Enhancement of the ESSENZ Method and Application in a Case Study on Batteries

Abstract

:1. Introduction

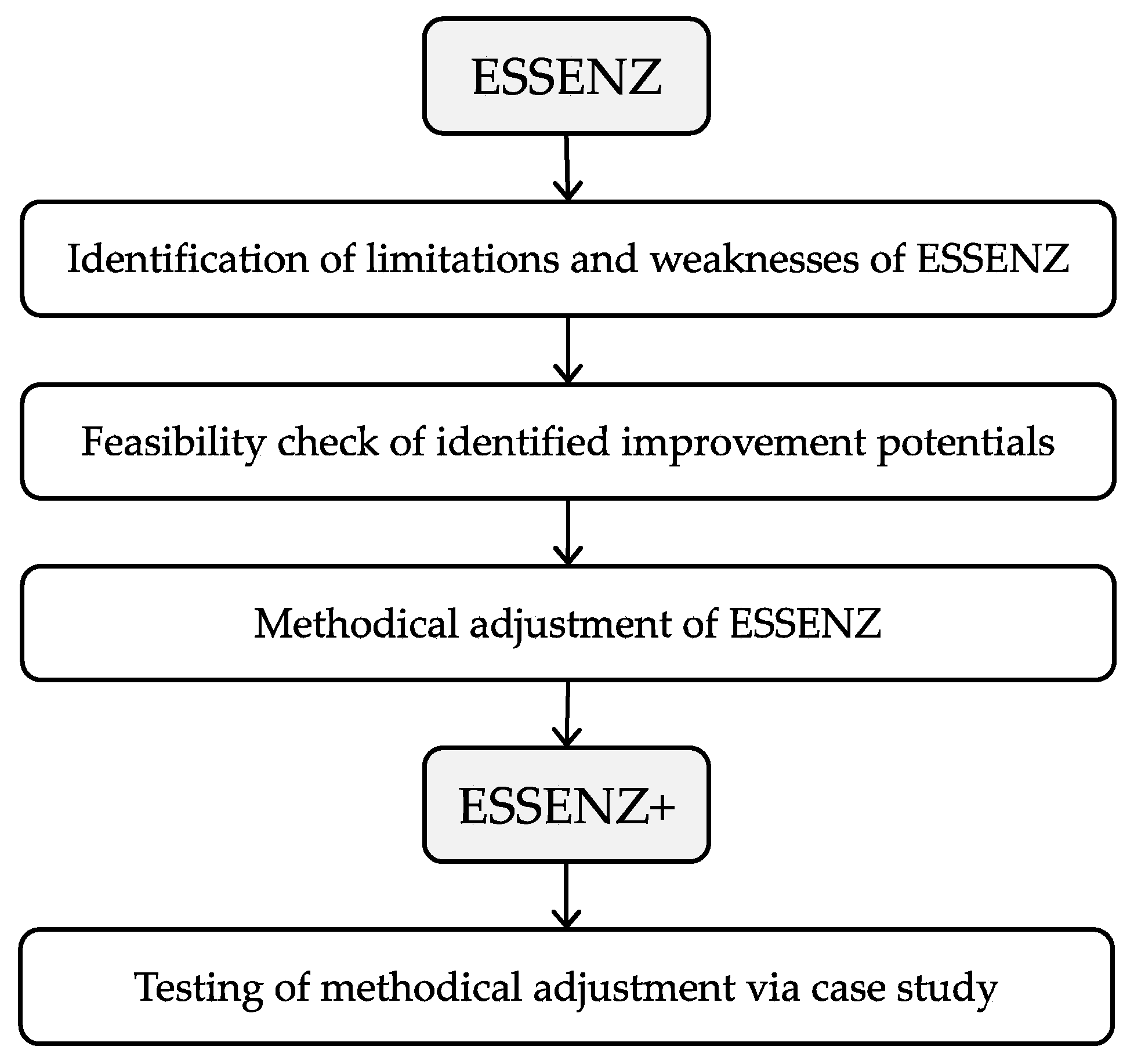

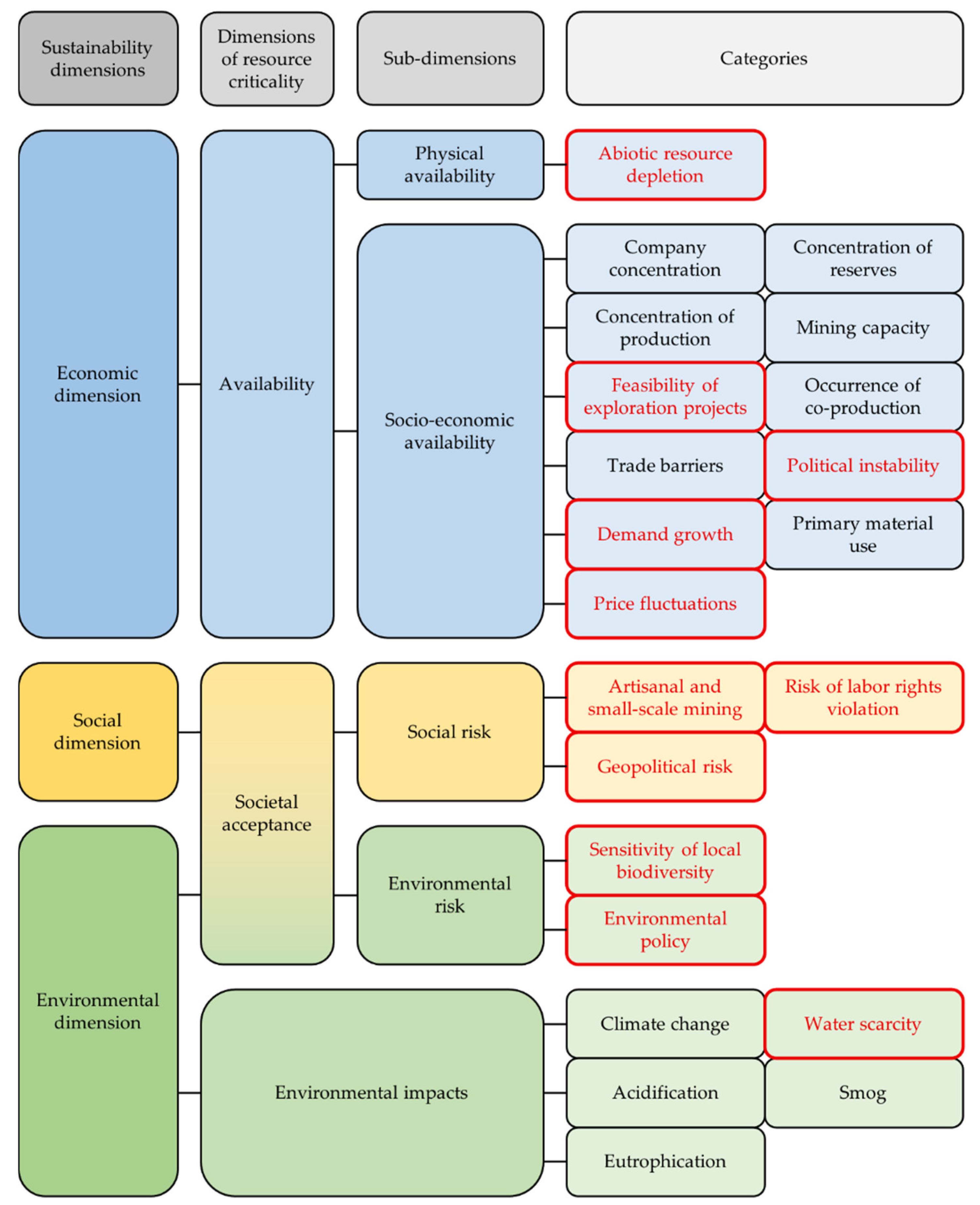

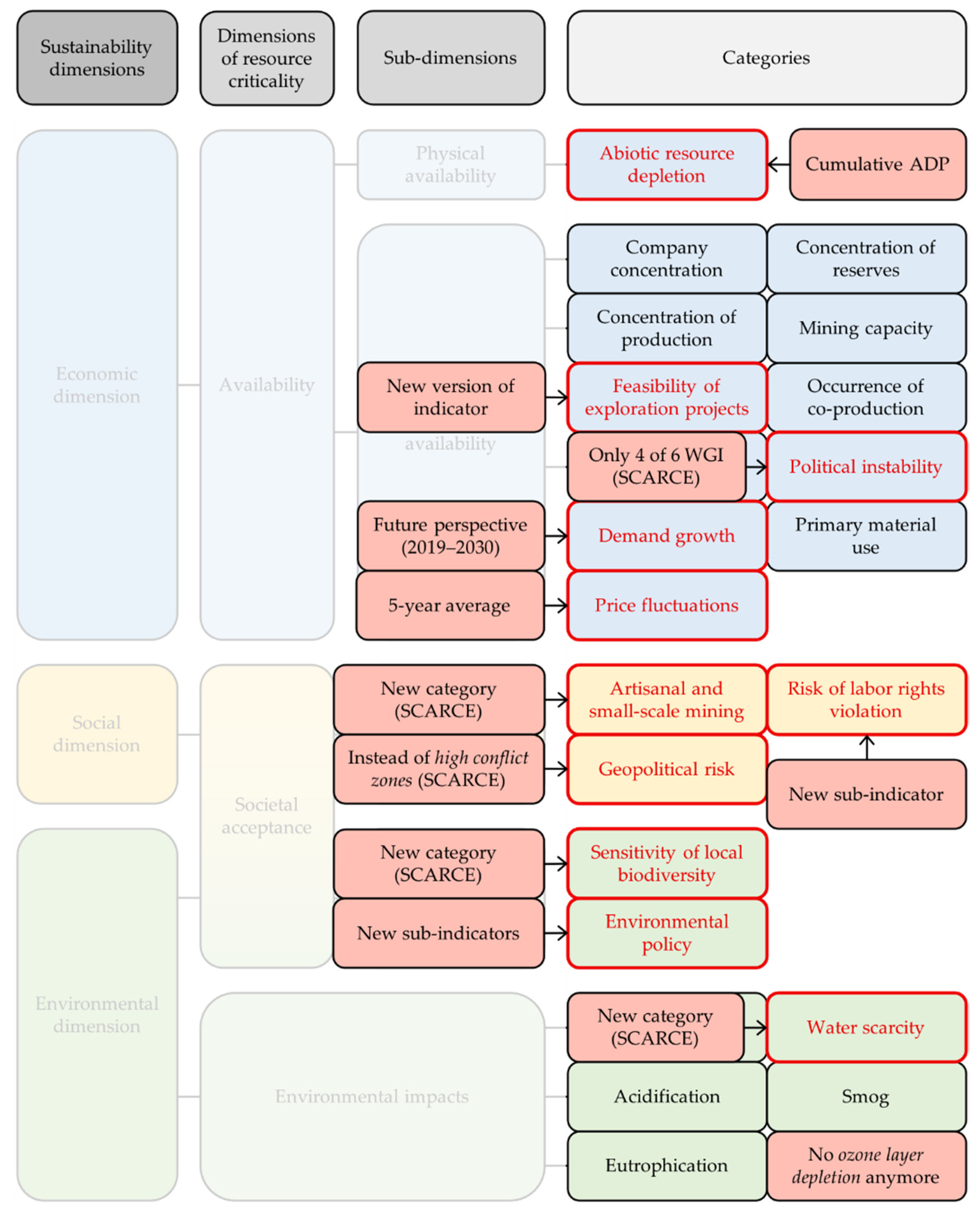

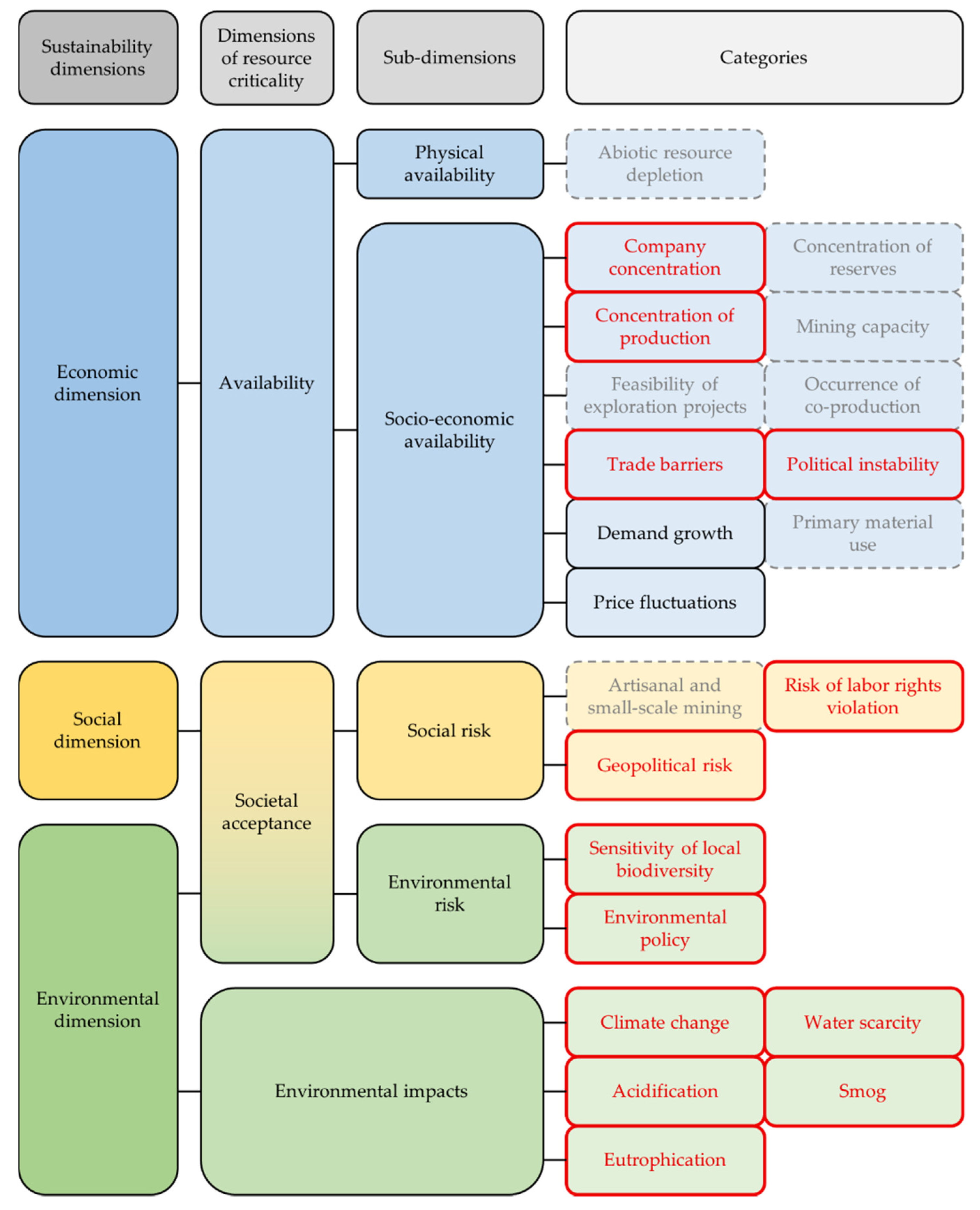

2. Methods for the Derivation of ESSENZ+

2.1. Identification of Limitations and Weaknesses of ESSENZ

- Societal acceptance categories

- Future trends in the demand growth

- Recognition of mine site certification

- Mine-site-specific assessment

- Assessment of secondary materials

- Company-specific assessment

- Data update

- Set Distance-to-Target (DtT) results below one to zero

- Indicator uncertainties

2.2. Feasibility Check of Identified Improvement Potentials

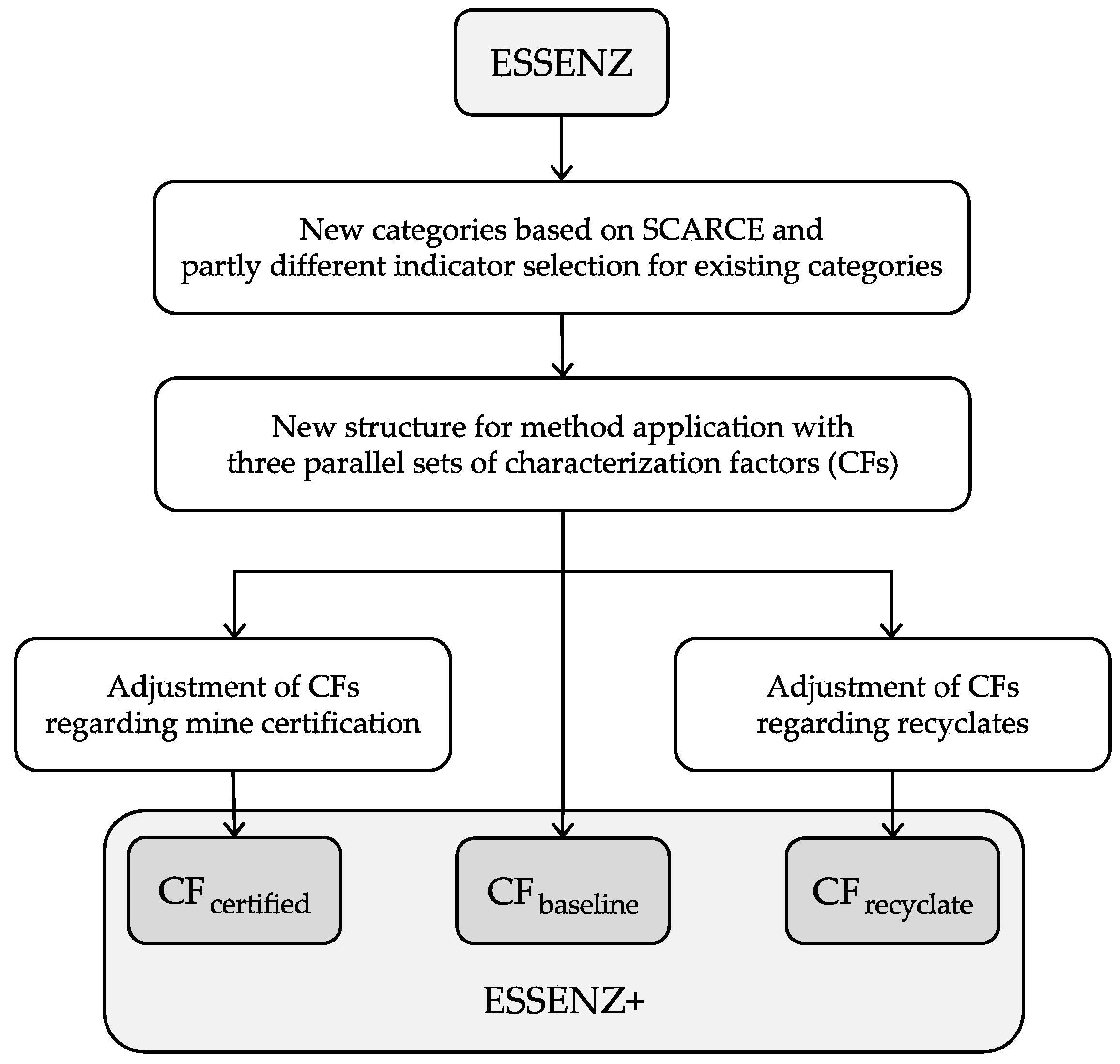

2.3. Methodical Adjustment of ESSENZ

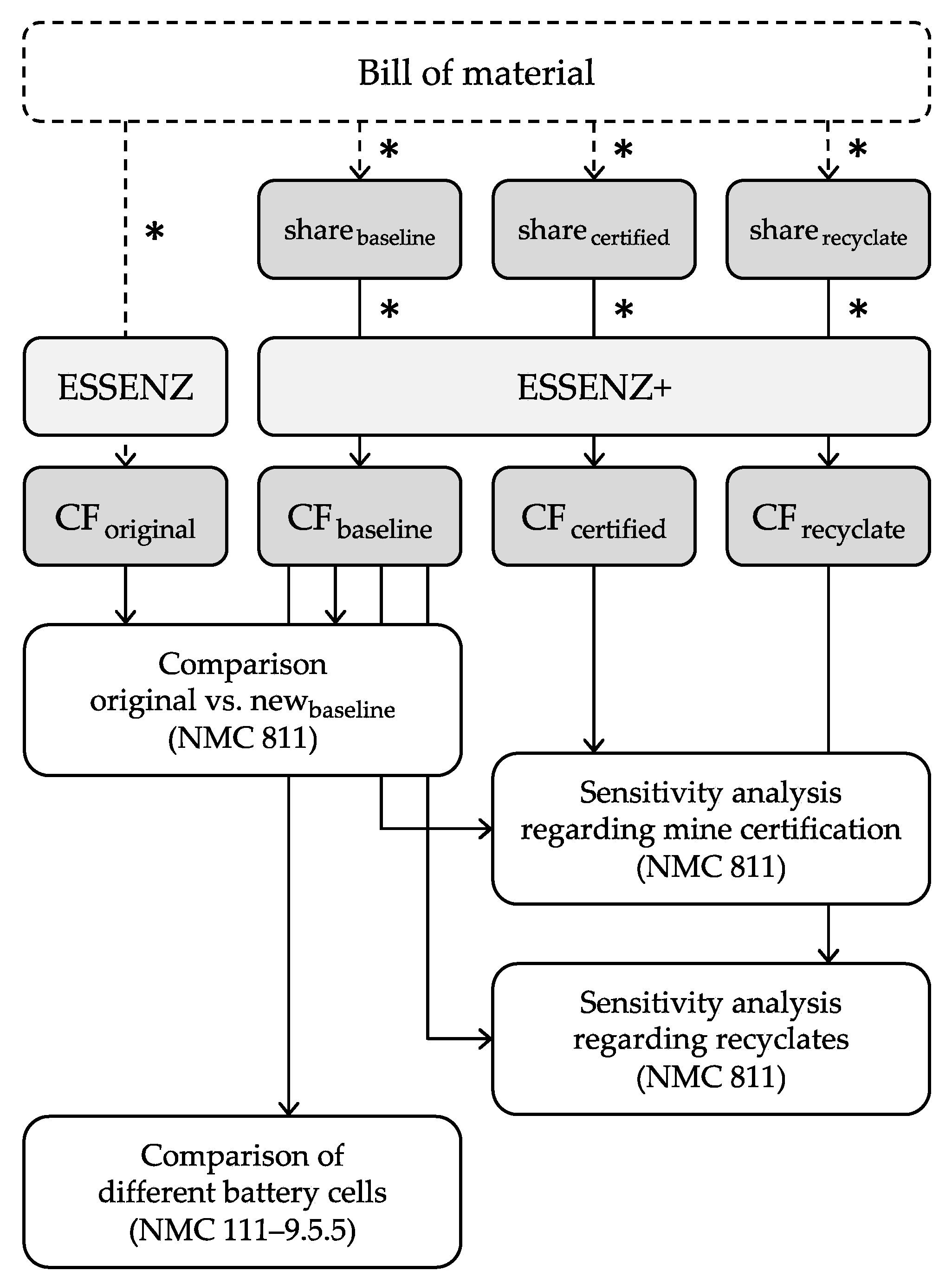

2.4. Testing of Methodical Adustment via Case Study

3. ESSENZ+ Method

3.1. Adjusted Categories and Indicators

- Abiotic resource depletion

- Feasibility of exploration projects

- Political instability

- Demand growth

- Price fluctuations

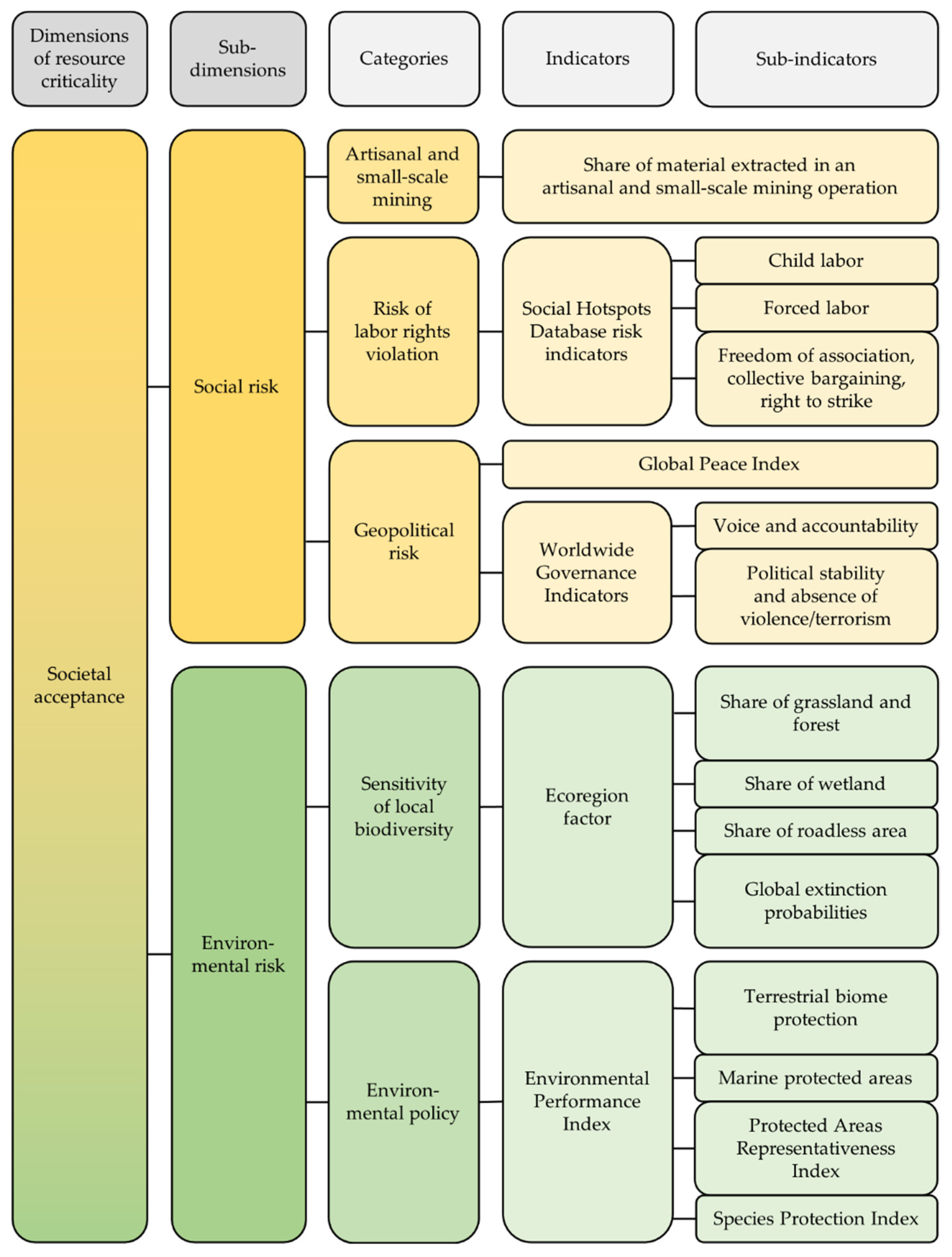

- Risk of labor rights violation

- Geopolitical risk

- Artisanal and small-scale mining

