Trends and Opportunities of Bivalve Shells’ Waste Valorization in a Prospect of Circular Blue Bioeconomy

Abstract

1. Introduction

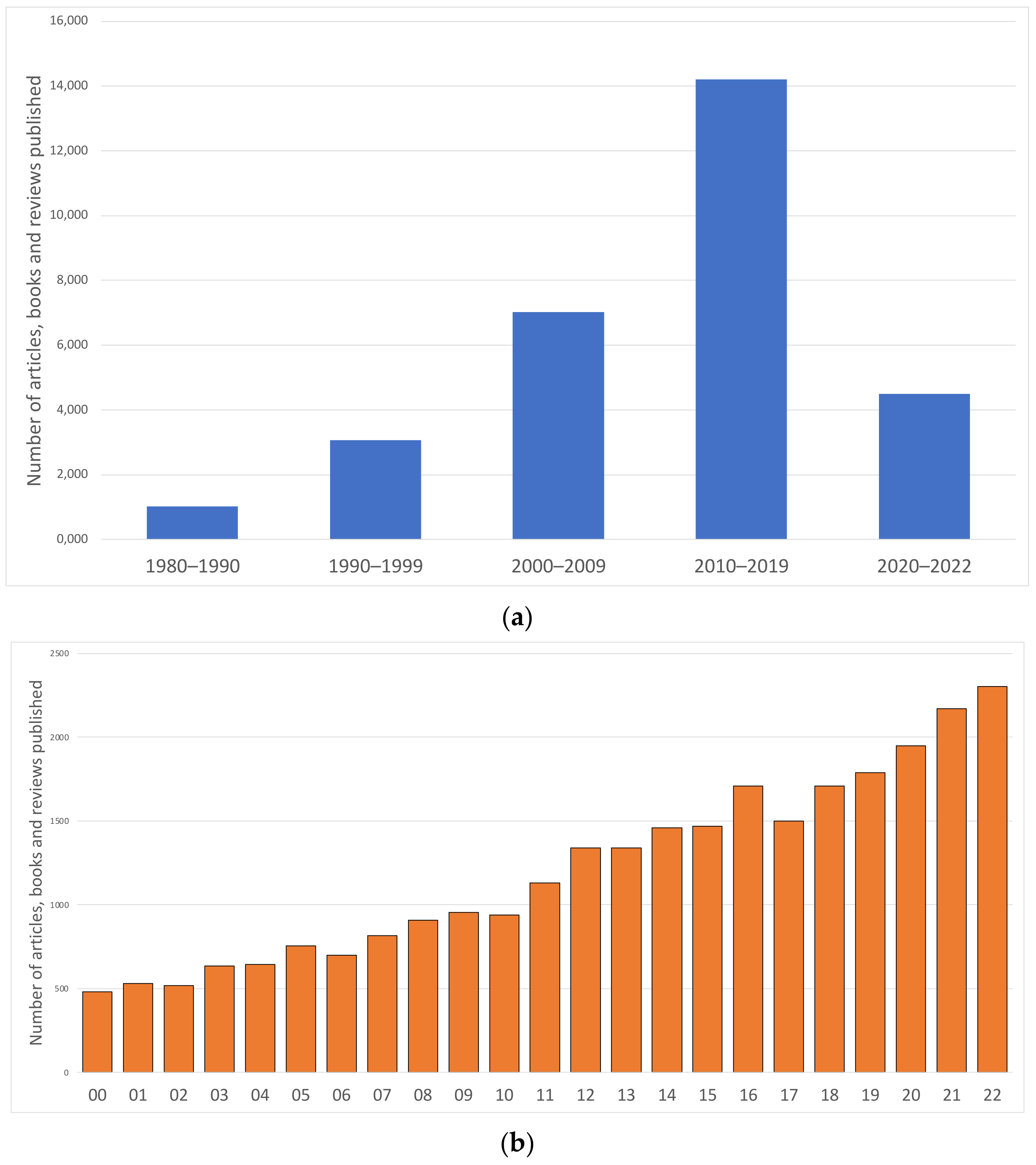

2. Materials and Methods

- -

- In agriculture and livestock feed supplements;

- -

- In soils, water, and wastewater remediation;

- -

- In substitution of mined CaCO3 in mortar and concrete;

- -

- In heterogeneous catalysis for biodiesel production;

- -

- As biofilters.

3. Valorization in Agriculture and Livestock Feed Supplement

4. Valorization in Contaminated Soils Remediation

5. Valorization as Biofilters in Water and Wastewater Treatment for Removing Metals

6. Valorization as a Substitute for Mined CaCO3 in Mortar and Concrete

7. Valorization as a Catalyst in Biodiesel Production

8. Niche Applications

9. Discussion of Effective Sustainability Perspectives

Funding

Data Availability Statement

Conflicts of Interest

References

- World Population by Country. 2022. Available online: https://worldpopulationreview.com/ (accessed on 24 February 2022).

- Fukase, E.; Martin, W. Economic growth, convergence, and world food demand and supply. World Dev. 2020, 132, 104954. [Google Scholar] [CrossRef]

- Long, S.P.; Ainsworth, E.A.; Leakey, A.D.B.; Nösberger, J.; Ort, D.R. Food for Thought: Lower-Than-Expected Crop Yield Stimulation with Rising CO2 Concentrations. Science 2006, 312, 1918–1921. [Google Scholar] [CrossRef] [PubMed]

- Drewnowski, A.P. What Lies behind the Transition from Plant-Based to Animal Protein? AMA J. Ethics 2018, 20, E987–E993. [Google Scholar] [PubMed]

- Tso, R.; Forde, C. Unintended Consequences: Nutritional Impact and Potential Pitfalls of Switching from Animal to Plant-Based Foods. Nutrients 2021, 13, 2527. [Google Scholar] [CrossRef] [PubMed]

- Racioppo, A.; Speranza, B.; Campaniello, D.; Sinigaglia, M.; Corbo, M.R.; Bevilacqua, A. Fish Loss/Waste and Low-Value Fish Challenges: State of Art, Advances, and Perspectives. Foods 2021, 10, 2725. [Google Scholar] [CrossRef] [PubMed]

- THE 17 GOALS | Sustainable Development. Available online: https://sdgs.un.org/goals (accessed on 25 February 2022).

- The State of Food & Agriculture 2021. Available online: https://www.fao.org/state-of-food-agriculture/en/ (accessed on 25 February 2022).

- UN Environment Programme. UNEP Food Waste Index Report 2021. Available online: http://www.unep.org/resources/report/unep-food-waste-index-report-2021 (accessed on 25 February 2022).

