New Lime-Based Hybrid Composite of Sugarcane Bagasse and Hemp as Aggregates

Abstract

1. Introduction

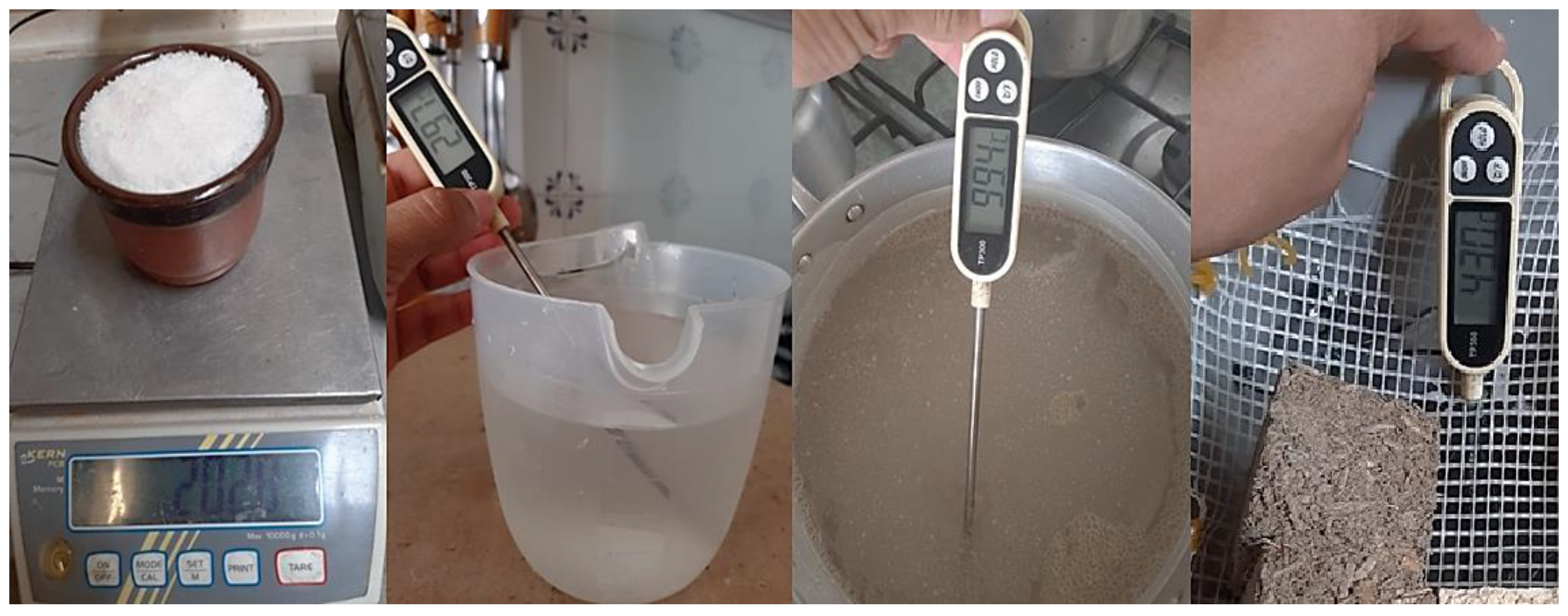

2. Materials and Methods

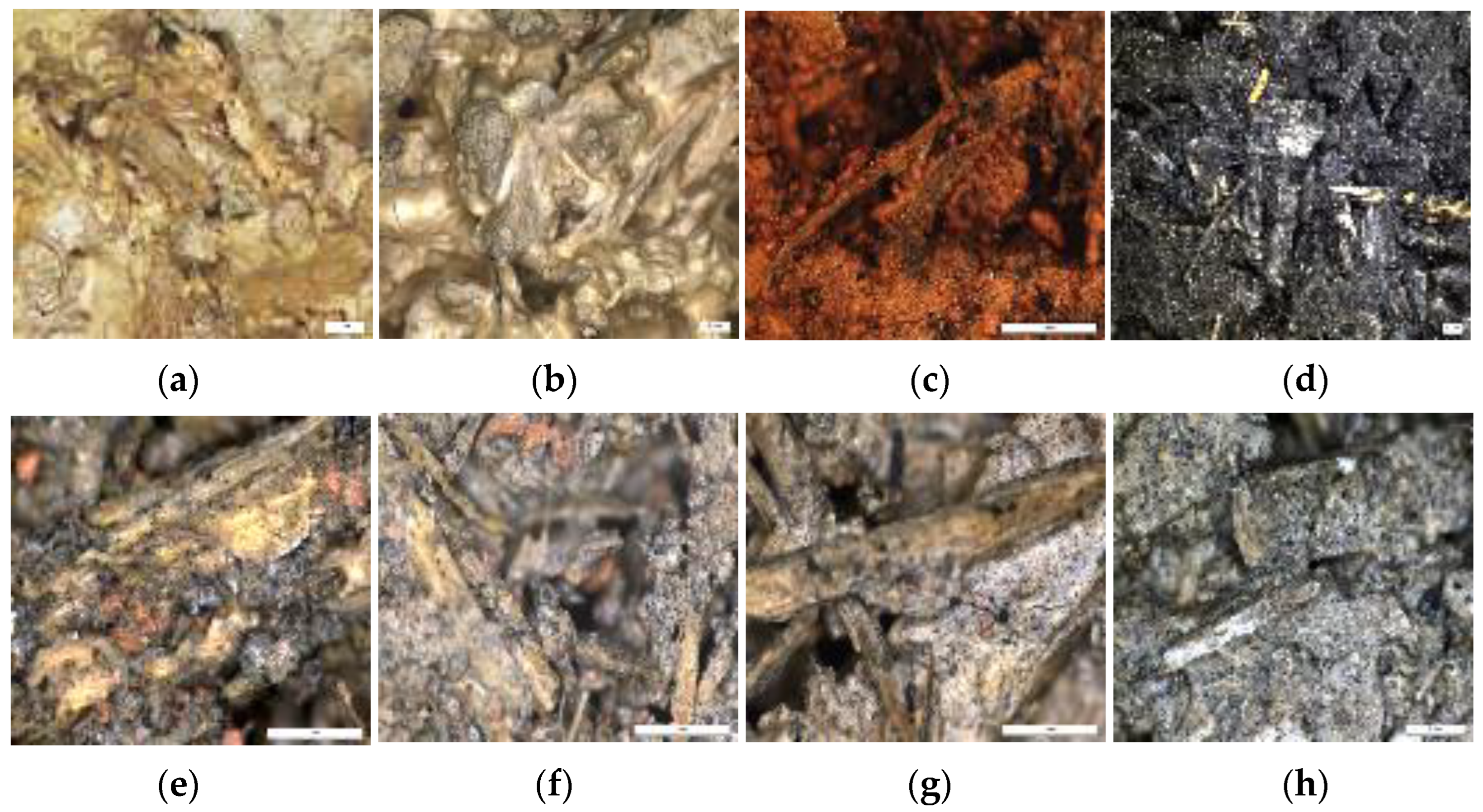

2.1. Materials

2.2. Compositions

2.3. Methods Applied

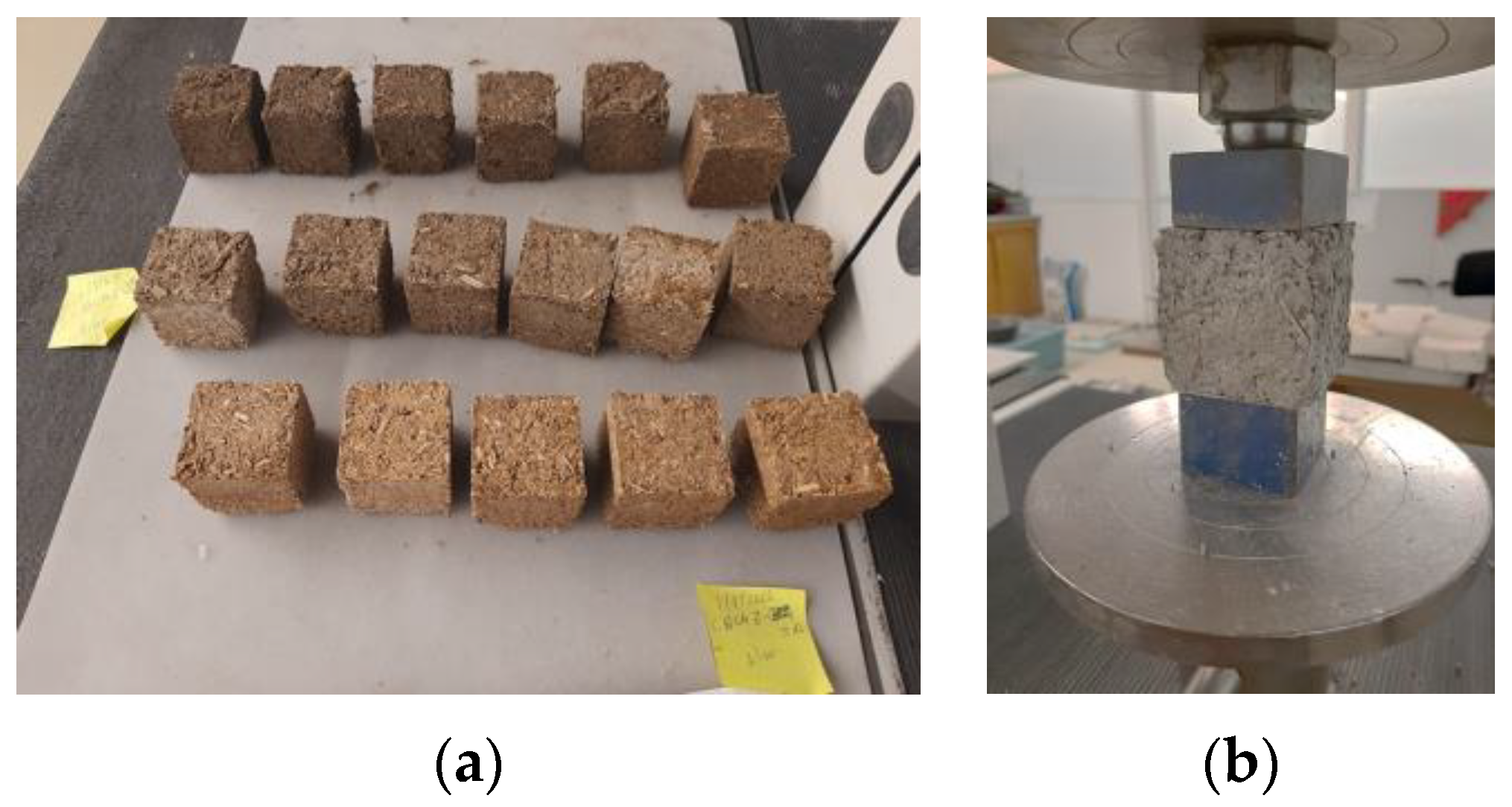

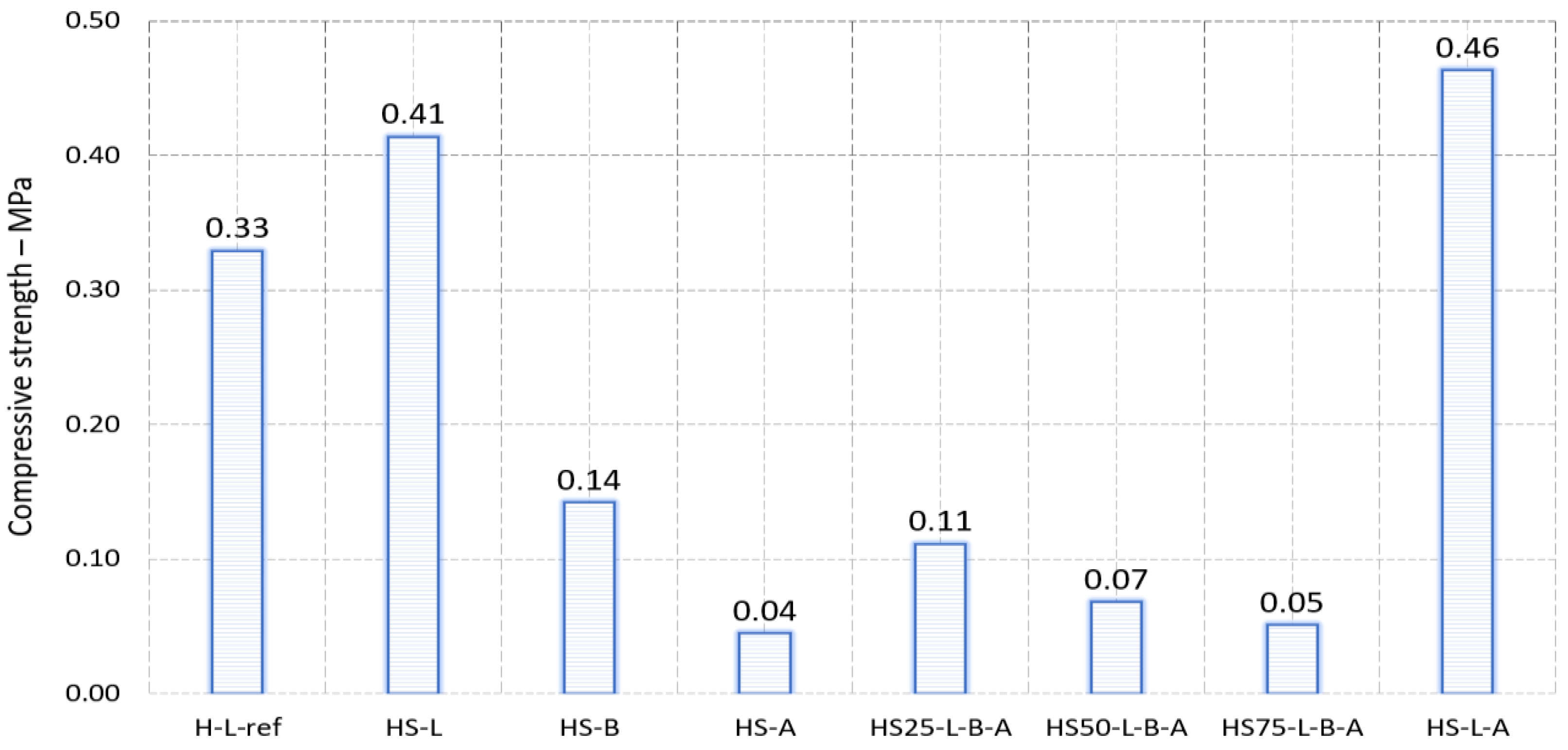

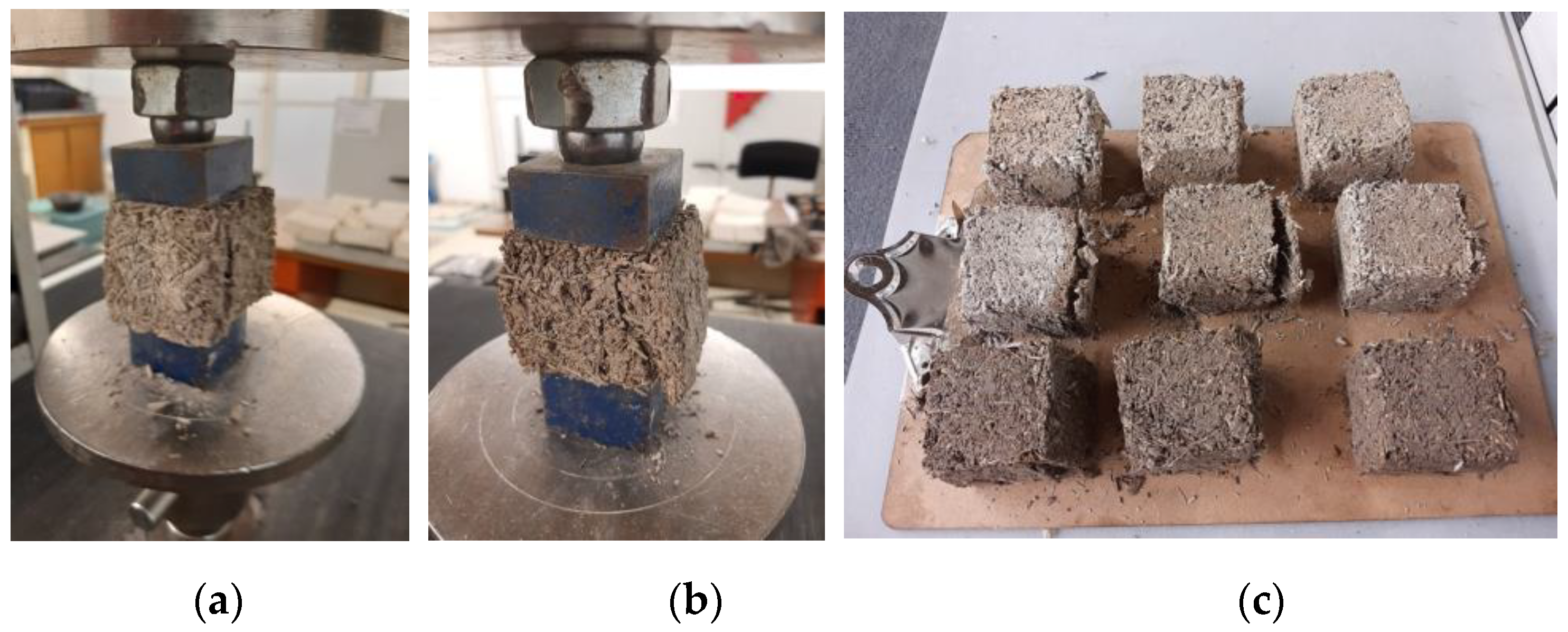

2.3.1. Compressive Strength Performance

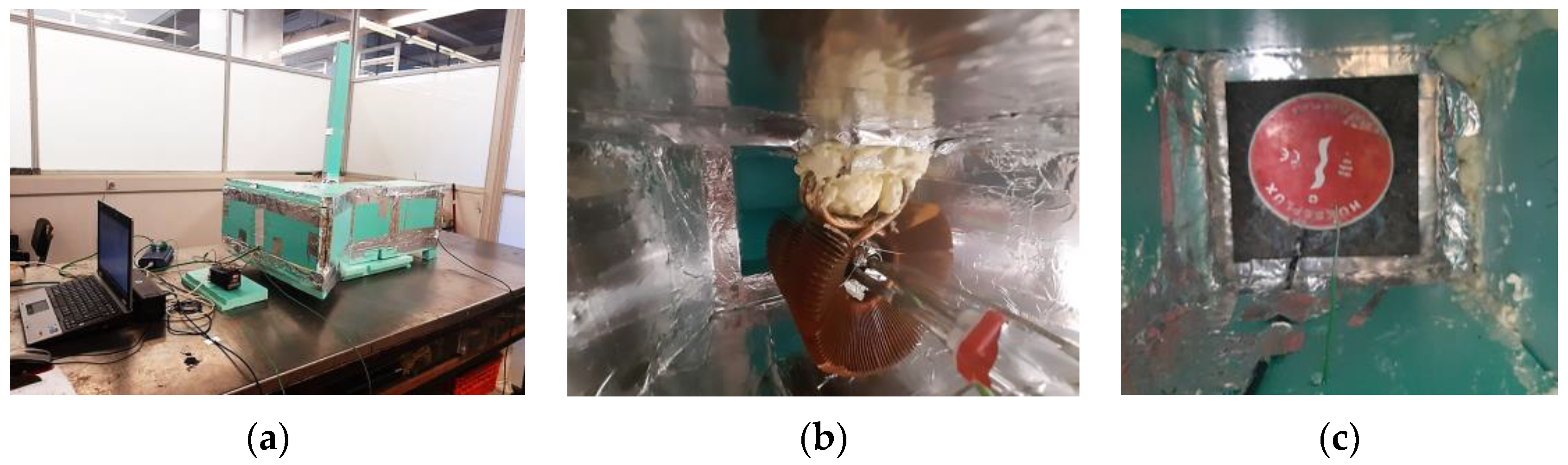

2.3.2. Thermal Conductivity Test

2.3.3. Coefficient of Water Absorption by Capillarity

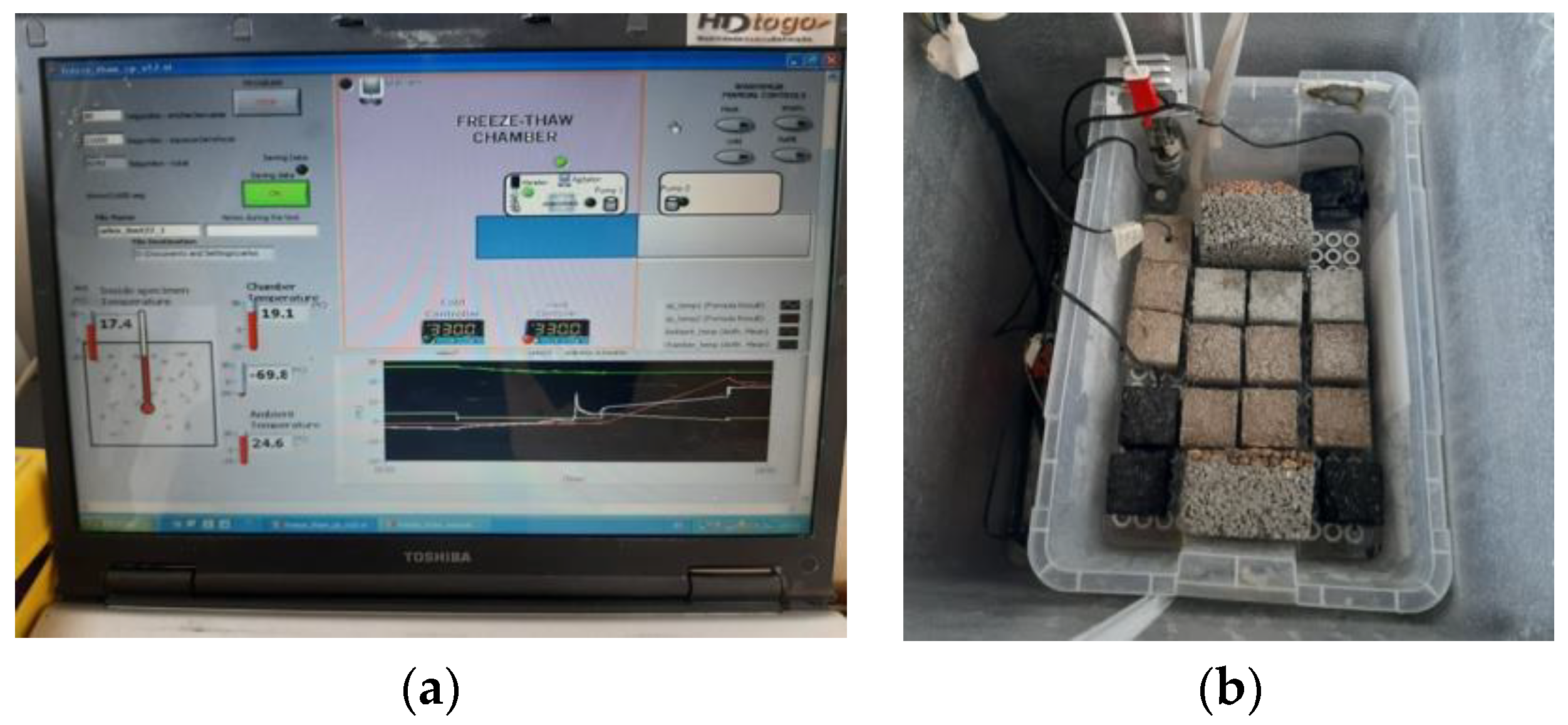

2.3.4. Freezing and Thawing Resistance

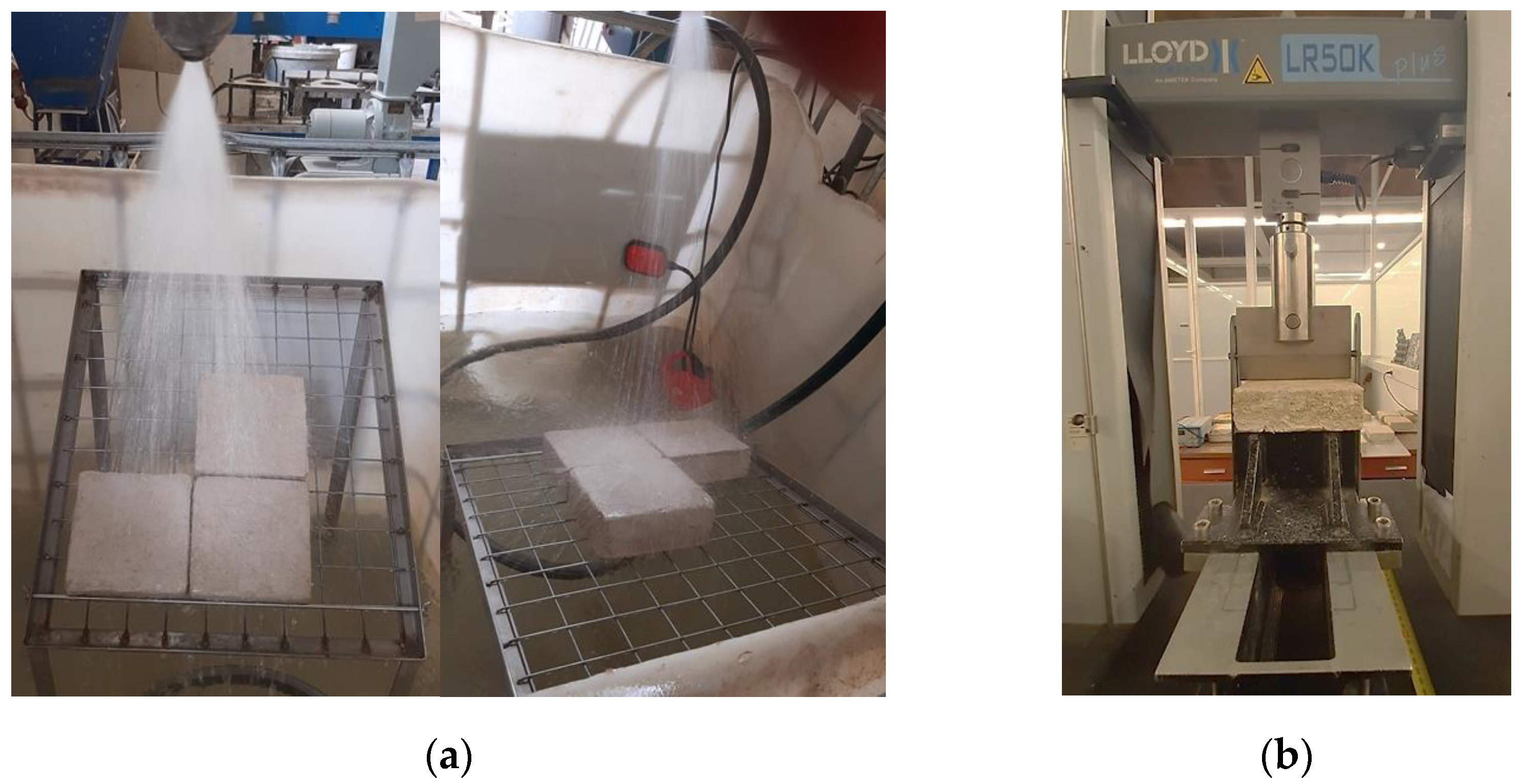

2.3.5. Degradation by Exposure to Simulated Rain

2.3.6. Saline Exposure

3. Results: Strength and Durability of the New HC-SCB Composite

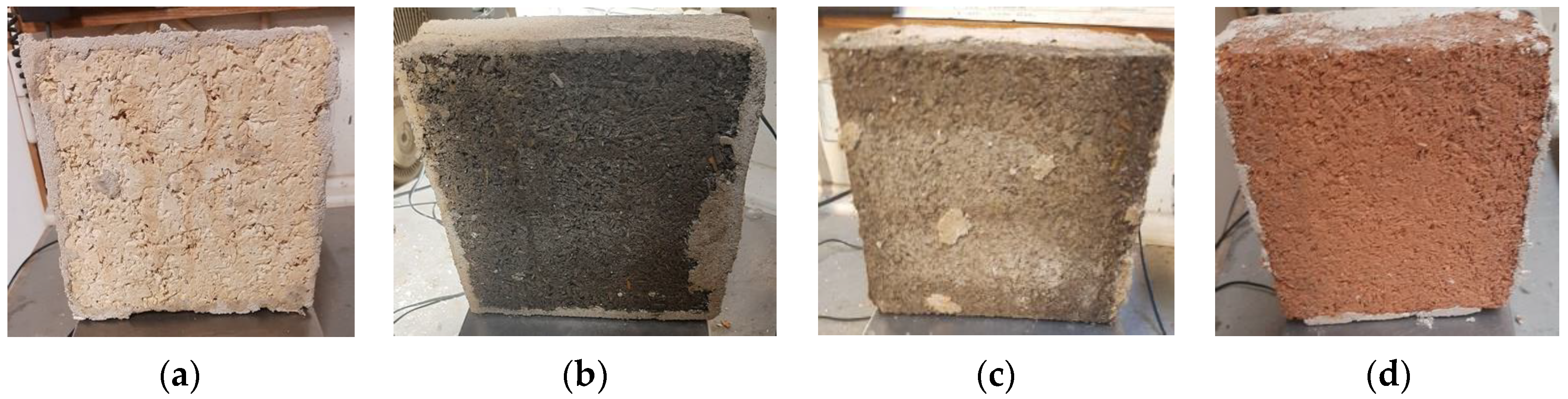

3.1. Compositions (Fresh State)

3.2. Compressive Strength Performance

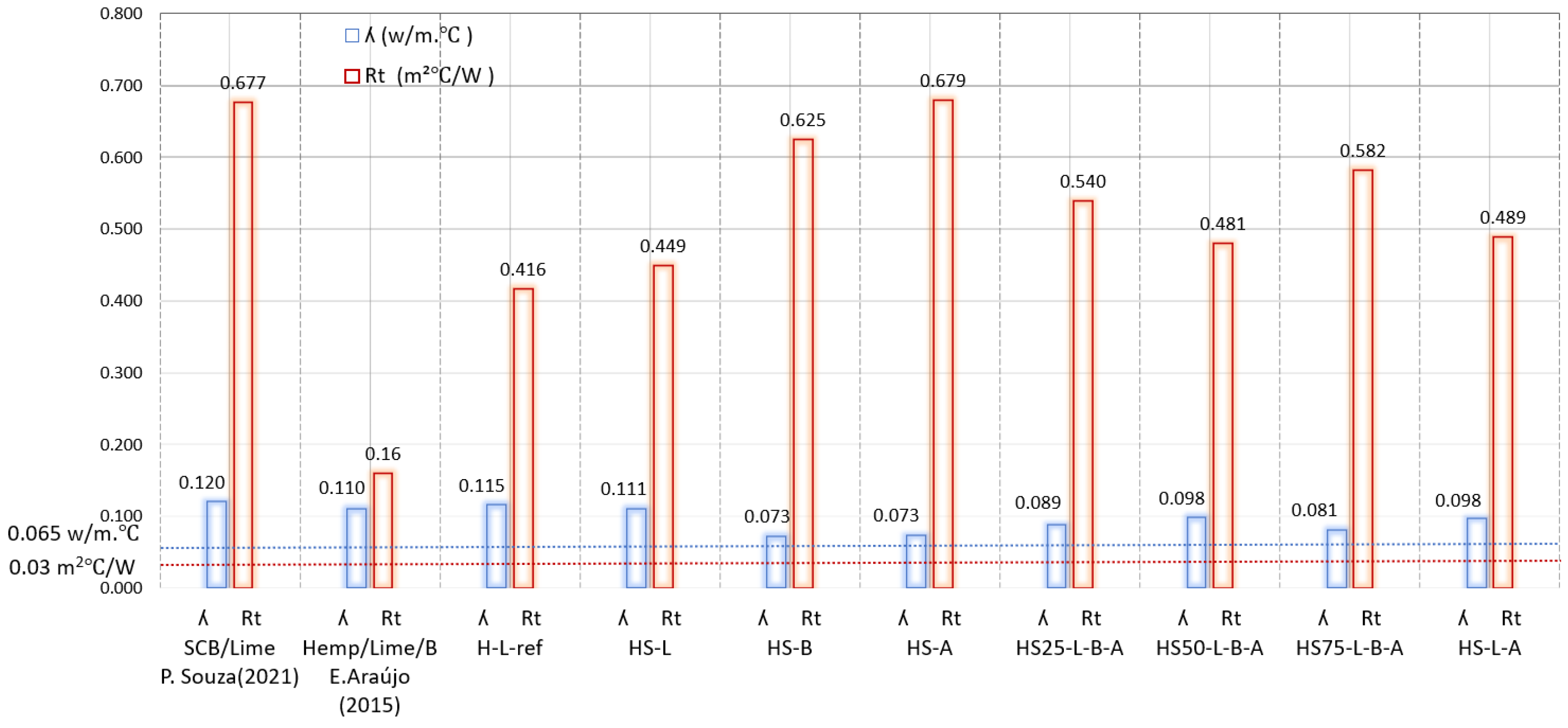

3.3. Thermal Conductivity Test

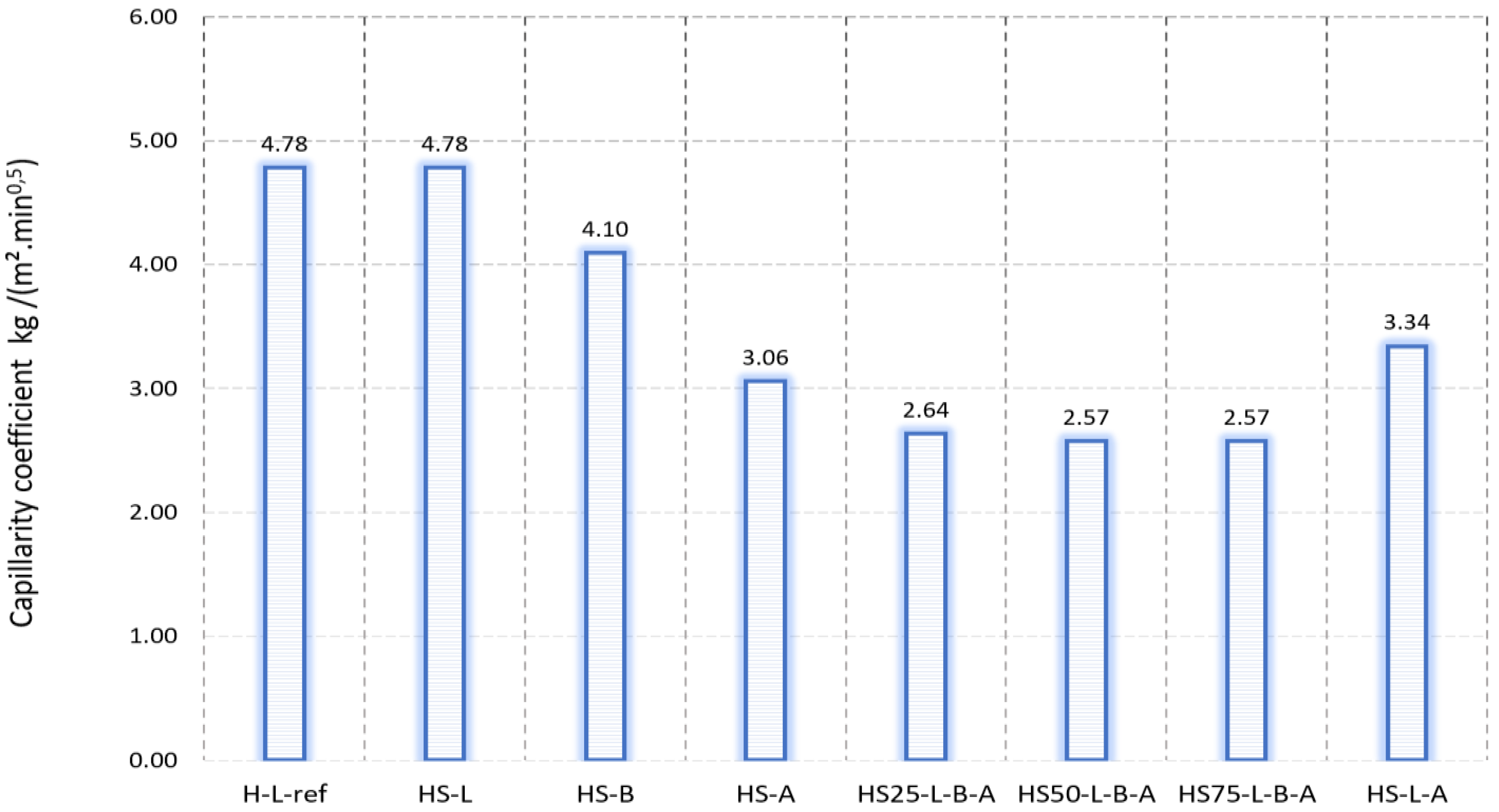

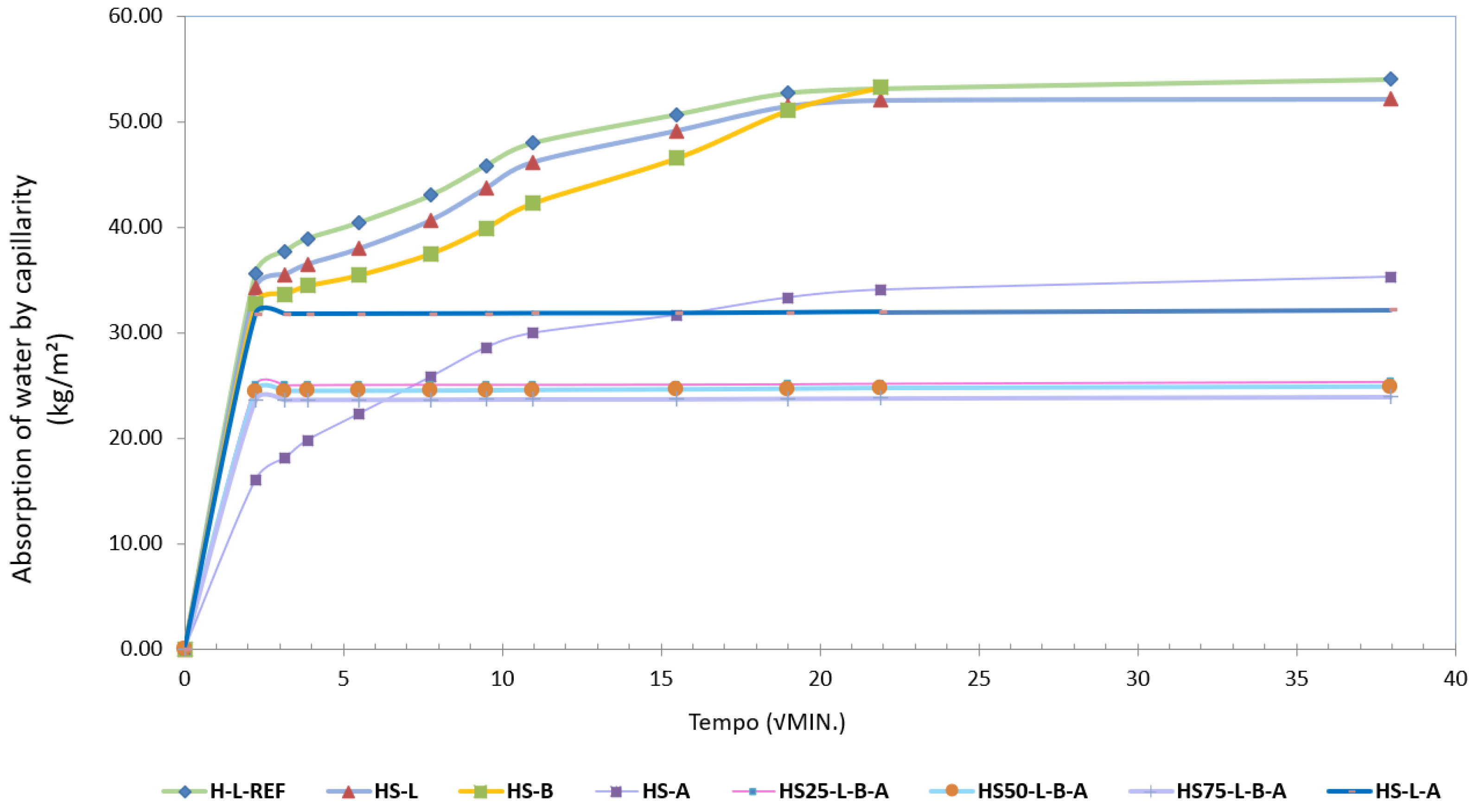

3.4. Coefficient of Water Absorption by Capillarity

3.5. Freezing and Thawing Resistance

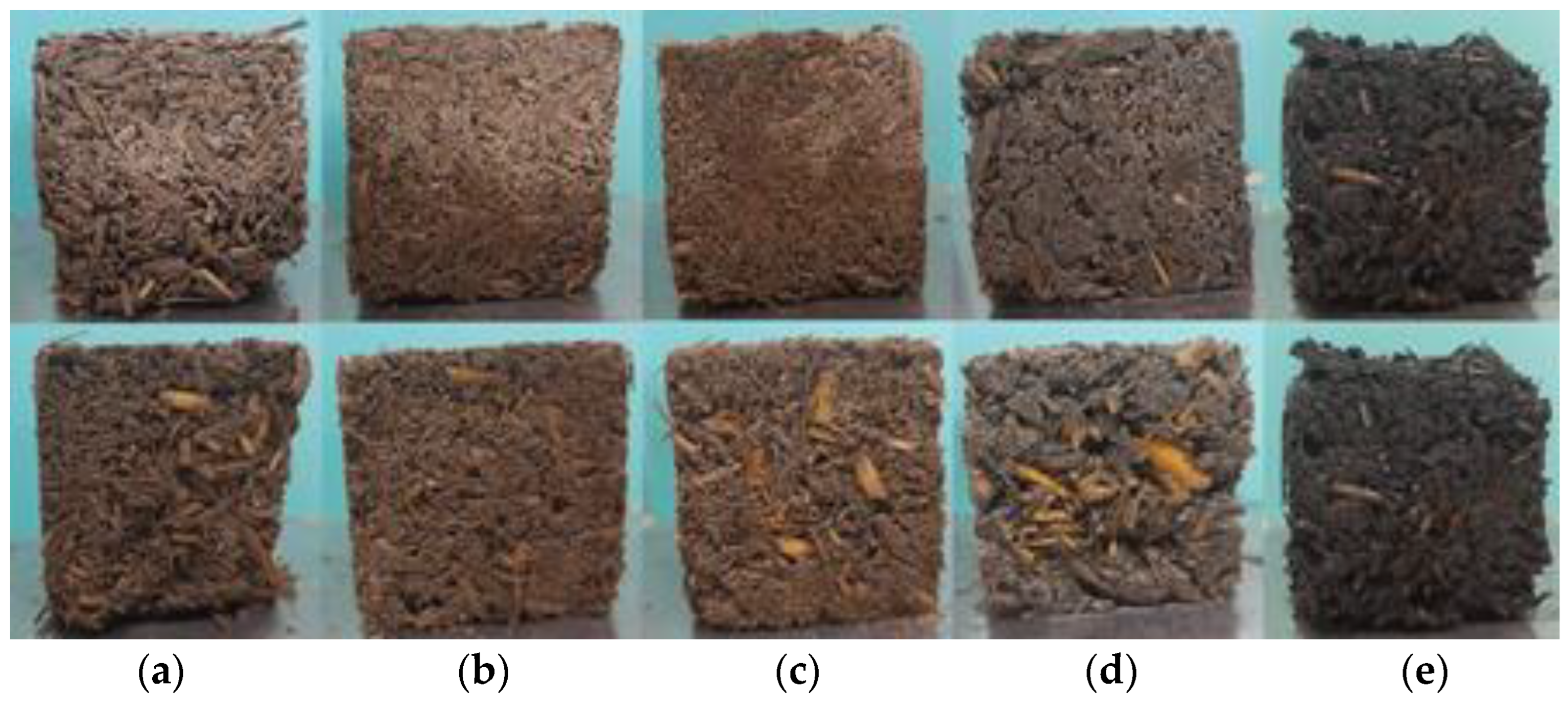