- Sensitivity of local biodiversity

- Environmental policy

- Water scarcity

- Ozone layer depletion

3.2. Three Parallel Sets of Characterization Factors

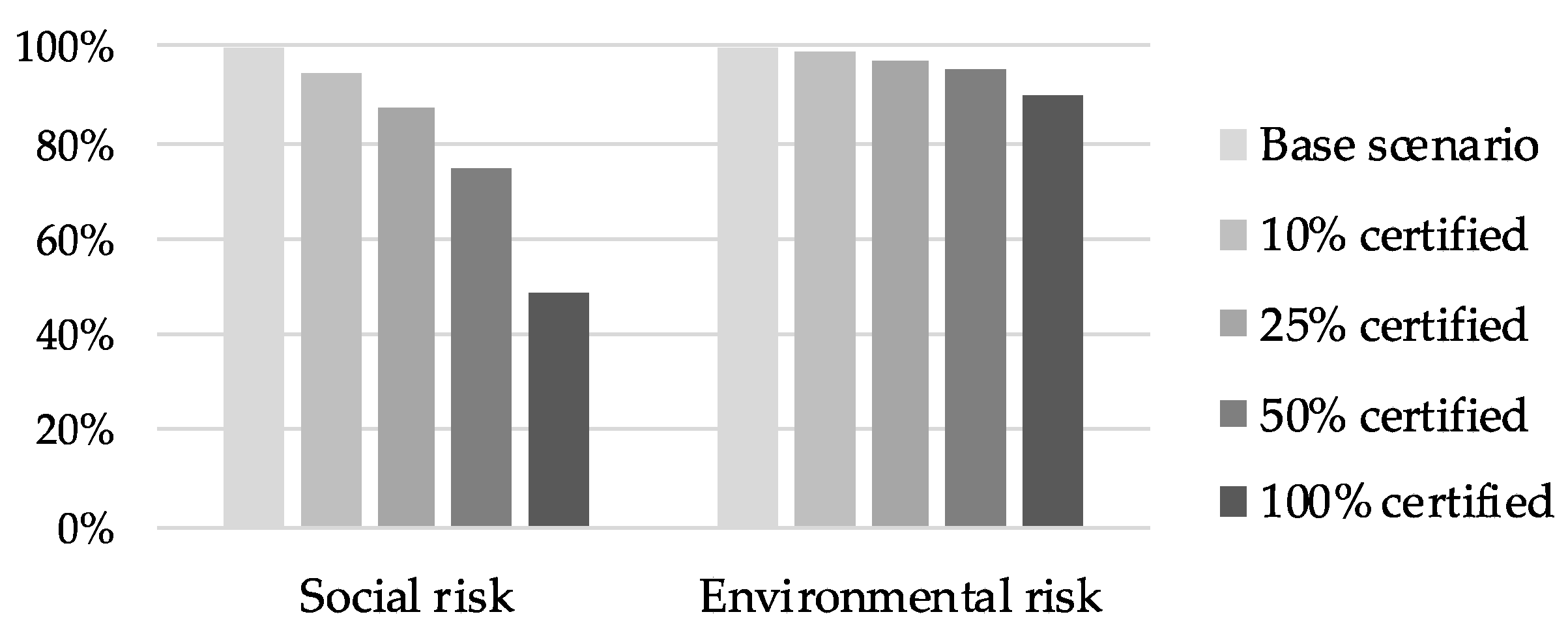

3.2.1. Considering Mine Site Certification in ESSENZ+

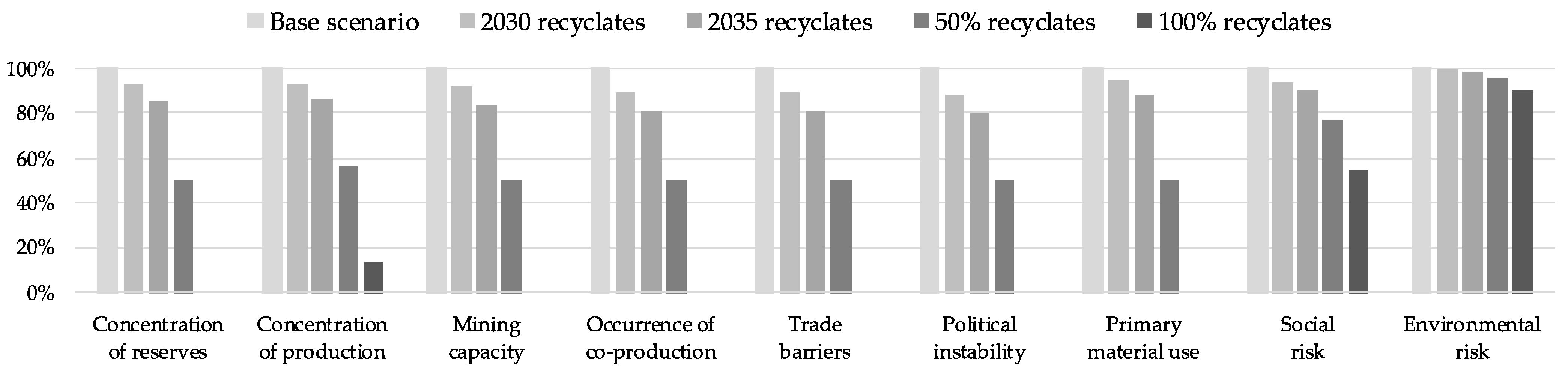

3.2.2. Considering Recyclate Use in ESSENZ+

4. Case Study: Battery Cells

4.1. Goal and Scope of the Case Study

4.2. Results of the Case Study

4.2.1. General Results

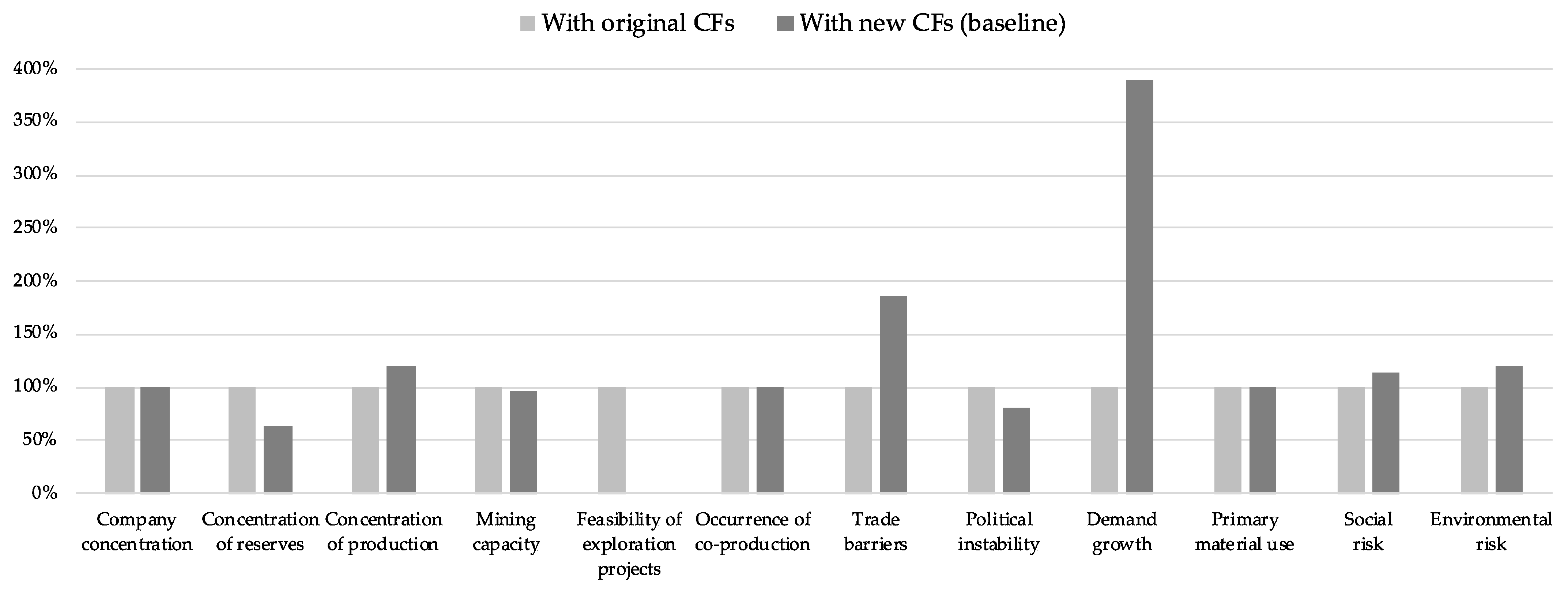

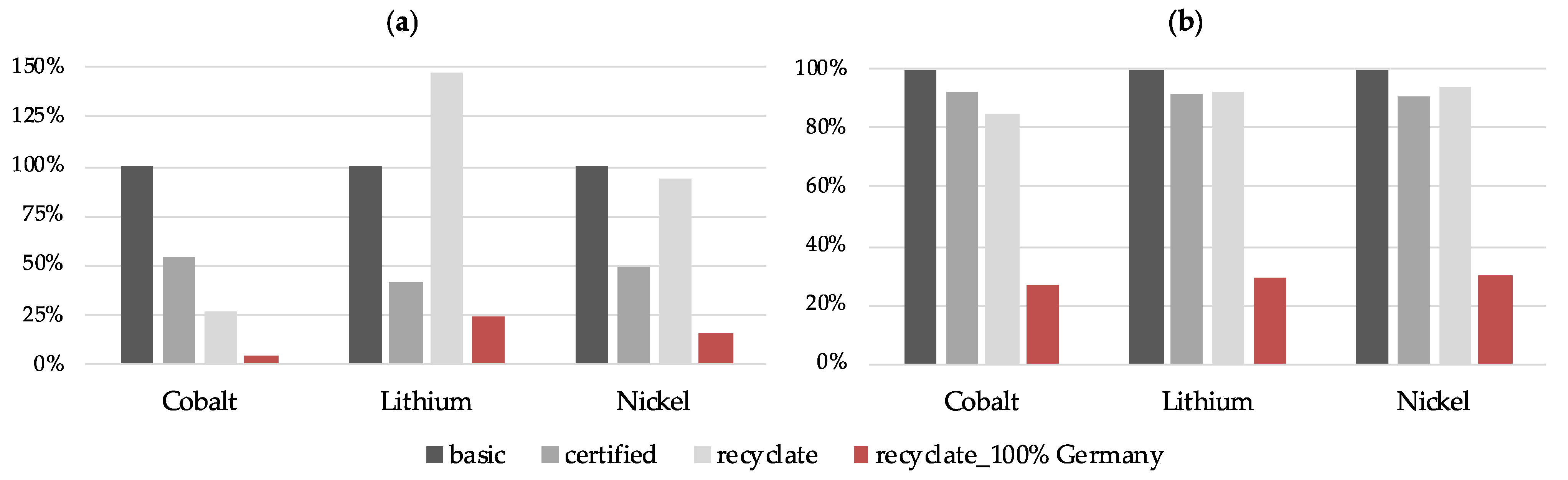

4.2.2. Comparison of Original ESSENZ and ESSENZ+

4.2.3. Sensitivity Analyses

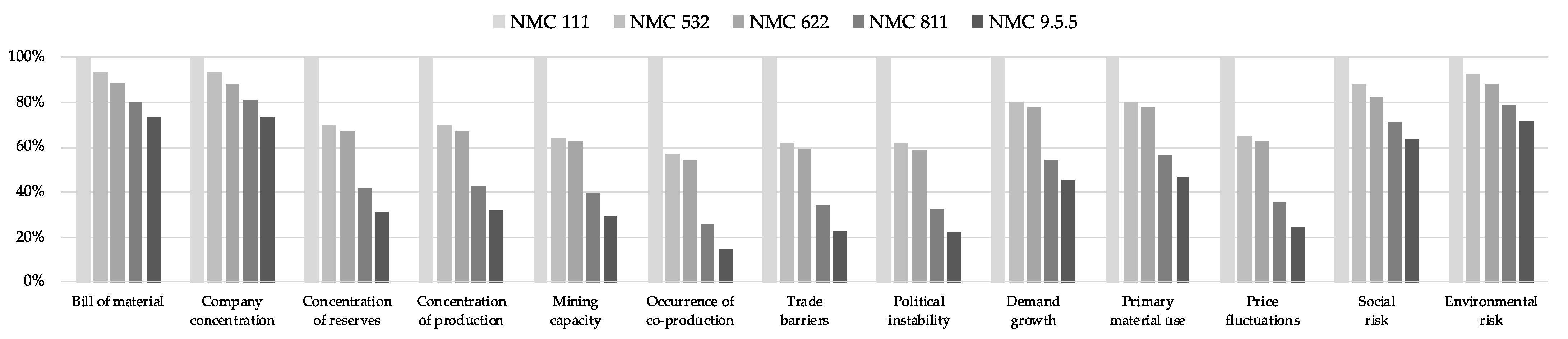

4.2.4. Comparison of Different NMC Battery Cells

5. Discussion

5.1. Discussion of the Methodical Approach of ESSENZ+

5.2. Discussion of the Methodical Approach of the Case Study

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- International Resource Panel (IRP). Mineral Resource Governance in the 21st Century: Gearing Extractive Industries towards Sustainable Development; United Nations Environment Programme (UNEP): Nairobi, Kenya, 2020; ISBN 978-92-807-3779-0. [Google Scholar]