- Chen, C.; Chaudhary, A.; Mathys, A. Nutritional and environmental losses embedded in global food waste. Resour. Conserv. Recycl. 2020, 160, 104912. [Google Scholar] [CrossRef]

- Choudhary, P.; Khade, M.; Savant, S.; Musale, A.; Chelliah, M.S.; Dasgupta, S. Empowering blue economy: From underrated ecosystem to sustainable industry. J. Environ. Manag. 2021, 291, 112697. [Google Scholar] [CrossRef]

- FAO (Ed.) The State of Food and Agriculture: Moving Forward on Food Loss and Waste Reduction; Food and Agriculture Organization of the United Nations: Rome, Italy, 2019; ISBN 978-92-5-131789-1. [Google Scholar]

- FAOSTAT, Food and Agriculture Organization of the United Nation. Available online: http://www.fao.org/faostat/en/#home (accessed on 24 August 2021).

- Wijsman, J.W.M.; Troost, K.; Fang, J.; Roncarati, A. Global Production of Marine Bivalves. Trends and Challenges. In Goods and Services of Marine Bivalves; Smaal, A.C., Ferreira, J.G., Grant, J., Petersen, J.K., Strand, Ø., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 7–26. ISBN 978-3-319-96776-9. [Google Scholar]

- Ishangulyyev, R.; Kim, S.; Lee, S.H. Understanding Food Loss and Waste—Why Are We Losing and Wasting Food? Foods 2019, 8, 297. [Google Scholar] [CrossRef]

- Kruijssen, F.; Tedesco, I.; Ward, A.; Pincus, L.; Love, D.; Thorne-Lyman, A.L. Loss and waste in fish value chains: A review of the evidence from low and middle-income countries. Glob. Food Secur. 2020, 26, 100434. [Google Scholar] [CrossRef]

- Khan, M.D.; Chottitisupawong, T.; Vu, H.H.T.; Ahn, J.W.; Kim, G.M. Removal of Phosphorus from an Aqueous Solution by Nanocalcium Hydroxide Derived from Waste Bivalve Seashells: Mechanism and Kinetics. ACS Omega 2020, 5, 12290–12301. [Google Scholar] [CrossRef]

- Morris, J.P.; Backeljau, T.; Chapelle, G. Shells from Aquaculture: A Valuable Biomaterial, Not a Nuisance Waste Product. Rev. Aquac. 2019, 11, 42–57. [Google Scholar] [CrossRef]

- Jung, J.; Lee, J.-J.; Lee, G.; Yoo, K.; Sho, B.-H. Reuse of Waste Shells as a SO2/NOx Removal Sorbent. In Material Recycling—Trends and Perspectives; InTech: Rijeka, Croatia, 2012; Volume 13, pp. 301–322. ISBN 978-953-51-0327-1. [Google Scholar]

- Chiaraluce, G.; Bentivoglio, D.; Finco, A. Circular Economy for a Sustainable Agri-Food Supply Chain: A Review for Current Trends and Future Pathways. Sustainability 2021, 13, 9294. [Google Scholar] [CrossRef]

- Osorio, L.L.D.R.; Flórez-López, E.; Grande-Tovar, C.D. The Potential of Selected Agri-Food Loss and Waste to Contribute to a Circular Economy: Applications in the Food, Cosmetic and Pharmaceutical Industries. Molecules 2021, 26, 515. [Google Scholar] [CrossRef]

- Jović, M.; Mandić, M.; Šljivić-Ivanović, M.; Smičiklas, I. Recent trends in application of shell waste from mariculture. Stud. Mar. 2019, 32, 47–62. [Google Scholar] [CrossRef]

- Olivier, A.V.D.S.; Jones, L.; Le Vay, L.; Christie, M.; Wilson, J.; Malham, S.K. A global review of the ecosystem services provided by bivalve aquaculture. Rev. Aquac. 2018, 12, 3–25. [Google Scholar] [CrossRef]

- Zhan, J.; Lu, J.; Wang, D. Review of shell waste reutilization to promote sustainable shellfish aquaculture. Rev. Aquac. 2021, 14, 477–488. [Google Scholar] [CrossRef]

- Alonso, A.; Álvarez-Salgado, X.; Antelo, L. Assessing the impact of bivalve aquaculture on the carbon circular economy. J. Clean. Prod. 2020, 279, 123873. [Google Scholar] [CrossRef]

- Fraga-Corral, M.; Ronza, P.; Garcia-Oliveira, P.; Pereira, A.; Losada, A.; Prieto, M.; Quiroga, M.; Simal-Gandara, J. Aquaculture as a circular bio-economy model with Galicia as a study case: How to transform waste into revalorized by-products. Trends Food Sci. Technol. 2021, 119, 23–35. [Google Scholar] [CrossRef]

- Uzcátegui, L.U.M.; Vergara, K.; Bordes, G.M. Sustainable alternatives for by-products derived from industrial mussel processing: A critical review. Waste Manag. Res. J. Sustain. Circ. Econ. 2021, 40, 123–138. [Google Scholar] [CrossRef]

- Snyder, H. Literature review as a research methodology: An overview and guidelines. J. Bus. Res. 2019, 104, 333–339. [Google Scholar] [CrossRef]

- Barros, M.; Bello, P.; Bao, M.; Torrado, J. From waste to commodity: Transforming shells into high purity calcium carbonate. J. Clean. Prod. 2009, 17, 400–407. [Google Scholar] [CrossRef]

- Taboada, J.; Pereira-Crespo, S.; Bande-Castro, M.J. Use of Limestone from Mussel Shells in Acid Soil of Galicia (NW Spain). In Treatment and Use of Non-Conventional Organic Residues in Agriculture: Challenges and Opportunities towards Sustainable Management, Proceedings of the 14th Ramiran International Conference, Lisboa, Portugal, 12–15 September 2010; FAO European Cooperative Research Network on the Recycling of Agricultural, Municipal and Industrial Residues in Agriculture: Lisboa, Portugal, 2010. [Google Scholar]

- Álvarez, E.; Fernández-Sanjurjo, M.; Seco, N.; Núñez, A. Use of Mussel Shells as a Soil Amendment: Effects on Bulk and Rhizosphere Soil and Pasture Production. Pedosphere 2012, 22, 152–164. [Google Scholar] [CrossRef]

- Lee, M.; Tsai, W.-S.; Chen, S.-T. Reusing shell waste as a soil conditioner alternative? A comparative study of eggshell and oyster shell using a life cycle assessment approach. J. Clean. Prod. 2020, 265, 121845. [Google Scholar] [CrossRef]