3.6. Degradation by Exposure to Simulated Rain

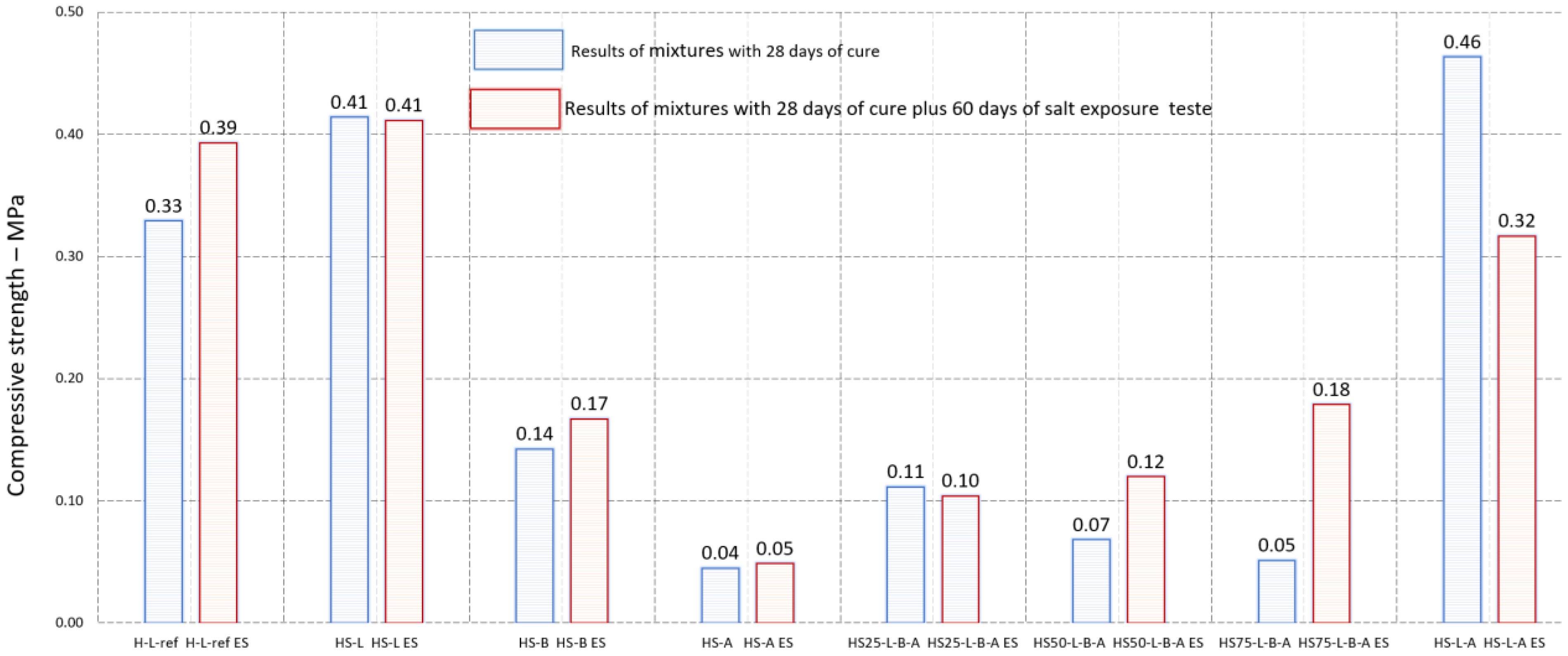

3.7. Saline Exposure

4. Comparative Analysis of Trials

5. Conclusions

6. Recommendations

- Develop microscopic studies to better understand the adherence and reactions between the materials.

- Try different percentages of sugar cane bagasse ash.

- Study the effects of other binders, such as hydraulic lime and metakaolin, in combination with SCBA ash.

- Study methods to standardize the compaction process to assess the influence of the compaction process on the mechanical and thermal strength of the mixtures.

- To carry out pre-treatment procedures of sugarcane bagasse ash to reduce the effects of high water absorption and to be able to control the amount of water in the mixture.

- Develop tests with real scale walls with blocks or cast and compacted in situ.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Janet, L.S.; Jay, R.; Freyr, S. Renewables 2018-Global Status Report. A Comprehensive Annual Overview of the State of Renewable Energy. Advancing the Global Renewable Energy Transition-Highlights of the REN21 Renewables 2018 Global Status Report in Perspective. 2018. Available online: https://ren21.net/gsr-2018/pages/foreword/foreword/ (accessed on 22 March 2023).