- International Resource Panel (IRP). Resource Efficiency and Climate Change: Material Efficiency Strategies for a Low-Carbon Future; United Nations Environment Programme (UNEP): Nairobi, Kenya, 2020; ISSN 978-92-807-3771-4. [Google Scholar]

- Marimuthu, R.; Sankaranarayanan, B.; Ali, S.M.; de Jabbour, A.B.L.S.; Karuppiah, K. Assessment of Key Socio-Economic and Environmental Challenges in the Mining Industry: Implications for Resource Policies in Emerging Economies. Sustain. Prod. Consum. 2021, 27, 814–830. [Google Scholar] [CrossRef]

- European Commission. Study on the EU’s List of Critical Raw Materials—Final Report; European Commission: Brussels, Belgium, 2020. [Google Scholar] [CrossRef]

- Helbig, C.; Schrijvers, D.; Hool, A. Selecting and Prioritizing Material Resources by Criticality Assessments. One Earth 2021, 4, 339–345. [Google Scholar] [CrossRef]

- Koyamparambath, A.; Santillán-Saldivar, J.; McLellan, B.; Sonnemann, G. Supply Risk Evolution of Raw Materials for Batteries and Fossil Fuels for Selected OECD Countries (2000–2018). Resour. Policy 2022, 75, 102465. [Google Scholar] [CrossRef]

- Hao, H.; Sun, X. The Impacts of Electric Vehicles on Resources and Supply Chains Sustainability. In China’s Resources, Energy and Sustainable Development: 2020; Springer: Singapore, 2021; pp. 195–215. ISBN 978-981-336-100-3. [Google Scholar]