- Ramakrishna, C.; Thenepalli, T.; Nam, S.Y.; Kim, C.; Ahn, J.W. Extraction of Precipitated Calcium Carbonate from Oyster Shell Waste and Its Applications. J. Energy Eng. 2018, 27, 51–58. [Google Scholar] [CrossRef]

- Kwon, Y.; Lee, C.; Yun, J. Development of vermicast from sludge and powdered oyster shell. J. Clean. Prod. 2009, 17, 708–711. [Google Scholar] [CrossRef]

- Paz-Ferreiro, J.; Baez-Bernal, D.; Insúa, J.C.; Pomar, M.G. Effects of mussel shell addition on the chemical and biological properties of a Cambisol. Chemosphere 2012, 86, 1117–1121. [Google Scholar] [CrossRef] [PubMed]

- Muir, F.V.; Harris, P.C.; Gerry, R.W. The Comparative Value of Five Calcium Sources for Laying Hens. Poult. Sci. 1976, 55, 1046–1051. [Google Scholar] [CrossRef]

- Islam, M.A.; Nishibori, M. Use of extruded eggshell as a calcium source substituting limestone or oyster shell in the diet of laying hens. Vet. Med. Sci. 2021, 7, 1948–1958. [Google Scholar] [CrossRef]

- Tahamtani, F.M.; Kittelsen, K.; Vasdal, G. Environmental enrichment in commercial flocks of aviary housed laying hens: Relationship with plumage condition and fearfulness. Poult. Sci. 2022, 101, 101754. [Google Scholar] [CrossRef]

- Saki, A.; Rahmani, A.; Yousefi, A. Calcium particle size and feeding time influence egg shell quality in laying hens. Acta Sci. Anim. Sci. 2018, 41, 42926. [Google Scholar] [CrossRef]

- Safaa, H.; Serrano, M.P.; Valencia, D.G.; Frikha, M.; Jiménez-Moreno, E.; Mateos, G.G. Productive Performance and Egg Quality of Brown Egg-Laying Hens in the Late Phase of Production as Influenced by Level and Source of Calcium in the Diet. Poult. Sci. 2008, 87, 2043–2051. [Google Scholar] [CrossRef]

- Wang, S.; Chen, W.; Zhang, H.X.; Ruan, D.; Lin, Y.C. Influence of particle size and calcium source on production performance, egg quality, and bone parameters in laying ducks. Poult. Sci. 2014, 93, 2560–2566. [Google Scholar] [CrossRef]

- Hou, Y.; Shavandi, A.; Carne, A.; Bekhit, A.; Ng, T.B.; Cheung, R.C.F.; Bekhit, A.E.-D. Marine shells: Potential opportunities for extraction of functional and health-promoting materials. Crit. Rev. Environ. Sci. Technol. 2016, 46, 1047–1116. [Google Scholar] [CrossRef]

- de Alvarenga, R.A.F.; Galindro, B.M.; de Fátima Helpa, C.; Soares, S.R. The recycling of oyster shells: An environmental analysis using Life Cycle Assessment. J. Environ. Manag. 2012, 106, 102–109. [Google Scholar] [CrossRef]

- Ahmad, A.F.; Razali, A.R.; Razelan, I.S.M. Utilization of polyethylene terephthalate (PET) in asphalt pavement: A review. IOP Conf. Ser. Mater. Sci. Eng. 2017, 203, 12004. [Google Scholar] [CrossRef]

- Mathew, G.M.; Sukumaran, R.K.; Sindhu, R.; Binod, P.; Pandey, A. Green remediation of the potential hazardous shellfish wastes generated from the processing industries and their bioprospecting. Environ. Technol. Innov. 2021, 24, 101979. [Google Scholar] [CrossRef]

- Ok, Y.S.; Oh, S.-E.; Ahmad, M.; Hyun, S.; Kim, K.-R.; Moon, D.H.; Lee, S.S.; Lim, K.J.; Jeon, W.-T.; Yang, J.E. Effects of natural and calcined oyster shells on Cd and Pb immobilization in contaminated soils. Environ. Earth Sci. 2010, 61, 1301–1308. [Google Scholar] [CrossRef]

- Palansooriya, K.N.; Shaheen, S.M.; Chen, S.S.; Tsang, D.C.W.; Hashimoto, Y.; Hou, D.; Bolan, N.S.; Rinklebe, J.; Ok, Y.S. Soil amendments for immobilization of potentially toxic elements in contaminated soils: A critical review. Environ. Int. 2020, 134, 105046. [Google Scholar] [CrossRef]

- Ok, Y.S.; Lim, J.E.; Moon, D.H. Stabilization of Pb and Cd contaminated soils and soil quality improvements using waste oyster shells. Environ. Geochem. Health 2010, 33, 83–91. [Google Scholar] [CrossRef]

- Zhong, G.; Liu, Y.; Tang, Y. Oyster shell powder for Pb(II) immobilization in both aquatic and sediment environments. Environ. Geochem. Health 2020, 43, 1891–1902. [Google Scholar] [CrossRef]

- Chen, Y.; Xu, J.; Lv, Z.; Xie, R.; Huang, L.; Jiang, J. Impacts of biochar and oyster shells waste on the immobilization of arsenic in highly contaminated soils. J. Environ. Manag. 2018, 217, 646–653. [Google Scholar] [CrossRef]

- Bi, D.; Yuan, G.; Wei, J.; Xiao, L.; Feng, L. Conversion of Oyster Shell Waste to Amendment for Immobilising Cadmium and Arsenic in Agricultural Soil. Bull. Environ. Contam. Toxicol. 2020, 105, 277–282. [Google Scholar] [CrossRef]

- Moon, D.H.; Cheong, K.H.; Khim, J.; Wazne, M.; Hyun, S.; Park, J.-H.; Chang, Y.-Y.; Ok, Y.S. Stabilization of Pb2+ and Cu2+ contaminated firing range soil using calcined oyster shells and waste cow bones. Chemosphere 2013, 91, 1349–1354. [Google Scholar] [CrossRef]

- Zheng, X.; Zou, M.; Zhang, B.; Lai, W.; Zeng, X.; Chen, S.; Wang, M.; Yi, X.; Tao, X.; Lu, G. Remediation of Cd-, Pb-, Cu-, and Zn-contaminated soil using cow bone meal and oyster shell meal. Ecotoxicol. Environ. Saf. 2021, 229, 113073. [Google Scholar] [CrossRef]