- Monreal, P.; Mboumba-Mamboundou, L.B.; Dheilly, R.M.; Quéneudec, M. Effects of aggregate coating on the hygral properties of lignocellulosic composites. Cem. Concr. Compos. 2011, 33, 301–308. [Google Scholar] [CrossRef]

- Arnaud, L.; Gourlay, E. Experimental study of parameters influencing mechanical properties of hemp concretes. Constr. Build. Mater. 2012, 28, 50–56. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Bhusan Das, B. A comprehensive review on the use of hemp in concrete. Constr. Build. Mater. 2022, 341, 127857. [Google Scholar] [CrossRef]

- Jami, T.; Karade, S.R.; Singh, L.P. A review of the properties of hemp concrete for green building applications. J. Clean. Prod. 2019, 239, 117852. [Google Scholar] [CrossRef]

- Walker, R.; Pavia, S.; Mitchell, R. Mechanical properties and durability of hemp-lime concretes. Constr. Build. Mater. 2014, 61, 340–348. [Google Scholar] [CrossRef]

- Nozahic, V.; Amziane, S.; Torrent, G.; Saïdi, K.; Baynast, H. De Design of green concrete made of plant-derived aggregates and a pumice—Lime binder. Cem. Concr. Compos. 2012, 34, 231–241. [Google Scholar] [CrossRef]

