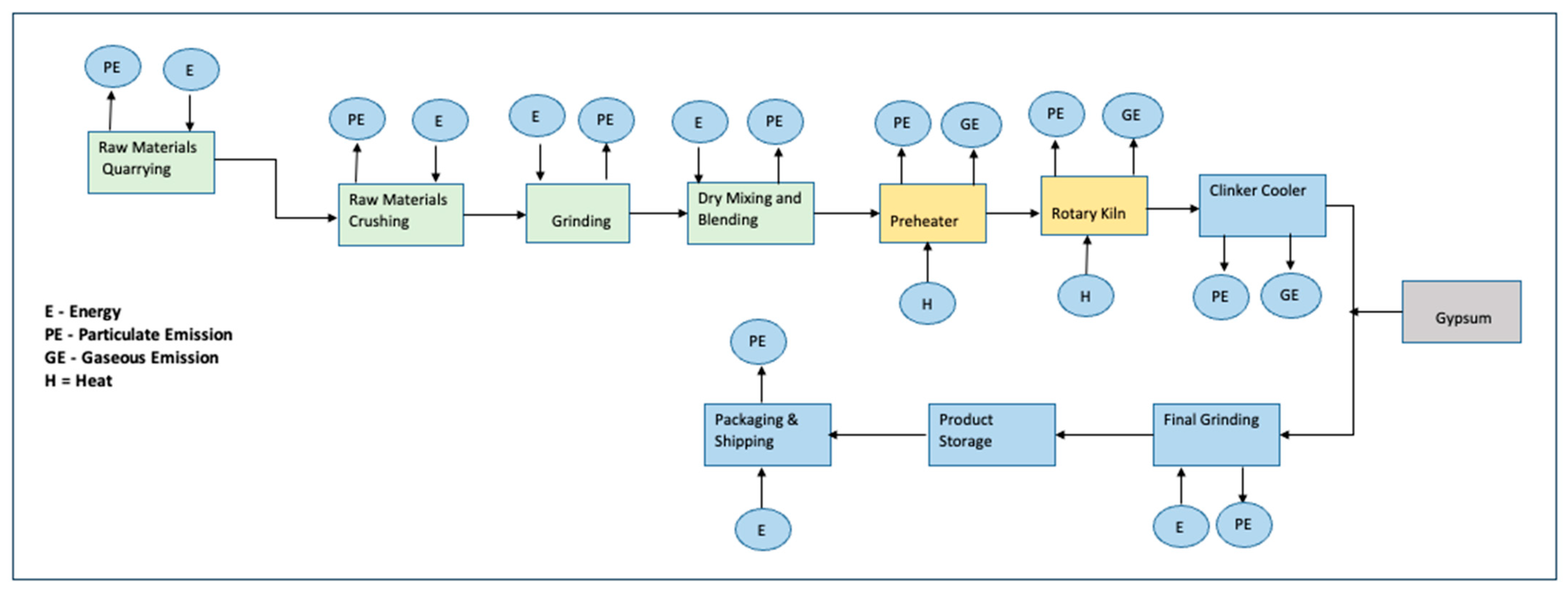

2.1.1. Scope of the Model: Functional Unit and System Boundaries

2.1.2. Life Cycle Inventory

- Union Bridge quarry operations;

- New Windsor quarry operations;

- Raw material transport and storage;

- Raw grinding;

- Raw meal—kiln feed;

- Kiln and clinker cooler;

- Coal grinding mill for kiln;

- Clinker transport and storage;

- Clinker finish mills;

- Cement storage and shipping with bag packing;

- Dried-biosolids-related processes;

- Emergency generator.