- Hannan, F.; Islam, F.; Huang, Q.; Farooq, M.A.; Ayyaz, A.; Fang, R.; Ali, B.; Xie, X.; Zhou, W. Interactive effects of biochar and mussel shell activated concoctions on immobilization of nickel and their amelioration on the growth of rapeseed in contaminated aged soil. Chemosphere 2021, 282, 130897. [Google Scholar] [CrossRef]

- Fernández-Calviño, D.; Pérez-Armada, L.; Cutillas-Barreiro, L.; Paradelo-Núñez, R.; Núñez-Delgado, A.; Fernández-Sanjurjo, M.J.; Álvarez-Rodriguez, E.; Arias-Estévez, M. Changes in Cd, Cu, Ni, Pb and Zn Fractionation and Liberation Due to Mussel Shell Amendment on a Mine Soil. Land Degrad. Dev. 2016, 27, 1276–1285. [Google Scholar] [CrossRef]

- Garrido-Rodriguez, B.; Cutillas-Barreiro, L.; Fernández-Calviño, D.; Arias-Estévez, M.; Fernández-Sanjurjo, M.J.; Álvarez-Rodríguez, E.; Núñez-Delgado, A. Competitive adsorption and transport of Cd, Cu, Ni and Zn in a mine soil amended with mussel shell. Chemosphere 2014, 107, 379–385. [Google Scholar] [CrossRef]

- Ramírez-Pérez, A.M.; Paradelo, M.; Nóvoa-Muñoz, J.C.; Arias-Estévez, M.; Fernández-Sanjurjo, M.J.; Álvarez-Rodríguez, E.; Núñez-Delgado, A. Heavy metal retention in copper mine soil treated with mussel shells: Batch and column experiments. J. Hazard. Mater. 2013, 248–249, 122–130. [Google Scholar] [CrossRef]

- Ahmad, M.; Lee, S.; Moon, D.; Yang, J.E.; Ok, Y. A Review of Environmental Contamination and Remediation Strategies for Heavy Metals at Shooting Range Soils. Environmental Protection Strategies for Sustainable Development. Strategies for Sustainability; Malik, A., Grohmann, E., Eds.; Springer: Dordrecht, Germany, 2012. [Google Scholar] [CrossRef]

- Farm, C. Metal sorption to natural filter substrates for storm water treatment—Column studies. Sci. Total Environ. 2002, 298, 17–24. [Google Scholar] [CrossRef]

- Tudor, H.E.A.; Gryte, C.C.; Harris, C.C. Seashells: Detoxifying Agents for Metal-Contaminated Waters. Water Air Soil Pollut. 2006, 173, 209–242. [Google Scholar] [CrossRef]

- Li, C.; Champagne, P. Fixed-bed column study for the removal of cadmium (II) and nickel (II) ions from aqueous solutions using peat and mollusk shells. J. Hazard. Mater. 2009, 171, 872–878. [Google Scholar] [CrossRef] [PubMed]

- Lim, A.P.; Aris, A.Z. A review on economically adsorbents on heavy metals removal in water and wastewater. Rev. Environ. Sci. Bio/Technol. 2013, 13, 163–181. [Google Scholar] [CrossRef]

- Liu, Y.; Sun, C.; Xu, J.; Li, Y. The use of raw and acid-pretreated bivalve mollusk shells to remove metals from aqueous solutions. J. Hazard. Mater. 2009, 168, 156–162. [Google Scholar] [CrossRef] [PubMed]

- Du, Y.; Zhu, L.; Shan, G. Removal of Cd2+ from contaminated water by nano-sized aragonite mollusk shell and the competition of coexisting metal ions. J. Colloid Interface Sci. 2012, 367, 378–382. [Google Scholar] [CrossRef]

- Gao, Y.-J. Removal of Cadmium and Cobalt from Heavy Metal Solution Using Oyster Shells Adsorbent. Asian J. Chem. 2013, 25, 8537–8540. [Google Scholar] [CrossRef]

- Yousefi, Z.; Mashayekh-Salehi, A.; Tahmtan, R.A.M. Biosorption of chromium in aqueous solutions using Bivalve Mollusk Shells through central composite design (CCD) model. Desalin. Water Treat. 2015, 57, 1106342. [Google Scholar] [CrossRef]

- Yen, H.Y. Taguchi optimization for Cd(II) removal from aqueous solutions using oyster shell powders. Desalin. Water Treat. 2015, 57, 20430–20438. [Google Scholar] [CrossRef]

- Removal of Arsenic with Oyster Shell: Experimental Measurements|Pakistan Journal of Analytical & Environmental Chemistry. Available online: http://pjaec.pk/index.php/pjaec/article/view/195 (accessed on 30 March 2022).

- Moon, D.H.; Kim, K.-W.; Yoon, I.-H.; Grubb, D.G.; Shin, D.-Y.; Cheong, K.H.; Choi, H.-I.; Ok, Y.S.; Park, J.-H. Stabilization of arsenic-contaminated mine tailings using natural and calcined oyster shells. Environ. Earth Sci. 2010, 64, 597–605. [Google Scholar] [CrossRef]

- Xu, Z.; Valeo, C.; Chu, A.; Zhao, Y. The Efficacy of Whole Oyster Shells for Removing Copper, Zinc, Chromium, and Cadmium Heavy Metal Ions from Stormwater. Sustainability 2021, 13, 4184. [Google Scholar] [CrossRef]

- Peña-Rodriguez, S.; Bermúdez-Couso, A.; Nóvoa-Muñoz, J.C.; Arias-Estévez, M.; Fernández-Sanjurjo, M.J.; Álvarez-Rodríguez, E.; Núñez-Delgado, A. Mercury removal using ground and calcined mussel shell. J. Environ. Sci. 2013, 25, 2476–2486. [Google Scholar] [CrossRef]

- Abeynaike, A.; Wang, L.; Jones, M.I.; Patterson, D.A. Pyrolysed powdered mussel shells for eutrophication control: Effect of particle size and powder concentration on the mechanism and extent of phosphate removal. Asia-Pac. J. Chem. Eng. 2011, 6, 231–243. [Google Scholar] [CrossRef]

- Paradelo, R.; Conde-Cid, M.; Cutillas-Barreiro, L.; Arias-Estévez, M.; Nóvoa-Muñoz, J.C.; Álvarez-Rodríguez, E.; Fernández-Sanjurjo, M.J.; Núñez-Delgado, A. Phosphorus removal from wastewater using mussel shell: Investigation on retention mechanisms. Ecol. Eng. 2016, 97, 558–566. [Google Scholar] [CrossRef]

- Oladoja, N.; Ahmad, A.; Adesina, O.; Adelagun, R. Low-cost biogenic waste for phosphate capture from aqueous system. Chem. Eng. J. 2012, 209, 170–179. [Google Scholar] [CrossRef]