- Chabannes, M.; Nozahic, V.; Amziane, S. Design and multi-physical properties of a new insulating concrete using sunflower stem aggregates and eco-friendly binders. Mater. Struct. Constr. 2015, 48, 1815–1829. [Google Scholar] [CrossRef]

- Chabannes, M.; Bénézet, J.; Clerc, L.; Garcia-diaz, E. Use of raw rice husk as natural aggregate in a lightweight insulating concrete: An innovative application. Constr. Build. Mater. 2014, 70, 428–438. [Google Scholar] [CrossRef]

- Ntimugura, F.; Vinai, R.; Harper, A.B.; Walker, P. Environmental performance of miscanthus-lime lightweight concrete using life cycle assessment: Application in external wall assemblies. Sustain. Mater. Technol. 2021, 28, e00253. [Google Scholar] [CrossRef]

- Garikapati, K.P.; Sadeghian, P. Physical and Mechanical Properties of Flax Lime Concrete. 2018. Conferência Anual da CSCE Em: Fredericton, NB, Canadá. Available online: https://www.researchgate.net/publication/325949496 (accessed on 14 April 2023).

- Brzyski, P.; Barnat-Hunek, D.; Suchorab, Z.; Łagód, G. Composite Materials Based on Hemp and. Flax Low-Energy Build. Mater. 2017, 10, 510. [Google Scholar] [CrossRef]

- Kumar, N.; Barbato, M. Effects of sugarcane bagasse fibers on the properties of compressed and stabilized earth blocks. Constr. Build. Mater. 2022, 315, 125552. [Google Scholar] [CrossRef]