2.1.3. Life Cycle Impact Modeling

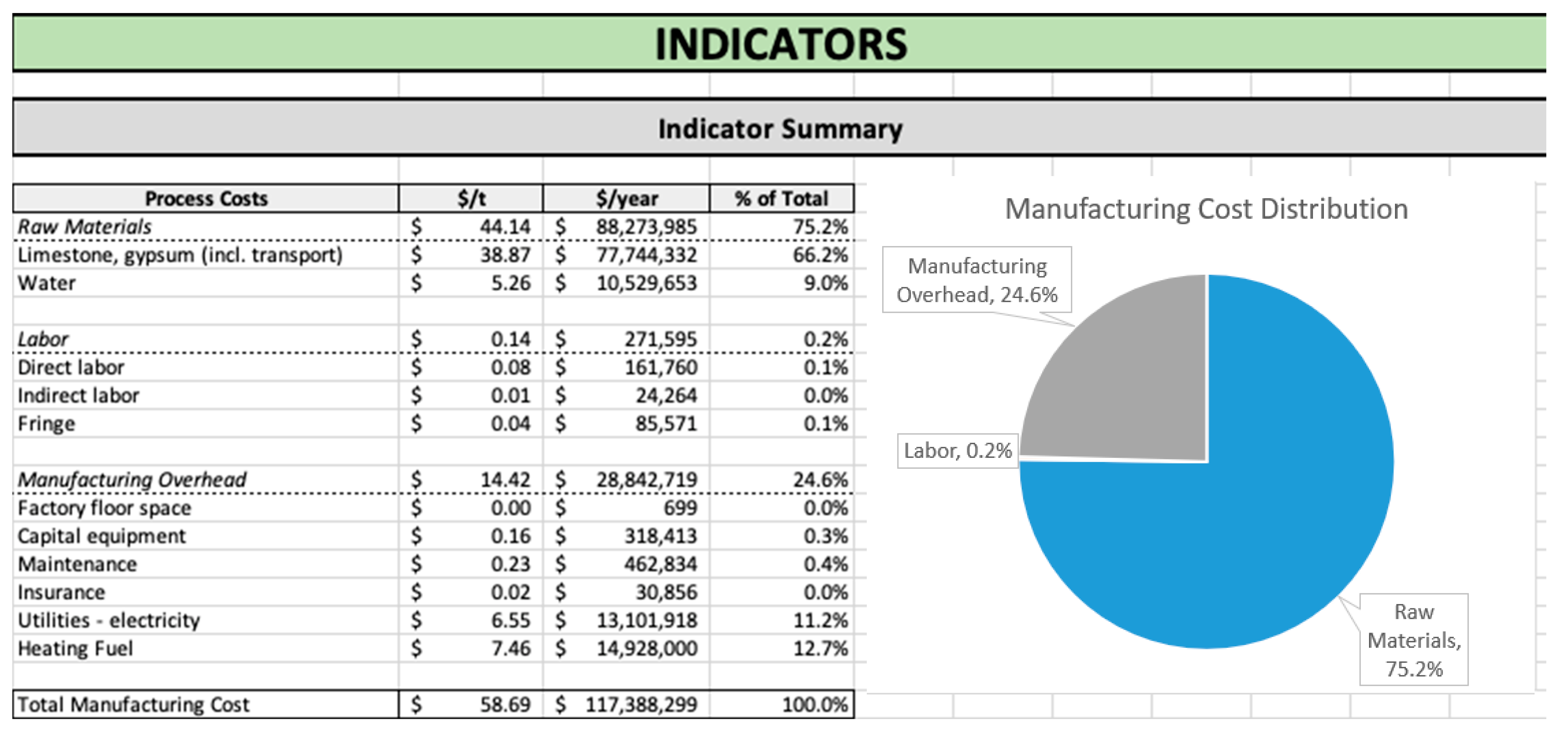

2.2. Techno-Economic Assessment

| Method | Decarbonization Lever | Materials/ Equipment | Process Summary | Cost Example | Reference |

|---|---|---|---|---|---|

| Methods Increasing Process Energy Efficiency—Process Decarbonization | |||||

| Introduction of energy-efficient clinker technology with low cooling air requirement | Process decarbonization | Modern grate clinker coolers | Optimization of clinker coolers | Varies due to site specifics | [13] |

| Waste heat recovery | Boiler/turbine system | Waste heat is used for drying, steam production, or feeding the local heat network. Decrease of 4–15 kg CO2/t clinker | Depends on local power prices | ||

| Replacing long wet/ semi-dry kilns with energy-efficient preheater/pre-calciner kilns | Construction may be required | Raw material has lower moisture content. Additional cyclone stage. Thermal energy decrease of 900–2800 MJ/t clinker. Electrical energy decrease of 0–5 kWh/t clinker | A 35–50 M EUR investment and 2.85–9.2 EUR/t clinker decrease in operating cost | ||

| Methods utilizing alternative fuels—Circular Economy, e.g., solid wastes, different biomass sorts, and fuels with lower heating values | Circular economy | Sewage sludge, wood waste, grain rejects, animal meal, mixed industrial waste, waste oil, tires, and plastics | Use for combustion in a pre-calciner vessel. Integrate waste management. Processing compliant with international environmental agreements and local policies | Investment costs for storage, handling, and pretreatment, lower operational costs, and 15–30% of coal price in Europe | [13] |

| Methods utilizing different raw materials to reduce emissions from limestone decomposition—Circular Economy | Circular Economy | Already decarbonated materials, e.g., metallurgical slags, coal ashes, and concrete crusher residues | Limits process-related and fuel-related CO2 emissions | Limited availability of materials | [13] |

| Decarbonization strategies—process decarbonization | |||||

| Post-combustion capture. Decarbonizes flue gases generated from the total oxidation process | Process decarbonization | Solvents that react with CO2, e.g., MDEA, MEA, DEA, AMP, and PZ * | CO2 absorbing reaction, heat to reverse absorption, moisture removal, compression, transportation, and storage/utilization | 50.6 USD/ton [46] | [47] |

| Natural and synthetic calcium-based sorbents | |||||

| Polymeric membranes | Compress flue gas, pass through stages of membranes and compression to capture CO2 | [48] | |||

| Pre-combustion capture. Decarbonizes syngas resulting from fuel partial oxidation process before combustion | Synthetic gas from feedstock (e.g., coal), steam, air, and heat | Water–gas shift reaction, CO2 capture, separation, transportation, and sequestering | 60 USD/ton capture cost | [49] | |

| Oxy-combustion uses oxygen rather than air for fuel total oxidation | Oxygen-rich medium | Fuel combustion in a pure or enriched oxygen stream | 60–70 EUR/ton CO2 avoided cost | [50] | |

| Other methods | |||||

| Electrification and renewable procurement—clean energy | Clean energy | Synchronous power such as hydropower and biomass. Variable generation, such as wind and solar | Reusability, recyclability, and product longevity | Varies by site and is influenced by the price and availability of zero-carbon electricity | [51] |

| Eco planet and efficiency gains in construction—carbon-efficient Construction | Carbon-efficient Construction | Design and engineering techniques to reduce the amount of concrete required | Examples: curved fabric molds, pre-stressed concrete using tensioned steel cables. Concrete mixture optimization. | Varies | |