- Mancini, L.; Sala, S. Social Impact Assessment in the Mining Sector: Review and Comparison of Indicators Frameworks. Resour. Policy 2018, 57, 98–111. [Google Scholar] [CrossRef]

- Sovacool, B.K. When Subterranean Slavery Supports Sustainability Transitions? Power, Patriarchy, and Child Labor in Artisanal Congolese Cobalt Mining. Extr. Ind. Soc. 2021, 8, 271–293. [Google Scholar] [CrossRef]

- Ullah, S.; Adams, K.; Adams, D.; Attah-Boakye, R. Multinational Corporations and Human Rights Violations in Emerging Economies: Does Commitment to Social and Environmental Responsibility Matter? J. Environ. Manag. 2021, 280, 111689. [Google Scholar] [CrossRef]

- Helbig, C.; Bruckler, M.; Thorenz, A.; Tuma, A. An Overview of Indicator Choice and Normalization in Raw Material Supply Risk Assessments. Resources 2021, 10, 79. [Google Scholar] [CrossRef]

- Berger, M.; Sonderegger, T.; Alvarenga, R.; Bach, V.; Cimprich, A.; Dewulf, J.; Frischknecht, R.; Guinée, J.; Helbig, C.; Huppertz, T.; et al. Mineral Resources in Life Cycle Impact Assessment: Part II—Recommendations on Application-Dependent Use of Existing Methods and on Futuremethod Development Needs. Int. J. Life Cycle Assess. 2020, 25, 798–813. [Google Scholar] [CrossRef] [Green Version]