- Lavarack, B.P.; Griffin, G.J.; Rodman, D. Measured kinetics of the acid-catalyzed hydrolysis of sugar cane bagasse to produce xylose. Catal. Today 2000, 63, 257–265. [Google Scholar] [CrossRef]

- Salih, M.M.; Osofero, A.I.; Imbabi, M.S. Constitutive models for fibre reinforced soil bricks. Constr. Build. Mater. 2020, 240, 117806. [Google Scholar] [CrossRef]

- Dineshkumar, R.; Balamurugan, P. Behavior of high-strength concrete with sugarcane bagasse ash as replacement for cement. Innov. Infrastruct. Solut. 2021, 6, 63. [Google Scholar] [CrossRef]

- Katare, V.D.; Madurwar, M.V. Process standardization of sugarcane bagasse ash to develop durable high-volume ash concrete. J. Build. Eng. 2021, 39, 102151. [Google Scholar] [CrossRef]

- Kazmi, S.M.S.; Abbas, S.; Saleem, M.A.; Munir, M.J.; Khitab, A. Manufacturing of sustainable clay bricks: Utilization of waste sugarcane bagasse and rice husk ashes. Constr. Build. Mater. 2016, 120, 29–41. [Google Scholar] [CrossRef]

- Nancy, T.; Hussien, A.F.O. The use of sugarcane wastes in concrete. J. Eng. Appl. Sci. 2022, 4–9. [Google Scholar] [CrossRef]