Techno-Economic Assessment Method

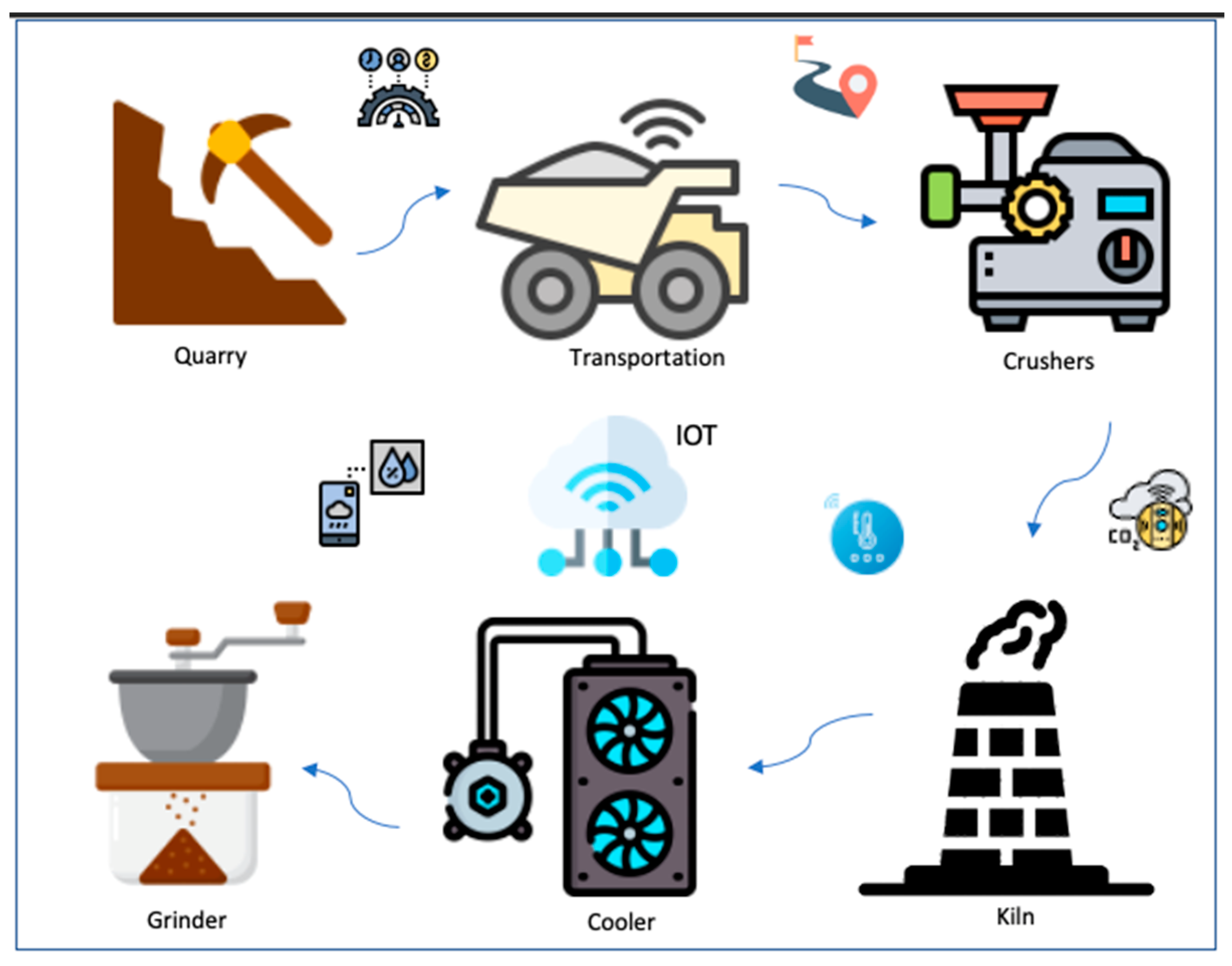

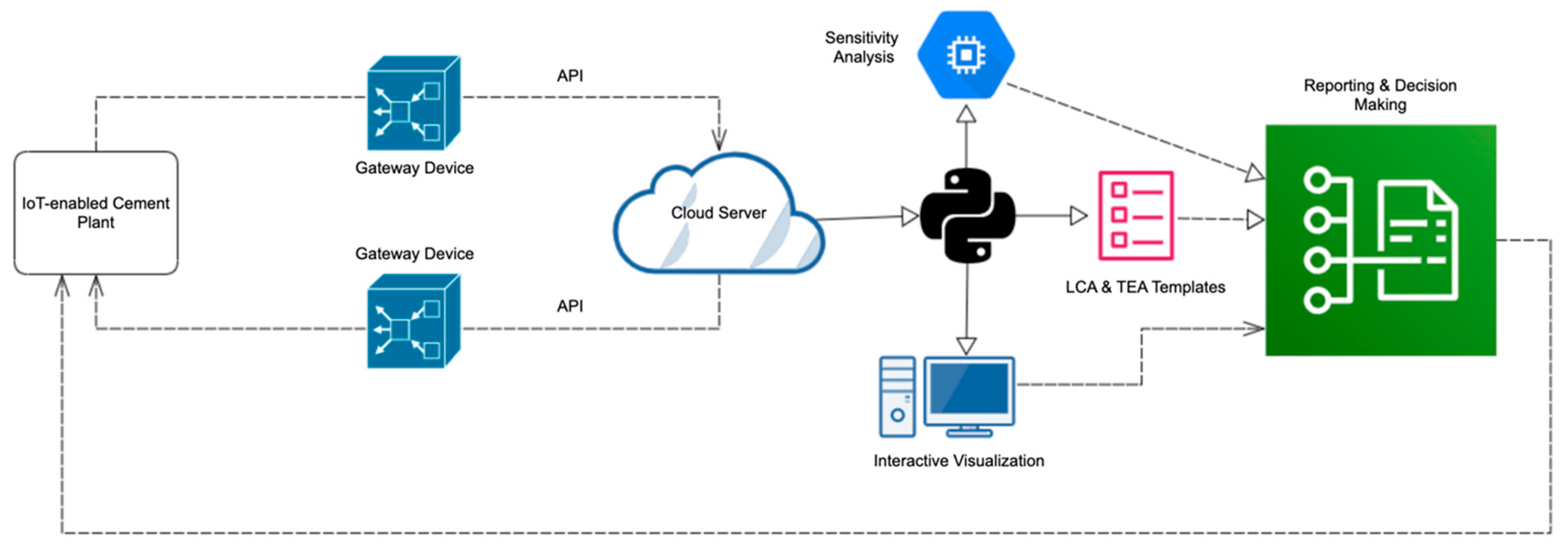

2.3. Continuous Assessment and Improvement Deployment Framework

- Secured deployment [54];

- Event tracking in supervisory control and data acquisition system [55];

- Fuzzy-logic-based flame image processing for rotary kiln temperature control [56];

- IoT-regulated moisture sensor [57];

- Real-time carbon dioxide monitoring based on IoT cloud technologies—MQ135 carbon dioxide sensor, ESP8266 Wi-Fi module, Firebase cloud storage service, and Android application [58].