- Sonderegger, T.; Berger, M.; Alvarenga, R.; Bach, V.; Cimprich, A.; Dewulf, J.; Frischknecht, R.; Guinée, J.; Helbig, C.; Huppertz, T.; et al. Mineral Resources in Life Cycle Impact Assessment—Part I: A Critical Review of Existing Methods. Int. J. Life Cycle Assess. 2020, 25, 784–797. [Google Scholar] [CrossRef]

- UNEP. Global Guidance for Life Cycle Impact Assessment Indicators (GLAM) Volume 2. In Life Cycle Initiative; Frischknecht, R., Jolliet, O., Eds.; UNEP: Nairobi, Kenya, 2019. [Google Scholar]

- Cimprich, A.; Bach, V.; Helbig, C.; Thorenz, A.; Schrijvers, D.; Sonnemann, G.; Young, S.B.; Sonderegger, T.; Berger, M. Raw Material Criticality Assessment as a Complement to Environmental Life Cycle Assessment: Examining Methods for Product-Level Supply Risk Assessment. J. Ind. Ecol. 2019, 23, 1226–1236. [Google Scholar] [CrossRef]

- Santillán-Saldivar, J.; Cimprich, A.; Shaikh, N.; Laratte, B.; Young, S.B.; Sonnemann, G. How Recycling Mitigates Supply Risks of Critical Raw Materials: Extension of the Geopolitical Supply Risk Methodology Applied to Information and Communication Technologies in the European Union. Resour. Conserv. Recycl. 2021, 164, 105108. [Google Scholar] [CrossRef]