- Berenguer, R.; Lima, N.; Valdés, A.C.; Medeiros, M.H.F.; Lima, N.B.D.; Delgado, J.M.P.Q.; Silva, F.A.N.; Azevedo, A.C.; Guimarães, A.S.; Rangel, B. Durability of Concrete Structures with Sugar Cane Bagasse Ash. Adv. Mater. Sci. Eng. 2020, 2020, 6907834. [Google Scholar] [CrossRef]

- Athira, V.S.; Charitha, V.; Athira, G.; Bahurudeen, A. Agro-waste ash based alkali-activated binder: Cleaner production of zero cement concrete for construction. J. Clean. Prod. 2021, 286, 125429. [Google Scholar] [CrossRef]

- Murphy, F.; Pavia, S.; Walker, R. An assessment of the physical properties of lime-hemp concrete. In Proceedings of BRI/CRI; Ní Nualláin, N.A., Walsh, D., West, R., Cannon, E., Caprani, C., McCabe, B., Eds.; University College Cork: Cork, Ireland, 2010; Volume 2, pp. 431–439. Available online: https://www.researchgate.net/publication/235641051 (accessed on 22 March 2023).

- Araújo, E.F. Materiais Compósitos com Incorporação de Cânhamo Industrial. Master’s Thesis, University of Minho, Braga, Portugal, 2015. Available online: https://hdl.handle.net/1822/40358 (accessed on 22 March 2023).

- Atlas Big Los Principales Países Productores de Caña de Azúcar del Mundo Países. 2020. 2021–2022. Available online: https://www.atlasbig.com/es-mx/paises-por-produccion-de-cana-de-azucar (accessed on 22 March 2023).