3. Results and Discussion

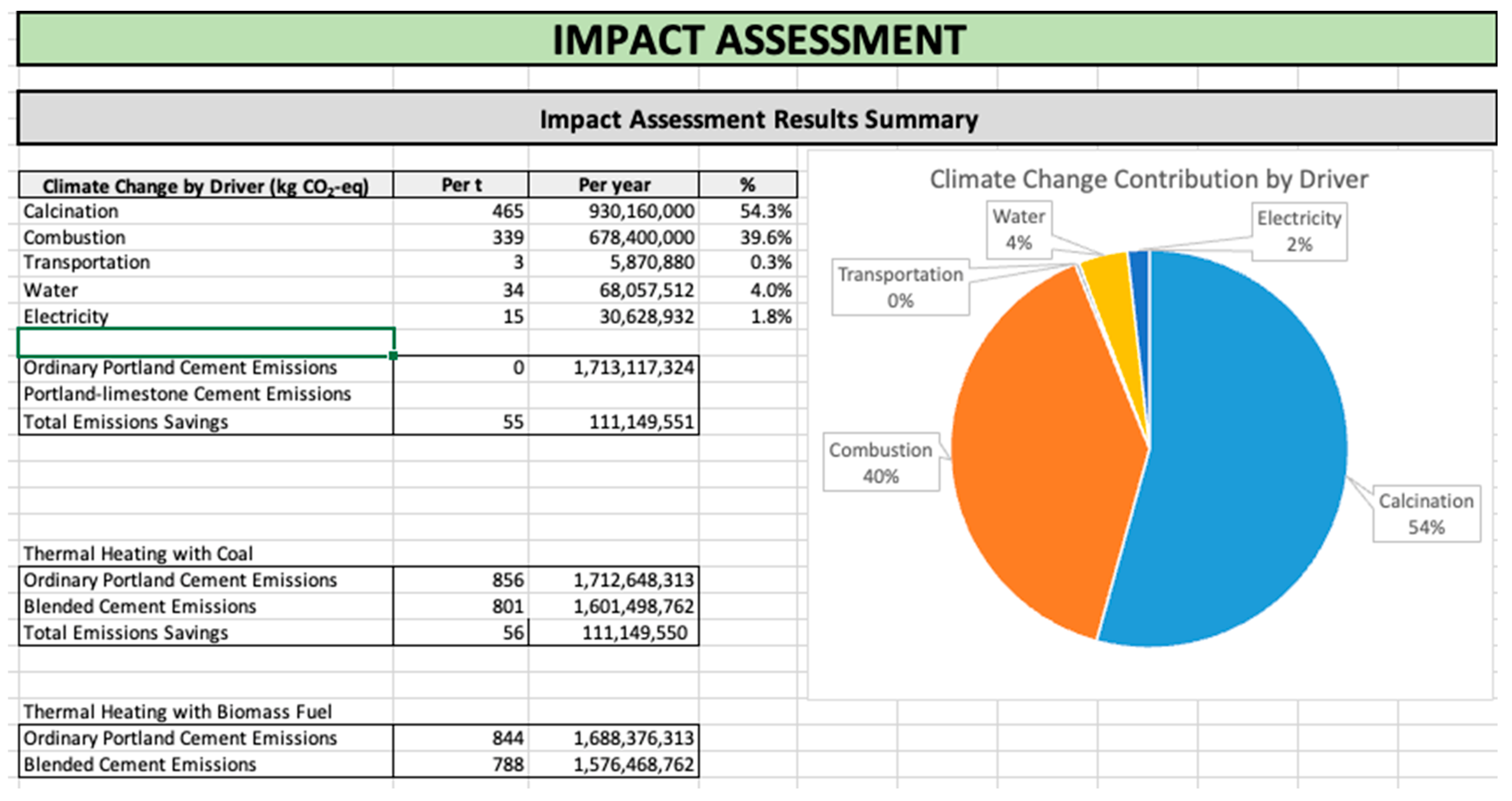

3.1. Impacts Analysis

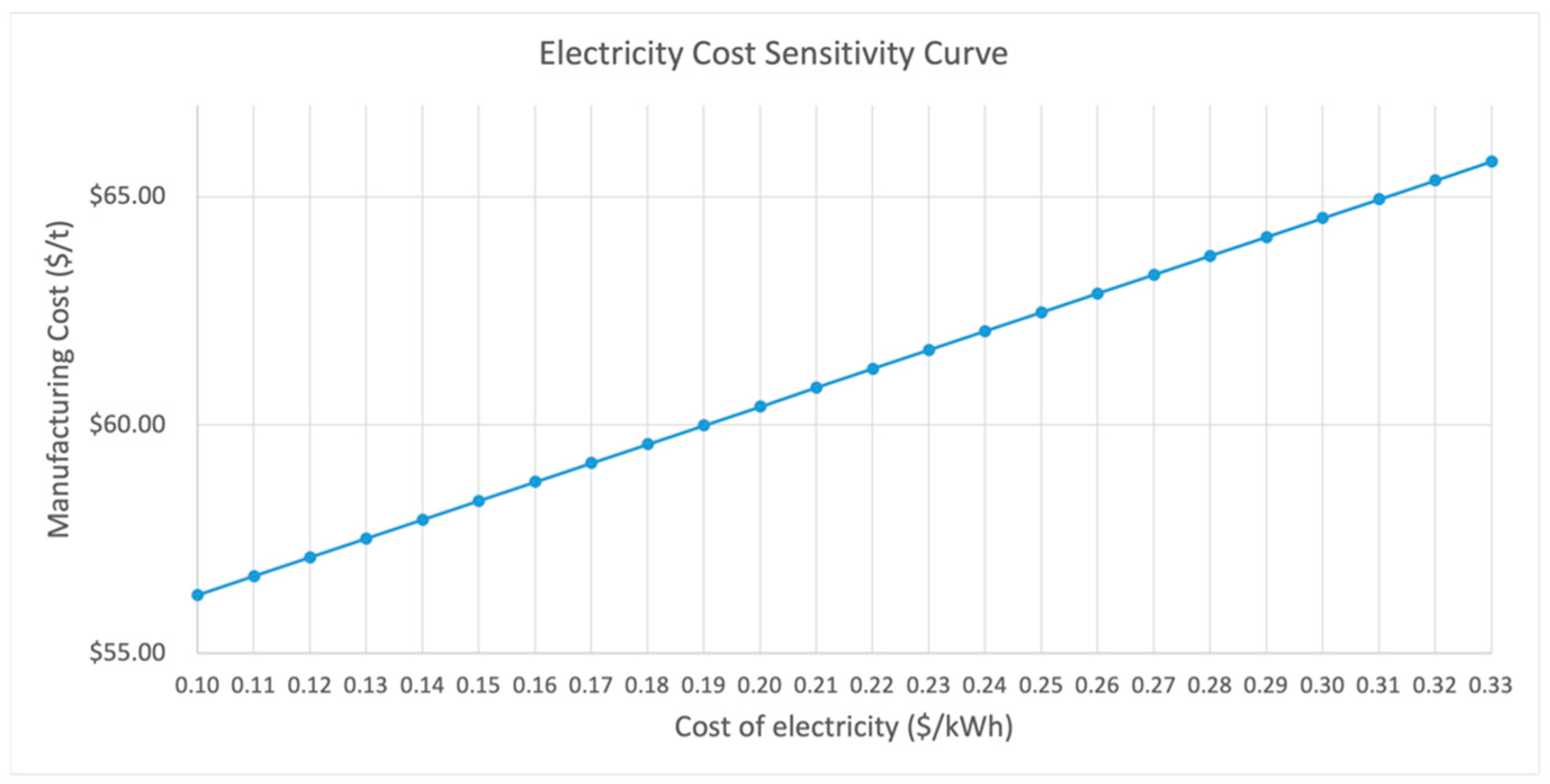

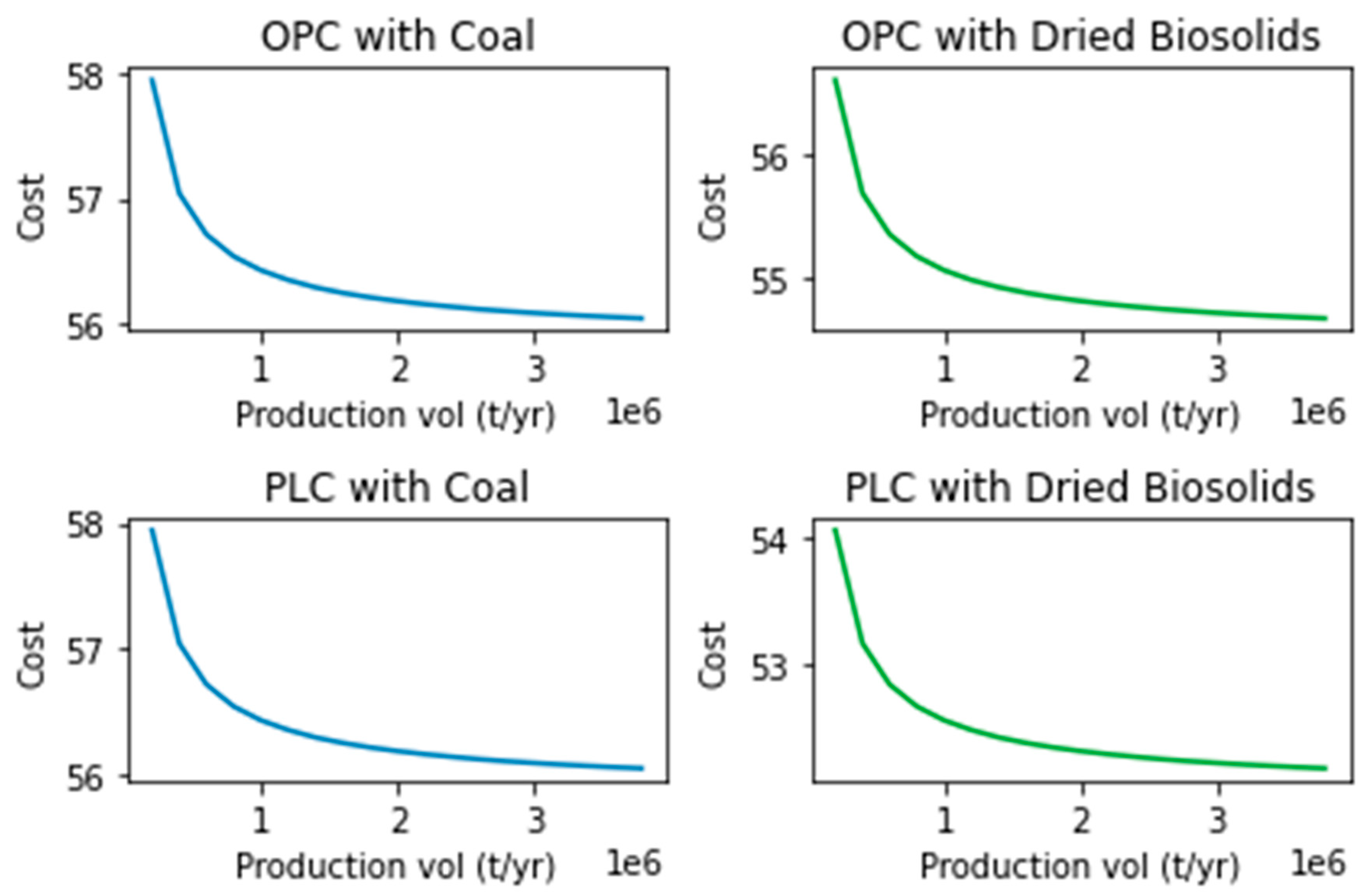

3.2. Economic Analysis

3.3. The Deployment Framework

3.4. Limitations

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ellis, L.D.; Badel, A.F.; Chiang, M.L.; Park, R.J.-Y.; Chiang, Y.-M. Toward electrochemical synthesis of cement—An electrolyzer-based process for decarbonating CaCO3 while producing useful gas streams. Proc. Natl. Acad. Sci. USA 2019, 117, 12584–12591. [Google Scholar] [CrossRef] [PubMed]

- Habert, G.; Miller, S.A.; John, V.M.; Provis, J.L.; Favier, A.; Horvath, A.; Scrivener, K.L. Environmental impacts and decarbonization strategies in the cement and concrete industries. Nat. Rev. Earth Environ. 2020, 1, 559–573. [Google Scholar] [CrossRef]

- Lehne, J.; Preston, F. Making Concrete Change: Innovation in Low-Carbon Cement and Concrete; The Royal Institute of International Affairs: London, UK, 2018. [Google Scholar]

- Fennell, P.S.; Davis, S.J.; Mohammed, A. Decarbonizing cement production. Joule 2021, 5, 1305–1311. [Google Scholar] [CrossRef]