- Bach, V.; Berger, M.; Henßler, M.; Kirchner, M.; Leiser, S.; Mohr, L.; Rother, E.; Ruhland, K.; Schneider, L.; Tikana, L.; et al. Integrated Method to Assess Resource Efficiency—ESSENZ. J. Clean. Prod. 2016, 137, 118–130. [Google Scholar] [CrossRef] [Green Version]

- Bach, V.; Berger, M.; Henßler, M.; Kirchner, M.; Leiser, S.; Mohr, L.; Rother, E.; Ruhland, K.; Schneider, L.; Tikana, L.; et al. Messung von Ressourceneffizienz mit der ESSENZ-Methode; Springer: Berlin/Heidelberg, Germany, 2016; ISBN 978-3-662-49263-5. [Google Scholar]

- Bach, V.; Berger, M.; Finogenova, N.; Finkbeiner, M. Analyzing Changes in Supply Risks for Abiotic Resources over Time with the ESSENZ Method—A Data Update and Critical Reflection. Resources 2019, 8, 83. [Google Scholar] [CrossRef] [Green Version]

- Yavor, K.M.; Bach, V.; Finkbeiner, M. Adapting the ESSENZ Method to Assess Company-Specific Criticality Aspects. Resources 2021, 10, 56. [Google Scholar] [CrossRef]

- Bach, V.; Finogenova, N.; Berger, M.; Winter, L.; Finkbeiner, M. Enhancing the Assessment of Critical Resource Use at the Country Level with the SCARCE Method—Case Study of Germany. Resour. Policy 2017, 53, 283–299. [Google Scholar] [CrossRef] [Green Version]

- Arendt, R.; Muhl, M.; Bach, V.; Finkbeiner, M. Criticality Assessment of Abiotic Resource Use for Europe—Application of the SCARCE Method. Resour. Policy 2020, 67, 101650. [Google Scholar] [CrossRef]

- Bian, J.; Liao, Y.; Wang, Y.-Y.; Tao, F. Analysis of Firm CSR Strategies. Eur. J. Oper. Res. 2021, 290, 914–926. [Google Scholar] [CrossRef]

- Calvão, F.; Gronwald, V. Blockchain in the Mining Industry: Implications for Sustainable Development in Africa. Policy Insights 2019, 74, 1–12. [Google Scholar]

- Ruokonen, E. Preconditions for Successful Implementation of the Finnish Standard for Sustainable Mining. Extr. Ind. Soc. 2020, 7, 611–620. [Google Scholar] [CrossRef]

- van den Brink, S.; Kleijn, R.; Tukker, A.; Huisman, J. Approaches to Responsible Sourcing in Mineral Supply Chains. Resour. Conserv. Recycl. 2019, 145, 389–398. [Google Scholar] [CrossRef]

- USGS. Mineral Commodity Summaries 2021; U.S. Geological Survey: Reston, VA, USA, 2021. [Google Scholar] [CrossRef]

- Or, T.; Gourley, S.W.D.; Kaliyappan, K.; Yu, A.; Chen, Z. Recycling of Mixed Cathode Lithium-Ion Batteries for Electric Vehicles: Current Status and Future Outlook. Carbon Energy 2020, 2, 6–43. [Google Scholar] [CrossRef] [Green Version]

- Pinegar, H.; Smith, Y.R. Recycling of End-of-Life Lithium Ion Batteries, Part I: Commercial Processes. J. Sustain. Metall. 2019, 5, 402–416. [Google Scholar] [CrossRef]

- Werner, D.; Peuker, U.A.; Mütze, T. Recycling Chain for Spent Lithium-Ion Batteries. Metals 2020, 10, 316. [Google Scholar] [CrossRef] [Green Version]

- Graedel, T.E.; Allwood, J.; Birat, J.P.; Buchert, M.; Hagelüken, C.; Reck, B.K.; Sibley, S.F.; Sonnemann, G. Rates of Metals: A Status Report; UNEP: Nairobi, Kenya, 2011. [Google Scholar]

- Buchert, M.; Dolega, P.; Degreif, S. Gigafactories für Lithium-Ionen-Zellen—Rohstoffbedarfe für die globale Elektromobilität bis 2050; Oeko-Inst. e.V.: Darmstadt, Germany, 2019. [Google Scholar]

- Liu, W.; Agusdinata, D.B. Interdependencies of Lithium Mining and Communities Sustainability in Salar de Atacama, Chile. J. Clean. Prod. 2020, 260, 120838. [Google Scholar] [CrossRef]

- Schüler, D.; Dolega, P.; Degreif, S. Social, Economic and Environmental Challenges in Primary Lithium and Cobalt Sourcing for the Rapidly Increasing Electric Mobility Sector; Oeko-Inst. e.V.: Darmstadt, Germany, 2018. [Google Scholar]

- Sun, X.; Bach, V.; Finkbeiner, M.; Yang, J. Criticality Assessment of the Life Cycle of Passenger Vehicles Produced in China. Circ. Econ. Sustain. 2021, 1, 435–455. [Google Scholar] [CrossRef]

- Dolganova, I.; Rödl, A.; Bach, V.; Kaltschmitt, M.; Finkbeiner, M. A Review of Life Cycle Assessment Studies of Electric Vehicles with a Focus on Resource Use. Resources 2020, 9, 32. [Google Scholar] [CrossRef] [Green Version]

- Bongartz, L.; Shammugam, S.; Gervais, E.; Schlegl, T. Multidimensional Criticality Assessment of Metal Requirements for Lithium-Ion Batteries in Electric Vehicles and Stationary Storage Applications in Germany by 2050. J. Clean. Prod. 2021, 292, 126056. [Google Scholar] [CrossRef]

- Greenwood, M.; Wentker, M.; Leker, J. A Region-Specific Raw Material and Lithium-Ion Battery Criticality Methodology with an Assessment of NMC Cathode Technology. Appl. Energy 2021, 302, 117512. [Google Scholar] [CrossRef]

- Wentker, M.; Greenwood, M.; Asaba, M.C.; Leker, J. A Raw Material Criticality and Environmental Impact Assessment of State-of-the-Art and Post-Lithium-Ion Cathode Technologies. J. Energy Storage 2019, 26, 101022. [Google Scholar] [CrossRef]

- van Oers, L.; Koning, A.; Guinée, J.B.; Huppes, G. Abiotic Resource Depletion in LCA; Road and Hydraulic Engineering Institute: Amsterdam, The Netherlands, 2002. [Google Scholar]

- van Oers, L.; Guinée, J.B.; Heijungs, R. Abiotic Resource Depletion Potentials (ADPs) for Elements Revisited—Updating Ultimate Reserve Estimates and Introducing Time Series for Production Data. Int. J. Life Cycle Assess. 2020, 25, 294–308. [Google Scholar] [CrossRef] [Green Version]

- Schneider, L.; Berger, M.; Finkbeiner, M. Abiotic Resource Depletion in LCA—Background and Update of the Anthropogenic Stock Extended Abiotic Depletion Potential (AADP) Model. Int. J. Life Cycle Assess. 2015, 20, 709–721. [Google Scholar] [CrossRef]

- Yunis, J.; Aliakbari, E. Fraser Institute Annual Survey of Mining Companies 2020; Fraser Institute: Vancouver, BC, Canada, 2021. [Google Scholar]

- Kaufmann, D.; Kraay, A. The Worldwide Governance Indicators, 2020 Update—Aggregate Governance Indicators 1996–2019; World Bank: Washington, DC, USA, 2020. [Google Scholar]

- CRUX Investor. The Cobalt Market 2021–2030F; CRUX Investor: London, UK, 2021. [Google Scholar]

- Minerals Council of Australia & Commodity Insights. Commodity Demand Outlook 2030; Minerals Council of Australia: Canberra, Australia, 2020. [Google Scholar]

- Mitchell, P. Why Mineral Supply May Be an E-Mobility Roadblock. Available online: https://www.ey.com/en_gl/mining-metals/why-mineral-supply-may-be-an-e-mobility-roadblock (accessed on 4 October 2021).

- United Nations. Transforming Our World: The 2030 Agenda for Sustainable Development—Resolution Adopted by the General Assembly on 25 September 2015; United Nations: New York, NY, USA, 2015. [Google Scholar]

- Science Based Targets initiative. Companies Taking Action. Available online: https://sciencebasedtargets.org/companies-taking-action (accessed on 4 October 2021).

- DERA. Volatilitätsmonitor May 2021; German Mineral Resources Agency (DERA): Berlin, Germany, 2021. [Google Scholar]

- DERA. Volatilitätsmonitor November 2021; German Mineral Resources Agency (DERA): Berlin, Germany, 2021. [Google Scholar]

- SHDB. Social Hotspots Database—Table of Supply Chain Risks for Multiple Issues in “Labor Rights & Decent Work”. Available online: http://www.socialhotspot.org/ (accessed on 1 October 2021).