- Food and Agriculture Organization of the United Nations. Perspectivas Agrícolas OCDE-FAO 2020–2029 FAO Perspectivas Agrícolas. FAO 2020. Available online: https://www.fao.org/3/ca8861es/ca8861es.pdf (accessed on 22 March 2023).

- United States Department of Agriculture. 2017 Census of Agriculture: Louisiana; United States Dep, Agric, 2019. Louisiana State and Parish Data 2019, 1. Available online: https://www.nass.usda.gov/Publications/AgCensus/2017/Full_Report/Volume_1,_Chapter_1_US/usv1.pdf (accessed on 22 March 2023).

- CNPA NIC. 2021–2022 Comité Nacional de Produtores de Azucar de Nicaragua, Datos Finales de Producción Zafra 2021–2022 Zafra 2021/22. Available online: https://cnpa.com.ni/wp-content/uploads/2022/06/Nic_Zafra-21-22S.pdf (accessed on 22 March 2023).

- Products, H.V. Lignocellulosic Materials for Production of Cement Composites: Valorization of the Alkali Treated Soybean Pod and Eucalyptus Wood Particles to Obtain Higher Value-Added Products. Waste Biomass Valorization 2020, 11, 2235–2245. [Google Scholar] [CrossRef]

- Karade, S.R. Cement-bonded composites from lignocellulosic wastes. Constr. Build. Mater. 2010, 24, 1323–1330. [Google Scholar] [CrossRef]

- Beskopylny, A.N.; Shcherban, E.M.; Stel, S.A.; Meskhi, B.; Shilov, A.A.; Varavka, V.; Evtushenko, A.; Özkılıç, Y.O.; Aksoylu, C.; Karalar, M. Composition Component Influence on Concrete Properties with the Additive of Rubber Tree Seed Shells. Appl. Sci. 2022, 12, 11744. [Google Scholar] [CrossRef]

- Shcherban, E.M.; Stel, S.A.; Beskopylny, A.N.; Mailyan, L.R.; Meskhi, B.; Shilov, A.A.; Chernil, A.; Özkılıç, Y.O.; Aksoylu, C. Normal-Weight Concrete with Improved Stress—Strain Characteristics Reinforced with Dispersed Coconut Fibers. Appl. Sci. 2022, 12, 11734. [Google Scholar] [CrossRef]

- Ferraz, P.; Mendes, R.F.; Marin, D.B.; Paes, J.L.; Cecchin, D.; Barbari, M. Agricultural Residues of Lignocellulosic Materials in Cement Composites. Appl. Sci. 2020, 10, 8019. [Google Scholar] [CrossRef]

- Bock-Hyeng, C.; Ofori-Boadu, A.N.; Yamb-Bell, E.; Shofoluwe, M.A. Mechanical Properties of Sustainable Adobe Bricks Stabilized With Recycled Sugarcane Fiber Waste. Int. J. Eng. Res. Appl. 2016, 6, 50–59. [Google Scholar]

- Lee, S.C.; Mariatti, M. The effect of bagasse fibers obtained (from rind and pith component) on the properties of unsaturated polyester composites. Mater. Lett. 2008, 62, 2253–2256. [Google Scholar] [CrossRef]

- Memon, S.A.; Wahid, I.; Khan, M.K.; Tanoli, M.A.; Bimaganbetova, M. Environmentally friendly utilization of wheat straw ash in cement-based composites. Sustainability 2018, 10, 1322. [Google Scholar] [CrossRef]

- Charitha, V.; Athira, V.S.; Jittin, V.; Bahurudeen, A.; Nanthagopalan, P. Use of different agro-waste ashes in concrete for effective upcycling of locally available resources. Constr. Build. Mater. 2021, 285, 122851. [Google Scholar] [CrossRef]

- Sousa, P.L. Compósitos de Bagaço de Cana-de-Açúcar para Blocos Construtivos. Master’s Thesis, University of Minho, Braga, Portugal, 2021. Available online: https://hdl.handle.net/1822/75869 (accessed on 22 March 2023). (In Portuguese).

- Bahurudeen, A.; Santhanam, M. Performance evaluation of sugarcane bagasse ash-based cement for durable concrete. In Proceedings of the 4th International Conference on the Durability of Concrete Structures, ICDCS 2014, Madrid, Spain, 30 June–3 July 2014; pp. 275–281. [Google Scholar]

- Zúniga, A.L.G. Desenvolvimento de Compósito à base de Cânhamo e Bagaço de Cana-de-açúcar para Blocos Construtivos. Master’s Thesis, University of Minho, Braga, Portugal, 2022. (In Portuguese). [Google Scholar]

- Elfordy, S.; Lucas, F.; Tancret, F.; Scudeller, Y.; Goudet, L. Mechanical and thermal properties of lime and hemp concrete (“hempcrete”) manufactured by a spraying process. Constr. Construir. Mater. 2008, 22, 2116–2123. [Google Scholar] [CrossRef]

- EN 1015-11; Methods of Test for Mortar for Masonry EN 1015-11:1999. Part 11 Determ. Flexural Compressive Strength Hardened Mortar. CEN: Brussels, Belgium, 2006; Volume 3.

- Gomes, F.C.F. Sousa Fangueiro Placas à base de Desperdícios Industriais para paredes Interiores. Master’s Thesis, Universidade do Minho, Braga, Portugal, 2021. [Google Scholar]

- ISO 9869; Thermal Insulation—Building Elements—In-Situ Measurement of Thermal Resistance and Thermal Transmittance. CEN: Brussels, Belgium, 1994; Volume 994, p. 32.

- BS EN 1015-18:2002; Methods of Test for Mortar for Masonry. Determination of Water Absorption Coefficient Due to Capillary Action of Hardened Mortar. British Standard Institution: London, UK, 2002.

- ASTM C 1585 04; Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic-Cement Concretes. ASTM: West Conshohocken, PA, USA, 2007; pp. 1–6.

- ASTM C666/C666M; Standard Test Method for Resistance of Concrete to Rapid Freezing and Thawing. ASTM Int.: West Conshohocken, PA, USA, 2003; Volume 3, pp. 1–6.

- Rezende, M.L.; Camões, A.; Eires, R.; Jesus, C.M.G.; Soares, E. Proposta de Ensaio Acelerado de Exposição a Chuvas Dirigidas (in English—Proposal of Accelerated Test Exposure To Driving Rain), TEST&E 2019, 2° Congresso de Ensaios e Experimentação em Engenharia Civil, 2019. Available online: https://hdl.handle.net/1822/63248 (accessed on 22 March 2023). (In Portuguese).

- BS 3900-0:2010; Standards Publication Methods of Test for Paints—Part 0: Index of Test Methods. Third Revision, May 2010. BSI: London, UK, 2010.

- Eires, R.M.G. Materiais Não Convencionais para uma Construção Sustentável Utilizando Cânhamo, Pasta de Papel e Cortiça. Master’s Thesis, University of Minho, Braga, Portugal, 2006. Available online: https://hdl.handle.net/1822/7053 (accessed on 22 March 2023). (In Portuguese).

- Benfratello, S.; Capitano, C.; Peri, G.; Rizzo, G.; Scaccianoce, G.; Sorrentino, G. Thermal and structural properties of a hemp-lime biocomposite. Constr. Build. Mater. 2013, 48, 745–754. [Google Scholar] [CrossRef]

- Kasaniya, M.; Alaibani, A.; Thomas, M.D.A.; Riding, K.A. Exploring the efficacy of emerging reactivity tests in screening pozzolanic materials. Constr. Build. Mater. 2022, 325, 126781. [Google Scholar] [CrossRef]

- Sinka, M.; Sahmenko, G. Sustainable-thermal-insulation-biocomposites-from-locally-available-hemp-and-lime. In Environment Technology Resources, Proceedings of the International Scientific and Practical Conference, Rēzekne, Latvia, 20–22 June 2013; Rēzeknes Augstskola: Rēzekne, Latvia, 2013; pp. 73–77. [Google Scholar]

- Su-cadirci, T.B.; Ball, R.J.; Calabria-holley, J. Use of brick dust to optimise the dewatering process of hydrated lime mortars for conservation applications. Mater. Struct. 2023, 56, 1–19. [Google Scholar] [CrossRef]

- Abdellatef, Y.; Khan, M.A.; Khan, A.; Alam, M.I.; Kavgic, M. Mechanical, thermal, and moisture buffering properties of novel insulating hemp-lime composite building materials. Materials 2020, 13, 5000. [Google Scholar] [CrossRef] [PubMed]

- LNEC—Laboratório Nacional de Engenharia Civil. ITE50—Thermal transmission coefficients of building envelope elements. Available online: www.lnec.pt (accessed on 22 March 2023).