- Frauke, S.; Ioanna, K.; Maria, S.B.; Serge, R.; Luis, D.S. Best Available Techniques (BAT) Reference Document for the Production of Cement, Lime and Magnesium Oxide: Industrial Emissions Directive 2010/75/EU:(Integrated Pollution Preven-tion and Control); Publications Office of the European Union: Luxembourg, 2013. [Google Scholar]

- Peridas, G.; Schmidt, B.M. The role of carbon capture and storage in the race to carbon neutrality. Electr. J. 2021, 34, 106996. [Google Scholar] [CrossRef]

- Usón, A.A.; López-Sabirón, A.M.; Ferreira, G.; Sastresa, E.L. Uses of alternative fuels and raw materials in the cement industry as sustainable waste management options. Renew. Sustain. Energy Rev. 2013, 23, 242–260. [Google Scholar] [CrossRef]

- Scripcariu, M.; Gheorghiu, C.; Gheorghiu, M.; Dobrica, A.G. Improving energy performance of a Cement Manufacturing factory by using Waste Heat Recovery Systems, Estimated vs. Actual achievements. E3S Web Conf. 2021, 286, 01007. [Google Scholar] [CrossRef]

- Zimmermann, A.W.; Langhorst, T.; Moni, S.; Schaidle, J.A.; Bensebaa, F.; Bardow, A. Life-Cycle and Techno-Economic Assessment of Early-Stage Carbon Capture and Utilization Technologies—A Discussion of Current Challenges and Best Practices. Front. Clim. 2022, 4, 841907. [Google Scholar] [CrossRef]

- Busch, P.; Kendall, A.; Murphy, C.W.; Miller, S.A. Literature review on policies to mitigate GHG emissions for cement and concrete. Resour. Conserv. Recycl. 2022, 182, 106278. [Google Scholar] [CrossRef]

- Boakye, K.; Winters, D.; Simske, S. Literature review and challenges for the adaptation, implementation of digitiza-tion, and data analytics for operational excellence in the cement and aggregate production industry. In Proceedings of the 2022 SME Annual Meeting & Expo, Salt Lake City, UT, USA, 27 February–2 March 2022. [Google Scholar]

- Fatahi, R.; Nasiri, H.; Dadfar, E.; Chelgani, S.C. Modeling of energy consumption factors for an industrial cement vertical roller mill by SHAP-XGBoost: A “conscious lab” approach. Sci. Rep. 2022, 12, 7543. [Google Scholar] [CrossRef]

- IEA Paris. Cement. 2021. Available online: https://www.iea.Org/Reports/Cement (accessed on 6 February 2023).

- Heidelberg Materials. Available online: https://heidelbergmaterials.us/products/cement/EcoCemPLC (accessed on 3 January 2023).

- Faber, G.; Mangin, C.; Sick, V. Life Cycle and Techno-Economic Assessment Templates for Emerging Carbon Management Technologies. Front. Sustain. 2021, 2, 764057. [Google Scholar] [CrossRef]

- Klöpffer Grahl, B.; Grahl, B. Life Cycle Assessment (LCA): A Guide to Best Practice; Wiley-VCH: Weinheim, Germany, 2014. [Google Scholar]

- Huntzinger, D.N.; Eatmon, T.D. A life-cycle assessment of Portland cement manufacturing: Comparing the traditional process with alternative technologies. J. Clean. Prod. 2009, 17, 668–675. [Google Scholar] [CrossRef]

- Feiz, R.; Ammenberg, J.; Baas, L.; Eklund, M.; Helgstrand, A.; Marshall, R. Improving the CO2 performance of ce-ment, part I: Utilizing lifecycle assessment and key performance indicators to assess development within the cement industry. J. Clean. Prod. 2015, 98, 272–281. [Google Scholar] [CrossRef]

- Valderrama, C.; Granados, R.; Cortina, J.L.; Gasol, C.M.; Guillem, M.; Josa, A. Implementation of best available techniques in cement manufacturing: A life-cycle assessment study. J. Clean. Prod. 2012, 25, 60–67. [Google Scholar] [CrossRef]

- Stafford, F.N.; Raupp-Pereira, F.; Labrincha, J.A.; Hotza, D. Life cycle assessment of the production of cement: A Brazilian case study. J. Clean. Prod. 2016, 137, 1293–1299. [Google Scholar] [CrossRef]

- Li, C.; Nie, Z.; Cui, S.; Gong, X.; Wang, Z.; Meng, X. The life cycle inventory study of cement manufacture in China. J. Clean. Prod. 2014, 72, 204–211. [Google Scholar] [CrossRef]

- Finkbeiner, M.; Inaba, A.; Tan, R.; Christiansen, K.; Klüppel, H.-J. The New International Standards for Life Cycle Assessment: ISO 14040 and ISO 14044. Int. J. Life Cycle Assess. 2006, 11, 80–85. [Google Scholar] [CrossRef]

- Sinden, G. The contribution of PAS 2050 to the evolution of international greenhouse gas emission standards. Int. J. Life Cycle Assess. 2009, 14, 195–203. [Google Scholar] [CrossRef]

- Sánchez, A.R.; Ramos, V.C.; Polo, M.S.; Ramón, M.V.L.; Utrilla, J.R. Life Cycle Assessment of Cement Production with Marble Waste Sludges. Int. J. Environ. Res. Public Health 2021, 18, 10968. [Google Scholar] [CrossRef]

- Zulcão, R.; Calmon, J.L.; Rebello, T.A.; Vieira, D.R. Life cycle assessment of the ornamental stone processing waste use in cement-based building materials. Constr. Build. Mater. 2020, 257, 119523. [Google Scholar] [CrossRef]

- Tait, M.W.; Cheung, W.M. A comparative cradle-to-gate life cycle assessment of three concrete mix designs. Int. J. Life Cycle Assess. 2016, 21, 847–860. [Google Scholar] [CrossRef]

- Nakic, D. Environmental evaluation of concrete with sewage sludge ash based on LCA. Sustain. Prod. Consum. 2018, 16, 193–201. [Google Scholar] [CrossRef]

- Liew, K.M.; Akbar, A. The recent progress of recycled steel fiber reinforced concrete. Constr. Build. Mater. 2020, 232, 117232. [Google Scholar] [CrossRef]