- Kaufmann, D.; Kraay, A. Worldwide Governance Indicators—Documentation—Political Stability and Absence of Violence/Terrorism; World Bank: Washington, DC, USA, 2020. [Google Scholar]

- ILO. ILO Declaration on Fundamental Principles and Rights at Work and Its Follow-Up. In Proceedings of the International Labour Conference, Geneva, Switzerland, 18 June 1998. Annex Revised 15 June 2010. [Google Scholar]

- Bundesanzeiger Verlag. Gesetz über die unternehmerischen Sorgfaltspflichten in Lieferketten. In Bundesgesetzblatt Jahrgang 2021 Teil I Nr. 46; Bundesanzeiger Verlag: Bonn, Germany, 2021. [Google Scholar]

- Lindner, J.P.; Fehrenbach, H.; Winter, L.; Bloemer, J.; Knuepffer, E. Valuing Biodiversity in Life Cycle Impact Assessment. Sustainability 2019, 11, 5628. [Google Scholar] [CrossRef] [Green Version]

- Wendling, Z.A.; Emerson, J.W.; Sherbinin, A.; Esty, D.C.; Hoving, K.; Ospina, C.D.; Murray, J.; Gunn, L.; Ferrato, M.; Schreck, M.; et al. Environmental Performance Index 2020—Global Metrics for the Environment: Ranking Country Performance on Sustainability Issues. Yale Center for Environmental Law & Policy: New Haven, CT, USA, 2020. [Google Scholar]

- Boulay, A.-M.; Bare, J.; Benini, L.; Berger, M.; Lathuillière, M.J.; Manzardo, A.; Margni, M.; Motoshita, M.; Núñez, M.; Pastor, A.V.; et al. The WULCA Consensus Characterization Model for Water Scarcity Footprints: Assessing Impacts of Water Consumption Based on Available Water Remaining (AWARE). Int. J. Life Cycle Assess. 2018, 23, 368–378. [Google Scholar] [CrossRef] [Green Version]

- Chipperfield, M.P.; Bekki, S.; Dhomse, S.; Harris, N.R.P.; Hassler, B.; Hossaini, R.; Steinbrecht, W.; Thiéblemont, R.; Weber, M. Detecting Recovery of the Stratospheric Ozone Layer. Nature 2017, 549, 211–218. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- IRMA. IRMA Standard for Responsible Mining IRMA-STD_001; Initiative for Responsible Mining Assuranc: Seattle, WA, USA, 2018. [Google Scholar]

- IRMA. IRMA Certification Body Requirements—Version 1.0; Initiative for Responsible Mining Assurance: Seattle, WA, USA, 2019. [Google Scholar]

- Tedesco, R.; Barczak, P.; Sommer, P.; Keynes, A. Enhancing the Sustainability of Batteries—A Joint NGOs’ Position Paper on the EU Battery Regulation Proposal; ECOS: Brussels, Belgium; European Environment Bureau: Brussels, Belgium; DUH: Hannover, Germany; T&E: Brussels, Belgium, 2021. [Google Scholar]

- Mudd, G.M. Sustainable/Responsible Mining and Ethical Issues Related to the Sustainable Development Goals. Geol. Soc. Lond. Spec. Publ. 2021, 508, 187–199. [Google Scholar] [CrossRef]

- Kickler, K.; Franken, G. Sustainability Schemes for Mineral Resources: A Comparative Overview. Federal Institute for Geosciences and Natural Resources (BGR): Hannover, Germany, 2017. [Google Scholar]

- UNEP. Sustainability Reporting in the Mining Sector—Current Status and Future Trends; UNEP: Nairobi, Kenya, 2020. [Google Scholar]

- Sauer, P.C.; Hiete, M. Multi-Stakeholder Initiatives as Social Innovation for Governance and Practice: A Review of Responsible Mining Initiatives. Sustainability 2020, 12, 236. [Google Scholar] [CrossRef] [Green Version]

- BGR. Mapping of the Artisanal Copper-Cobalt Mining Sector in the Provinces of Haut-Katanga and Lualaba in the Democratic Republic of the Congo; Federal Institute for Geosciences and Natural Resources (BGR): Hannover, Germany, 2019. [Google Scholar]

- Mancini, L.; Eslava, N.A.; Traverso, M.; Mathieux, F. Assessing Impacts of Responsible Sourcing Initiatives for Cobalt: Insights from a Case Study. Resour. Policy 2021, 71, 102015. [Google Scholar] [CrossRef]

- Schwartz, F.W.; Lee, S.; Darrah, T.H. A Review of Health Issues Related to Child Labor and Violence Within Artisanal and Small-Scale Mining. GeoHealth 2021, 5, e2020GH000326. [Google Scholar] [CrossRef]

- Frey, D.F. Conflict over Conflict: The Right to Strike in International Law. Glob. Labour J. 2017, 8, 17–31. [Google Scholar] [CrossRef] [Green Version]

- Renner, S.; Wellmer, F.W. Volatility Drivers on the Metal Market and Exposure of Producing Countries. Miner. Econ. 2020, 33, 311–340. [Google Scholar] [CrossRef] [Green Version]

- Hettesheimer, T.; Thielmann, A.; Neef, C.; Möller, K.; Wolter, M.; Lorentz, V.; Gepp, M.; Wenger, M.; Prill, T.; Zausch, J.; et al. Entwicklungsperspektiven für Zellformate von Lithium-Ionen-Batterien in der Elektromobilität; Fraunhofer-Allianz Batterien: Pfinztal, Germany, 2017. [Google Scholar]

- Vekić, N. Lithium-Ionen-Batterien für die Elektromobilität: Status, Zukunftsperspektiven, Recycling; Thinktank Industrielle Ressourcenstrategien: Karlsruhe, Germany, 2020. [Google Scholar]

- Mathieu, L.; Mattea, C. From Dirty Oil to Clean Batteries—Batteries vs. Oil: A Systemic Comparison of Material Requirements; Transport & Environment: Brussels, Belgium, 2021. [Google Scholar]

- EC. Proposal for a Regulation of the European Parliament and of the Council Concerning Batteries and Waste Batteries, Repealing Directive 2006/66/EC and Amending Regulation (EU) No 2019/1020; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- Buchert, D.M.; Sutter, J. Stand und Perspektiven des Recyclings von Lithium-Ionen- Batterien aus der Elektromobilität; Oeko-Inst. e.V.: Darmstadt, Germany, 2020. [Google Scholar]

- Fitch Solutions Country Risk & Industry Research. Aluminium Demand Growth Will Soon Outpace Production Growth. Available online: https://www.pipingmart.com/news/aluminium-demand-growth-will-soon-outpace-production-growth-110042 (accessed on 30 December 2021).

- Basov, V. Global Refined Copper Demand to Rise 31% by 2030—Report. Available online: https://www.kitco.com/news/2021-06-08/Global-refined-copper-demand-to-rise-31-by-2030-report.html (accessed on 30 December 2021).

- Prescient & Strategic Intelligence. Graphite Market Research Report—Global Industry Trend and Growth Forecast to 2030. Available online: https://www.psmarketresearch.com/market-analysis/graphite-market (accessed on 30 December 2021).

- Barrera, P. Graphite Outlook 2021: Demand from Battery Segment to Grow. Available online: https://investingnews.com/daily/resource-investing/battery-metals-investing/graphite-investing/graphite-outlook/ (accessed on 30 December 2021).

- Qizhong, Z.; Damm, S. Supply and Demand of Natural Graphite—DERA Rohstoffinformationen Nr. 43; German Mineral Resources Agency (DERA): Berlin, Germany, 2020. [Google Scholar]

- Lasley, S. EV Batteries to Drive 9x Graphite Growth. Available online: https://www.miningnewsnorth.com/story/2019/06/01/critical-minerals/ev-batteries-to-drive-9x-graphite-growth/5754.html (accessed on 30 December 2021).

- Foundry Informatics Centre. Global Iron Ore Demand to Double in 2030. Available online: http://foundryinfo-india.org/Global%20iron%20ore%20demand%20to%20double%20in%202030.aspx (accessed on 30 December 2021).

- Accenture Strategy. Steel Demand Beyond 2030—Forecast Scenarios; Accenture Strategy: Chicago, IL, USA, 2017. [Google Scholar]

- World Steel Association. Apparent Iron Ore Consumption Worldwide from 2010 to 2019. Available online: https://www.statista.com/statistics/1168853/apparent-iron-ore-consumption-worldwide/ (accessed on 30 December 2021).

- The Business Research Company. Global Iron Ore Market Growth: Drivers and Trends 2020–2030. Available online: https://www.einnews.com/pr_news/530803327/global-iron-ore-market-growth-drivers-and-trends-2020–2030 (accessed on 30 December 2021).

- Comisión Chilena del Cobre. Projection of Total Worldwide Lithium Demand from 2016 to 2030. Available online: https://www.statista.com/statistics/452025/projected-total-demand-for-lithium-globally/ (accessed on 30 December 2021).

- Mordor Intelligence. Manganese Market—Growth, Trends, COVID-19 Impact, and Forecasts (2021–2026). Available online: https://www.mordorintelligence.com/industry-reports/manganese-market (accessed on 30 December 2021).

- Invest Saudi. Manganese Metal—Investment Opportunity Scorecard—Mining & Metals; Invest Saudi: Riyadh, Saudi Arabia, 2020. [Google Scholar]

- Fraser, J.; Anderson, J.; Lazuen, J.; Lu, Y.; Heathman, O.; Brewster, N.; Bedder, J.; Masson, O. Study on Future Demand and Supply Security of Nickel for Electric Vehicle Batteries; JRC.; Publications Office of the European Union: Luxembourg, 2021; ISBN 978-92-76-29139-8. [Google Scholar]

- Norilsk, N. Global Consumption of Nickel from 2010 to 2020. Available online: https://www.statista.com/statistics/273635/consumption-of-nickel-since-2007/ (accessed on 30 December 2021).