- Press, S.; Park, M. Ebook Set Up and Use Instructions; Routledge & CRC Press Spon Press: Abingdon; UK, 2020; ISBN 9780367271084. [Google Scholar]

- Ganesan, K.; Rajagopal, K.; Thangavel, K. Evaluation of bagasse ash as supplementary cementitious material. Cem. Concr. Compos. 2007, 29, 515–524. [Google Scholar] [CrossRef]

- Walker, R.; Pavía, S. Moisture transfer and thermal properties of hemp—Lime concretes. Constr. Build. Mater. 2014, 64, 270–276. [Google Scholar] [CrossRef]

- Botas, S.M.S.; Rato, V.M.; Faria, P. Testing the Freeze/Thaw Cycles in Lime Mortar. In Proceedings of the 2nd Historic Mortars Conference—HMC 2010 and RILEM TC 203-RHM Final Workshop, Prague, Czech Republic, 22–24 September 2010; pp. 417–425. [Google Scholar]

- Ip, K.; Miller, A. Life cycle greenhouse gas emissions of hemp-lime wall constructions in the UK. Resour. Conserv. Recycl. 2012, 69, 1–9. [Google Scholar] [CrossRef]

- Delannoy, G.; Marceau, S.; Glé, P.; Gourlay, E.; Guéguen-Minerbe, M.; Amziane, S.; Farcas, F. Durability of hemp concretes exposed to accelerated environmental aging. Constr. Build. Mater. 2020, 252, 119043. [Google Scholar] [CrossRef]

- Zerrouki, R.; Benazzouk, A.; Courty, M.; Ben, H. Potential use of matakaolin as a partial replacement of preformulated lime binder to improve durability of hemp concrete under cyclic wetting/drying aging. Constr. Build. Mater. 2022, 333, 127389. [Google Scholar] [CrossRef]

- Sinka, M.; Korjakins, A. Mechanical Properties of Pre-Compressed Hemp-Lime Concrete. 2014. Available online: https://www.researchgate.net/publication/287503987_ (accessed on 22 March 2023).

| Characteristic | Measurement |

|---|---|

| Density | 100 to 110 kg/m3 (depending on relative humidity), loosely packed, not compressed |

| Water absorption | 198% |

| Water absorption of mineral elements | 24 mEq per 100g of raw material |

| Calorific value | 3804 cal/g |

| Thermal conductivity (10 °C in a dry state) | 0.0486 W/m.K |

| Water | 9 to 13% |

| Dry material | 85 to 90% of which |

| Total organic material | 97.5% on a dry basis of which: |

| Net cellulose: | 52% |

| Lignin: | 18% |

| Hemicellulose: | 9% |

| Calcium: 1% on a dry basis | |

| Magnesium: 0.03% on a dry basis | |

| Phosphorus: 9 mg/100 g | |

| Potassium: 0.8% on a dry basis | |

| Minerals | Total nitrogen: 0.4 to 1% on a dry basis |

| Total carbon: 496 g/kg on a dry basis | |

| C/N: 87 | |

| Ash: 2% | |

| pH in suspension at 10%: 6.7 |

| Components | CL | SCBA | BD |

|---|---|---|---|

| SiO2 (%) | 54.13 | 58.83 | |

| Al2O3 (%) | 10.61 | 25.39 | |

| Fe2O3 (%) | 12.553 | 7.92 | |

| CaO (%) | 10.852 | 0.5 | |

| MgO (%) | ≤5 | 0.324 | 1.59 |

| TiO2 (%) | 0.919 | 1.22 | |

| P2O5 (%) | 3.606 | ||

| SO3 (%) | ≤2 | ||

| MnO (%) | 0.324 | ||

| Na2O (%) | 0.42 | ||

| K2O (%) | 6.292 | 4.13 | |

| Cu | 0.04 | ||

| Zn | 0.052 | ||

| Sr | 0.155 | ||

| LOI (%) | |||

| CO2 | ≤4 | ||

| Cal Livre | ≥80 | ||

| CaO + MgO | ≥90% |

| Mix | Total Aggregates/ Binders Ratio (%) | Aggregates | Binders | |||

|---|---|---|---|---|---|---|

| Hemp | SCB | Hydrated Lime | BD | SCBA | ||

| (%) | (%) | |||||

| H-L-ref | 25/75 | 100 | 100 | |||

| HS-L | 25/75 | 75 | 25 | 100 | ||

| HS-B | 25/75 | 75 | 25 | 100 | ||

| HS-A | 25/75 | 75 | 25 | 100 | ||

| HS25-L-B-A | 30/70 | 75 | 25 | 50 | 25 | 25 |

| HS50-L-B-A | 30/70 | 50 | 50 | 50 | 25 | 25 |

| HS75-L-B-A | 30/70 | 25 | 75 | 50 | 25 | 25 |

| HS-L-A | 25/75 | 75 | 25 | 75 | 25 | |

| Mix | Abr | MLr | Fr | F |

|---|---|---|---|---|

| (%) | (%) | (Mpa) | (Mpa) | |

| H-L-ref | 35.39 | 5.42 | 0.09 | 0.09 |

| HS-L | 37.00 | 5.46 | 0.16 | 0.17 |

| HS-B | 42.80 | 3.78 | 0.05 | 0.04 |

| HS25-L-B-A | 9.36 | 4.84 | 0.22 | 0.25 |

| HS50-L-B-A | 12.56 | 6.22 | 0.26 | 0.27 |

| HS75-L-B-A | 12.50 | 5.12 | 0.17 | 0.24 |

| HS-L-A | 8.88 | 5.06 | 0.34 | 0.39 |

| Tests | H-L-ref | HS-L | HS-B | HS-A | HS25-L-B-A | HS50-L-B-A | HS75-L-B-A | HS-L-A |

|---|---|---|---|---|---|---|---|---|

| Compressive strength performance | 3 | 2 | 4 | 8 | 5 | 6 | 7 | 1 |

| Thermal coefficient | 8 | 7 | 1 | 2 | 4 | 6 | 3 | 5 |

| Thermal Resistance | 8 | 7 | 2 | 1 | 4 | 5 | 3 | 6 |

| Coefficient of water absorption by capillarity | 6 | 7 | 5 | 8 | 1 | 3 | 2 | 4 |

| Freezing and thawing resistance | 6 | 5 | 7 | 8 | 3 | 1 | 4 | 2 |

| Degradation by exposure to simulated rain (% absorption) | 5 | 6 | 7 | 8 | 2 | 4 | 3 | 1 |

| Degradation by exposure to simulated rain (% erosion wear) | 5 | 6 | 1 | 8 | 2 | 7 | 4 | 3 |

| Degradation by exposure to simulated rain, Flexural strength | 6 | 5 | 7 | 8 | 3 | 2 | 4 | 1 |

| Saline exposure, Compressive strength performance | 2 | 1 | 5 | 8 | 7 | 6 | 4 | 3 |

| Total | 49 | 46 | 39 | 59 | 31 | 40 | 34 | 26 |

| Position | 7 | 6 | 4 | 8 | 2 | 5 | 3 | 1 |

| References | (HS-L-A) | [35] | [6] | [21] | [3] | [61] | [62] | [63] | |

|---|---|---|---|---|---|---|---|---|---|

| Text | Aggregates/ Binders | SCB/Lime SCBA | SCB/Lime | Hemp/ Lime | Hemp/ Lime | Hemp/ Hydraulic Lime—Pozzolanic Lime | Hemp/ Lime-Based and Natural Cement | Hemp/ Lime-Metakaolin | Hemp/ Lime- |

| Compressive strength performance | 0.46 MPa | 0.49 MPa | 0.37 MPa | 0.6 MPa | 0.3 MPa | 0.2 MPa | 1.64 MPa | 0.266 MPa | |

| Thermal coefficient | 0.098 W/m °C | 0.12 W/m °C | 0.11 W/m °C | 0.10 to 0.12 W/m °C | |||||

| Thermal Resistance | 0.48 m2 °C/W | 0.67 m2 °C/W | 0.16 m2 °C/W | ||||||

| Coefficient of water absorption by capillarity | 3.34 kg/m2 | 5.26 kg/m2 | 4.29 kg/m2 | ||||||

| Freezing and thawing resistance | −1.59%/31 cycle | −0.23%/No inf. | |||||||

| Degradation by exposure to water action Flexural strength, Ft Compressive strength, Fc | 0.34 MPa Ft better result with SCBA simulated rain (equivalent of 100 years) | 0.2 to 0.5 Fc without significant changes in compressive strength (2 years high humidity/drying cycles) | 0.56 MPa Ft flexural strength better results in mixtures with metakaolin (50 wetting/drying cycles) | ||||||

| Saline exposure, Compressive strength performance | 0.32 MPa | 0.43 MPa | |||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zúniga, A.; Eires, R.; Malheiro, R. New Lime-Based Hybrid Composite of Sugarcane Bagasse and Hemp as Aggregates. Resources 2023, 12, 55. https://doi.org/10.3390/resources12050055

Zúniga A, Eires R, Malheiro R. New Lime-Based Hybrid Composite of Sugarcane Bagasse and Hemp as Aggregates. Resources. 2023; 12(5):55. https://doi.org/10.3390/resources12050055

Chicago/Turabian StyleZúniga, Arlen, Rute Eires, and Raphaele Malheiro. 2023. "New Lime-Based Hybrid Composite of Sugarcane Bagasse and Hemp as Aggregates" Resources 12, no. 5: 55. https://doi.org/10.3390/resources12050055

APA StyleZúniga, A., Eires, R., & Malheiro, R. (2023). New Lime-Based Hybrid Composite of Sugarcane Bagasse and Hemp as Aggregates. Resources, 12(5), 55. https://doi.org/10.3390/resources12050055