- Patel, D.; Shrivastava, R.; Tiwari, R.; Yadav, R. Properties of cement mortar in substitution with waste fine glass powder and environmental impact study. J. Build. Eng. 2019, 27, 100940. [Google Scholar] [CrossRef]

- Boesch, M.E.; Koehler, A.; Hellweg, S. Model for Cradle-to-Gate Life Cycle Assessment of Clinker Production. Environ. Sci. Technol. 2009, 43, 7578–7583. [Google Scholar] [CrossRef] [PubMed]

- Jolliet, O.; Margni, M.; Charles, R.; Humbert, S.; Payet, J.; Rebitzer, G.; Rosenbaum, R. IMPACT 2002+: A new life cycle impact assessment methodology. Int. J. Life Cycle Assess. 2003, 8, 324–330. [Google Scholar] [CrossRef]

- van den Heede, P.; De Belie, N. Environmental impact and life cycle assessment (LCA) of traditional and ‘green’ concretes: Literature review and theoretical calculations. Cem. Concr. Compos. 2012, 34, 431–442. [Google Scholar] [CrossRef]

- Papanikolaou, I.; Arena, N.; Al-Tabbaa, A. Graphene nanoplatelet reinforced concrete for self-sensing structures—A lifecycle assessment perspective. J. Clean. Prod. 2019, 240, 118202. [Google Scholar] [CrossRef]

- Weidema, B.P. Improving the performance of life cycle assessment. In Proceedings of the 2. International Conference on EcoBalance, Tsukuba, Japan, 18–20 November 1996; pp. 247–252. [Google Scholar]

- Operating Permit (2017). Available online: https://mde.maryland.gov/programs/permits/AirManagementPermits/Test/Lehigh%20Union%20Bridge.pdf (accessed on 6 February 2023).

- Zimmermann, A.; Müller, L.; Wang, Y.; Langhorst, T.; Wunderlich, J.; Marxen, A.; Armstrong, K.; Buchner, G.; Kätelhön, A.; Bachmann, M.; et al. Deep Blue Home Login Home/Research Collections/Global CO2 Initiative/View Item Techno-Economic Assessment & Life Cycle Assessment Guidelines for CO2 Utilization (Version 1.1). 2020. Available online: https://deepblue.lib.umich.edu/handle/2027.42/162573 (accessed on 6 February 2023).

- Josa, A.; Aguado, A.; Cardim, A.; Byars, E. Comparative analysis of the life cycle impact assessment of available cement inventories in the EU. Cem. Concr. Res. 2007, 37, 781–788. [Google Scholar] [CrossRef]

- Proaño, L.; Sarmiento, A.T.; Figueredo, M.; Cobo, M. Techno-economic evaluation of indirect carbonation for CO2 emissions capture in cement industry: A system dynamics approach. J. Clean. Prod. 2020, 263, 121457. [Google Scholar] [CrossRef]

- De Lena, E.; Spinelli, M.; Gatti, M.; Scaccabarozzi, R.; Campanari, S.; Consonni, S.; Cinti, G.; Romano, M.C. Techno-economic analysis of calcium looping processes for low CO2 emission cement plants. Int. J. Greenh. Gas Control. 2019, 82, 244–260. [Google Scholar] [CrossRef]

- Romeo, L.M.; Catalina, D.; Lisbona, P.; Lara, Y.; Martínez, A. Reduction of greenhouse gas emissions by integration of cement plants, power plants, and CO2 capture systems. Greenh. Gases Sci. Technol. 2011, 1, 72–82. [Google Scholar] [CrossRef]

- Kuramochi, T.; Ramírez, A.; Turkenburg, W.; Faaij, A. Comparative assessment of CO2 capture technologies for carbon-intensive industrial processes. Prog. Energy Combust. Sci. 2011, 38, 87–112. [Google Scholar] [CrossRef]

- Nwaoha, C.; Beaulieu, M.; Tontiwachwuthikul, P.; Gibson, M.D. Techno-economic analysis of CO2 capture from a 1.2 million MTPA cement plant using AMP-PZ-MEA blend. Int. J. Greenh. Gas Control. 2018, 78, 400–412. [Google Scholar] [CrossRef]

- Leeson, D.; Mac Dowell, N.; Shah, N.; Petit, C.; Fennell, P. A Techno-economic analysis and systematic review of carbon capture and storage (CCS) applied to the iron and steel, cement, oil refining and pulp and paper industries, as well as other high purity sources. Int. J. Greenh. Gas Control. 2017, 61, 71–84. [Google Scholar] [CrossRef]

- Rahman, A.; Rasul, M.; Khan, M.; Sharma, S. Recent development on the uses of alternative fuels in cement manufacturing process. Fuel 2015, 145, 84–99. [Google Scholar] [CrossRef]

- Fierro, J.J.; Nieto-Londoño, C.; Escudero-Atehortua, A.; Giraldo, M.; Jouhara, H.; Wrobel, L.C. Techno-economic assessment of a rotary kiln shell radiation waste heat recovery system. Therm. Sci. Eng. Prog. 2021, 23, 100858. [Google Scholar] [CrossRef]

- Driving Down Carbon Capture Costs to $50.6 per Tonne. PNNL. Available online: https://www.pnnl.gov/publications/driving-down-carbon-capture-costs-506-tonne (accessed on 6 February 2023).

- Kohl, A.L.; Nielsen, R. Gas Purification; Elsevier: Amsterdam, The Netherlands, 1997. [Google Scholar]

- Powell, C.E.; Qiao, G.G. Polymeric CO2/N2 gas separation membranes for the capture of carbon dioxide from power plant flue gases. J. Membr. Sci. 2006, 279, 1–49. [Google Scholar] [CrossRef]

- CO2 Utilization. Available online: https://www.energy.gov/eere/bioenergy/co2-utilization (accessed on 8 November 2022).