- Hussain, Z.; Sultan, N.; Ali, M.; Naz, M.Y.; AbdEl-Salam, N.M.; Ibrahim, K.A. Thermochemical Conversion of Waste Glass and Mollusk Shells into an Absorbent Material for Separation of Direct Blue 15 Azo Dye from Industrial Wastewater. ACS Omega 2020, 5, 18114–18122. [Google Scholar] [CrossRef]

- Shariffuddin, J.H.; Jones, M.I.; Patterson, D. Greener photocatalysts: Hydroxyapatite derived from waste mussel shells for the photocatalytic degradation of a model azo dye wastewater. Chem. Eng. Res. Des. 2013, 91, 1693–1704. [Google Scholar] [CrossRef]

- Elwakeel, K.; Elgarahy, A.; Mohammad, S. Use of beach bivalve shells located at Port Said coast (Egypt) as a green approach for methylene blue removal. J. Environ. Chem. Eng. 2017, 5, 578–587. [Google Scholar] [CrossRef]

- Thakur, S.; Singh, S.; Pal, B. Superior adsorption removal of dye and high catalytic activity for transesterification reaction displayed by crystalline CaO nanocubes extracted from mollusc shells. Fuel Process. Technol. 2020, 213, 106707. [Google Scholar] [CrossRef]

- Henrique, D.C.; Quitela, D.U.; Ide, A.H.; Lins, P.V.; Perazzini, M.T.; Perazzini, H.; Oliveira, L.M.; Duarte, J.L.; Meili, L. Mollusk shells as adsorbent for removal of endocrine disruptor in different water matrix. J. Environ. Chem. Eng. 2021, 9, 105704. [Google Scholar] [CrossRef]

- Henrique, D.C.; Quintela, D.U.; Ide, A.H.; Erto, A.; Duarte, J.L.D.S.; Meili, L. Calcined Mytella falcata shells as alternative adsorbent for efficient removal of rifampicin antibiotic from aqueous solutions. J. Environ. Chem. Eng. 2020, 8, 103782. [Google Scholar] [CrossRef]

- Quintela, D.U.; Henrique, D.C.; dos Santos Lins, P.V.; Ide, A.H.; Erto, A.; da Silva Duarte, J.L.; Meili, L. Waste of Mytella Falcata shells for removal of a triarylmethane biocide from water: Kinetic, equilibrium, regeneration and thermodynamic studies. Colloids Surf. B Biointerfaces 2020, 195, 111230. [Google Scholar] [CrossRef]

- Papadimitriou, C.A.; Krey, G.; Stamatis, N.; Kallianiotis, A. The use of waste mussel shells for the adsorption of dyes and heavy metals. J. Chem. Technol. Biotechnol. 2017, 92, 1943–1947. [Google Scholar] [CrossRef]

- El Biriane, M.; Barbachi, M. State-of-the-art review on recycled mussel shell waste in concrete and mortar. Innov. Infrastruct. Solut. 2020, 6, 29. [Google Scholar] [CrossRef]

- Mo, K.H.; Alengaram, U.J.; Jumaat, M.Z.; Lee, S.C.; Goh, W.I.; Yuen, C.W. Recycling of seashell waste in concrete: A review. Constr. Build. Mater. 2018, 162, 751–764. [Google Scholar] [CrossRef]

- Ferraz, E.; Gamelas, J.A.F.; Coroado, J.; Monteiro, C.; Rocha, F. Recycling Waste Seashells to Produce Calcitic Lime: Characterization and Wet Slaking Reactivity. Waste Biomass-Valorization 2018, 10, 2397–2414. [Google Scholar] [CrossRef]

- Peceño, B.; Arenas, C.; Alonso-Fariñas, B.; Leiva, C. Substitution of Coarse Aggregates with Mollusk-Shell Waste in Acoustic-Absorbing Concrete. J. Mater. Civ. Eng. 2019, 31, 04019077. [Google Scholar] [CrossRef]

- Adewuyi, A.P.; Franklin, S.O.; Ibrahim, K.A. Utilization of Mollusc Shells for Concrete Production for Sustainable Environment. Int. J. Sci. Eng. Res. 2015, 6, 201–208. [Google Scholar]

- Eziefula, U.; Ezeh, J.C.; Eziefula, B.I. Properties of seashell aggregate concrete: A review. Constr. Build. Mater. 2018, 192, 287–300. [Google Scholar] [CrossRef]

- Mohammad, W.A.S.B.W.; Othman, N.H.; Ibrahim, M.H.W.; Rahim, M.A.; Shahidan, S.; Abd Rahman, R. A Review on Seashells Ash as Partial Cement Replacement. IOP Conf. Ser. Mater. Sci. Eng. 2017, 271, 012059. [Google Scholar] [CrossRef]

- AlShareedah, O.; Nassiri, S. Pervious concrete mixture optimization, physical, and mechanical properties and pavement design: A review. J. Clean. Prod. 2020, 288, 125095. [Google Scholar] [CrossRef]

- Shakrani, S.A.; Ayob, A.; Ab Rahim, M.A. Applications of waste material in the pervious concrete pavement: A review. AIP Conf. Proc. 2017, 1885, 020048. [Google Scholar] [CrossRef]

- Rios, J.D.; Arenas, C.; Cifuentes, H.; Peceño, B.; Leiva, C. Porous Structure by X-Ray Computed Tomography and Sound Absorption in Pervious Concretes with Air Cooled Blast Furnace Slag as Coarse Aggregate. Acoust. Aust. 2019, 47, 271–276. [Google Scholar] [CrossRef]

- Yoon, H.; Park, S.; Lee, K.; Park, J. Oyster Shell as Substitute for Aggregate in Mortar. Waste Manag. Res. J. Sustain. Circ. Econ. 2004, 22, 158–170. [Google Scholar] [CrossRef]

- Seo, J.H.; Park, S.M.; Yang, B.J.; Jang, J.G. Calcined Oyster Shell Powder as an Expansive Additive in Cement Mortar. Materials 2019, 12, 1322. [Google Scholar] [CrossRef]

- Martínez-García, C.; González-Fonteboa, B.; Carro-López, D.; Martínez-Abella, F. Effects of mussel shell aggregates on hygric behaviour of air lime mortar at different ages. Constr. Build. Mater. 2020, 252, 119113. [Google Scholar] [CrossRef]

- Ballester, P.; Mármol, I.; Morales, J.; Sanchez, L. Use of limestone obtained from waste of the mussel cannery industry for the production of mortars. Cem. Concr. Res. 2007, 37, 559–564. [Google Scholar] [CrossRef]