- S&P Global. SNL Metals & Mining Dataset. Marketplace—Market Intelligence. Available online: https://www.marketplace.spglobal.com/en/datasets/snl-metals-mining-(19) (accessed on 21 November 2021).

- Gulia, J.; Jain, S. Recycling of Lithium-Ion Batteries in India—$1,000 Million Opportunity; JMK Research & Analytics: Gurgaon, India, 2019. [Google Scholar]

- Harrison, D.; Ludwig, C. Electric Vehicle Battery Supply Chain Analysis—How Battery Demand and Production Are Reshaping the Automotive Industry; Automotive from Ultima Media Ltd.: London, UK, 2021. [Google Scholar]

- Chen, M.; Ma, X.; Chen, B.; Arsenault, R.; Karlson, P.; Simon, N.; Wang, Y. Recycling End-of-Life Electric Vehicle Lithium-Ion Batteries. Joule 2019, 3, 2622–2646. [Google Scholar] [CrossRef]

- Lv, W.; Wang, Z.; Cao, H.; Sun, Y.; Zhang, Y.; Sun, Z. A Critical Review and Analysis on the Recycling of Spent Lithium-Ion Batteries. ACS Sustain. Chem. Eng. 2018, 6, 1504–1521. [Google Scholar] [CrossRef]

- Betz, J.; Degreif, S.; Dolega, P. State of Play and Roadmap Concept: Mobility Sector—RE-SOURCING Deliverable 4.2; Oeko-Inst. e.V.: Darmstadt, Germany, 2021. [Google Scholar]

- Fan, E.; Li, L.; Wang, Z.; Lin, J.; Huang, Y.; Yao, Y.; Chen, R.; Wu, F. Sustainable Recycling Technology for Li-Ion Batteries and Beyond: Challenges and Future Prospects. Chem. Rev. 2020, 120, 7020–7063. [Google Scholar] [CrossRef] [PubMed]

- IEP. Global Peace Index 2020: Measuring Peace in a Complex World; Institute for Economics & Peace: Sydney, Australia, 2020. [Google Scholar]

- OICA. World Motor Vehicle Production—2019 Production Statistics. Available online: https://www.oica.net/category/production-statistics/2019-statistics/ (accessed on 10 August 2021).

- IEA. Global EV Data Explorer. Available online: https://www.iea.org/articles/global-ev-data-explorer (accessed on 29 July 2021).

- Automotive Logistics. Lithium-Ion Battery Gigafactory Database; Automotive from Ultima Media Ltd.: London, UK, 2021. [Google Scholar]

- Yu, A.; Sumangil, M. Top Electric Vehicle Markets Dominate Lithium-Ion Battery Capacity Growth. Available online: https://www.spglobal.com/marketintelligence/en/news-insights/blog/top-electric-vehicle-markets-dominate-lithium-ion-battery-capacity-growth (accessed on 14 October 2021).

- Mlambo, D.N.; Adetiba, T.C. Post-1994 South Africa’s Peacekeeping and Military Intervention in Southern Africa, Reference from the Democratic Republic of Congo (DRC) and Lesotho. J. Public Aff. 2020, 20, e1984. [Google Scholar] [CrossRef]

- DERA. Battery Raw Materials for E-Mobility; German Mineral Resources Agency (DERA): Berlin, Germany, 2021. [Google Scholar]

- Bobba, S.; Carrara, S.; Huisman, J.; Mathieux, F.; Pavel, C. Critical Raw Materials for Strategic Technologies and Sectors in the EU—A Foresight Study; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- Anner, M. Monitoring Workers’ Rights: The Limits of Voluntary Social Compliance Initiatives in Labor Repressive Regimes. Glob. Policy 2017, 8, 56–65. [Google Scholar] [CrossRef]

- Franceschini, I.; Nesossi, E. State Repression of Chinese Labor NGOs: A Chilling Effect? China J. 2018, 80, 111–129. [Google Scholar] [CrossRef] [Green Version]

- Roskill. Market Reports—Roskill. Available online: https://roskill.com/market-reports/ (accessed on 25 October 2021).

- SAI. Guidance Document for Social Accountability 8000 (SA8000®:2014); Social Accountability International: New York, NY, USA, 2016. [Google Scholar]

- RMI. Standards. Available online: http://www.responsiblemineralsinitiative.org/minerals-due-diligence/standards/ (accessed on 3 January 2022).

- BGR. Certified Trading Chains. Available online: https://www.bgr.bund.de/EN/Themen/Min_rohstoffe/CTC/Concept_MC/CTC-Standards-Principles/ctc_standards-principles_node_en.html (accessed on 3 January 2022).

- Müller-Hoff, C.; Leifker, M.; Paasch, A. Menschenrechtsfitness von Audits und Zertifizierern? Eine sektorübergreifende Analyse der aktuellen Herausforderungen und möglicher Antworten; ECCHR: Berlin, Germany; Brot für die Welt: Berlin, Germany; MISEREOR e.V.: Aachen, Germany, 2021. [Google Scholar]

- Rüttinger, L.; Scholl, C. Responsible Mining? Challenges, Perspectives and Approaches—Summary of the Findings of the Research Project “Approaches to Reducing Negative Environmental and Social Impacts in the Production of Raw Materials (UmSoRess)”; German Environment Agency: Dessau-Roßlau, Germany, 2017. [Google Scholar]

- Willuhn, M. Europe’s Battery Recycling Quotas Are Blunt and a Decade Too Late. Available online: https://www.pv-magazine.com/2020/12/16/europes-battery-recycling-quotas-are-blunt-and-a-decade-too-late/ (accessed on 29 October 2021).

- Benoit Norris, C.B.; Bennema, M.; Norris, G. The Social Hotspots Database—Supporting Documentation—Update 2019; Social Hotspots Database: York, ME, USA, 2018. [Google Scholar]

- Ellingsen, L.A.-W.; Singh, B.; Strømman, A.H. The Size and Range Effect: Lifecycle Greenhouse Gas Emissions of Electric Vehicles. Environ. Res. Lett. 2016, 11, 054010. [Google Scholar] [CrossRef]

| # | Identified Improvement Potentials | Feasibility | Explanation |

|---|---|---|---|

| (1) | Societal acceptance categories | yes | Methodical adjustment of categories |

| (2) | Future trends in the demand growth | yes | Methodical adjustment of category |

| (3) | Recognition of mine site certification | yes | Methodical introduction in ESSENZ |

| (4) | Mine site specific assessment | only via (3) | Outside the scope of ESSENZ, but workaround via (3) |

| (5) | Assessment of secondary materials | yes | Methodical introduction in ESSENZ |

| (6) | Company-specific assessment | only via (3) and (5) | Outside the scope of ESSENZ 1, but workaround via (3) and (5) |

| (7) | Data update | yes | Only case-study-specific update of characterization factors |

| (8) | Set DtT results below one to zero | no 2 | Fundamental methodical adjustment to be dealt with in future work |

| (9) | Indicator uncertainties | no | Shortcoming not changeable |

| Qualitative Risk Level | Quantitative Value |

|---|---|

| no risk | 0.0 |

| low | 0.25 |

| medium | 0.5 |

| high | 0.75 |

| very high | 1.0 |

| Category | (Sub-)Indicator | Risk Multiplier |

|---|---|---|

| Artisanal and small-scale mining | Share of material extracted in an ASM operation | 0.5 |

| Risk of labor rights violation | Child labor | 0.25 |

| Forced labor | 0.25 | |

| Freedom of association, collective bargaining, right to strike | 0.5 | |

| Environmental policy | Environmental Performance Index | 0.75 |

| Scenario | Percentage of Raw Materials Coming from Certified Mine Sites [%] |

|---|---|

| 1 | 0 |

| 2 | 10 |

| 3 | 25 |

| 4 | 50 |

| 5 | 100 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pelzeter, J.; Bach, V.; Henßler, M.; Ruhland, K.; Finkbeiner, M. Enhancement of the ESSENZ Method and Application in a Case Study on Batteries. Resources 2022, 11, 52. https://doi.org/10.3390/resources11060052

Pelzeter J, Bach V, Henßler M, Ruhland K, Finkbeiner M. Enhancement of the ESSENZ Method and Application in a Case Study on Batteries. Resources. 2022; 11(6):52. https://doi.org/10.3390/resources11060052

Chicago/Turabian StylePelzeter, Julia, Vanessa Bach, Martin Henßler, Klaus Ruhland, and Matthias Finkbeiner. 2022. "Enhancement of the ESSENZ Method and Application in a Case Study on Batteries" Resources 11, no. 6: 52. https://doi.org/10.3390/resources11060052

APA StylePelzeter, J., Bach, V., Henßler, M., Ruhland, K., & Finkbeiner, M. (2022). Enhancement of the ESSENZ Method and Application in a Case Study on Batteries. Resources, 11(6), 52. https://doi.org/10.3390/resources11060052