- Portillo, E.; Fernández, L.M.G.; Cano, M.; Alonso-Fariñas, B.; Navarrete, B. Techno-Economic Comparison of Integration Options for an Oxygen Transport Membrane Unit into a Coal Oxy-Fired Circulating Fluidized Bed Power Plant. Membranes 2022, 12, 1224. [Google Scholar] [CrossRef]

- Rissman, J.; Bataille, C.; Masanet, E.; Aden, N.; Morrow, W.R.; Zhou, N.; Elliott, N.; Dell, R.; Heeren, N.; Huckestein, B.; et al. Technologies and policies to decarbonize global industry: Review and assessment of mitigation drivers through 2070. Appl. Energy 2020, 266, 114848. [Google Scholar] [CrossRef]

- WattBuy. Available online: https://wattbuy.com/electricity-rates/maryland#:~:text=The%20average%20price%20of%20electricity%20in%20Maryland%20is%2013.96%C2%A2%20per%20kWh (accessed on 6 February 2023).

- Zimmermann, A.W.; Wunderlich, J.; Müller, L.; Buchner, G.A.; Marxen, A.; Michailos, S.; Armstrong, K.; Naims, H.; McCord, S.; Styring, P.; et al. Techno-Economic Assessment Guidelines for CO2 Utilization. Front. Energy Res. 2020, 8, 5. [Google Scholar] [CrossRef]

- McNeil, P. Secure IoT deployment in the cement industry. In Proceedings of the 2017 IEEE-IAS/PCA Cement Industry Technical Conference, Calgary, AB, Canada, 21–25 May 2017; pp. 1–12. [Google Scholar]

- Goncalves, M.; Sousa, P.; Mendes, J.; Danishvar, M.; Mousavi, A. Real-Time Event-Driven Learning in Highly Volatile Systems: A Case for Embedded Machine Learning for SCADA Systems. IEEE Access 2022, 10, 50794–50806. [Google Scholar] [CrossRef]

- Nagadasari, M.P.; Bojja, P. Industrial IoT enabled fuzzy logic-based flame image processing for rotary kiln control. Wirel. Pers. Commun. 2022, 125, 2647–2665. [Google Scholar] [CrossRef]

- Charan, R.; Kumar, A.; Harika, B.; Goel, V.; Nath, V. IoT-Based Moisture Sensor in Cement Industry. In International Conference on Nanoelectronics, Circuits and Communication Systems; Springer: Singapore, 2018; pp. 513–522. [Google Scholar]

- Ming, F.X.; Habeeb, R.A.A.; Md Nasaruddin, F.H.B.; Gani, A.B. Real-time carbon dioxide monitoring based on IoT & cloud technologies. In Proceedings of the 2019 8th International Conference on Software and Computer Applications, Penang, Malaysia, 19–21 February 2019; pp. 517–521. [Google Scholar]

- Python for Excel. Best Open-Source Python Libraries for Working with Excel. Available online: https://www.excelpython.org/ (accessed on 6 February 2023).

- IPCC. Climate Change 2013: The Physical Science Basis. Contribution of Working Group I to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change, Batumi, Georgia, 14–17 October 2013; Stocker, T.F., Qin, D., Plattner, G.-K., Tignor, M., Allen, S.K., Boschung, J., Nauels, A., Xia, Y., Bex, V., Midgley, P.M., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2013; 1535p. [Google Scholar] [CrossRef]

- Statista. Prices of Implemented Carbon Taxes Worldwide 2022, by Country. Available online: https://www.statista.com/statistics/483590/prices-of-implemented-carbon-pricing-instruments-worldwide-by-select-country/ (accessed on 6 February 2023).

- EMC: Continuous Emission Monitoring Systems|US EPA. US EPA. Available online: https://www.epa.gov/emc/emc-continuous-emission-monitoring-systems (accessed on 13 September 2022).

- ElectricChoice.com. Electric Rates (Updated February 2023)—Electric Choice. Available online: https://www.electricchoice.com/electricity-prices-by-state/ (accessed on 27 February 2023).

- Matplotlib Documentation—Matplotlib 3.7.1 documentation. Available online: https://matplotlib.org/stable/index.html (accessed on 6 February 2023).

- Portland-Limestone Cement. Available online: https://www.cement.org/sustainability/portland-limestone-cement (accessed on 6 February 2023).

- Martinez, D.M.; Horvath, A.; Monteiro, P.J.M. Comparative environmental assessment of limestone calcined clay cements and typical blended cements. Environ. Res. Commun. 2023, 5, 055002. [Google Scholar] [CrossRef]

- Oguntola, O. Cement production LCA and TEA. Retrieved from osf.io/5kcyp. Available online: https://osf.io/5kcyp/?view_only=8cbfc104711c4b91b551a7579e054080 (accessed on 18 May 2023).

| Scenario | Product | Thermal Energy | |

|---|---|---|---|

| 1. | OPC + Coal | Ordinary Portland Cement | Coal |

| 2. | PLC + Coal | Portland-Limestone Cement | Coal |

| 3. | OPC + DBS | Ordinary Portland Cement | Dried Biosolids |

| 4. | PLC + DBS | Portland-Limestone Cement | Dried Biosolids |

| # | Scenario | Calcination | Combustion | Others | GWP (kg CO2-eq) |

|---|---|---|---|---|---|

| 1 | OPC + Coal | 54.3% | 39.6% | 6.1% | 856 |

| 2 | OPC + DBS | 55.1% | 38.7% | 6.2% | 844 |

| 3 | PLC + Coal | 51.3% | 42.4% | 6.4% | 801 |

| 4 | PLC + DBS | 52.1% | 41.1% | 6.5% | 788 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oguntola, O.; Simske, S. Continuous Assessment of the Environmental Impact and Economic Viability of Decarbonization Improvements in Cement Production. Resources 2023, 12, 95. https://doi.org/10.3390/resources12080095

Oguntola O, Simske S. Continuous Assessment of the Environmental Impact and Economic Viability of Decarbonization Improvements in Cement Production. Resources. 2023; 12(8):95. https://doi.org/10.3390/resources12080095

Chicago/Turabian StyleOguntola, Olurotimi, and Steven Simske. 2023. "Continuous Assessment of the Environmental Impact and Economic Viability of Decarbonization Improvements in Cement Production" Resources 12, no. 8: 95. https://doi.org/10.3390/resources12080095

APA StyleOguntola, O., & Simske, S. (2023). Continuous Assessment of the Environmental Impact and Economic Viability of Decarbonization Improvements in Cement Production. Resources, 12(8), 95. https://doi.org/10.3390/resources12080095