- Martínez-García, C.; González-Fonteboa, B.; Carro-López, D.; Martínez-Abella, F. Impact of mussel shell aggregates on air lime mortars. Pore structure and carbonation. J. Clean. Prod. 2019, 215, 650–668. [Google Scholar] [CrossRef]

- Carro-López, D.; González-Fonteboa, B.; Martínez, C.; Martínez-Abella, F.; Seara-Paz, S.; Rodríguez, R. Design and Properties of Mortar with Seashells Fine Aggregates. Acad. J. Civ. Eng. 2015, 33, 289–294. [Google Scholar] [CrossRef]

- Akhwady, R.; Maududi, M.A.; Dewi, D.C.; Luthfi, O.M. Effectivity of Normal Concrete and Clamshell as Materials of Artificial Pyramid Reef at Pasir Putih Beach, Situbondo—Indonesia. J. Segara 2021, 17, 1–10. [Google Scholar] [CrossRef]

- Callaway, R. Interstitial Space and Trapped Sediment Drive Benthic Communities in Artificial Shell and Rock Reefs. Front. Mar. Sci. 2018, 5, 288. [Google Scholar] [CrossRef]

- Yao, Z.; Chen, T.; Li, H.; Xia, M.; Ye, Y.; Zheng, H. Mechanical and thermal properties of polypropylene (PP) composites filled with modified shell waste. J. Hazard. Mater. 2013, 262, 212–217. [Google Scholar] [CrossRef]

- Yao, Z.; Xia, M.; Li, H.; Chen, T.; Ye, Y.; Zheng, H. Bivalve Shell: Not an Abundant Useless Waste but a Functional and Versatile Biomaterial. Crit. Rev. Environ. Sci. Technol. 2014, 44, 2502–2530. [Google Scholar] [CrossRef]

- Zahid, A.Z.M.; Zin, M.M.; Saifullizam, N.Z.; Khalid, N.; Kamaruddin, S.F.; Chik, W.S.W. Palm Oil Fuel Ash and Mussel Shell Powder as Supplementary Cementitious Materials in Non-Load Concrete Brick. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1176, 012023. [Google Scholar] [CrossRef]

- Kuo, W.-T.; Wang, H.-Y.; Shu, C.-Y.; Su, D.-S. Engineering properties of controlled low-strength materials containing waste oyster shells. Constr. Build. Mater. 2013, 46, 128–133. [Google Scholar] [CrossRef]

- Cuadrado-Rica, H.; Sebaibi, N.; Boutouil, M.; Boudart, B. Properties of ordinary concretes incorporating crushed queen scallop shells. Mater. Struct. 2015, 49, 1805–1816. [Google Scholar] [CrossRef]

- Falade, F. An investigation of periwinkle shells as coarse aggregate in concrete. Build. Environ. 1995, 30, 573–577. [Google Scholar] [CrossRef]

- Lertwattanaruk, P.; Makul, N.; Siripattarapravat, C. Utilization of ground waste seashells in cement mortars for masonry and plastering. J. Environ. Manag. 2012, 111, 133–141. [Google Scholar] [CrossRef]

- Yang, E.-I.; Kim, M.-Y.; Park, H.-G.; Yi, S.-T. Effect of partial replacement of sand with dry oyster shell on the long-term performance of concrete. Constr. Build. Mater. 2010, 24, 758–765. [Google Scholar] [CrossRef]

- Kovářová, B. Possibilities of Dry Shell Construction in the Area Family and Residential Houses. Appl. Mech. Mater. 2013, 405–408, 2943–2946. [Google Scholar] [CrossRef]

- Kawashima, A.; Matsubara, K.; Honda, K. Acceleration of catalytic activity of calcium oxide for biodiesel production. Bioresour. Technol. 2009, 100, 696–700. [Google Scholar] [CrossRef]

- Karmakar, A.; Karmakar, S.; Mukherjee, S. Properties of various plants and animals feedstocks for biodiesel production. Bioresour. Technol. 2010, 101, 7201–7210. [Google Scholar] [CrossRef]

- Meher, L.C.; Vidya Sagar, D.; Naik, S.N. Technical aspects of biodiesel production by transesterification—A review. Renew. Sustain. Energy Rev. 2006, 10, 248–268. [Google Scholar] [CrossRef]

- Boro, J.; Deka, D.; Thakur, A.J. A review on solid oxide derived from waste shells as catalyst for biodiesel production. Renew. Sustain. Energy Rev. 2012, 16, 904–910. [Google Scholar] [CrossRef]

- Hu, S.; Wang, Y.; Han, H. Utilization of waste freshwater mussel shell as an economic catalyst for biodiesel production. Biomass-Bioenergy 2011, 35, 3627–3635. [Google Scholar] [CrossRef]

- Rezaei, R.; Mohadesi, M.; Moradi, G. Optimization of biodiesel production using waste mussel shell catalyst. Fuel 2013, 109, 534–541. [Google Scholar] [CrossRef]

- Hadiyanto, H.; Afianti, A.H.; Navi’A, U.I.; Adetya, N.; Widayat, W.; Sutanto, H. The development of heterogeneous catalyst C/CaO/NaOH from waste of green mussel shell ( Perna varidis ) for biodiesel synthesis. J. Environ. Chem. Eng. 2017, 5, 4559–4563. [Google Scholar] [CrossRef]

- Buasri, A.; Chaiyut, N.; Loryuenyong, V.; Worawanitchaphong, P.; Trongyong, S. Calcium Oxide Derived from Waste Shells of Mussel, Cockle, and Scallop as the Heterogeneous Catalyst for Biodiesel Production. Sci. World J. 2013, 2013, e460923. [Google Scholar] [CrossRef]

- Nurdin, S.; Rosnan, N.A.; Ghazali, N.S.; Gimbun, J.; Nour, A.H.; Haron, S.F. Economical Biodiesel Fuel Synthesis from Castor Oil Using Mussel Shell-Base Catalyst (MS-BC). Energy Procedia 2015, 79, 576–583. [Google Scholar] [CrossRef][Green Version]

- Bet-Moushoul, E.; Farhadi, K.; Mansourpanah, Y.; Nikbakht, A.M.; Molaei, R.; Forough, M. Application of CaO-based/Au nanoparticles as heterogeneous nanocatalysts in biodiesel production. Fuel 2016, 164, 119–127. [Google Scholar] [CrossRef]

- EswaraRao, Y.; Niju, S.; Begum, K.M.S.; Anantharaman, N.; Raj, S.M. Transesterification of jatropha oil using a mixture of natural shells as solid catalyst. Biofuels 2016, 7, 345–351. [Google Scholar] [CrossRef]

- Jayakumar, M.; Karmegam, N.; Gundupalli, M.P.; Gebeyehu, K.B.; Asfaw, B.T.; Chang, S.W.; Balasubramani, R.; Awasthi, M.K. Heterogeneous base catalysts: Synthesis and application for biodiesel production—A review. Bioresour. Technol. 2021, 331, 125054. [Google Scholar] [CrossRef]

- Perea, A.; Kelly, T.; Hangun-Balkir, Y. Utilization of waste seashells and Camelina sativa oil for biodiesel synthesis. Green Chem. Lett. Rev. 2016, 9, 27–32. [Google Scholar] [CrossRef]

- Wang, J.; Tao, S.; Zhao, Y.; Shen, B.; Zhang, Z.; Tang, Y. Utilization of Waste Clam Shell as Cost-Effective Catalyst for Heterogeneous Biodiesel Production. J. Biobased Mater. Bioenergy 2021, 15, 296–301. [Google Scholar] [CrossRef]

- Shan, R.; Lu, L.; Shi, Y.; Yuan, H.; Shi, J. Catalysts from renewable resources for biodiesel production. Energy Convers. Manag. 2018, 178, 277–289. [Google Scholar] [CrossRef]

- Taufiqyap, Y.H.; Lee, H.V.; Lau, P. Transesterification of Jatropha Curcas Oil to Biodiesel by Using Short Necked Clam (Orbicularia Orbiculata) Shell Derived Catalyst. Energy Explor. Exploit. 2012, 30, 853–866. [Google Scholar] [CrossRef]

- Shobana, M.; Prasad, R.K.; Ragula, U.B.R.; Kumaresan, D. Kinetics and characterization of transesterification of cottonseed oil to biodiesel using calcined clam shells as catalyst. Biofuels 2017, 11, 597–605. [Google Scholar] [CrossRef]

- Niju, S.; Begum, K.M.S.; Anantharaman, N. Enhancement of biodiesel synthesis over highly active CaO derived from natural white bivalve clam shell. Arab. J. Chem. 2016, 9, 633–639. [Google Scholar] [CrossRef]

- Jairam, S.; Kolar, P.; Sharma-Shivappa, R.; Osborne, J.A.; Davis, J.P. KI-impregnated oyster shell as a solid catalyst for soybean oil transesterification. Bioresour. Technol. 2012, 104, 329–335. [Google Scholar] [CrossRef]

- Nakatani, N.; Takamori, H.; Takeda, K.; Sakugawa, H. Transesterification of soybean oil using combusted oyster shell waste as a catalyst. Bioresour. Technol. 2009, 100, 1510–1513. [Google Scholar] [CrossRef]

- Shobana, R.; Vijayalakshmi, S.; Deepanraj, B.; Ranjitha, J. Biodiesel production from Capparis spinosa L seed oil using calcium oxide as a heterogeneous catalyst derived from oyster shell. Mater. Today Proc. in press. 2021. [Google Scholar] [CrossRef]

- Lin, Y.-C.; Amesho, K.T.; Chen, C.-E.; Cheng, P.-C.; Chou, F.-C. A cleaner process for green biodiesel synthesis from waste cooking oil using recycled waste oyster shells as a sustainable base heterogeneous catalyst under the microwave heating system. Sustain. Chem. Pharm. 2020, 17, 100310. [Google Scholar] [CrossRef]

- Shen, Y.; Yang, S.; Liu, J.; Xu, H.; Shi, Z.; Lin, Z.; Ying, X.; Guo, P.; Lin, T.; Yan, S.; et al. Engineering Scaffolds Integrated with Calcium Sulfate and Oyster Shell for Enhanced Bone Tissue Regeneration. ACS Appl. Mater. Interfaces 2014, 6, 12177–12188. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, S.A.; Gibriel, A.A.Y.; Abdellatif, A.K.; Ebied, H.M. Evaluation of food products fortified with oyster shell for the prevention and treatment of osteoporosis. J. Food Sci. Technol. 2015, 52, 6816–6820. [Google Scholar] [CrossRef] [PubMed]

- Feng, X.; Jiang, S.; Zhang, F.; Wang, R.; Zhao, Y.; Zeng, M. Shell water-soluble matrix protein from oyster shells promoted proliferation, differentiation and mineralization of osteoblasts in vitro and vivo. Int. J. Biol. Macromol. 2022, 201, 288–297. [Google Scholar] [CrossRef] [PubMed]

- Lee, Y.-K.; Jung, S.K.; Chang, Y.H.; Kwak, H.-S. Highly bioavailable nanocalcium from oyster shell for preventing osteoporosis in rats. Int. J. Food Sci. Nutr. 2017, 68, 931–940. [Google Scholar] [CrossRef]

- Swetha, M.; Sahithi, K.; Moorthi, A.; Srinivasan, N.; Ramasamy, K.; Selvamurugan, N. Biocomposites containing natural polymers and hydroxyapatite for bone tissue engineering. Int. J. Biol. Macromol. 2010, 47, 1–4. [Google Scholar] [CrossRef]

- Amini, A.R.; Laurencin, C.T.; Nukavarapu, S.P. Bone Tissue Engineering: Recent Advances and Challenges. Crit. Rev. Biomed. Eng. 2012, 40, 363–408. [Google Scholar] [CrossRef]

- Kim, Y.; Kim, G. Highly roughened polycaprolactone surfaces using oxygen plasma-etching and in vitro mineralization for bone tissue regeneration: Fabrication, characterization, and cellular activities. Colloids Surf. B Biointerfaces 2015, 125, 181–189. [Google Scholar] [CrossRef]

- Didekhani, R.; Sohrabi, M.R.; Soleimani, M.; Seyedjafari, E.; Hanaee-Ahvaz, H. Incorporating PCL nanofibers with oyster shell to improve osteogenic differentiation of mesenchymal stem cells. Polym. Bull. 2019, 77, 701–715. [Google Scholar] [CrossRef]

- Kumar, C.S.; Dhanaraj, K.; Vimalathithan, R.; Ilaiyaraja, P.; Suresh, G. Hydroxyapatite for bone related applications derived from sea shell waste by simpleprecipitation method. J. Asian Ceram. Soc. 2020, 8, 416–429. [Google Scholar] [CrossRef]

- Zhang, X.; Vecchio, K.S. Conversion of natural marine skeletons as scaffolds for bone tissue engineering. Front. Mater. Sci. 2013, 7, 103–117. [Google Scholar] [CrossRef]

- Scialla, S.; Carella, F.; Dapporto, M.; Sprio, S.; Piancastelli, A.; Palazzo, B.; Adamiano, A.; Degli Esposti, L.; Iafisco, M.; Piccirillo, C. Mussel Shell-Derived Macroporous 3D Scaffold: Characterization and Optimization Study of a Bioceramic from the Circular Economy. Mar. Drugs 2020, 18, 309. [Google Scholar] [CrossRef]

- Shavandi, A.; Bekhit, A.E.-D.; Ali, M.A.; Sun, Z. Bio-mimetic composite scaffold from mussel shells, squid pen and crab chitosan for bone tissue engineering. Int. J. Biol. Macromol. 2015, 80, 445–454. [Google Scholar] [CrossRef]

- Ghazali, S.R.; Rosli, N.H.; Hassan, L.S.; Rozaini, M.Z.H.; Hamzah, H. Determination of New Biomaterials of Clams as An Active Ingredient in Sunscreen. J. Phys. Conf. Ser. 2021, 1874, 012075. [Google Scholar] [CrossRef]

- Rosli, N. Determination of New Biomaterials Derived from Clams Shell as Potential Sunscreen. Res. Commun. Eng. Sci. Technol. 2019, 3, 37. [Google Scholar]

- Wu, J.; Guo, X.; Liu, H.; Chen, L. Isolation and Comparative Study on the Characterization of Guanidine Hydrochloride Soluble Collagen and Pepsin Soluble Collagen from the Body of Surf Clam Shell (Coelomactra antiquata). Foods 2019, 8, 11. [Google Scholar] [CrossRef]

- Wu, C.-S.; Wu, D.-Y.; Wang, S.-S. Antibacterial Properties of Biobased Polyester Composites Achieved through Modification with a Thermally Treated Waste Scallop Shell. ACS Appl. Biol. Mater. 2019, 2, 2262–2270. [Google Scholar] [CrossRef]

- Roy: Antimicrobial Activity of CaO Nanoparticles—Google Scholar. Available online: https://scholar.google.com/scholar_lookup?hl=en&volume=9&publication_year=2013&pages=1570-1578&author=A.+Royauthor=S.+S.+Gauriauthor=M.+Bhattacharyaauthor=J.+Bhattacharya&title=Antimicrobial+activity+of+CaO+nanoparticles&doi=10.1166%2Fjbn.2013.1681 (accessed on 1 April 2022).

- Gigante, V.; Cinelli, P.; Righetti, M.C.; Sandroni, M.; Tognotti, L.; Seggiani, M.; Lazzeri, A. Evaluation of Mussel Shells Powder as Reinforcement for PLA-Based Biocomposites. Int. J. Mol. Sci. 2020, 21, 5364. [Google Scholar] [CrossRef]

- O’Neil, D.D.; Gillikin, D.P. Do freshwater mussel shells record road-salt pollution? Sci. Rep. 2014, 4, 7168. [Google Scholar] [CrossRef]

- Weiler, S.; Scholz-Barth, K. Green Roof Systems: A Guide to the Planning, Design, and Construction of Landscapes over Structure; John Wiley & Sons: Hoboken, NJ, USA, 2009; ISBN 978-0-471-67495-5. [Google Scholar]

- Cohen, F.P.; Cabral, A.E.; Lillebø, A.I.; Calado, R. Relieving pressure from coral reefs: Artificial oyster rocks can replace reef rocks used for biological filtration in marine aquariums. J. Clean. Prod. 2021, 325, 129326. [Google Scholar] [CrossRef]

- Simões, N.; Altamira, A.; Shei, M.; Perissonotti, F. Live Rock. In Marine Ornamental Species Aquaculture; John Wiley & Sons, Ltd: Hoboken, NJ, USA, 2017; pp. 385–401. ISBN 978-1-119-16914-7. [Google Scholar]

- Hernández, A.B.; Brumbaugh, R.D.; Frederick, P.; Grizzle, R.; Luckenbach, M.W.; Peterson, C.H.; Angelini, C. Restoring the eastern oyster: How much progress has been made in 53 years? Front. Ecol. Environ. 2018, 16, 463–471. [Google Scholar] [CrossRef]

- Iribarren, D.; Moreira, M.T.; Feijoo, G. Life Cycle Assessment of fresh and canned mussel processing and consumption in Galicia (NW Spain). Resour. Conserv. Recycl. 2010, 55, 106–117. [Google Scholar] [CrossRef]

- EUMOFA—Osservatorio Europeo Del Mercato Dei Prodotti Della Pesca e dell’acquacoltura. Available online: https://www.eumofa.eu/it/home (accessed on 19 January 2022).

- Presentazione del Rapporto Rifiuti Urbani—Edizione 2021. Available online: https://www.isprambiente.gov.it/it/archivio/eventi/2021/12/presentazione-del-rapporto-rifiuti-urbani-edizione-2021 (accessed on 1 April 2022).

- Ragon, P.-L.; Rodriguez, F. CO2 Emissions from Trucks in the EU: An Analysis of the Heavy-Duty CO2 Standards Baseline Data; International Council on Clean Transportation: San Francisco, CA, USA, 2021; Available online: https://theicct.org/sites/default/files/publications/eu-hdv-co2-standards-baseline-data-sept21.pdf (accessed on 1 April 2022).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Summa, D.; Lanzoni, M.; Castaldelli, G.; Fano, E.A.; Tamburini, E. Trends and Opportunities of Bivalve Shells’ Waste Valorization in a Prospect of Circular Blue Bioeconomy. Resources 2022, 11, 48. https://doi.org/10.3390/resources11050048

Summa D, Lanzoni M, Castaldelli G, Fano EA, Tamburini E. Trends and Opportunities of Bivalve Shells’ Waste Valorization in a Prospect of Circular Blue Bioeconomy. Resources. 2022; 11(5):48. https://doi.org/10.3390/resources11050048

Chicago/Turabian StyleSumma, Daniela, Mattia Lanzoni, Giuseppe Castaldelli, Elisa Anna Fano, and Elena Tamburini. 2022. "Trends and Opportunities of Bivalve Shells’ Waste Valorization in a Prospect of Circular Blue Bioeconomy" Resources 11, no. 5: 48. https://doi.org/10.3390/resources11050048

APA StyleSumma, D., Lanzoni, M., Castaldelli, G., Fano, E. A., & Tamburini, E. (2022). Trends and Opportunities of Bivalve Shells’ Waste Valorization in a Prospect of Circular Blue Bioeconomy. Resources, 11(5), 48. https://doi.org/10.3390/resources11050048